Asset Administration Shell Tool Comparison: A Case Study with Real Digital Twins Used in Petrochemical Industry

Abstract

1. Introduction

2. Materials and Method

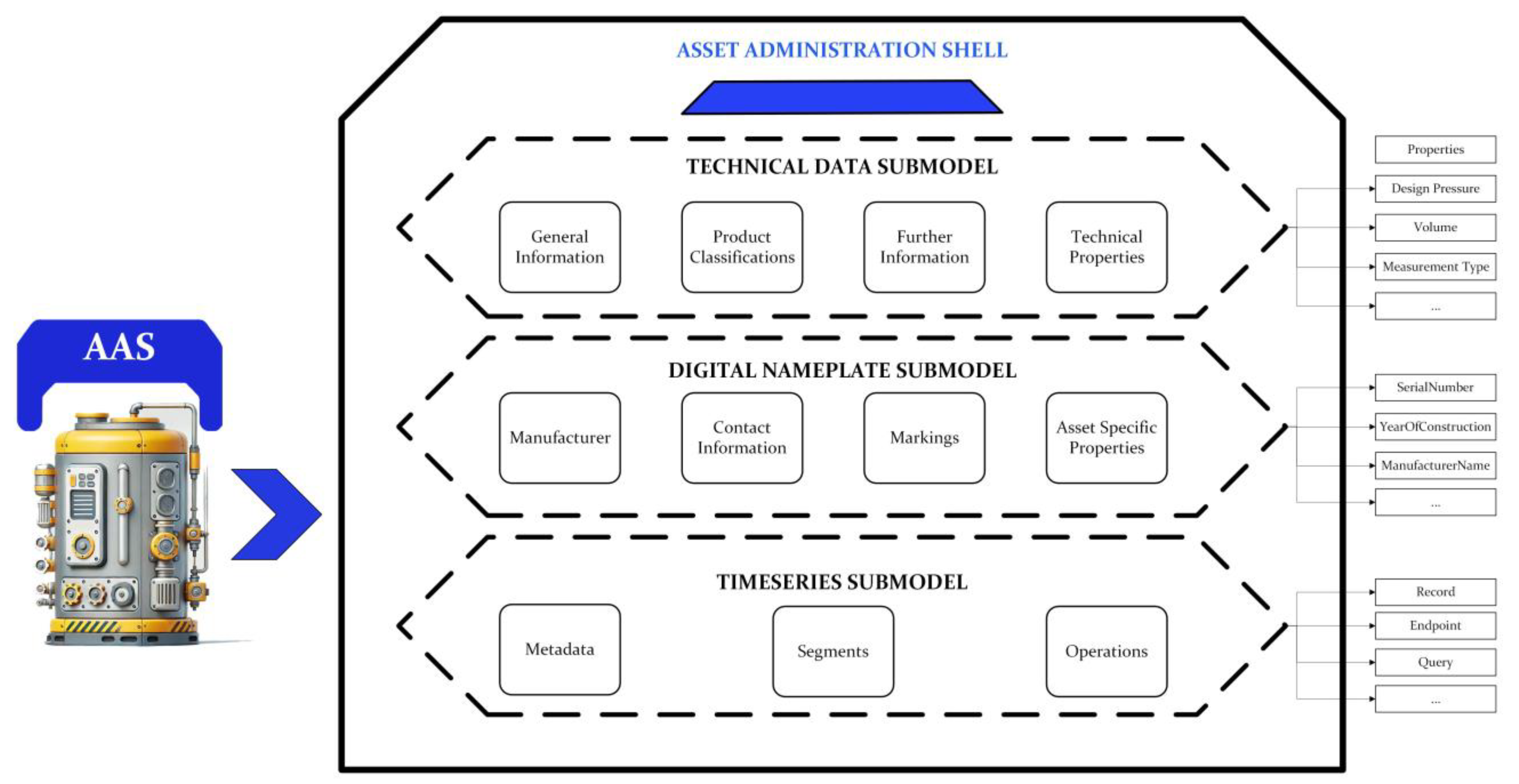

2.1. AAS Metamodel

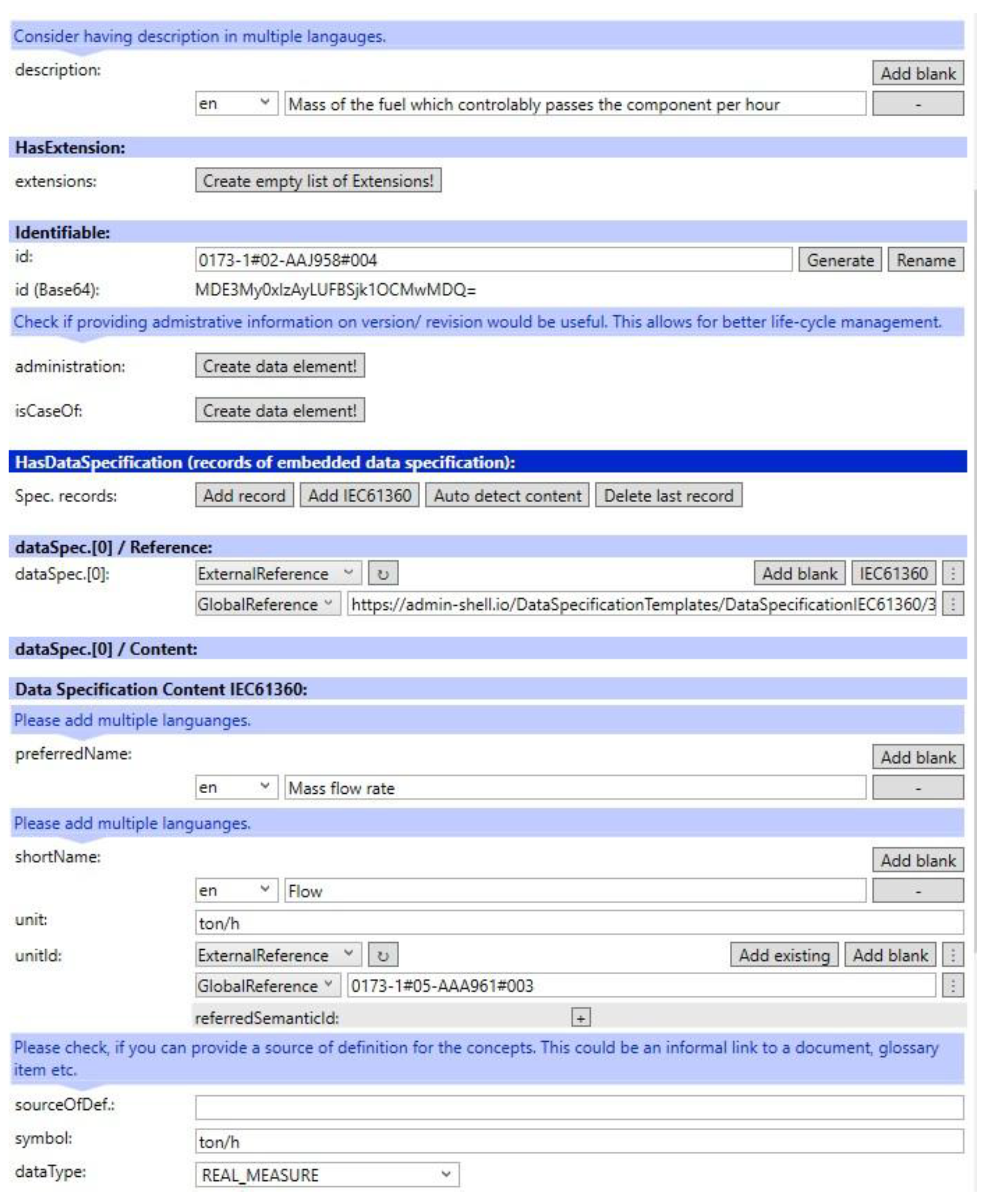

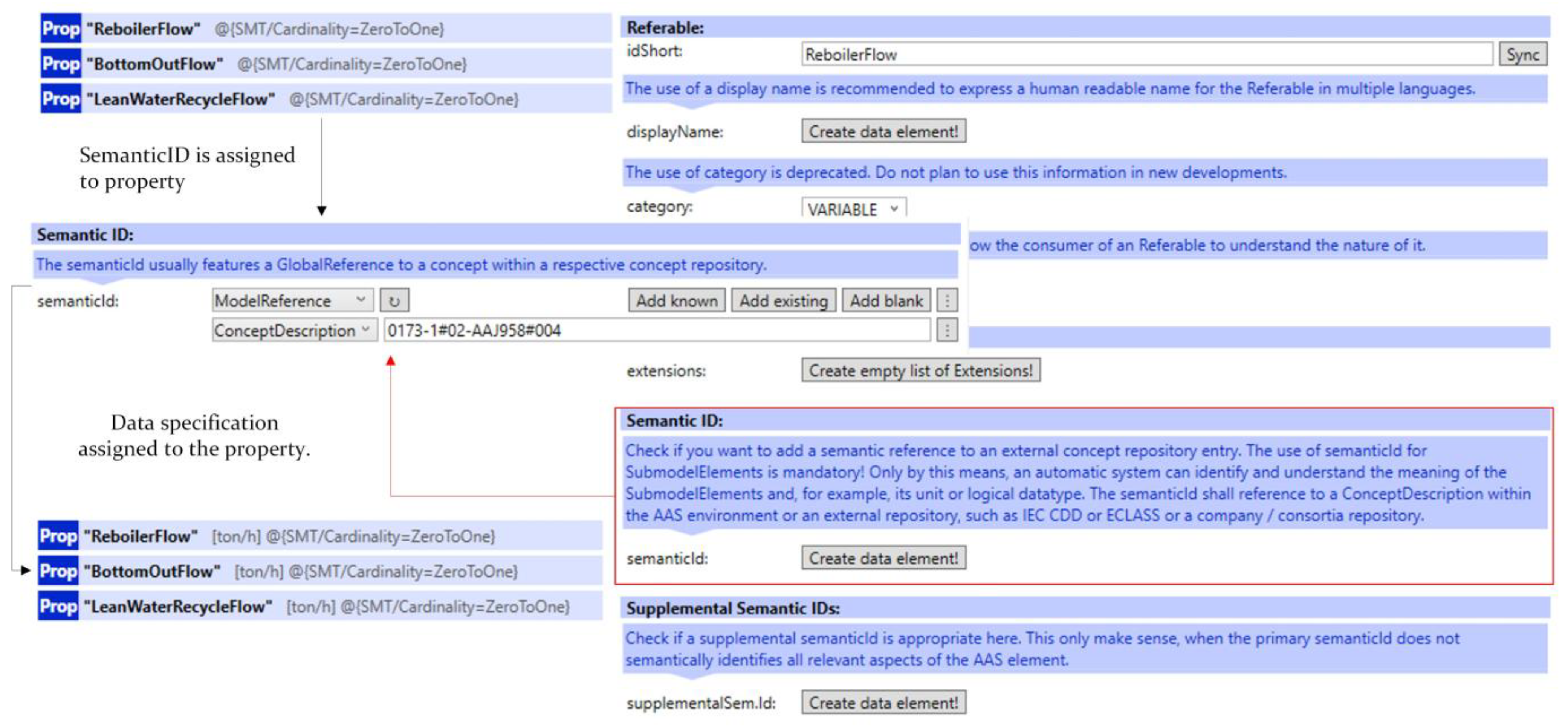

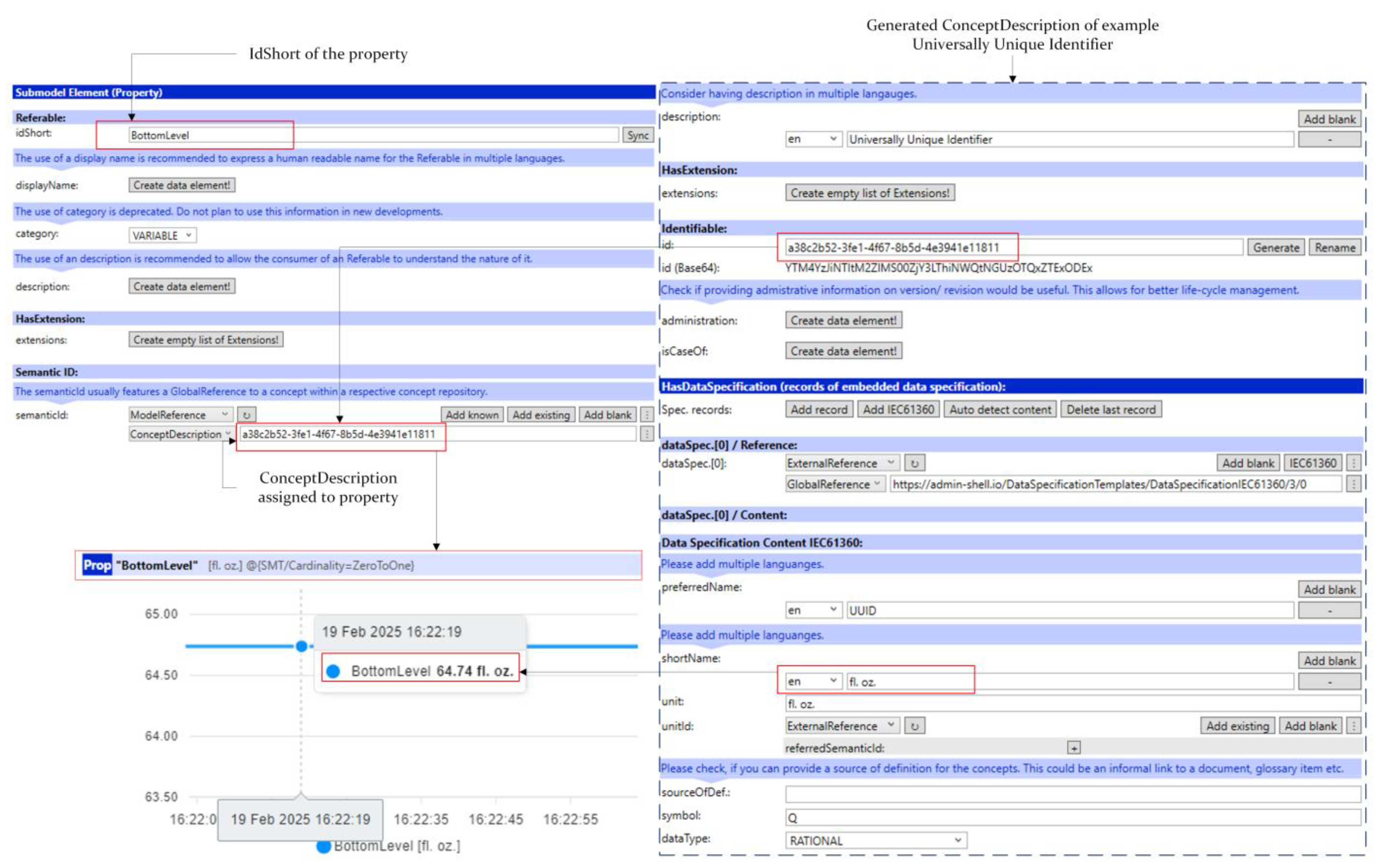

2.2. Data Specification

2.3. Submodel Descriptions

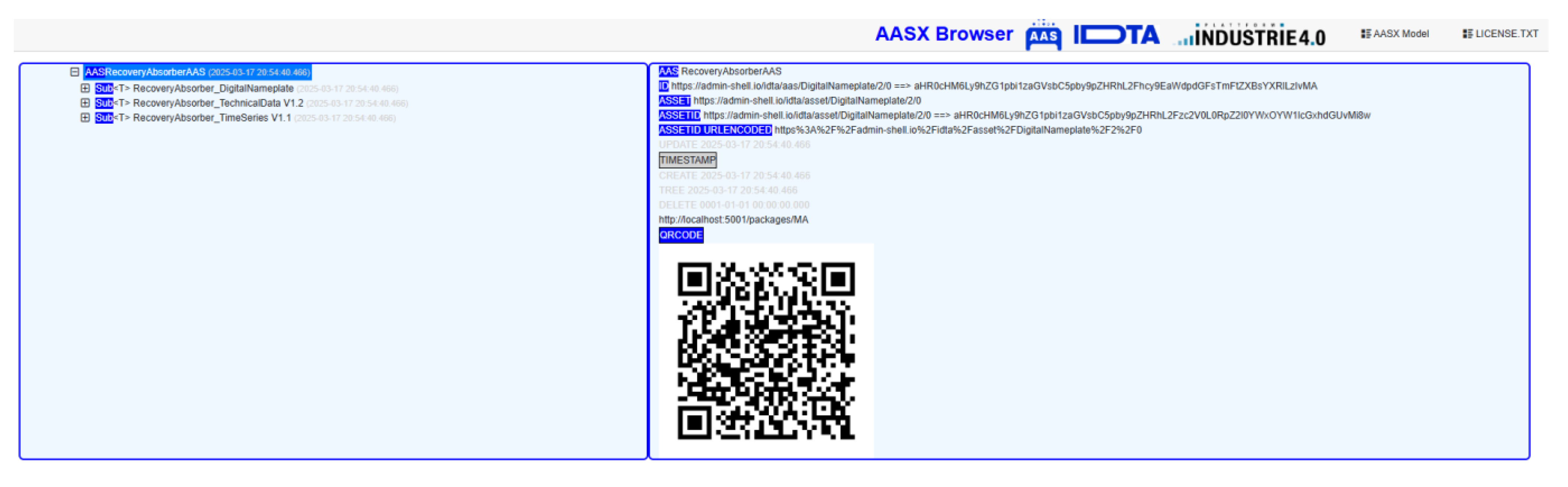

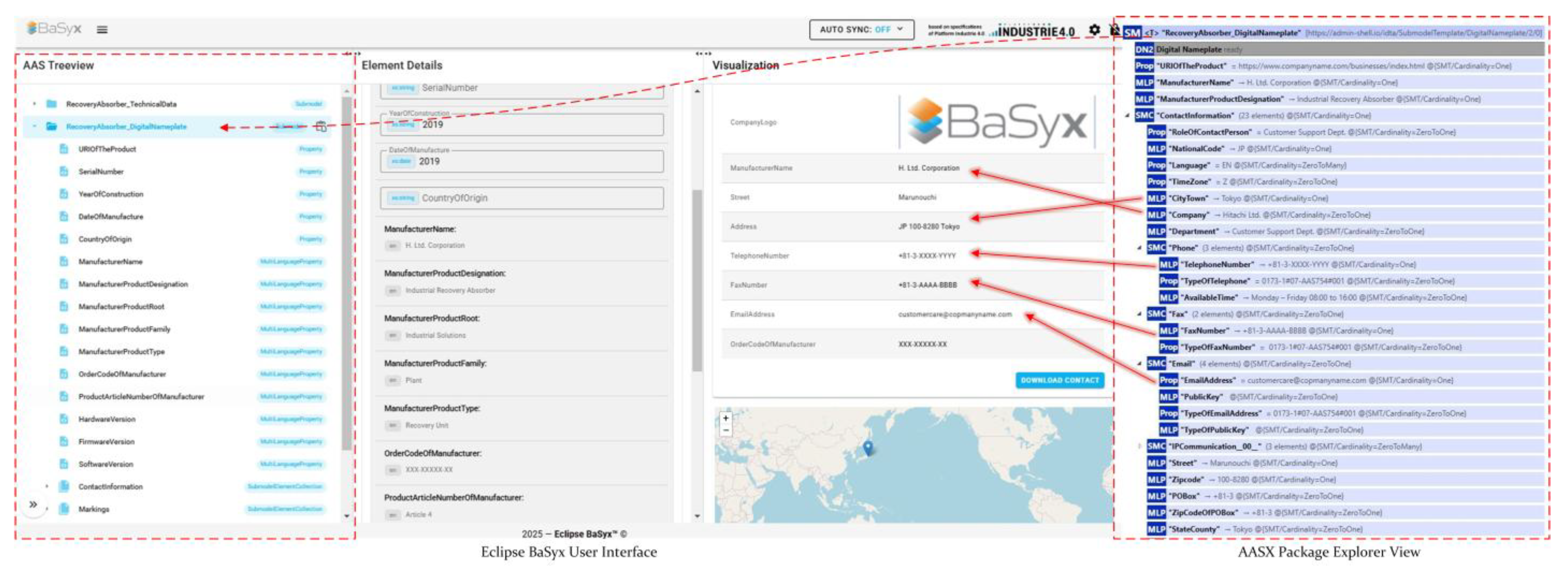

2.3.1. Digital Nameplate Submodel

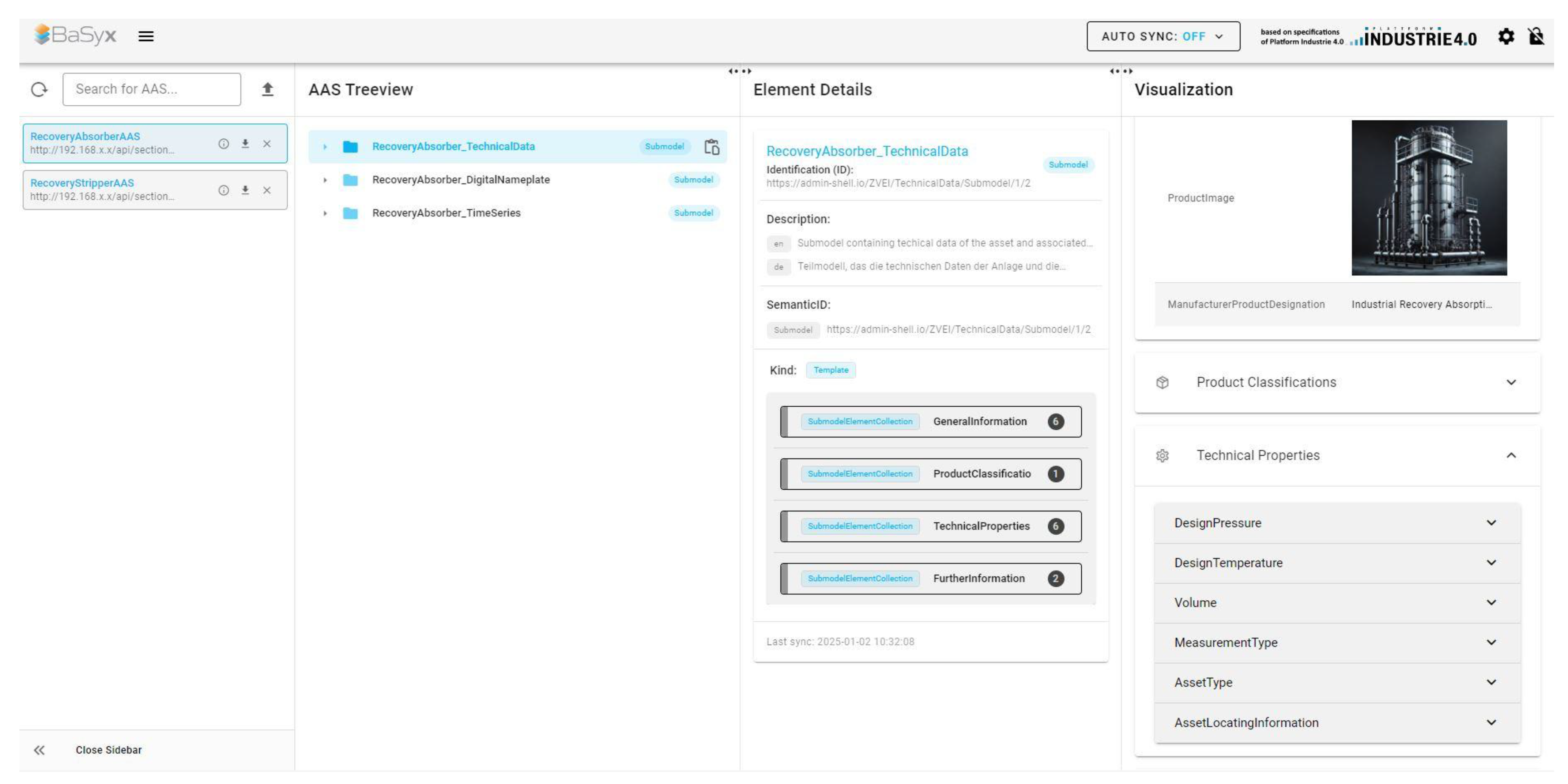

2.3.2. Technical Data Submodel

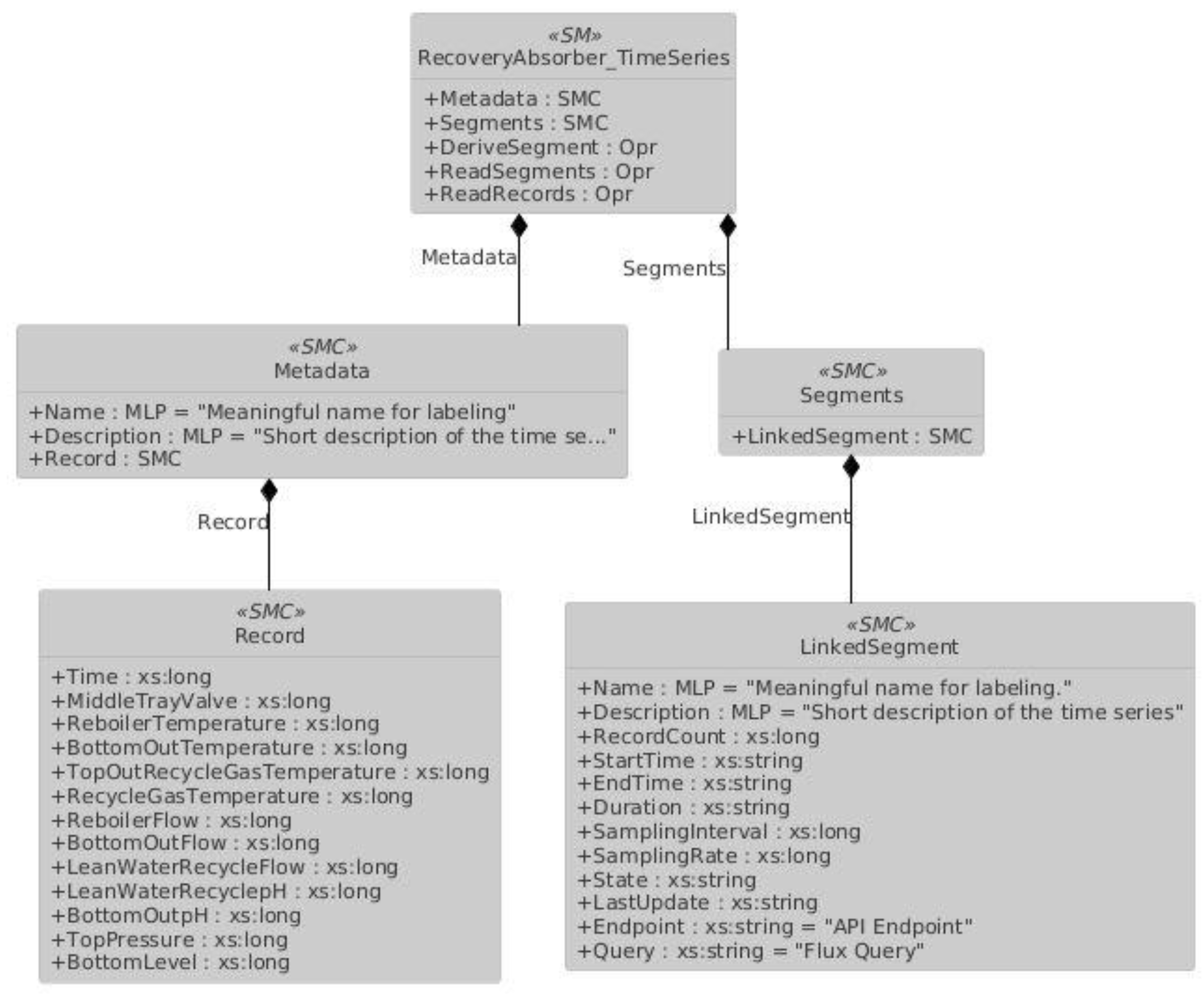

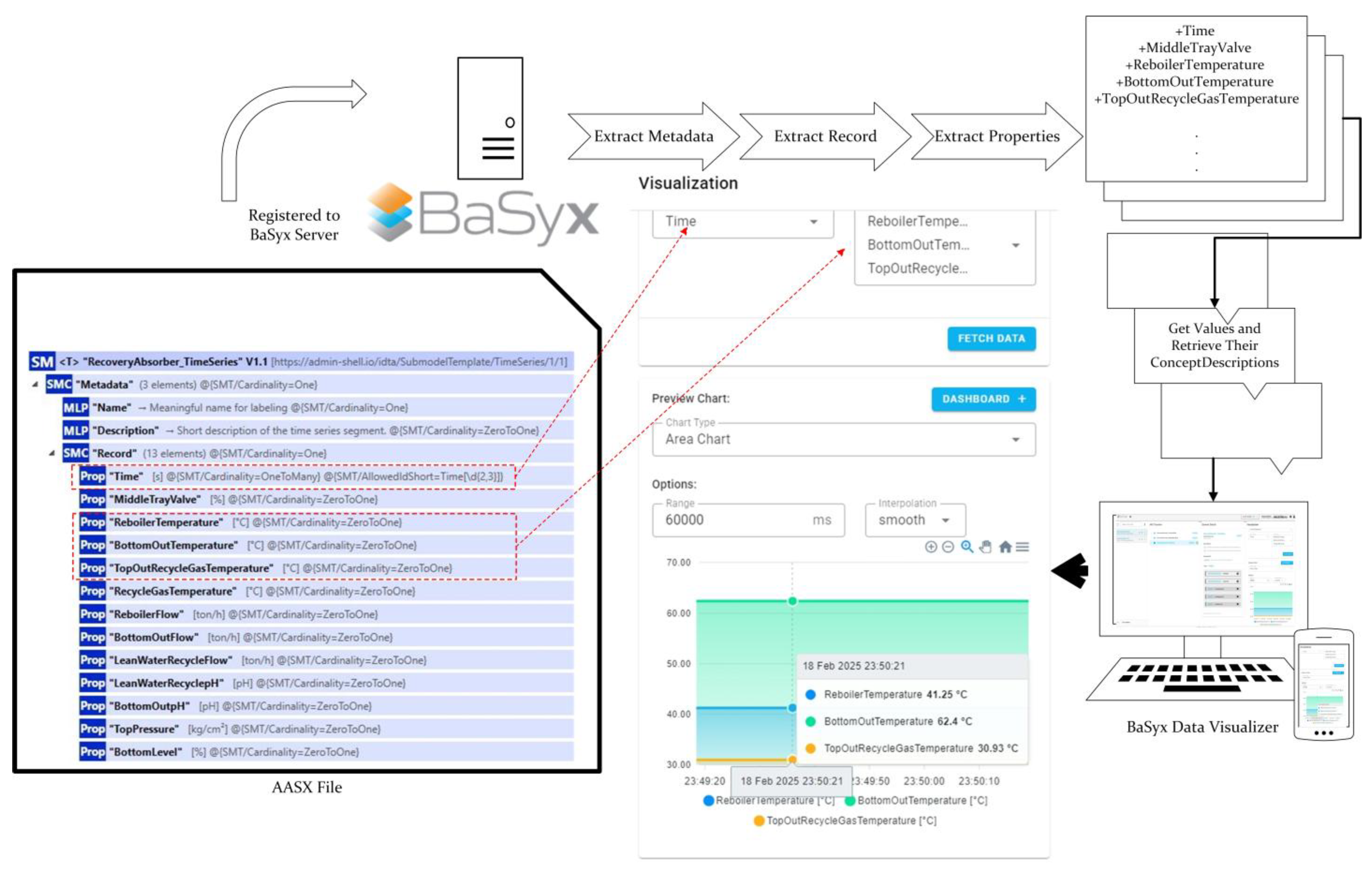

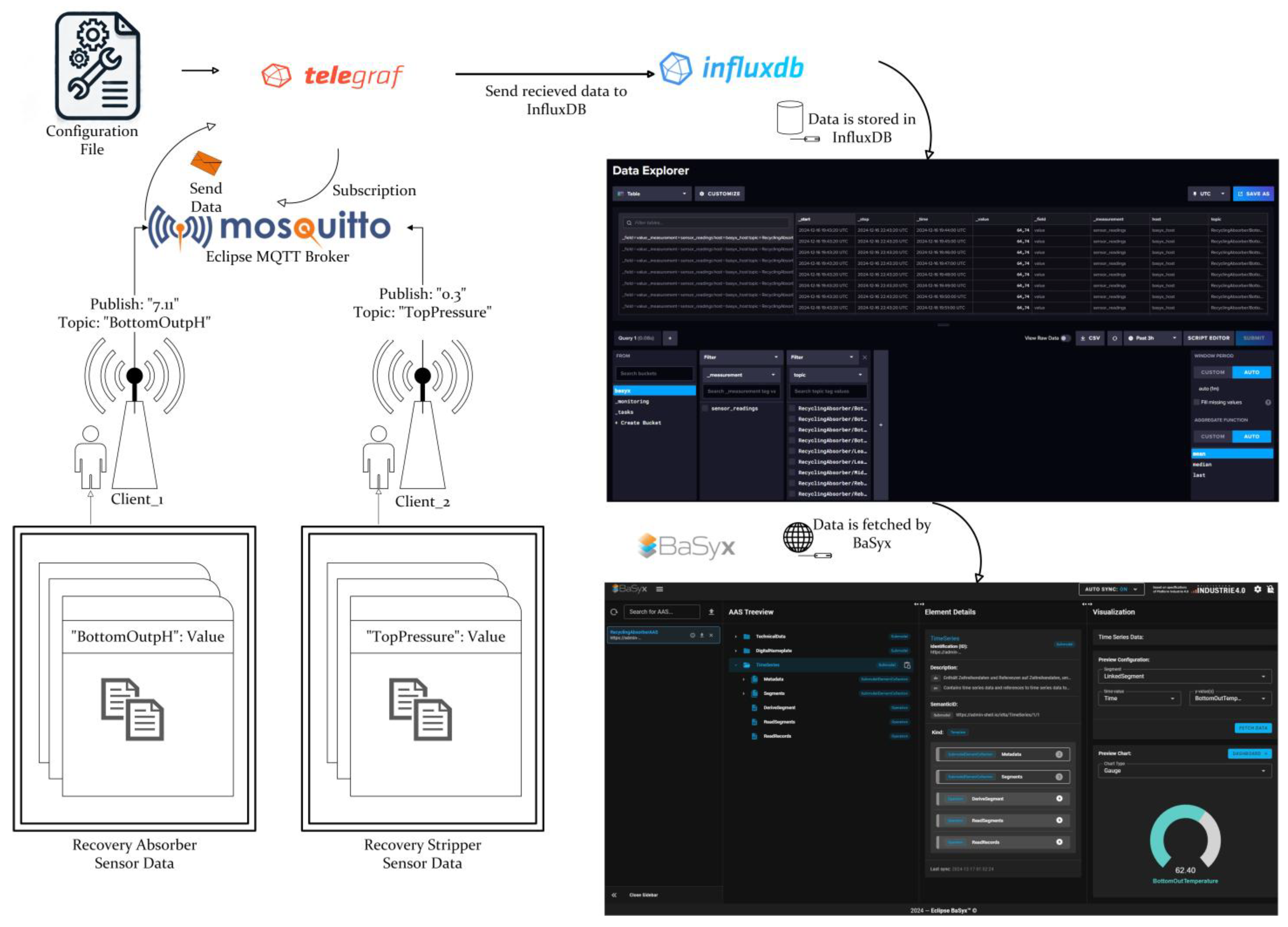

2.3.3. Time Series Submodel

- InternalSegments: Allows the management of the time series data structure and content directly within the AAS, for example, pre-adding data records as Submodel Collections during the creation of an AASX file;

- LinkedSegments: Enables the client to access an endpoint and query an external system to manage the time series in real time outside the AAS;

- ExternalSegments: Involves embedding a data file containing time series data with different formats into the AASX file.

2.4. Semantic Versioning

3. Results

3.1. Evaluation Approach

- Documentation Review and Theoretical Assessment:

- 2.

- Practical Deployment and Performance Testing:

3.2. Evaluation Results

- Deprecation of AAS Metamodel V2: Since metamodel V2 has deprecated, and further developments are focused on metamodel V3, the AAS file for this study was generated with the metamodel V3 structure. While the other three applications have versions compatible with metamodel V3, NOVAAS has a current version fully compatible with metamodel V2. There is also another version with limited sub-element support for metamodel V3, which might be extended to full support in the future, but since the other sub-elements in the AAS file we created that are not yet supported by NOVAAS caused reading errors in the file, the focus was shifted to the other three implementations;

- Monitoring Capabilities: For the three selected software options, monitoring capabilities are critical in industrial applications. Hence, preference was given to software with a built-in graphical interface, excluding FA3ST service, which currently operates via a CLI (Command-Line Interface);

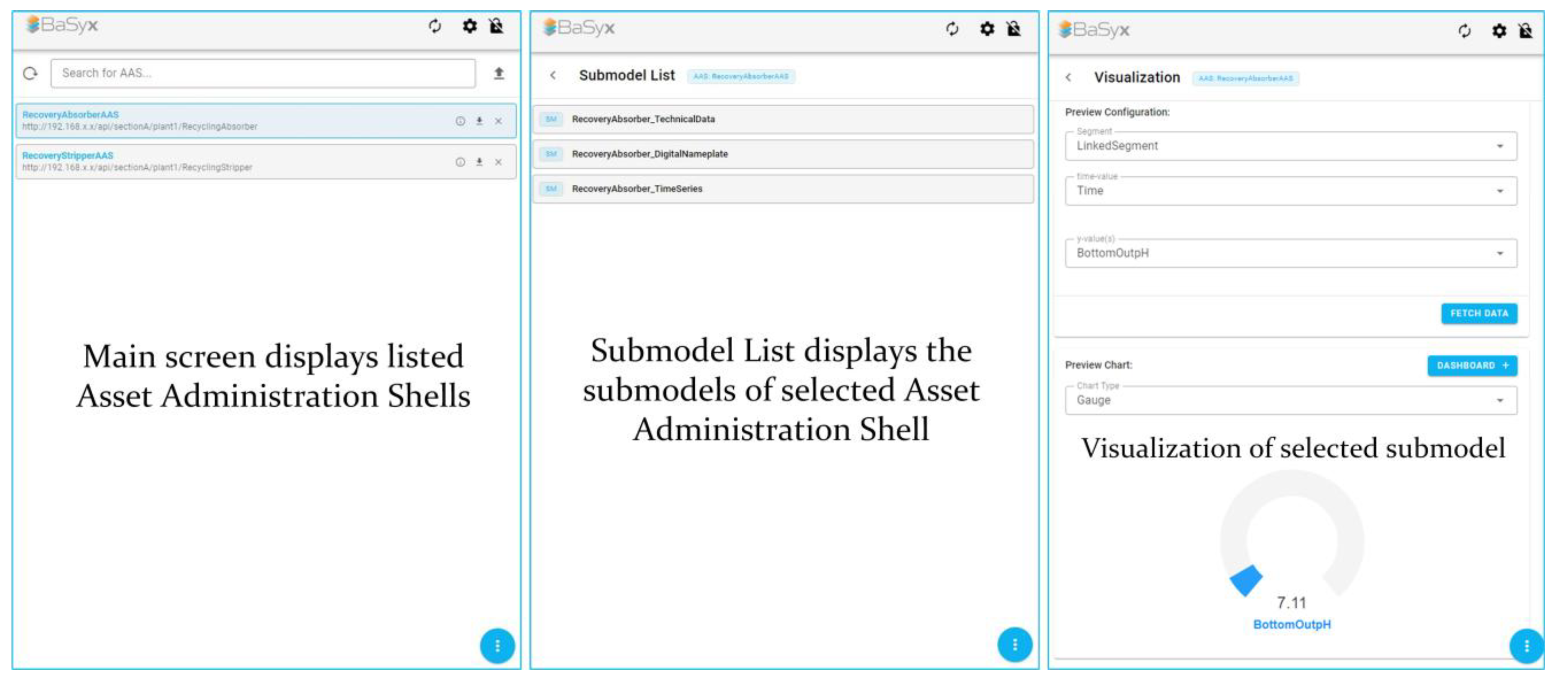

- Visual Interface: While the AASX server primarily displays data in a list format, Eclipse BaSyx provides submodel-specific visualizations by utilizing semanticIds within submodels. This enables better recognition and understanding of the submodel’s details;

- Time Series Data Monitoring: Eclipse BaSyx offers a graphical interface for Time Series Submodels through its semantic visualization feature, enabling effective data monitoring;

- Mobile Platform Support: In industrial environments, access to a computer is not always feasible. Eclipse BaSyx is the only solution that provides mobile platform support, addressing this need;

- Comprehensive Documentation: Eclipse BaSyx offers detailed documentation for both users and developers. Additionally, GitHub repositories provide example use cases for various integrated end-user applications and protocol integrations, significantly speeding up and simplifying the creation of different test scenarios;

- Eclipse BaSyx supports real-time AASX import and export functionalities and offers an AAS editor tool within its UI. This allows visual modifications to AAS elements, making Eclipse BaSyx a useful tool for partial AAS editing as well.

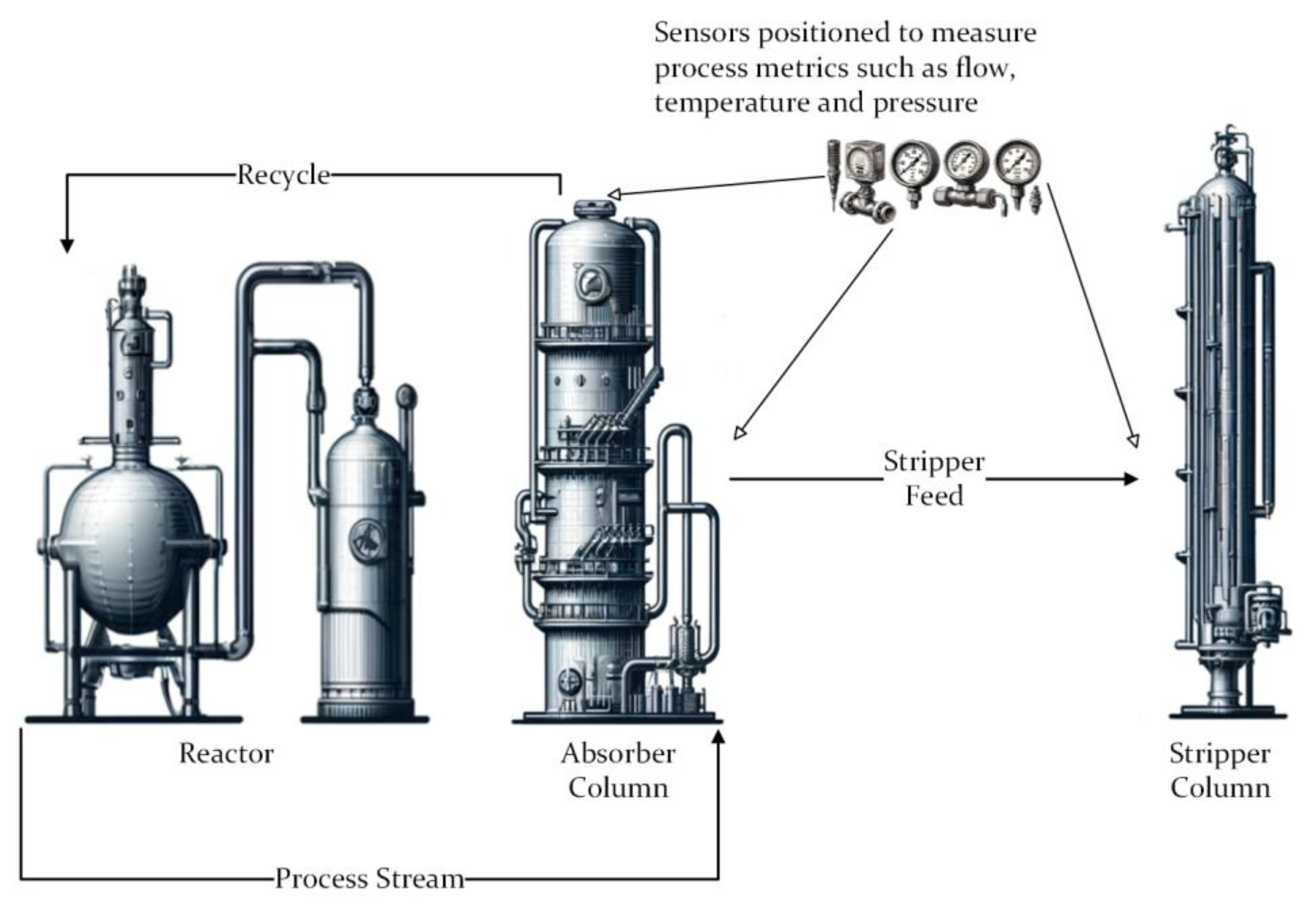

4. Case Study

Asset Administration Shell

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Cavalieri, S.; Salafia, M.G. Asset Administration Shell for PLC Representation Based on IEC 61131–3. IEEE Access 2020, 8, 142606–142621. [Google Scholar] [CrossRef]

- DIN. Reference Architecture Model Industrie 4.0 (RAMI4.0), DIN SPEC 91345:2016-04; Beuth Verlag GmbH: Berlin, Germany, 2016. [Google Scholar]

- Jacoby, M.; Baumann, M.; Bischoff, T.; Mees, H.; Müller, J.; Stojanovic, L.; Volz, F. Open-Source Implementations of the Reactive Asset Administration Shell: A Survey. Sensors 2023, 23, 5229. [Google Scholar] [CrossRef] [PubMed]

- Bader, S.; Barnstedt, E.; Bedenbender, H.; Berres, B.; Billmann, M.; Boss, B.; Braunisch, N.; Braunmandl, A.; Clauer, E.; Diedrich, C.; et al. Details of the Asset Administration Shell. Part 1—The Exchange of Information Between Partners in the Value Chain of Industrie 4.0 (Version 3.0RC02); Federal Ministry for Economic Affairs and Climate Action (BMWK) Public Relations: Berlin, Germany, 2022. [Google Scholar] [CrossRef]

- Cavalieri, S.; Gambadoro, S. Digital Twin of a Water Supply System Using the Asset Administration Shell. Sensors 2024, 24, 1360. [Google Scholar] [CrossRef] [PubMed]

- Ye, X.; Hong, S.H.; Song, W.S.; Kim, Y.C.; Zhang, X. An Industry 4.0 Asset Administration Shell-Enabled Digital Solution for Robot-Based Manufacturing Systems. IEEE Access 2021, 9, 154448–154459. [Google Scholar] [CrossRef]

- Arm, J.; Benesl, T.; Marcon, P.; Bradac, Z.; Schröder, T.; Belyaev, A.; Werner, T.; Braun, V.; Kamensky, P.; Zezulka, F.; et al. Automated Design and Integration of Asset Administration Shells in Components of Industry 4.0. Sensors 2021, 21, 2004. [Google Scholar] [CrossRef] [PubMed]

- Lang, D.; Grunau, S.; Wisniewski, L.; Jasperneite, J. Utilization of the Asset Administration Shell to Support Humans During the Maintenance Process. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 768–773. [Google Scholar] [CrossRef]

- Deuter, A.; Imort, S. Product Lifecycle Management with the Asset Administration Shell. Computers 2021, 10, 84. [Google Scholar] [CrossRef]

- Kim, B.; Kim, S.; Teijgeler, H.; Lee, J.; Lee, J.Y.; Lim, D.; Suh, H.-W.; Mun, D. Use of Asset Administration Shell Coupled with ISO 15926 to Facilitate the Exchange of Equipment Condition and Health Status Data of a Process Plant. Processes 2022, 10, 2155. [Google Scholar] [CrossRef]

- Fimmers, C.; Blanke, P.; Wieczorek, M.; Petrovic, O.; Herfs, W. Asset Administration Shells in Tool Lifecycle Monitoring. Procedia CIRP 2023, 120, 1209–1214. [Google Scholar] [CrossRef]

- Kühn, M.; Baumann, M.; Volz, F.; Stojanovic, L. Digital Product Passport Design Supporting the Circular Economy Based on the Asset Administration Shell. Sustainability 2025, 17, 969. [Google Scholar] [CrossRef]

- Xia, Y.; Xiao, Z.; Jazdi, N.; Weyrich, M. Generation of Asset Administration Shell With Large Language Model Agents: Toward Semantic Interoperability in Digital Twins in the Context of Industry 4.0. IEEE Access 2024, 12, 84863–84877. [Google Scholar] [CrossRef]

- Treuk, I.; Oliveira Júnior, A.; Lopes, R.; Mota, G.; Mira, J.; Leitão, P. Digitalization of Industrial Inspection Assets through the Asset Administration Shell. In Proceedings of the 2024 IEEE International Conference on Industrial Cyber-Physical Systems (ICPS), St. Louis, MO, USA, 12–15 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Cavalieri, S.; Salafia, M.G. Insights into Mapping Solutions Based on OPC UA Information Model Applied to the Industry 4.0 Asset Administration Shell. Computers 2020, 9, 28. [Google Scholar] [CrossRef]

- Platenius-Mohr, M.; Malakuti, S.; Grüner, S.; Schmitt, J.; Goldschmidt, T. File- and API-Based Interoperability of Digital Twins by Model Transformation: An IIoT Case Study Using Asset Administration Shell. Future Gener. Comput. Syst. 2020, 113, 94–105. [Google Scholar] [CrossRef]

- Schmidt, C.; Volz, F.; Stojanovic, L.; Sutschet, G. Increasing Interoperability between Digital Twin Standards and Specifications: Transformation of DTDL to AAS. Sensors 2023, 23, 7742. [Google Scholar] [CrossRef] [PubMed]

- Di Orio, G.; Maló, P.; Barata, J. NOVAAS: A Reference Implementation of Industrie4.0 Asset Administration Shell with Best-of-Breed Practices from IT Engineering. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 5505–5512. [Google Scholar] [CrossRef]

- Jacoby, M.; Volz, F.; Weißenbacher, C.; Müller, J. FA³ST Service—An Open Source Implementation of the Reactive Asset Administration Shell. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Guo, W.; Miny, T.; Kleinert, T.; Schnicke, F.; Käbisch, S.; Liepert, C. Comparison of Data Integration Concepts for Asset Administration Shell. In Proceedings of the 2024 IEEE 29th International Conference on Emerging Technologies and Factory Automation (ETFA), Padova, Italy, 10–13 September 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Yallıç, F.; Albayrak, Ö.; Ünal, P. Asset Administration Shell Generation and Usage for Digital Twins: A Case Study for Non-destructive Testing. In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics—ETCIIM, Valletta, Malta, 24–26 October 2022; SciTePress: Setúbal, Portugal, 2022; pp. 299–306, ISBN 978-989-758-612-5. [Google Scholar] [CrossRef]

- GitHub Repository. Available online: https://github.com/kayalaboratory/AAS_Tools (accessed on 26 December 2024).

- Industrial Digital Twin Association. Specification of the Asset Administration Shell—Part 1: Metamodel, IDTA Number: 01001-3-0-1; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2024; Available online: https://industrialdigitaltwin.org/en/content-hub/downloads (accessed on 26 December 2024).

- Industrial Digital Twin Association. Specification of the Asset Administration Shell—Part 3a: Data Specification—IEC 61360, IDTA Number: 01003-a-3-0-2; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2024; Available online: https://www.industrialdigitaltwin.org/en/content-hub/downloads (accessed on 26 December 2024).

- ECLASS. Available online: https://eclass.eu/en/ (accessed on 26 December 2024).

- Published Submodel Templates. Available online: https://github.com/admin-shell-io/submodel-templates/tree/main/published (accessed on 26 December 2024).

- AASX Package Explorer. Available online: https://github.com/eclipse-aaspe/package-explorer (accessed on 26 December 2024).

- Digital Nameplate for Industrial Equipment (Version 2.0). Available online: https://github.com/admin-shell-io/submodel-templates/tree/main/published/Digital%20nameplate/2/0 (accessed on 26 December 2024).

- Industrial Digital Twin Association. Specification of the Asset Administration Shell—Submodel Template, IDTA Number: 02006-2-0; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2022. [Google Scholar]

- Generic Frame for Technical Data for Industrial Equipment in Manufacturing (Version 1.2). Available online: https://github.com/admin-shell-io/submodel-templates/tree/main/published/Technical_Data/1/2 (accessed on 26 December 2024).

- Industrial Digital Twin Association. Specification of the Asset Administration Shell—Submodel Template: Generic Frame for Technical Data for Industrial Equipment in Manufacturing, IDTA Number: 02003-1-2; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2022. [Google Scholar]

- Time Series Data Version 1.1. Available online: https://github.com/admin-shell-io/submodel-templates/tree/main/published/Time%20Series%20Data/1/1 (accessed on 26 December 2024).

- Industrial Digital Twin Association. Specification of the Asset Administration Shell—Submodel Template: Time Series Data, IDTA Number: 02008-1-1; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2023. [Google Scholar]

- Industrial Digital Twin Association. Specification of the Asset Administration Shell—Part 5: Package File Format (AASX), IDTA Number: 01005-3-0-1; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2024. [Google Scholar]

- Asset Administration Shell Identifiers. Available online: https://github.com/admin-shell-io/id (accessed on 26 December 2024).

- International Electrotechnical Commission. Available online: https://cdd.iec.ch/ (accessed on 26 December 2024).

- Self-Registration Space. Available online: https://github.com/admin-shell-io/id/tree/master/sandbox (accessed on 26 December 2024).

- Industrial Digital Twin Association. Guideline: How To Create a Submodel Template Specification; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2022. [Google Scholar]

- Registered AAS Submodel Templates. Available online: https://industrialdigitaltwin.org/en/content-hub/submodels (accessed on 26 December 2024).

- Submodel Templates Published by IDTA. Available online: https://github.com/admin-shell-io/submodel-templates (accessed on 26 December 2024).

- Basyx Plugin Mechanism. Available online: https://wiki.basyx.org/en/latest/content/user_documentation/basyx_components/web_ui/features/plugin_mechanism.html (accessed on 26 December 2024).

- AASX Package Explorer v2024-06-10.alpha Release. Available online: https://github.com/eclipse-aaspe/package-explorer/releases/tag/v2024-06-10.alpha (accessed on 26 December 2024).

- Eclipse AASX Server. Available online: https://github.com/eclipse-aaspe/server (accessed on 26 December 2024).

- FA3ST Service. Available online: https://github.com/FraunhoferIOSB/FAAAST-Service (accessed on 26 December 2024).

- Eclipse BaSyx. Available online: https://github.com/eclipse-basyx (accessed on 26 December 2024).

- NOVAAS. Available online: https://gitlab.com/novaas/catalog/nova-school-of-science-and-technology/novaas (accessed on 26 December 2024).

- BaSyx Time Series GitHub Repository. Available online: https://github.com/eclipse-basyx/basyx-aas-web-ui/tree/6f90eaeb962851d6744d0c1f0598a590c890cdf5 (accessed on 26 December 2024).

- Industrial Digital Twin Association. Specification of the Asset Administration Shell, IDTA Number: 01002-3-0, Part 2: API; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2023. [Google Scholar]

- BaSyx OPC2AAS Repository. Available online: https://github.com/eclipse-basyx/basyx-applications/tree/main/opc2aas (accessed on 26 December 2024).

Disclaimer/Publisher’s Note: The statements, opinions, and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

| Aspect | Description |

|---|---|

| Higher Flexibility | Revised asset representations improve interoperability and ensure that the metamodel is compatible with global standards. |

| Robust Formalization | Comprehensive constraints and formal grammar definitions provide data integrity and consistency and facilitate reliable implementations across diverse applications. |

| Simplification | The removal of deprecated and unused elements reduces complexity, making the metamodel more focused and easier to implement. |

| Future Enhancements | The introduction of experimental features paves the way for continuous development and innovation in the AAS ecosystem. |

| Data Specification | Aligning data specifications with IEC61360 and introducing new data types allows many data integrity issues to be included in the AAS methodology. |

| Criteria/Specs | AASX Server | Eclipse BaSyx | FA3ST Service | NOVAAS |

|---|---|---|---|---|

| Development Context | Eclipse Foundation | Eclipse Foundation | Fraunhofer IOSB | NOVA School of Science and Technology |

| Programming Languages | C# (.NET Core, Blazor, .NET Framework) | Java (primary), Python, C++, Rust, .NET | Java | Node-RED (low-code) |

| Metamodel Support | V3: Full | V3: Full | V3: Full | V3: Partial |

| Licensing | Apache 2.0 License | MIT License | Apache 2.0 License | EUPL v1.2 License |

| Focus Areas | Lightweight server implementation, companion app for AASX Package Explorer | Rich ecosystem, integration with many tools and visualization | AAS edge synchronization | No/low-code tools for GUI/dashboard |

| Interface | CLI, GUI | CLI, GUI | CLI | GUI |

| Documentation Quality | Moderate | Extensive | High | Low |

| Dashboard | ✕ | ✓ | ✕ | ✓ |

| Docker Image | ✓ | ✓ | ✓ | ✓ |

| Data Monitoring | ✕ | ✓ | ✕ | ✓ |

| Import/Export AASX File | Export only | ✓ | ✕ | ✕ |

| Mobile Support | ✕ | ✓ | ✕ | ✕ |

| UI Semantic Identifier | ✕ | ✓ | ✕ | ✕ |

| AAS Editing Interface | ✕ | ✓ | ✕ | ✕ |

| Deployment Aspect | AASX Server | Eclipse BaSyx | FA3ST Service | NOVAAS |

|---|---|---|---|---|

| Distribution Modes | • CLI executable (.NET console) • Docker image | • Java JAR (CLI) • Docker containers for each component • SDK | • Java JAR (CLI) • Docker image | • Docker image • Run by importing Node-RED flows |

| Startup Time | • Fast (<2 s) • Instant REST/OPC UA availability | • Moderate (a few seconds due to container startup and optional DB loading) | • Fast (<2 s) • Lightweight initialization | • Fast (<2 s) • Near-instant startup for small flows |

| CPU and Concurrency | • Multi-threaded • Low resource consumption | • Multi-threaded • Parallel integration (e.g., Camel routes) | • Multi-threaded • Efficient update propagation via internal bus | • Single-threaded event loop • May become CPU-bound under heavy simultaneous load |

| Scalability | • Vertical: Supports multiple AAS within per instance • Horizontal: Multiple instances possible; external discovery needed | • Vertical: Supports multiple AAS and multiple submodels per instance (multiple distinct shells) • Horizontal: Built-in registry supports multi-instance | • Vertical: Supports multiple submodels per instance • Horizontal: External registry required for multiple AAS instances | • Vertical: Supports multiple submodels per instance • Horizontal: External coordination required; best for small deployments |

| Edge/Device Deployment | • Suitable for industrial devices | • Java-based deployment on PCs and gateways | • Suitable for IoT gateways and high-end controllers | • Runs on Raspberry Pi and similar Linux-based gateways |

| Cloud Deployment | • Cloud-ready via Docker • Lacks multi-instance coordination without extra tools | • Cloud-friendly: modular services, Kubernetes deployment • Can integrate with cloud digital twin scenarios | • Cloud-ready via Docker • Can work in serverless environments; integrates with Eclipse Data Space connectors | • Primarily designed for on-prem/edge; not ideal for large-scale cloud production |

| Persistence | • In-memory by default; basic DB (SQLite) in v3 | • Supports MongoDB or SQL for persistence • Offloads data from memory | • In-memory by default | • AAS state in-memory with importing on start |

| Remote Access | • Web UI accessible via browser | • Web UI can be hosted and accessed remotely for monitoring | • Remote access is via API | • Web dashboard accessible via browser |

| Access Control | • Supports OAuth2/OIDC token-based auth | • Integrates with OAuth2/JWT authentication | • No authentication by default (open API) | • Basic authentication for the web UI (username/password) |

| Open Source | Build Time | Image Size | Start-Up Time | Memory Usage (Idle) | CPU Usage (Idle) | Test Scenario (Load) | Average Memory Usage (Load) | Average CPU Usage (Load) |

|---|---|---|---|---|---|---|---|---|

| AASX Server | 25 s | 627 MB | ~1 s | 88 MB | 0.6% | 400 requests in 20 s | ~91.83 MB | ~12.31% |

| FA3ST Service | 39 s | 669 MB | ~1 s | 976 MB | 0.24% | 400 requests in 20 s | ~798.08 MB | ~84.59% |

| Eclipse BaSyx | 127 s | ~2.3 GB | 57 s | 1.28 GB | 1.03% | 400 requests in 20 s | ~1.61 GB | ~23.09% |

| NOVAAS | 309 s | 3.24 GB | ~1 s | 193.8 MB | 1.1% | 400 requests in 20 s | ~241.15 MB | ~16.89% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaya, F.; Şanlı, E.; Albayrak, Ö.; Ünal, P.; Kirci, P. Asset Administration Shell Tool Comparison: A Case Study with Real Digital Twins Used in Petrochemical Industry. Sensors 2025, 25, 1978. https://doi.org/10.3390/s25071978

Kaya F, Şanlı E, Albayrak Ö, Ünal P, Kirci P. Asset Administration Shell Tool Comparison: A Case Study with Real Digital Twins Used in Petrochemical Industry. Sensors. 2025; 25(7):1978. https://doi.org/10.3390/s25071978

Chicago/Turabian StyleKaya, Fatih, Ezgi Şanlı, Özlem Albayrak, Perin Ünal, and Pinar Kirci. 2025. "Asset Administration Shell Tool Comparison: A Case Study with Real Digital Twins Used in Petrochemical Industry" Sensors 25, no. 7: 1978. https://doi.org/10.3390/s25071978

APA StyleKaya, F., Şanlı, E., Albayrak, Ö., Ünal, P., & Kirci, P. (2025). Asset Administration Shell Tool Comparison: A Case Study with Real Digital Twins Used in Petrochemical Industry. Sensors, 25(7), 1978. https://doi.org/10.3390/s25071978