Displacement Sensing Using Bimodal Resonance in Over-Coupled Inductors

Abstract

1. Introduction

2. Theory

2.1. Self-Resonance Equivalent Circuit Model

2.2. Two-Coil Mutual Resonance Model

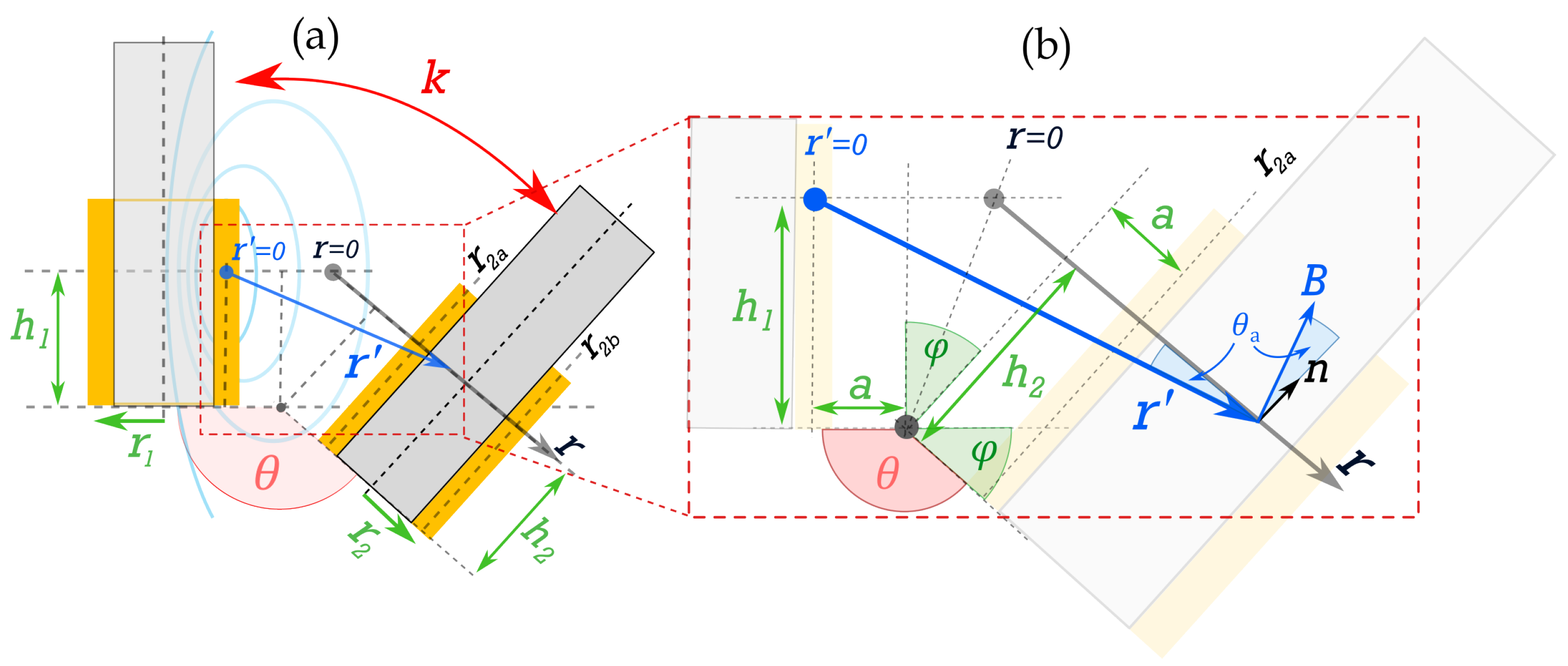

2.3. Coupling Coefficients

2.3.1. Co-Planar Separation

2.3.2. Angular Displacement—Planar Coils

2.3.3. Angular Displacement—Solenoid Coils

3. Materials and Methods

3.1. Sensor Designs

3.2. Finite Element Modelling

3.3. Experimental Measurements

3.3.1. Data Acquisition

3.3.2. Co-Planar Separation, a

3.3.3. Angular Displacement,

4. Results and Discussion

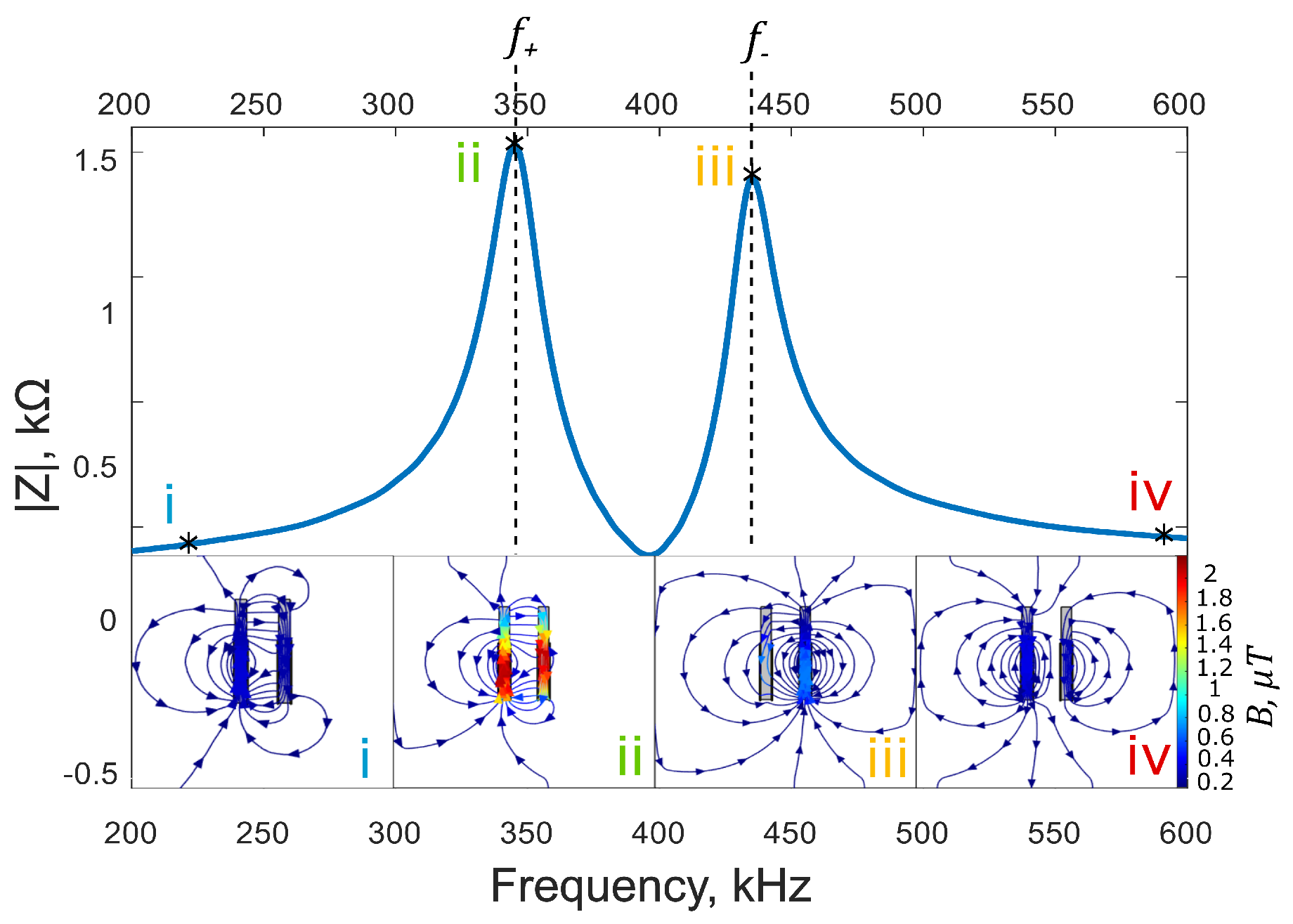

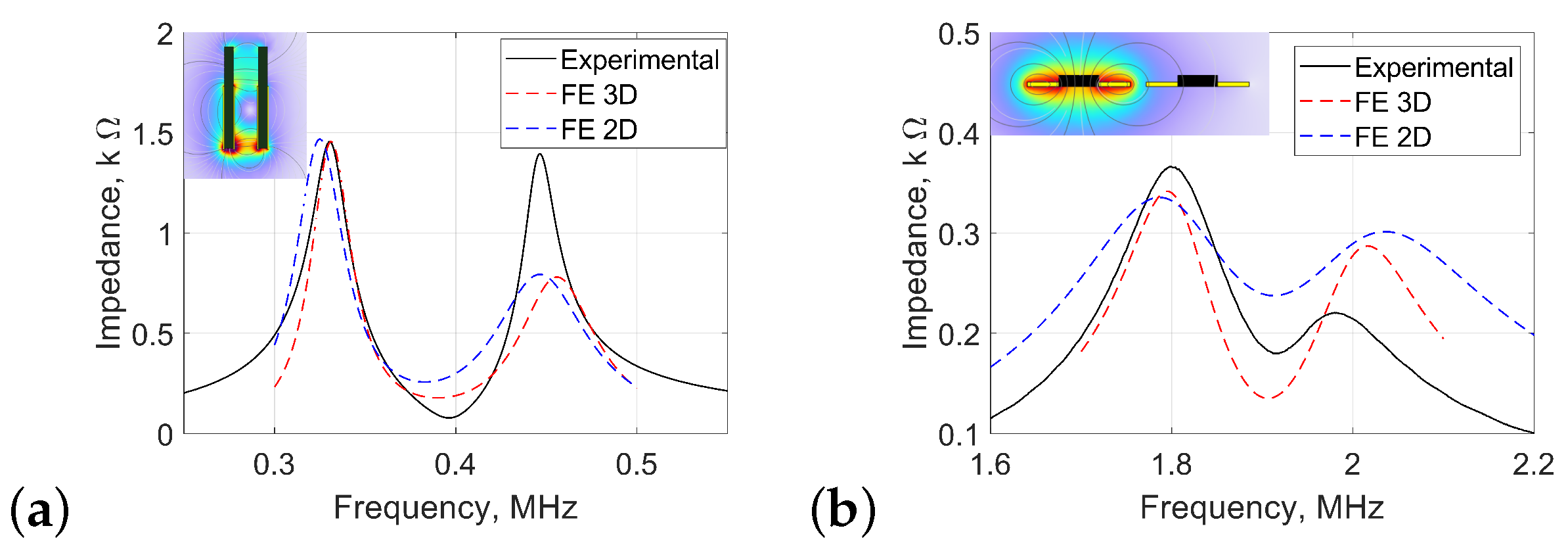

4.1. FE Model Validation

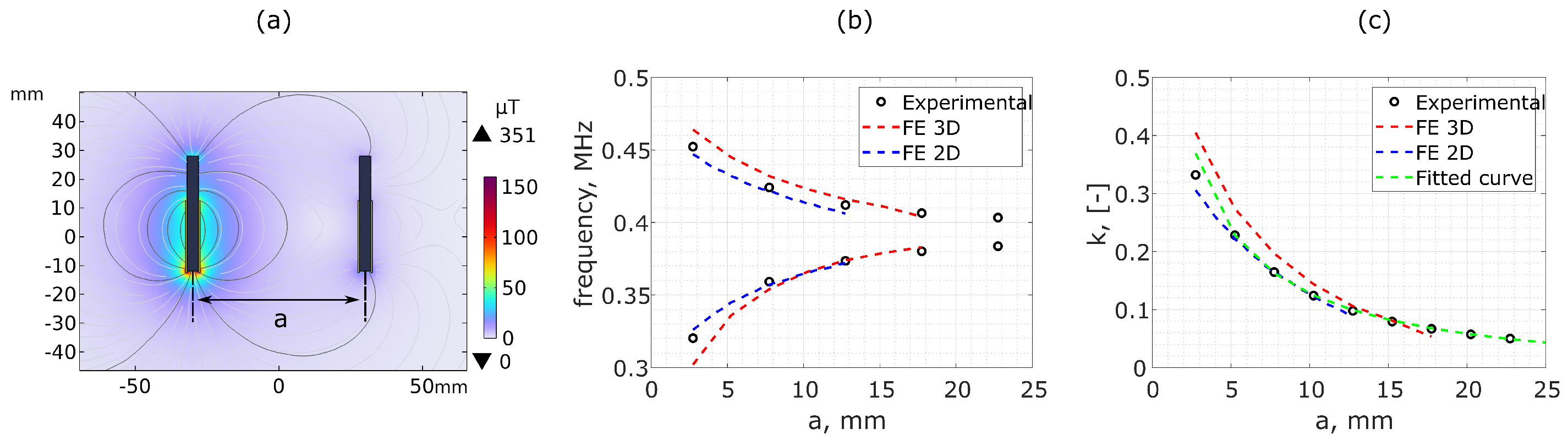

4.2. Co-Planar Separation, a

4.3. Angular Displacement,

4.4. Displacement Prediction

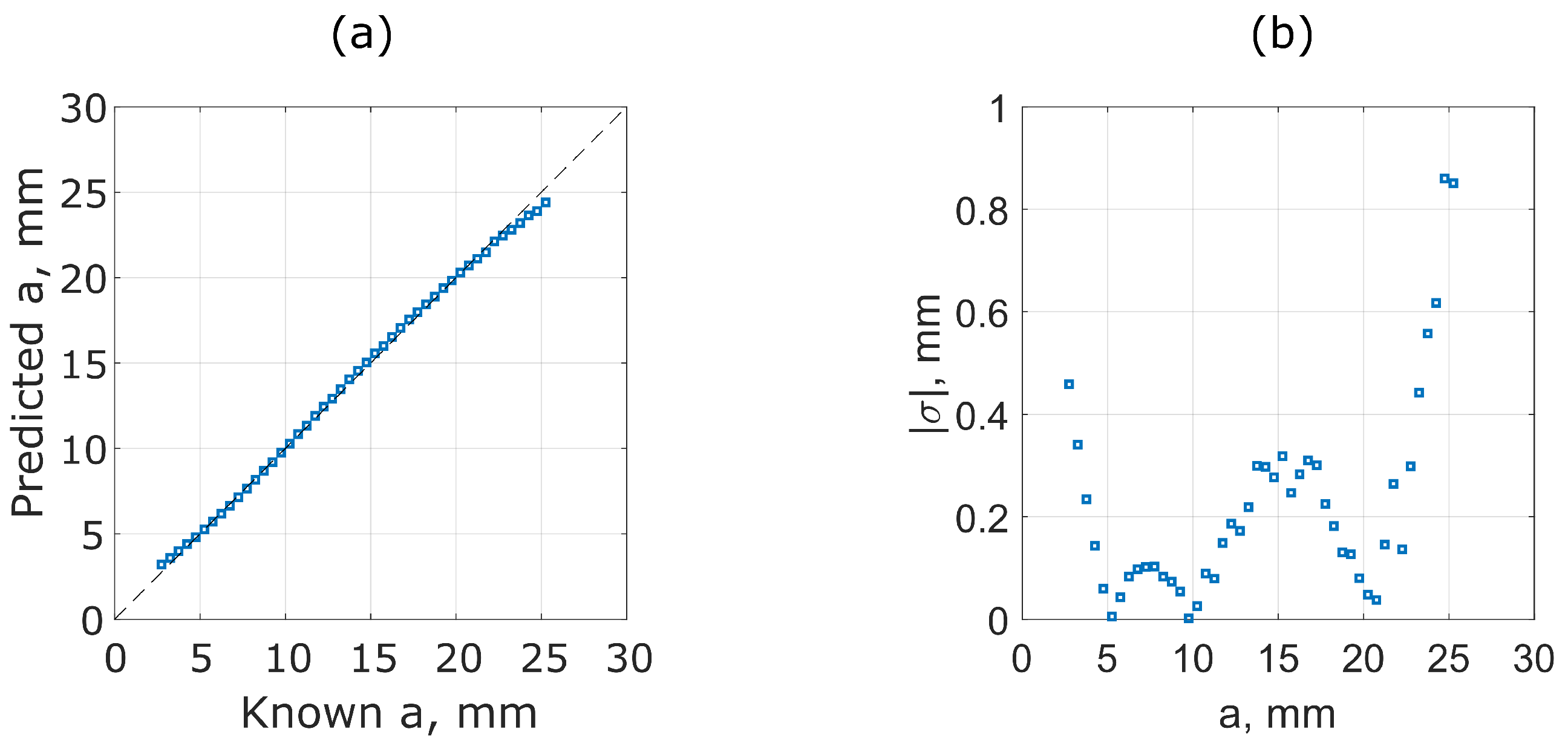

4.4.1. Evaluating Separation, a

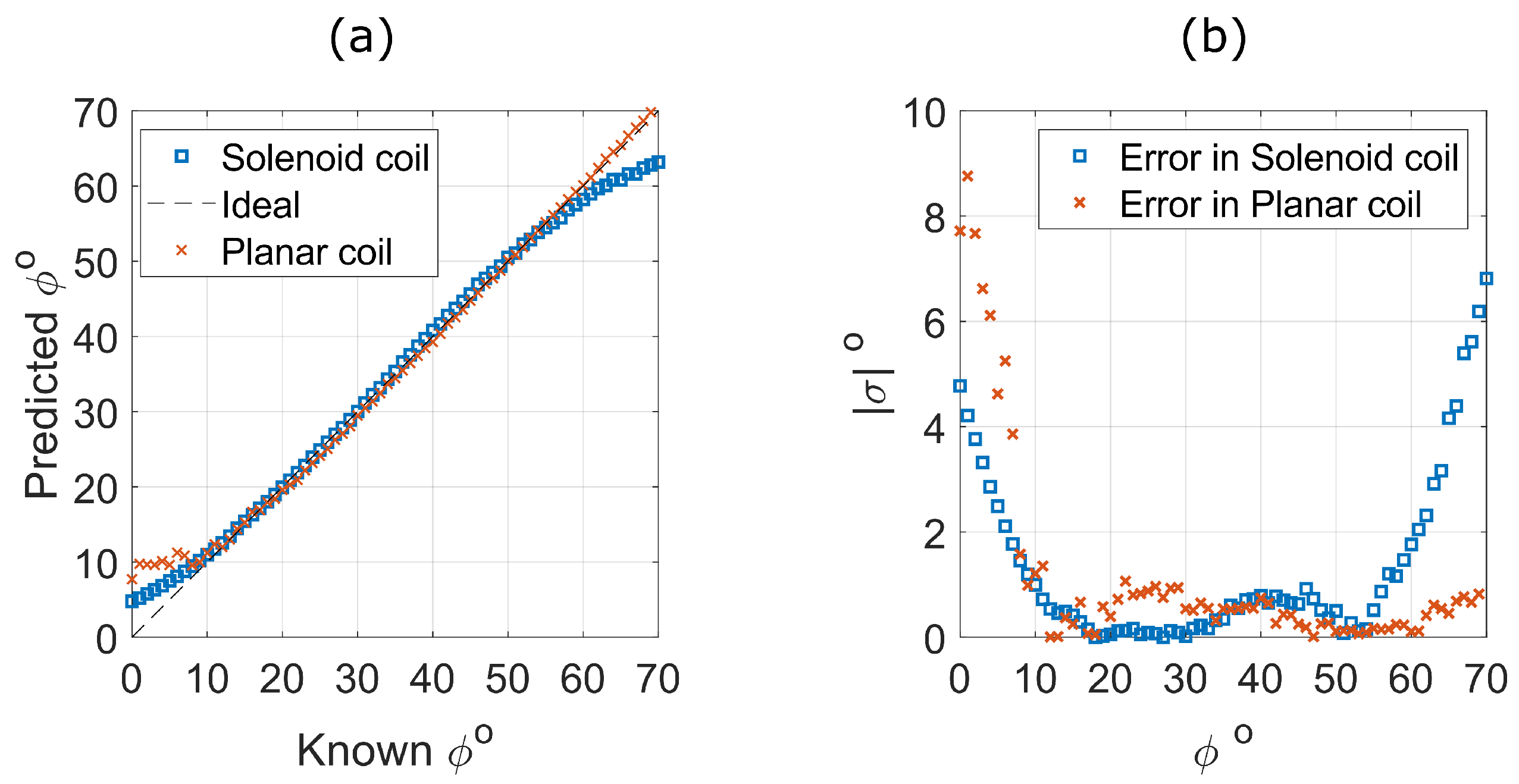

4.4.2. Evaluating Angle,

4.4.3. Prediction Error,

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Derivation of Resonant Frequency of Coupled Coils

References

- Yu, X.; Hu, Q.; Xu, D.; Li, P.; Liu, X. Common Sensors in Industrial Robots: A Review. J. Phys. Conf. Ser. 2019, 1267, 012036. [Google Scholar] [CrossRef]

- Melzer, M.; Makarov, D.; Schmidt, O.G. A review on stretchable magnetic field sensorics. J. Phys. D Appl. Phys. 2019, 53, 083002. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, Y.; Huang, Y.; Liang, C.; Dong, Y.; Kang, Y.; Feng, B. A Displacement Sensing Method Based on Permanent Magnet and Magnetic Flux Measurement. Sensors 2022, 22, 4326. [Google Scholar] [CrossRef]

- Jiang, S.; Li, J.; Li, Z.; Li, Z.; Li, W.; Huang, X.; Zhang, H.; Zhang, G.; Huang, A.; Xiao, Z. Experimental realization of exceptional surfaces enhanced displacement sensing with robustness. Appl. Phys. Lett. 2023, 123, 201106. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, L.; Cao, B.; Zhang, H.; Liu, J. A Moving Magnetic Grid-Type Long-Range Linear Absolute Displacement Sensor. Sensors 2023, 23, 700. [Google Scholar] [CrossRef]

- Zhu, C.; Zhuang, Y.; Liu, B.; Huang, J. Review of Fiber Optic Displacement Sensors. IEEE Trans. Instrum. Meas. 2022, 71, 7008212. [Google Scholar] [CrossRef]

- Berkovic, G.; Shafir, E. Optical methods for distance and displacement measurements. Adv. Opt. Photon. 2012, 4, 441–471. [Google Scholar] [CrossRef]

- Sciammarella, C.A. A Review: Optical Methods That Evaluate Displacement. In Advancement of Optical Methods & Digital Image Correlation in Experimental Mechanics; Lamberti, L., Lin, M.T., Furlong, C., Sciammarella, C., Reu, P.L., Sutton, M.A., Eds.; Springer: Cham, Switzerland, 2019; Volume 3, pp. 23–52. [Google Scholar]

- Ye, Y.; Zhang, C.; He, C.; Wang, X.; Huang, J.; Deng, J. A Review on Applications of Capacitive Displacement Sensing for Capacitive Proximity Sensor. IEEE Access 2020, 8, 45325–45342. [Google Scholar] [CrossRef]

- Blaž, N.; Kisić, M.; Žlebič, C.; Mišković, G.; Radosavljević, G.; Živanov, L. Displacement sensor based on interdigital capacitor. In Proceedings of the 2015 38th International Spring Seminar on Electronics Technology (ISSE), Eger, Hungary, 6–10 May 2015; pp. 477–481. [Google Scholar] [CrossRef]

- George, B.; Tan, Z.; Nihtianov, S. Advances in Capacitive, Eddy Current, and Magnetic Displacement Sensors and Corresponding Interfaces. IEEE Trans. Ind. Electron. 2017, 64, 9595–9607. [Google Scholar] [CrossRef]

- Micro-Epsilon. Precise Distance Sensors. Available online: https://www.micro-epsilon.co.uk/distance-sensors/ (accessed on 2 March 2025).

- Jagiella, M.; Fericean, S.; Droxler, R.; Dorneich, A. New magneto-inductive sensing principle and its implementation in sensors for industrial applications. In Proceedings of the SENSORS, 2004 IEEE, Vienna, Austria, 24–27 October 2004; Volume 2, pp. 1020–1023. [Google Scholar] [CrossRef]

- Jiao, D.; Ni, L.; Zhu, X.; Zhe, J.; Zhao, Z.; Lyu, Y.; Liu, Z. Measuring gaps using planar inductive sensors based on calculating mutual inductance. Sens. Actuators A Phys. 2019, 295, 59–69. [Google Scholar] [CrossRef]

- Ripka, P.; Janosek, M. Advances in Magnetic Field Sensors. IEEE Sens. J. 2010, 10, 1108–1116. [Google Scholar] [CrossRef]

- Tzemanaki, A.; Gao, X.; Pipe, A.G.; Melhuish, C.; Dogramadzi, S. Hand exoskeleton for remote control of minimally invasive surgical anthropomorphic instrumentation. In Proceedings of the 6th Hamlyn Symposium on Medical Robotics, London, UK, 22–25 June 2013. [Google Scholar]

- Dupre, N.; Bidaux, Y.; Dubrulle, O.; Close, G.F. A Stray-Field-Immune Magnetic Displacement Sensor with 1% Accuracy. IEEE Sens. J. 2020, 20, 11405–11411. [Google Scholar] [CrossRef]

- Reddy, B.P.; Murali, A.; Shaga, G. Low cost planar coil structure for inductive sensors to measure absolute angular position. In Proceedings of the 2017 2nd International Conference on Frontiers of Sensors Technologies, ICFST 2017, Shenzhen, China, 14–16 April 2017; pp. 14–18. [Google Scholar] [CrossRef]

- Owston, C.N. A high frequency eddy-current, non-destructive testing apparatus with automatic probe positioning suitable for scanning applications. J. Phys. E Sci. Instrum. 1970, 3, 814–818. [Google Scholar] [CrossRef]

- Bonfitto, A.; Gabai, R.; Tonoli, A.; Castellanos, L.M.; Amati, N. Resonant inductive displacement sensor for active magnetic bearings. Sens. Actuators A Phys. 2019, 287, 84–92. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z. Frequency splitting analysis of two-coil resonant wireless power transfer. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 400–402. [Google Scholar] [CrossRef]

- Niu, W.; Jiang, J.; Ye, C.; Gu, W. Frequency splitting suppression in wireless power transfer using hemispherical spiral coils. AIP Adv. 2022, 12, 055016. [Google Scholar] [CrossRef]

- Zhu, P.W.; Wang, X.; Zhao, W.S.; Wang, J.; Wang, D.W.; Hou, F.; Wang, G. Design of H-shaped planar displacement microwave sensors with wide dynamic range. Sens. Actuators A Phys. 2022, 333, 113311. [Google Scholar] [CrossRef]

- Horestani, A.K.; Naqui, J.; Shaterian, Z.; Abbott, D.; Fumeaux, C.; Martín, F. Two-dimensional alignment and displacement sensor based on movable broadside-coupled split ring resonators. Sens. Actuators A Phys. 2014, 210, 18–24. [Google Scholar] [CrossRef]

- Babu, A.; George, B. A linear and high sensitive interfacing scheme for wireless passive LC sensors. IEEE Sens. J. 2016, 16, 8608–8616. [Google Scholar] [CrossRef]

- Babu, A.; George, B. An Efficient Readout Scheme for Simultaneous Measurement from Multiple Wireless Passive LC Sensors. IEEE Trans. Instrum. Meas. 2018, 67, 1161–1168. [Google Scholar] [CrossRef]

- Babu, A.; George, B. Sensor System to Aid the Vehicle Alignment for Inductive EV Chargers. IEEE Trans. Ind. Electron. 2019, 66, 7338–7346. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Beziuk, G.; Scott, J.; Ghorbani, K. Microwave Differential Frequency Splitting Sensor Using Magnetic-LC Resonators. Sensors 2020, 20, 1066. [Google Scholar] [CrossRef]

- Schormans, M.; Valente, V.; Demosthenous, A. Frequency Splitting Analysis and Compensation Method for Inductive Wireless Powering of Implantable Biosensors. Sensors 2016, 16, 1229. [Google Scholar] [CrossRef]

- Kalhor, H.A. The Degree of Intelligence of the Law of Biot-Savart. IEEE Trans. Educ. 1990, 33, 365–366. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Chen, K. Frequency-splitting analysis of four-coil resonant wireless power transfer. IEEE Trans. Ind. Appl. 2014, 50, 2436–2445. [Google Scholar] [CrossRef]

- Hughes, R.; Fan, Y.; Dixon, S. Investigating electrical resonance in eddy-current array probes. AIP Conf. Proc. 2016, 1706, 090001. [Google Scholar] [CrossRef]

- Hughes, R. High-Sensitivity Eddy-Current Testing Technology for Defect Detection in Aerospace Superalloys. Ph.D. Thesis, University of Warwick, Department of Physics, Coventry, UK, 2016. [Google Scholar]

- Hughes, R.; Fan, Y.; Dixon, S. Near electrical resonance signal enhancement (NERSE) in eddy-current crack detection. NDT E Int. 2014, 66, 82–89. [Google Scholar] [CrossRef]

- Mazlouman, S.J.; Mahanfar, A.; Kaminska, B. Mid-range wireless energy transfer using inductive resonance for wireless sensors. In Proceedings of the IEEE International Conference on Computer Design: VLSI in Computers and Processors, Lake Tahoe, CA, USA, 4–7 October 2009; pp. 517–522. [Google Scholar] [CrossRef]

- Moghaddami, M.; Sundararajan, A.; Sarwat, A.I. Sensorless electric vehicle detection in inductive charging stations using self-tuning controllers. In Proceedings of the 2017 IEEE Transportation Electrification Conference, ITEC-India 2017, Pune, India, 13–15 December 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Tyurnev, V.V. Coupling Coefficients of Resonators in Microwave Filter Theory. Prog. Electromagn. Res. B 2010, 21, 47–67. [Google Scholar] [CrossRef]

- Tung, W.S.; Chiang, Y.C.; Cheng, J.C. A new compact LTCC bandpass filter using negative coupling. IEEE Microw. Wirel. Compon. Lett. 2005, 15, 641–643. [Google Scholar] [CrossRef]

- Petrov, P.; Radkovskaya, A.; Shamonina, E. Retrieval of electric and magnetic coupling coefficients. In Proceedings of the 2015 9th International Congress on Advanced Electromagnetic Materials in Microwaves and Optics, METAMATERIALS 2015, Oxford, UK, 7–12 September 2015; pp. 259–261. [Google Scholar] [CrossRef]

- Hughes, R.R.; Arroyo, A.H.; Mulholland, A.J. Analytical Approximations for Fitting Magnetic Coupling Coefficients Between Adjacent Coils. IEEE Trans. Magn. 2024, 60, 8400309. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.; Liu, X.; Xu, D.; Cai, L. An LC/S Compensation Topology and Coil Design Technique for Wireless Power Transfer. IEEE Trans. Power Electron. 2018, 33, 2007–2025. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, T.; Zhao, Z.; He, F.; Chen, K.; Yuan, L. Selective Wireless Power Transfer to Multiple Loads Using Receivers of Different Resonant Frequencies. IEEE Trans. Power Electron. 2015, 30, 6001–6005. [Google Scholar] [CrossRef]

- Yang, D.; Won, S.; Hong, H. Design of Range Adaptive Wireless Power Transfer System Using Non-coaxial Coils. IOP Conf. Ser. Mater. Sci. Eng. 2017, 199, 012008. [Google Scholar] [CrossRef]

| Coil Dimensions (mm) | |||||

|---|---|---|---|---|---|

| Coil Type | l | ||||

| Sol | 43 | 40 | 25 | 8 | 11 |

| Plan. | 20 | 1.5 | 1.0 | 5 | 12 |

| Circuit Parameters | |||||

| Coil Type | Turns | L () | C (nF) | R () | I (mA) |

| Sol. (2D) | 40 | 708 | 0.2 | 0.1 | 10 |

| Sol. (3D) | 40 | 170 | 1 | 1 | 10 |

| Sol. (exp.) | 40 | 166 | 1 | 1 | 10 |

| Plan. (2D) | 28 | 7.9 | 0.9 | 0.01 | 1 |

| Plan. (3D) | 28 | 7.5 | 1 | 0.01 | 1 |

| Plan. (exp.) | 28 | 6.7 | 1 | 0.01 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernandez Arroyo, A.; Overton, G.; Mulholland, A.J.; Hughes, R.R. Displacement Sensing Using Bimodal Resonance in Over-Coupled Inductors. Sensors 2025, 25, 1822. https://doi.org/10.3390/s25061822

Hernandez Arroyo A, Overton G, Mulholland AJ, Hughes RR. Displacement Sensing Using Bimodal Resonance in Over-Coupled Inductors. Sensors. 2025; 25(6):1822. https://doi.org/10.3390/s25061822

Chicago/Turabian StyleHernandez Arroyo, Alexis, George Overton, Anthony J. Mulholland, and Robert R. Hughes. 2025. "Displacement Sensing Using Bimodal Resonance in Over-Coupled Inductors" Sensors 25, no. 6: 1822. https://doi.org/10.3390/s25061822

APA StyleHernandez Arroyo, A., Overton, G., Mulholland, A. J., & Hughes, R. R. (2025). Displacement Sensing Using Bimodal Resonance in Over-Coupled Inductors. Sensors, 25(6), 1822. https://doi.org/10.3390/s25061822