The wafer transport robotic arm is an important actuator in semiconductor manufacturing equipment, and its performance directly affects production throughput and yield. As semiconductor process nodes continue to shrink, stringent requirements are placed on the robotic arm’s positioning accuracy, stability, and operational efficiency [

1,

2,

3]. Traditional time-optimal trajectory planning methods often focus on achieving the fastest point-to-point motion of the robotic arm’s end effector while neglecting the issue of residual vibrations at the end effector caused by the flexible characteristics of the transmission system. Such vibrations can lead to a decrease in the positioning accuracy of the robotic arm’s end effector, and in severe cases, may cause wafer displacement or breakage, resulting in reduced productivity and significant economic losses [

4,

5]. Therefore, efficient and precise vibration-suppression trajectory planning has become one of the core technologies in the development of advanced wafer robots.

The vibration suppression methods for robotic arms can be categorized into passive and active vibration suppression. Passive vibration suppression primarily involves optimizing the topology to improve mass distribution, using lightweight, stiff materials to enhance the equivalent stiffness, and incorporating damping devices and energy-absorbing components to suppress vibrations through physical mechanisms. These passive vibration suppression schemes do not require external energy input, are cost-effective, but have limited adaptability to time-varying operating conditions, making them difficult to meet the requirements of wafer transport robotic arms [

6]. Active vibration suppression, on the other hand, reduces the vibrations of the robot by improving control strategies, thereby enhancing motion precision and stability. PID control, with its simple and intuitive structure and low implementation difficulty, is widely used in the motion control of industrial robots to suppress elastic vibrations in robotic arms. Yang C et al. employed PID fuzzy control to suppress elastic vibrations in flexible robotic arms, improving the positioning and control accuracy of piezoelectric flexible arm ends [

7]. Guo et al. proposed a tracking control system integrating an incremental PID controller and a sliding mode robust controller, which demonstrated stronger accuracy, stability, and anti-interference capabilities compared to traditional PID control [

8]. In addressing similar robotic arm control problems, Wazzan utilized PID sliding mode control combined with a genetic algorithm to tune controller parameters, effectively improving the performance of the robotic arm’s PID controller [

9]. Despite the simplicity and intuitiveness of these control methods, these controllers are often optimized based on specific models, and their control parameters are difficult to meet the requirements for high precision and stability, especially when dealing with complex robotic arm structures or variable working environments.

Recently, researchers have commonly employed vibration suppression trajectory optimization to address the limitations of both passive and active vibration suppression, providing a more cost-effective and universally applicable solution for robotic arm vibration control. This approach has become one of the key research focuses in the field of robotic arm control [

10]. These methods formulate trajectory planning as a multi-objective or constrained optimization problem by simultaneously considering system dynamics, motion time, energy consumption, joint smoothness, and end-effector vibration, and they commonly introduce metaheuristic optimization algorithms to search for optimal solutions. These optimization algorithms, inspired by natural phenomena and biological behaviors, offer new approaches for solving trajectory planning and constrained optimization problems of this nature [

11]. The development of metaheuristic optimization algorithms can be broadly divided into two directions: global search and local optimization. Among them, the Genetic Algorithm (GA) is widely used in various global search optimization problems due to its strong capability in handling complex constraints, combinatorial optimization, and global exploration. Xu Qiang et al. proposed a genetic algorithm combined with a simulated annealing mechanism, which further improved the optimization accuracy, shortened the robotic arm’s motion time, and enhanced its work efficiency [

12]. Meanwhile, Kheshti et al. applied genetic algorithms to adjust the gain optimization of sliding mode controllers, reducing the time required for a manipulator arm to complete a predefined motion trajectory [

13]. However, the computational model of genetic algorithms is relatively complex, and its use has certain limitations. In contrast, Particle Swarm Optimization (PSO) has a simpler algorithm structure and stronger local optimization capability. In this context, Wu N et al. proposed an improved particle swarm optimization algorithm (RTPPSO) to optimize the robotic arm’s joint angles or path. By introducing an adaptive weight strategy, they significantly improved the robotic arm’s work efficiency [

14]. However, when solving complex problems with multiple dimensions, strong constraints, and strong coupling, PSO is prone to accuracy degradation and insufficient global search capability due to the influence of random disturbances [

15,

16,

17]. Researchers have proposed various new optimization algorithms and introduced different solution strategies to address the shortcomings of these two algorithms. Yue et al. applied a gray wolf optimization algorithm with a probabilistic disturbance strategy to solve the time-optimal problem. This optimization strategy effectively balanced the weight between local optimization and global search [

18]. However, the gray wolf population may converge around suboptimal individuals, leading to premature convergence issues [

19,

20]. Pu Q et al. introduced an improved wild dog optimization algorithm for robotic arm time-impact optimization [

21,

22], but they did not perform tests for solving high-dimensional problems using the wild dog optimization algorithm. Additionally, to improve global search capability and address the issue of search direction disturbance, Lv Yun peng et al. proposed an inverse kinematics solver based on a multi-strategy improved dung beetle optimization algorithm. However, this improved algorithm has not been applied to the multi-objective vibration optimization direction [

23]. Widyianto Agus et al. addressed the issue of the shipboard two-degree-of-freedom robotic arm being affected by environmental factors and proposed a real-time tuning of PD control parameters based on an ant colony algorithm, significantly improving the stability of shipboard equipment [

24]. Abro et al. combined ant colony optimization’s pheromone learning with the Denavit–Hartenberg (DH) method to develop a robotic arm error model, further enhancing the accuracy of global search and improving the reliability and accuracy of industrial robotic systems [

25]. However, the ant colony algorithm is heavily dependent on the initial model, making it difficult to avoid local optimal solutions. The Whale Optimization Algorithm (WOA) introduced a random spiral search step, eliminating the need for crossover and mutation operators, with a simpler program structure. Wang Fang et al. applied a hybrid whale optimization algorithm to optimize the time-impact optimal trajectory of industrial robotic arms, using fifth-order B-splines for interpolation planning of motion trajectories in joint space [

26]. However, the performance of this algorithm significantly deteriorates in a multi-constraint environment and requires further integration with various improvement strategies [

27]. The Graylag Goose Optimization (GGO) algorithm introduced a group migration strategy [

28], demonstrating strong search capabilities in multi-objective problems and efficient local optimization when facing suboptimal solutions. Ashish Sharma et al. conducted eight multi-objective benchmark tests, with the results showing that the Multi-Objective Graylag Goose Optimization (MOGGO) algorithm exhibited excellent performance in terms of convergence [

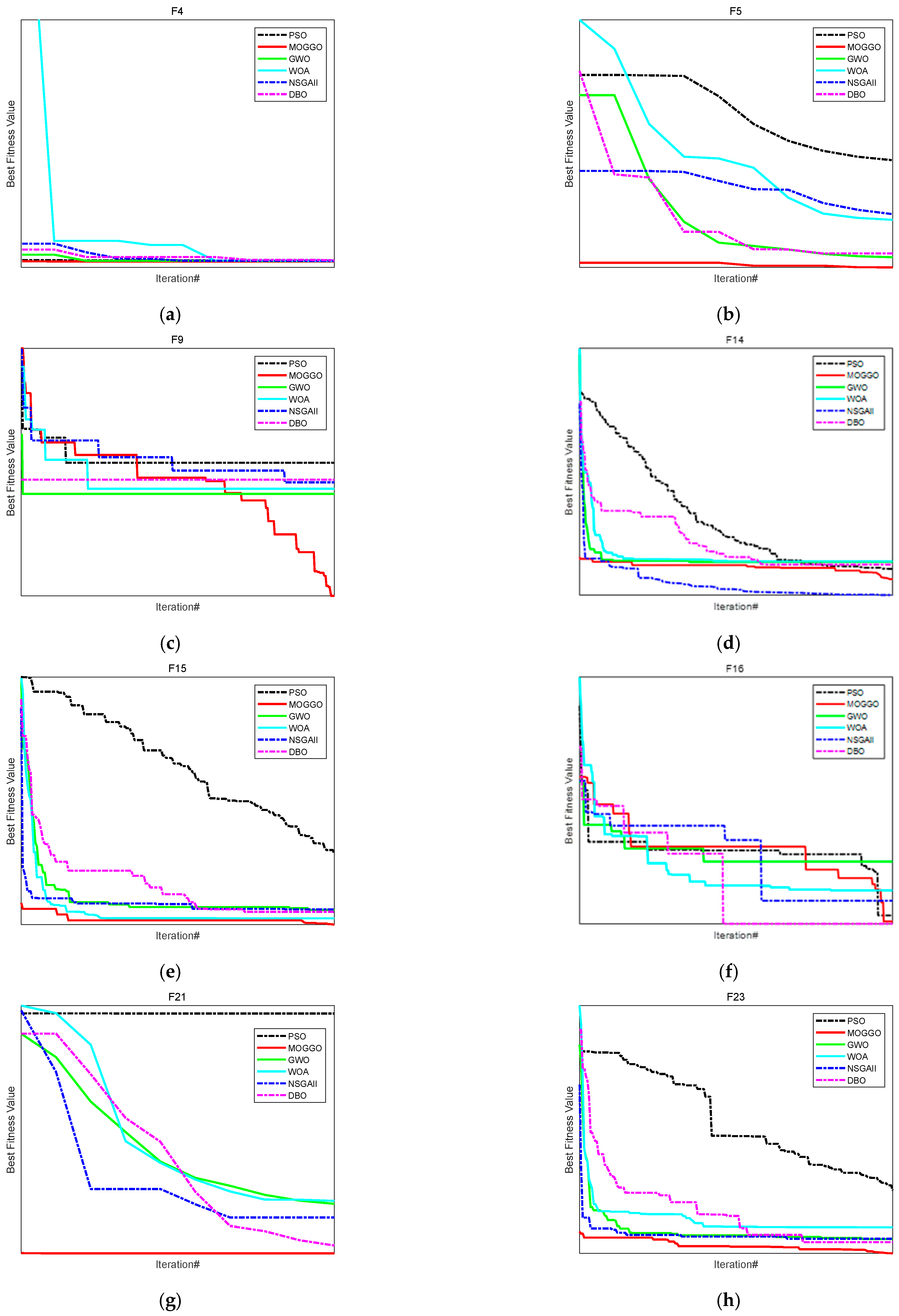

29].

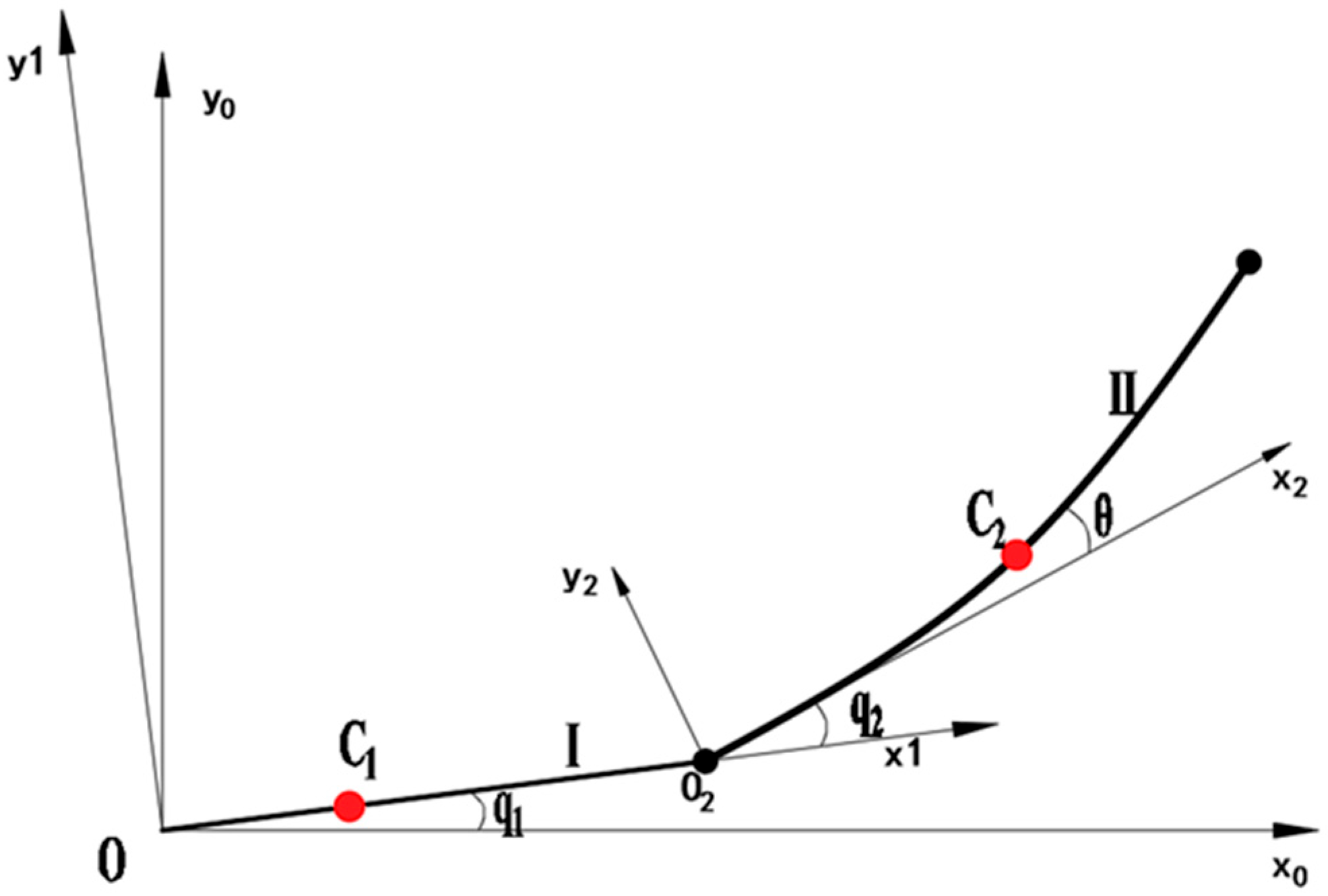

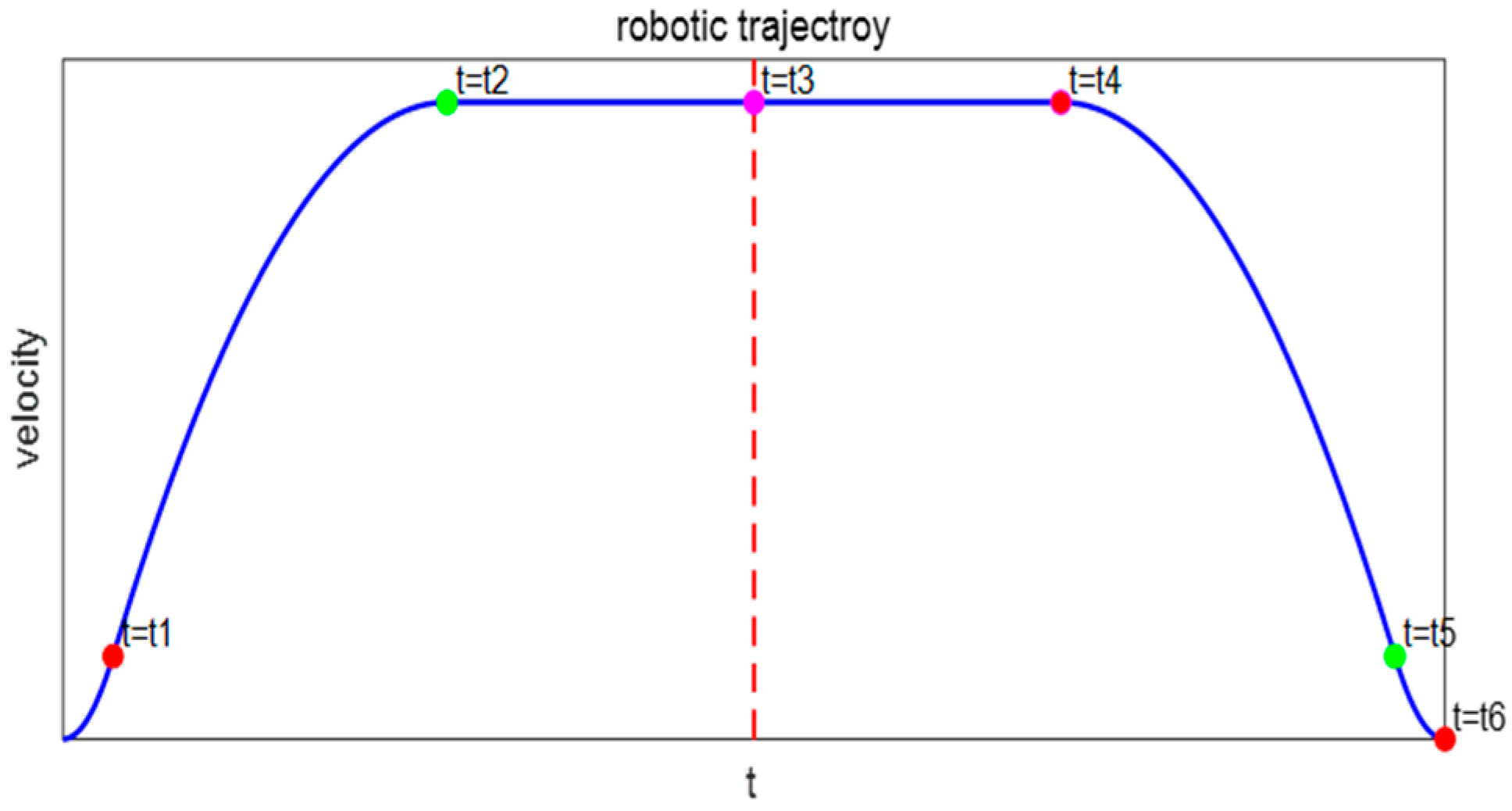

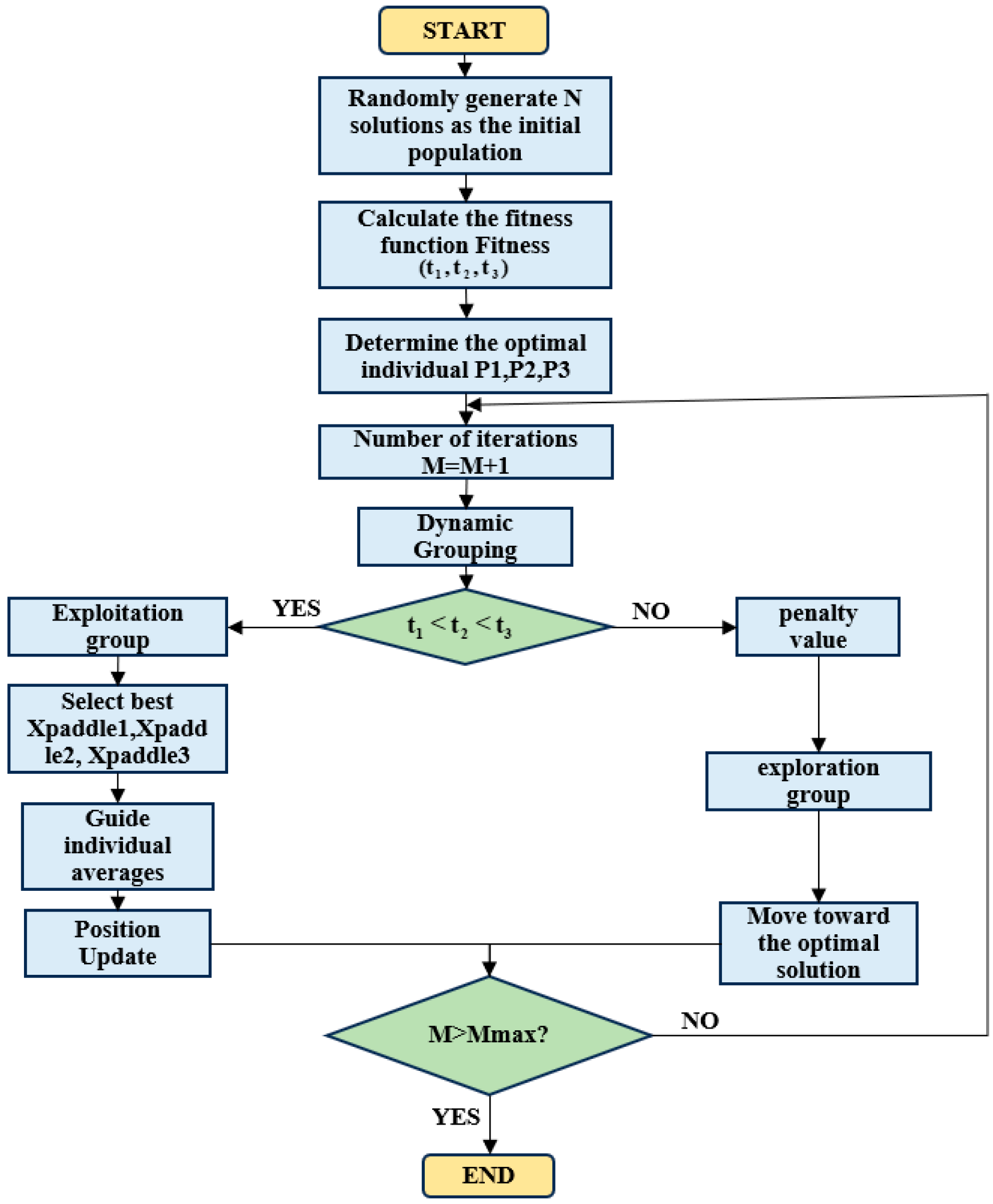

In summary, this paper introduces the GGO algorithm into the vibration suppression trajectory optimization problem of wafer transport robotic arms, providing a new feasible solution for multi-objective trajectory optimization. This study constructs the end dynamics equation of the flexible lower arm and integrates a multi-objective optimization model involving motion time, energy, and impact. Based on the multi-objective GGO algorithm, the trajectory parameters are solved, aiming to generate a set of Pareto-optimal trajectories with superior overall performance, offering a novel and efficient solution to improve the performance of the wafer transport system.