Comparative Analysis of Spectral Broadening Techniques for Optical Temperature Sensing in Yttrium Fluoride (YF3) Doped with Neodymium

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis and Structural Characterization of YF3:1%Nd

2.2. Luminescence Experimental Setup

3. Results

3.1. Structural and Morphological Properties

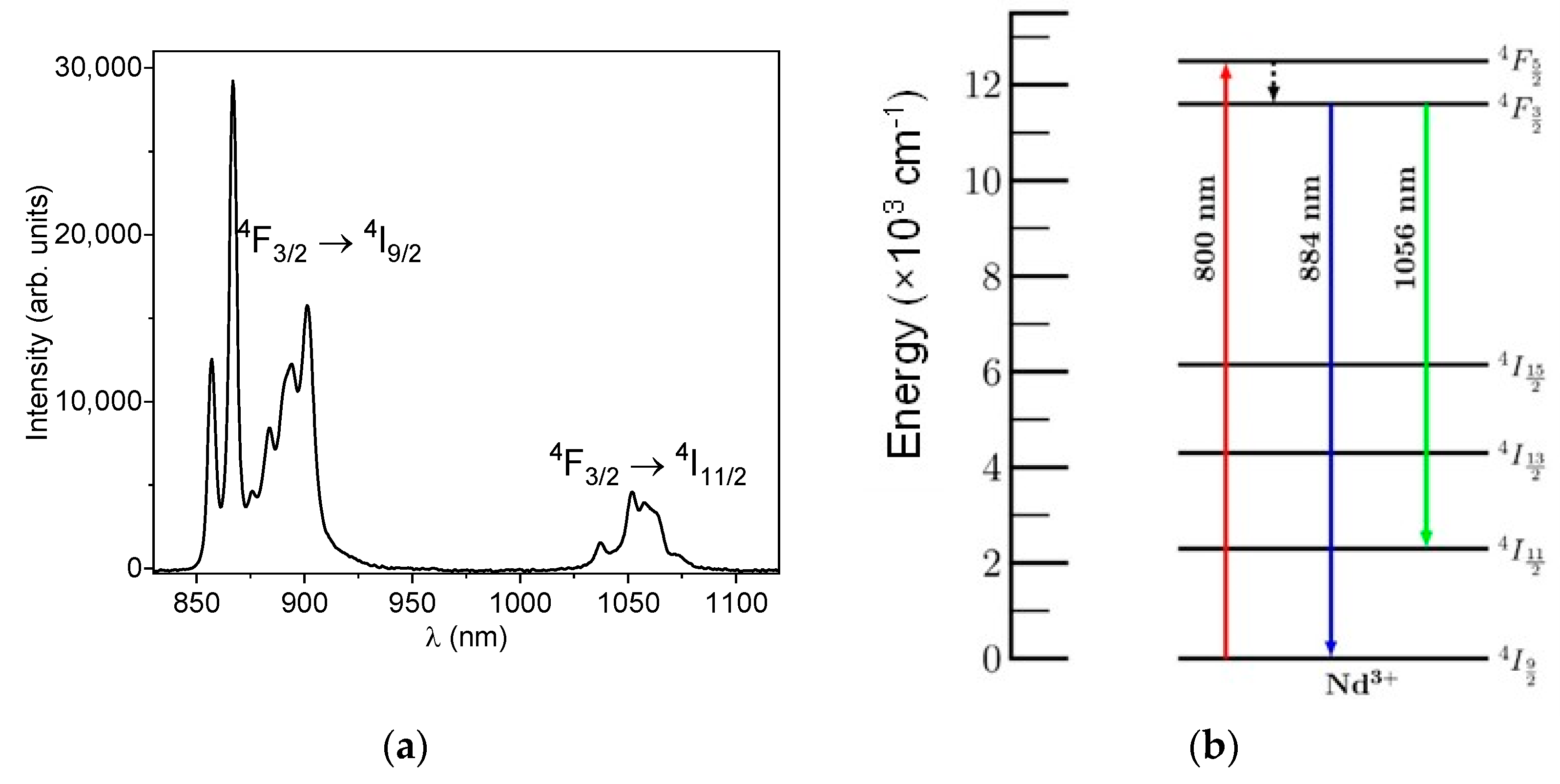

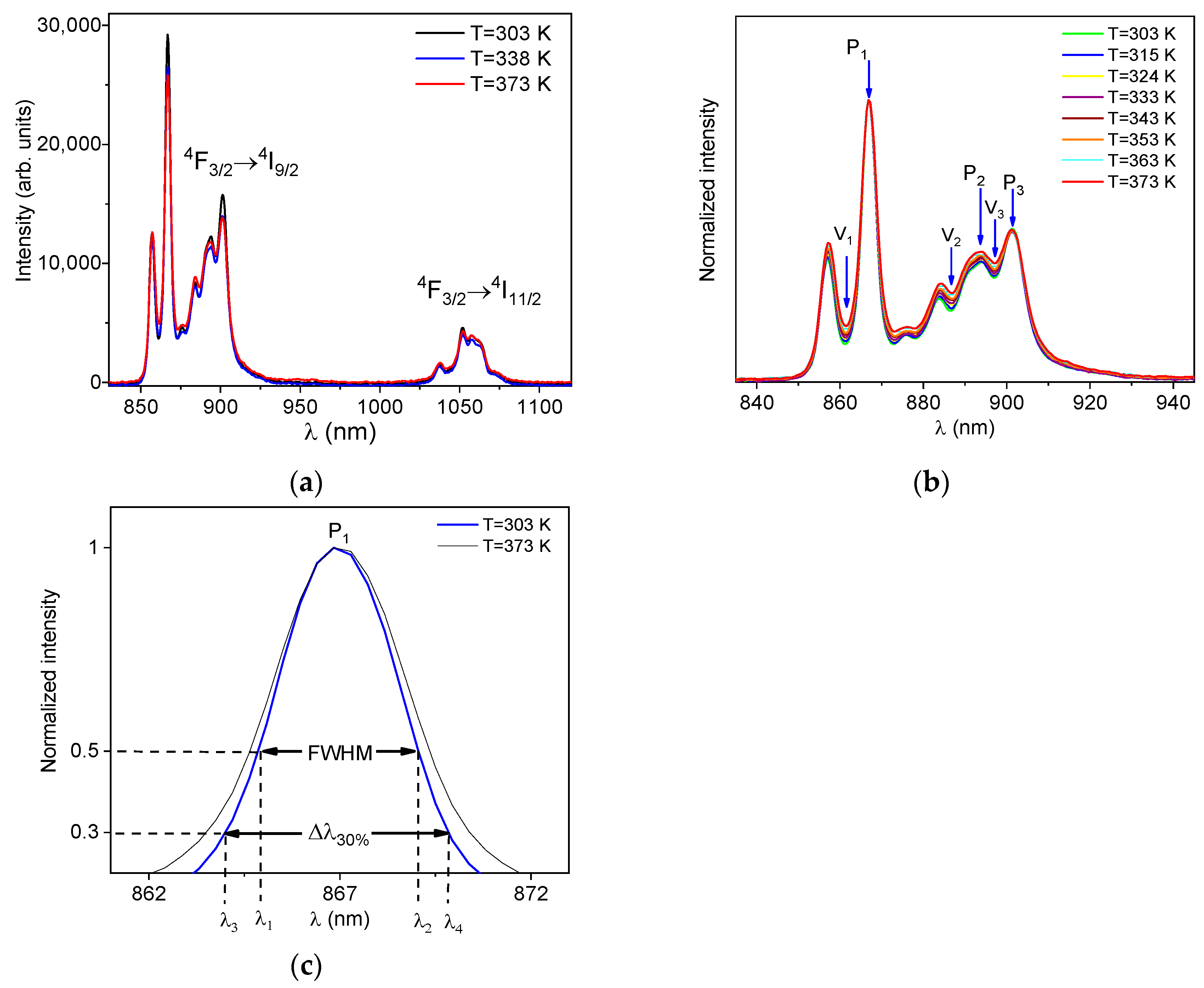

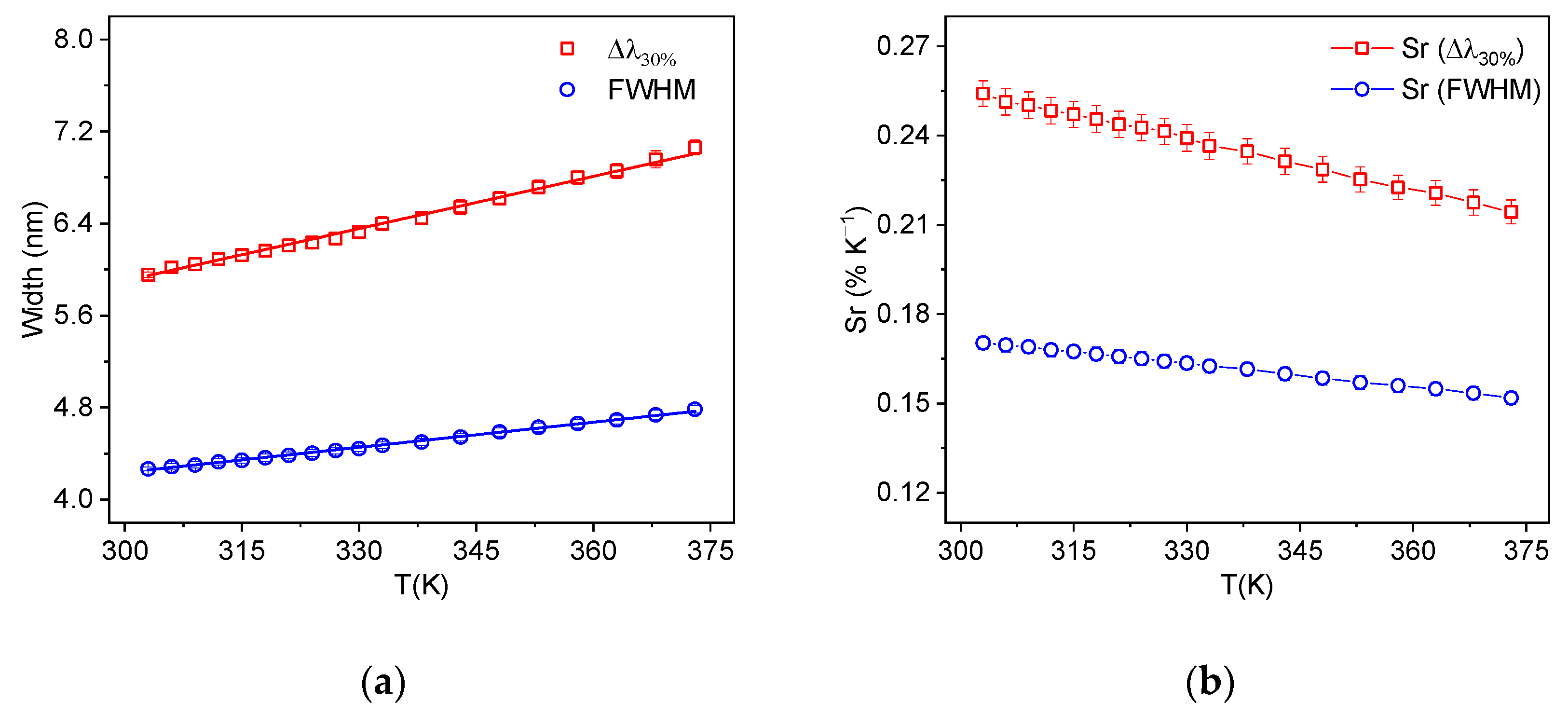

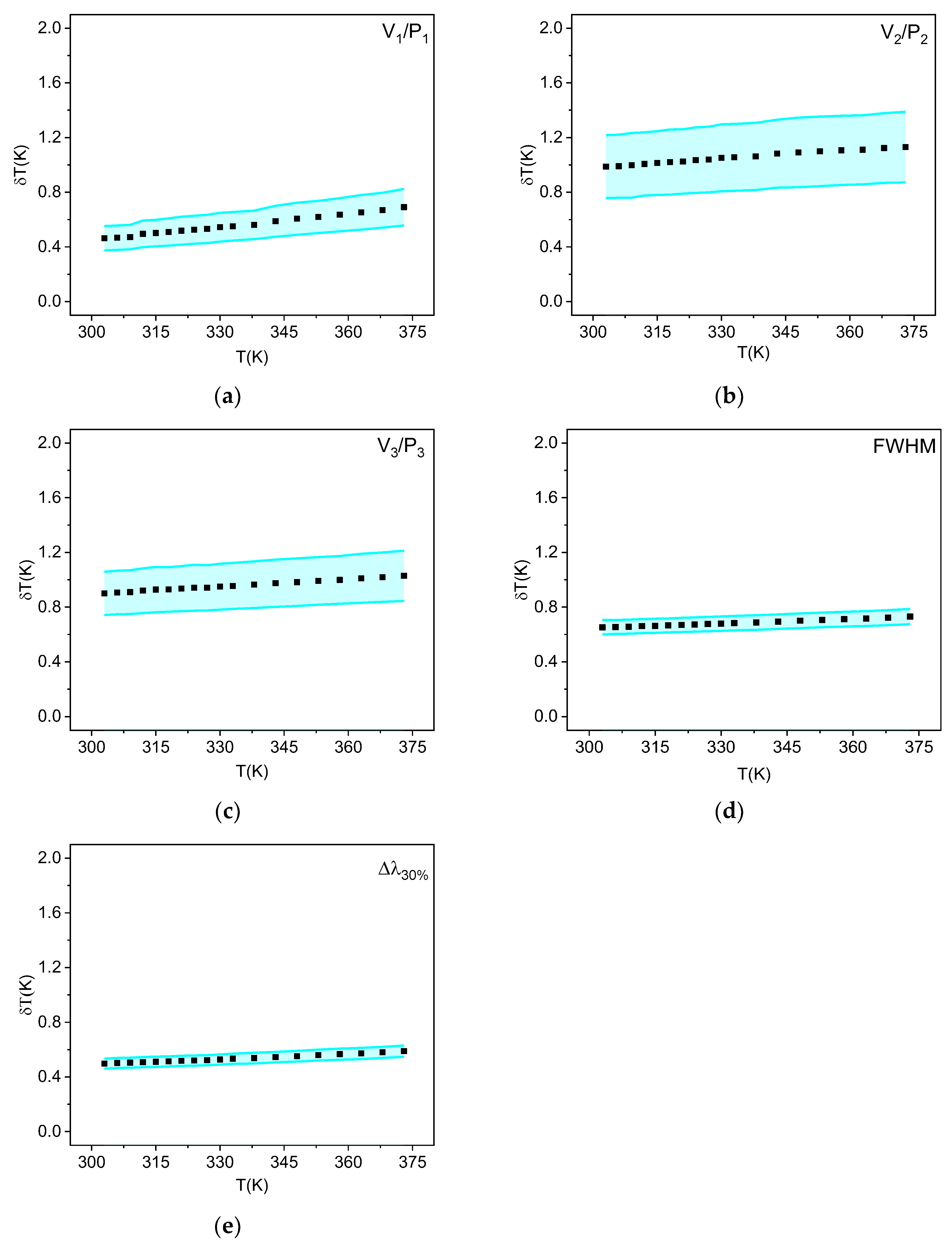

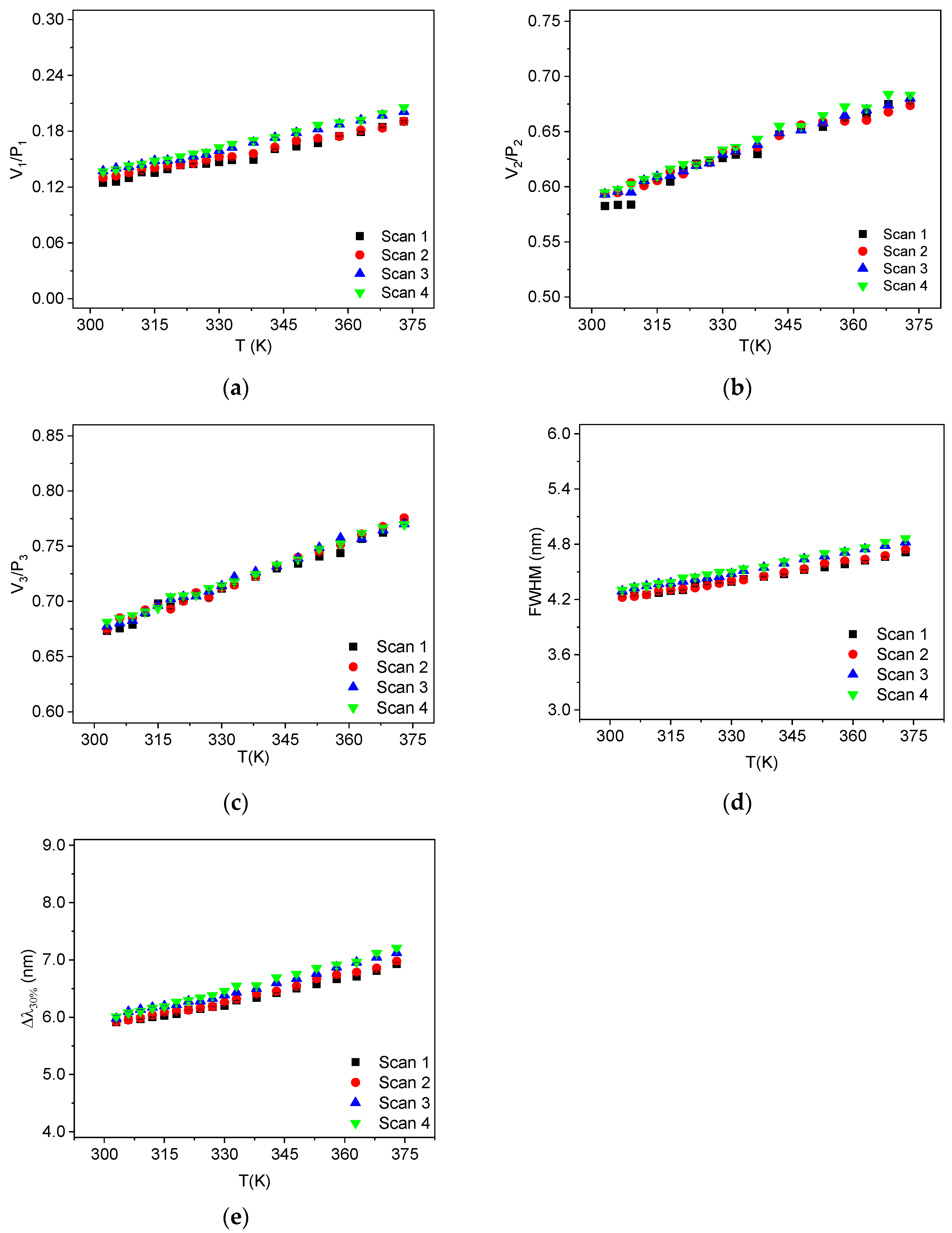

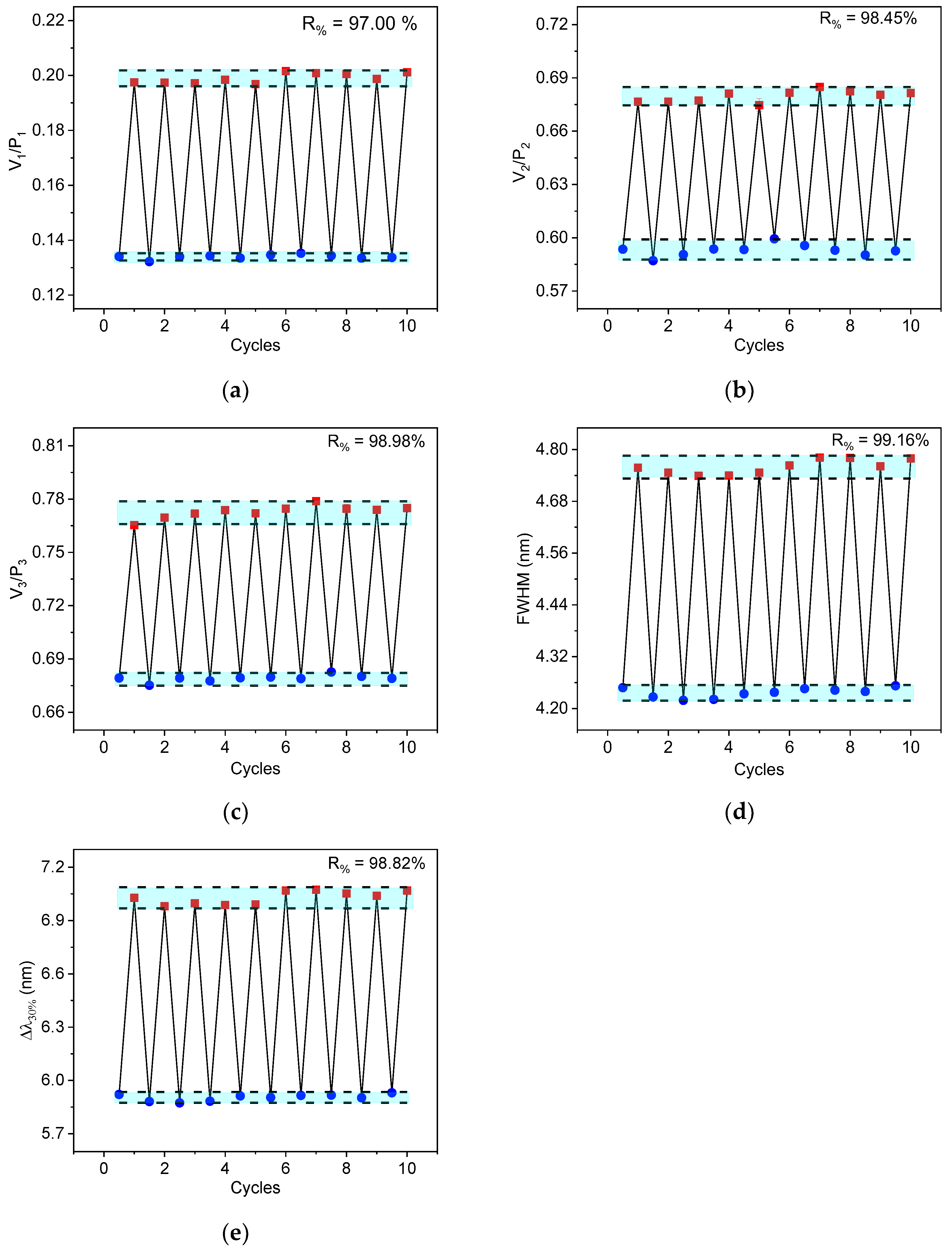

3.2. Optical Characterization and Sensing Analyses

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LIR | Luminescence intensity ratio |

| VPR | Valley-to-peak intensity ratio |

| FWHM | Full width at half maximum |

| Δλ30% | Bandwidth broadening measured at 30% of the maximum intensity |

References

- Brites, C.D.; Marin, R.; Suta, M.; Carneiro Neto, A.N.; Ximendes, E.; Jaque, D.; Carlos, L.D. Spotlight on luminescence thermometry: Basics, challenges, and cutting-edge applications. Adv. Mater. 2023, 35, 2302749. [Google Scholar]

- Abbas, M.T.; Khan, N.Z.; Mao, J.; Qiu, L.; Wei, X.; Chen, Y.; Khan, S.A. Lanthanide and transition metals doped materials for non-contact optical thermometry with promising approaches. Mater. Today Chem. 2022, 24, 100903. [Google Scholar]

- Bradac, C.; Lim, S.F.; Chang, H.-C.; Aharonovich, I. Optical nanoscale thermometry: From fundamental mechanisms to emerging practical applications. Adv. Opt. Mater. 2020, 8, 2000183. [Google Scholar] [CrossRef]

- Matuszewska, C.; Elzbieciak-Piecka, K.; Marciniak, L. Transition metal ion-based nanocrystalline luminescent thermometry in SrTiO3:Ni2+, Er3+ nanocrystals operating in the second optical window of biological tissues. J. Phys. Chem. C 2019, 123, 18646–18653. [Google Scholar]

- Kniec, K.; Tikhomirov, M.; Pozniak, B.; Ledwa, K.; Marciniak, L. LiAl5O8:Fe3+ and LiAl5O8:Fe3+, Nd3+ as a new luminescent nanothermometer operating in 1st biological optical window. Nanomaterials 2020, 10, 189. [Google Scholar] [CrossRef]

- Kalaivani, S.; Guleria, A.; Kumar, D.; Kannan, S. Bulk yttria as a host for lanthanides in biomedical applications: Influence of concentration gradients on structural, mechanical, optical, and in vitro imaging behavior. ACS Appl. Bio Mater. 2019, 2, 4634–4647. [Google Scholar] [CrossRef] [PubMed]

- Nexha, A.; Carvajal, J.J.; Pujol, M.C.; Díaz, F.; Aguiló, M. Lanthanide doped luminescence nanothermometers in the biological windows: Strategies and applications. Nanoscale 2021, 13, 7913–7987. [Google Scholar]

- Wang, Z.; Jia, M.; Zhang, M.; Jin, X.; Xu, H.; Fu, Z. Trimodal ratiometric luminescent thermometer covering three near-infrared transparency windows. Inorg. Chem. 2021, 60, 14944–14951. [Google Scholar]

- Rocha, U.; Kumar, K.U.; Jacinto, C.; Villa, I.; Sanz-Rodríguez, F.; de la Cruz, M.C.I.; Juarranz, A.; Carrasco, E.; van Veggel, F.C.J.M.; Bovero, E.; et al. Neodymium-doped LaF3 nanoparticles for fluorescence bioimaging in the second biological window. Small 2014, 10, 1141–1154. [Google Scholar] [CrossRef]

- Runowski, M.; Stopikowska, N.; Szeremeta, D.; Goderski, S.; Skwierczyńska, M.; Lis, S. Upconverting lanthanide fluoride core@ shell nanorods for luminescent thermometry in the first and second biological windows: β-NaYF4:Yb3+–Er3+@ SiO2 temperature sensor. ACS Appl. Mater. Interfaces 2019, 11, 13389–13396. [Google Scholar]

- Xiang, G.T.; Yang, M.L.; Ding, Y.X.; Wu, H.X.; Yao, L.; Wang, Y.J.; Zhou, X.J.; Li, L.; Ma, L.; Wang, X.J.; et al. Ratiometric nanothermometer CaSc2O4:Nd3+ operating in biological window for deep-tissue photothermal therapy. Ceram. Int. 2023, 49, 13816–13822. [Google Scholar] [CrossRef]

- Suo, H.; Hu, F.F.; Zhao, X.Q.; Zhang, Z.Y.; Li, T.; Duan, C.K.; Yin, M.; Guo, C.F. All-in-one thermometer-heater up-converting platform YF3: Yb3+, Tm3+ operating in the first biological window. J. Mater. Chem. C 2017, 5, 1501–1507. [Google Scholar] [CrossRef]

- Back, M.; Xu, J.; Ueda, J.; Benedetti, A.; Tanabe, S. Thermochromic narrow band gap phosphors for multimodal optical thermometry: The case of Y3+-stabilized β-Bi2O3:Nd3+. Chem. Mater. 2022, 34, 8198–8206. [Google Scholar] [CrossRef]

- Li, L.; Tian, G.; Deng, Y.S.; Wang, Y.J.; Cao, Z.M.; Ling, F.L.; Li, Y.H.; Jiang, S.; Xiang, G.T.; Zhou, X.J. Constructing ultra-sensitive dual-mode optical thermometers: Utilizing FIR of Mn4+/Eu3+ and lifetime of Mn4+ based on double perovskite tellurite phosphor. Opt. Express 2020, 28, 33747–33757. [Google Scholar] [CrossRef]

- Wang, C.L.; Jin, Y.H.; Zhang, R.T.; Yao, Q.; Hu, Y.H. A review and outlook of ratiometric optical thermometer based on thermally coupled levels and non-thermally coupled levels. J. Alloys Compd. 2022, 894, 162494. [Google Scholar] [CrossRef]

- Chen, S.Y.Z.; Song, W.H.; Cao, J.K.; Hu, F.F.; Guo, H. Highly sensitive optical thermometer based on FIR technique of transparent NaY2F7:Tm3+/Yb3+ glass ceramic. J. Alloys Compd. 2020, 825, 154011. [Google Scholar] [CrossRef]

- Runowski, M.; Wozny, P.; Martín, I.R.; Lavín, V.; Lis, S. Praseodymium doped YF3:Pr3+ nanoparticles as optical thermometer based on luminescence intensity ratio (LIR)–Studies in visible and NIR range. J. Lumin. 2019, 214, 116571. [Google Scholar] [CrossRef]

- Zhong, J.S.; Chen, D.Q.; Peng, Y.Z.; Lu, Y.D.; Chen, X.; Li, X.Y.; Ji, Z.G. A review on nanostructured glass ceramics for promising application in optical thermometry. J. Alloys Compd. 2018, 763, 34–48. [Google Scholar] [CrossRef]

- Dramićanin, M.D. Trends in luminescence thermometry. J. Appl. Phys. 2020, 128, 040902. [Google Scholar] [CrossRef]

- Liu, L.W.; Zhong, K.; Munro, T.; Alvarado, S.; Côte, R.; Creten, S.; Fron, E.; Ban, H.; Van der Auweraer, M.; Roozen, N.B.; et al. Wideband fluorescence-based thermometry by neural network recognition: Photothermal application with 10 ns time resolution. J. Appl. Phys. 2015, 118, 184906. [Google Scholar] [CrossRef]

- Ćirić, A.; Dramićanin, M.D. LumTHools-Software for fitting the temperature dependence of luminescence emission intensity, lifetime, bandshift, and bandwidth and luminescence thermometry and review of the theoretical models. J. Lumin. 2022, 252, 119413. [Google Scholar]

- Hernández-Rodríguez, M.A.; Lozano-Gorrín, A.D.; Martín, I.R.; Rodríguez-Mendoza, U.R.; Lavín, V. Comparison of the sensitivity as optical temperature sensor of nano-perovskite doped with Nd3+ ions in the first and second biological windows. Sens. Actuators B Chem. 2018, 255, 970–976. [Google Scholar] [CrossRef]

- Laia, A.S.; Hora, D.A.; Rezende, M.V.; Xing, Y.; Rodrigues, J.J.; Maciel, G.S.; Alencar, M.A.R.C. Comparing the performance of Nd3+-doped LiBaPO4 phosphors as optical temperature sensors within the first biological window exploiting luminescence intensity ratio and bandwidth methods. J. Lumin. 2020, 227, 117524. [Google Scholar]

- Zhou, Y.; Qin, F.; Zheng, Y.; Zhang, Z.; Cao, W. Fluorescence intensity ratio method for temperature sensing. Opt. Lett. 2015, 40, 4544–4547. [Google Scholar] [PubMed]

- Zhou, J.; Lei, R.; Wang, H.; Chen, C.; Chen, B.; Pan, E.; Xu, S. Er3+/Yb3+-codoped ZrO2 nanocrystals as ratiometric luminescence nanothermometers that cover three biological windows. ACS Appl. Nano Mater. 2019, 3, 186–194. [Google Scholar]

- Cruz, B.M.; Lilge, T.S.; Andrade, A.B.; Moura, R.P.R.; Alencar, M.A.R.C.; Rodrigues, J.J.; Valerio, M.E.G.; Macedo, Z.S. One-step synthesis of YF3:Nd rod-like particles for contactless luminescent thermometers. Opt. Mater. 2022, 131, 112661. [Google Scholar]

- Ansari, A.A.; Parchur, A.K.; Nazeeruddin, M.K.; Tavakoli, M.M. Luminescent lanthanide nanocomposites in thermometry: Chemistry of dopant ions and host matrices. Coord. Chem. Rev. 2021, 444, 214040. [Google Scholar]

- Brites, C.D.; Balabhadra, S.; Carlos, L.D. Lanthanide-based thermometers: At the cutting-edge of luminescence thermometry. Adv. Opt. Mater. 2019, 7, 1801239. [Google Scholar] [CrossRef]

- Dramićanin, M.D. Sensing temperature via downshifting emissions of lanthanide-doped metal oxides and salts. A review. Methods Appl. Fluoresc. 2016, 4, 042001. [Google Scholar]

- Suo, H.; Zhao, X.; Zhang, Z.; Wang, Y.; Sun, J.; Jin, M.; Guo, C. Rational design of ratiometric luminescence thermometry based on thermally coupled levels for bioapplications. Laser Photonics Rev. 2021, 15, 2000319. [Google Scholar]

- Kolesnikov, I.E.; Kalinichev, A.A.; Kurochkin, M.A.; Golyeva, E.V.; Kolesnikov, E.Y.; Kurochkin, A.V.; Mikhailov, M.D. YVO4:Nd3+ nanophosphors as NIR-to-NIR thermal sensors in wide temperature range. Sci. Rep. 2017, 7, 18002. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Li, L.P.; Qin, F.; Wang, C.W.; Zhang, Z.G. A multi-mode self-referenced optical thermometer based on low-doped YVO4:Eu3+ phosphor. J. Lumin. 2023, 263, 120168. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Wang, M.W.; Zhu, Y.Q.; Zhu, H.C.; Yan, D.T.; Liu, C.G.; Xu, C.S.; Liu, Y.X. Tm3+/Yb3+ codoped CaGdAlO4 phosphors for wide-range optical temperature sensing. J. Lumin. 2022, 248, 118935. [Google Scholar] [CrossRef]

- Rakov, N.; Xing, Y.; Maciel, G.S. Optical thermometry operation within all three biological windows using Nd3+:Er3+:Y2O3 nanocomposite phosphors. ACS Appl. Nano Mater. 2020, 3, 10479–10486. [Google Scholar] [CrossRef]

- Laia, A.S.; Gomes, M.A.; Brandao, S.A.C.; Xing, Y.T.; Maciel, G.S.; Macedo, Z.S.; Valerio, M.E.G.; Rodrigues, J.J., Jr.; Alencar, M.A.R.C. Nd3+ doped Y2O3 micro-and nanoparticles: A comparative study on temperature sensing and optical heating performance within the 1st biological window. Opt. Mater. 2023, 142, 114126. [Google Scholar] [CrossRef]

- Rakov, N.; Matias, F.; Maciel, G.S. Eu3+-doped Y7O6F9 ceramic powder phosphor for optical thermometry based on fluorescence spectral techniques. Phys. B Condens. Matter 2023, 652, 414625. [Google Scholar] [CrossRef]

- Chen, D.; Liang, Y.; Miao, S.; Bi, J.; Sun, K. Nd3+-doped Bi2SiO5 nanospheres for stable ratiometric optical thermometry in the first biological window. J. Lumin. 2021, 234, 117967. [Google Scholar] [CrossRef]

- Back, M.; Casagrande, E.; Trave, E.; Cristofori, D.; Ambrosi, E.; Dallo, F.; Riello, P. Confined-melting-assisted synthesis of bismuth silicate glass-ceramic nanoparticles: Formation and optical thermometry investigatio. ACS Appl. Mater. Interfaces 2020, 12, 55195–55204. [Google Scholar] [CrossRef]

- Far, L.Đ.; Lukić-Petrović, S.R.; Đorđević, V.; Vuković, K.; Glais, E.; Viana, B.; Dramićanin, M.D. Luminescence temperature sensing in visible and NIR spectral range using Dy3+ and Nd3+ doped YNbO4. Sens. Actuators A Phys. 2018, 270, 89–96. [Google Scholar]

- Gschwend, P.M.; Gschwend, P.M.; Starsich, F.H.L.; Keitel, R.C.; Pratsinis, S.E. Nd3+-Doped BiVO4 luminescent nanothermometers of high sensitivity. Chem. Commun. 2019, 55, 7147–7150. [Google Scholar] [CrossRef]

- Suo, H.; Zhao, X.; Zhang, Z.; Guo, C. Ultra-sensitive optical nano-thermometer LaPO4:Yb3+/Nd3+ based on thermo-enhanced NIR-to-NIR emissions. Chem. Eng. J. 2020, 389, 124506. [Google Scholar] [CrossRef]

- Balabhadra, S.; Debasu, M.L.; Brites, C.D.S.; Nunes, L.A.O.; Malta, O.L.; Rocha, J.; Carlos, L.D. Boosting the sensitivity of Nd3+-based luminescent nanothermometers. Nanoscale 2015, 7, 17261–17267. [Google Scholar] [CrossRef] [PubMed]

| Material | Ln3+ | Technique | λexc (nm) | T (K) | δT (K) | Sr (% K−1) | Ref. |

|---|---|---|---|---|---|---|---|

| Y2O3 | Nd3+/Er3+ | VPR | 808 | 298 | 4.8 | 0.45 | [34] |

| Y2O3 | Nd3+ | VPR | 800 | 294 | 1.6 | 0.304 | [35] |

| Y7O6F9 | Eu3+ | VPR | 532 | 318 | 0.5 | 0.35 | [36] |

| YVO4 | Nd3+ | FWHM | 808 | 298 | 3 | 0.14 | [31] |

| YVO4 | Eu3+ | FWHM | 305 | 313 | 3.3 | 0.10 | [32] |

| CaGdAlO4 | Tm3+/Yb3+ | FWHM | 980 | 300 | 1.25 | 0.124 | [33] |

| YAP | Nd3+ | FWHM | 532 | 293 | 0.37 | 3.3 | [22] |

| Bi2SiO5 | Nd3+ | LIR | 808 | 310 | 3.8 | 0.34 | [37] |

| Bi4Si3O12 | Nd3+ | LIR | 745 | 300 | 1 | 0.18 | [38] |

| YNbO4 | Nd3+ | LIR | 808 | 303 | 1.1 | 0.28 | [39] |

| BiVO4 | Nd3+ | LIR | 750 | 310 | 0.26 | 1.53 | [40] |

| LaPO4 | Yb3+/Nd3+ | LIR | 980 | 280 | 0.02 | 3.51 | [41] |

| Gd2O3 | Nd3+ | LIR | 532 | 288 | 0.14 | 1.75 | [42] |

| YF3 | Nd3+ | LIR | 800 | 303 | 0.7 ± 0.1 | 0.22 | [26] |

| YF3 | Nd3+ | VPR (V1/P1) | 800 | 303 | 0.46 ± 0.09 | 0.69 ± 0.02 | This work |

| YF3 | Nd3+ | VPR (V2/P2) | 800 | 303 | 1.0 ± 0.2 | 0.23 ± 0.02 | This work |

| YF3 | Nd3+ | VPR (V3/P3) | 800 | 303 | 0.9 ± 0.2 | 0.194 ± 0.006 | This work |

| YF3 | Nd3+ | FWHM | 800 | 303 | 0.65 ± 0.05 | 0.170 ± 0.002 | This work |

| YF3 | Nd3+ | Δλ30% | 800 | 303 | 0.50 ± 0.03 | 0.254 ± 0.004 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moura, R.P.R.; Cruz, B.M.; Lilge, T.S.; Andrade, A.B.; Valerio, M.E.G.; Macedo, Z.S.; Rodrigues, J.J., Jr.; Alencar, M.A.R.C. Comparative Analysis of Spectral Broadening Techniques for Optical Temperature Sensing in Yttrium Fluoride (YF3) Doped with Neodymium. Sensors 2025, 25, 2324. https://doi.org/10.3390/s25072324

Moura RPR, Cruz BM, Lilge TS, Andrade AB, Valerio MEG, Macedo ZS, Rodrigues JJ Jr., Alencar MARC. Comparative Analysis of Spectral Broadening Techniques for Optical Temperature Sensing in Yttrium Fluoride (YF3) Doped with Neodymium. Sensors. 2025; 25(7):2324. https://doi.org/10.3390/s25072324

Chicago/Turabian StyleMoura, Ruan P. R., Bárbara M. Cruz, Tatiane S. Lilge, Adriano B. Andrade, Mario E. G. Valerio, Zélia S. Macedo, José J. Rodrigues, Jr., and Márcio A. R. C. Alencar. 2025. "Comparative Analysis of Spectral Broadening Techniques for Optical Temperature Sensing in Yttrium Fluoride (YF3) Doped with Neodymium" Sensors 25, no. 7: 2324. https://doi.org/10.3390/s25072324

APA StyleMoura, R. P. R., Cruz, B. M., Lilge, T. S., Andrade, A. B., Valerio, M. E. G., Macedo, Z. S., Rodrigues, J. J., Jr., & Alencar, M. A. R. C. (2025). Comparative Analysis of Spectral Broadening Techniques for Optical Temperature Sensing in Yttrium Fluoride (YF3) Doped with Neodymium. Sensors, 25(7), 2324. https://doi.org/10.3390/s25072324