1. Introduction

Thin-walled structures occur in many aeronautical and aerospace engineering applications, such as fuselages of aircraft or hulls of spaceships, where demands on the structures’ weight are paramount [

1]. In these applications, thin-walled components not only entail constructive functionalities but also contribute to the overall structural performance. Thus, their integrity is of key importance for the overall structural safety and reliability. In addition to conventional inspections using non-destructive testing methods, structural health monitoring (SHM) can continuously provide information about the health state of critical structural components. Therefore, sensors and possibly actuators are permanently attached on or even integrated into a structure [

2]. The resulting self-sensing functionality of these so-called smart structures enables advanced SHM procedures to complement conventional non-destructive evaluation methods for even safer and more reliable operation of structures [

3]. Besides that, certain traditional non-destructive testing methods, e.g., optical crack detection [

4], have the potential for automation, which can significantly increase accuracy while saving inspection time.

SHM methods typically exploit various physical phenomena that are altered by structural damage. For example, traditional strain-based approaches monitor strain distributions in critical areas, which change notably as damage occurs [

5]. These variations can be detected using simple strain gauges [

6] or fiber optical sensors [

7]. Other sensor technologies are based on magnetic fields [

8,

9] or pneumatic principles [

10]. Lightweight and inexpensive piezoelectric transducers, i.e., piezoelectric wafer active sensors (PWASs), are commonly employed in SHM applications and can be easily mounted to or seamlessly integrated into structures. These PWASs leverage the reversible piezoelectric effect, allowing for their dual function as both actuators and sensors, while even a simultaneous use of both functions is possible [

11]. The alternative use by alternating their role provides exceptional versatility and makes them capable of employing several SHM methods, such as passive acoustic emission methods [

12] or active guided wave-based [

13] and electro-mechanical impedance techniques [

14].

In particular, guided wave-based SHM methods have attracted significant attention in recent decades [

15]. In a traditional pitch–catch configuration, possible damage influences the propagating guided waves on the way from the actuator to the sensor [

16]. Hence, the sensor signal differs in comparison to a baseline from the assumed pristine condition [

17]. Analyzing these differences allows us to draw certain conclusions about the damage, where the existence of damage is commonly revealed by baseline subtraction [

18] or anomaly detection [

19]. By using a typical sparse sensor network, e.g., an array of PWASs, the location of the damage can be determined by various imaging methods, e.g., delay-and-sum [

20] or time reversal methods [

21]. Advanced data processing algorithms even allow us to localize multiple damages based on coefficient matrices constructed from guided wave reflections [

22]. Furthermore, tomographic imaging techniques can reconstruct the damage location, but they require a relatively dense sensor array [

23,

24]. This might hinder their application on large-scale structures.

Generally, SHM systems need smart and powerful computational techniques to achieve accurate results. Hence, state-of-the art SHM approaches increasingly combine traditional methods, e.g., guided wave-based techniques, with machine learning methods due to their high potential for efficient dissemination of information and knowledge discovery. For example, these machine learning approaches can create a model based on training data to predict or decide on a specific task without explicitly implementing the solution. The performance of such self-adaptive models improves solely by learning from the given training data. Artificial neural networks are inspired by biological neural networks and employ non-linear regression models, where the chain rule of differentiation and the gradient descent method are used to learn their parameters incrementally. Sbarufatti et al. [

25] employed such an artificial neural network to locate and quantify fatigue cracks in aluminum plates using numerically simulated Lamb wave signals. Support vector machines use statistical learning theory to maximize the margins of selected data samples, i.e., support vectors. This optimization problem is typically solved in a recursive manner by dynamic programming to reveal optimal decision bounds. In the context of guided wave-based SHM, these support vector machines are utilized by Zhang et al. [

26] to detect damages in an aluminum beam using numerical simulation data. Xu [

27] proposed an impact identification system based on least squares support vector machines to estimate the location and amplitude of an impact. The classification and regression tasks in a guided wave-based SHM configuration were studied by Miorelli et al. [

28] for automatic detection, localization and characterization of damages using non-linear support vector machines and a kernel-based feature mapping. Hoell and Omenzetter [

29] present a damage localization technique based on hierarchical neuro-fuzzy models using experimental data from a laboratory-scale wind turbine blade. The proposed model architecture enables the application of neural network-related optimization techniques.

However, easily available high-computational-power and dedicated open-source software packages, e.g., TensorFlow [

30], have empowered modern SHM methods based on highly complex models using so-called deep learning [

31,

32]. These deep learning algorithms typically utilize artificial neural networks with multiple layers to learn complex relationships between defined inputs and outputs by non-linear mappings, where several classes can be distinguished on the basis of different architectures or applications. Convolutional neural networks utilize two specific types of layers, i.e., convolutional layers and pooling layers, for their hidden layers in between input and output layers. The convolutional layer performs convolutions for feature extraction, and the pooling layer is used to compress the feature dimensionality. The subsequent fully connected layers derive the actual structural state from the given data by using non-linear mappings. Sony et al. [

33] found that these convolutional neural networks are mainly utilized for time series analysis and vision-based approaches in SHM-related applications. Lomazzi et al. [

34] proposed a framework for damage diagnosis using two convolutional neural networks, one for classification and one for regression, to determine the existence and location of a damaged area, respectively. An efficient learning architecture based on convolutional neural networks is presented by Ye and Toyama [

35] to detect damages by analyzing ultrasonic wave propagation videos. The evaluation of several successive frames allows us to combine spatial and temporal information of the wavefield. Keshmiri Esfandabadi et al. [

36] employed convolutional neural networks with compressive sensing to recover high spatial frequency information from low-resolution wavefields measured by a scanning laser Doppler vibrometer (SLDV). Gonzalez-Jimenez et al. [

37] use these networks to accurately localize damages with different sizes in anisotropic composite plates. A multi-level classification technique using convolutional neural networks is proposed by Shao et al. [

38], where the damage presence, location and size are the outputs of the different levels.

Another class of deep learning models is that of deep autoencoders. In SHM, they are typically used to reduce the feature dimensionality, where the input data are reproduced in the outputs by using hidden layers with lower dimensions. Abbassi et al. [

39] compared their performance for compressing features to other different unsupervised learning techniques, e.g., principal component analysis (PCA), and presented promising results for damage detection and localization using a guided wave-based approach under varying temperature conditions. Lee et al. [

40] proposed an automated diagnosis technique based on autoencoders to detect and characterize fatigue damages in composite materials. Gao and Hua [

41] employ a hybrid approach that combines convolutional neural networks with a stacked autoencoder to analyze broadband guided wave signals for corrosion mapping. A two-step SHM approach for the classification of frequency domain features is presented by Mousavi et al. [

42], where a deep neural network (DNN) is trained by a combination of an autoencoder and backpropagation algorithms. In general, these DNNs use multiple hidden layers to learn complex non-linear relationships between given input data and defined outputs. Bao et al. [

43] employed them to detect anomalies due to potential damages in recorded acceleration data from a real SHM system monitoring a long-span bridge. They also discussed the influence of an unbalanced training data set on the recognition accuracy. A DNN-based SHM technique is presented by Yoon et al. [

44] to detect and localize cracks by predicting the strain distribution from local strain measurements using a sparse array of strain gauges. The dimensions of the DNN predictions are efficiently reduced by employing PCA.

However, to obtain further information beyond the existence and location of a damaged area, advanced data processing of the guided wave signals is required. Balasubramaniam et al. [

45] propose a hybrid global–local approach to efficiently quantify damages in composites using a pixel-based confusion matrix. Migot et al. [

46] successfully estimate the size and orientation of a crack in an aluminum plate from experimental measurements using advanced imaging methods. In a different approach, the guided wave scattering, i.e., the interaction between the incident probing waves and the damage, is analyzed. Wu et al. [

47] proposed a Bayesian framework for damage identification using a semi-analytical approach to model the wave damage interaction. The presented numerical and experimental scattering coefficients of a partly through-thickness hole in an aluminum plate show good agreement. The so-called wave damage interaction coefficients (WDICs) consider not only the amplitude but also the phase of the scattered wavefield around a damaged area to describe the scattering comprehensively [

48]. Both amplitude and phase coefficients form characteristic scattering patterns and reveal sensible frequencies as well as sensing directions as shown by Humer et al. [

49] in a detailed comparison of experimental and numerical WDICs. These WDICs uniquely describe the damage with its characteristics for the given host structure. Hence, Humer et al. [

50] employed them as highly sensitive features for damage identification in a study using solely numerical simulation data. They propose the use of a DNN to learn the complex relationships between damage characteristics, e.g., size or orientation, and the corresponding WDICs from only a limited number of selected damage cases as training data. The smart interpolations of the trained DNN can predict WDICs even for unseen damage scenarios, which allows for creating a large WDIC database for damage identification. The calculation of such a large WDIC database by solely using numerical finite element (FE) simulations is computationally prohibitive.

In general, such simulation-based approaches have certain disadvantages that limit their applicability in practical SHM systems. Inherent modeling inaccuracies caused by inevitable model simplifications or uncertainties in the estimated numerical model parameters affect the accuracy of the model output. Hence, the development and validation of applicable numerical models can be challenging. These limitations do not apply to data-based techniques employing a statistical model solely built on experimental data. Therefore, this paper presents a novel damage identification procedure based on ad hoc WDIC predictions using experiment-based DNNs. This study proposes the use of DNNs to learn complex relationships between damage properties and imperfect experimental WDIC patterns measured by an SLDV. DNNs are chosen for their proven ability to model such highly non-linear relationships and their superior performance compared to simpler regression-based methods, as demonstrated in a prior study [

50]. Additionally, the strong generalization capabilities of these DNNs enable accurate WDIC predictions, even when trained on a compact training data set of a few damage cases. These WDIC predictions are available within a relatively short time, i.e., ad hoc, and can be calculated directly on site during inspection. This innovative approach eliminates the need for a potentially storage-intensive database by utilizing customized WDIC predictions tailored for each specific scenario. This means, that for guided wave-based SHM applications using a sparse sensor array, the exact requested sensor positions can be employed to predict the WDICs as a reliable foundation for precise damage identification. The geometrical scaling property of WDICs enables the reuse of the already-trained DNNs for different but geometrically similar combinations of damage and host structure without any additional effort. Additionally, an anglewise PCA is proposed that not only compresses the high-dimensional WDIC features but also preserves their angular dependencies critical for accurate damage identification. Tailoring the dimensionality reduction to individual sensing angles enables optimal feature compression with improved accuracy and robustness. The proposed damage identification method is further tested in a simulation-based SHM approach. Here, another DNN is trained by numerical simulation data, and its predictions are employed to identify unknown damages from experimental measurement data in the same ad hoc manner. The performance of both data-based and simulation-based approaches is tested and statistically analyzed for a common three-sensor configuration by using 10,000 unique combinations of three different sensing angles. Furthermore, this study discusses an efficient technique for substantially reducing the dimension of the feature vector. This feature compression is based on an anglewise PCA conducted ad hoc individually for each sensing angle. Hence, the proposed novel technique significantly extends previous research and could pave the way towards future practical SHM applications.

The structure of this paper is as follows. First, the general methodology and the underlying theory of the WDICs, the DNN, the PCA and the damage identification procedure are explained. Second, details about the physical experiments, the numerical simulations, the DNN modeling and the anglewise PCA are described. Third, the damage identification results for different scenarios are presented and discussed. Fourth, the conclusion and future work are summarized.

2. Methodology and Theory

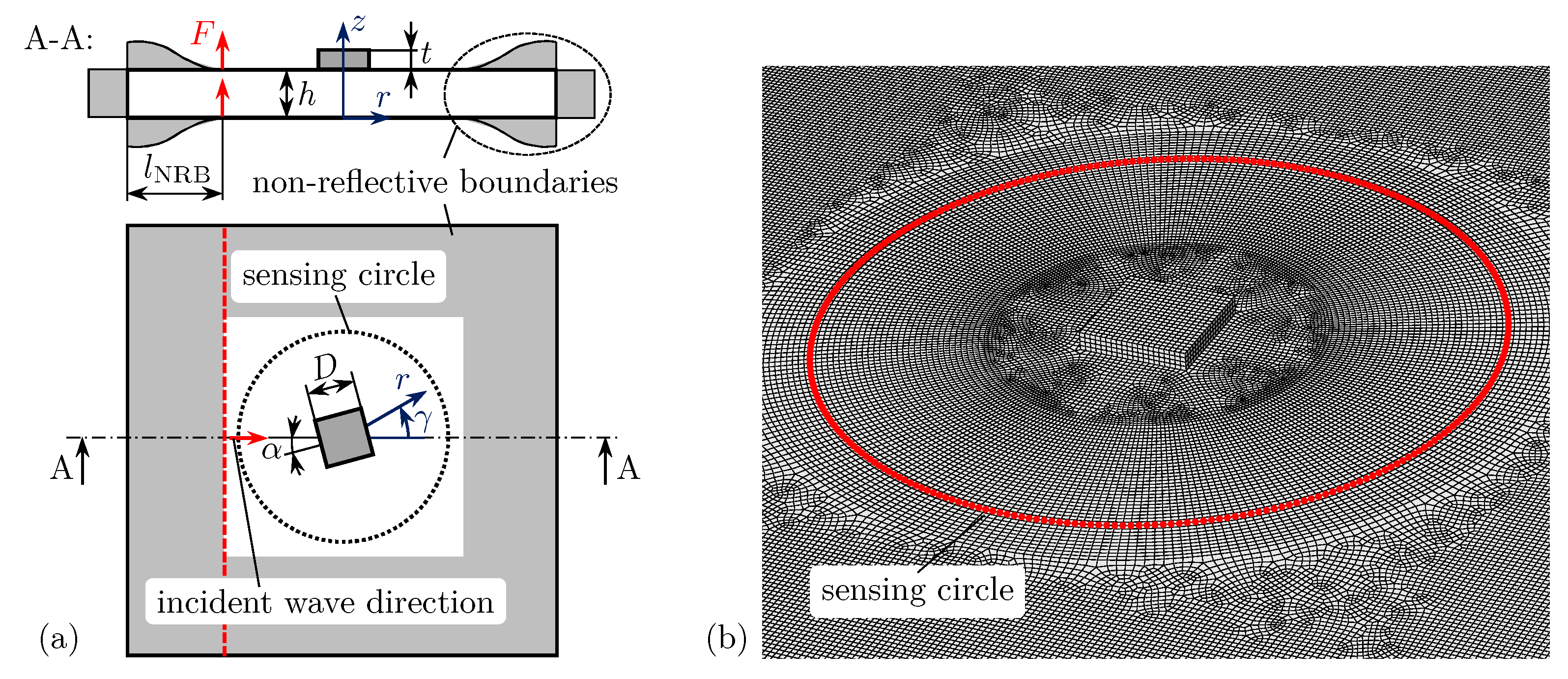

This paper proposes a damage identification method based on ad hoc WDIC predictions using DNNs. These WDICs uniquely describe the guided wave scattering due to damage and depend solely on the damage characteristics, i.e., type, size, orientation, etc., for a given host structure. This study uses reversible surface-bonded structural disturbances, i.e., artificial damages, as commonly employed in laboratory experiments using a pseudo-damage approach [

37,

38,

51,

52]. It is noteworthy that the presented methodology for damage identification is universally applicable and not limited to any specific type of damage. The artificial damages selected herein are solely for demonstration purposes and proof of concept. However, these artificial damages have square shapes with the properties thickness

t, size

D and orientation

with respect to the incident wave direction. The relations between these damage properties and the plate thickness

h of the host structure define the dimensionless damage-to-plate thickness ratio

, the dimensionless damage size-to-thickness ratio

and the dimensionless damage size-to-wavelength ratio

. The latter uses the wavelength

, which depends on the frequency

f for a given plate thickness

h. Using the characteristic product of frequency

f and half plate thickness

ensures identical dimensionless size-to-wavelength ratios

[

49]. This allows for comparing the WDICs of geometrically similar damages directly.

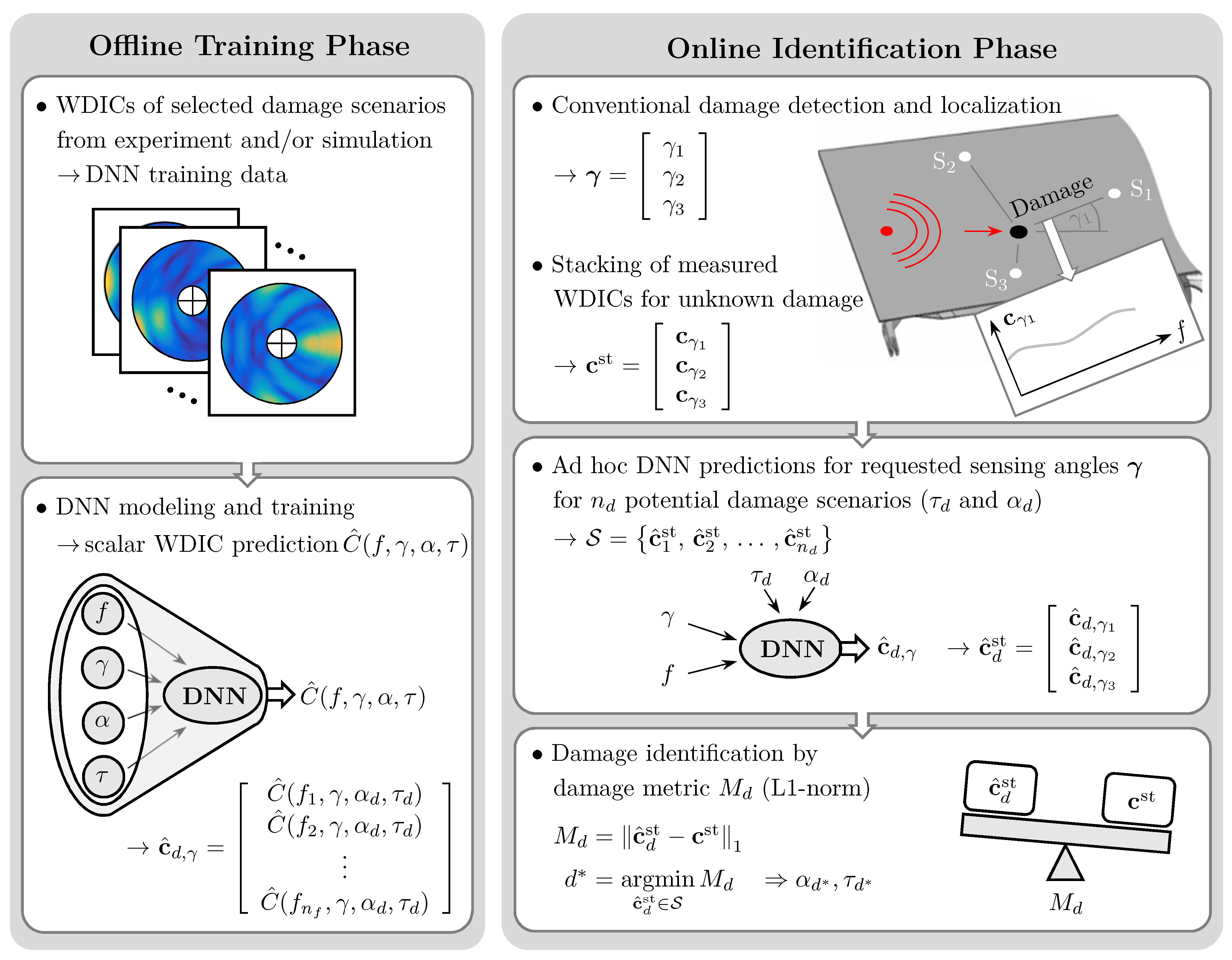

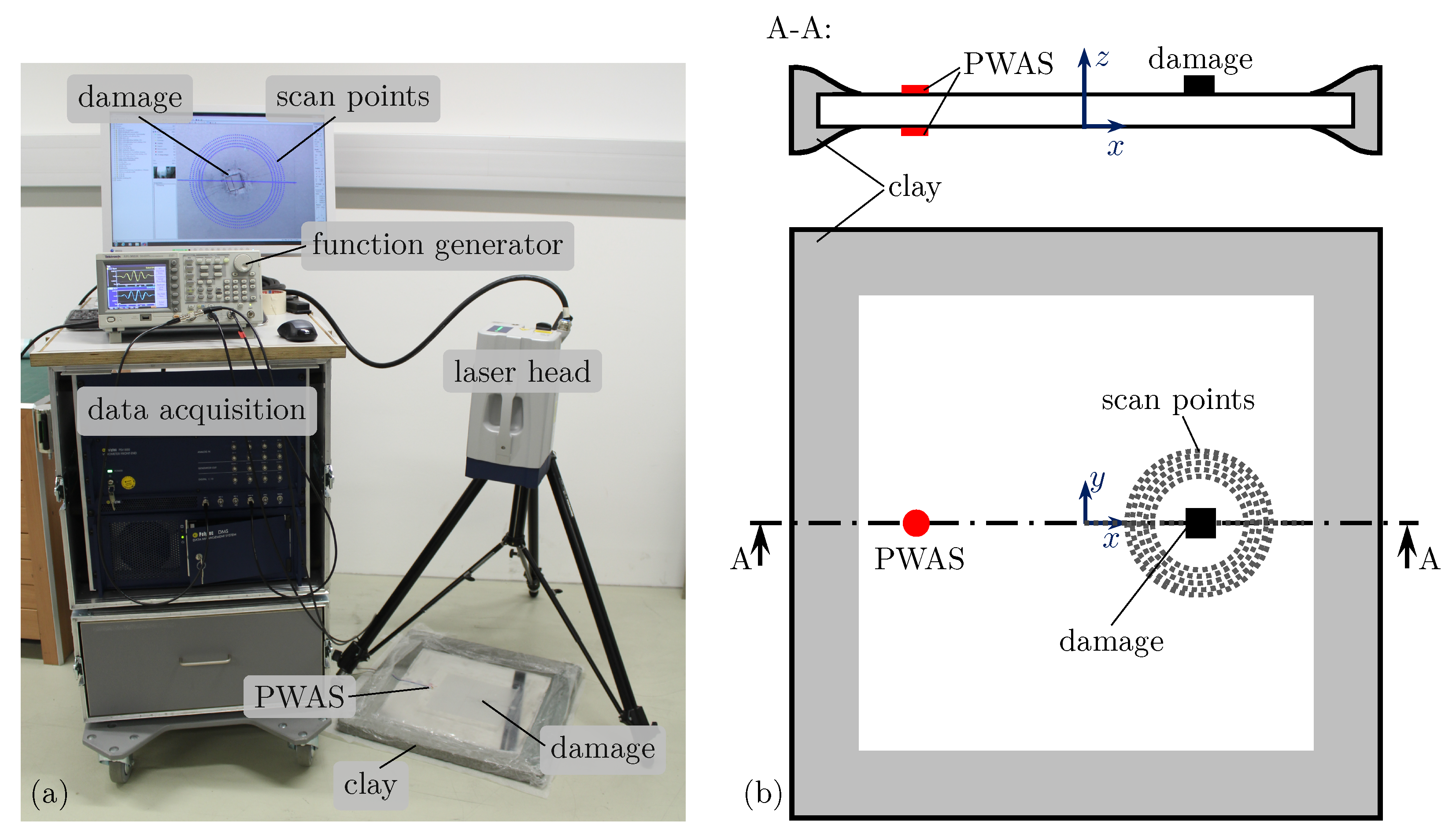

The proposed damage identification method can be divided into two main parts, namely, an offline training and an online identification phase; see

Figure 1. In the offline training phase, the WDICs of only a limited number of selected damage scenarios are used as training data set for a DNN. In this study, these WDICs are either experimentally measured using an SLDV or numerically simulated using an FE model. The orientation

and the dimensionless thickness ratio

of the utilized artificial damages are varied to generate twelve different damage scenarios; see

Table 1. The training data sets are used separately to train two different DNNs, i.e., an experiment-based and a simulation-based DNN, respectively. The generalization capabilities of these DNNs enable smart interpolations to predict WDICs with different frequency resolutions and arbitrary damage properties. Hence, the WDIC databases used for damage identification can be substantially extended [

50].

In the online identification phase, a typical guided wave-based SHM setup is assumed [

20,

53]. Here, a structure is equipped with a sparse sensor array, e.g., PWASs. If damage occurs, it can be detected and localized by conventional methods, such as baseline subtraction [

18] and time-of-flight evaluation [

54], using one actuator and a minimum of three sensors. In practical applications, varying operational conditions, e.g., temperature or loading, can significantly influence guided wave propagation. Hence, the baseline subtraction must incorporate such variations to effectively isolate the scattered waves originating from the damage without artifacts in the measurement signals [

55,

56]. However, in this study, the existence and position of the damage are assumed to be known. This enables us to determine the sensing angle

in relation to the direction of the incident wave and the distance from the damage to the

i-th sensor, respectively. The latter can be used to compensate for the different attenuation due to the geometrical spreading for each sensor prior to the identification [

57]. By assuming a three-sensor setup, the damage feature vector of an unknown damage

is built by stacking the WDIC vectors

estimated from the three sensors (

,

and

) according to their previously determined sensing angles

.

The already-trained DNNs enable WDIC predictions of exactly these sensing angles for many potential damage scenarios. The properties of these scenarios can be selected with respect to the training data set as well as practical considerations, such as required resolution or likeliness of occurrence. The calculation of the predictions only needs a very short time using DNNs. Thus, the prediction set can be obtained ad hoc once the damage is detected and localized. Finally, the damage metric evaluates the damage feature vectors of the present unknown damage and all predictions in the set using the L1-norm. The minimal value of this damage metric indicates the identified damage with its properties.

This study uses experimental measurement and numerical simulation data for the training of two different DNNs. However, the proposed damage identification method was tested by experimental WDICs of a damage scenario unseen during training for both cases. Hence, the prediction accuracy of the DNN interpolations as well as the overall identification performance can be analyzed for a data-driven experimental DNN and a simulation-based model. Additionally, the length of the utilized feature vector can be significantly reduced by using the scores of an anglewise PCA. The damage identification results using these reduced feature vectors are presented in comparison, which results in a total of four different test cases, i.e., experiment-based and simulation-based DNN predictions using full and compressed feature vectors.

In the following, the theory of the WDICs as well as the DNN are explained in detail. Furthermore, the proposed damage identification method and the optional feature vector compression based on anglewise PCA are described.

2.1. Wave Damage Interaction Coefficients

The interaction of a probing guided wave packet and possible damage is generally complex, and analytical solutions are only available for geometrically well-defined cases, e.g., thickness changes [

58] or through-thickness and partly through-thickness holes [

59]. The combined analytical finite element method approach (CAFA) simulates the guided wave scattering using a detailed FE model and, thus, enables investigations of arbitrary damage geometries. Generally, the wave damage interaction generates a unique scattering pattern due to constructive and deconstructive interference in the scattered wavefield around the damage. The CAFA describes these scattering patterns by complex-valued WDICs, i.e., the amplitude and phase coefficients, and approximates the damage as a direction-dependent wave source [

48]. The underlying idea is that the amplitude and phase of the incident wave are modified by these WDICs to result in the scattered wavefield. Further detailed information can be found in references [

48,

49,

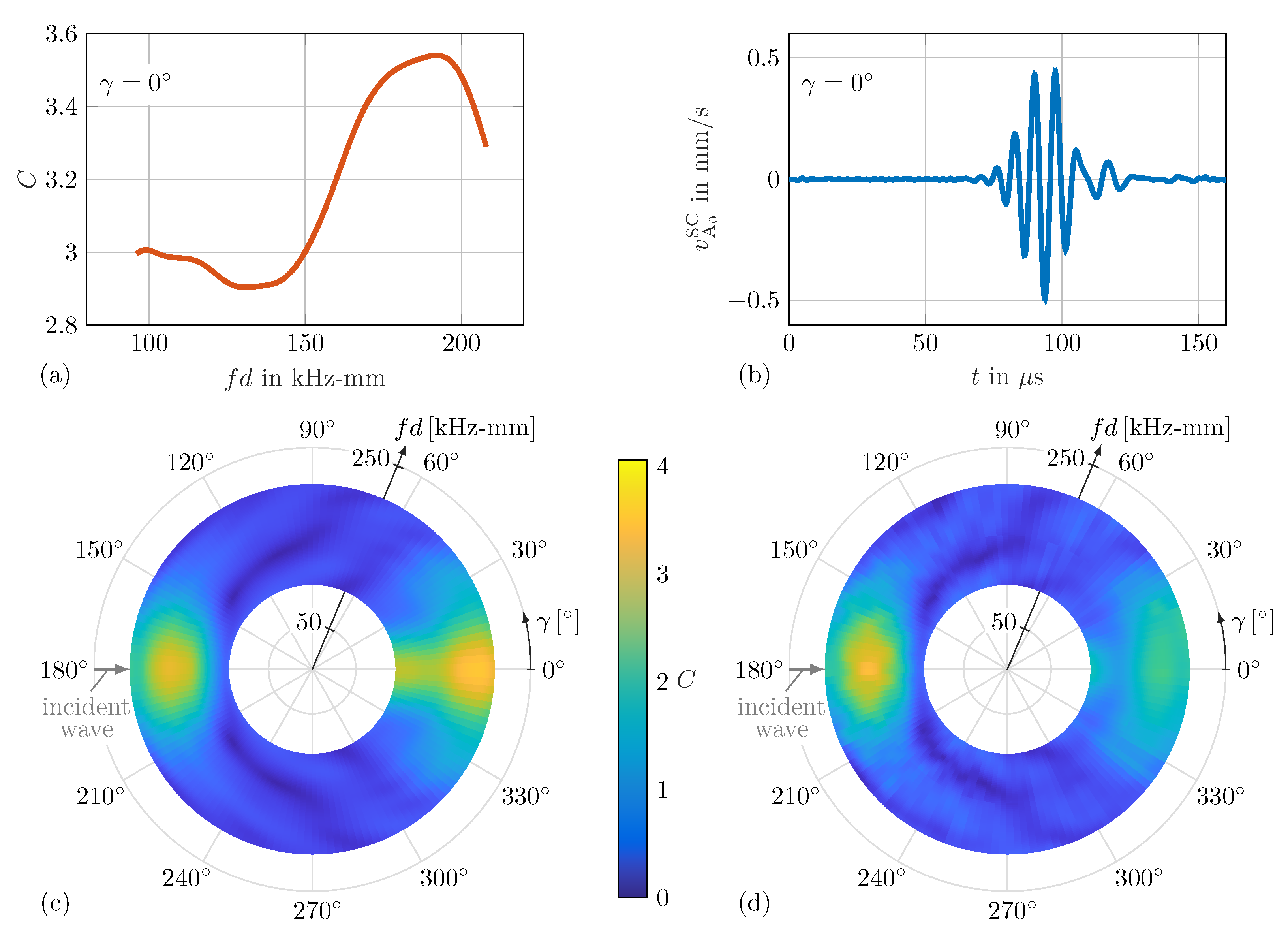

60]. However, the scalar amplitude coefficient

is defined by

where

describes the out-of-plane displacement of the incident wavefield at the damage center position depending on frequency

f with wave mode

A. The scattered waves are described by

and are measured at certain sensing points with sensing angle

along a sensing circle with radius

. In Equation (

1),

defines the absolute value. The first kind of Hankel function of the first order

describes the propagation of the scattered waves from the origin, i.e., the point source at the damage center position, to the sensing point with mode

B using the wavenumber

. To capture only the propagating wave components generated by the complex wave damage interaction, the sensing circle needs to be outside the near field of the scattered wavefield. Typically, this near field ends already several plate thicknesses away from the damage [

61].

Generally, the WDICs, i.e., the amplitude coefficients in Equation (

1), also cover possible mode conversion phenomena. This means that an incident wave with mode

A is scattered to a different wave mode

B, e.g., an incident wave with fundamental symmetric

mode is converted to a scattered wave with fundamental asymmetric wave mode

or vice versa. However, this study focuses on the wave damage interaction for the direct scattering from an incident

to a scattered

wave mode, i.e.,

. This can be explained by two reasons. First, the experimental measurements of guided waves with the fundamental asymmetric

wave mode using a single SLDV gives better results due to its reasonable out-of-plane wave motion. Second, its wavelength is smaller in comparison to the symmetric

mode, and this increases the sensitivity to small damages. Hence, for simplicity, from now on, the amplitude coefficients

are abbreviated as

C. The phase information of the generally complex-valued WDICs, i.e., the phase coefficients, could be additionally integrated in the proposed methodology for damage identification. However, the phase coefficients and their integration are not presented herein for the conciseness of the discussion.

For guided wave applications, the effect of possible damage is typically evaluated by analyzing the scattered wavefield, which is isolated by the baseline subtraction method [

18]. Therefore, the scattered wave displacement

is calculated by

where

is the incident wave displacement in the pristine scenario and

is the total wave displacement in the damaged scenario. Furthermore, these wavefields can be decomposed by

in the fundamental symmetric

and asymmetric

wave modes. In Equation (

3),

and

are the out-of-plane displacements at the top and bottom sides of the structure, respectively. It is to say that Equations (

1)–(

3) can also be used for given out-of-plane velocities

v, e.g., experimental SLDV measurements, by substituting the out-of-plane displacements

u.

In general, the scattering of the incident waves by the damage might also generate higher guided wave modes. The WDICs can describe such higher-mode conversion phenomena. This requires a more sophisticated decomposition of the wavefields based on the varying mode shapes in the thickness direction [

62]. However, in the present study, only the fundamental guided wave modes exist in the selected frequency range for the investigated structure. Hence, the elementary wave decomposition in Equation (

3) is sufficient.

2.2. Deep Neural Networks

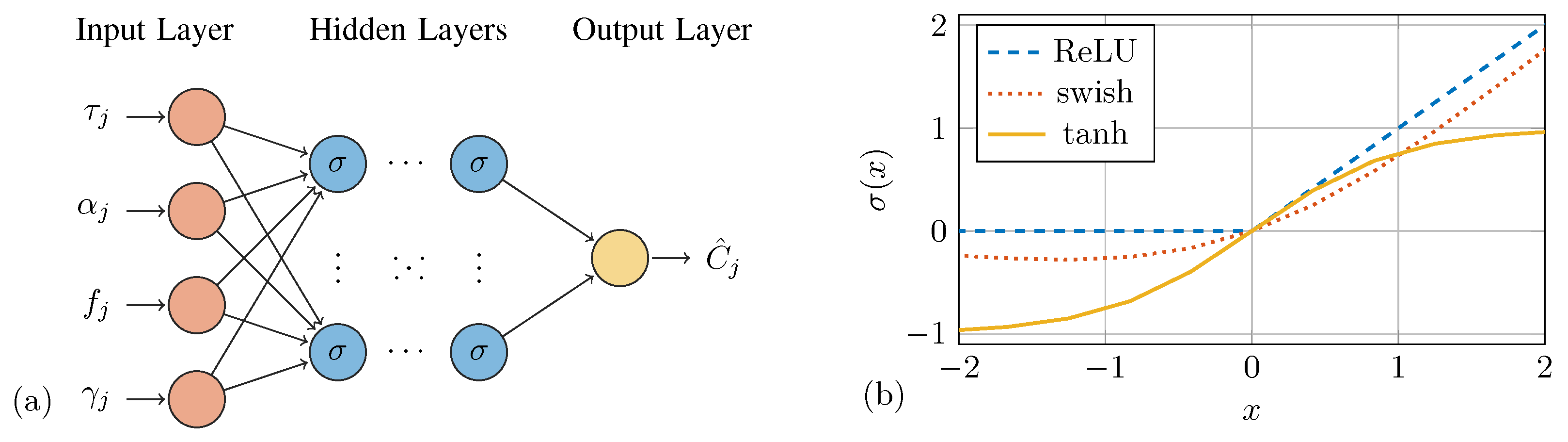

Complex relationships between variables can be learned from data using DNNs. They are non-linear models inspired by biological neural systems. The present study considers only deep feed-forward neural networks with an input layer of four neurons. This allows for passing an input vector

containing a given frequency

, sensing angle

, thickness ratio

and orientation

to the DNN for predicting a scalar WDIC amplitude

. The

denotes DNN prediction. The four input features were selected based on their direct physical relevance to the problem, which ensures an informative feature space. The output layer thus contains only a single neuron for solving the corresponding regression problem.

Figure 2a shows this architecture as a graph of interconnected neurons.

The model can be mathematically stated as

where

is the affine mapping for the layers

. The mapping

from the

-th layer with vector

to the

i-th layer is given as

where

is the

-dimensional weight matrix and

is the

-dimensional bias vector. The activation function of layer

i is denoted by

, which is applied element-wise. By using non-linear functions, a DNN becomes a non-linear model. The output

of the

i-th layer is, therefore, a non-linearly transformed weighted sum of its input. The selection of activation functions was motivated by their respective advantages: ReLU mitigates vanishing gradient issues, swish offers smooth non-linearity, and the hyperbolic tangent function provides symmetric output ranges; see

Figure 2b. It should be noted that the output layer uses the identity function as an activation function to reproduce unrestricted sets as required for regression tasks.

The actual values of the model parameters, i.e., weights and biases, are obtained by so-called training. This is an optimization procedure that minimizes a loss function. The mean squared error (MSE) is commonly utilized for regression problems. The MSE can be calculated for

training samples by

where

and

are the

j-th samples of the estimated and true model outputs, respectively. Common optimization algorithms are based on gradient descent minimization and mini-batch training. In the present study, stochastic gradient descent (SGD), RMSprop, AdaGrad and Adam are considered. The root mean square error (RMSE), defined as

is a common metric for evaluating the final performance of regression models. Lower values indicate smaller differences between the predicted and true model outputs.

Furthermore, the mean absolute error (MAE) is utilized to evaluate the performances of selected models. The MAE is defined by

and calculates the sum of absolute errors, i.e., the L1-norm, normalized by the sample size

. Analogous to RMSE, lower values signify a closer match between the predicted and true outputs of the model. Additionally, the coefficient of determination

serves as a statistical measure of model performance. It quantifies the variance of the model prediction errors in comparison to the total variance of the true outputs and can be calculated by

where

is the mean of the true model outputs. An

value of

implies that the model performs no better than simply predicting the mean of the outputs, while

indicates that the model underperforms compared to simply using the mean value as a predictor. The maximum of

describes an ideal model that perfectly predicts the true outputs without error.

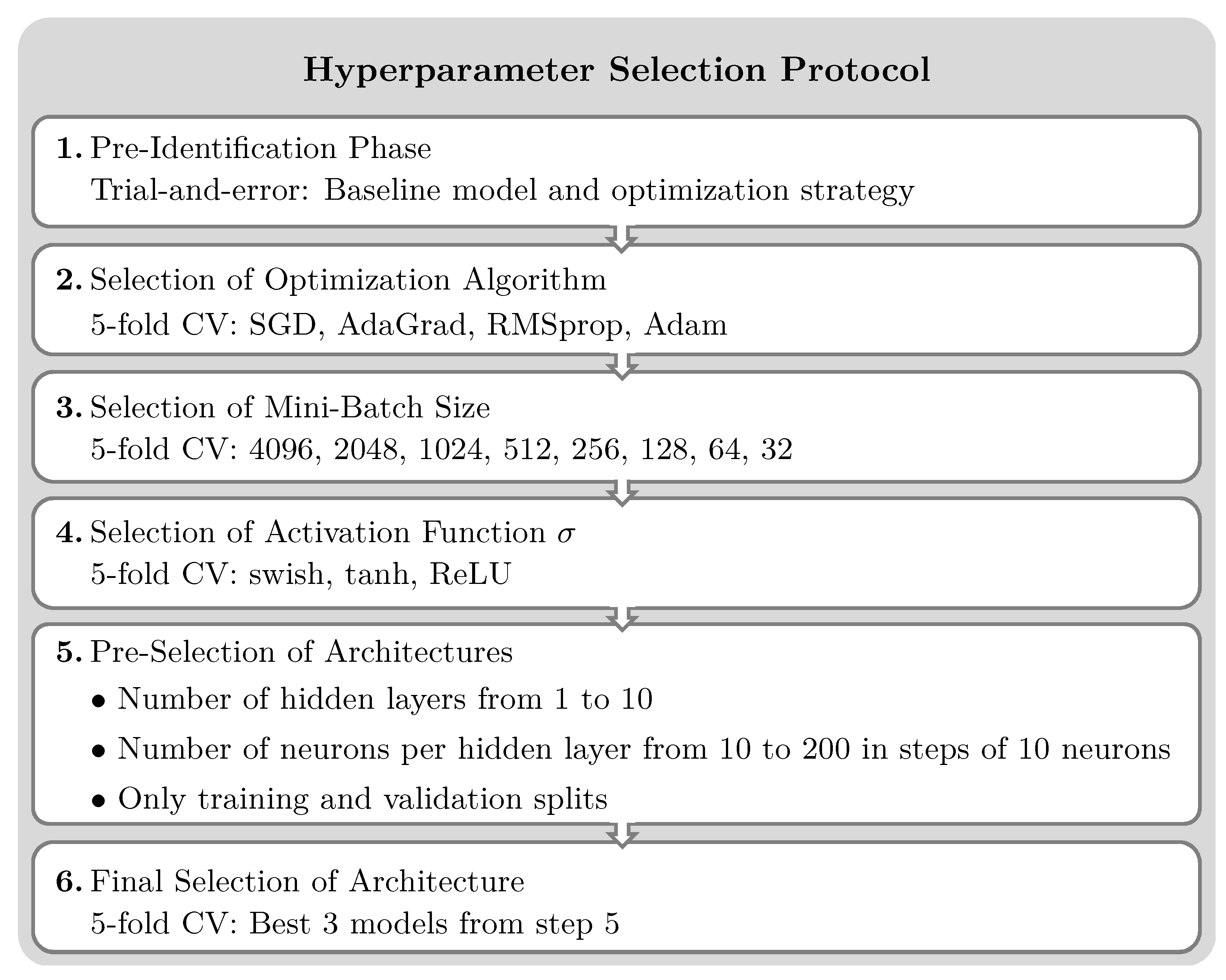

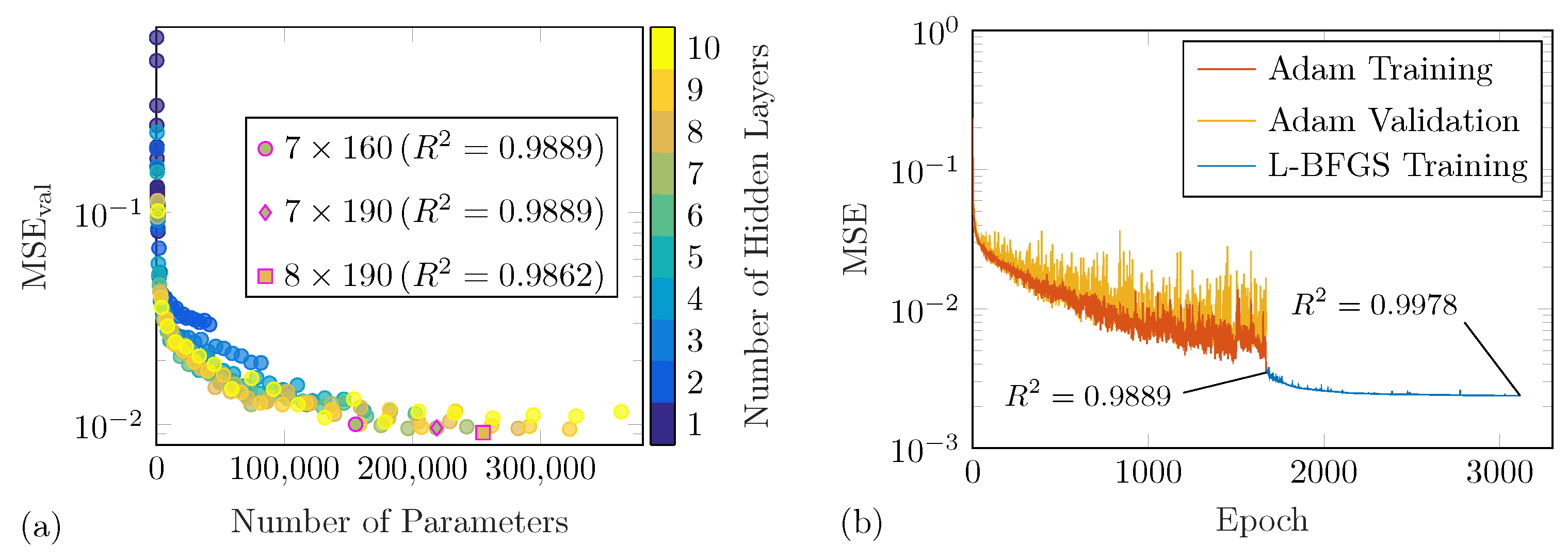

However, for obtaining an optimal performance in the present application, several hyperparameters need to be identified. The model architecture entails the selection of the number of layers and neurons per layer as well as the type of activation functions. Additionally, hyperparameters of the optimization procedure, i.e., the algorithm and the mini-batch size, are required. A hyperparameter selection protocol introduced in [

50] is employed for this task; see

Figure 3.

It is a sequential procedure starting from an initial trial-and-error phase for obtaining a baseline model and optimization strategy. Next, the optimization algorithm, the mini-batch size and the activation function are varied one after another. For a reliable selection,

k-fold cross-validation is employed. For this task, a statistically motivated model selection criterion,

, is defined:

where

and

are the mean and standard deviation of the MSE estimated from the unseen cross-validation estimates. The minimal value indicates the optimal parameter. Then, the model architecture, i.e., number of layers and neurons per layer, is pre-selected using only a single hold-out cross-validation with lower computation burdens due to the high number of model candidates. The final architecture is obtained by

k-fold cross-validation of the best three models obtained in the previous step. This final model architecture is then trained with early stopping and the available data using the selected stochastic optimizer followed by optimization with the help of the limited-memory Broyden–Fletcher–Goldfarb–Shanno (L-BFGS) optimizer, as a quasi-Newton method, for reaching the optimum faster. It should be noted that the exclusive use of the latter optimizer did not allow for learning the WDIC patterns.

The results of the hyperparameter selection procedure with the final architecture are presented in the Deep Neural Network Modeling Section. The final DNN enables predicting a scalar WDIC amplitude

for a given frequency

f, sensing angle

, thickness ratio

and orientation

, where the range of input values should be within the training data for reliable results. However, the geometrical scalability of WDICs increases the applicability for a large number of geometrical similar structures [

49]. Furthermore, it should be noted that the selected architecture enables interpolation not only between different damage scenarios but also for frequencies and angles. This means that WDICs can be predicted for any angle, and the frequency resolution can be changed according to the task without additional training. Finally, in a previous study [

50], it was found that other machine learning algorithms, i.e., support vectors, k-nearest neighbors and random forests, do not enable an interpolation between the training data at all or result in lower performance. Thus, only the discussed DNN approach is considered herein.

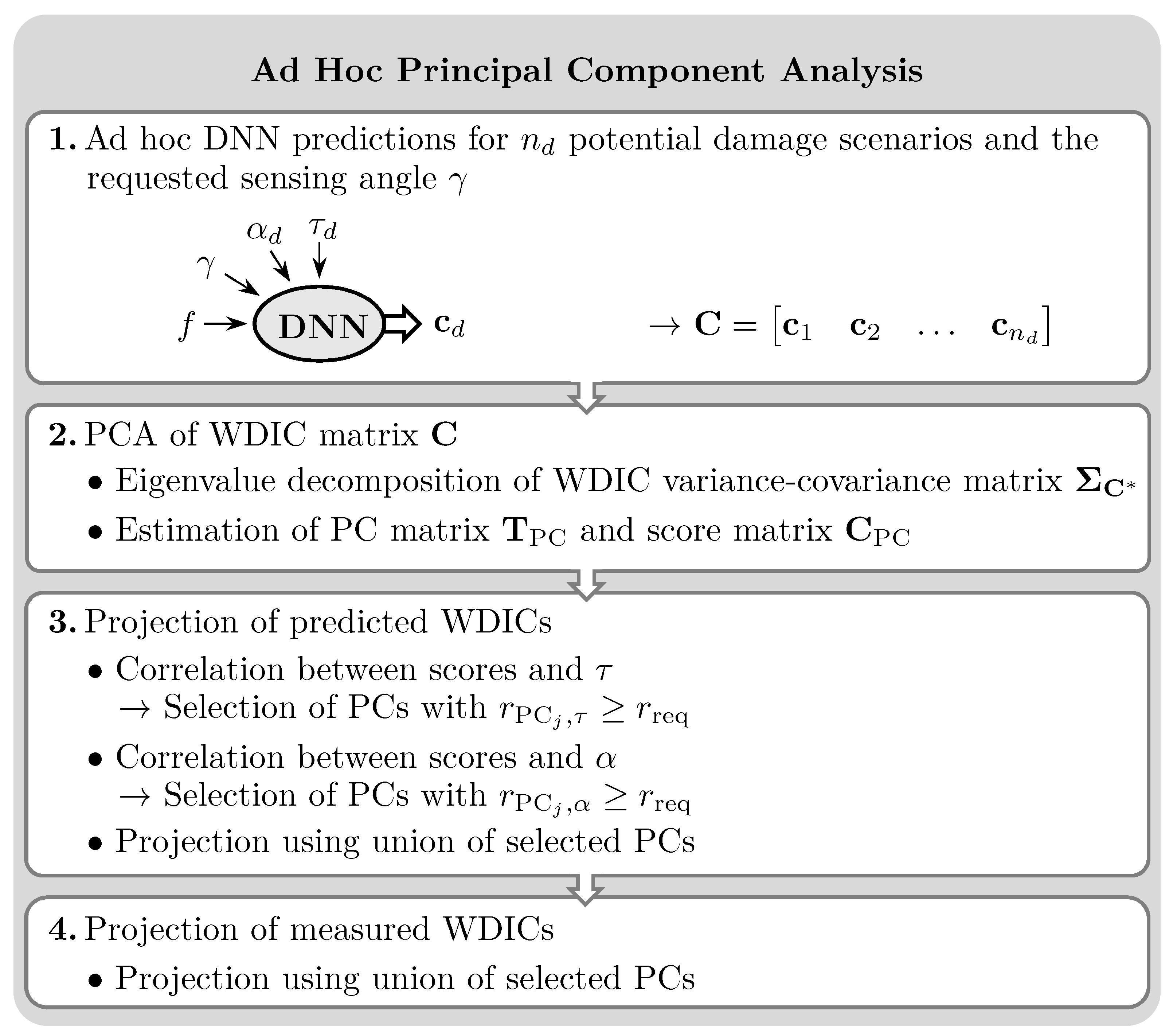

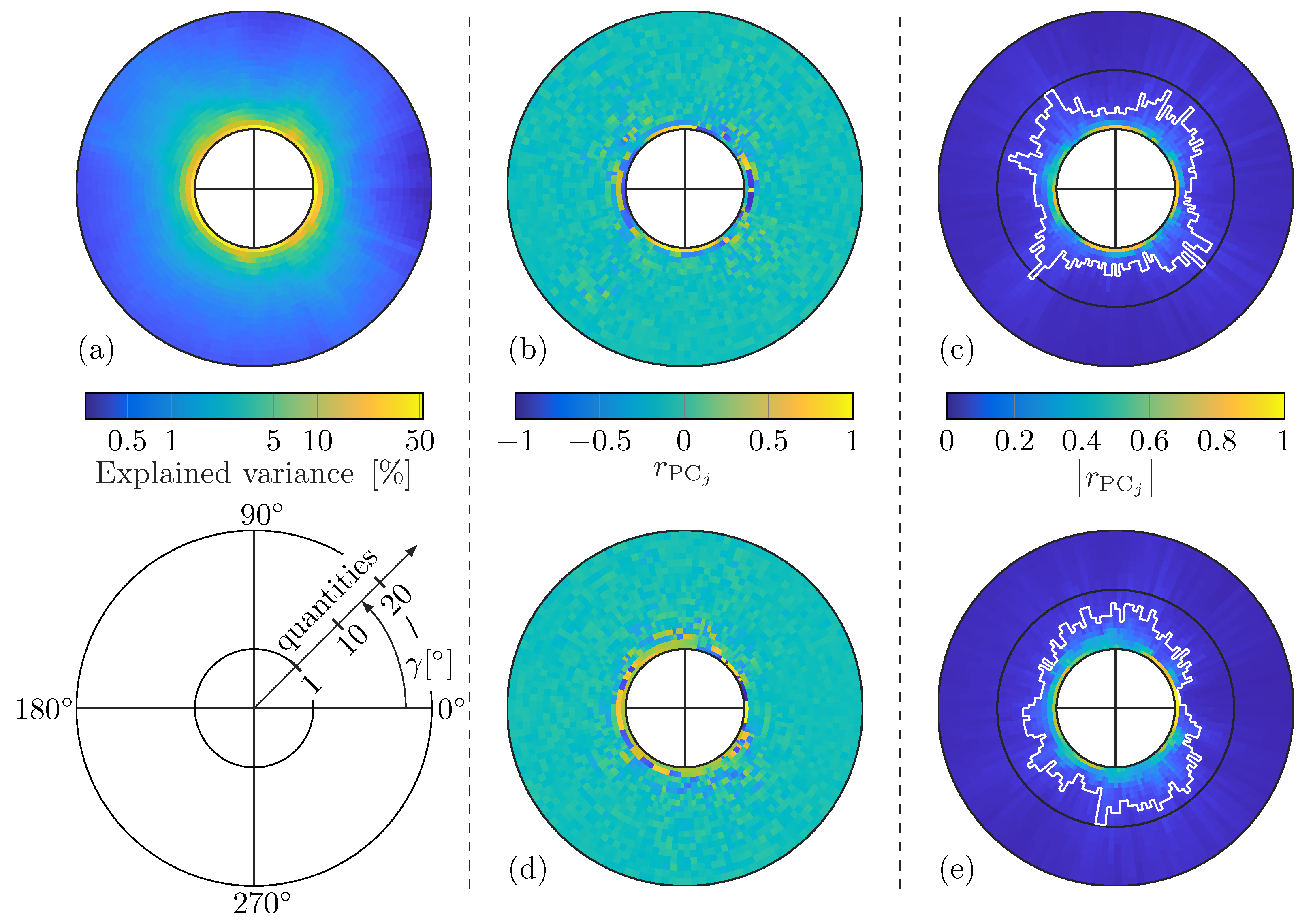

2.3. Anglewise Principal Component Analysis

High feature dimensionality and uncertainties due to the limited availability of potentially noisy training data can adversely affect the performance of an SHM algorithm [

29]. To reduce such effects, PCA is a common technique. For the present application, an anglewise PCA of WDICs of a large number of predicted damage scenarios is proposed, i.e., selected combinations of thickness ratios

and damage orientations

.

The WDICs are inherently represented in polar coordinates to describe the angular dependencies of the wave damage interaction patterns. To preserve these angular dependencies, the PCA is calculated individually for each requested sensing angle . This anglewise approach ensures optimal feature compression by tailoring the dimensionality reduction to the specific characteristics of the WDICs at each sensing angle. Consequently, the number of principal components (PCs) required for each sensing direction can vary and is not known beforehand. This variability allows the proposed anglewise PCA to adapt to the unique complexity of the WDICs for each angle, ensuring both computational efficiency and accuracy. An individual PCA can be performed for each requested sensing angle as follows.

First, WDICs are predicted by the DNN for a selected sensing angle. The vector of

frequencies

is kept fixed for each damage scenario

d to obtain a single frequency line, i.e., the amplitude coefficient vector

, given as

where

is a scalar WDIC prediction. In the following, the sensing angle

and the denomination of DNN predictions by

are omitted for the sake of simplicity. The frequencies are defined by the damage identification application, where the resolution can be different from the training data set. Due to the interpolation capabilities and computational efficiency of the proposed DNNs, such amplitude coefficient vectors

can be calculated ad hoc for a large number of damage scenarios to construct a WDIC matrix

of dimension

as

Second, a centered WDIC matrix

can be obtained by removing the estimated mean

of the frequency lines from each column as

where

The variance–covariance matrix

is estimated from the centered WDIC matrix

by

and can be expressed as an eigenvalue decomposition

where

is the PCA transformation matrix and the diagonal matrix

contains the eigenvalues of

arranged in descending order by the variance of the corresponding PCA scores. The PCs are the normalized eigenvectors stored as column vectors in

. Fourth, the obtained PCs allow for calculating the PCA scores

of the initial features by a linear transformation as

where the resulting features/scores

are linearly independent and their variances are maximized in the first few dimensions. The score matrix

contains the PCA scores as its columns.

Finally, by selecting PCs, the performance of an SHM algorithm can be improved and, at the same time, the feature dimensionality can be reduced. A common quantity for choosing PCs is the explained variance or other related variables, such as the eigenvalues, because this allows for maximizing the variability of a data set in a few dimensions. However, this is not necessarily optimal for damage identification because variations not related to damage, such as noise, may reduce the feature sensitivity [

63]. Therefore, the Pearson correlation coefficient between scalar scores and values of a certain damage characteristic is employed as a selection criterion, where a higher absolute value of the correlation coefficient indicates a more sensitive feature. For example, the Pearson correlation coefficient

between the scores of the

j-th PC

and the thickness ratio

can be calculated over

damage scenarios as

where the

indicates the estimated mean. The Pearson correlation coefficient is bounded between

, where higher absolute values indicate higher linear correlation. The PCs with

are selected for calculating scores with improved sensitivity. This can be similarly performed for the damage orientation

or other damage characteristics. For damage identification, the union of all selected PC subsets can be used to obtain scores of the DNN-predicted WDICs as well as the measured WDICs. This allows for accounting for the rotational WDIC characteristics and sensitivities concerning damage.

The flowchart in

Figure 4 summarizes the calculation steps for the ad hoc anglewise PCA for feature compression. These compressed feature vectors can be used analogously in the proposed damage identification method. Therefore, the anglewise PCA can be inserted as an additional step in the online identification phase of the presented methodology; see

Figure 1. The length of the compressed feature vector results from the number of selected PCs, which depend on the sensing angle. Therefore, the PCA is calculated from the ad hoc WDIC predictions for exactly the requested sensing angles, which are previously unknown in the offline training phase. However, the WDIC predictions are required anyway by the proposed damage identification technique. Thus, the additional computation time for performing PCA is negligible.

2.4. Damage Identification by Ad Hoc Predictions

Generally, WDICs are highly sensitive damage features and depend on the characteristics of the damage, e.g., size, orientation and type. This means that any changes in these damage characteristics cause variations in the WDIC scattering pattern in angular direction as well as over frequency, which stimulates the idea of a WDIC-based damage identification approach [

50]. In practical applications, the damage is detected and localized prior to the identification procedure. Anomaly detection [

19] or the baseline subtraction method [

18] can be used to indicate the existence of damage. The latter reveals the scattered waves caused by the damage. Further analysis, e.g., by time-of-flight [

54] or time-reversal approaches [

52], enables us to estimate the damage position from the wave scattering. These localization procedures require at least three different actuator–sensor pairs for a unique result. The positions of the actuator and the sensors related to the estimated damage position determine the sensing angles

and

, which are used for damage identification. For each sensing angle

, the amplitude coefficient vector

of the unknown damage is calculated for the frequency vector

from the measured scattered wave signals using Equation (

1). They are then combined into a single feature vector

for the unknown damage with dimensions

as

The proposed damage identification method compares this feature vector to DNN predictions for the requested sensing angles, which can be analyzed ad hoc, i.e., during an inspection within a short time, directly on site. Therefore, the previously trained DNN predicts the amplitude coefficient vectors

for every sensing angle

, which are combined (analogously to

in Equation (

19)) into a single feature vector

for each damage scenario

d. According to Humer et al. [

50], the damage metric

is selected for damage identification as

and calculates the L1-norm (Manhattan distance) between the feature vectors of the DNN predictions

for each damage scenario

d and the feature vector

measured from the unknown damage. Small values of the damage metric

represent small differences between the feature vectors. Hence, the minimal value of the damage metric indicates the identified damage scenario

and its properties, i.e., thickness ratio

and orientation

.

In the present study, the performance of the proposed damage identification method is tested additionally using an anglewise PCA for feature compression. Therefore, the amplitude coefficient vectors in the feature vector are replaced by their scores calculated by PCA for each requested sensing angle used for identification. This feature compression is applied to the DNN’s predicted feature vector for all damage scenarios d as well as to the measured feature vector of the unknown damage . Thus, the dimensions of the resulting feature vectors are reduced significantly. Due to the dependency of PCA on the sensing angle, the calculations are performed ad hoc for the requested sensing angles.

4. Damage Identification

In this section, the performance of the proposed damage identification method is tested and discussed. Therefore, the WDIC patterns are predicted by two different DNNs trained either by numerical simulation or by experimental measurement data. Due to the generalization capabilities of these DNNs, the predictions of the WDICs can be interpolated in between the training data ranges. This means that the amplitude coefficients can be predicted at any arbitrary point in the design space, which is defined by the damage properties thickness ratio and orientation as well as the frequency range and the sensing angles. For the following discussion, both DNNs predict in total 9191 different damage cases, i.e., 101 thickness ratios

and 91 damage orientations

, in a frequency range

. These predictions are compared to the measured WDICs of an unknown damage by the damage metric

in Equation (

20) for a given sensing angle vector

. The present study employs 10,000 unique triplets of sensing angles using a

grid for assessing the performance for a wide range of potential sensor and damage locations. By means of these variations for the damage properties and the sensing angles, a statistical analysis of the damage identification results is presented for different test cases. Moreover, the damage identification results using the feature compression based on PCA are analyzed.

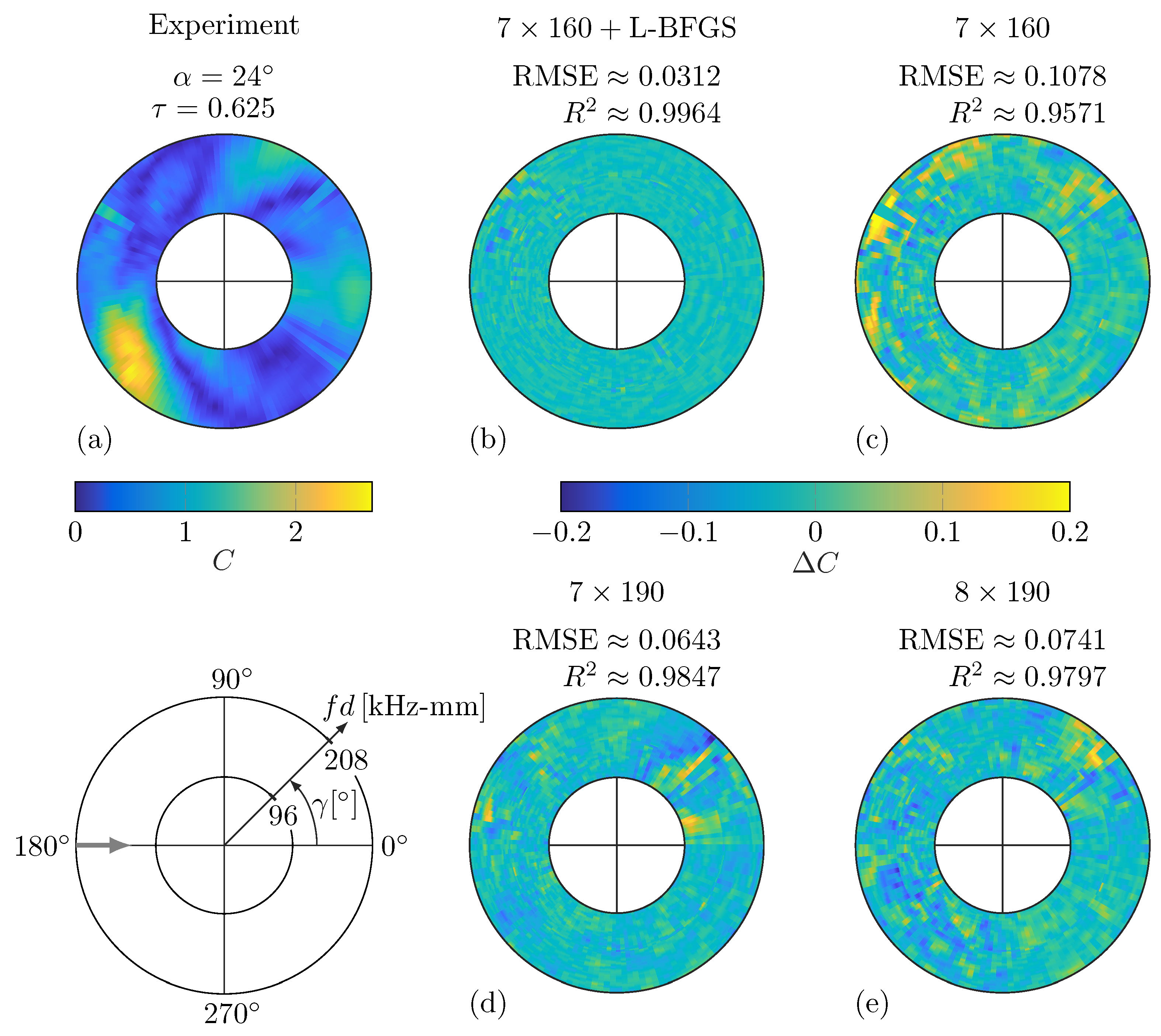

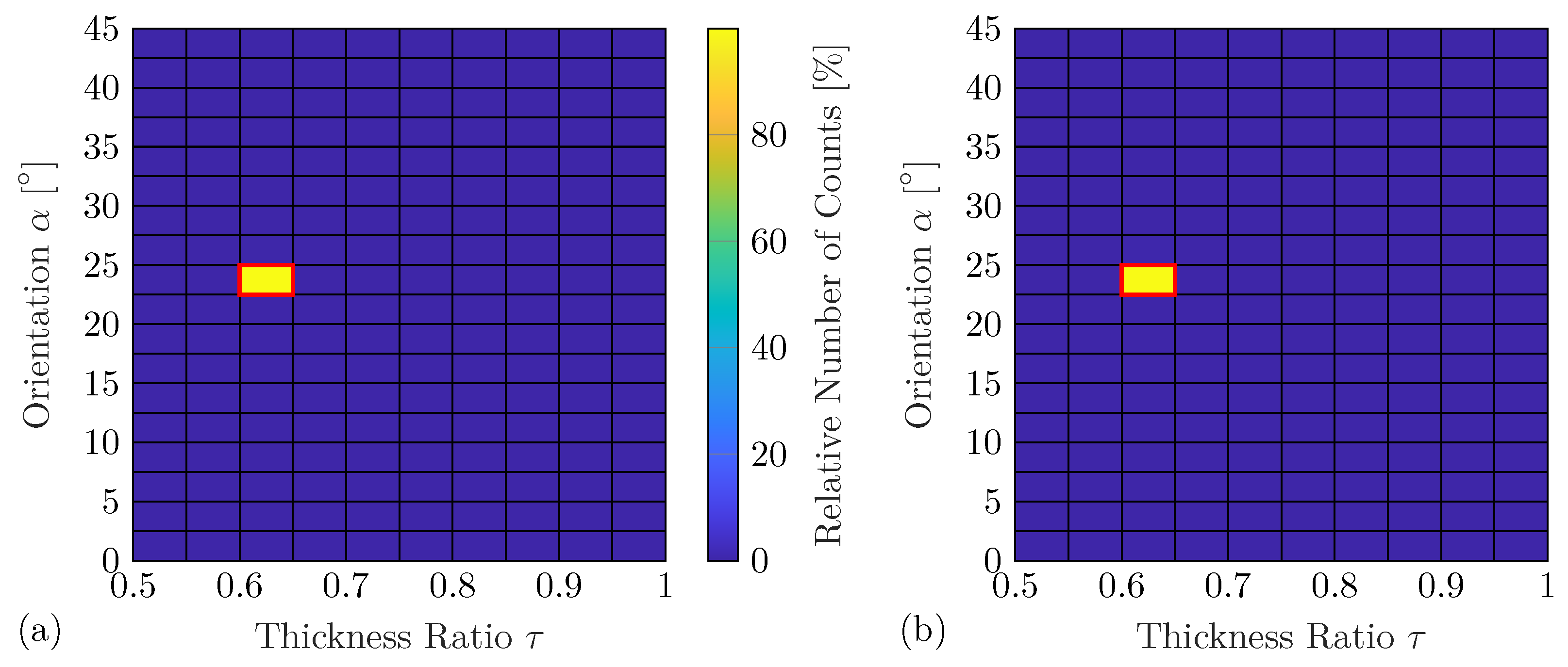

4.1. Experiment-Based Approach

In this test case, the experimental measurements of twelve different damage scenarios (see

Table 1) are utilized as training data for the experimental DNN (see

Section 3.4). This experiment-based DNN predicts the feature vectors

for

different damage cases. All these predictions in the data set

are compared to the feature vector

of an unknown damage by the damage metric

for the given sensing angles. The smallest damage metric indicates the identified damage and, with it, its damage properties for each of the tested 10,000 unique sensing angle combinations. However, the proposed damage identification method is first tested for the measurements of damage No. 6 (see

Table 1), which is contained in the training data of the experiment-based DNN. For this example, the technique indicates in 8669 out of the 10,000 sensor combinations, i.e., approximately 86.7%, the exact damage properties

and

from the 9191 predicted damage scenarios, whereas 99.61% of classifications fall in a range of

and

. These excellent identification results might be expected for damage cases contained in the training data set. Nevertheless, it indicates accurate DNN predictions even when using potentially noisy experimental measurement data for training. Furthermore, this underpins the high sensitivity of the WDICs utilized as damage features. Additionally, damage identification is performed using compressed feature vectors based on the anglewise PCA. In this case, only 7037 angle combinations or 70.37% are perfectly identified, while 97.73% of classifications lay in the range of

and

. Similar results are obtained for the remaining training damage scenarios. This is underpinned by the statistical summary given in

Table 7 with almost perfect mean estimates

and

as well as very small standard deviations

and

.

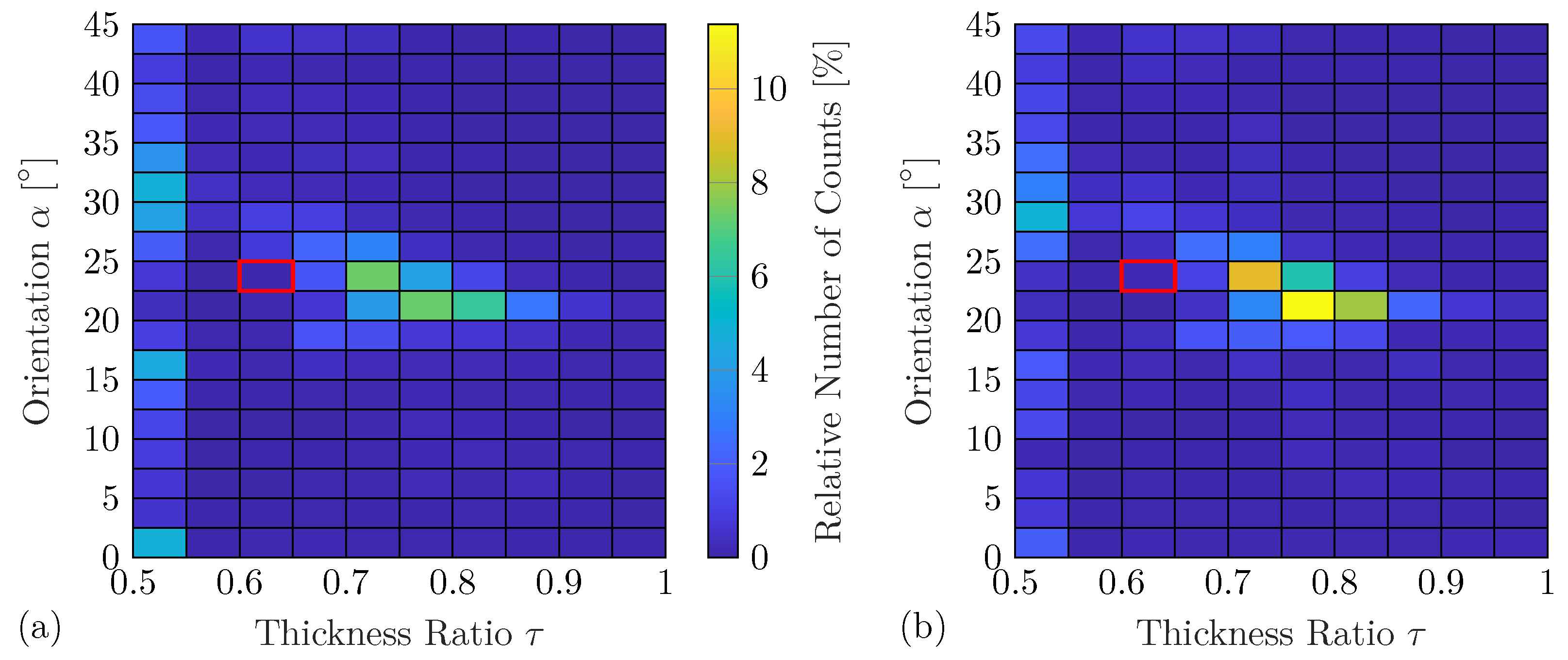

The next example represents a more realistic scenario in terms of a practical application of the damage identification method using damage with a thickness ratio

and orientation

. This damage is not contained in the training data set of the DNN, and, thus, the interpolation accuracy of the WDIC predictions can be investigated. The technique indicates in 8582 out of the 10,000 sensor combinations, i.e., 85.82%, exactly the correct damage properties from the 9191 predicted damage scenarios. In the following, the intervals

and

are selected for visualization purposes, which results in 180 different damage scenarios. A previous study discusses the effect of different resolutions on the damage identification performance, where smaller intervals lead to decreasing correct classification rates [

50]. However,

Figure 11a shows that 99.93% of the samples fall in the bin of unseen damage. Comparably good results are obtained when using the compressed feature vectors based on anglewise PCA; see

Figure 11b. The correct bin (

and

) contains 99.63% of the classifications. The statistical analysis summarized in

Table 7 reveals that on average the correct damage properties are identified. For the reduced features, a significant increase in the standard deviations can be observed for both damage properties and over all damage scenarios in comparison to using the full feature vector. By using PCA, small differences between the predicted highly sensitive WDIC lines might become indistinguishable, which naturally increases the range of predicted properties.

However, the proposed damage identification method has an outstanding performance in a data-driven application when solely experimental measurement data are used. These results demonstrate the high accuracy of the smart interpolations and generalization capabilities of a DNN obtained by the hyperparameter selection protocol even for imperfect experimental training data.

4.2. Simulation-Based Approach

In this section, the proposed damage identification methodology is assessed in a simulation-based setting. Therefore, a DNN is created and trained solely by numerical simulation results of the twelve selected damage scenarios given in

Table 1. Then, the experimental measurements according to these twelve training scenarios and additionally the unseen damage with a thickness ratio

and orientation

are used again for assessing the performance of the simulation-based DNN. Hence, this test case represents a possible application in a practical simulation-based SHM approach. However, the statistical analysis for this case using the full feature vector shows that the mean values are still within one standard deviation of the correct values for both damage properties

and

; see

Table 7. It is noticeable that the error of the mean values

and

in relation to the correct values as well as the standard deviations

and

are significantly increasing in comparison to the previous cases using the experiment-based DNN predictions. This might be explained by certain simplifications in the numerical FE model, e.g., the adhesive layer between the surface-bonded artificial damage and the host structure is neglected. Hence, the numerical and experimental WDIC patterns show differences; see

Figure 6c,d. This enables us to investigate the influence of these common simplifications on the damage identification performance using the developed method. However, it is noticeable that for damages with orientation

the error for the mean estimates of the orientation

are higher in comparison to the remaining orientations for all thickness ratios. This could be caused by a possibly too-coarse mesh near the corner regions of the damage in the FE model, which has a particularly high influence in this damage orientation.

For the simulation-based approach using the compressed feature vector, for the majority of the investigated damage cases, the mean values and are marginally closer to the correct values for both damage properties and . At the same time, the standard deviations and tend to be slightly lower in comparison to the results using the full feature vector.

However, the following example again uses damage with a thickness ratio

and an orientation

, which is unseen during the training of the DNN, to evaluate the identification performance for a more realistic application scenario.

Figure 12a shows the corresponding damage identification results using the complete feature vectors. It can be seen that the variations in these results are significantly increased in comparison to the results using the experiment-based DNN predictions; see

Figure 11. Furthermore, the smallest thickness ratio

is often falsely identified for all damage orientations. These effects might be caused by the differences between the numerical and experimental WDIC patterns. Besides that, the proposed damage identification method uses a single damage metric to identify two different damage properties. It has been found that changes in the damage orientation

more strongly affect the WDIC pattern than changes in the thickness ratio

[

49]. Thus, the identified damage orientation might be more accurate in comparison to the damage thickness ratio.

However, in

Figure 12b, the damage identification results using the compressed feature vector based on the anglewise PCA are presented. It can be seen that the feature compression significantly reduces the variation for both damage properties. In particular, the number of false identifications with the lowest thickness ratio

is decreased. The feature compression using anglewise PCA seems to reduce the influences of the differences between the experimentally measured and the numerically predicted WDICs and, thus, improves the results. Therefore, it seems reasonable to incorporate the computationally very efficient anglewise PCA into the proposed technique due to the trend to improve damage identification accuracy. Nevertheless, the performance should be verified to avoid an unexpected deterioration.

4.3. Discussion

The proposed damage identification method is tested in different cases using an experiment-based and a simulation-based approach. For the purely data-driven technique, the experimental training data might be affected by small imperfections, i.e., small position and orientation errors of the damage. Furthermore, SLDV measurements tend to be noisy due to the small guided wave amplitudes. This noise can be significantly reduced by averaging and further data processing, e.g., bandpass filtering [

49]. These steps minimize the measurement error, which is not exactly quantifiable due to the unknown groundtruth. Nevertheless, the remaining measurement error influences the WDIC patterns as described by Humer et al. [

49] and depicted in

Figure 6d and

Figure 9a. The experiment-based DNN predictions do not perfectly replicate the noisy WDIC patterns, which is partly intentional to prevent overfitting, i.e., fluctuations in the WDIC patterns caused by the measurement noise are also learned by the DNN. Generally, the measurement error has only minor effects on the damage identification method, which is underpinned by the excellent experiment-based identification results (see

Figure 11) and high prediction accuracies (see

Table 4). Although even a relatively small number of damage scenarios is sufficient to create and train the DNN, it might often be difficult or even impossible to measure the required data in practical SHM applications. In general, this limitation does not apply for a simulation-based approach, where the training data can be generated using numerical simulation models. The calculation of these data is typically very fast and cost-effective in comparison to experimental measurements using elaborate measurement equipment, e.g., an SLDV. However, numerical models require certain simplifications of the real damage scenario, e.g., in this study, the bonding layer between the artificial damage and the plate is simulated by an ideal tie connection. Hence, the numerical and experimental WDIC patterns show certain differences [

49]. These differences influence the accuracy of the damage identification significantly, whereas the statistical analysis still indicates reasonable mean values of the damage properties.

However, this paper presents an anglewise PCA for reducing the feature dimensionality. Using this technique enables us to compress the feature vector on average by more than 90% for both the simulation- and experiment-based approach. Such a compressed feature vector with reduced dimensions might be useful in terms of several aspects. For example, if the experimental measurements of the unknown damage are corrupted by errors, e.g., due to temperature variations or measurement noise, this feature compression might help to reduce their effects. Nevertheless, the neglected scores of the anglewise PCA decrease the amount of information contained in the compressed feature vector. Therefore, the performance of the proposed feature compression technique should be verified to avoid an unexpected deterioration. However, the simple damage metric utilized herein could be replaced by an advanced machine learning algorithm. The general complexity and modeling effort, e.g., the size of the training data set, computational time for training, etc., of such algorithms can be significantly reduced with lower feature vector dimensionality. Besides that, it seems possible to implement a machine learning model, which learns the WDICs from training data to directly predict the damage properties of a given compressed feature vector.

In this study, the WDICs of an enormous number of different damages are predicted by the DNNs in a relatively short time, i.e., ad hoc. The calculation times for 9191 different damage scenarios and 1000 random triplets of sensing angles using a conventional desktop computer (HP EliteDesk 800 G5; Intel(R) Core(TM) i7-9700 with 3000 MHz and 32 GB RAM [

72]) are listed in

Table 8. It can be seen that both DNNs predict the various damage cases below 10 s for a random combination of three sensing angles, which might justify the designation ad hoc. The computation time for the anglewise PCA utilized for feature compression is almost negligible in comparison to the ones for the DNN predictions, while the damage identification, i.e., the evaluation of the damage metric, can basically be performed in real time. However, it seems counterintuitive that the simulation-based DNN needs more time to calculate the WDIC predictions despite its simpler architecture (7 × 80) in comparison to the experiment-based DNN (7 × 160). This can be explained by the increased computational effort due to more complex swish activation function. The total time for damage identification using the proposed approach is below 10 s despite the selected high number of 9191 different damage scenarios. Here, a very fine resolution was chosen for the predictions as a limiting scenario. However, the calculation times (see

Table 8) already seem reasonable for practical SHM applications directly on site. A course resolution may allow for reducing computational efforts and, with it, damage identification times. Generally, the interval sizes used for damage identification are design parameters for the SHM system, where the actual choice may depend on several practical considerations.

However, the presented damage identification method assumes in each case a very challenging situation by using only three sensors and still performs mostly very well. It is assumed that including more sensors in the feature vector increases the contained damage information. This might further improve the reliability and accuracy of the presented damage identification method.