1. Introduction

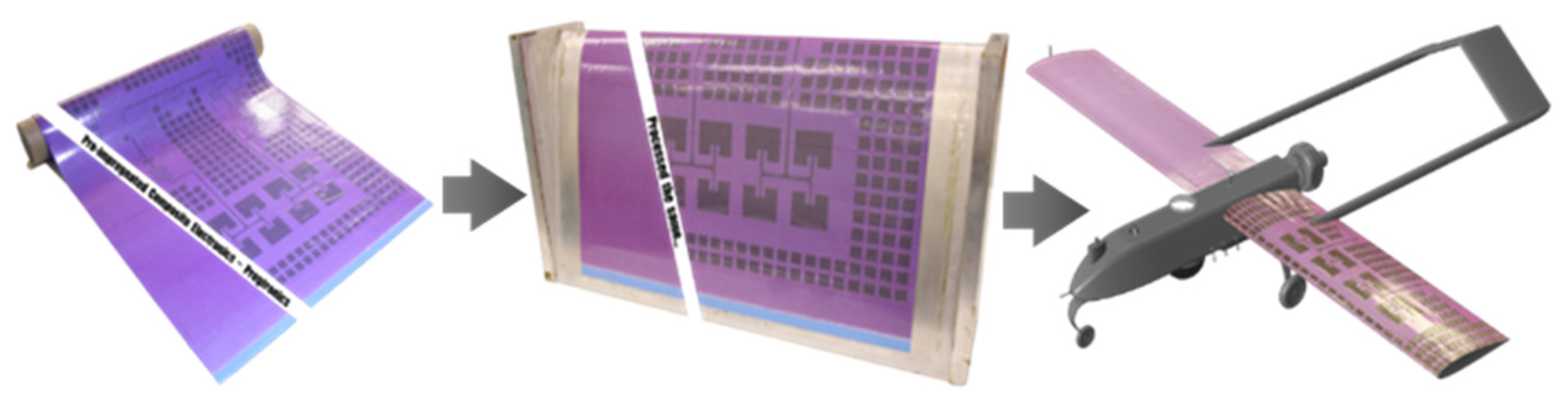

With the rapid advancement of UAVs in the aerospace industry, there is a significant need for increased functionality and efficiency despite volume constraints [

1], necessitating greater integration and miniaturisation of electronics in UAV systems. Multifunctional composite structures (MFCSs) are essential research fields with large-scale applications in the aerospace, automotive, and sports sectors. Conformal load-bearing smart skin (CLSS), a subset of MFCSs, has attracted interest recently. With the growing demand for the integration and miniaturisation of UAV systems, CLSSs offer a promising solution. Specifically, conformal load-bearing antenna structures (CLASs), a recent development within CLSSs, focus on integrating radiofrequency devices into the composite skins of airframes. (see

Figure 1).

Traditional communication and radar elements on aerostructures are considered separate sub-systems and have independent design and manufacturing considerations. It reduces synergy when optimising electromagnetic and structural requirements. Additionally, conventional radiofrequency devices are externally mounted, protruding into the airflow, disrupting aerodynamics, increasing drag, and reducing environmental tolerance during flight. In contrast, the CLAS system embeds these devices directly into the skin of load-bearing structures with minimal mechanical performance degradation. This integration reduces drag, which potentially improves fuel efficiency, enhances structural integrity, and reduces the radar cross-section (RCS) of the UAV, thereby enhancing its stealth capabilities. Strategically positioning radiofrequency elements along the exterior can further improve antenna performance. Additionally, the system is significantly more resilient to environmental damage than conventional antenna structures [

3], leading to lower maintenance costs and increased operational reliability.

Material selection is a crucial aspect of designing and fabricating CLSSs, driven by the need to fulfil additional functional requirements. The chosen material must exhibit flexibility and strength comparable with the rest of the structure to ensure seamless integration. In CLASs, the substrate plays an important role in determining the performance of embedded communication elements.

Traditionally, CLAS designs feature a carbon fibre composite structural skin and an electrically insulating, radar-transparent window, often fabricated from glass fibre-reinforced polymer (GFRP) [

4]. GFRP offers mechanical properties comparable with carbon fibre composites [

5] and is used in fabricating UAVs and aerospace structures. Moreover, as reported in [

6,

7], GFRP’s radar transparency and dielectric stability ensure that its use as an antenna substrate does not adversely affect antenna efficiency, making it a highly suitable material for integrating antenna elements while maintaining CLAS’s structural and electromagnetic performance.

In addition, to enhance the utility of CLASs, a microstrip antenna, widely regarded as one of the best options for modern communication systems, is selected for CLAS applications. This choice is driven by its numerous advantages, including ease of manufacture, adaptability to both planar and non-planar surfaces, and high customizability to meet specific design requirements [

1,

7,

8]. An example of a CLAS is the conventional microstrip antenna shown in

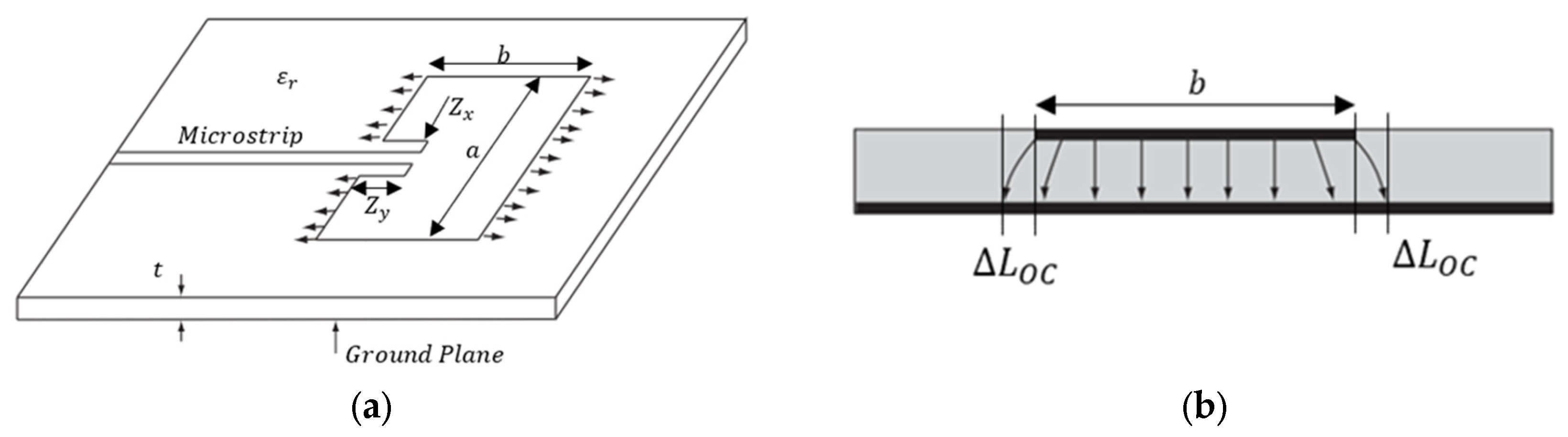

Figure 2a.

Equation (1) shows the relationship between the resonant frequency,

, for a microstrip antenna, the total effective length

of the CLAS, and the dielectric properties

of the substrate (GFRP). The schematic representation of total effective length

is shown in

Figure 2b. The fringing fields extend beyond the physical boundaries

of the antenna patch. This extension causes the total effective length of the cavity to be greater than the physical length of the antenna patch. Specifically, an additional effective length is added at each edge due to the microstrip open-end effect.

where

is the speed of light in vacuum,

is the dimension of the CLAS (shown in

Figure 2),

is the open circuit length extension defined in Equation (2), and

is the effective permittivity of the substrate defined in Equation (3) [

9].

where

and

are the physical properties of the CLAS (shown in

Figure 2).

where

is the relative permittivity, which is defined as the ratio of the material’s permittivity (ϵ) to the permittivity of free space

.

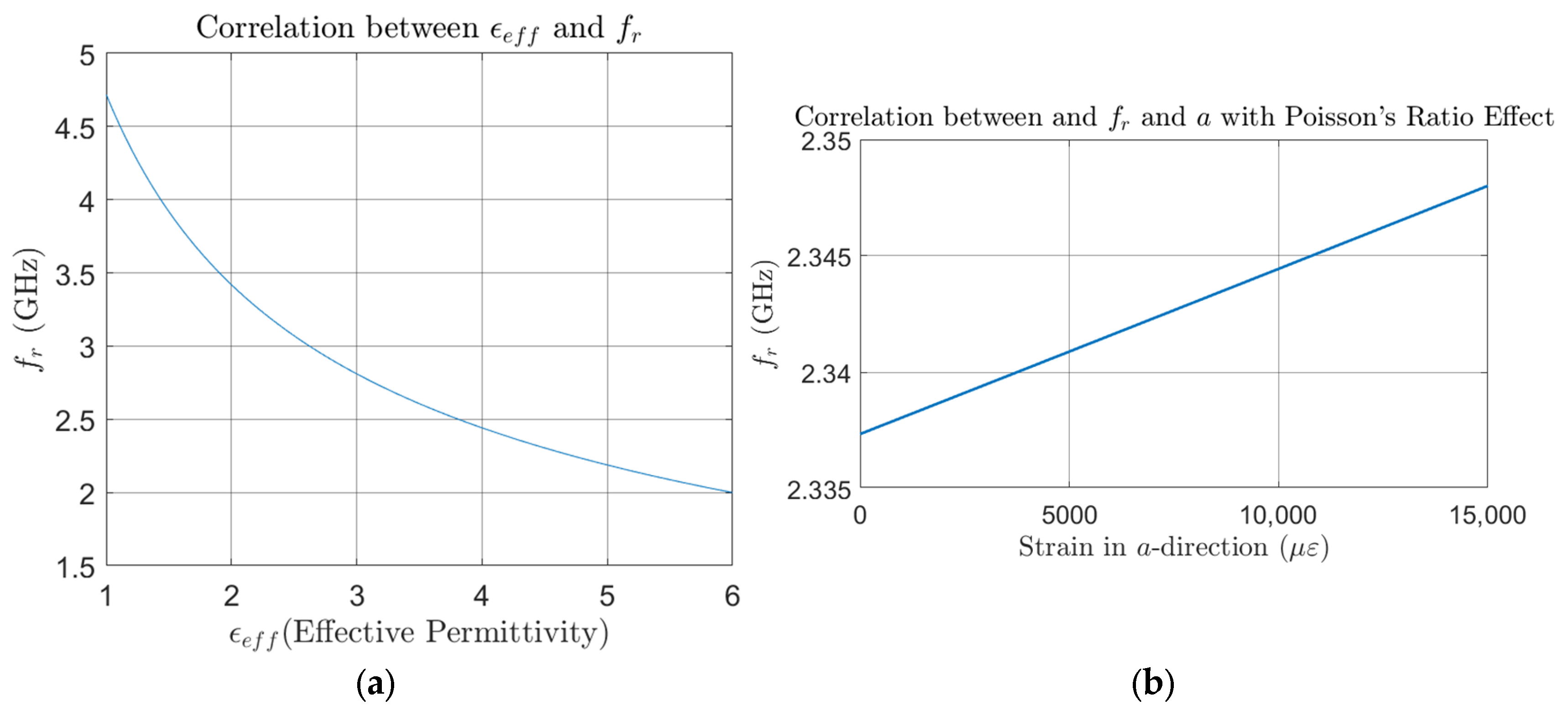

The relationship between effective permittivity

, strain in dimension

, and the resonant frequency

of the CLAS system, based on the properties of the system employed in this study, is shown in

Figure 3a,b. These figures show a clear inverse correlation, where an increase in

leads to a corresponding decrease in

. This relationship highlights how the permittivity change influences the resonant frequency of the CLAS system.

Potential Parameters That Affect the CLAS Resonant Performance

The antenna’s physical geometry and the substrate’s electromagnetic properties will define the CLAS’s resonant frequency. According to Equation (1) mentioned above, changes in the geometry due to mechanical loading can alter the resonant behaviour. This relationship was explored in research by Healey et al. [

2], which investigated the resonant frequency response of CLASs under various mechanical loading conditions, such as uniaxial, biaxial, and twisting loads, through numerical simulations. The study only considered the effect of mechanical loading on the antenna geometry and substrate thickness. The results highlighted that with uniaxial tension being applied along dimension

, which affects dimension

, due to the Poisson’s ratio, the resonance frequency of CLAS shows a clear increasing trend as the tensile strain applied to the GFRP substrate progresses, as shown in

Figure 4. This behaviour is consistent with Equation (1) above, which states that the changes in the patch’s physical dimensions directly impact the resonance, leading to frequency shifts. This result also reveals that the resonant frequency still falls within acceptable bandwidth after the tensile strain reaches 15,000 µε.

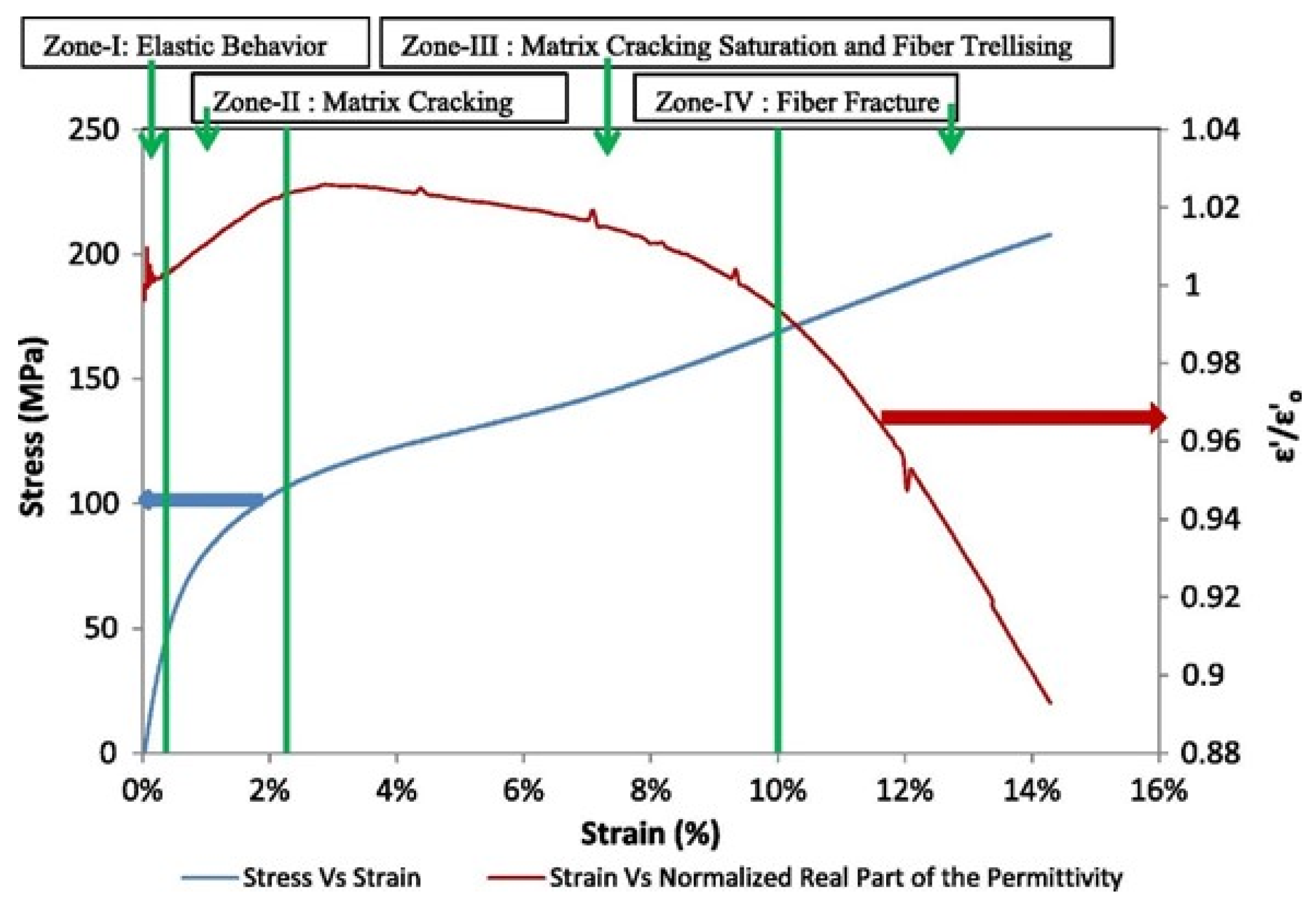

In addition, when applied to aerostructures, the mechanical loading will influence the CLAS’s geometry and damage the CLAS’s substrate. The relationship between damage sustained by the substrate and its dielectric properties has been a research focus in recent publications. For instance, Raihan R. et al. [

10] conducted an in-depth study on the dielectric behaviour of [±45]

5 GFRP under the quasi-static tensile test. The results (see

Figure 5) illustrated that the effective permittivity

increased during the initial stage of damage accumulation, which is attributed to microcracking in the matrix. As the microcracking reached saturation, the permittivity began to decline, with a significant reduction observed when fibre fracture occurred. Similar results were reported in computational publications [

11,

12,

13] and experimental data in [

14]. Therefore, based on Equation (1), when CLAS underwent a quasi-static test, the resonant frequency of the CLAS initially decreased, followed by an increase until specimen failure. The work reported by Lu et al. [

15] confirmed this trend. In this work, they examined the resonant behaviour of the CLAS with [±45]

6 GFRP as the substrate under both quasi-static tension and cyclic fatigue tests. This investigation also introduced a novel method involving a removable antenna patch that isolates the patch from mechanical loading, thereby highlighting the primary influence of substrate damage on the resonant behaviour of the CLAS. The results from the quasi-static test demonstrated a similar trend in resonant frequency shifts consistent with predictions based on fundamental resonant frequency equations and the literature on permittivity. Additionally, the results from the cyclic fatigue tests indicated that the resonant frequency of the CLAS gradually shifted downward as substrate damage accumulated, evidenced by a progressively expanding whitened region near the fixed support as fatigue cycles increased.

The literature confirms that mechanical loading significantly impacts the dielectric properties of ±45° GFRP which, in turn, influences the electromagnetic performance of the CLAS. GFRP is highly anisotropic, meaning its material properties vary depending on the fibre alignment. Different fibre orientations can alter strain distribution, directly affecting damage accumulation and the electromagnetic response under mechanical loading. Therefore, understanding how fibre orientation influences both the structural integrity and electromagnetic properties of the CLAS under various loading conditions is essential for optimising material selection and antenna placement.

To address this, the present study incorporates the existing literature on the electromagnetic behaviours of GFRP with different fibre orientations under mechanical loading.

Vamsee. V. et al. utilised a cured GFRP panel of [(0°)]

8, cut into five different orientations. These specimens underwent uniaxial tensile testing, with electrode blocks being attached to the gage region for in situ dielectric measurements [

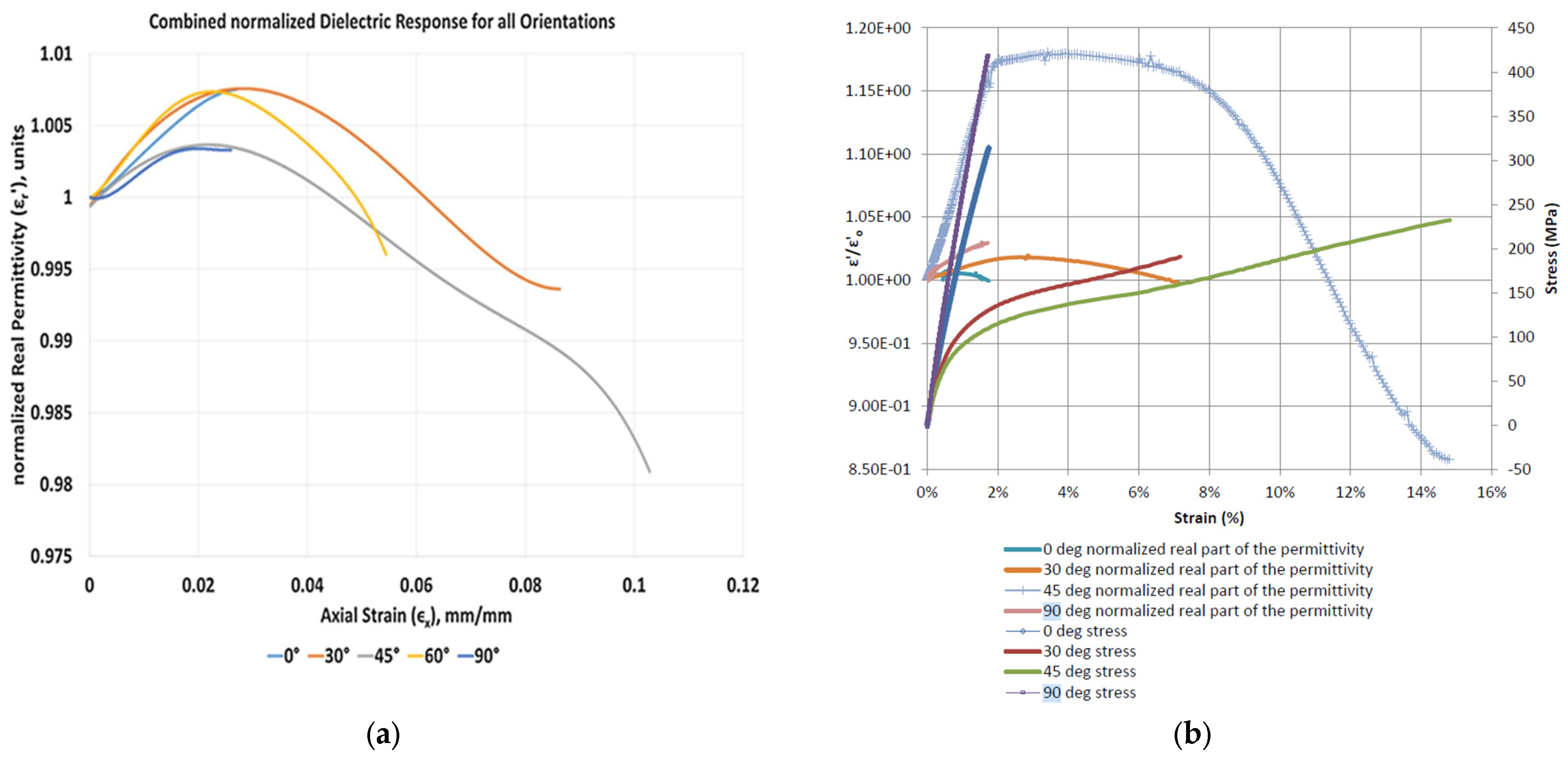

14]. The results, shown in

Figure 6a, revealed that fibre orientations of 30°, 45°, and 60° exhibited an initial increase in permittivity, followed by a decrease until failure. In contrast, 0° and 90° fibre orientations displayed a relatively monotonic positive correlation between strain and permittivity. Similar results were also reported in the study conducted by Raihan, M.R. [

16], in which uniaxial tensile tests were conducted on woven [0/90°]

5 GFRP specimens. The result in

Figure 6b demonstrated a generally positive trend in permittivity with increasing strain under tensile loading at principal angles of 0° and 90°, respectively. According to Equations (1) and (2) and

Figure 3a, the increase in permittivity leads to a decrease in the CLAS’s resonant frequency under the condition that only GFRP is subjected to the loads.

These above findings demonstrate that mechanical loading can influence the CLAS’s performance through two primary mechanisms: (1) geometric deformation of the antenna patch; and (2) changes in the dielectric properties of the GFRP substrate due to material degradation. However, previous research has predominantly focused on isolated aspects of the system rather than addressing the combined effects of mechanical loading on the overall performance of the CLAS. A holistic understanding of how antenna deformation and substrate material degradation interact under mechanical stress remains lacking.

Furthermore, the electromagnetic response of the CLAS to mechanical loading varies with fibre orientation. Studies show that [±45°] GFRP undergoes significant changes in permittivity, whereas [0/90°] GFRP exhibits a more gradual increase in the dielectric response under tensile loads. This variation suggests that fibre orientation plays a crucial role in the electromagnetic stability of the CLAS and must be carefully considered in its design and application.

However, the combined effects of mechanical loading, material degradation, and fibre orientation on CLAS performance remain unexplored, posing a critical research gap that requires further investigation. To ensure the successful integration of the CLAS into aerostructures, it is essential to study how mechanical deformation, dielectric property variations, and fibre orientation collectively impact the CLAS’s structural and electromagnetic behaviour. Addressing this gap is crucial for realising the full potential of CLASs and their reliability for long-term aerospace applications.

The motivation for this study stems from the need to test and validate CLAS performance under various mechanical loading conditions, including uniaxial tension and localised cyclic fatigue. This study aims to bridge the gap between structural mechanics and electromagnetic performance in CLASs by analysing both substrate-only effects and combined antenna–substrate system responses. In addition, this paper investigates a CLAS integrated with [0/90°] GFRP, providing further insights into its mechanical and electromagnetic behaviours. The findings will contribute to optimising antenna placement, structural resilience, and electromagnetic reliability in future aerospace designs.

This research is essential for ensuring that CLAS-integrated UAV airframes maintain consistent and reliable communication performance despite mechanical deformations encountered during flight operations. A comprehensive understanding of these interactions will be crucial for designing robust, load-bearing antenna structures that retain electromagnetic performance under real-world operational conditions.

4. Discussion

According to Equation (1), the resonant frequency of the CLAS system is predominantly influenced by the antenna’s physical geometry and the substrate’s electromagnetic properties. Previous studies have demonstrated that mechanical loading significantly alters CLAS’s performance when either the antenna patch’s geometry or the substrate sustains damage. Specifically, the resonant frequency positively correlates with tensile strain applied along the antenna patch’s dimension,

[

2]. Additionally, mechanical loading induces changes in the substrate’s relative permittivity (

) due to damage accumulation which, in turn, impacts the resonant frequency of CLAS [

14,

16]. These findings underscore the critical need to understand the effects of mechanical loading on the electromagnetic performance of CLASs.

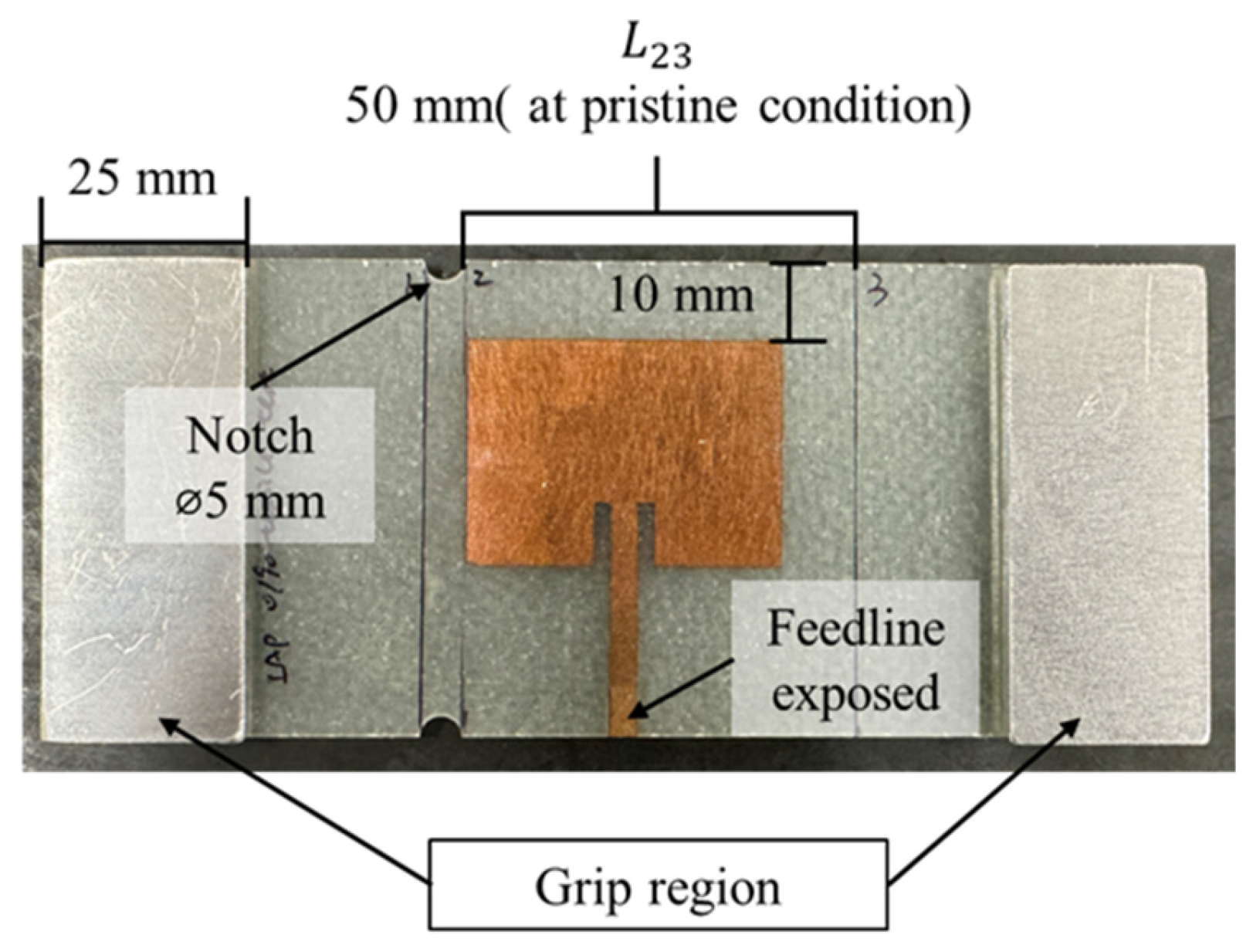

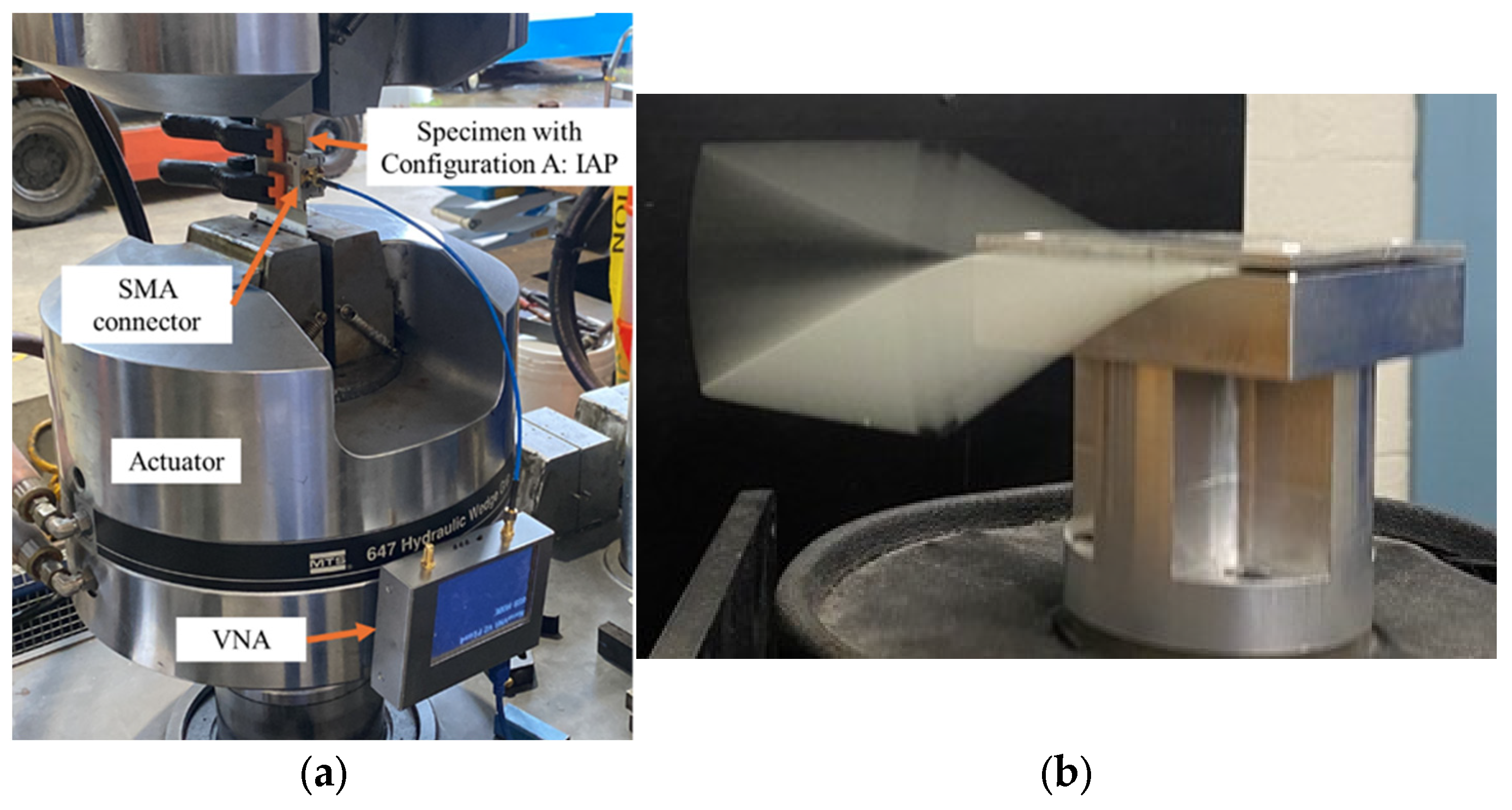

The research presented in this paper provides a systematic investigation of a CLAS system utilising a 6-ply [0/90] GFRP substrate, focusing on the resonant frequency shifts observed under various mechanical loading conditions. This research encompasses two mechanical loading scenarios: quasi-static uniaxial tensile testing (QS), which examines how the CLAS responds to significant elongation of the specimen, and cyclic fatigue testing (C), which focuses on highly localised damage in the substrate that gradually propagates toward the antenna patch.

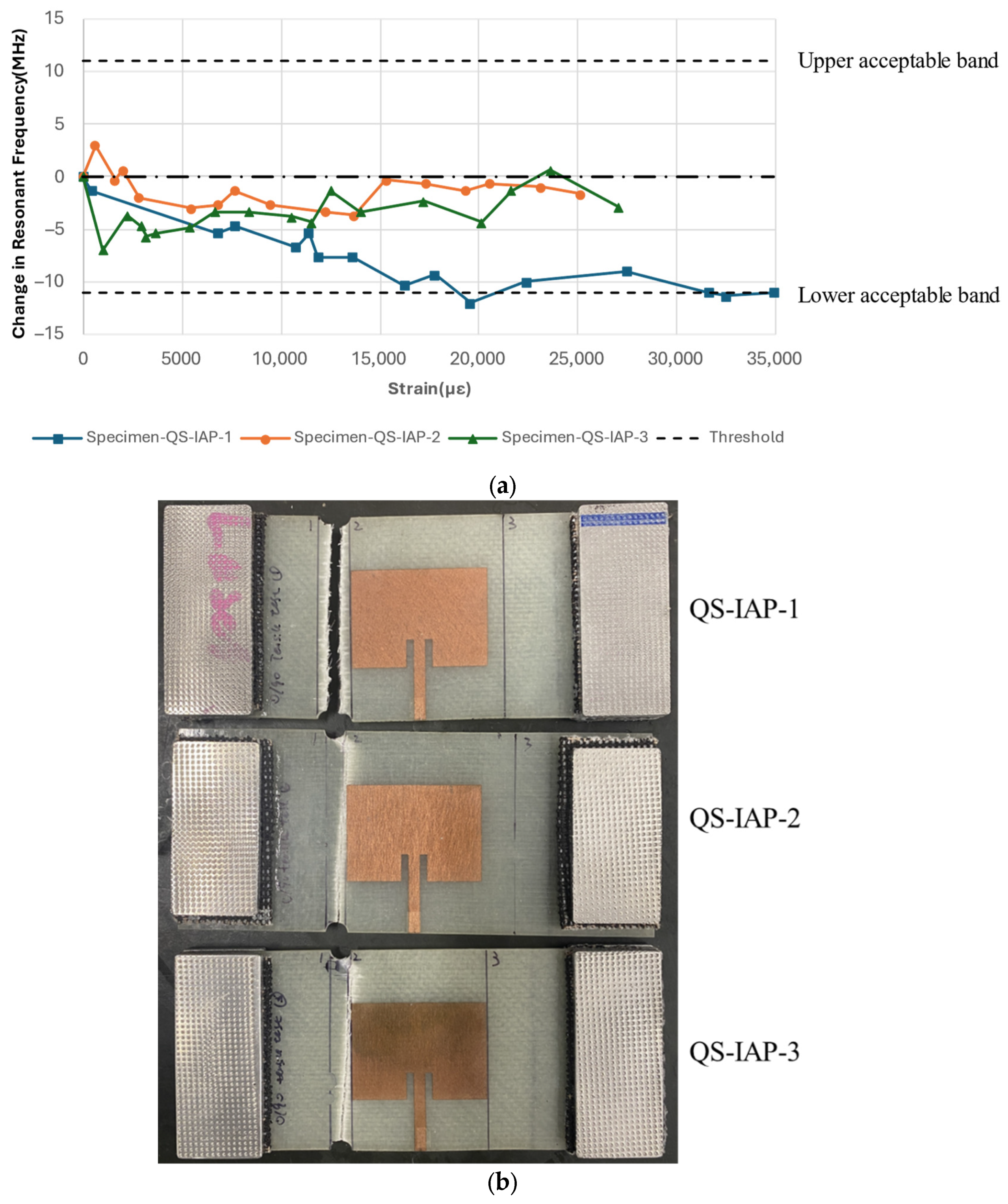

4.1. Quasi-Static Tension Test (QS)

Three specimens with Configuration A: IAP underwent an identical testing procedure in the quasi-static tests. The antenna patch and the substrate were both subjected to mechanical strain. This specimen configuration induced two competing factors affecting the resonant frequency of the CLAS under tensile loading: (a) the geometry-induced increase in frequency [

2] and (b) the material-induced increase in permittivity leading to a frequency decrease [

14,

16]. The results indicate that the dominant effect under uniaxial loading along the substrate’s principal direction is the increase in permittivity, causing a decrease in resonant frequency. Additionally, the resilience of the CLAS was evident as the resonant frequency remained within the acceptable bandwidth before specimen failure. However, the elongation observed in the quasi-static test is unlikely to occur in aerospace structures with integrated antennas.

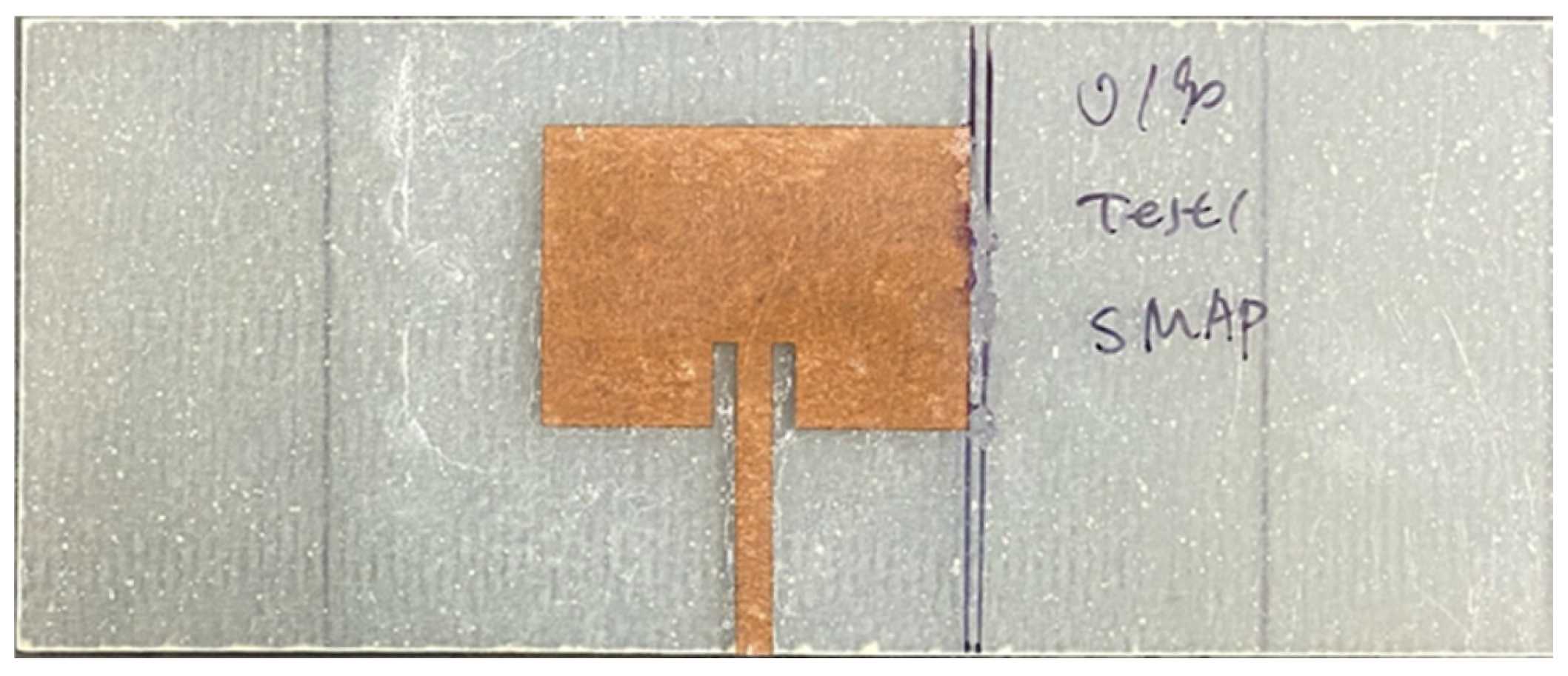

4.2. Cyclic Fatigue Tests (C)

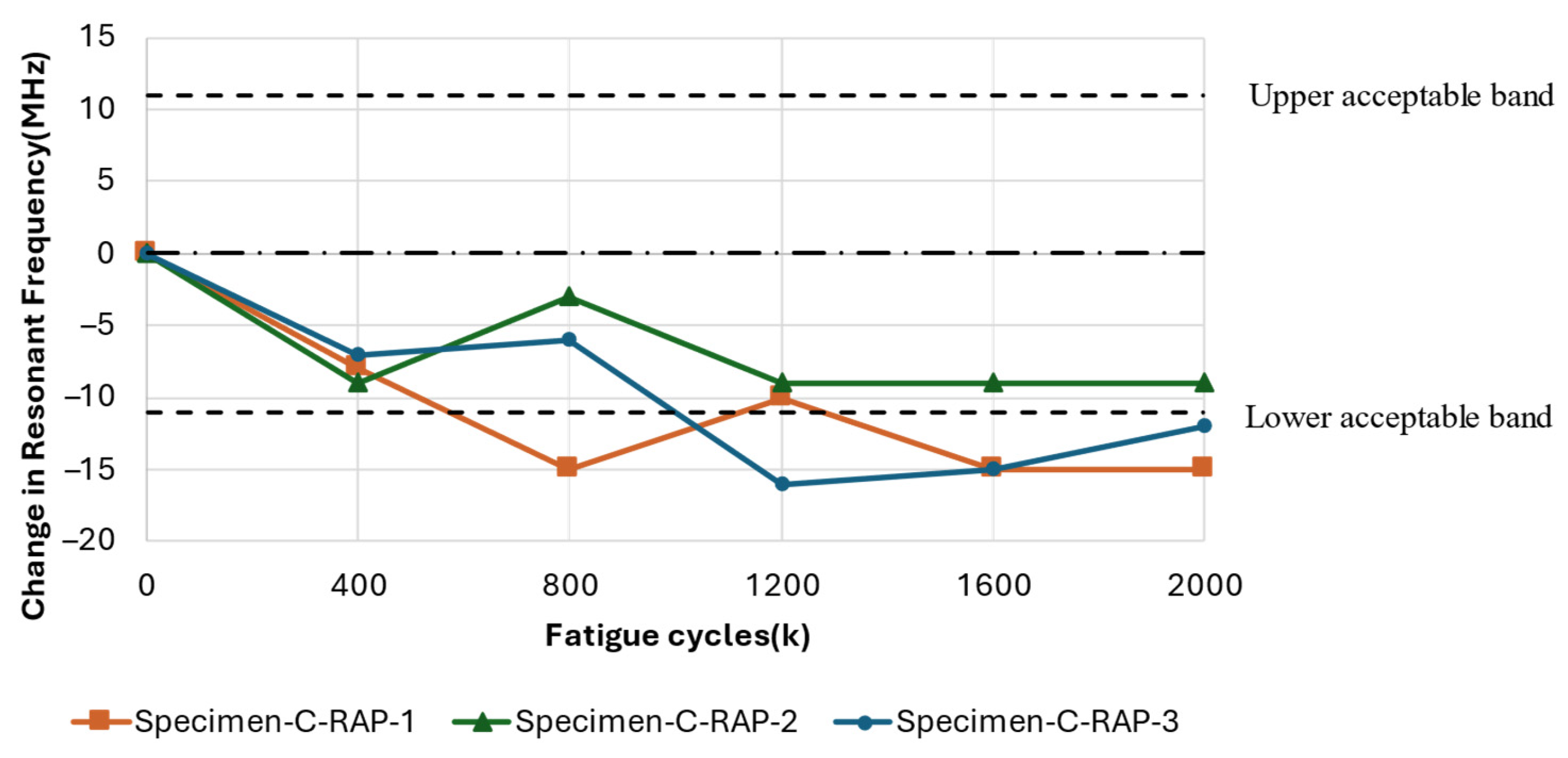

Fatigue tests were conducted on Configuration B: RAP, where the antenna patch was removed before testing, leaving only the substrate to experience fatigue damage independently. The antenna is re-installed onto the test specimen for measurement when the specimen has completed a defined number of fatigue cycles. The results consistently demonstrated a decrease in resonant frequency with increasing fatigue cycles. This frequency shift was strongly correlated with the extent of damage sustained by the substrate, highlighting a clear relationship between substrate damage severity and frequency change magnitude. These findings align with the previous literature, which identified competing factors, including factor (b), as mentioned above.

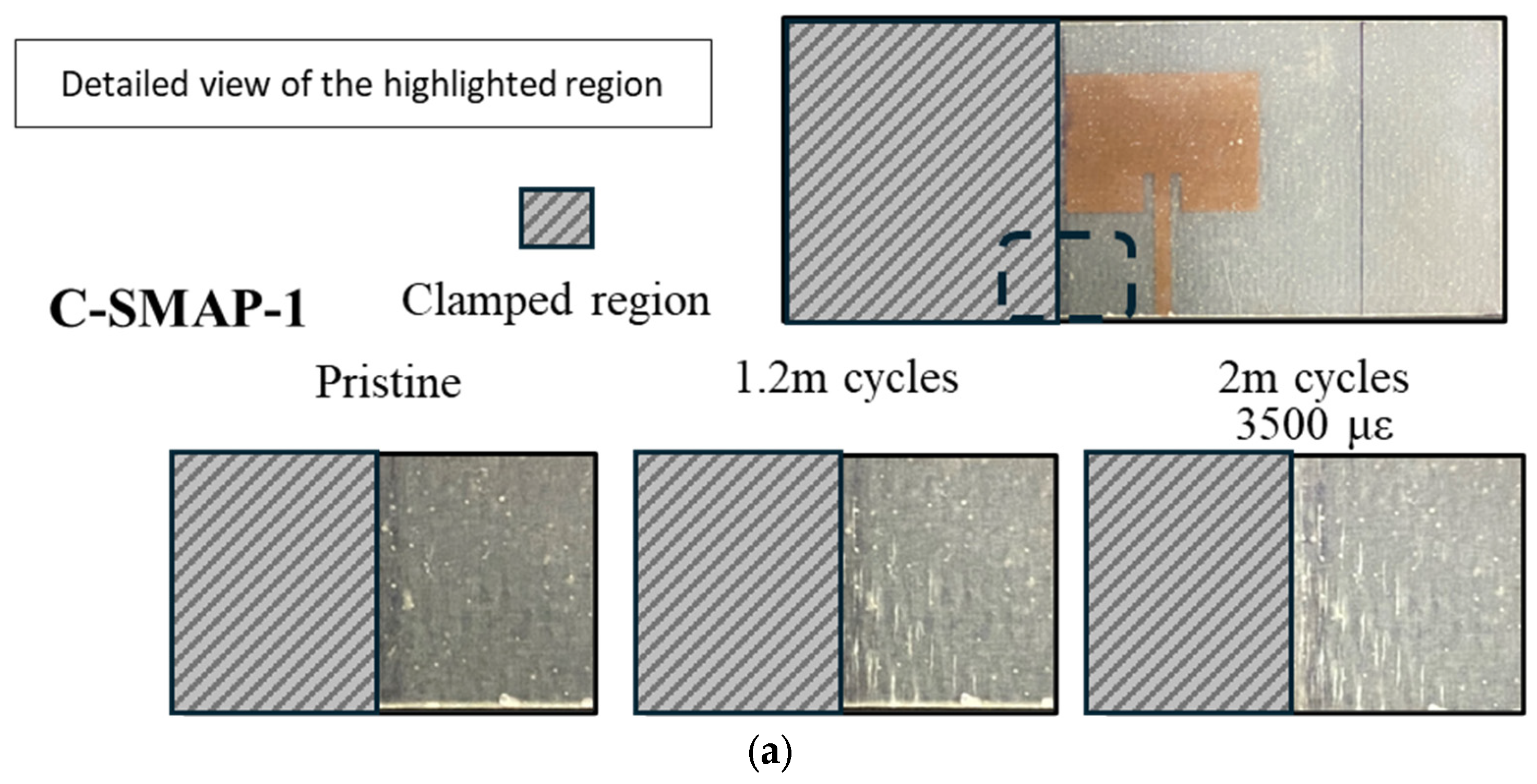

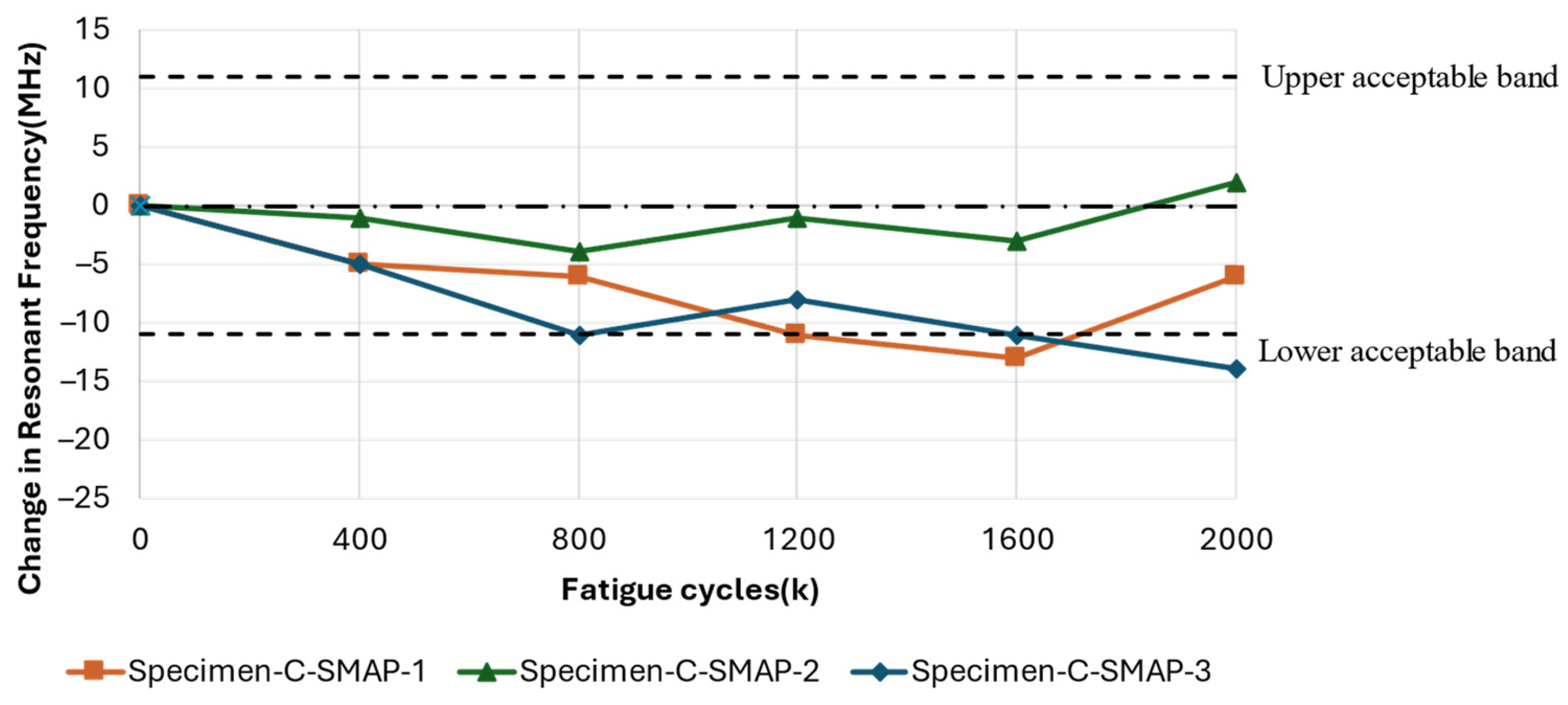

The results from Configuration C: SMAP, where the antenna was bonded to the substrate, exhibited complex behaviour. Resonant frequency shifts did not consistently correlate with the severity of substrate damage due to competing effects. This interaction led to unexpected trends, such as the most significant frequency decrease being observed in C-SMAP-3 (−14 MHz), despite showing the least visible damage. Conversely, C-SMAP-2, which exhibited considerable whitening damage near the clamping region, demonstrated minimal frequency change, remaining close to the 0 MHz line. As fatigue cycles extended to 2 million, the interplay between substrate damage and antenna elongation became increasingly apparent. In C-SMAP-1, the resonant frequency initially decreased due to substrate damage but subsequently increased as the mechanical effects on the antenna patch began to dominate, ultimately recovering within the acceptable bandwidth.

The differing resonant responses between RAP and SMAP configurations highlight the competing effects of substrate damage and antenna patch elongation. Understanding this interplay is critical for accurately assessing the overall performance of the CLAS under localised fatigue induced by operational loads.

4.3. Comparing CLAS with [±45]6 GFRP

The dielectric properties of GFRP under mechanical loading varied with fibre orientations, as illustrated in

Figure 5 and

Figure 6. Compared with our previous work presented in [

15], where we reported on a similar set of experiments with a 6-ply [±45] layout, we observed notable differences in the results of quasi-static tensile tests. However, the outcomes under cyclic fatigue loading were comparable between the GFRP specimens prepared with the two different ply configurations.

Under significant elongation from quasi-static tensile loading, the resonant frequency of the specimen prepared by [0/90] GFRP was reported to decrease with increasing residual strain. In contrast, for [±45] GFRP, the frequency initially decreased, then increased, and eventually shifted out of the operational bandwidth. These two distinct trends can be attributed to differences in how permittivity responds to mechanical loading at different fibre orientations of GFRP, highlighting a common underlying mechanism: under conditions of significant elongation, the substrate’s determining factor for resonant frequency shifts is the permittivity.

We attribute this difference in dielectric response to the extensive damage accumulated in the matrix material for [±45] GFRP. In contrast, for [0/90] GFRP substrate, the applied loading is taken predominantly by the fibre, and the specimen will not elongate as much as that in [

15]. It is interesting to note that the limited matrix deformation reduced the resonant frequency of the CLAS. This observation underscores the influence of the substrate’s dielectric properties, which are directly impacted by damage accumulation. When the substrate alone was subjected to cyclic loading (Configuration B: RAP), both [0/90] and [±45] GFRP displayed a similar response: a general decrease in resonant frequency. This behaviour was attributed to an increase in permittivity, which corresponded to the initial damage accumulation on the substrate, aligning with the previous literature [

10,

14,

16]. Furthermore, the results from specimens with Configuration C: SMAP for both types of GFRP revealed comparable fluctuations and a slight decreasing trend in frequency with increasing fatigue cycles. These consistent observations indicate that, during the initial stages of damage accumulation in the CLAS system, competing effects are present regardless of the substrate’s fibre configuration. The results presented in this paper and those in [

15] show that the parameters in Equation (1) must be accounted for when designing CLASs. The material response to the accumulation of damage, whether static or fatigue, and its corresponding impact on its relative permittivity must be considered to achieve a damage-tolerant CLAS.

These findings establish a clear relationship between damage progression sustained by the CLAS system and the resonant frequency shifts in the CLAS. These results offer critical insights into the effects of quasi-static tension and cyclic fatigue loading on CLAS performance, underscoring the importance of a good understanding of the material behaviour and the effects of mechanical loading on the physical dimensions. The presented results set the foundation for interpreting future experimental data and enhance the understanding needed to predict these structures’ service life and reliability.

Building on these findings, future research should explore the competing effects of mechanical loading on the antenna patch and substrate and the potential impact of pre-existing defects and moisture exposure in the CLAS system. Such investigations could provide deeper insights into the interplay of these factors, further enhancing reliability predictions and supporting the development of robust designs for CLAS systems.

5. Conclusions

This study systematically investigated the effects of mechanical loading on the electromagnetic performance of the CLAS, with resonant frequency shifts serving as the primary performance indicator. The research examined two mechanical loading scenarios: quasi-static tensile testing and cyclic fatigue. The results demonstrate that substrate permittivity and mechanical deformation changes significantly impact CLAS’s resonant frequency.

In the quasi-static tests, the dominant influence of increased permittivity due to substrate damage resulted in a general decrease in resonant frequency. Variations in failure modes across specimens revealed the critical role of load distribution in determining performance. Cyclic fatigue tests further highlighted the interplay between substrate damage and antenna elongation. The RAP configuration isolates substrate effects and confirms a consistent correlation between the severity of substrate damage and frequency decrease. Conversely, the SMAP configuration exhibited complex behaviour, with competing effects of substrate damage and antenna elongation causing unexpected trends in resonant frequency shifts.

In addition, compared with [±45]6 GFRP, the CLAS with [0/90] GFRP predominantly bears loading through the fibres, resulting in less elongation. Differences in resonant behaviour underscore the need to fully account for all parameters in Equation (1), including material response to damage and its effect on relative permittivity, to design a damage-tolerant CLAS.

These findings establish a fundamental understanding of the relationship between damage progression sustained by the CLAS system and its performance under mechanical loading. The research underscores the importance of understanding the competing factors to ensure CLAS’s reliability and service life in aerostructures. This research provides a solid foundation for future experimental investigations and offers insights critical to advancing CLAS technology for practical applications.