Abstract

Artificial neural networks (ANN) were applied for use with electronic-nose generated analytical signals. The use of ANN as a sensor calibration means was evaluated. Piezoelectric quartz sensors array in addition to the ANN data allow recognition of aliphatic nitrohydrocarbons C1–C3.

Introduction

Touch-sensitive electronic-nose systems include nonselective sensors and methods of analytical signals processing based on the modern artificial intelligence development [1-2]. It is applied, for example, to pattern recognition methods and multiparametrical graduation. The multitouch-sensitive approach allows simultaneous qualitative and quantitative analysis of complex mixtures.

The use of artificial neural networks (ANN) seems to be very progressive for measuring information coming from separate sensors or their combination (the multitouch-sensitive system) [3-7].

Experimental work

The main task of the qualitative analysis is the components recognition of aliphatic nitrohydrocar-bons mixes (AN). The mixes of various mixtures were prepared in a thermostatic amalgamator. The analysis was done at 25 ± 0.5 °C.

The quantitative analysis was carried out in a number of the multicomponent systems simulating possible applications of an “electronic nose”. Modeling gas mixes containing AN in amount of 5 103 – 7.5 102 g/m3 were analyzed.

Component concentration was measured simultaneously after the appropriate system training using the modeling mixes set (24-48), containing AN in various ratios. The “Electronic nose” consisted from 3 to 6 sensors depending on the task. To minimize the humidity influence, piezosensors were kept in the evaporator between the measurements. Before starting the analysis, the touch-sensitive block was blown by dried air up to the moment of the constant quartz plate fluctuations frequency. The duration of the analysis took 2-5 min.

The piezosensor analytical signals were processed using linear (principal component analysis) and nonlinear (ANN) methods.

The “electronic nose” application was investigated for the detection of widespread dangerous substances such as aliphatic nitrohydrocarbons (nitromethane, nitroethane, 1– and 2– nitropropane) in air. As piezosensors modifiers, we applied squalan, l-apiezon, 1,2,3-tris(-cianoethoxy)propane, triton X -100, triton X - 305, triethanolamine. The modifier solution was deposited onto the piezosensor electrode surface with the help of a microsyringe.

The use of piezosensors is a special case of more general touch-sensitive devices. Piezosensors are simple in use, compact and applicable for pollutant detection directly in gas emission. However in complex systems, their selectivity is insufficient; the outside components cause significant touch-sensitive function deviations from the theoretical (linear) dependence (Sauerbrey equation).

Results and discussion

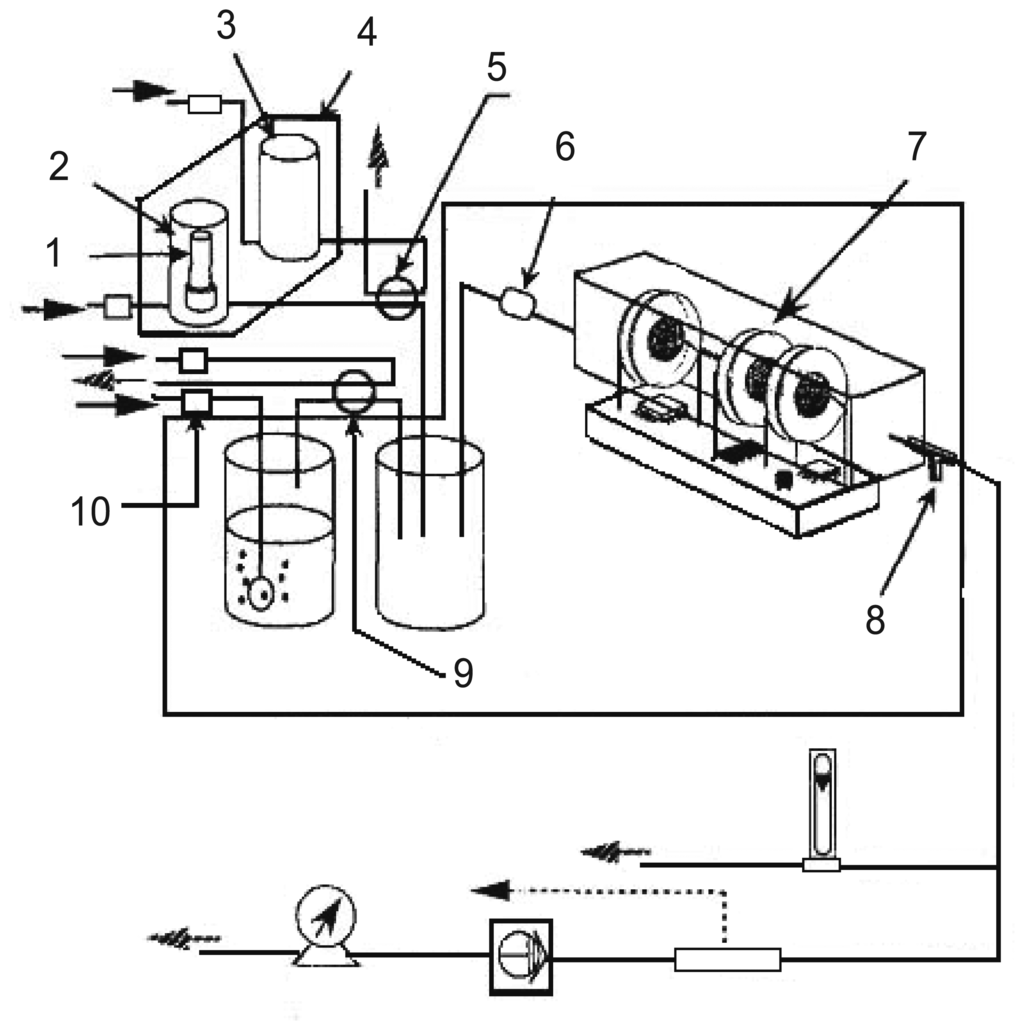

The circuit of the multitouch-sensitive gas-sorption system called the “electronic nose” (Figure 1) was developed. The sensor included in the system is characterized by a cross-sensitivity to the analyzed gas environments components and possess rather high signal reproducibility that is easily identifiable through AN. Moreover, the realization of an environment for on-line monitoring is possible; the “electronic nose” is applicable both for chemical component recognition and foodstuff components [1, 8-10].

Figure 1.

Circuit of gas-sorption experimental set:1,2 ampoule with compound; 3 intermediate buffer capacity; 4 thermostatic capacity; 5, 9 three-running crane; 6 buffer capacity; 7 cell of detecting; 8 two-running crane; 10 traps for impurity.

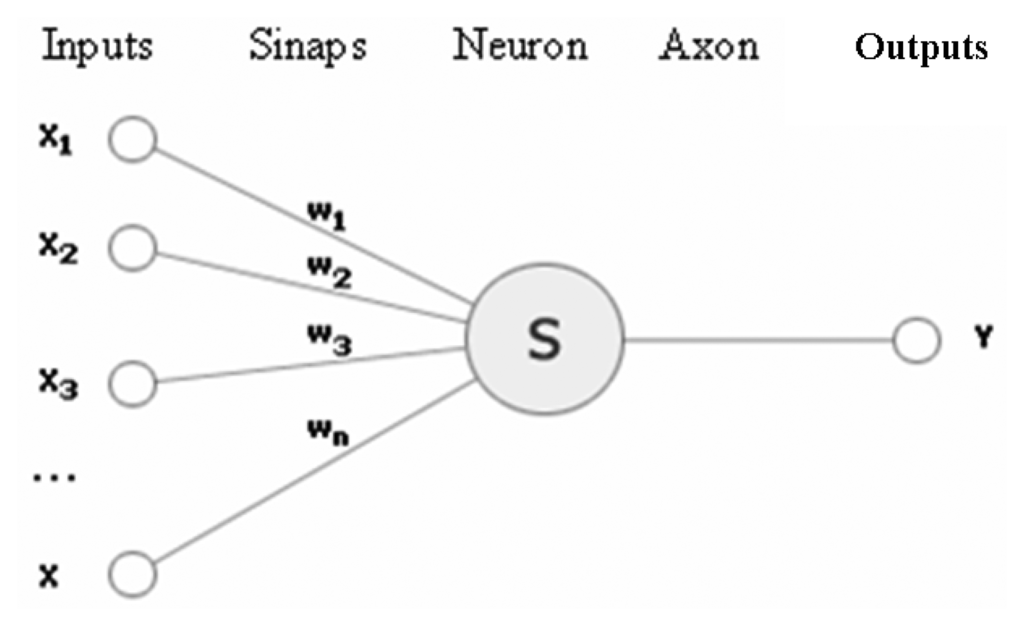

Formal ANN are made from artificial (formal) neurons. The most widespread variant is the Mac-Culloh and Pitts neuron [8], representing the elementary model of the biological neuron (Figure 2). Its functioning is described by the following equation:

Figure 2.

Artifical neuron.

where Y ∈ R – a neuron output; xj ∈ R, j – input neuron signals; wj – weight factors; F – linear or nonlinear neuron activation function with the range of R definition.

The following sigmoid functions are used as the function of activation:

For the effective decision of the qualitative or quantitative substances analysis, ANN should pass a training stage. In addition, the adjustment of topology, weight factors, and function parameters of activation or other network parameters are carried out by specially formed training selection.

At training, the artificial neural networks should have the correct output signals. To achieve, it the training sample is made from pairs (zg, xg) . The training is considered to be complete, when the criterion of the quality of training is stabilized at some level. By the way of such criterion residual dispersion is applied:

where yg is a target signal of ANN.

At small dispersion, the accuracy of artificial neural networks approximation of the graduation characteristic is considered to be sufficient. Once the training comes to an end, if the accuracy is not achieved, the complexity of ANN must be increased, increasing k or passing larger number of layers to the network.

The training procedure is reduced to criterion function minimization on the set of possible values of wj. For ANN training, the method of back-mistake propagation received the greatest attention and it is called the algorithmic version of the gradient method.

Construction of the sensors graduation parameters

The graduation of a sensor (gauge, measuring channel) consists in the measurement of the input value (factor) and the output signal of X sensor. As a result one has a set of values (Zg, Xg); g=1, N, where N is a number of experiences. The unknown quantity is the graduation dependence Z=Z(X) found by the results of the experiment.

The task is reduced to the standard approximation and there are numerous methods and techniques to solve it. As the values Zg and Xg can have measuring errors, then in order to obtain the dependence of graduation the statistical methods (regression or the confluent analysis) are used.

The principle of the use of the artificial neural network approach is based on the well-known theorem [8], according to which the continuous function, given on an individual cube, variable quantities can approximate with the given accuracy of formal three-layered neural networks. Such networks contain a layer of the input units representing input signal forks. One intermediate (latent) layer and output layer (last two layers) consist from formal neurons. In ANN structure, only the neuron number of the latent layer k needs solving. To calculate it we use the following ratio:

where n and m – are the number of inputs and outputs of neural network accordingly. It is recommended to choose the number k close to the top borders of values.

ANN provide the exact reproduction of the approximation function so it makes them effective, in contradistinction to the traditional methods.

The ANN advantages consist in the absence of the necessity of the detailed information of a priority concerning the approximation function (in the regress analysis at absence of such information function display on basic) and universality. The ANN restrictions are caused by the unusual form of the representation of a result as the program simulating the work of a trained network. At the neural network approach, the substantial interpretation of the received dependences is also complicated. For example, in multitouch-sensitive systems it is impossible to the separate sensors' level selectivity in relation to the determined substance or to the range on the information level.

The responses of multitouch-sensitive system to the influence of aliphatic nitrohydrocarbons C1 - C3 vapors in a wide range of concentration (0.005-0.075 g/m3) are studied. This interval includes their extreme admissible concentration in the air of the working zone (0.03 g/m3). The ANN structure and its parameters are optimized to decrease the detection mistake. The accuracy of detection AN is 1.5-2.3 %, besides the array did not contain sensors, which were selective to the separate components of a mixture. The ANN property to be trained makes them more perspective in comparison with the algorithms of the information processing based on the use of the rigid system of the preconditions.

Thus, the solution of problems of the chemical analysis of complex environments is possible using the multitouch-sensitive approach. This approach consists of the simultaneous use of measurements of chemical sensor arrays in combination with the mathematical method of data processing, taking into account nonlinearity of the response or other distortions of the function of sensors in the multicompo-nent environment. With the multitouch approach it becomes possible to get the known accurate information about the compound concentration in the multicomponent environment. The selectivity of separate sensors used as a set does not have any meaning of principle. On the contrary, it is important that the sensors have sensitivity to the maximal compound number and differ in parameters of this sensitivity.

The combination of a matrix of non-selective piezoelectric sensors and the method of signal processing has resulted in the creation of an analytical device for the qualitative recognition of complex gas mixes, and the multicomponent analysis. As required, both operations can be carried out with one experimental measurement of an analytical signal from an “electronic nose”.

Acknowledgments

The author thanks Dr. Natalya Ezhova for her assistance in correcting the article translation into English.

References

- Vlasov, Yu.G.; Legin, A.V.; Rudnit'kaya, A.M. Electronic language multitouch system on the basis of a file of nonselective sensor controls and methods of recognition of images. Gauges and systems 1999, 6, 3. [Google Scholar]

- Rudnitskaya, A.; Ehlert, A.; Legin, A.; Vlasov, Y.; Büttgenbach, S. Multisensor system on the basis of an array of non-specific chemical sensors and artificial neural networks for the determination of inorganic pollutants in a model groundwater. Talanta 2001, 2, 425. [Google Scholar]

- Lu, Y.; Bian, L.; Yang, P. Quantitative artificial neural network for electronic noses. Anal. Chim. Acta 2000, 417, 101. [Google Scholar]

- Mahfouz, I.A. Drilling wear detection and classification using vibration signals and artificial neural network. Int. Journal of Machine Tools & Manufac. 2003, 43, 707. [Google Scholar]

- Kuo, R.J. Multi-sensor integration for on-line tool wear estimation through artificial neural networks and fuzzy neural network. Engin. Appl. of Art. Intel. 2000, 13, 249. [Google Scholar]

- Sriyudthsak, M.; Teeramongkolrasasmee, A.; Moriizumi, T. Radial basis neural networks for identification of volatile organic compounds, Sens. Actuators B 2000, 65, 358. [Google Scholar]

- Zhang, H.; Balaban, M.O.; Principe, J.P. Improving pattern recognition of electronic nose data with time-delay neural networks. Sens. Actuators B 2003, 96, 385. [Google Scholar]

- Wasserman, F. Neurocomputing engineering: the theory and practice; Moscow; World, 1992. [Google Scholar]

- Filaretov, G.F.; Zhitkov, A.N. Application of artificial networks in touch systems. Gauges and systems 1999, 5, 2. [Google Scholar]

- Semenov, L.A.; Siraya, T.N. Methods of construction of the graduation characteristics of means of measurement; Moscow; Standards, 1986. [Google Scholar]

© 2005 by MDPI ( http://www.mdpi.org). Reproduction is permitted for non-commercial purposes.