Crack Detection in Metallic Structures Using Planar Monopole Antenna

Highlights

- A monopole antenna is established as a crack sensor for Structural Health Monitoring (SHM) applications.

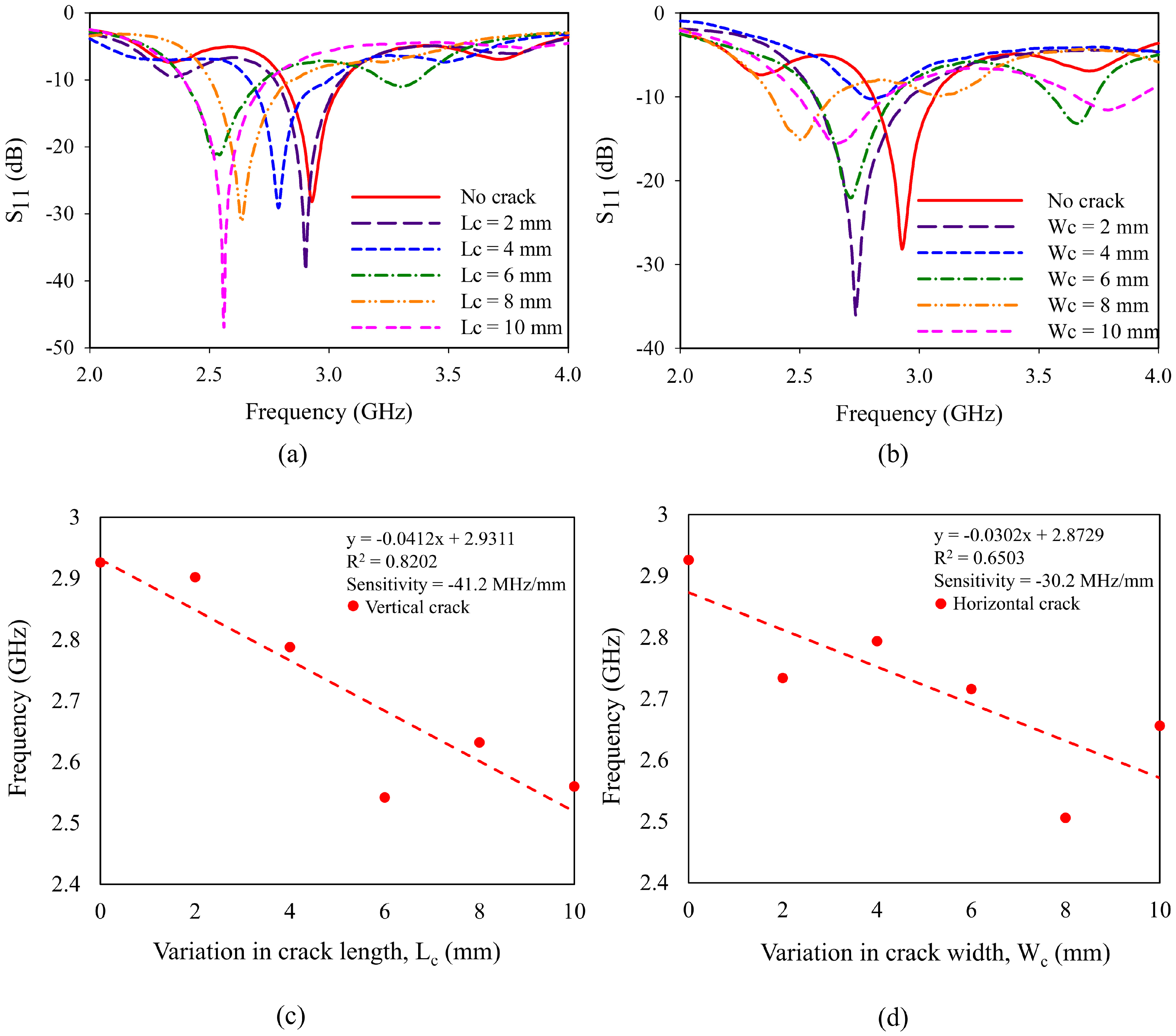

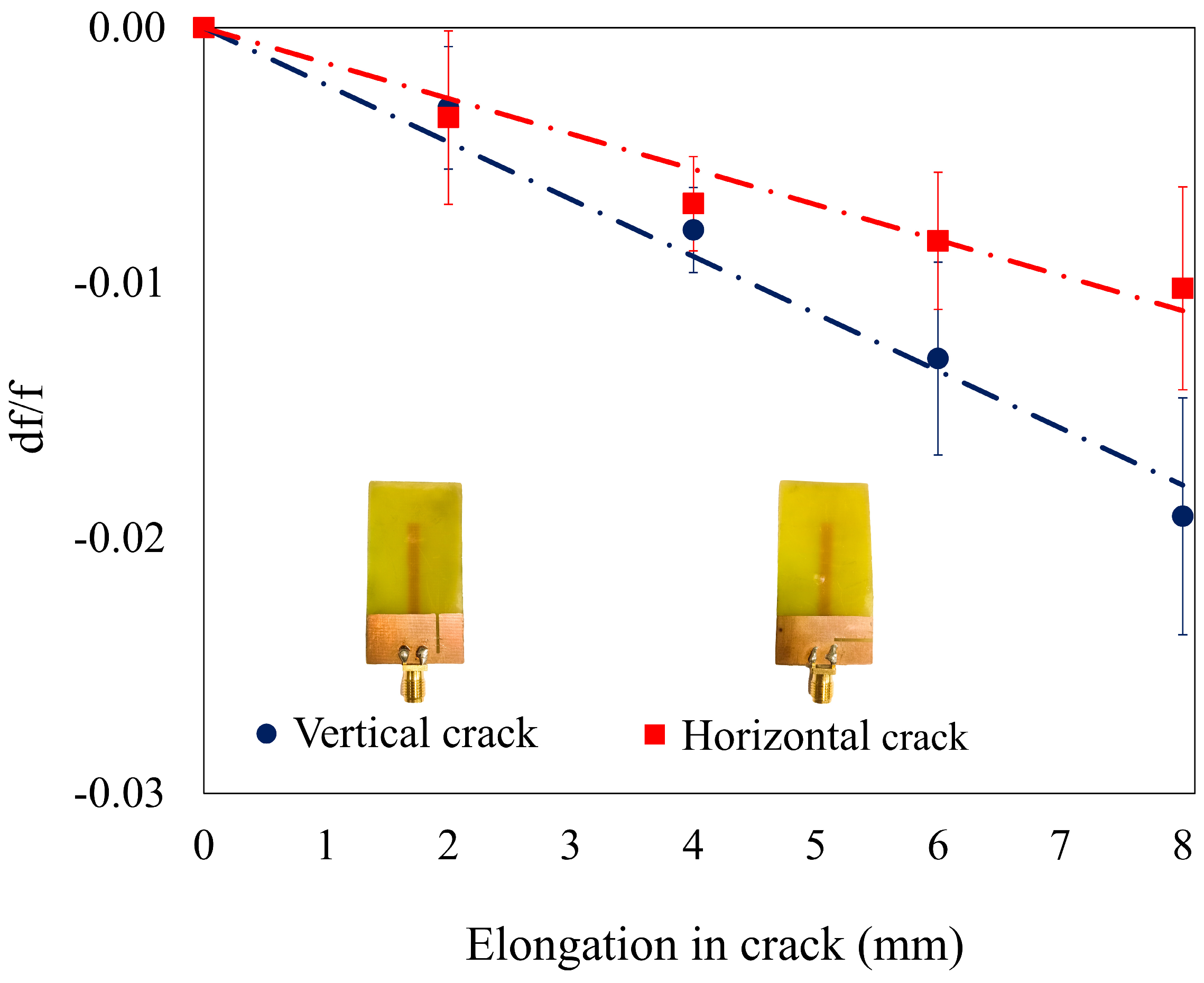

- Distinguishable sensitivities of −41.2 MHz/mm and −30.2 MHz/mm are observed along the crack propagation directions (X and Y) on the ground plane.

- The proposed sensor can be attached to planar metallic surfaces to monitor the health condition of the structure.

- Among the other Radio Frequency (RF) sensors, the proposed monopole antenna sensor is unique due to its higher sensitivity, compactness and ease of fabrication.

Abstract

1. Introduction

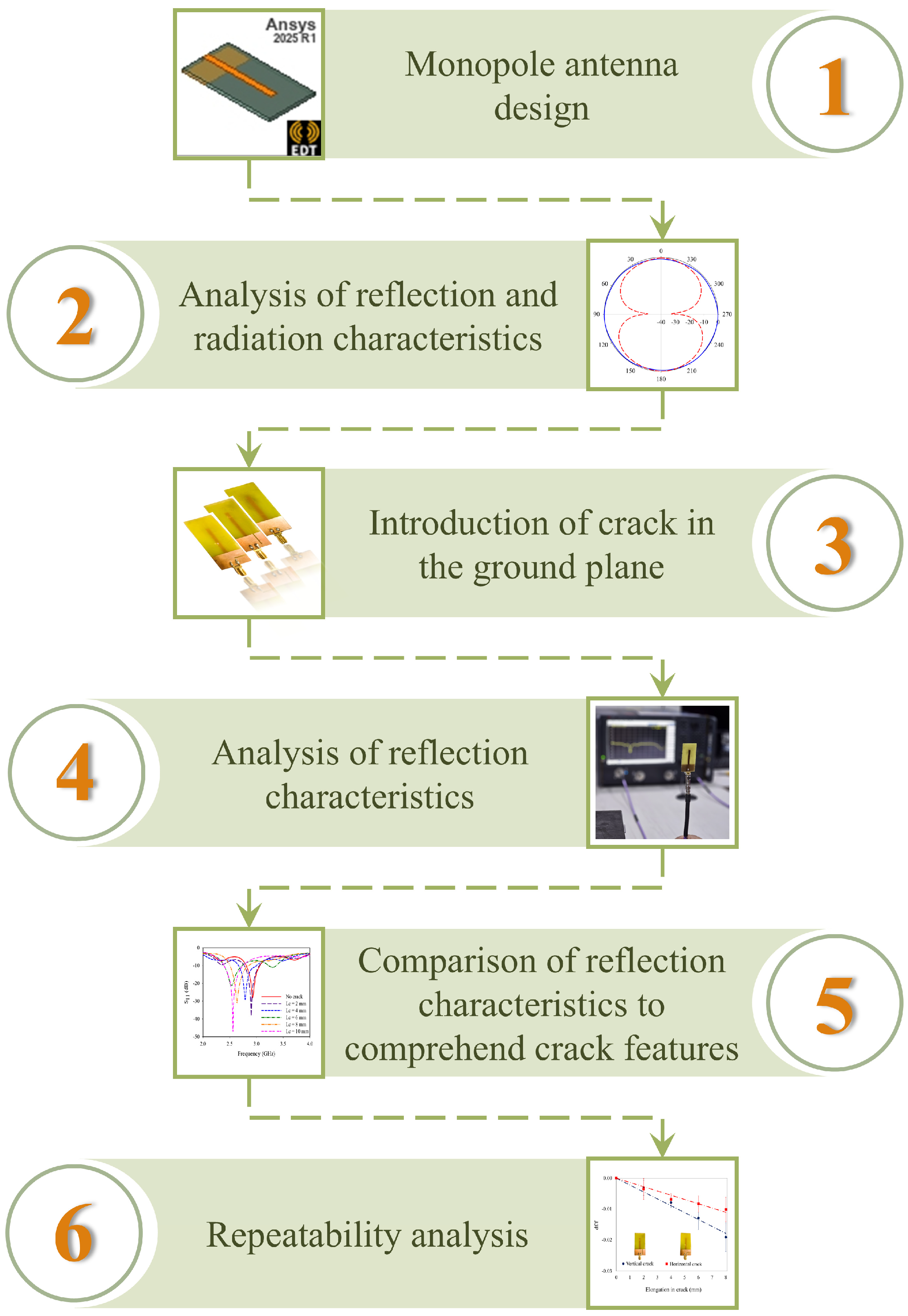

2. Methodology

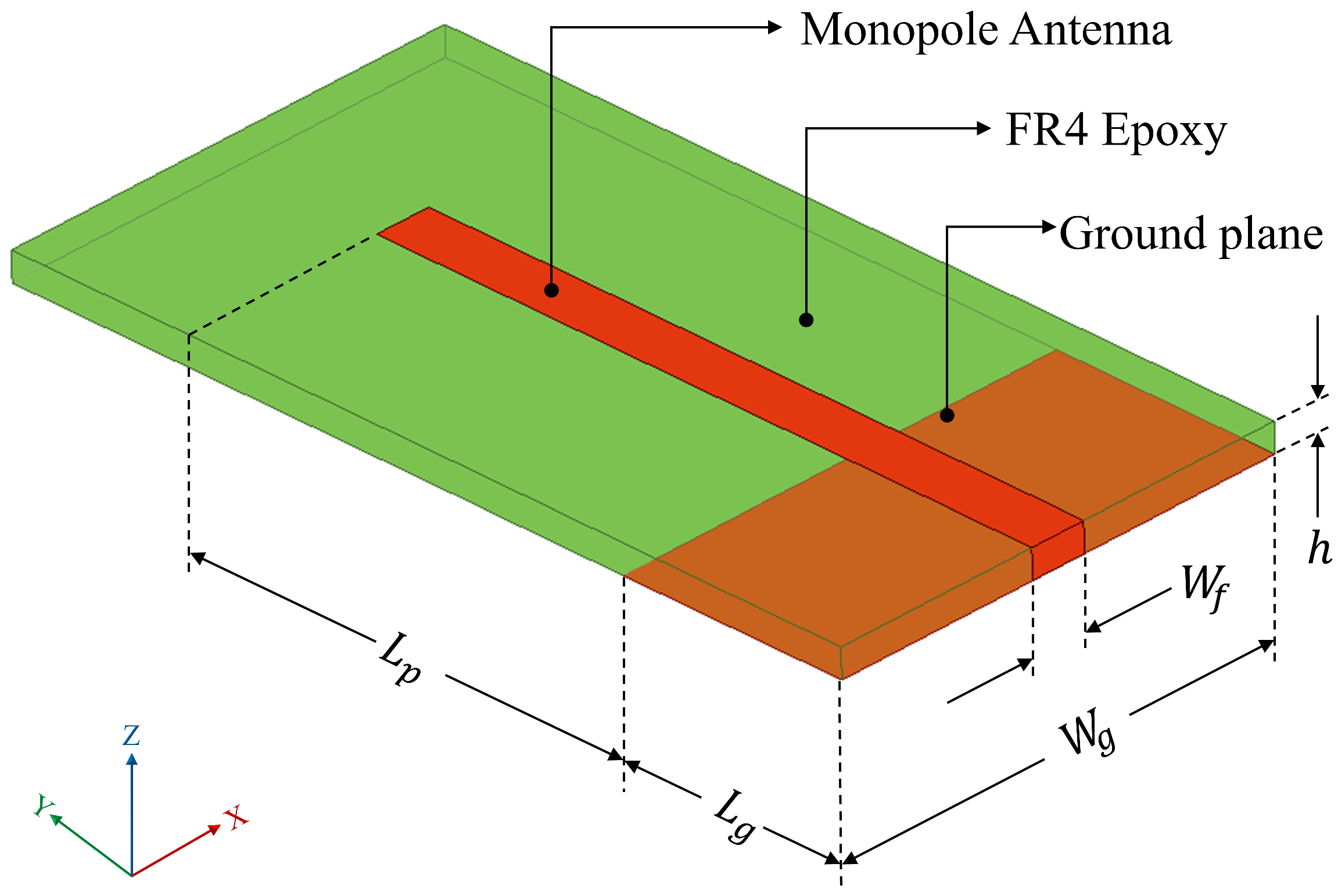

3. Antenna Design

3.1. Analytical Design

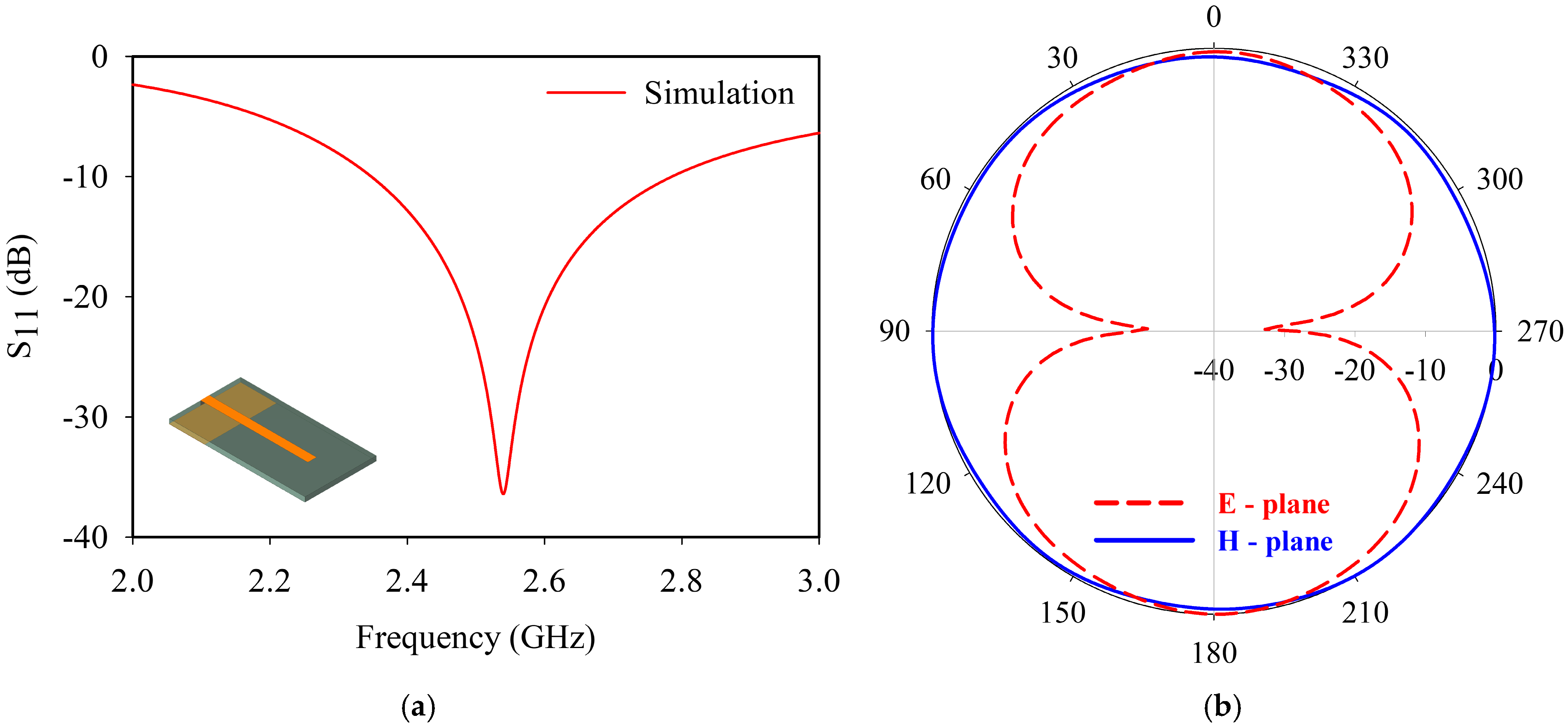

3.2. Numerical Simulation Using Finite Element Analysis (FEA)

4. Analysis of Monopole Antenna as Sensor

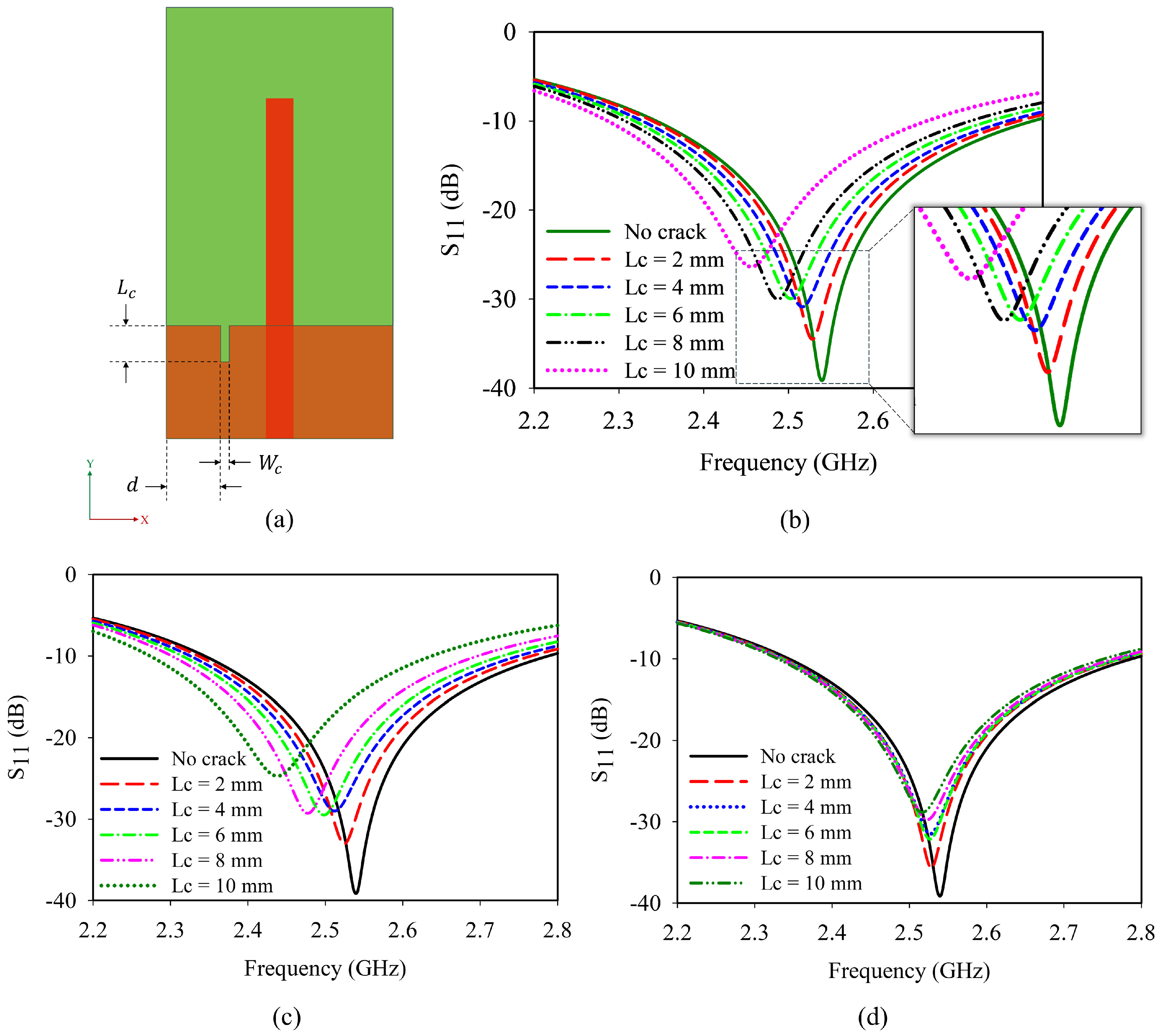

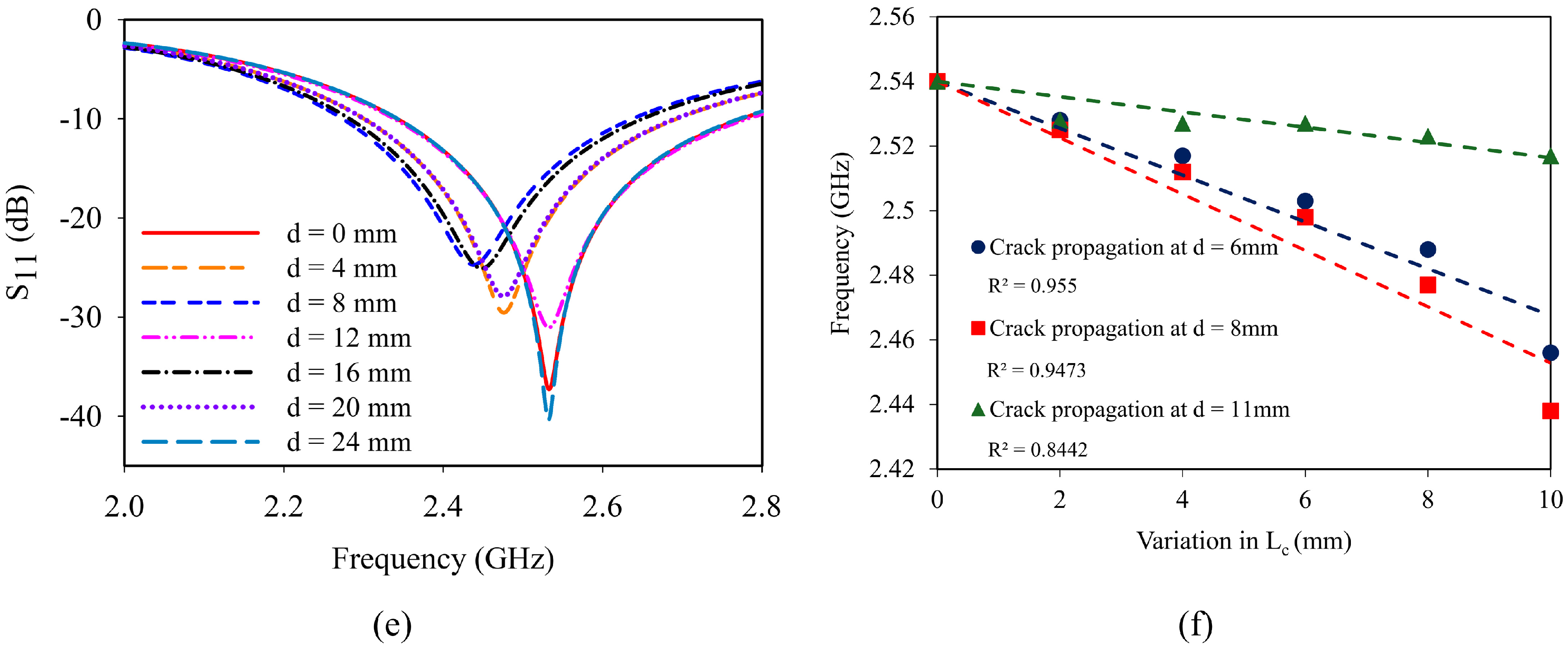

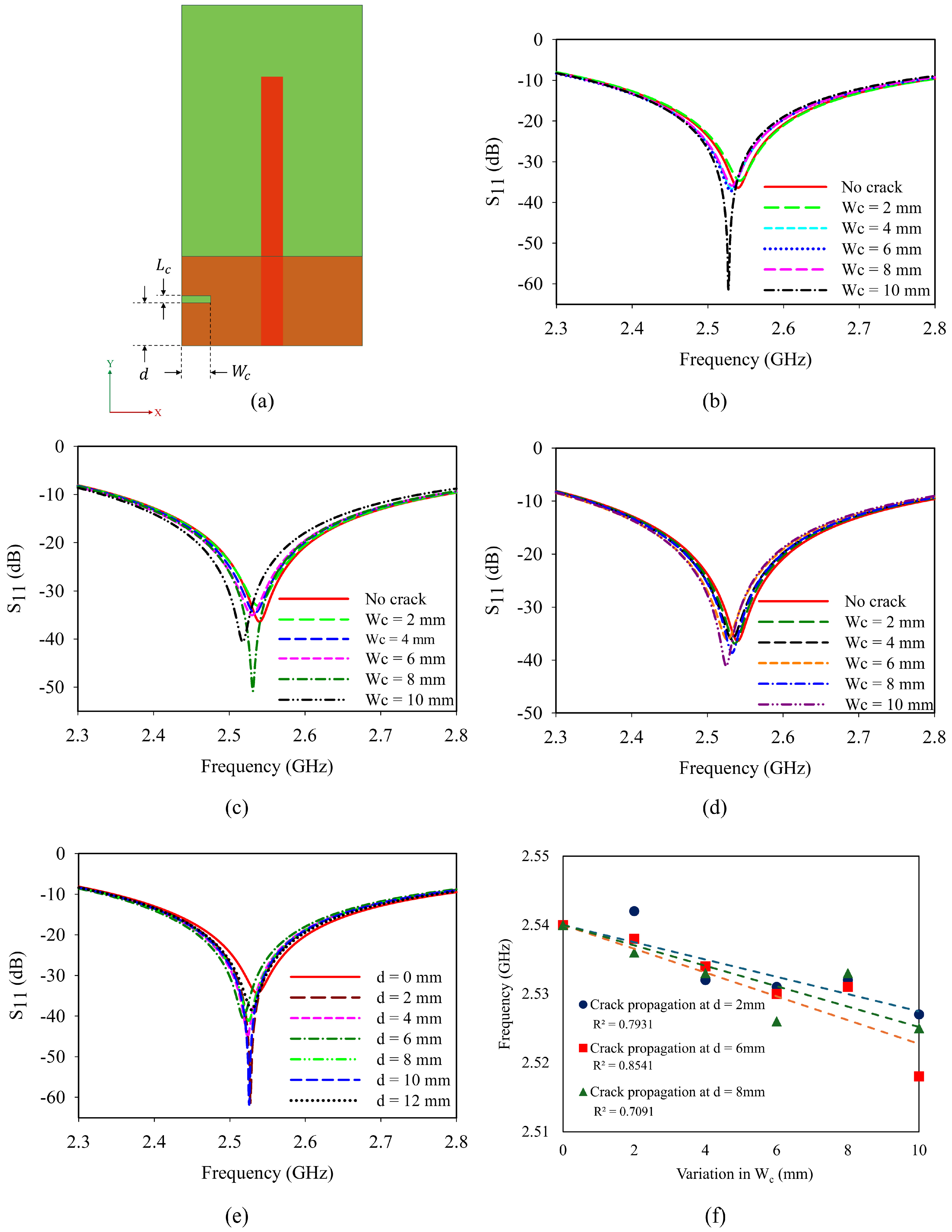

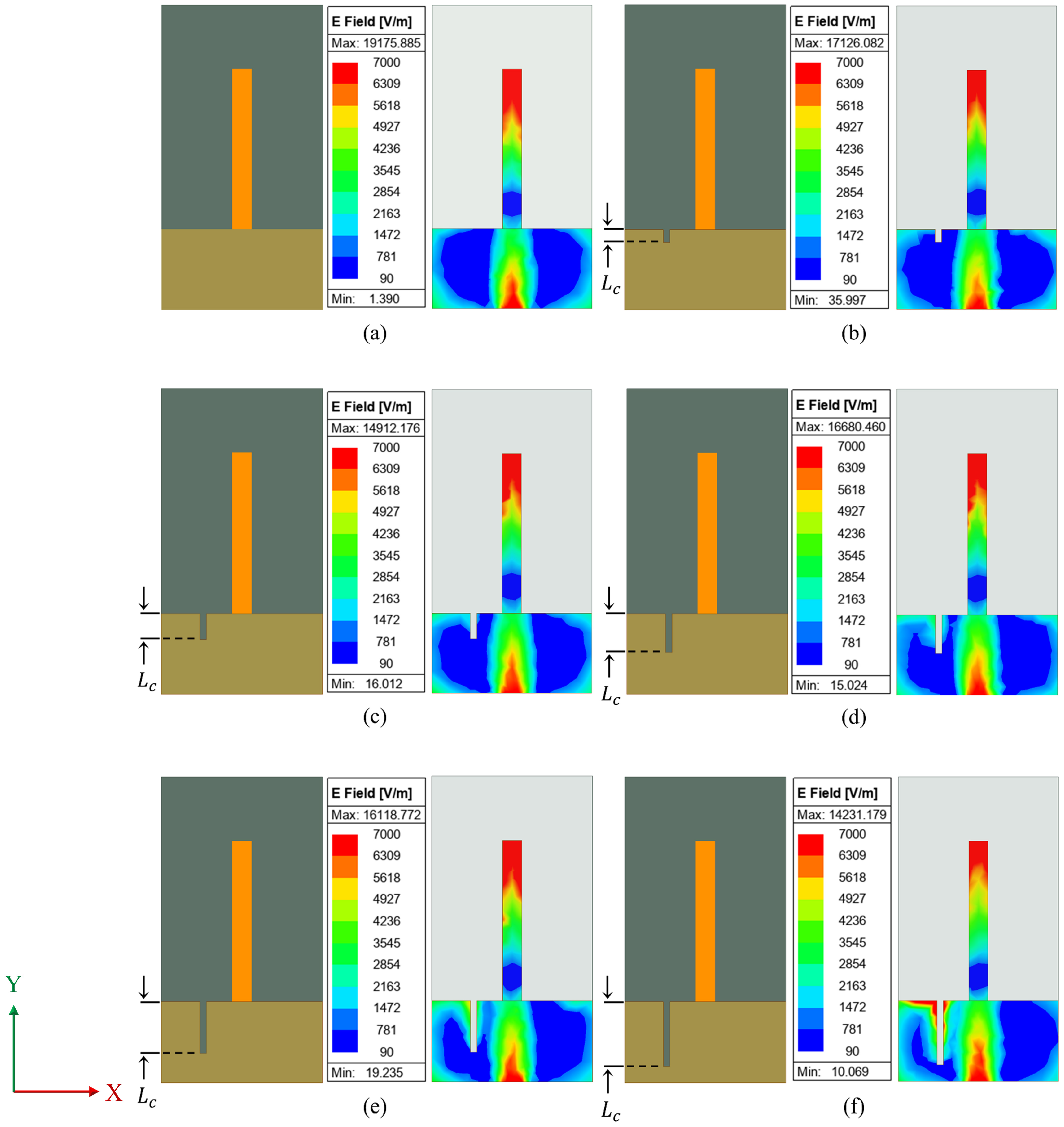

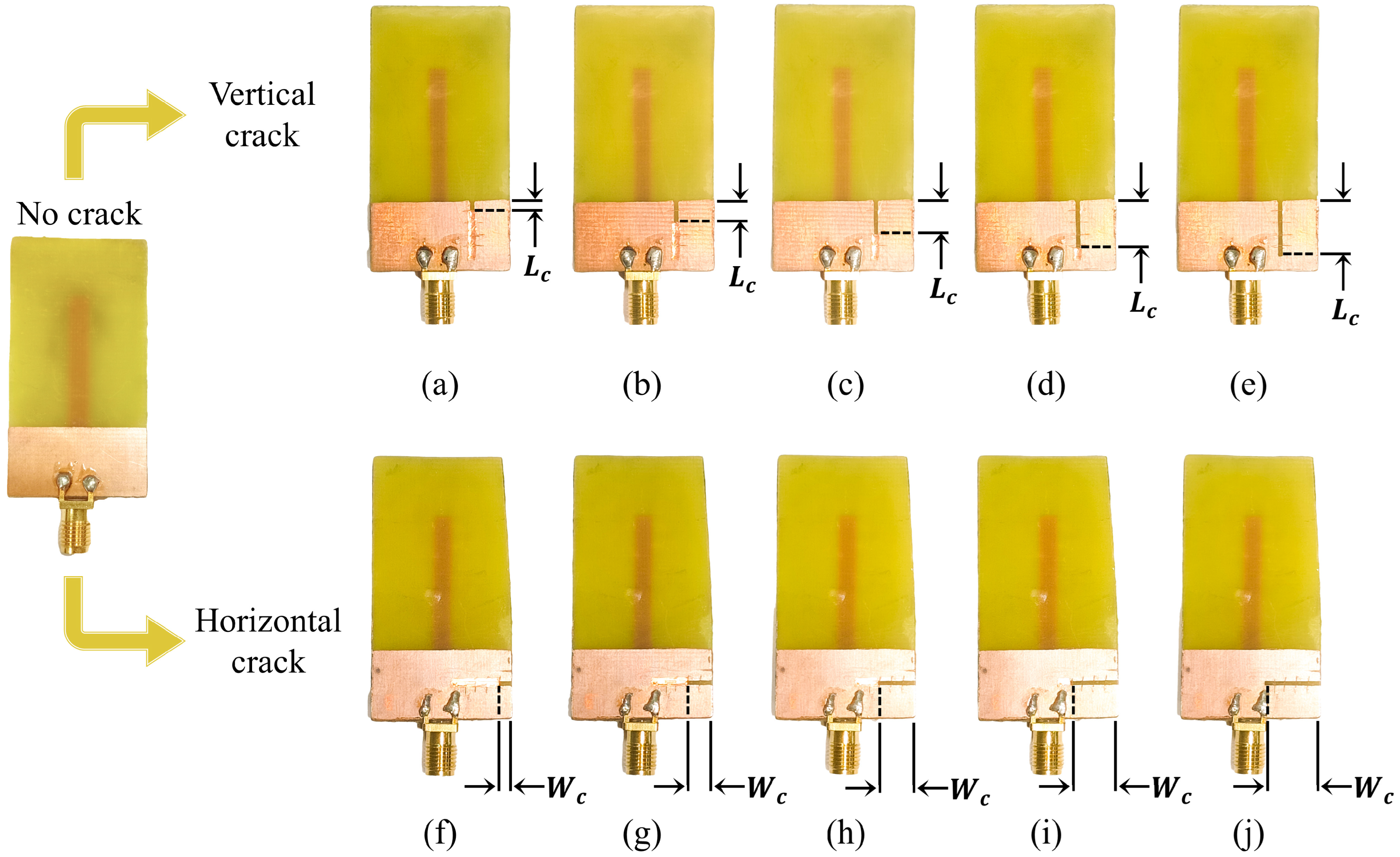

4.1. Variation in Crack Propagation in Longitudinal (Y) Direction

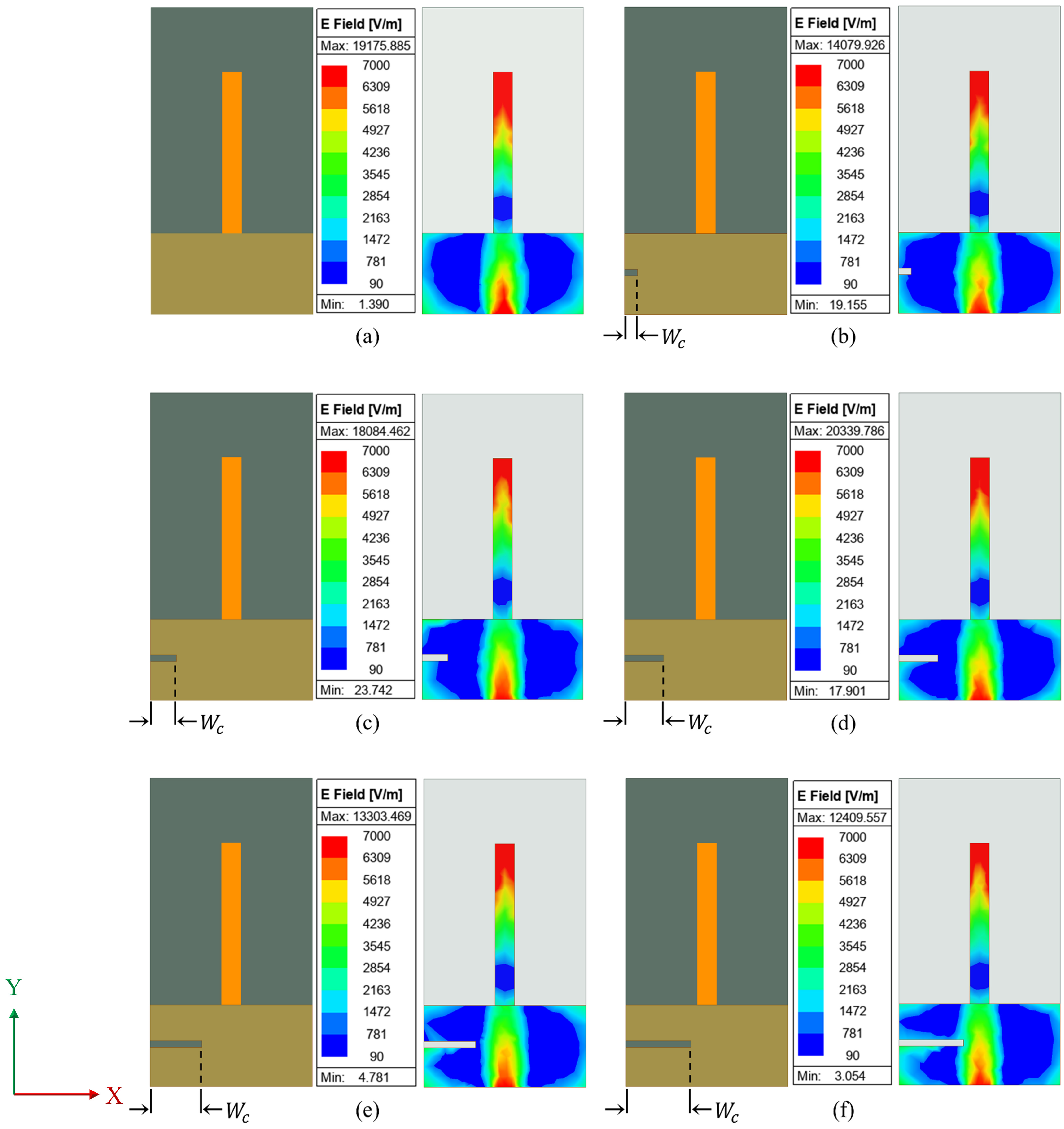

4.2. Variation in Crack Propagation in Transverse (X) Direction

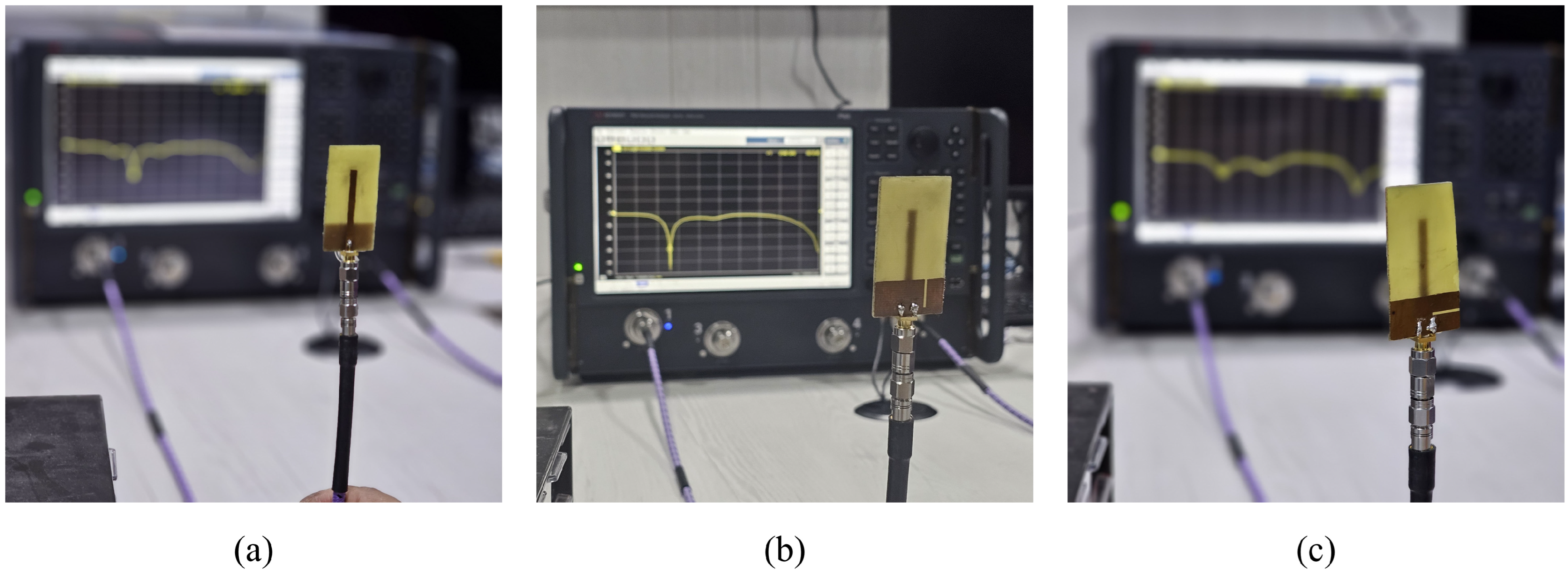

5. Experimental Assessment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, G.; Wang, Q.-A.; Jiao, G.; Dang, P.; Nie, G.; Liu, Z.; Sun, J. Review of Wireless RFID Strain Sensing Technology in Structural Health Monitoring. Sensors 2023, 23, 6925. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Li, M.; Guo, Q. Temperature Self-Compensation Method for Crack Length Measurement Based on a Microstrip Antenna Sensor. IEEE Sens. J. 2022, 22, 16036–16045. [Google Scholar] [CrossRef]

- Xiao, F.; Mao, Y.; Tian, G.; Chen, G.S. Partial-model-based Damage Identification of Long-span Steel Truss Bridge Based on Stiffness Separation Method. Struct. Control Health Monit. 2024, 2024, 5530300. [Google Scholar] [CrossRef]

- Shen, Z.; Luo, F.; Qin, Q.; Guo, L. The Metamaterial Sensors for Multi-Parameter Measurement in Structural Health Monitoring. Measurement 2025, 245, 116652. [Google Scholar] [CrossRef]

- Nair, B.; Praveen, A.P.; Gil, I.; Hariprasad, M.P.; Menon, S.K. Adaptable Gauge Length Extensometer Using Coplanar Waveguide Fed Extended Monopole Antenna. IEEE Sens. J. 2025, 25, 21229–21237. [Google Scholar] [CrossRef]

- Tang, L.; Xie, F.; Li, Q. A Phase Shift-Based and Quadrant-Distinguishable Passive Microstrip Antenna Sensor for Metal Crack Detection. IEEE Sens. J. 2024, 24, 7796–7806. [Google Scholar] [CrossRef]

- Guo, S.; Yu, M.; Xu, Z.; Yue, G.; Cai, W.; Tian, P. Study on the Attribute Characteristics of Road Cracks Detected by Ground-Penetrating Radar. Sensors 2025, 25, 595. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, Q.; Li, J.; Deng, L.; Zhou, T.; Li, Y.; Yin, B.; Jiang, G.; Yang, Y.; Wu, J. Nondestructive Detection on Defects of High-Voltage Polymeric Insulators with a RF/Microwave Patch Antenna. Sens. Actuators A Phys. 2025, 387, 116366. [Google Scholar] [CrossRef]

- Tang, F.; Zhao, L.; Tian, H.; Li, H.-N.; Li, H. Localization and Monitoring of Initiation and Propagation of Corrosion-Induced Mortar Cracking Based on OFDR Distributed Optical Fiber Sensor. J. Intell. Mater. Syst. Struct. 2021, 32, 1948–1965. [Google Scholar] [CrossRef]

- Ghaderiaram, A.; Schlangen, E.; Fotouhi, M. Structural Fatigue Life Monitoring with Piezoelectric-Based Sensors: Fundamentals, Current Advances, and Future Directions. Sensors 2025, 25, 334. [Google Scholar] [CrossRef]

- Hai, T.T.; Hang, P.T.; Khiem, N.T. A Novel Criterion for Crack Identification in Beam-like Structures Using Distributed Piezoelectric Sensor and Controlled Moving Load. J. Sound. Vib. 2024, 572, 118155. [Google Scholar] [CrossRef]

- Pasadas, D.J.; Barzegar, M.; Ribeiro, A.L.; Ramos, H.G. Crack Depth Evaluation and Imaging Using Lamb Wavefield Measurements by a Movable PZT Sensor. IEEE Sens. J. 2024, 24, 37514–37523. [Google Scholar] [CrossRef]

- He, Y.; Li, M.M.; Wan, G.C.; Tong, M.S. A Passive and Wireless Sensor Based on RFID Antenna for Detecting Mechanical Deformation. IEEE Open J. Antennas Propag. 2020, 1, 426–434. [Google Scholar] [CrossRef]

- Suresh, S.; Chakaravarthi, G. A Novel Passive Wireless RFID Sensor for Localized Surface Crack Characterization on Metals. Measurement 2024, 231, 114651. [Google Scholar] [CrossRef]

- Dey, S.; Kalansuriya, P.; Karmakar, N.C. Novel Chipless RFID High Resolution Crack Sensor Based on SWB Technology. IEEE Sens. J. 2020, 21, 2908–2920. [Google Scholar] [CrossRef]

- Li, X.; Xue, S.; Xie, L.; Wan, G. A Miniaturized Passive Wireless Patch Antenna Sensor for Structural Crack Sensing. Struct. Health Monit. 2024, 23, 3276–3295. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Han, L.; Chen, X.; Han, G.; Yang, R. Chipless RFID Sensor Detecting the Angle and Width of Crack in the Metal With High Sensitivity. IEEE Trans. Instrum. Meas. 2025, 74, 3545988. [Google Scholar] [CrossRef]

- Kang, L.; Chen, L.; Liu, L.; Wan, Z.; Wan, G.; Xie, L. Characteristics Analysis of RFID Multiparameter Sensor Tags Based on Various Substrate Materials. IEEE Sens. J. 2022, 23, 1875–1884. [Google Scholar] [CrossRef]

- Praveen, A.P.; Menon, S.K.; Babu, J.S.; Donelli, M.; Hariprasad, M.P. An Auxetic Based Geometric Tuning Approach in Microwave Sensors for Enhanced Sensitivity in Strain Measurements. Measurement 2025, 253, 117826. [Google Scholar] [CrossRef]

- Menon, S.K.; Donelli, M. L-Shaped Coplanar Strip Dipole Antenna Sensor for Adulteration Detection. Sensors 2025, 25, 506. [Google Scholar] [CrossRef]

- Abbasi, Z.; Niazi, H.; Abdolrazzaghi, M.; Chen, W.; Daneshmand, M. Monitoring PH Level Using High-Resolution Microwave Sensor for Mitigation of Stress Corrosion Cracking in Steel Pipelines. IEEE Sens. J. 2020, 20, 7033–7043. [Google Scholar] [CrossRef]

- Yee, T.S.; Shrifan, N.H.M.M.; Al-Gburi, A.J.A.; Isa, N.A.M.; Akbar, M.F. Prospect of Using Machine Learning-Based Microwave Nondestructive Testing Technique for Corrosion under Insulation: A Review. IEEE Access 2022, 10, 88191–88210. [Google Scholar] [CrossRef]

- Li, X.; Xue, S.; Xie, L.; Wan, G. Simultaneous Crack and Temperature Sensing with Passive Patch Antenna. Struct. Health Monit. 2024, 23, 1299–1312. [Google Scholar] [CrossRef]

- Chen, N.-W.; Chen, C.-Y.; Guo, R.-R. Stub-Loaded Patch Antenna for Development of High Sensitivity Crack Monitoring Sensor. IEEE J. Sel. Areas Sens. 2024, 1, 29–35. [Google Scholar] [CrossRef]

- Tong, C.; Song, R.; Guan, H.; Yang, Y.; He, D. Conformal Metal Crack Detection Sensor Based on Flexible Graphene Film Antenna. Int. J. RF Microw. Comput. Aided Eng. 2022, 32, e23172. [Google Scholar] [CrossRef]

- Pang, Q.; Dong, G.; Yang, X. Metal Crack Detection Sensor Based on Microstrip Antenna. IEEE Sens. J. 2023, 23, 8375–8384. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y. Thermally Stable Wireless Patch Antenna Sensor for Strain and Crack Sensing. Sensors 2020, 20, 3835. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Gao, Y.; Tan, J.; Xuan, F.; Ling, X. Flexible Multimode Antenna Sensor with Strain and Humidity Sensing Capability for Structural Health Monitoring. Sens. Actuators A Phys. 2022, 347, 113960. [Google Scholar] [CrossRef]

- Menon, A.K.; Abhinav, C.B.; Menon, S.K.; Hariprasad, M.P. Investigation of an Open Loop Resonator for Crack Detection. Eng. Proc. 2025, 93, 6. [Google Scholar]

- Abou-Khousa, M.A.; Rahman, M.S.U.; Donnell, K.M.; Al Qaseer, M.T. Detection of Surface Cracks in Metals Using Microwave and Millimeter-Wave Nondestructive Testing Techniques—A Review. IEEE Trans. Instrum. Meas. 2023, 72, 8000918. [Google Scholar] [CrossRef]

- Balanis, C.A. Antenna Theory: Analysis and Design; John Wiley & Sons: Hoboken, NJ, USA, 2016; ISBN 1118642066. [Google Scholar]

- Paffi, A.; Carrasco, E.; Balzano, Q. Influence of the Mesh Size on the Computation of the Close Near Fields of Dipole Antennas. IEEE Open J. Antennas Propag. 2022, 3, 1234–1241. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, H.; Huang, C.; Zhang, B.; Li, Y.; Wang, K.; Su, D.; Tian, G.Y. A Configurable Dielectric Resonator-Based Passive Wireless Sensor for Crack Monitoring. IEEE Trans. Antennas Propag. 2019, 67, 5746–5749. [Google Scholar] [CrossRef]

- Ke, L.; Liu, Z.; Yu, H. Characterization of a Patch Antenna Sensor’s Resonant Frequency Response in Identifying the Notch-Shaped Cracks on Metal Structure. Sensors 2018, 19, 110. [Google Scholar] [CrossRef]

- Zhang, S.; Zhai, W.; Hou, D. Simulation of Metal Surface Crack Detection of RFID Tagantenna. In Proceedings of the Journal of Physics: Conference Series, Beijing, China, 16–17 December 2022; IOP Publishing: Bristol, UK, 2022; Volume 2395, p. 012036. [Google Scholar]

- Marindra, A.M.J.; Tian, G.Y. Chipless RFID Sensor Tag for Metal Crack Detection and Characterization. IEEE Trans. Microw. Theory Tech. 2018, 66, 2452–2462. [Google Scholar] [CrossRef]

| Parameters | Optimized Values (mm) |

|---|---|

| Length of the monopole, Lp | 25 |

| Length of the ground, Lg | 12.5 |

| Width of the ground, Wg | 25 |

| Width of the feedline, Wf | 3 |

| Height of the substrate, h | 1.6 |

| Properties | Values |

|---|---|

| Dielectric constant, (εr) | 4.4 |

| Loss tangent (tan δ) | 0.02 |

| Modulus of Elasticity, E (GPa) | 20.4 |

| Poisson’s ratio (ν) | 0.12 |

| Height of the substrate, h (mm) | 1.6 |

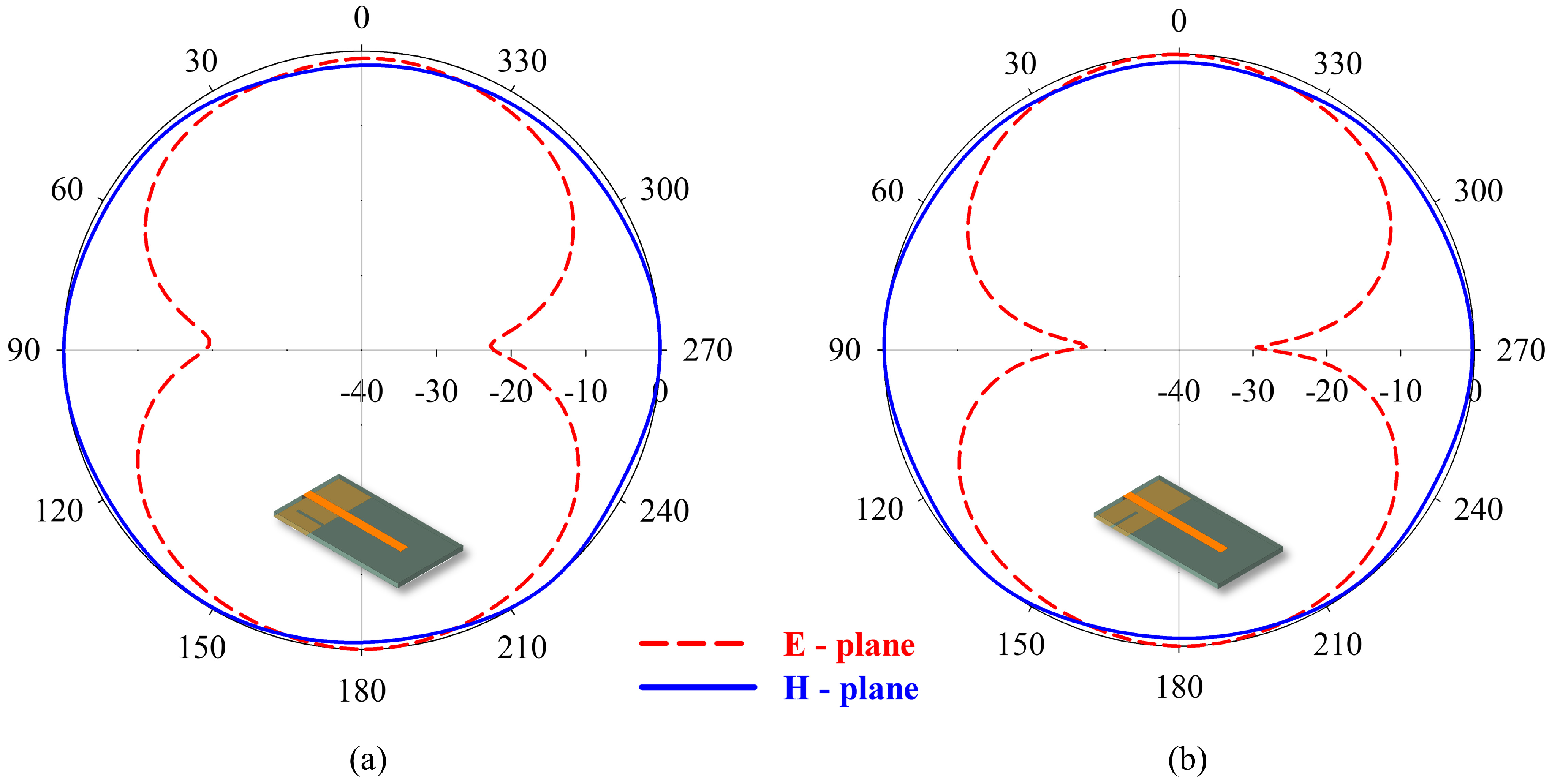

| Axis | Presence of Crack | Gain (dBi) | Bandwidth (MHz) |

|---|---|---|---|

| X-axis | No | 2.7 | 444 |

| Yes | 2.83 | 418 | |

| Y-axis | No | 2.7 | 444 |

| Yes | 2.73 | 378 |

| Sl. No. | Orientation of Crack | Lc/Wc (mm) | % Change in Frequency | |

|---|---|---|---|---|

| Simulation | Measurement | |||

| 1 | No crack | - | 0 | 0 |

| 2 | Y-axis | 2 | 0.47 | 0.82 |

| 4 | 0.90 | 4.71 | ||

| 6 | 1.45 | 13.12 | ||

| 8 | 3.62 | 10.05 | ||

| 10 | 3.26 | 12.5 | ||

| 3 | X-axis | 2 | 0.078 | 6.56 |

| 4 | 0.24 | 4.51 | ||

| 6 | 0.39 | 7.17 | ||

| 8 | 0.39 | 14.35 | ||

| 10 | 0.86 | 9.22 | ||

| Type of Sensor | Methodology | Substrate (εr) | Frequency (GHz) | Dimension (mm × mm × mm) | Sensitivity |

|---|---|---|---|---|---|

| [23] | Patch antenna | RT/duroid 5880 (2.2) | 1.95 GHz | - | 45.3 MHz/mm |

| [24] | Open stub in patch antenna | FR4 (4.4) | 4 GHz | - | - |

| [25] | Flexible antenna | Polyethylene terephthalate (3.5) | 2.25 GHz | 60 × 50 × 0.5 | 36.82 MHz/mm |

| 3.1 GHz | |||||

| [26] | Microstrip antenna | Rogers 4003c (3.38) | 2.8233 GHz | 90 × 35 × 1.524 | 7 MHz/mm |

| 3.4788 GHz | 4.7 MHz/mm | ||||

| [27] | Patch antenna | RT/duroid 6202 (2.90) | 900 MHz | 62 × 119.1 × 0.762 | - |

| [29] | Open-loop resonator | FR4 (4.4) | 2.5 GHz | 19.8 × 19.2 × 1.6 | 36–39 MHz/mm |

| [33] | Cylindrical dielectric resonator | Ceramic (90) | 1.318 GHz | 24.0 (diameter) × 9.0 (height) | 25.4 MHz/mm |

| [34] | Patch antenna sensor | FR4 (4.4) | 1.8 GHz | 64 × 44 × 0.6 | - |

| 2.5 GHz | |||||

| [14] | Circular patch RFID antenna sensor | Rogers RO4350b (3.66) | 902–928 MHz | 50.0 (diameter) × 1.524 | 1.08 MHz/mm2 |

| [35] | Microstrip RFID tag antenna | FR4 (4.4) | 925 MHz | 80 × 84 × 1.5 | - |

| [36] | Circular microstrip patch antenna | Taconic CER-10-0500 (10) | 4.70 GHz | 35 × 15 × 1.27 | −13.43 MHz/0.1 mm |

| 6.67 MHz/0.1 mm | |||||

| Present work | Monopole antenna | FR4 (4.4) | 2.5 GHz | 47.5 × 25 × 1.6 | −41.2 MHz/mm −30.2 MHz/mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radhakrishnan, N.; Donelli, M.; Menon, S.K. Crack Detection in Metallic Structures Using Planar Monopole Antenna. Sensors 2025, 25, 7150. https://doi.org/10.3390/s25237150

Radhakrishnan N, Donelli M, Menon SK. Crack Detection in Metallic Structures Using Planar Monopole Antenna. Sensors. 2025; 25(23):7150. https://doi.org/10.3390/s25237150

Chicago/Turabian StyleRadhakrishnan, Nandana, Massimo Donelli, and Sreedevi K. Menon. 2025. "Crack Detection in Metallic Structures Using Planar Monopole Antenna" Sensors 25, no. 23: 7150. https://doi.org/10.3390/s25237150

APA StyleRadhakrishnan, N., Donelli, M., & Menon, S. K. (2025). Crack Detection in Metallic Structures Using Planar Monopole Antenna. Sensors, 25(23), 7150. https://doi.org/10.3390/s25237150