A2-Mode Lamb Passive-Wireless Surface-Acoustic-Wave Micro-Pressure Sensor Based on Cantilever Beam Structure

Abstract

1. Introduction

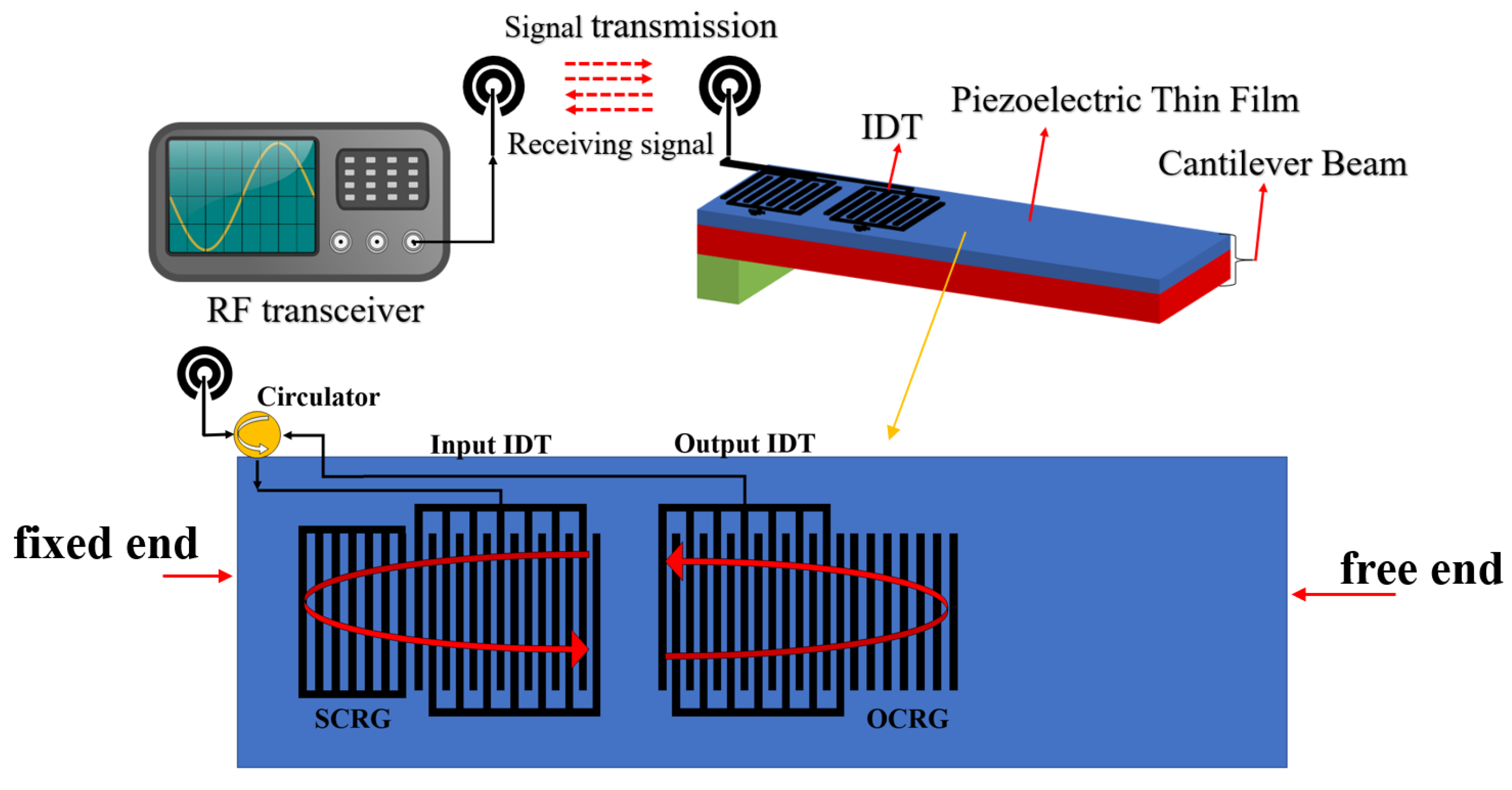

2. System Design and Parameter Optimization

2.1. Design of Micro-Pressure Sensing System

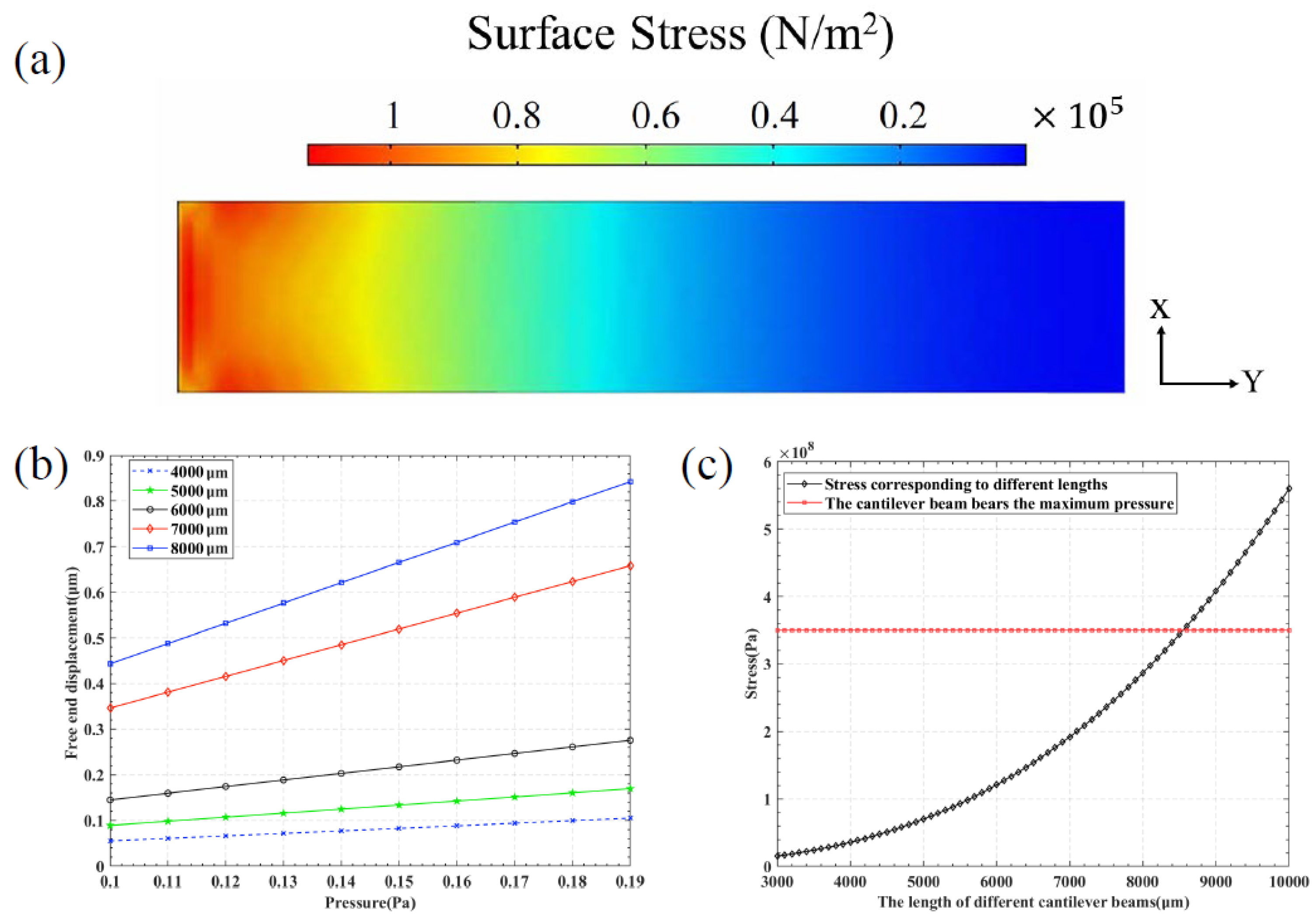

2.2. Parameter Optimization of SAW Micro-Pressure Sensors

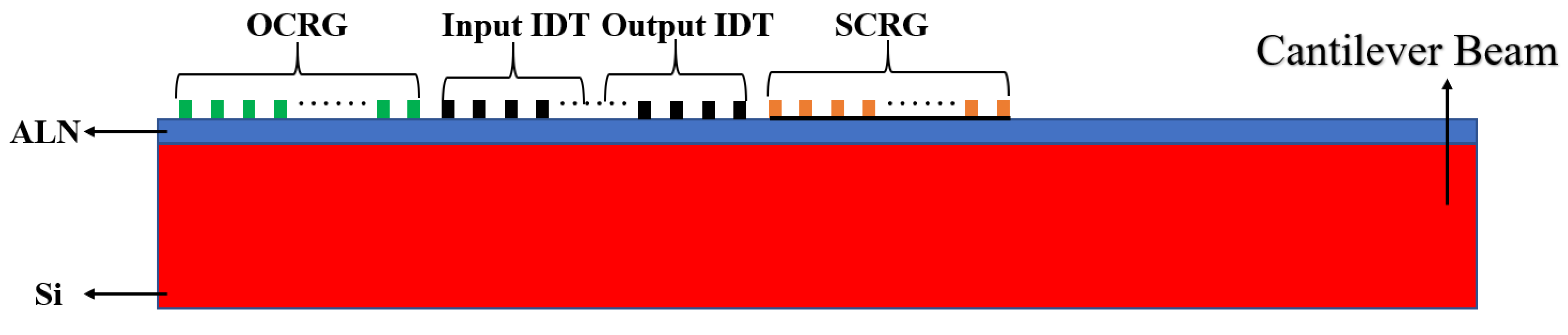

2.2.1. Piezoelectric Films

2.2.2. Cantilever Beam

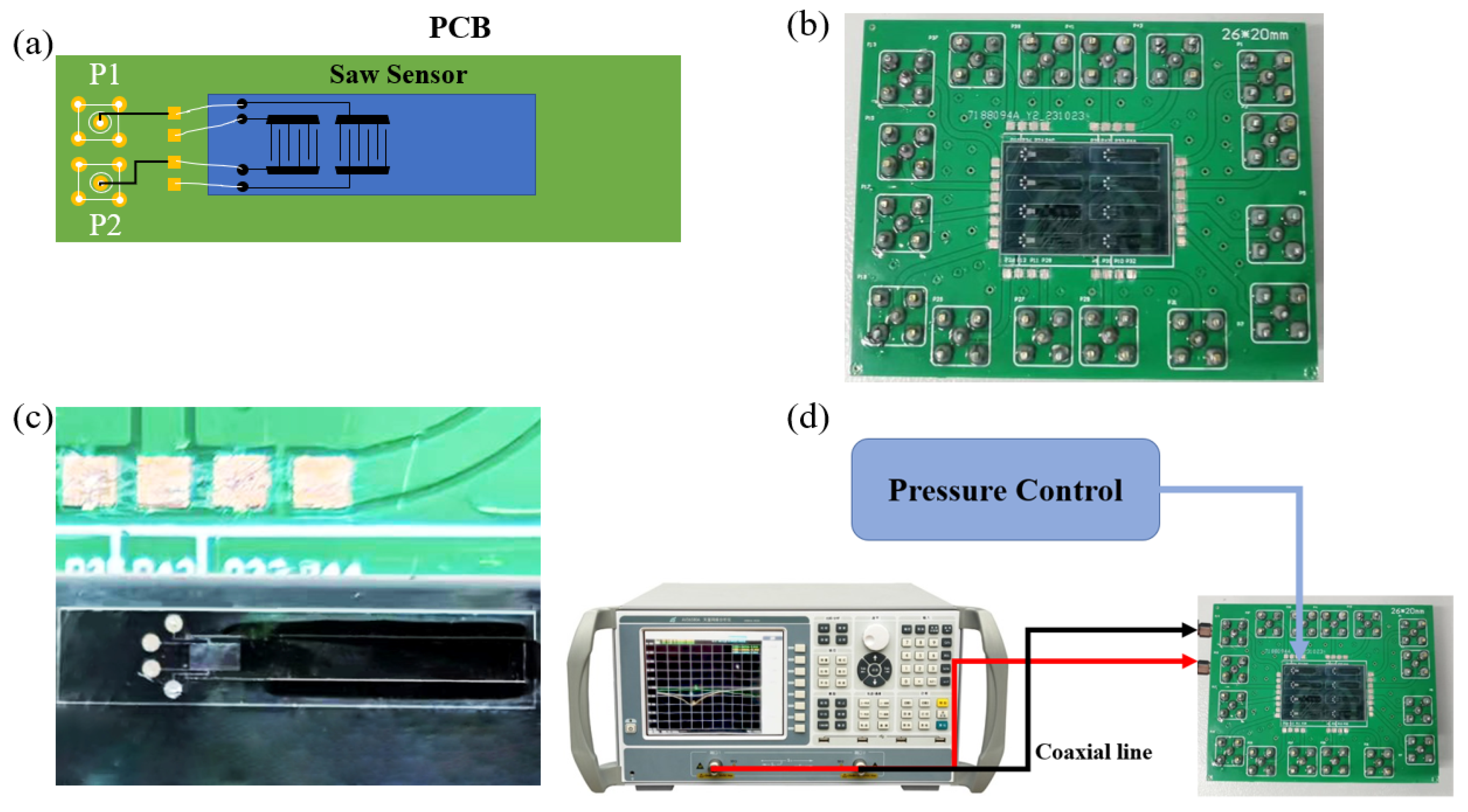

2.2.3. Integrated Digital Terminal

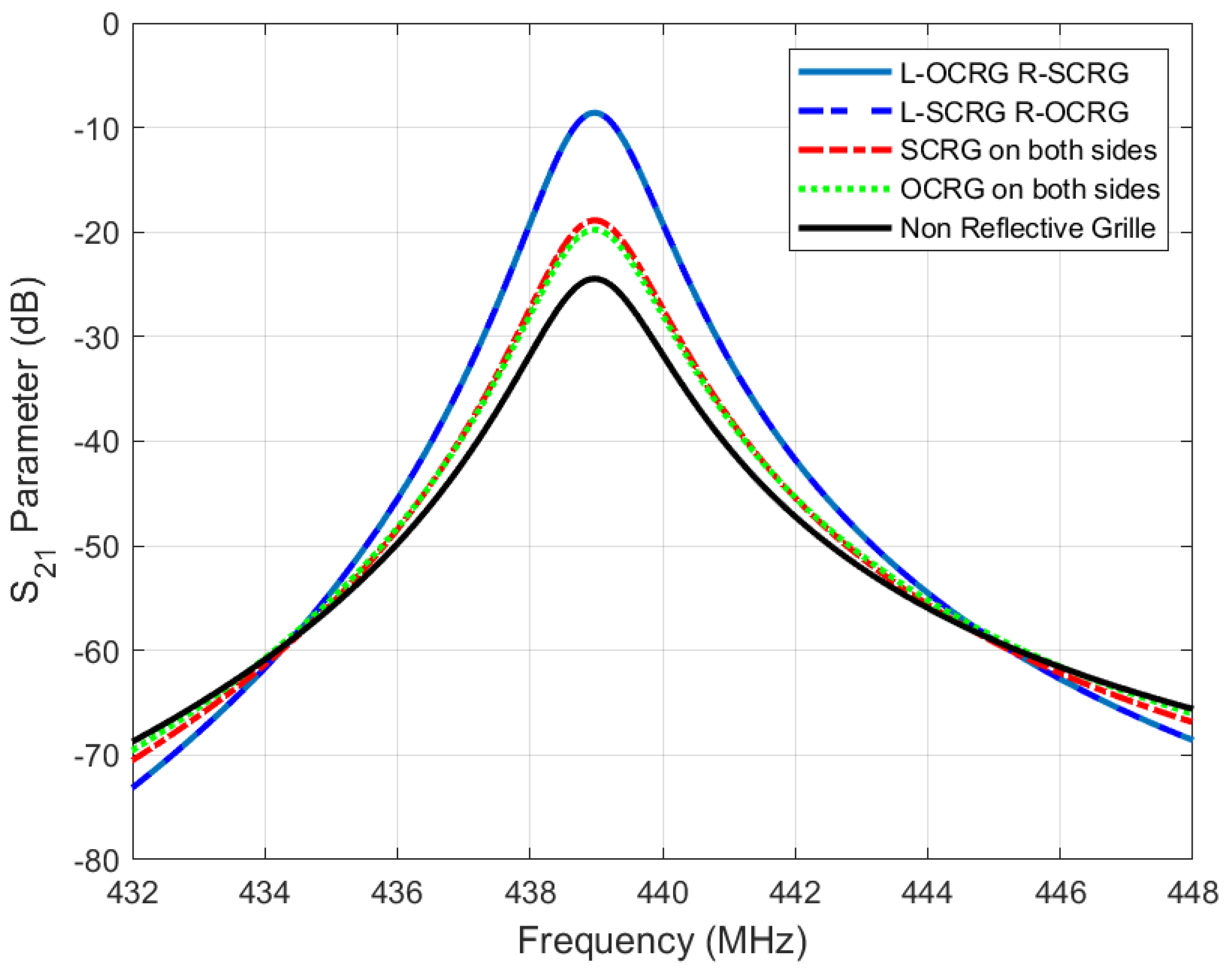

2.2.4. Reflective Grating Design

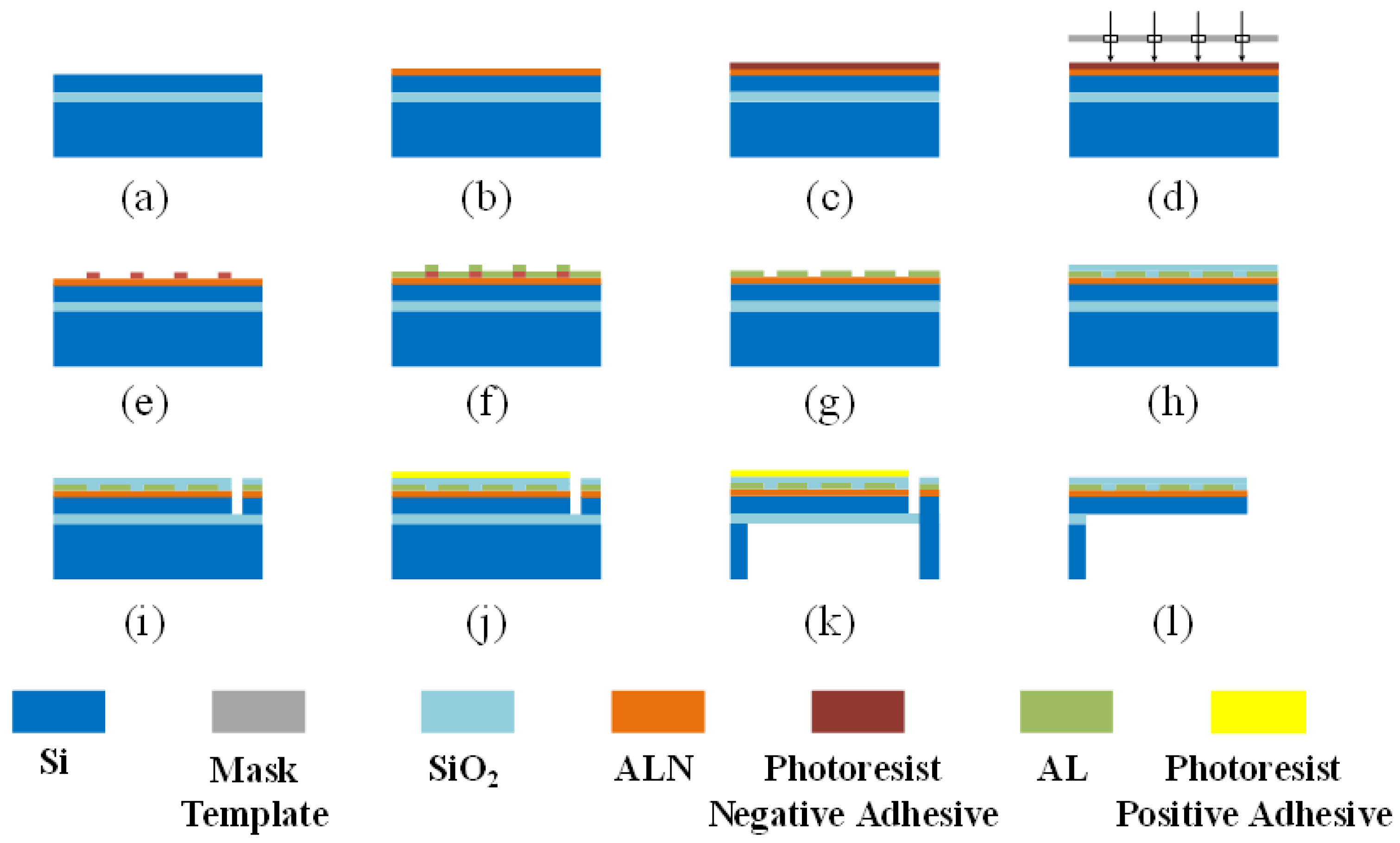

3. Preparation of SAW Micro-Pressure Sensor

3.1. Layout Determination

3.2. Device Manufacturing

4. Performance Analysis and System Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adu-Manu, K.S.; Abdulai, J.D.; Engmann, F.; Akazue, M.; Appati, J.K.; Baiden, G.E.; Sarfo-Kantanka, G. WSN architectures for environmental monitoring applications. J. Sens. 2022, 2022, 7823481. [Google Scholar] [CrossRef]

- Rovera, A.; Tancau, A.; Boetti, N.; Dalla Vedova, M.D.; Maggiore, P.; Janner, D. Fiber optic sensors for harsh and high radiation environments in aerospace applications. Sensors 2023, 23, 2512. [Google Scholar] [CrossRef] [PubMed]

- Mathews, Z.; Quiriconi, L.; Schüpbach, C.; Weber, P. Learning resource allocation in active-passive radar sensor networks. Front. Signal Process. 2022, 2, 822894. [Google Scholar] [CrossRef]

- Dou, Y.; Li, C.; Luo, W.; Qian, L.; Wang, L.; Li, D.; Li, H.; Li, M. Surface acoustic wave relative humidity sensor based on GO/TiO2 sensitive film. Sens. Actuators A Phys. 2024, 365, 114906. [Google Scholar] [CrossRef]

- Li, Y.; Lu, W.; Zhu, C.; Liu, Q.; Zhang, H.; Lei, B. Finite element analysis of surface acoustic wave based on a micro force sensor. Measurement 2015, 65, 112–119. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Jiang, B.; Cao, L.; Shen, X.; Shao, M. Finite element simulation for sensitivity measurement of a shear horizontal surface acoustic wave micro pressure sensor with a groove structure. Meas. Sci. Technol. 2020, 32, 015103. [Google Scholar] [CrossRef]

- Mo, W.; Fu, X.; Jin, F.; Song, J.; Dong, K. Design and experiment of a cantilever beam pressure sensor using an optical microring resonator. Optik 2021, 243, 167466. [Google Scholar] [CrossRef]

- Xin, Z.; Sun, H.; Wang, D. A high-performance dual-channel MEMS microwave power sensor with cantilever beam. IEEE Sens. J. 2023, 23, 11540–11546. [Google Scholar] [CrossRef]

- Wu, G.; Gong, Z.; Ma, J.; Li, H.; Guo, M.; Chen, K.; Peng, W.; Yu, Q.; Mei, L. High-sensitivity miniature dual-resonance photoacoustic sensor based on silicon cantilever beam for trace gas sensing. Photoacoustics 2022, 27, 100386. [Google Scholar] [CrossRef]

- Quintero, S.M.; Figueiredo, S.W.; Takahashi, V.L.; Llerena, R.A.; Braga, A.M. Passive downhole pressure sensor based on surface acoustic wave technology. Sensors 2017, 17, 1635. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Madrid, J.; Iriarte, G.; Williams, O.A.; Calle, F. High precision pressure sensors based on SAW devices in the GHz range. Sens. Actuators A Phys. 2013, 189, 364–369. [Google Scholar] [CrossRef]

- Grousset, S.; Augendre, E.; Benaissa, L.; Signamarcheix, T.; Baron, T.; Courjon, E.; Ballandras, S. SAW pressure sensor based on single-crystal quartz layer transferred on silicon. In Proceedings of the 2013 Joint European Frequency and Time Forum & International Frequency Control Symposium (EFTF/IFC), Prague, Czech Republic, 21–25 July 2013; pp. 980–983. [Google Scholar]

- Hu, B.; Li, Z.; Wan, Y.; Zhou, P.; Zhang, C.; San, H. 3D printed pressure sensor based on surface acoustic wave resonator. Meas. Sci. Rev. 2021, 21, 76–81. [Google Scholar] [CrossRef]

- Luo, Z.; Li, D.; Le, X.; He, T.; Shao, S.; Lv, Q.; Liu, Z.; Lee, C.; Wu, T. Ultra-compact and high-performance suspended aluminum scandium nitride Lamb wave humidity sensor with a graphene oxide layer. Nanoscale 2024, 16, 10230–10238. [Google Scholar] [CrossRef] [PubMed]

- Bharati, M.; Rana, L.; Jindal, K.; Gupta, R.; Sharma, A.; Tomar, M. Lamb Wave Resonator for UV Photodetection and Impact of Induced Piezopotential on Schottky Barrier Height Toward Enhanced Sensitivity. IEEE Sens. J. 2023, 23, 10568–10576. [Google Scholar] [CrossRef]

- Liang, C.; Yan, C.; Zhai, S.; Wang, Y.; Hu, A.; Wang, W.; Pan, Y. Recent progress in flexible surface acoustic wave sensing technologies. Micromachines 2024, 15, 357. [Google Scholar] [CrossRef] [PubMed]

- Vlasov, S.; Koposova, E. Diffraction of Wave Beams from a Reflective Grating. Radiophys. Quantum Electron. 2023, 66, 345. [Google Scholar] [CrossRef]

- Lu, W.; Feng, Y.; Zhu, C.; Zheng, J. Temperature compensation of the SAW yarn tension sensor. Ultrasonics 2017, 76, 87–91. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Wang, X.H.; Fan, G.F.; Fu, M.; Lei, W.; Wang, X.C.; Liang, F.; Lu, W.Z. Effect of oxidation on flexural strength and thermal properties of AlN ceramics with residual stress and impedance spectroscopy analysis of defects and impurities. Ceram. Int. 2019, 45, 13019–13023. [Google Scholar] [CrossRef]

- Yang, S.; Ai, Y.; Zhang, Y.; Cheng, Z.; Zhang, L.; Jia, L.; Dong, B.; Zhang, B.; Wang, J. Impact of device parameters on performance of one-port type SAW resonators on AlN/sapphire. J. Micromech. Microeng. 2018, 28, 085005. [Google Scholar] [CrossRef]

- Auld, B.A. Acoustic Fields and Waves in Solids; John Wiley & Sons: Hoboken, NJ, USA, 1973. [Google Scholar]

| Author | Sensitivity | Wave Type | Substrate | Structure | Wireless |

|---|---|---|---|---|---|

| Quintero et al. [10] | 8.3 kHz/bar | Rayleigh Wave | ST-cut Quartz | Circular Diaphragm | Yes |

| Rodríguez-Madrid et al. [11] | 330 kHz/bar | Rayleigh Wave | AIN on CVD Nanocrystaline | Free-standing | No |

| Grousset et al. [12] | 25.8 kHz/bar | Rayleigh Wave | AT-Cut Quartz (YXl)/37° | Membrane | No |

| Hu et al. [13] | 589 ppm/Mpa | Rayleigh Wave | 128° Y-X LiNbO3 | Chamber Structure | Yes |

| Material Name | SAW Speed (m/s) | Electromechanical Coupling Coefficient (%) | Propagation Loss (dB/cm) |

|---|---|---|---|

| 3301 | 1.5 | 0.35 (1 GHz) | |

| 5000 | 6.5 | 0.31 (1 GHz) | |

| 3506 | 3.5 | 0.26 (1 GHz) |

| Geometric Variables | Parameter |

|---|---|

| IDT width | 8.5 |

| IDT interval | 8.5 |

| Width of OSR and SRC | 8.5 |

| Interval of OSR and SRC | 8.5 |

| Interval between IDT and OSR | 4.25 |

| Interval between IDT and SRC | 8.5 |

| Electrode heights for IDT, OSR, and SRC | 200 nm |

| Thickness of AlN | 600 nm |

| Thickness of Si | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Z.; Wang, T.; Ji, W.; Feng, L.; Yin, P.; Lu, J.; Yin, L. A2-Mode Lamb Passive-Wireless Surface-Acoustic-Wave Micro-Pressure Sensor Based on Cantilever Beam Structure. Sensors 2025, 25, 1873. https://doi.org/10.3390/s25061873

Duan Z, Wang T, Ji W, Feng L, Yin P, Lu J, Yin L. A2-Mode Lamb Passive-Wireless Surface-Acoustic-Wave Micro-Pressure Sensor Based on Cantilever Beam Structure. Sensors. 2025; 25(6):1873. https://doi.org/10.3390/s25061873

Chicago/Turabian StyleDuan, Zhuoyue, Tao Wang, Wei Ji, Lihui Feng, Peng Yin, Jihua Lu, and Litong Yin. 2025. "A2-Mode Lamb Passive-Wireless Surface-Acoustic-Wave Micro-Pressure Sensor Based on Cantilever Beam Structure" Sensors 25, no. 6: 1873. https://doi.org/10.3390/s25061873

APA StyleDuan, Z., Wang, T., Ji, W., Feng, L., Yin, P., Lu, J., & Yin, L. (2025). A2-Mode Lamb Passive-Wireless Surface-Acoustic-Wave Micro-Pressure Sensor Based on Cantilever Beam Structure. Sensors, 25(6), 1873. https://doi.org/10.3390/s25061873