Posture Control of Hydraulic Flexible Second-Order Manipulators Based on Adaptive Integral Terminal Variable-Structure Predictive Method

Abstract

1. Introduction

- (1)

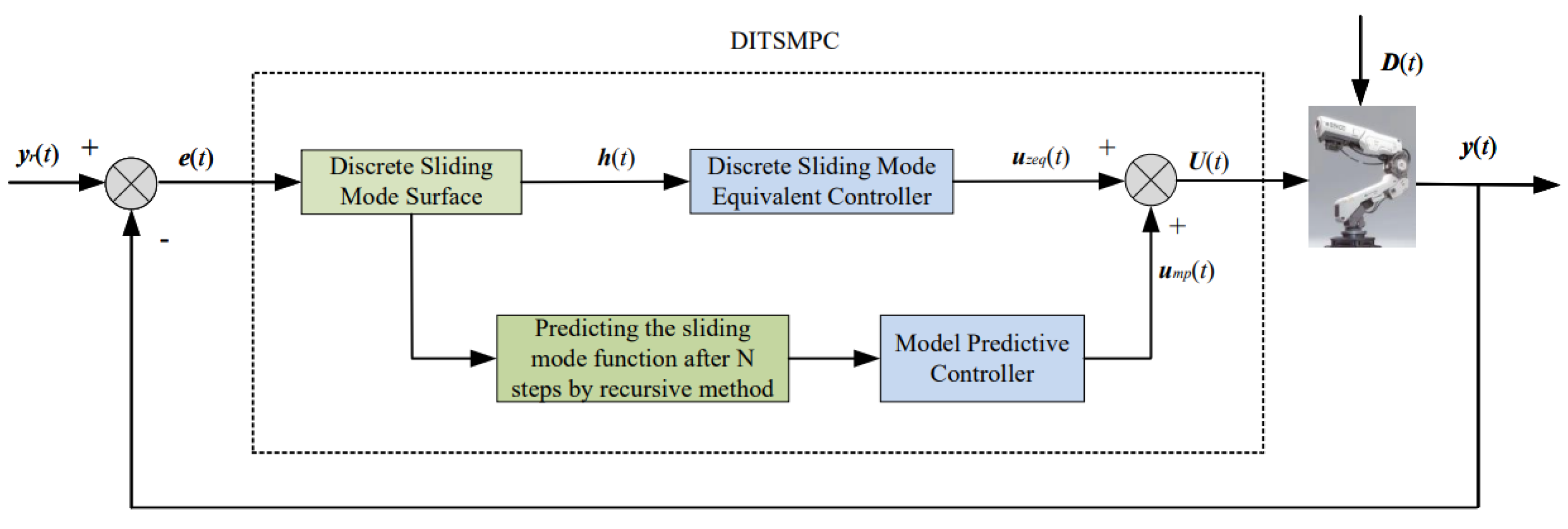

- A DITSMPC algorithm is proposed, which uses a one-step delay estimation method to compensate for disturbances affecting the controlled system. The method also utilizes an adaptive reaching law and MPC to enhance the trajectory tracking accuracy of the robotic arm and suppress system chattering.

- (2)

- Compared with existing methods that use MPC, neural network control, robust control, etc. [5,6,7,8], this approach does not rely on an exact mathematical model. In contrast to [18,19], this method results in smaller chattering and higher tracking accuracy when dealing with disturbances. Compared to [20,21], it requires fewer tuning parameters and is easier to implement. Compared with [24], this method can be extended to MIMO systems and has stronger applicability.

- (3)

- The main advantage of the proposed DITSMPC scheme is that it provides a control method that is easy to implement and capable of addressing model uncertainties and white noise disturbances in multi-input multi-output systems.

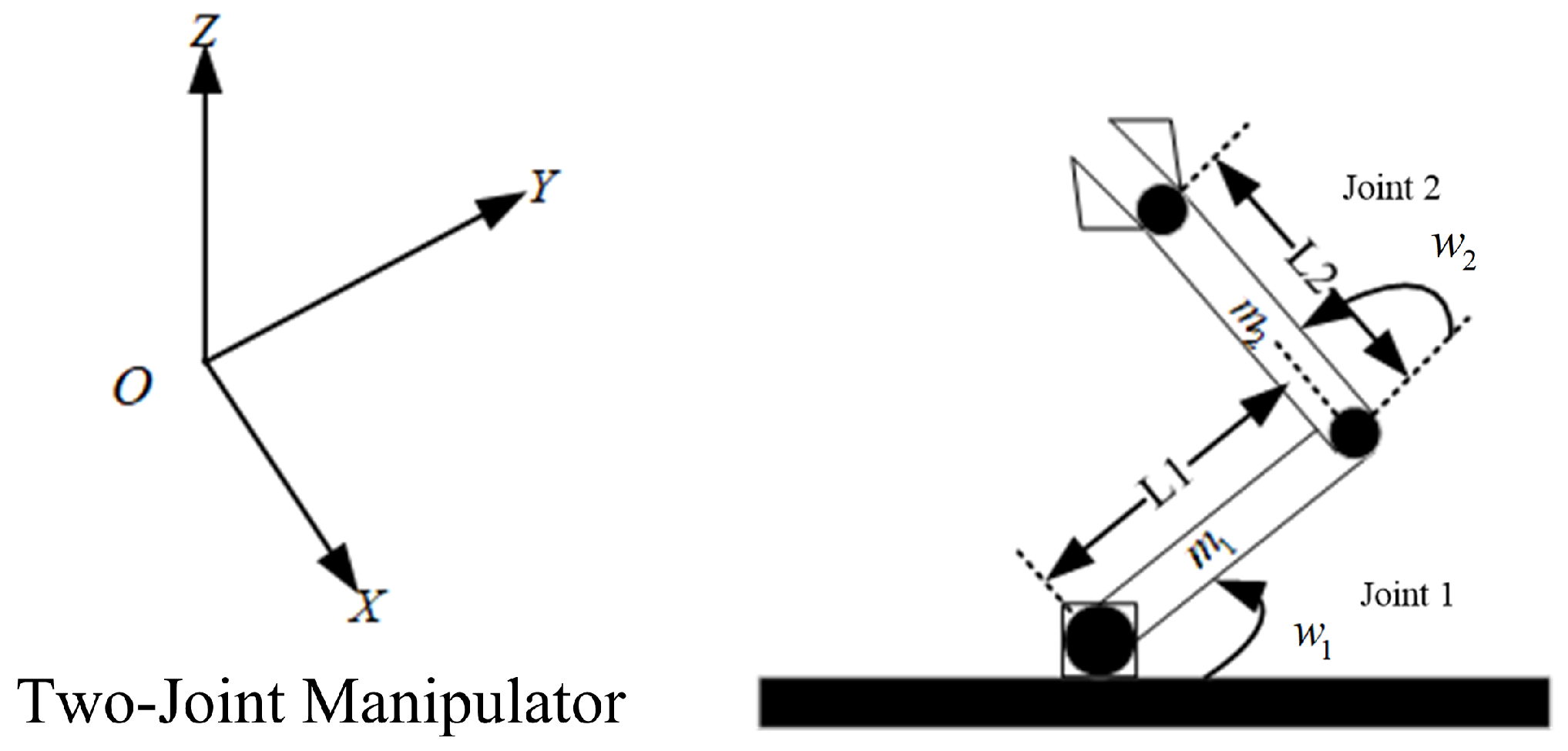

2. Mechanical Arm Dynamics Model

2.1. Mechanism Model

2.2. Discretization of Dynamic Model

3. Adaptive Discrete Integral Terminal Sliding Mode Control (ADITSMC) Scheme for Industrial Manipulator

3.1. Sliding Mode Control Law

3.2. Proof of Convergence

4. Design of DITSMPC Scheme

4.1. DITSMPC Law

4.2. Proof of Convergence

5. Simulation Experiment

5.1. Two-Joint Manipulator

5.2. Simulation Parameter Settings

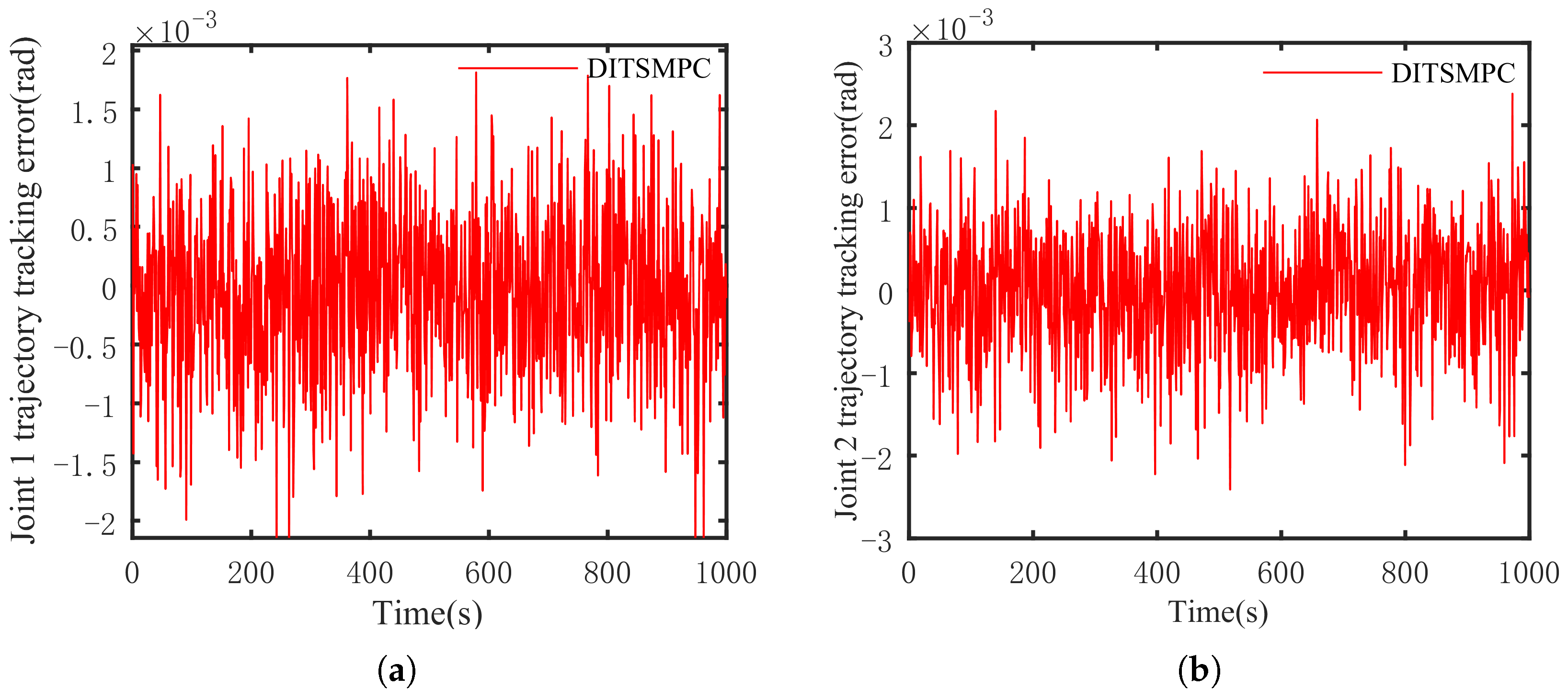

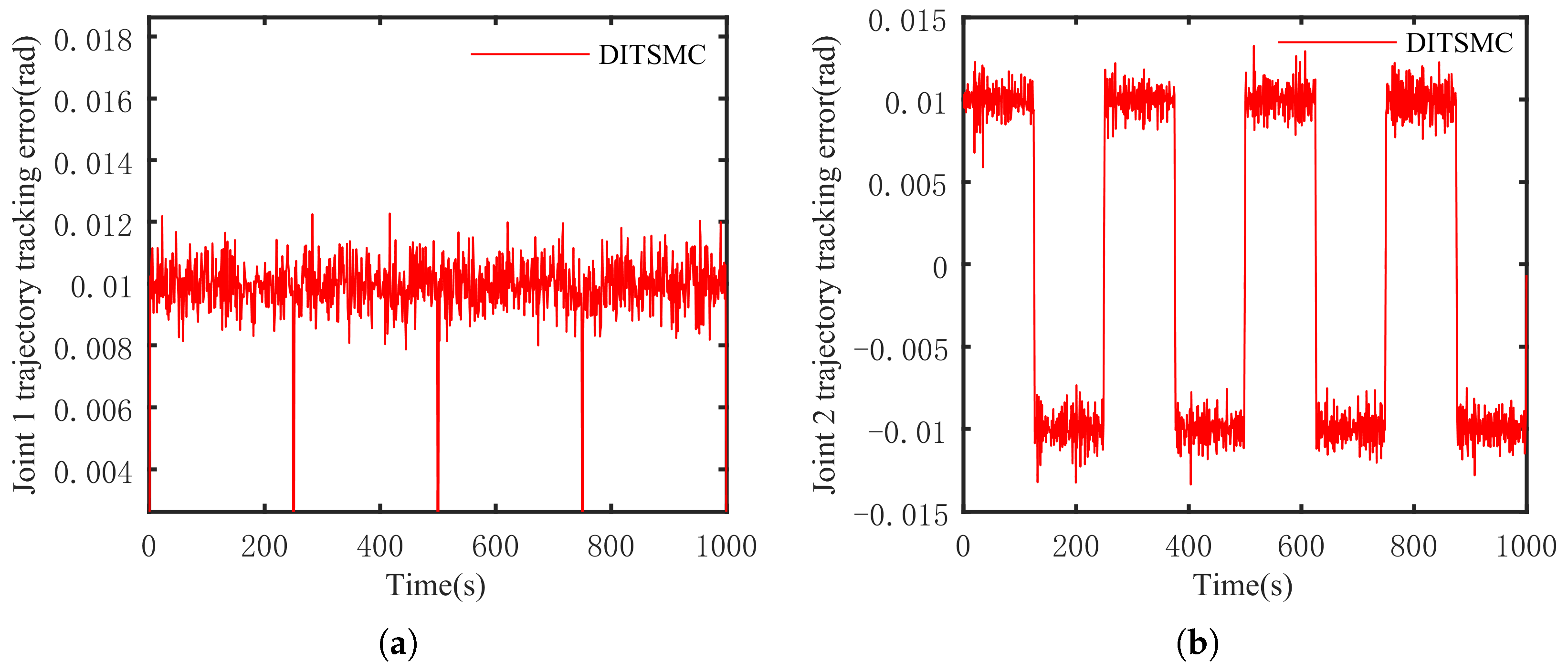

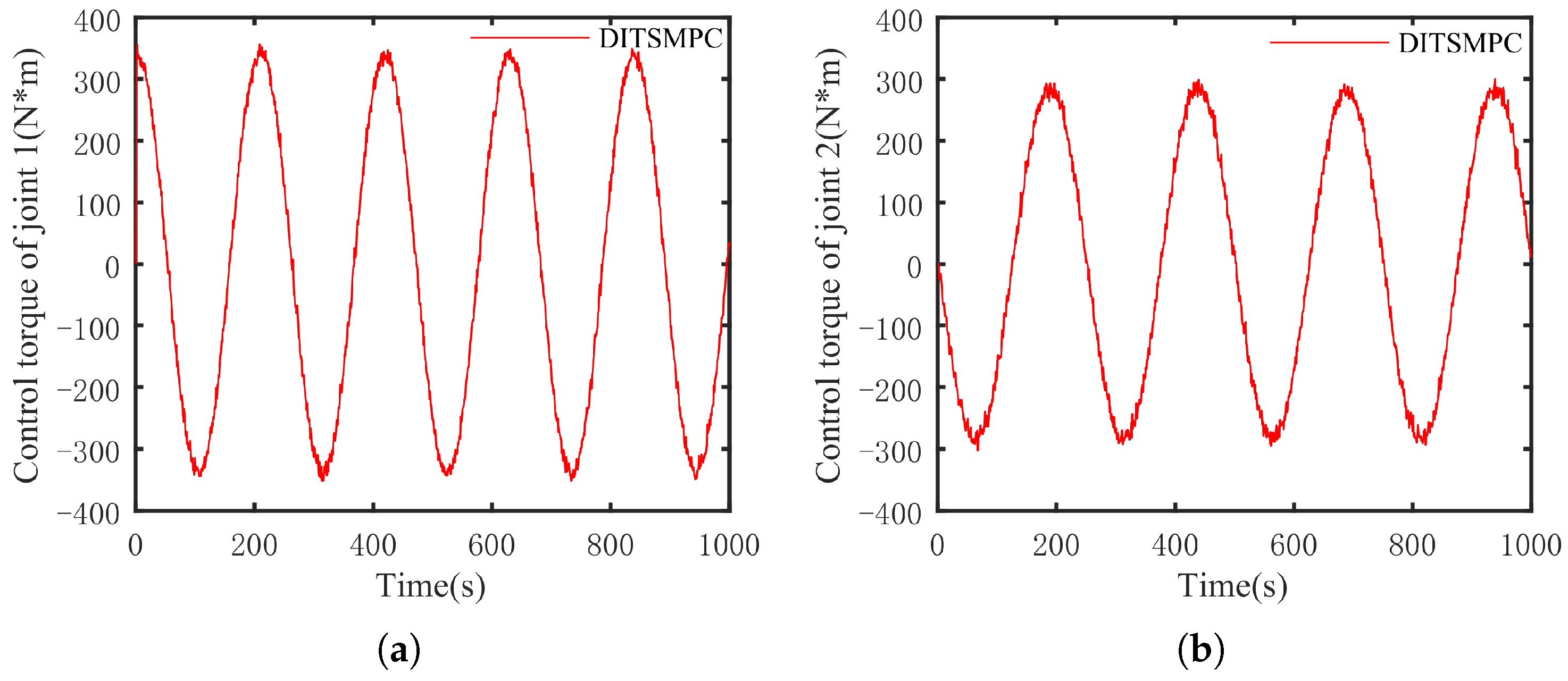

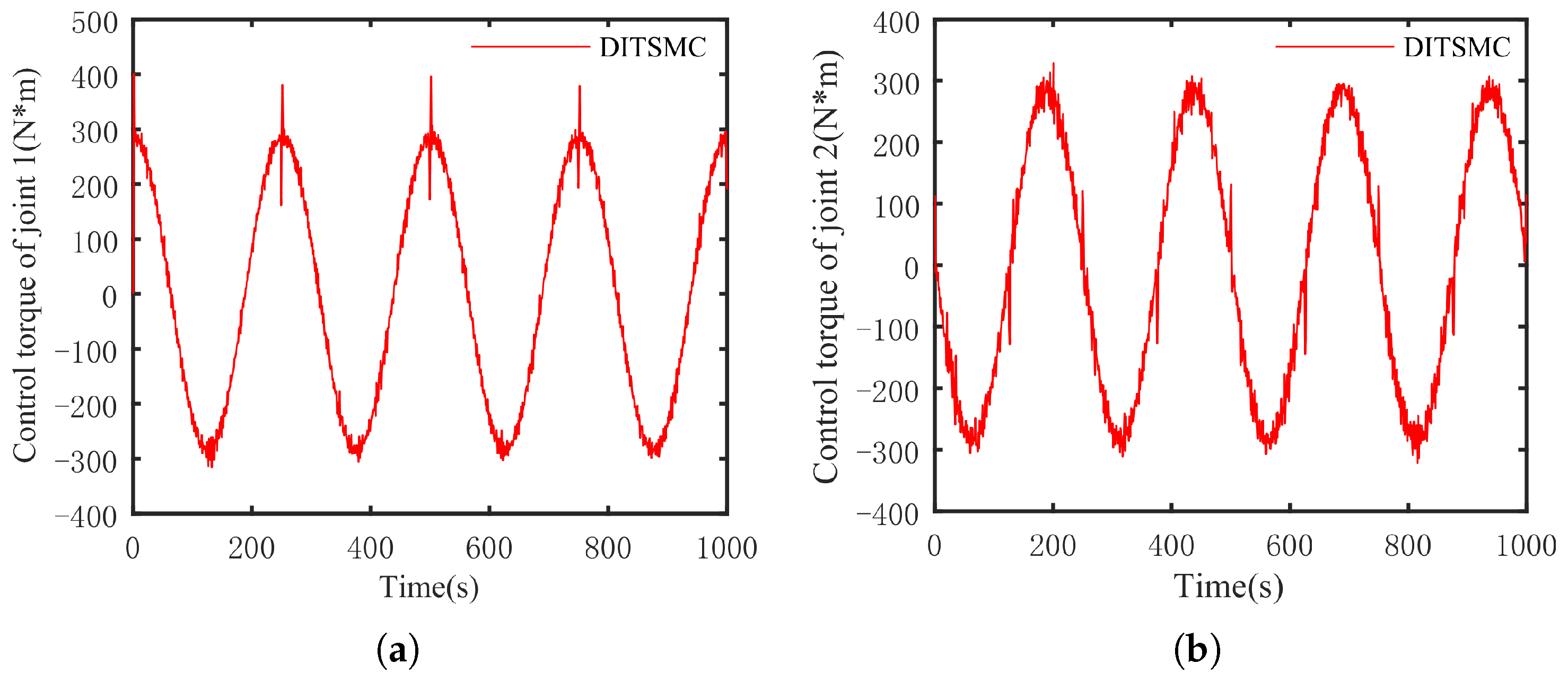

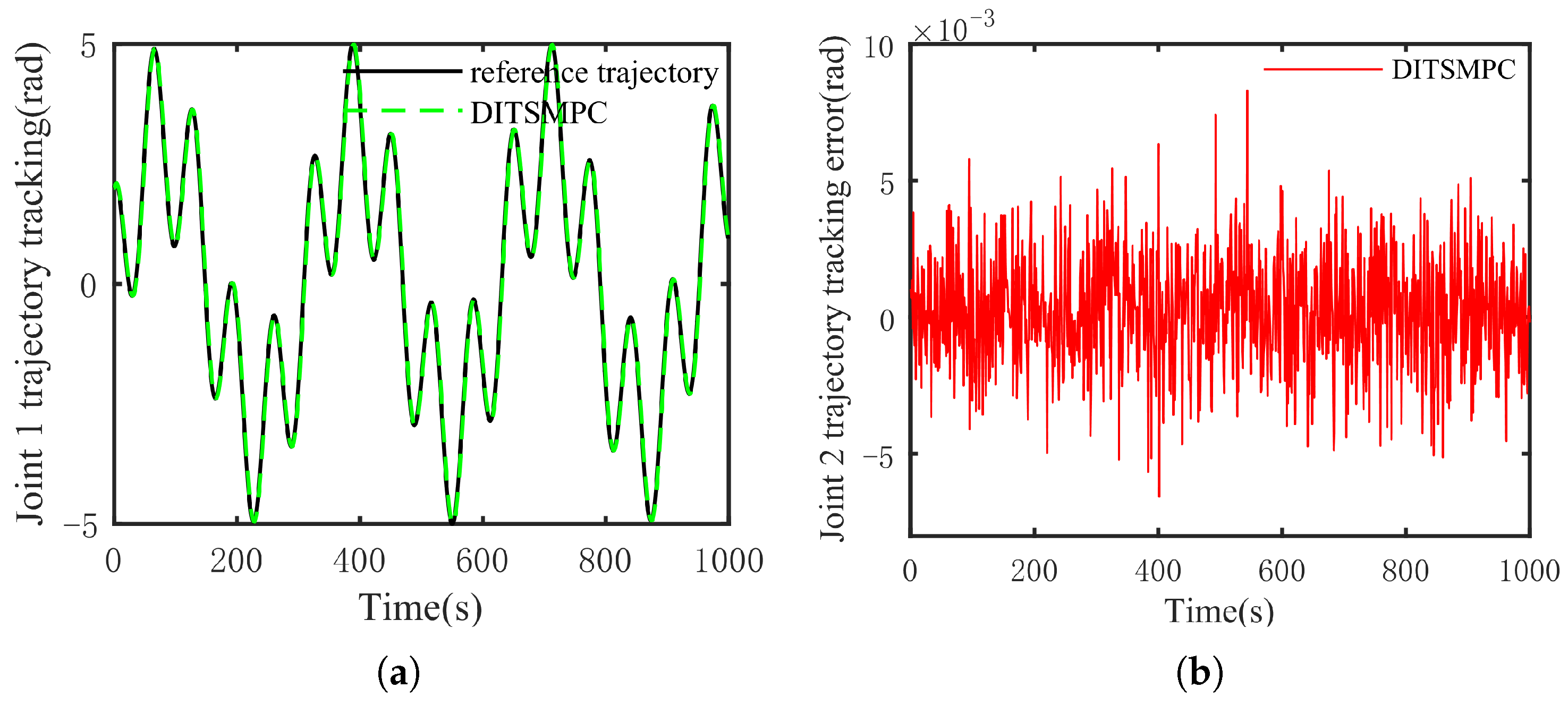

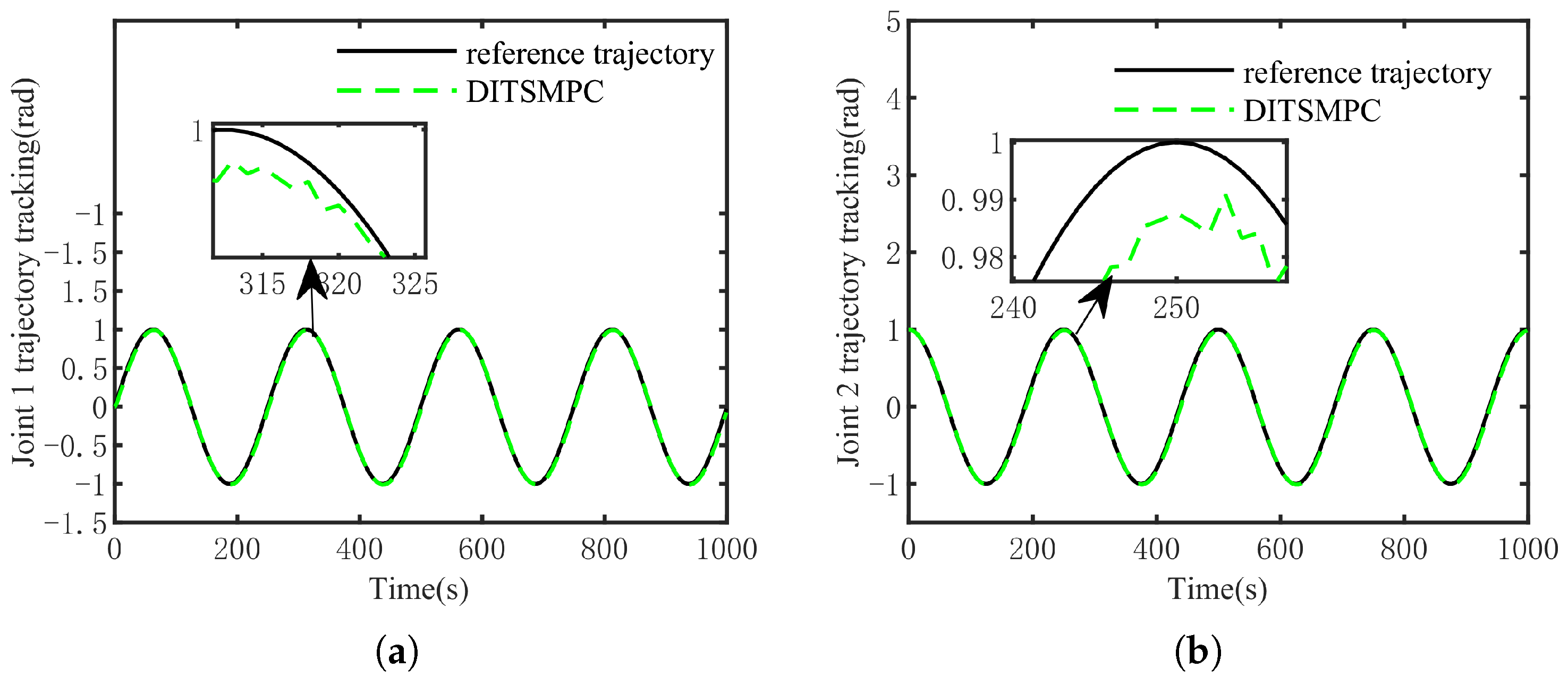

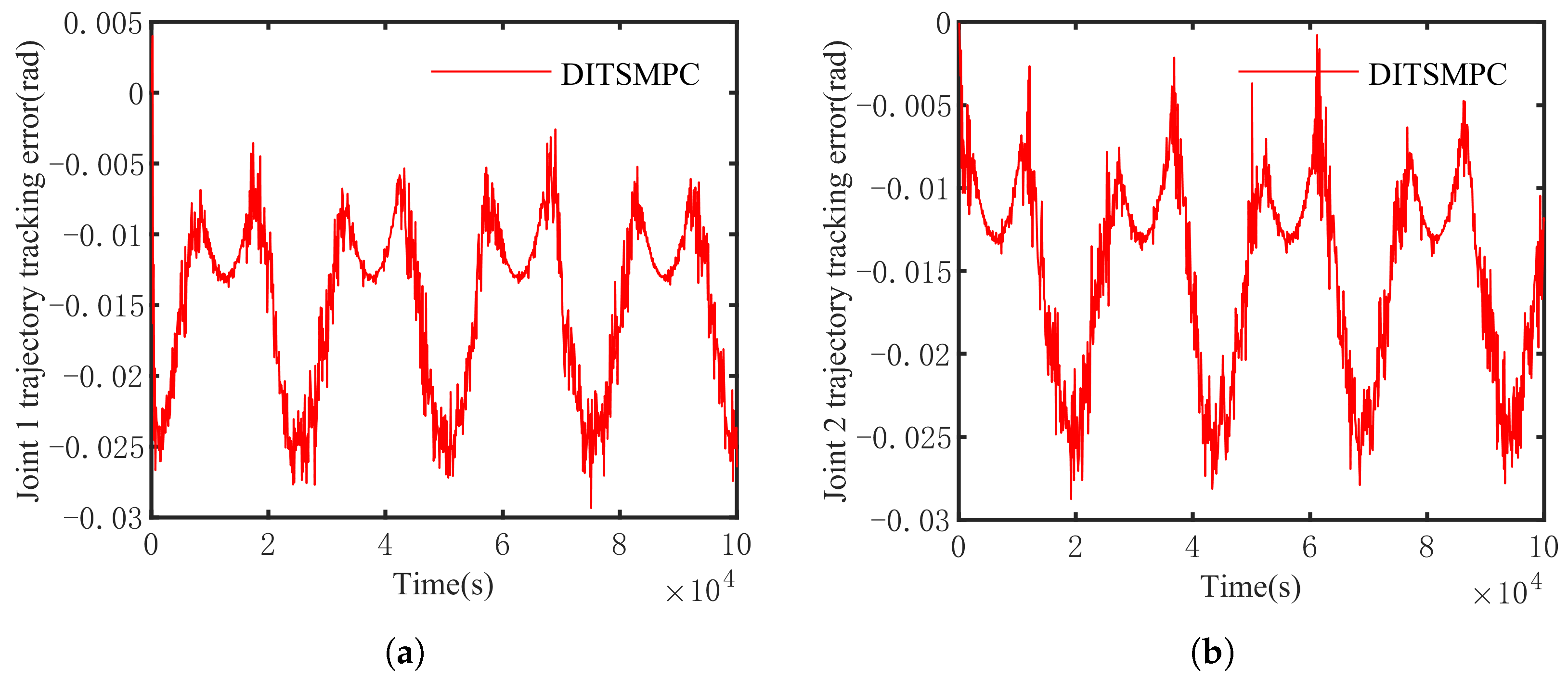

5.3. Simulation Results

- (1)

- MSE

- (2)

- IAFV

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Billard, A.; Kragic, D. Trends and challenges in robot manipulation. Science 2019, 364, eaat8414. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Li, S.; Yu, J.; He, J. Robot manipulator control using neural networks: A survey. Neurocomputing 2018, 285, 23–34. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Liu, J.; Dai, C.; Sun, Y. Robotic micromanipulation: Fundamentals and applications. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 181–203. [Google Scholar] [CrossRef]

- Carron, A.; Arcari, E.; Wermelinger, M.; Hewing, L.; Hutter, M.; Zeilinger, M.N. Data-driven model predictive control for trajectory tracking with a robotic arm. IEEE Robot. Autom. Lett. 2019, 4, 3758–3765. [Google Scholar] [CrossRef]

- Xu, K.; Wang, Z. The design of a neural network-based adaptive control method for robotic arm trajectory tracking. Neural Comput. Appl. 2023, 35, 8785–8795. [Google Scholar] [CrossRef]

- Huang, H.L.; Cheng, M.Y.; Huang, T.Y. A Rapid Base Parameter Physical Feasibility Test Algorithm for Industrial Robot Manipulator Identification Using a Recurrent Neural Network. IEEE Access 2023, 11, 145692–145705. [Google Scholar] [CrossRef]

- Zhou, S.; Shen, C.; Xia, Y.; Chen, Z.; Zhu, S. Adaptive robust control design for underwater multi-dof hydraulic manipulator. Ocean Eng. 2022, 248, 110822. [Google Scholar] [CrossRef]

- Xi, R.D.; Xiao, X.; Ma, T.N.; Yang, Z.X. Adaptive sliding mode disturbance observer based robust control for robot manipulators towards assembly assistance. IEEE Robot. Autom. Lett. 2022, 7, 6139–6146. [Google Scholar] [CrossRef]

- Huo, Z.; Wang, B. Distributed resilient multi-event cooperative triggered mechanism based discrete sliding-mode control for wind-integrated power systems under denial of service attacks. Appl. Energy 2023, 333, 120636. [Google Scholar] [CrossRef]

- Li, Z.Q.; Sun, P.X.; Yang, H.; Zhou, L. Discrete integral terminal sliding mode predictive control for heavy haul train. Control Theory Appl. 2024, 41, 1–10. [Google Scholar]

- Zhang, J.; Ding, F.; Liu, J.; Lei, F.; Wang, Y.; Wei, C. Event Triggered Finite-Time Adaptive Sliding-Mode Coordinated Control of Uncertain Hysteretic Leaf Spring Suspension With Prescribed Performance. IEEE Trans. Intell. Transp. Syst. 2025, 26, 2621–2632. [Google Scholar] [CrossRef]

- Zhang, T.; Shi, P.; Li, W.; Yue, X. Discrete nonsingular terminal sliding mode control for trajectory tracking of space manipulators with mismatched multiple disturbances and noisy measurements. Aerosp. Sci. Technol. 2024, 144, 108766. [Google Scholar] [CrossRef]

- Chen, H.; Wu, W.; Qin, C. Composite nonlinear feedback integral sliding mode control for uncertain discrete-time system. Control Theory Appl. 2023, 40, 297–303. [Google Scholar]

- Hui, J. Discrete-time integral terminal sliding mode load following controller coupled with disturbance observer for a modular high-temperature gas-cooled reactor. Energy 2024, 292, 130479. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.Q.; Yang, H.; Fu, Y.T.; Wang, H. Data-driven integral sliding mode control based on disturbance decoupling technology for electric multiple unit. J. Frankl. Inst. 2023, 360, 9399–9426. [Google Scholar] [CrossRef]

- Huang, J.; Li, H.; Yang, L.; Zhao, H.; Zhang, P. Discrete terminal integral sliding-mode backstepping speed control of SMPMSM drives based on ultra-local mode. J. Electr. Eng. Technol. 2023, 18, 3009–3020. [Google Scholar] [CrossRef]

- Zheng, C.; Zhang, J.; Xu, R.; Zhang, G.C. Robust Discrete Integral Sliding Mode Control for Buck Converters. Trans. China Electrotech. Soc. 2019, 34, 4306–4313. [Google Scholar]

- Fu, Y.; Zhu, H.; Yang, H. An optimal adhesion control of heavy haul train considering system uncertainty estimation. J. Railw. Sci. Eng. 2022, 19, 1734–1742. [Google Scholar]

- Xu, J.; Sui, Z.; Wang, W.; Xu, F. An Adaptive Discrete Integral Terminal Sliding Mode Control Method for a Two-Joint Manipulator. Processes 2024, 12, 1106. [Google Scholar] [CrossRef]

- Fan, Y.; Sun, L.; Bai, X.; Zhao, Y.; Hui, X.; Wang, Y. Trajectory Tracking Control of an Underwater Manipulator Based on Adaptive Arctangent Non-singular Terminal Sliding Mode Control. Control Decis. 2025, 40, 205–213. [Google Scholar] [CrossRef]

- Yao, X.; Park, J.H.; Dong, H.; Guo, L.; Lin, X. Robust adaptive nonsingular terminal sliding mode control for automatic train operation. IEEE Trans. Syst. Man Cybern. Syst. 2018, 49, 2406–2415. [Google Scholar] [CrossRef]

- Xu, Q. Digital integral terminal sliding mode predictive control of piezoelectric-driven motion system. IEEE Trans. Ind. Electron. 2015, 63, 3976–3984. [Google Scholar] [CrossRef]

- Xu, Y.T.; Wu, A.G. Integral sliding mode predictive control with disturbance attenuation for discrete-time systems. IET Control Theory Appl. 2022, 16, 1751–1766. [Google Scholar] [CrossRef]

- Du, H.; Chen, X.; Wen, G.; Yu, X.; Lü, J. Discrete-Time Fast Terminal Sliding Mode Control for Permanent Magnet Linear Motor. IEEE Trans. Ind. Electron. 2018, 65, 9916–9927. [Google Scholar] [CrossRef]

- Yazıcı, İ.; Yaylacı, E.K. Discrete-time integral terminal sliding mode based maximum power point controller for the PMSG-based wind energy system. IET Power Electron. 2019, 12, 3688–3696. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.; Yang, H.; Tan, C.; Fu, Y. Adaptive terminal sliding mode control for high-speed EMU: A MIMO data-driven approach. IEEE Trans. Autom. Sci. Eng. 2025. [CrossRef]

- Velez-Lopez, G.C.; Hernandez-Martinez, L.; Vazquez-Leal, H.; Sandoval-Hernandez, M.A.; Jimenez-Fernandez, V.M.; Gonzalez-Lee, M.; Mayorga-Cruz, D. Collision-Free Path Planning Applied to Multi-Degree-of-Freedom Robotic Arms Using Homotopy Methods. IEEE Access 2024, 12, 150702–150718. [Google Scholar] [CrossRef]

- Qin, C.; Zhang, Z.; Fang, Q. Adaptive Backstepping Fast Terminal Sliding Mode Control With Estimated Inverse Hysteresis Compensation for Piezoelectric Positioning Stages. IEEE Trans. Circuits Syst. II Express Briefs 2024, 71, 1186–1190. [Google Scholar] [CrossRef]

| Parameter | Parameter Value |

|---|---|

| 0.975 | |

| 1.247 | |

| 98 | |

| 0.04 | |

| 0.01 s | |

| 4500 | |

| 10 |

| Control Method | MSE | IAFV |

|---|---|---|

| ADITSMC | ||

| DITSMC | ||

| DITSMPC |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Sui, Z.; Xu, F. Posture Control of Hydraulic Flexible Second-Order Manipulators Based on Adaptive Integral Terminal Variable-Structure Predictive Method. Sensors 2025, 25, 1351. https://doi.org/10.3390/s25051351

Xu J, Sui Z, Xu F. Posture Control of Hydraulic Flexible Second-Order Manipulators Based on Adaptive Integral Terminal Variable-Structure Predictive Method. Sensors. 2025; 25(5):1351. https://doi.org/10.3390/s25051351

Chicago/Turabian StyleXu, Jianliang, Zhen Sui, and Feng Xu. 2025. "Posture Control of Hydraulic Flexible Second-Order Manipulators Based on Adaptive Integral Terminal Variable-Structure Predictive Method" Sensors 25, no. 5: 1351. https://doi.org/10.3390/s25051351

APA StyleXu, J., Sui, Z., & Xu, F. (2025). Posture Control of Hydraulic Flexible Second-Order Manipulators Based on Adaptive Integral Terminal Variable-Structure Predictive Method. Sensors, 25(5), 1351. https://doi.org/10.3390/s25051351