Hybrid Machine Learning-Based Fault-Tolerant Sensor Data Fusion and Anomaly Detection for Fire Risk Mitigation in IIoT Environment

Abstract

1. Introduction

1.1. Motivation

1.2. Contribution

- Multi-sensor fusion that accounts for faulty sensor data.

- The use of machine learning algorithms and probabilistic adjustments based on model outputs and sensor status refine and improve fire detection accuracy and reliability.

- DSET updates belief masses dynamically, mitigating faulty sensor impact through adaptive weighting.

- Handling faulty sensor data in edge computing results in immediate fire detection, enhancing security, and reducing latency compared to cloud computing.

- Integrated sensor inputs, including faulty sensor data, ensure that no fire-related signal parameters are missed or disregarded.

1.3. Organization

2. Related Work

2.1. Existing Research Studies

2.2. Significant Consideration

- Integrated Sensors Preprocessing (normal and faulty sensors): If sensor data were not pre-processed, it could lead to inaccurate, unreliable, or misleading analysis due to noise, errors, and inconsistencies. This could result in poor decision-making and reduced ML model performance. The proposed approach focused on preprocessing sensor data from multiple sensors by evaluating the sensor readings in real-time using anomaly detection to identify and filter out faulty readings [30,31]. Statistical methods should be used to assess the reliability of sensor readings. Data received from multiple types of sensors should be standardized by using normalization methods. This multi-layered pre-processing supports the identification of outliers. By this combined multi-sensor [32] pre-processing approach, clean sensor data and also faulty sensor data marked as anomaly-detected were sent to the machine learning model for further analysis. The challenges include handling real-time conflicts in sensor data and ensuring the integration of faulty sensors without compromising the overall system’s accuracy and managing sensor inconsistencies.

- Machine Learning-Based Probabilistic Model Adjustment and Sensor Reliability Enhancement for Optimized Predictions: It was recognized that sensor data would still have issues like noise, missing data, outliers, sensor drift, and other sensor-related problems. The proposed method used machine learning (ML) algorithms [33,34], which identified complex patterns and relationships within data. ML models learned and adapted to changing data over time and were designed to make predictions or classifications. The approach utilized machine learning algorithms to dynamically adjust probabilistic models based on sensor reliability and status, filtering out unreliable or faulty data. A combined weight factor, determined by the ML algorithms, was applied to each sensor’s data, resulting in precise predictions, even in the presence of unreliable or faulty sensors. Challenges include ensuring that the ML models remain robust and adaptable under changing conditions, processing large volumes of data in real-time, and making precise fire predictions despite unreliable sensor data.

- Improved Fire Prediction by Handling Sensor Data Dynamically: Relying on incomplete or faulty sensor data [35] could lead to inaccurate fire predictions. The proposed method ensured real-time adaptation to new sensor data, improving prediction accuracy. It handled conflicting sensor inputs [36] and provided timely updates, allowing the system to respond to changing conditions. This led to more reliable decision-making for fire detection. Challenges could be ensuring that the fire prediction model could adapt dynamically in real-time, handle unpredictable fire conditions, manage conflicting sensor data, and provide accurate predictions without compromising system reliability. Moreover, the model had to balance environmental changes and sensor data inconsistencies while ensuring that no critical fire risks were missed.

- Uncertainty Measurements and Decision-Making by Handling Faulty Sensors: This approach improved fire prediction accuracy by handling uncertainty and conflicting sensor data [37]. When multiple sensors provided data, the similarity and uncertainty between sensor readings and faulty sensor readings were measured to ensure reliable inputs. Using Hellinger and Deng Entropy, the Dempster–Shafer theory [38] with combined BPA helped combine multiple sources of evidence, even when data were incomplete or contradictory [39]. By combining belief and plausibility, this approach made real-time fire predictions that adapted to changing conditions, including sensor data issues. Challenges include the computational complexity of integrating multiple data sources in real-time while ensuring timely and accurate decision-making under unpredictable fire conditions was a major difficulty. Additionally, managing uncertainty in sensor data while ensuring effective and accurate fire predictions remained a significant challenge.

3. Hybrid Machine Learning-Based Fault-Tolerant Fire Prediction and Decision-Making

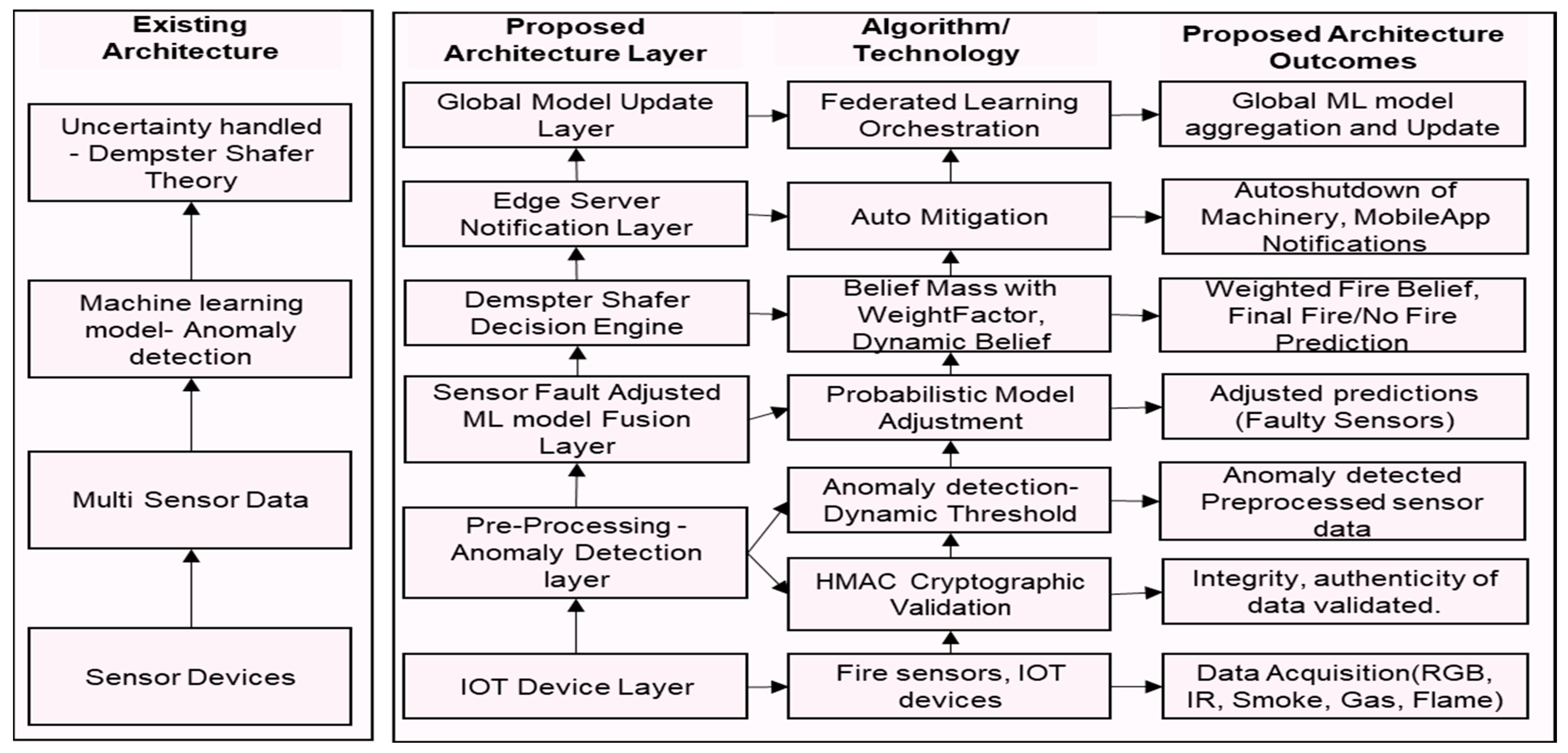

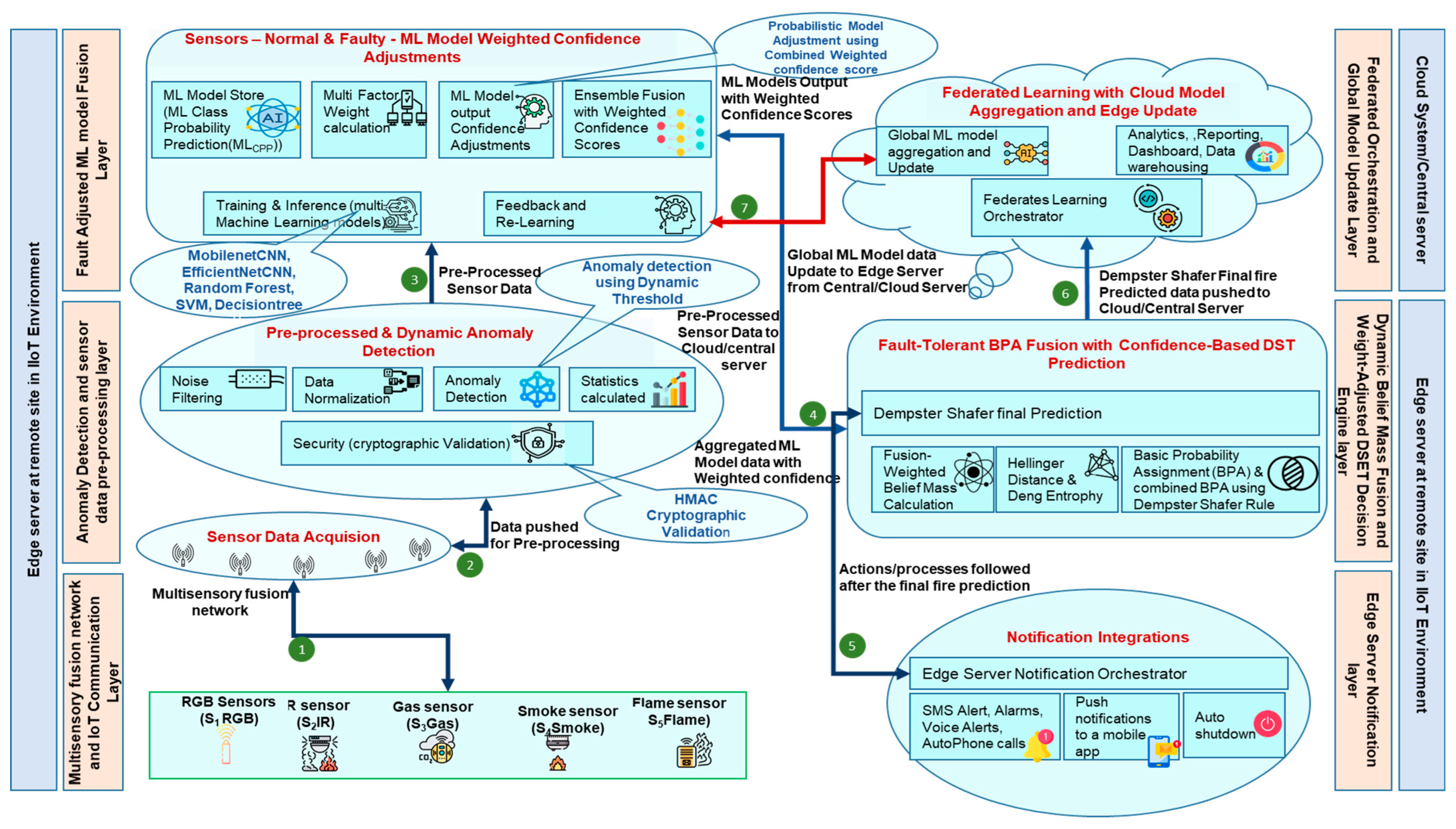

3.1. Proposed Architecture

- Multi-sensory Fusion Network and IoT Communication Layer: This layer consists of IoT devices and fire sensors; multiple types of sensors are used [41]. This work addresses the limitations of relying on a single sensor type, which may lead to false positives. Research is still in progress to have reliable multi-sensor fusion [42] and to provide the prediction for fire. Fire sensors collect and transmit data using LoRa over long distances. LoRaWAN Gateway receives the data from fire sensors and forwards it to the edge server locally. This type of technology solves the challenges of network range, battery life, security, and network scalability.

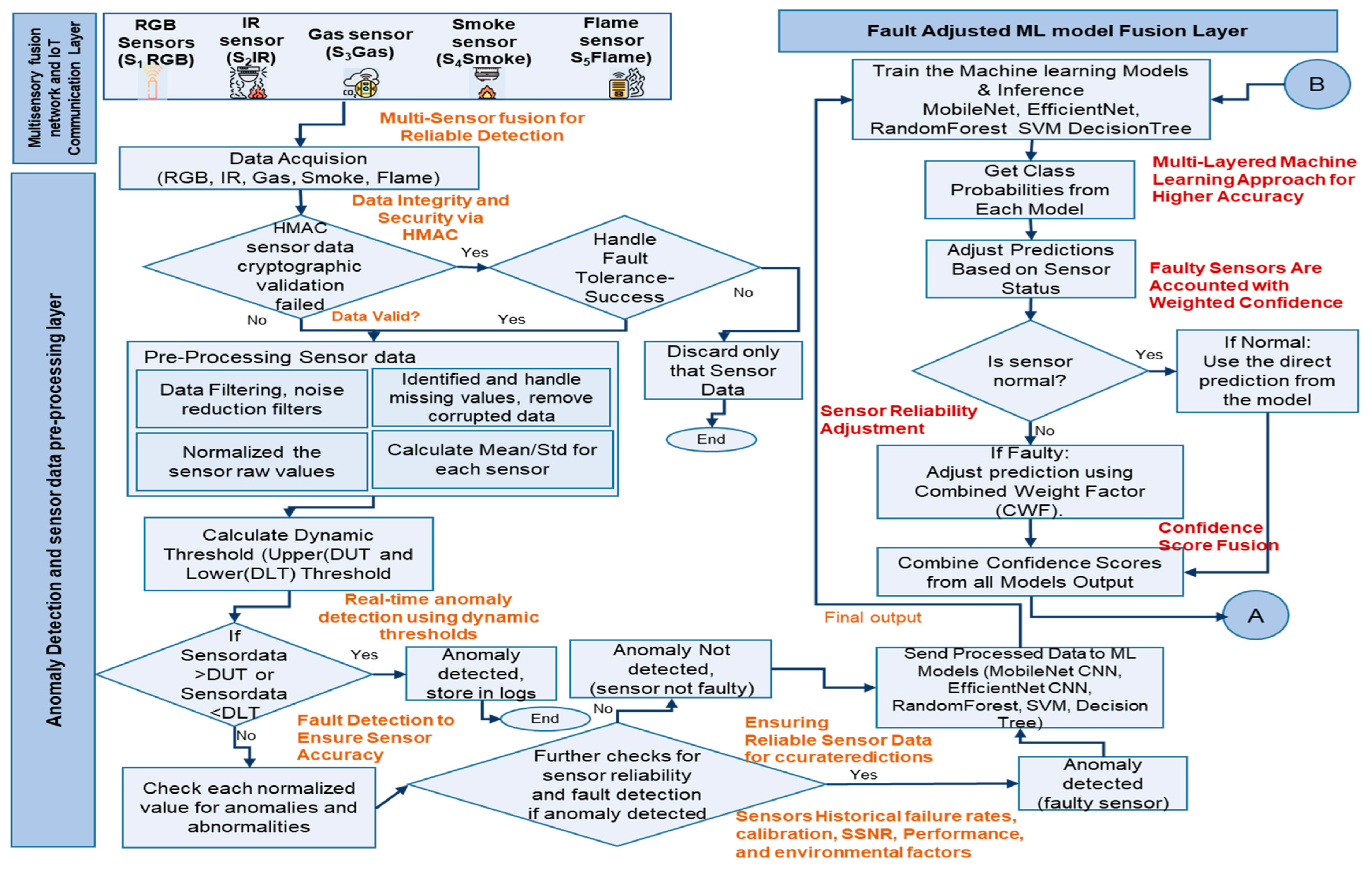

- Anomaly Detection and Sensor Data Pre-Processing Layer: The greatest challenge in predictive fire analysis is obtaining accurate data, as various conditions can affect the sensor readings, making the data unreliable and unclean, or it can be a faulty sensor [43]. After data acquisition (), this layer pre-processes the sensor data by accounting for the statuses of all sensors, including faulty ones and preprocessed {} output given to the ML model.

- Fault-Adjusted ML Model Fusion Layer: This layer is critical, as sensors may be faulty, degraded, or affected by noise, leading to inaccurate data [44]. This is solved by deploying multiple machine-learning models specific to every sensor type. Different machine learning models, specifically MobileNetCNN (for RGB image detection), EfficientNetCNN (for IR heat detection), RandomForest (for gas classification), SVM (for smoke), and decision tree (for flame detection), are used to extract evidence from sensor data, and by integrating and adjusting the multiple sensor inputs to enhance the overall model’s reliability by filtering out faulty or irrelevant data, ensuring more accurate fire predictions {}.

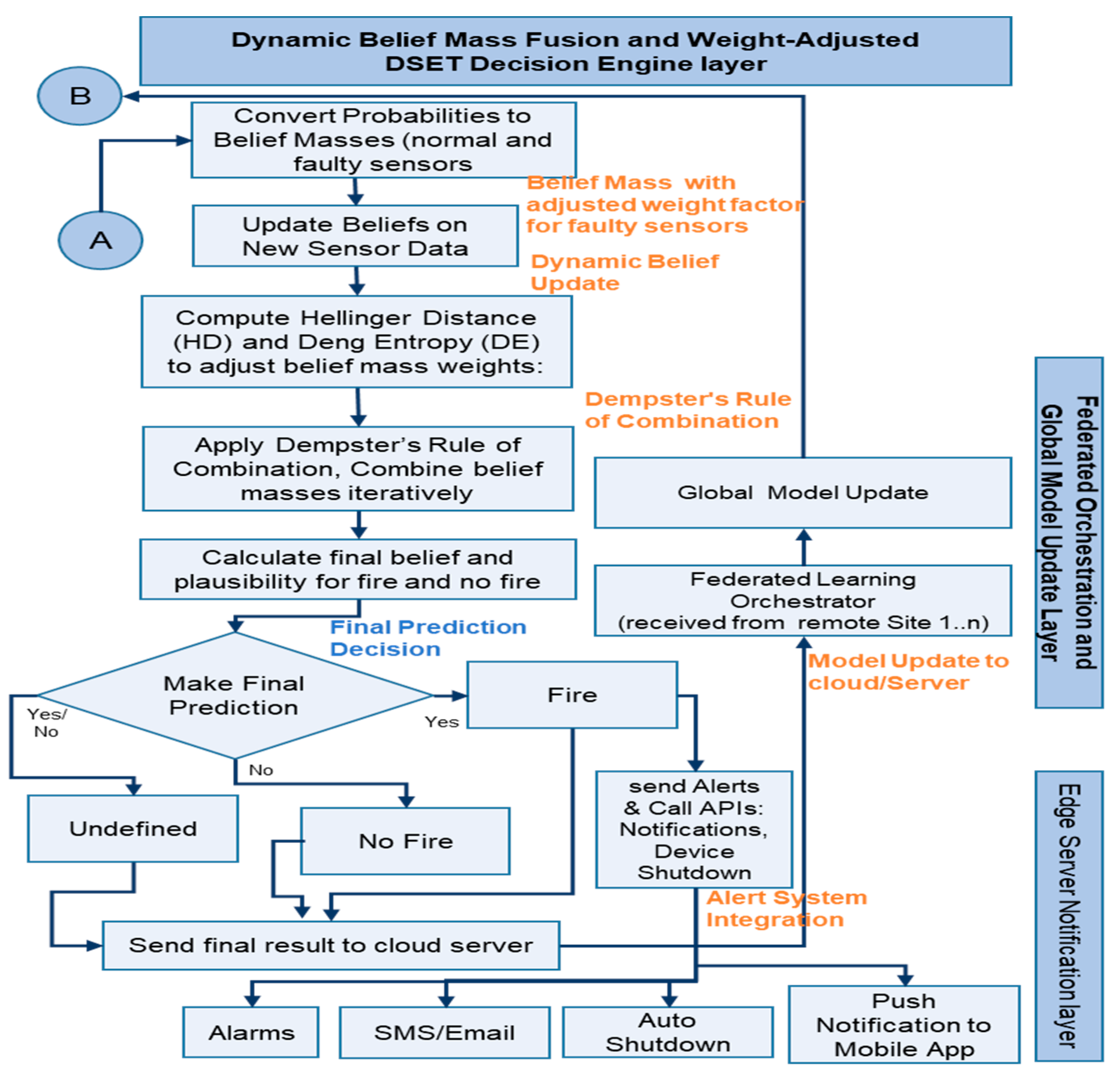

- Dynamic Belief Mass Fusion and Weight-Adjusted DSET Decision Engine layer: In an IIoT oil and gas environment where we have more uncertainties, a solution is required to make decisions in environments with conflicting, incomplete, or ambiguous data, and faulty sensors. This Dempster–Shafer evidence theory [45] decision engine layer combines uncertain or imprecise information from multiple sensors and handles faulty sensor data, supporting making decisions and fire predictions related to fire ( dynamically and supporting reducing risks related to fire.

- Federated Orchestration and Global Model Update Layer: This layer solves the issues of data privacy risks, data security concerns, and increased data transfer costs from local to cloud servers as sensor data are not shared with the cloud. ML models are trained locally on each remote site, and only the final model updates are sent to the central/cloud server. Global model updates are sent back to the remote sites to update their local models. This supports model updates in the remote sites with global model updates, which enhance the overall model’s reliability and provide more accurate fire prediction by reducing false alarms.

- Edge Server Notification layer: This layer integrates with devices/applications through API for sending notifications, and this plays a critical part in fire prediction by proactively taking action in the IIoT environment. This proactive approach reduces the risks of fire.

3.2. Technical Flow and Problem Formulation

| Algorithm 1: Handle faulty sensors using anomaly detection during sensor-processing pipeline |

|

| Algorithm 2: Adjusted prediction for faulty sensors and dynamic belief mass for final fire prediction |

#β controls how much weight the Deng Entropy has in adjusting belief mass.

Otherwise, predict “undefined” or “uncertain”.

|

4. Results

5. Discussion

- Sensor Fusion: The proposed architecture combines inputs from multiple unique types of sensors, each of which detects different types of fire. This ensures that multiple sensors reduce false positives or missed fire predictions [47]. As multiple unique types of sensors are used, early detection is possible as gas or smoke can be detected before the actual flame of fire or heat. This will result in faster response times and results in reducing the risks of fire.

- Adaptive Anomaly Detection for Fire Detection: As these sensors will be in an IIoT environment in remote sites, sensor data can be impacted because of various factors like temperature, location, etc. Anomaly detection with dynamic threshold support is also used in real-time to assist in the early prediction of fires. Anomalies found across multiple sensor data and abnormal sensor data are flagged. This procedure also reduces false predictions of fire as it differentiates between random sensor-related noise data and actual anomalies, which supports reducing fire risks.

| Existing Approach | Sensor Fusion | Adaptive Anomaly Detection | Multi ML Models Adjusted Prediction | Real-Time Adaptation to Sensor Faults | Uncertainty Handling | Fusion-Weighted Belief Mass | Decision-Making in Evolving Environments | Data Quality and Integrity |

|---|---|---|---|---|---|---|---|---|

| Sharma, M et al., 2022 [48] | Yes | No | No | No | Yes | No | No | Yes |

| Sung, S et al., 2024 [49] | Yes | Yes | No | No | No | No | No | Yes |

| Çavdar, T et al., 2022 [50] | Yes | No | No | No | Yes | No | No | Yes |

| Sharma, M et al., 2023 [51] | Yes | No | No | No | Yes | No | No | Yes |

| Ghosh, N et al., 2020 [24] | Yes | Yes | No | No | Yes | No | No | Yes |

| Proposed Approach | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

- Multi-ML Models Adjusted Prediction Based on Faulty Sensors: Machine learning models process the pre-processed sensor’s data. The combined weight factor adjusts the individual model predictions based on sensor status, either normal or faulty. This improves reliability, as this ensures that the faulty sensor data do not impact the fire prediction, and the proposed approach is supported to rely more on sensors that are functional and less on faulty sensors, which prevents false fire prediction and resulted in reducing the fire risks in such a complex IIoT environment.

- Real-Time Adaptation to sensor faults: In real-time, during sensor preprocessing, sensor faults or inconsistent sensor data are dealt with. Machine learning outputs are changed based on the status of faulty sensors, and the Dempster–Shafer Fusion-Weighted Belief Mass combines data and takes sensor status into account. This approach avoids inaccurate fire predictions caused by unreliable sensor data. Data are aggregated from various sources, and this provides more robust and accurate fire prediction as sensor faults are considered. The proposed approach ensures that faulty sensors never impact the final decision, and this improves the overall performance and accuracy of the fire detection system we proposed. This further supports in reducing the fire risks in the IIoT environment.

- Uncertainty Handling: The Dempster–Shafer theory approach handles uncertain, inconsistent, or faulty sensor data. This method helps in making decisions about fire predictions even when there is incomplete or conflicting sensor data, thereby supporting the reduction in fire risk in oil and gas industrial environments [52].

- Fusion-Weighted Belief Mass: Data from several machine learning models were combined, and inconsistent or unclear data were handled by giving faulty sensors extra weight [53,54]. This approach enhances decision-making accuracy by accounting for sensor failures and utilizing fire-related sensor data from critical oil and gas IIoT environments, thereby reducing the risks of fire.

- Stable Decision-Making In Evolving Environments: This attribute is critical for decision-making, as evidence was combined from multiple ML model outputs. Dynamic belief updates in the proposed approach were updated based on historical beliefs and new sensor data, which support adapting to changing environmental conditions in the IIoT environment. As current sensor readings were considered, this helps in reducing the risk of fire in a complex dynamic changing environment.

- Data Quality and Integrity: When a sensor fails, the proposed approach ensures data quality and integrity by employing sensor data fusion where readings from multiple sensors are combined to provide more accurate results. Multiple algorithms handle faulty sensor readings. Compared to other research studies, the proposed approach dynamically receives data from multiple fire-related sensors in real time, and it supports the reliability and accuracy of fire prediction even under sensor failures.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Notations | Descriptions |

| Data acquision from RGB, IR, Gas, Smoke and Flame sensor | |

. | Normalized the sensor raw values |

| Mean of the Normalized data | |

| Standard Deviation of the normalized data | |

| For Anomaly detection. | |

| record the anomaly detected for faulty sensor | |

| Anomaly detection of each sensor | |

| DE(mi) | Deng Entropy |

| Class probabilities prediction from each of 5 ML Models | |

| Combined weight factor | |

| PWC | Percentage of weight (%) for calculating combined weight factor |

| Probabilistic model adjustment based on sensor reliability | |

| confidence score from all models (both normal and faulty sensors) | |

m(+) | Belief mass for fire, Belief mass for No fire Belief mass for entire hypothesis |

| Mnew(fire) | Dynamically Belief |

| H(mi,mj) | Hellinger Distance |

| Pre-processed sensor data | |

| mcombined(A) | Dempster’s Rule of Combination |

| S1RGB, S2IR, S3Gas, S4Smoke, S5Flame | Multi sensor data type |

| Belief(A), Plausibility(A) | Belief and Plausibility for each class |

References

- Nesa, N.; Banerjee, I. IoT-Based sensor Data Fusion for occupancy sensing using Dempster–Shafer Evidence Theory for smart buildings. IEEE Internet Things J. 2017, 4, 1563–1570. [Google Scholar] [CrossRef]

- Zervas, E.; Mpimpoudis, A.; Anagnostopoulos, C.; Sekkas, O.; Hadjiefthymiades, S. Multisensor data fusion for fire detection. Inf. Fusion 2009, 12, 150–159. [Google Scholar] [CrossRef]

- Trapani, N.; Longo, L. Fault Detection and Diagnosis Methods for Sensors Systems: A Scientific Literature Review. IFAC-Pap. 2023, 56, 1253–1263. [Google Scholar] [CrossRef]

- Li, F.; Xie, R.; Wang, Z.; Guo, L.; Ye, J.; Ma, P.; Song, W. Online distributed IoT security monitoring with multidimensional streaming big data. IEEE Internet Things J. 2019, 7, 4387–4394. [Google Scholar]

- Habbouche, H.; Benkedjouh, T.; Amirat, Y.; Benbouzid, M. Gearbox failure diagnosis using a multisensor data-fusion machine learning-based approach. Entropy 2021, 23, 697. [Google Scholar] [CrossRef]

- Mellit, A.; Herrak, O.; Rus Casas, C.; Massi Pavan, A. A machine learning and internet of things-based online fault diagnosis method for photovoltaic arrays. Sustainability 2021, 13, 13203. [Google Scholar] [CrossRef]

- Rouzbahani, H.M.; Karimipour, H.; Lei, L. An ensemble deep convolutional neural network model for electricity theft detection in smart grids. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020; pp. 3637–3642. [Google Scholar]

- De Paola, A.; Ferraro, P.; Gaglio, S.; Re, G.L.; Das, S.K. An adaptive bayesian system for context-aware data fusion in smart environments. IEEE Trans. Mobile Comput. 2016, 16, 1502–1515. [Google Scholar]

- Hamda, N.E.I.; Hadjali, A.; Lagha, M. Multisensor Data Fusion in IoT Environments in Dempster–Shafer Theory Setting: An Improved Evidence Distance-Based Approach. Sensors 2023, 23, 5141. [Google Scholar] [CrossRef]

- Su, Z.; Wang, F.; Xiao, H.; Yu, H.; Dong, S. A fault diagnosis model based on singular value manifold features, optimized SVMs and multi-sensor information fusion. Meas. Sci. Technol. 2020, 31, 095002. [Google Scholar] [CrossRef]

- Qiao, S.; Song, B.; Fan, Y.; Wang, G. A Fuzzy Dempster–Shafer Evidence Theory Method with Belief Divergence for Unmanned Surface Vehicle Multi-Sensor Data Fusion. J. Mar. Sci. Eng. 2023, 11, 1596. [Google Scholar] [CrossRef]

- Li, S.; Liu, G.; Tang, X.; Lu, J.; Hu, J. An Ensemble Deep Convolutional Neural Network Model with Improved D-S Evidence Fusion for Bearing Fault Diagnosis. Sensors 2017, 17, 1729. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Xiao, F. An improved multisensor data fusion method and its application in fault diagnosis. IEEE Access 2018, 7, 3928–3937. [Google Scholar] [CrossRef]

- Attarha, S.; Förster, A. AssureSense: A framework for enabling sensor fault detection in Low-Power IoT edge devices. IEEE Sens. J. 2024, 24, 33791–33805. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, R.; Gao, J.; Gao, Z.; Liang, Y. Fault recognition using an ensemble classifier based on Dempster–Shafer Theory. Pattern Recognit. 2019, 99, 107079. [Google Scholar] [CrossRef]

- Hui, K.H.; Lim, M.H.; Leong, M.S.; Al-Obaidi, S.M. Dempster-Shafer evidence theory for multi-bearing faults diagnosis. Eng. Appl. Artif. Intell. 2016, 57, 160–170. [Google Scholar] [CrossRef]

- Xiao, F. Evidence combination based on prospect theory for multi-sensor data fusion. ISA Trans. 2020, 106, 253–261. [Google Scholar] [CrossRef]

- Lin, Y.; Li, Y.; Yin, X.; Dou, Z. Multisensor fault diagnosis modeling based on the evidence theory. IEEE Trans. Reliab. 2018, 67, 513–521. [Google Scholar] [CrossRef]

- Ullah, I.; Youn, J.; Han, Y. Multisensor data fusion based on Modified Belief Entropy in Dempster–Shafer Theory for smart Environment. IEEE Access 2021, 9, 37813–37822. [Google Scholar] [CrossRef]

- Boucherit, M.S.; Ladjouzi, S.; Kacimi, N.; Grouni, S.; Soufi, Y. Sensor fault detection in nonlinear system using threshold estimation. Int. J. Digit. Signals Smart Syst. 2017, 1, 336. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Schurgers, C.; Panigrahi, D.; Dey, S. Model-based techniques for data reliability in wireless sensor networks. IEEE Trans. Mobile Comput. 2008, 8, 528–543. [Google Scholar]

- Chirayil, A.; Maharjan, R.; Wu, C. Survey on Anomaly Detection in Wireless Sensor Networks (WSNs). In Proceedings of the 2019 20th IEEE/ACIS International Conference on Software Engineering, Artificial Intelligence, Networking and Parallel/Distributed Computing (SNPD), Toyama, Japan, 8–11 July 2019; pp. 150–157. [Google Scholar] [CrossRef]

- Yuan, K.; Xiao, F.; Fei, L.; Kang, B.; Deng, Y. Modeling sensor reliability in fault diagnosis based on evidence theory. Sensors 2016, 16, 113. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, N.; Paul, R.; Maity, S.; Maity, K.; Saha, S. Fault Matters: Sensor data fusion for detection of faults using Dempster–Shafer theory of evidence in IoT-based applications. Expert Syst. Appl. 2020, 162, 113887. [Google Scholar] [CrossRef]

- Luo, W.B.; Caselton, B. Using Dempster–Shafer theory to represent climate change uncertainties. J. Environ. Manag. 1997, 49, 73–93. [Google Scholar]

- Dinh, H.T.; Lee, C.; Niyato, D.; Wang, P. A survey of mobile cloud computing: Architecture, applications, and approaches. Wirel. Commun. Mob. Comput. 2013, 13, 1587–1611. [Google Scholar]

- Kumar, A.S.; Raja, S.; Pritha, N.; Raviraj, H.; Lincy, R.B.; Rubia, J.J. An adaptive transformer model for anomaly detection in wireless sensor networks in real-time. Meas. Sens. 2022, 25, 100625. [Google Scholar] [CrossRef]

- Zhao, K.; Li, L.; Chen, Z.; Sun, R.; Yuan, G.; Li, J. A survey: Optimization and applications of evidence fusion algorithm based on Dempster–Shafer theory. Appl. Soft Comput. 2022, 124, 109075. [Google Scholar] [CrossRef]

- Xia, J.; Feng, Y.; Liu, L.; Liu, D.; Fei, L. An Evidential Reliability Indicator-Based Fusion Rule for Dempster-Shafer Theory and its Applications in Classification. IEEE Access 2018, 6, 24912–24924. [Google Scholar] [CrossRef]

- Song, Y.; Deng, Y. Divergence measure of belief function and its application in data fusion. IEEE Access 2019, 7, 107465–107472. [Google Scholar] [CrossRef]

- Gaddam, A.; Wilkin, T.; Angelova, M.; Gaddam, J. Detecting sensor faults, anomalies and outliers in the internet of Things: A survey on the challenges and solutions. Electronics 2020, 9, 511. [Google Scholar] [CrossRef]

- Zhou, J.; Hu, L.; Wang, F.; Lu, H.; Zhao, K. An efficient multidimensional fusion algorithm for IoT data based on partitioning. Tsinghua Sci. Technol. 2013, 18, 369–378. [Google Scholar]

- Gao, J.; Jia, D.; Hu, N. Improved random forest model for smoke detection and early warning based on sparrow search algorithm. Appl. Comput. Eng. 2024, 76, 15–20. [Google Scholar] [CrossRef]

- Yang, L.; Shami, A. IoT data analytics in dynamic environments: From an automated machine learning perspective. Eng. Appl. Artif. Intell. 2022, 116, 105366. [Google Scholar] [CrossRef]

- Kiranyaz, S.; Gastli, A.; Ben-Brahim, L.; Al-Emadi, N.; Gabbouj, M. Real-Time fault detection and identification for MMC using 1-D convolutional neural networks. IEEE Trans. Ind. Electron. 2018, 66, 8760–8771. [Google Scholar] [CrossRef]

- Jeong, Y.; Hwang, J.; Lee, S.; Ndomba, G.E.; Kim, Y.; Kim, J. Sensor-Based indoor fire forecasting using transformer Encoder. Sensors 2024, 24, 2379. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Jiang, W.; Geng, J.; Deng, X.; Li, X. Fault diagnosis based on Non-Negative Sparse Constrained Deep Neural Networks and Dempster–Shafer theory. IEEE Access 2020, 8, 18182–18195. [Google Scholar] [CrossRef]

- Wang, H.; Shi, Y.; Chen, L.; Zhang, X. A Tunnel Fire Detection Method Based on an Improved Dempster-Shafer Evidence Theory. Sensors 2024, 24, 6455. [Google Scholar] [CrossRef]

- Munz, M.; Dietmayer, K. Using Dempster-Shafer-based modeling of object existence evidence in sensor fusion systems for advanced driver assistance systems. In Proceedings of the 2011 IEEE Intelligent Vehicles Symposium (IV), Baden-Baden, Germany, 5–9 June 2011; pp. 776–781. [Google Scholar] [CrossRef]

- Li, N.M.; Tao, N.Z. Health status identification of rolling bearing based on SVM and improved evidence theory. Equip. Health Status Identif. SVM. D-S Evid. Theory Datafusion Multi-Sens. 2016, 10, 378–382. [Google Scholar] [CrossRef]

- Khan, M.N.; Anwar, S. Paradox Elimination in Dempster–Shafer Combination Rule with Novel Entropy Function: Application in Decision-Level Multi-Sensor Fusion. Sensors 2019, 19, 4810. [Google Scholar] [CrossRef]

- Okafor, N. Advances and Challenges in IoT Sensors Data Handling and Processing in Environmental Monitoring Systems. TechRxiv 2023. [Google Scholar] [CrossRef]

- Gui, W.; Lu, Q.; Su, M.; Pan, F. Wireless Sensor Network Fault Sensor Recognition Algorithm Based on MM* Diagnostic Model. IEEE Access 2020, 8, 127084–127093. [Google Scholar] [CrossRef]

- Seiti, H.; Hafezalkotob, A. Developing pessimistic–optimistic risk-based methods for multi-sensor fusion: An interval-valued evidence theory approach. Appl. Soft Comput. 2018, 72, 609–623. [Google Scholar] [CrossRef]

- Yager, R.R. On the dempster-shafer framework and new combination rules. Inf. Sci. 1987, 41, 93–137. [Google Scholar] [CrossRef]

- Senouci, M.R.; Mellouk, A.; Aitsaadi, N.; Oukhellou, L. Fusion-based surveillance WSN deployment using Dempster–Shafer theory. J. Netw. Comput. Appl. 2016, 64, 154–166. [Google Scholar] [CrossRef]

- Azar, J.; Makhoul, A.; Barhamgi, M.; Couturier, R. An energy efficient IoT data compression approach for edge machine learning. Future Gener. Comput. Syst. 2019, 96, 168–175. [Google Scholar] [CrossRef]

- Sharma, M.; Maity, T. Multisensor Data-Fusion-Based Gas Hazard Prediction using DSET and 1DCNN for underground Longwall coal Mine. IEEE Internet Things J. 2022, 9, 21064–21072. [Google Scholar] [CrossRef]

- Sung, S.; Hong, S.; Choi, H.; Park, D.; Kim, S. Enhancing Fault Diagnosis in IoT Sensor Data through Advanced Preprocessing Techniques. Electronics 2024, 13, 3289. [Google Scholar] [CrossRef]

- Çavdar, T.; Ebrahimpour, N.; Kakız, M.T.; Günay, F.B. Decision-making for the anomalies in IIoTs based on 1D convolutional neural networks and Dempster–Shafer theory (DS-1DCNN). J. Supercomput. 2022, 79, 1683–1704. [Google Scholar] [CrossRef]

- Sharma, M.; Maity, T. Smart and Fault Tolerant Multi-Sensor Fusion Model for UCM Methane Hazard Monitoring Based on Belief Divergence Backed DS Filter and Hybrid CNN-LSTM Classifier. IEEE Internet Things J. 2023, 11, 3264–3273. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, S.K.; Kim, S. Hybrid deep learning-based cyberthreat detection and IoMT data authentication model in smart healthcare. Future Gener. Comput. Syst. 2025, 166, 107711. [Google Scholar] [CrossRef]

- Singh, S.K.; Kumar, M.; Khanna, A.; Virdee, B. Blockchain and FL-based secure architecture for enhanced external Intrusion detection in smart farming. IEEE Internet Things J. 2024, 12, 3297–3304. [Google Scholar] [CrossRef]

- Kumar, M.; Kim, C.; Son, Y.; Singh, S.K.; Kim, S. Empowering cyberattack identification in IoHT networks with neighborhood component-based improvised long short-term memory. IEEE Internet Things J. 2024, 11, 16638–16646. [Google Scholar] [CrossRef]

| Author(s) and Year | Objective/Research Problem | Methodology | Key Findings | Technology |

|---|---|---|---|---|

| Su, Z et al., (2020) [10] | Develop a robust fault diagnosis model combining advanced feature extraction, optimized classification methods, and multi-sensor data fusion for enhanced performance. | Singular value manifold features, support vector machines (SVMs) | Improves diagnostic accuracy and robustness in industrial fault diagnosis scenarios | Singular Value Decomposition (SVD), optimized SVM algorithms, and multi-sensor data fusion techniques. |

| Qiao, S et al., (2023) [11] | Enhance multi-sensor data fusion reliability for unmanned surface vehicles using belief divergence. | Fuzzy Dempster–Shafer evidence theory method with belief divergence adjustment. | Improved fusion accuracy and robustness. | Multi-sensor data fusion, unmanned surface vehicles, fuzzy Dempster–Shafer framework. |

| Li, S et al., (2017) [12] | Improve fault diagnosis of bearings by enhancing the fusion of deep learning outputs. | Deep convolutional neural networks with Dempster–Shafer evidence fusion. | Enhanced fault diagnosis accuracy. | Deep learning, bearing fault diagnosis, Dempster–Shafer evidence fusion. |

| Wang, Z et al., (2018) [13] | Develop a more effective multi-sensor data fusion approach for fault diagnosis. | Multi-sensor data fusion algorithm integrating reliability assessment. | Better fault diagnosis reliability. | Multi-sensor data fusion, fault diagnosis systems. |

| Wang, Z et al., (2019) [15] | Enhance fault recognition accuracy using advanced classification techniques. | Ensemble classifier integrated with Dempster–Shafer theory. | Improved fault recognition performance. | Fault recognition, ensemble classifier, Dempster–Shafer theory. |

| Hui, K. et al., (2016) [16] | Diagnose multiple bearing faults using advanced evidence fusion techniques. | Dempster–Shafer evidence theory for fault analysis. | Accurate multi-bearing fault diagnosis. | Bearing fault diagnosis, Dempster–Shafer evidence theory. |

| Xiao, F. (2020) [17] | Improve multi-sensor data fusion accuracy through enhanced evidence combination. | Evidence combination using prospect theory and Dempster–Shafer framework. | Enhanced fusion robustness and precision. | Multi-sensor data fusion, prospect theory, Dempster–Shafer evidence theory. |

| Lin, Y et al., (2018) [18] | Develop a fault diagnosis model integrating data from multiple sensors. | Evidence-theory-based fault diagnosis modeling. | Reliable multi-sensor fault diagnosis | Multi-sensor data fusion, evidence theory. |

| Ullah, I et al., (2021) [19] | Improve data fusion in smart environments by addressing belief uncertainty. | Modified belief entropy in Dempster–Shafer theory. | Enhanced fusion accuracy and reliability. | Smart environment, multi-sensor data fusion, Dempster–Shafer theory. |

| Boucherit, M. S et al., (2017) [20] | Detect sensor faults in nonlinear systems through adaptive threshold estimation. | Threshold estimation for fault detection in nonlinear systems. | Reliable sensor fault identification. | Nonlinear systems, sensor fault detection, threshold estimation. |

| Chirayil, A et al., (2019) [22] | Review and analyze anomaly detection methods in Wireless Sensor Networks (WSNs). | Comprehensive survey of anomaly detection algorithms. | Overview of strengths and limitations. | Wireless Sensor Networks, anomaly detection techniques. |

| Yuan, K et al., (2016) [23] | Model sensor reliability to improve fault diagnosis accuracy using evidence theory. | Evidence-theory-based sensor reliability modeling. | Enhanced fault diagnosis precision. | Sensor reliability, fault diagnosis, evidence theory. |

| Ghosh, N et al., (2020) [24] | Detect faults in IoT-based applications using sensor data fusion techniques. | Dempster–Shafer theory of evidence for multi-sensor data fusion. | Effective fault detection in IoT. | IoT, sensor data fusion, Dempster–Shafer theory. |

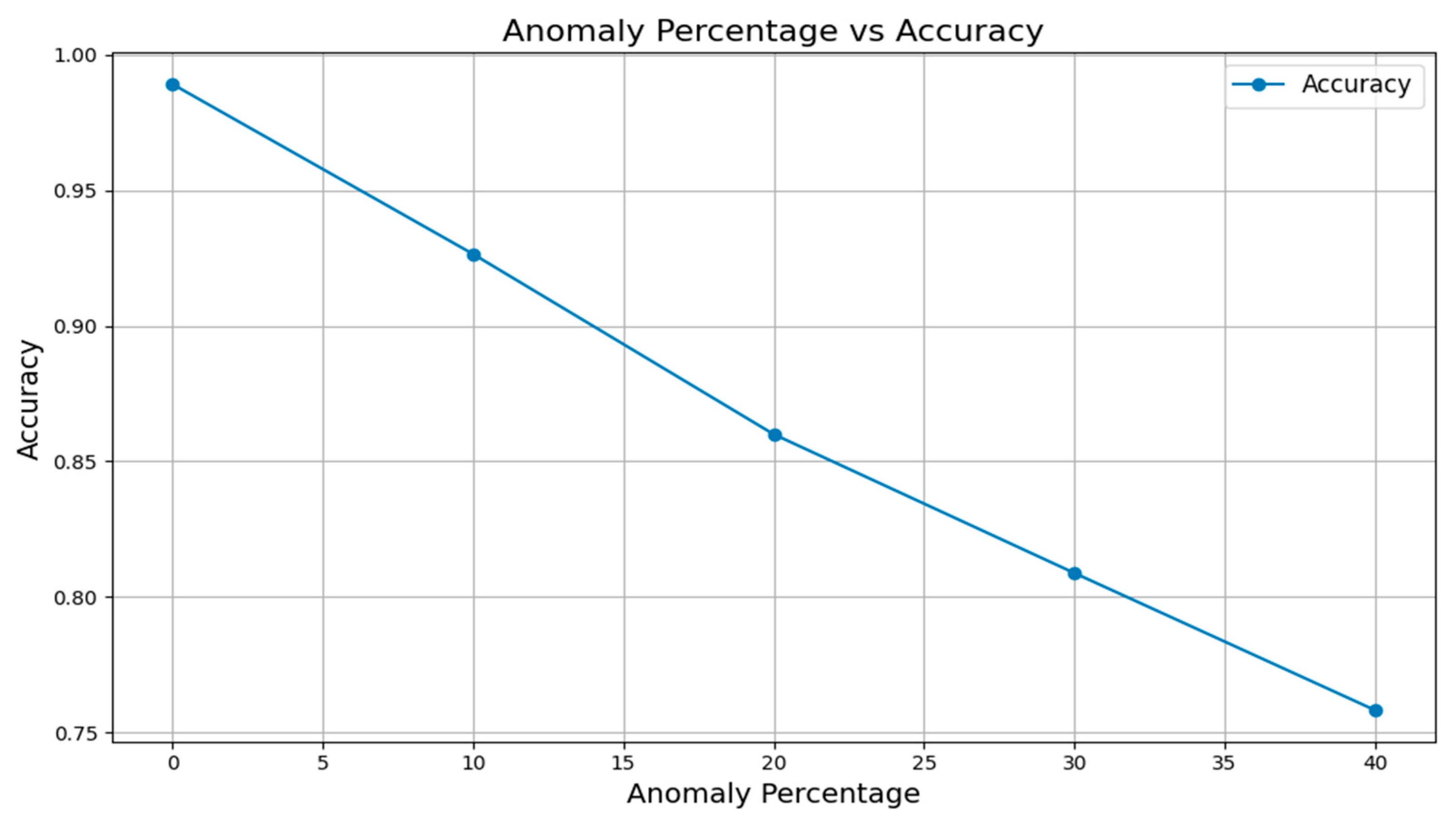

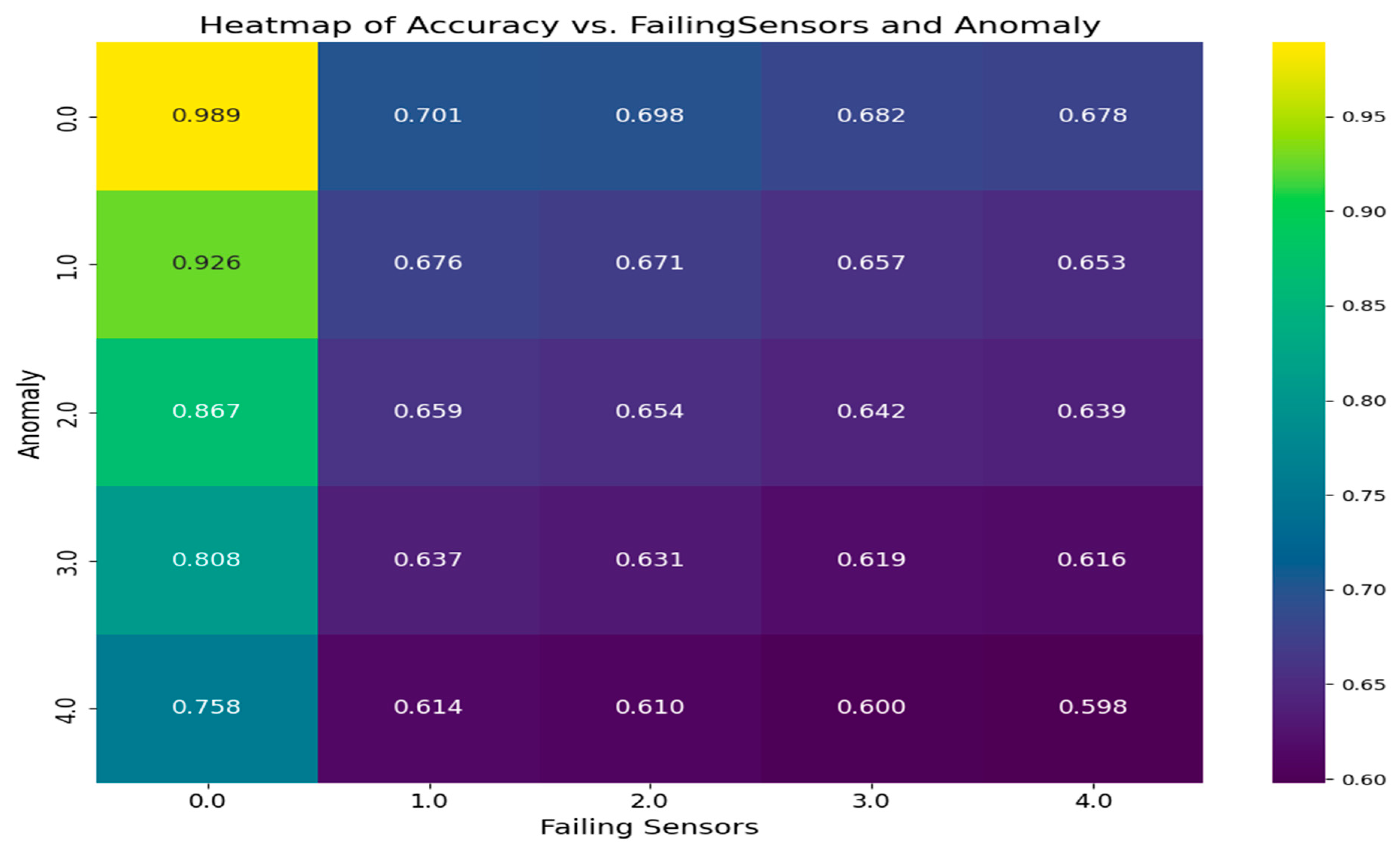

| Anomaly (%) | Failing Sensors | Precision | Recall | F1-Score | Accuracy |

|---|---|---|---|---|---|

| 0 | 0 | 0.984920 | 0.9834 | 0.986800 | 0.9892 |

| 10 | 0 | 0.953182 | 0.8958 | 0.923600 | 0.9259 |

| 20 | 0 | 0.921415 | 0.8020 | 0.857571 | 0.8668 |

| 30 | 0 | 0.878713 | 0.7158 | 0.788934 | 0.8085 |

| 40 | 0 | 0.849026 | 0.6276 | 0.721711 | 0.7580 |

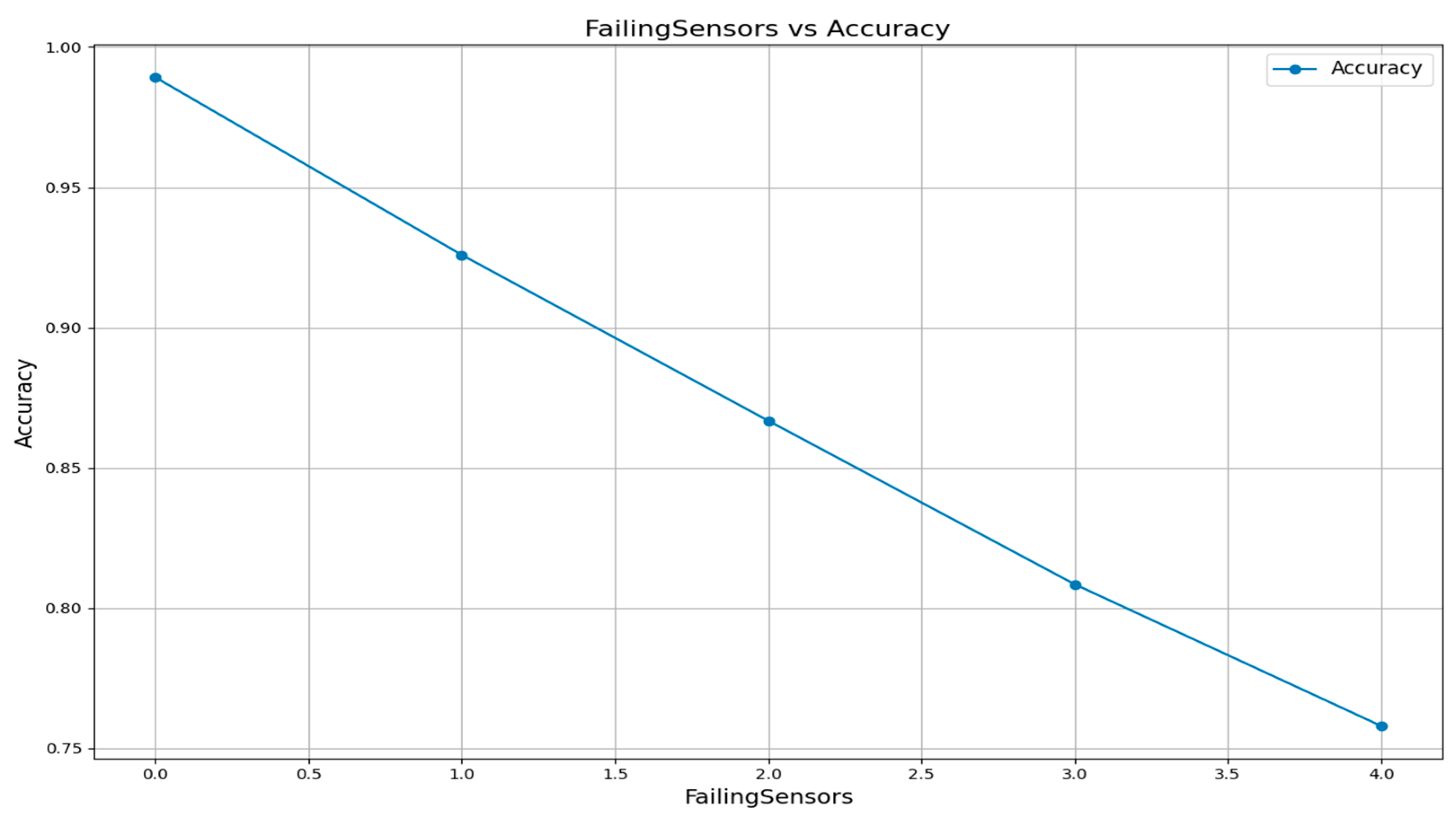

| Anomaly | Failing Sensors | Precision | Recall | F1-Score | Accuracy |

|---|---|---|---|---|---|

| 0.0 | 0 | 0.984920 | 0.9834 | 0.986800 | 0.9892 |

| 0.0 | 1 | 0.951873 | 0.4024 | 0.573873 | 0.7012 |

| 0.0 | 2 | 0.953902 | 0.3962 | 0.567540 | 0.6981 |

| 0.0 | 3 | 0.928484 | 0.3640 | 0.533724 | 0.6820 |

| 0.0 | 4 | 0.883599 | 0.3552 | 0.524203 | 0.6776 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Desikan, J.; Singh, S.K.; Jayanthiladevi, A.; Bhushan, S.; Rishiwal, V.; Kumar, M. Hybrid Machine Learning-Based Fault-Tolerant Sensor Data Fusion and Anomaly Detection for Fire Risk Mitigation in IIoT Environment. Sensors 2025, 25, 2146. https://doi.org/10.3390/s25072146

Desikan J, Singh SK, Jayanthiladevi A, Bhushan S, Rishiwal V, Kumar M. Hybrid Machine Learning-Based Fault-Tolerant Sensor Data Fusion and Anomaly Detection for Fire Risk Mitigation in IIoT Environment. Sensors. 2025; 25(7):2146. https://doi.org/10.3390/s25072146

Chicago/Turabian StyleDesikan, Jayameena, Sushil Kumar Singh, A. Jayanthiladevi, Shashi Bhushan, Vinay Rishiwal, and Manish Kumar. 2025. "Hybrid Machine Learning-Based Fault-Tolerant Sensor Data Fusion and Anomaly Detection for Fire Risk Mitigation in IIoT Environment" Sensors 25, no. 7: 2146. https://doi.org/10.3390/s25072146

APA StyleDesikan, J., Singh, S. K., Jayanthiladevi, A., Bhushan, S., Rishiwal, V., & Kumar, M. (2025). Hybrid Machine Learning-Based Fault-Tolerant Sensor Data Fusion and Anomaly Detection for Fire Risk Mitigation in IIoT Environment. Sensors, 25(7), 2146. https://doi.org/10.3390/s25072146