Pilot Study of Stretch Film for Securing Palletized Loads

Abstract

1. Introduction

1.1. Objectives

- Fs: static stabilizing force (N) acting perpendicular to the crate wall during wrapping;

- Fd: dynamic stabilizing force (N) measured during incremental deflection;

- Disk diameter = 150 mm, area = 0.0177 m2, forces projected per linear meter of film contact;

- Force projection: measured normal to the crate wall; equivalent film tension calculated as F/(width × contact perimeter).

- Force band equivalence: resulting linear load expressed as N m−1 of film contact.

1.2. Literature Review

- Transport safety in relation to load stability;

- Legal regulations concerning load stability;

- Practical studies and experimental methodologies;

- Theoretical aspects of load stability based on the characteristics and arrangement of packaging within the unit;

- Mechanical properties of the pallet unit, depending on its application;

- Load stability resulting from the applied solutions and use of packaging materials.

- Global manufacturers of stability testing equipment: Best Packing [7], ESTL [8], Lantech [9,10], Safe Load Testing Technologies [11], Lindum Packaging [12], Atlantic Packaging [13], Rocked Industrial, Plastanalisi [14], Impact Solutions [15], Testpolymer EU s.r.o. [16], EKOBAL [17], Manupackaging [18], OMPG [19];

2. Materials and Methods

2.1. Research Ideas

2.1.1. Cargo Safety and Experimental Context

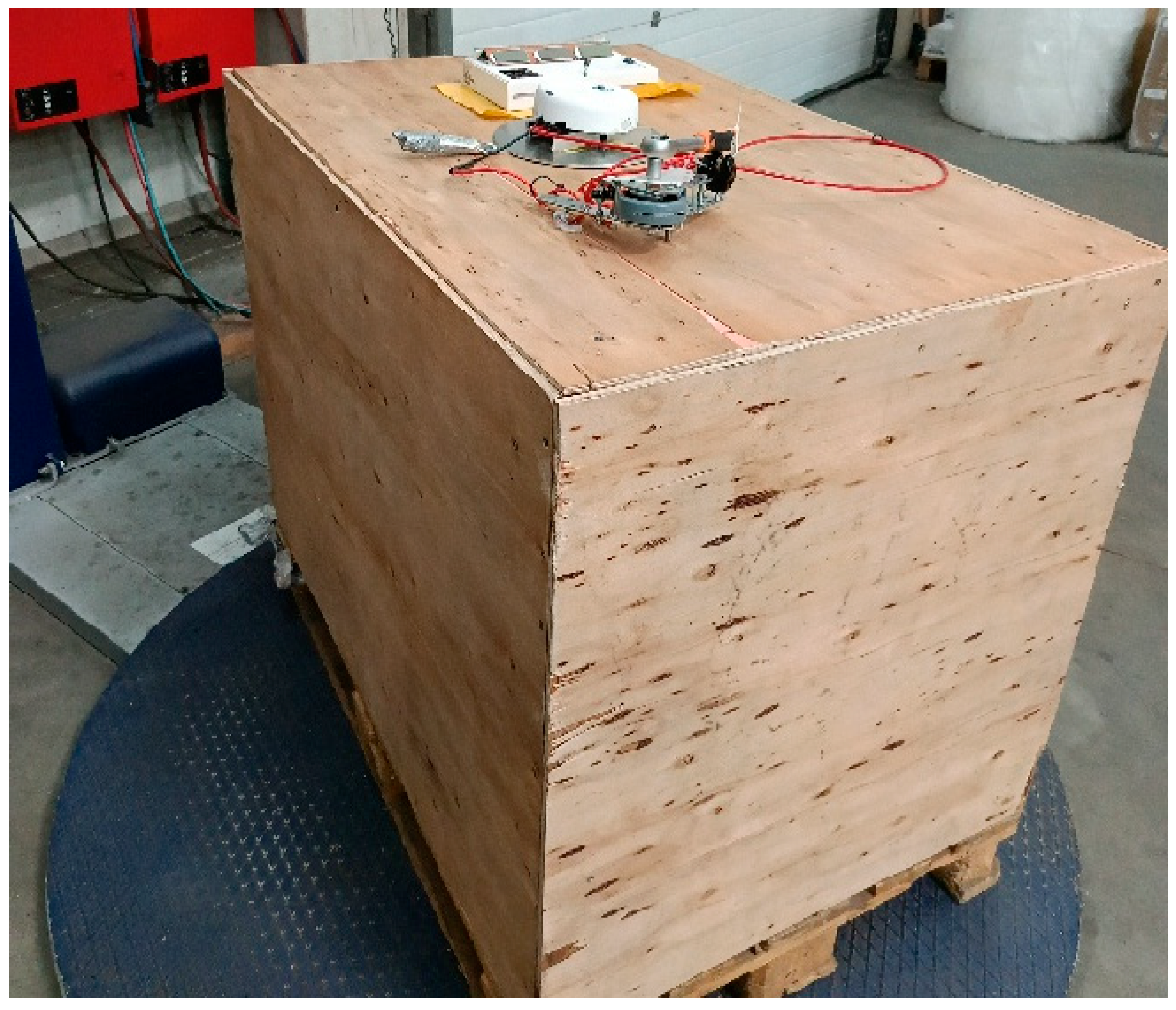

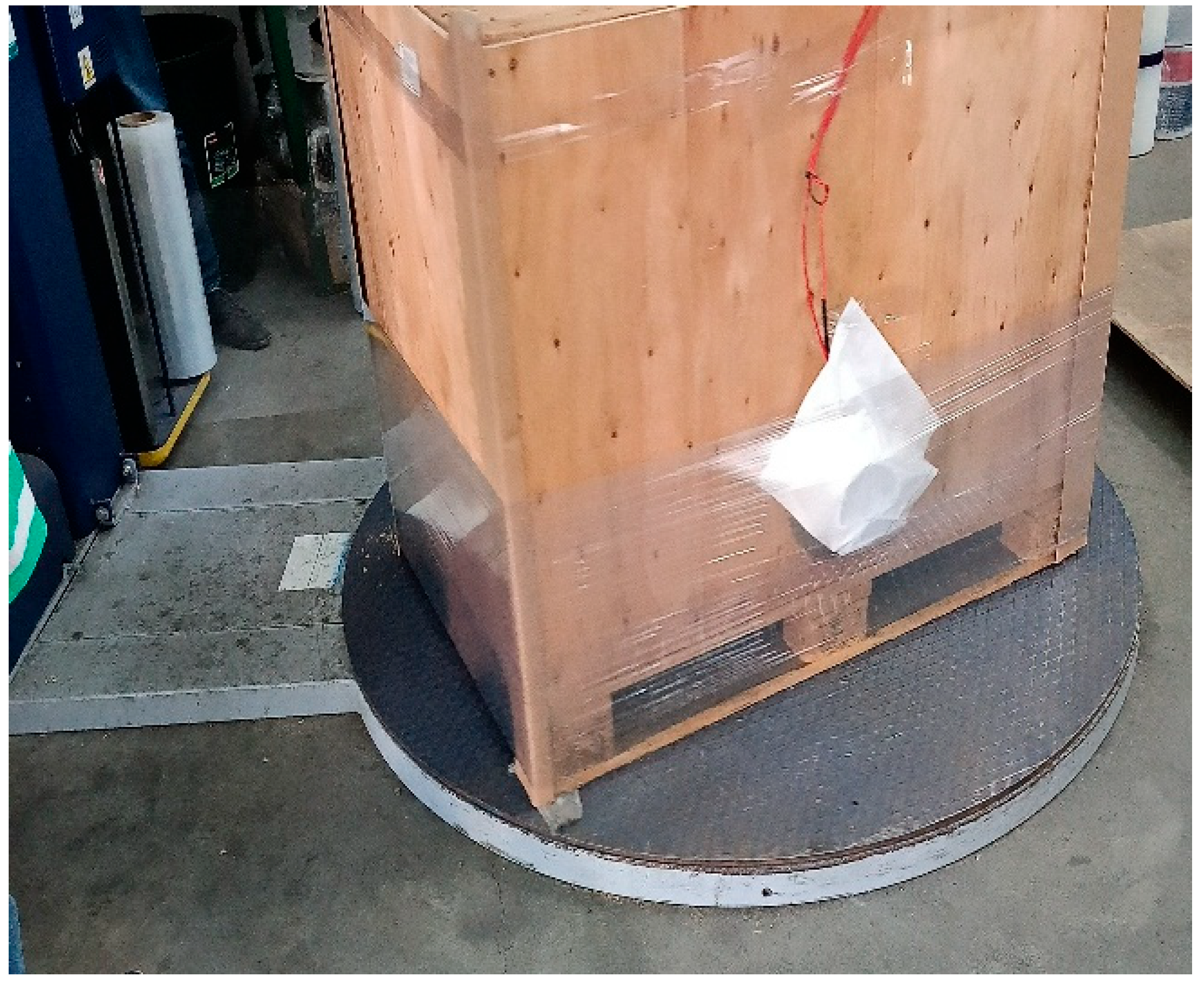

2.1.2. Test Stand and Apparatus

2.1.3. Stretch Films Tested

2.1.4. Experimental Procedure

2.1.5. Data Analysis

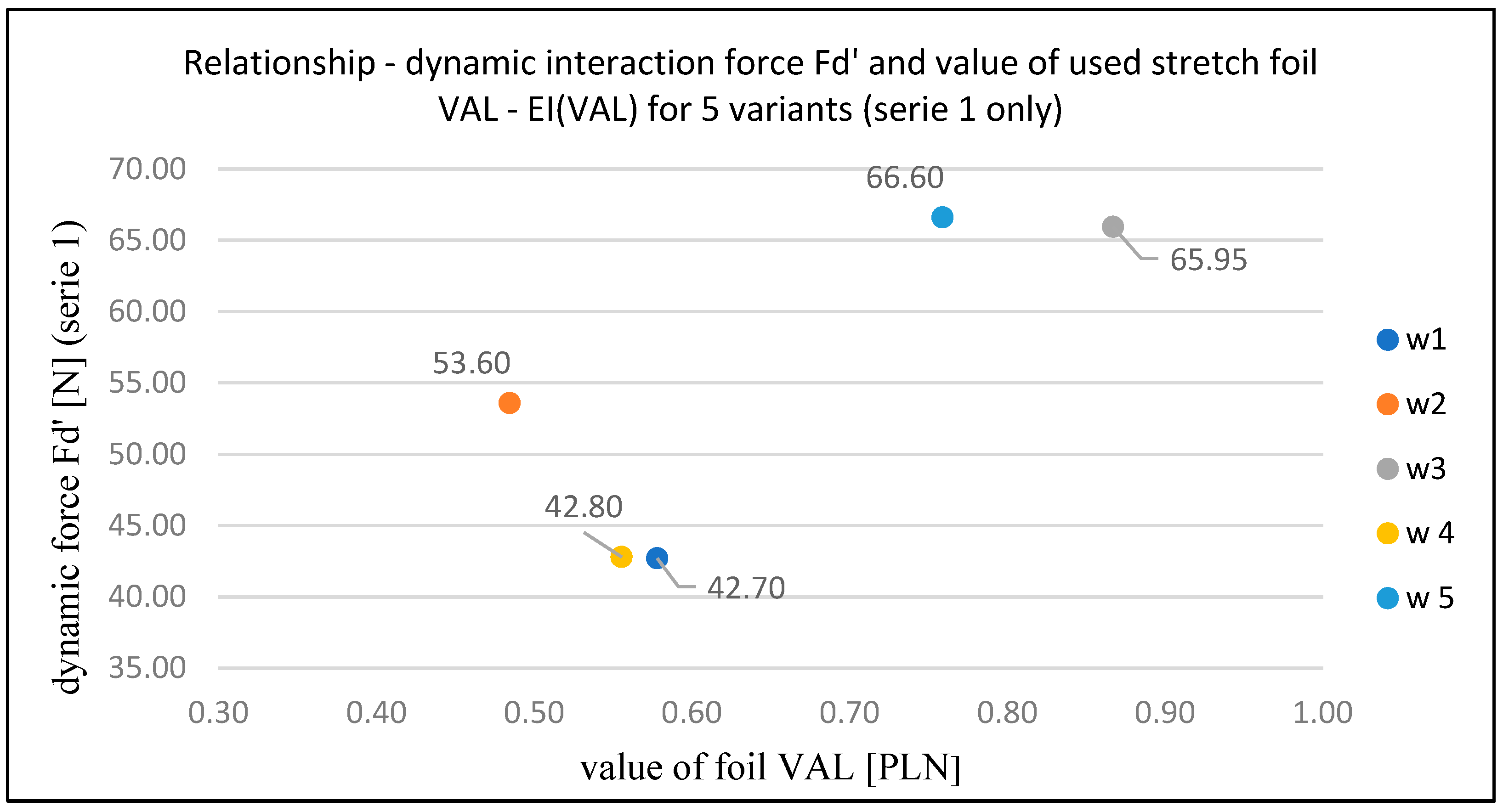

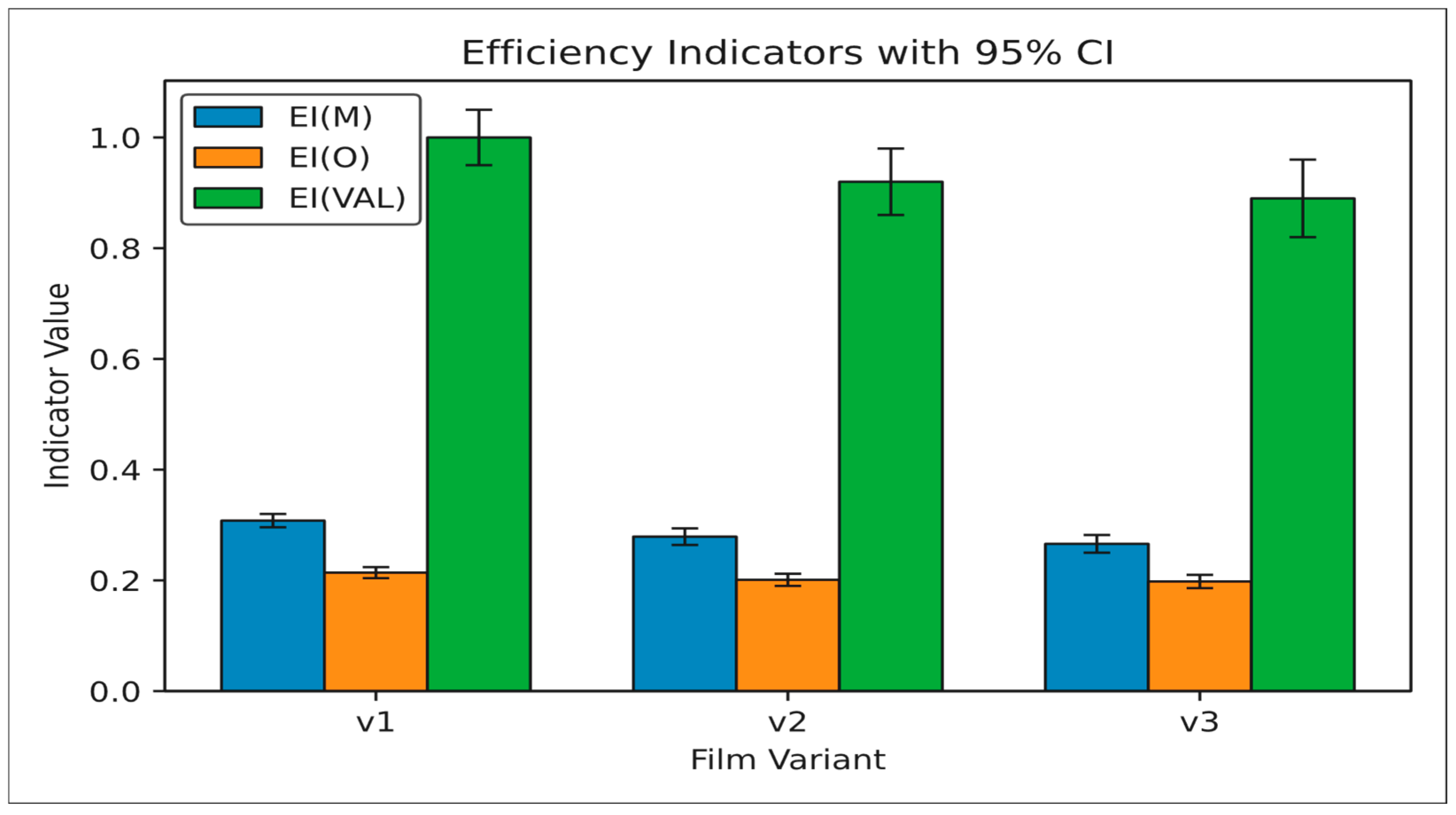

- EI(M)—magnitude of the force Fd exerted by the stretch film relative to the mass of film used (M), i.e., Fd/M;

- EI(O)—magnitude of the force Fd exerted by the stretch film resulting from wrapping the load with one layer (O) of film, i.e., Fd/O;

- EI(VAL)—magnitude of the force Fd exerted by the stretch film resulting from using film of a specific value or grade (VAL), i.e., Fd/VAL.

2.2. Issues in Selecting Stretch Film for Securing Palletized Loads

- Film trade volume in Europe: 50.3 million tons, worth €400 billion, including:

- -

- LDPE, LLDPE trade volume (16.8%): 8.5 million tons, worth €67.6 billion;

- -

- LDPE, LLDPE demand in Poland (7.5%): 0.64 million tons, worth €5.1 billion.

- LDPE, LLDPE demand in Poland for packaging (39.1%): 0.25 million tons, including:

- -

- LLDPE (stretch film) estimated at approx. 40–50%: 0.1–0.12 million tons.

3. Results and Analysis

3.1. Simplified Test Load

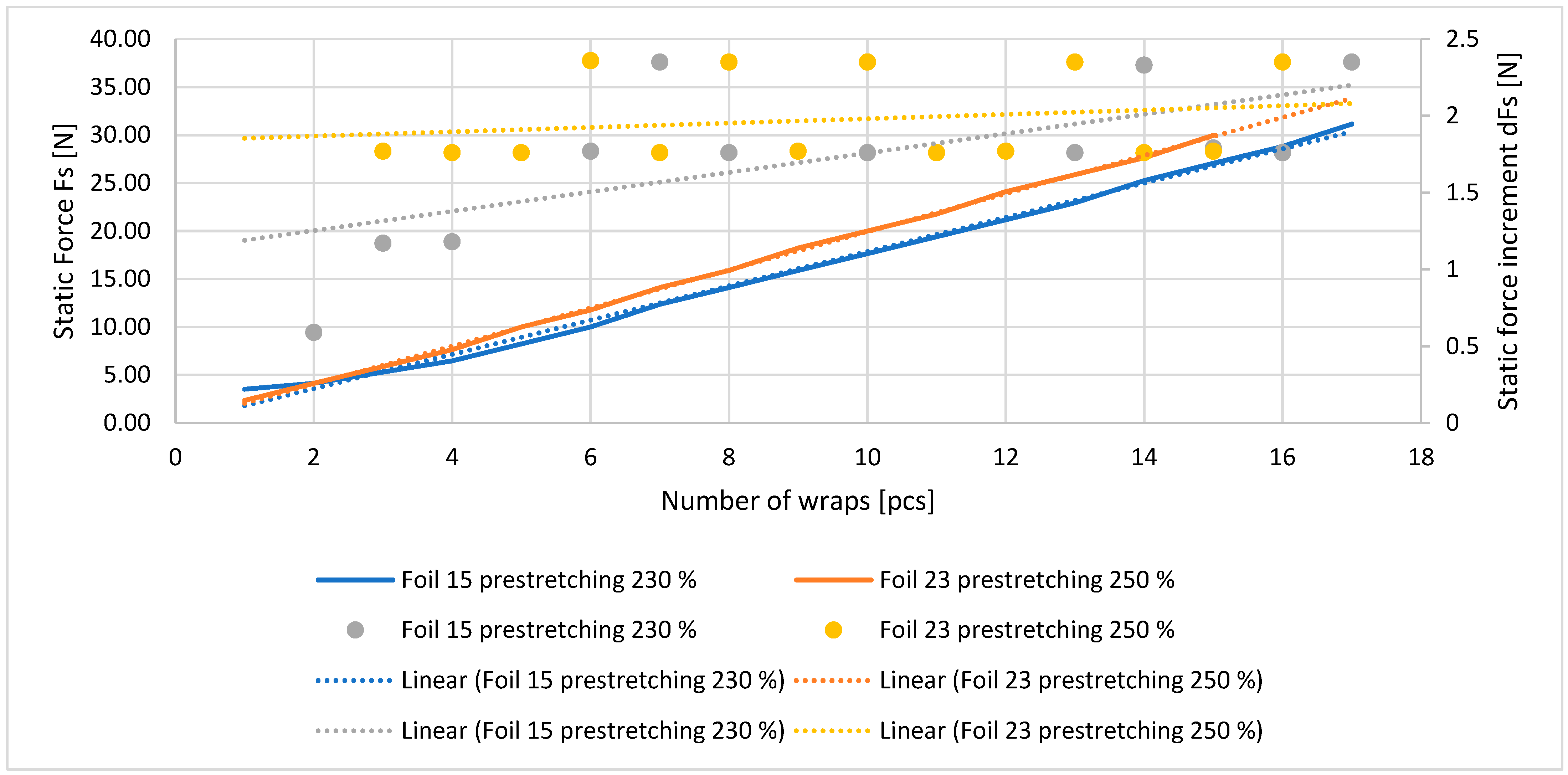

3.2. Static Testing Force Characteristics

- High-quality film with a thickness of 15 microns and a pre-stretch range of 150–300%;

- Standard film with a thickness of 23 microns and a pre-stretch range of 150–300%.

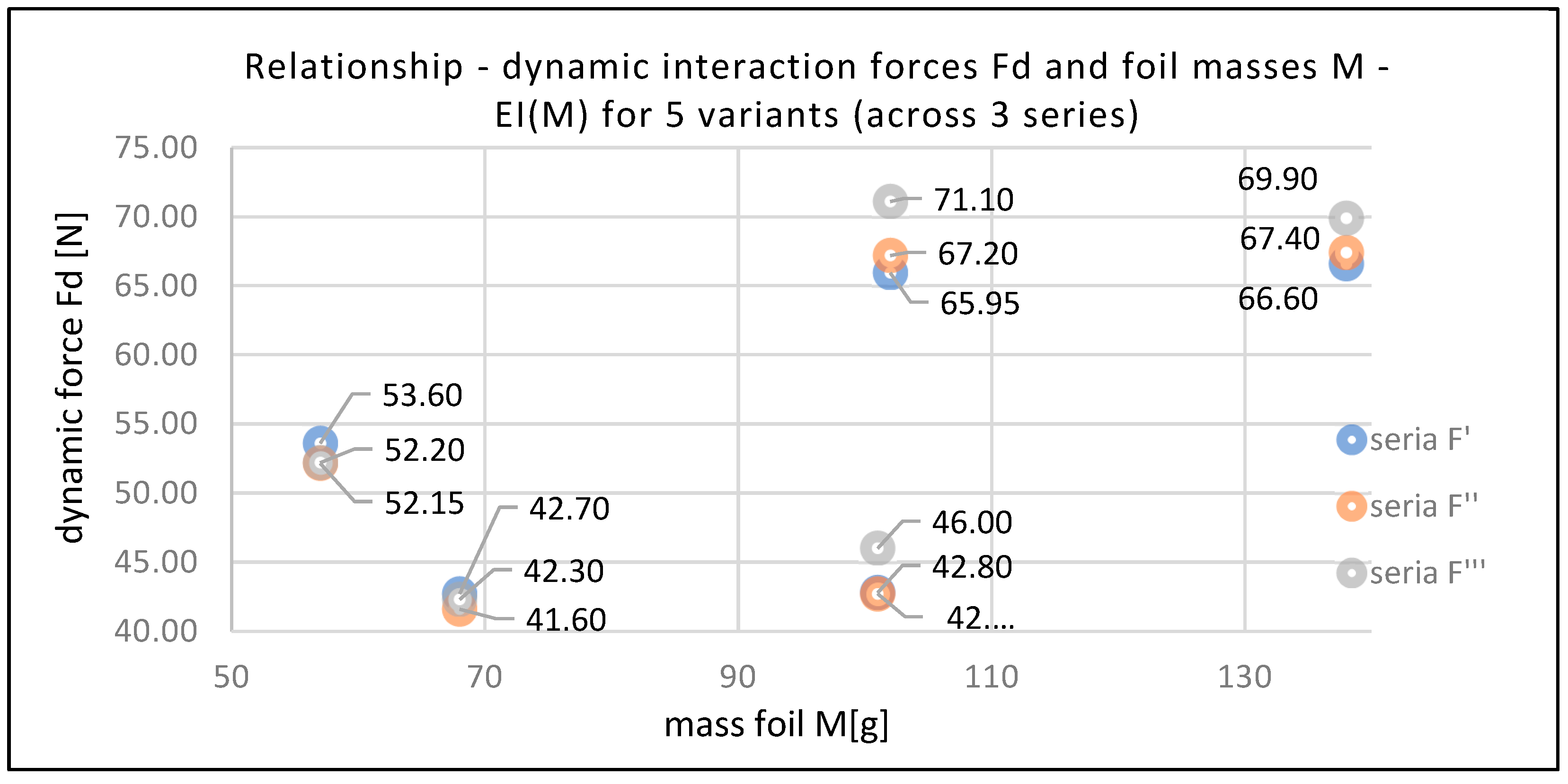

3.3. Dynamic Testing

- Three variants of 17-micron film;

- Two variants of 23-micron film.

- A fixed number of wraps (LO): 6 and 9 wraps;

- Measuring disk deflection (s) within the range of 65–123 mm (limited by the measuring device used);

- Disk deflection applied incrementally in 21 mechanical steps;

- Three measurement series, accounting for the time-dependent behavior of the film on the secured load:

- ○

- Series 1—measurements taken immediately after the load was initially wrapped with stretch film;

- ○

- Series 2—repeated measurements taken immediately after Series 1;

- ○

- Series 3—measurements taken 15 min after the completion of Series 2.

- Standard film—commonly used in Poland, with a thickness of 23 microns and 150% pre-stretch;

- High-quality film—with a thickness of 17 microns and a pre-stretch range of 100–300%.

3.4. Evaluation Indicators

- Develop a simple software tool or spreadsheet-based “Rational Stretch Film Selection Calculator for Securing Palletized Loads”, which would serve as a practical evaluation tool for all stretch film users and could be easily commercialized;

- Develop a “Method for Optimizing Stretch Film Consumption for Securing Palletized Loads”, a necessary tool for all large-scale consumers of stretch film.

3.5. Statistical Treatment of Efficiency Indicators

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| F | dynamic force |

| dF | dynamic force increment |

| s | disk deflection |

| ds | load deflection increments |

| LO | number of wraps |

| M | foil mass |

| O | single wrap |

| VAL | value of used stretch film |

| EI(M) | magnitude of the force F exerted by the stretch film relative to the mass of film used (M), i.e., F/M |

| EI(O) | magnitude of the force F exerted by the stretch film resulting from wrapping the load with one layer (L) of film, i.e., F/L |

| EI(VAL) | magnitude of the force F exerted by the stretch film resulting from using film of a specific value or grade (VAL), i.e., F/VAL |

References

- EUMOS—European Safe Logistics Association, Jules Bordetlaan 164, B-1140 Brussels, Belgium. Available online: https://eumos.eu/ (accessed on 8 November 2025).

- ISTA. 1400 Abbot Road, Suite 380, East Lansing, MI 48823-1900 USA. Available online: https://ista.org/test_procedures.php (accessed on 8 November 2025).

- ASTM D 4649; A1. Test Method or General Evaluation of Stretch Wrap Materials Under Non-Laboratory Conditions. ASTM: West Conshohocken, PA, USA, 2000.

- Directive of the European Parliament and of the Council of 3 April 2014 on the Technical Roadside Inspection of the Roadworthiness of Commercial Vehicles Circulating in the Union and Repealing Directive 2000/30/EC. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=CELEX:32014L0047 (accessed on 8 November 2025).

- Bisha, J.V. The Effect of Load Stabilizer Selection on Load Shift Within Unit Loads. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2008. [Google Scholar]

- Bisha, J.V. Correlation of the Elastic Properties of Stretch Film on Unit Load Containment. Ph.D. Dissertation, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2012. [Google Scholar]

- Best Packing. The Transportable Test Pallet. Available online: https://www.bestpackaging.com.au/ (accessed on 16 December 2019).

- ESTL: Transport Packaging Damage Reduction with ESTL. Available online: https//www.estl.be/packaging/ (accessed on 8 November 2025).

- Lantech. CRT-5 Containment Force Tool Instruction Guide; Lantech: Louisville, KY, USA, 2011. [Google Scholar]

- Lantech. Available online: https://www.lantech.com/stretch-wrapping/containment-force-tool/ (accessed on 8 November 2025).

- Safeload. Available online: https://www.safeloadtesting.com/package-testing/ (accessed on 8 November 2025).

- Lindum Packing LCD. Available online: www.lindumpackaging.com (accessed on 8 November 2025).

- Atlantic Packing. Available online: https://www.atlanticpkg.com/ (accessed on 8 November 2025).

- Plastanalisi. Available online: https://plastanalisi.com/it (accessed on 8 November 2025).

- Impactsolutions. Available online: https://www.impact-solutions.co.uk (accessed on 8 November 2025).

- Testpolymer EU—Accredited Testing Laboratory. Available online: https://www.testpolymer.com (accessed on 8 November 2025).

- EKOBAL. Available online: https://www.ekobal.cz/ (accessed on 8 November 2025).

- Manupackaging. Available online: www.manupackaging.co.uk (accessed on 8 November 2025).

- OMPG. Available online: https://www.ompg.de/en (accessed on 8 November 2025).

- Drozd, M.; Kędzierski, Ł.; Tkaczyk, S. Raport—Przykładowe Testy Stabilności; Materiały Ergis Load Stability Academy: Oława, Poland, 2020. [Google Scholar]

- ICC NESKOR. Available online: https://www.neskor.pl/ (accessed on 8 November 2025).

- P.P.H. FOLPAK Baranowski A. i T. s.c. Available online: https://folpak.com/dzial-br/ (accessed on 8 November 2025).

- Sigma Stretch Film of Europe Sp. z o.o. Available online: https://sigmastretchfilm.pl/ (accessed on 8 November 2025).

- Manuli Ekobal Sp. z o.o. Available online: https://manuliekobal.pl/manuliekobal (accessed on 8 November 2025).

- Warter Polymers. Available online: https://warterpolymers.pl/produkty/laboratorium/ (accessed on 8 November 2025).

- ASTM Internacional. Available online: https://www.astm.org/ (accessed on 8 November 2025).

- IRU. World Road Transport Organisation. Available online: https://www.iru.org/ (accessed on 8 November 2025).

- White, B.A. Preliminary Study of Unit Load/ Stretch Wrap Stability. Bachelor’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2008. [Google Scholar]

- Peacock, A.J. Handbook of Polyethylene, 10th ed.; Marcel Dekker, Inc.: New York, NY, USA, 2000. [Google Scholar]

- Brown, R. Handbook of Polymer Testing; Marcel Dekker, Inc.: New York, NY, USA, 1999; Volume 10. [Google Scholar]

- Matyja, T. Tilt Test of a Pallet Load Unit—Simulation Studies. Sci. J. Silesian Univ. Technol. Ser. Transport. 2020, 107, 107–117. [Google Scholar] [CrossRef]

- Matyja, T. Assessment of the Pallet Unit Load Stability by Simulation Methods. Commun. Sci. Lett. Univ. Zilina 2020, 22, 19–28. [Google Scholar] [CrossRef]

- Gnap, J.; Jagelcák, J.; Marienka, P.; Francák, M.; Kostrzewski, M. Application of MEMS Sensors for Evaluation of the Dynamics for Cargo Securing on Road Vehicles. Sensors 2021, 21, 2881. [Google Scholar] [CrossRef] [PubMed]

- Tkaczyk, S.; Szpotański, M. Metody w Testowe Zachowania Ładunku Transporcie. In Bezpieczeństwo Transportu i Logistyki; Remigiusz, W.T., Ed.; Defin: New Delhi, India, 2021; pp. 105–204. ISBN 978-83-66491-22-9. Available online: https://ksiegarnia.difin.pl/bezpieczenstwo-transportu-i-logistyki?search=Wa%C5%9Bniewski (accessed on 8 November 2025).

- Tkaczyk, S.; Drozd, M.; Kędzierski, Ł.; Santarek, K. Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench. Sensors 2021, 21, 5129. [Google Scholar] [CrossRef] [PubMed]

- Virginia Tech (VT). Available online: https://www.vt.edu/ (accessed on 8 November 2025).

- ExxonMobil Chemical. Available online: https://www.exxonmobilchemical.com/en (accessed on 8 November 2025).

- Rocket Industrial. Available online: https://www.rocketindustrial.com/ (accessed on 8 November 2025).

- Raportu Grand View Research, Inc. Stretch And Shrink Films Market Growth & Trends. Available online: https://www.grandviewresearch.com/press-release/global-stretch-and-shrink-films-market# (accessed on 8 November 2025).

- Plastics Europe (Stowarzyszenie Producentów Tworzyw Sztucznych w Europie). Available online: https://plasticseurope.org (accessed on 8 November 2025).

- Korzeb, J. Analiza drgań komunikacyjnych z zastosowaniem teorii falek. (Analysis of transport vibrations based on wavelet theory). WUT J. Transp. Eng. 2011, 77, 45–58. [Google Scholar]

- Nader, M.; Opala, M.; Korzeb, J. Selected studies of dynamics of railway flat-car used for transport of semi-triler truck (TIR). WUT J. Transp. Eng. 2019, 125, 101–111. [Google Scholar] [CrossRef]

| Foil 15 pre-stretching | foil parameters | width L [mm] | temp. TP [°C] | wrap O [pcs] | pre-stretching P [%] |

| 500 | 18 | machine | 230 | ||

| test parameters | type of test RB | number of wrap LO [pcs] | foil mass M [g] | measurement place MP | |

| static | 1–17 | A 0 | |||

| measurement results | step | LO [pcs] | static force Fs [N] | increase s.force dFs [N] | |

| 0 | 1 | 3.53 | 0 | ||

| 1 | 2 | 4.12 | 0.59 | ||

| 2 | 3 | 5.29 | 1.17 | ||

| 3 | 4 | 6.47 | 1.18 | ||

| 4 | 5 | 8.23 | 1.76 | ||

| 5 | 6 | 10.00 | 1.77 | ||

| 6 | 7 | 12.35 | 2.35 | ||

| 7 | 8 | 14.11 | 1.76 | ||

| 8 | 9 | 15.88 | 1.77 | ||

| 9 | 10 | 17.64 | 1.76 | ||

| 10 | 11 | 19.40 | 1.76 | ||

| 11 | 12 | 21.17 | 1.77 | ||

| 12 | 13 | 22.93 | 1.76 | ||

| 13 | 14 | 25.26 | 2.33 | ||

| 14 | 15 | 27.05 | 1.79 | ||

| 15 | 16 | 28.81 | 1.76 | ||

| 16 | 17 | 31.16 | 2.35 |

| Foil 23 prestreting | foil parameters | width L [mm] | temp. TP [°C] | wrap O [pcs] | pre-stretching P [%] |

| 500 | 18 | machine | 250 | ||

| test parameters | type of test RB | number of wrap LO [pcs] | foil mass M [g] | measuremet place MP | |

| static | 1–15 | A 0 | |||

| measurement results | step | LO(pcs) | Static force Fs [N] | increase s.force dFs [N] | |

| 0 | 1 | 2.35 | |||

| 1 | 2 | 4.12 | 1.77 | ||

| 2 | 3 | 5.88 | 1.76 | ||

| 3 | 4 | 7.64 | 1.76 | ||

| 4 | 5 | 10.00 | 2.36 | ||

| 5 | 6 | 11.76 | 1.76 | ||

| 6 | 7 | 14.11 | 2.35 | ||

| 7 | 8 | 15.88 | 1.77 | ||

| 8 | 9 | 18.23 | 2.35 | ||

| 9 | 10 | 19.99 | 1.76 | ||

| 10 | 11 | 21.76 | 1.77 | ||

| 11 | 12 | 24.11 | 2.35 | ||

| 12 | 13 | 25.87 | 1.76 | ||

| 13 | 14 | 27.64 | 1.77 | ||

| 14 | 15 | 29.99 | 2.35 |

| Foil 17 pre-stretching | foil parameters | width | temp. | Wrap | pre-stretching P [%] | ||

| L [mm] | TP [°C] | O [pcs] | |||||

| 500 | 25/27 | machine | 240 | ||||

| test parameters | type of test | number of wrap | foil mass M [g] | measurement place | |||

| RB | LO [pcs] | ||||||

| dynamic | 6 | 68 | A 0 | ||||

| measurement results | step | deflection s [mm] | dynamic force | dynamic force increment dFd [N] | |||

| Fd [N] | |||||||

| series 1 | 0 | 65.0 | 12.4 | 0.00 | 0.00 | ||

| 1 | 66.0 | 15.5 | 3.10 | ||||

| 2 | 67.3 | 17.45 | 1.95 | ||||

| 3 | 72.5 | 20.3 | 2.85 | ||||

| 4 | 77.5 | 22.75 | 2.45 | ||||

| 5 | 81.5 | 24.05 | 1.30 | 11.65 | |||

| 6 | 86.0 | 26.8 | 2.75 | ||||

| 7 | 89.0 | 28.2 | 1.40 | ||||

| 8 | 93.0 | 28.2 | 0.00 | ||||

| 9 | 95.8 | 28.3 | 0.10 | ||||

| 10 | 98.5 | 30.7 | 2.40 | 6.65 | |||

| 11 | 104.8 | 32.7 | 2.00 | ||||

| 12 | 107.0 | 33.15 | 0.45 | ||||

| 13 | 109.0 | 33.3 | 0.15 | ||||

| 14 | 111.0 | 35.5 | 2.20 | ||||

| 15 | 113.0 | 36.15 | 0.65 | 5.45 | |||

| 16 | 115.3 | 35.8 | −0.35 | ||||

| 17 | 117.0 | 37.8 | 2.00 | ||||

| 18 | 119.0 | 39.7 | 1.90 | ||||

| 19 | 121.0 | 41.2 | 1.50 | ||||

| 20 | 123.0 | 42.7 | 1.50 | 6.55 | |||

| 21 | 125.0 | 44.9 | 2.20 | ||||

| series 2 | 0 | 64.5 | 13.00 | 0.00 | |||

| 5 | 81.5 | 22.70 | 9.70 | ||||

| 10 | 98.5 | 26.00 | 3.30 | ||||

| 15 | 113.0 | 34.00 | 8.00 | ||||

| 20 | 119.0 | 41.60 | 7.60 | ||||

| series 3 | 0 | 64.5 | 12.20 | 0.00 | |||

| 5 | 81.5 | 20.30 | 8.10 | ||||

| 10 | 98.5 | 24.00 | 3.70 | ||||

| 15 | 113.0 | 32.80 | 8.80 | ||||

| 20 | 119.0 | 42.30 | 9.50 | ||||

| Disc Deflection s [mm] | Disc Deflection Increment ds [mm] | Series 1 | Series 2 | Series 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dynamic Force Fd’ [N] | Dynamic Force Increment dFd’ [N] | dFd’/ds [N/mm] | Dynamic Force Fd’’ [N] | Dynamic Force Increment dFd’’ [N] | dFd’’/ds [N/mm] | Dynamic Force Fd’’’ [N] | Dynamic Force Increment dFd’’’ [N] | dFd’’’/ds [N/mm] | ||

| 64.5 | 64.5 | 12.40 | 12.40 | 0.192 | 13.00 | 13.00 | 0.202 | 12.20 | 12.20 | 0.189 |

| 77.5 | 13 | 24.05 | 11.65 | 0.896 | 22.70 | 9.70 | 0.746 | 20.30 | 8.10 | 0.623 |

| 95.75 | 18.25 | 30.70 | 6.65 | 0.364 | 26.00 | 3.30 | 0.181 | 24.00 | 3.70 | 0.203 |

| 111 | 15.25 | 36.15 | 5.45 | 0.357 | 34.00 | 8.00 | 0.525 | 32.80 | 8.80 | 0.577 |

| 123 | 12 | 42.70 | 6.55 | 0.546 | 41.60 | 7.60 | 0.633 | 42.30 | 9.50 | 0.792 |

| Disc Deflection s [mm] | d Fd’/s [N/mm] | d Fd’’/s [N/mm] | d Fd’’’/s [N/mm] | Disc Deflection Increment ds [mm] | d Fd’/ds [N/mm] | d Fd’’/ds [N/mm] | d Fd’’’/ds [N/mm] |

|---|---|---|---|---|---|---|---|

| 64.5 | 0.192 | 0.202 | 0.189 | 64.5 | 12.40 | 13.00 | 12.20 |

| 77.5 | 0.896 | 0.746 | 0.623 | 13 | 11.65 | 9.70 | 8.10 |

| 95.75 | 0.364 | 0.181 | 0.293 | 18.25 | 6.65 | 3.30 | 3.70 |

| 111 | 0.357 | 0.525 | 0.577 | 15.25 | 5.45 | 8.00 | 8.80 |

| 123 | 0.546 | 0.633 | 0.792 | 12 | 6.55 | 7.60 | 9.50 |

| Variant | Type of Stretch Foil | Prestrething [%] | Number of Wrap LO [pcs] | Foil Mass M [g] | Dynamic Force Fd [N] | |||

|---|---|---|---|---|---|---|---|---|

| Deflection s [mm] | Series 1 Fd’ [N] | Series Fd’’ [N] | Series Fd’’’ [N] | |||||

| v1 | 17 IU | 240 | 6 | 68 | 64.5 | 12.40 | 13.00 | 12.20 |

| 77.5 | 24.05 | 22.70 | 20.30 | |||||

| 95.75 | 30.70 | 26.00 | 24.00 | |||||

| 111 | 36.15 | 34.00 | 32.80 | |||||

| 123 | 42.70 | 41.60 | 42.30 | |||||

| v2 | 17 IU | 320 | 6 | 57 | 64.5 | 15.00 | 11.65 | 12.50 |

| 77.5 | 31.85 | 26.65 | 26.60 | |||||

| 95.75 | 35.00 | 31.30 | 32.60 | |||||

| 111 | 44.00 | 40.70 | 39.55 | |||||

| 123 | 53.60 | 52.15 | 52.20 | |||||

| v3 | 17 IU | 240 | 9 | 102 | 64.5 | 22.40 | 15.70 | 19.70 |

| 77.5 | 36.20 | 32.70 | 35.40 | |||||

| 95.75 | 46.00 | 45.00 | 48.00 | |||||

| 111 | 53.60 | 56.30 | 62.20 | |||||

| 123 | 65.95 | 67.20 | 71.10 | |||||

| v4 | 23 standard | 150 | 6 | 101 | 64.5 | 15.20 | 14.00 | 15.90 |

| 77.5 | 25.70 | 23.45 | 24.00 | |||||

| 95.75 | 27.40 | 28.40 | 29.10 | |||||

| 111 | 31.00 | 35.10 | 38.90 | |||||

| 123 | 42.80 | 42.70 | 46.00 | |||||

| v5 | 23 standard | 150 | 9 | 138 | 64.5 | 23.00 | 19.90 | 21.30 |

| 77.5 | 36.70 | 33.90 | 33.90 | |||||

| 95.75 | 44.30 | 43.20 | 48.20 | |||||

| 111 | 55.70 | 56.50 | 59.30 | |||||

| 123 | 66.60 | 67.40 | 69.90 | |||||

| Variant | Mass M [g] | Dynamic Force Fd’ [N] | Fd’/M [N/g] (Series 1) | Dynamic Force Fd’’ [N] | Fd’’/M [N/g] (Series 2) | Dynamic Force Fd’’’ [N] | Fd’’’/M [N/g] (Series 3) | Ranking Fd’/EI(M) |

|---|---|---|---|---|---|---|---|---|

| v1 | 68 | 42.70 | 0.628 | 41.60 | 0.612 | 42.30 | 0.622 | 3 |

| v2 | 57 | 53.60 | 0.940 | 52.15 | 0.915 | 52.20 | 0.916 | 1 |

| v3 | 102 | 65.95 | 0.647 | 67.20 | 0.659 | 71.10 | 0.697 | 2 |

| v4 | 101 | 42.80 | 0.424 | 42.70 | 0.423 | 46.00 | 0.455 | 5 |

| v5 | 138 | 66.60 | 0.483 | 67.40 | 0.488 | 69.90 | 0.507 | 4 |

| EI | Mass M [g] | Wraps LO [pcs] | Dynamic Force Fd’ [N] | Fd’/O [N/1 Wrap] | Ranking Fd’/EI(O) | |

|---|---|---|---|---|---|---|

| Variant | ||||||

| w1 | 68 | 6 | 42.70 | 7.117 | 5 | |

| w2 | 57 | 6 | 53.60 | 8.933 | 1 | |

| w3 | 102 | 9 | 65.95 | 7.328 | 3 | |

| w4 | 101 | 6 | 42.80 | 7.133 | 4 | |

| w5 | 138 | 9 | 66.60 | 7.400 | 2 | |

| EI | Mass M [kg] | Price [PLN/kg] | Value VAL [PLN] | Dynamic Force Fd’ [N] | Fd’/EI(VAL) [N/PLN] | Ranking Fd’/EI(VAL) | |

|---|---|---|---|---|---|---|---|

| Variant | |||||||

| v1 | 0.068 | 8.50 | 0.58 | 42.70 | 73.875 | 5 | |

| v2 | 0.057 | 8.50 | 0.48 | 53.60 | 110.630 | 1 | |

| v3 | 0.102 | 8.50 | 0.87 | 65.95 | 76.067 | 4 | |

| v4 | 0.101 | 5.50 | 0.56 | 42.80 | 77.048 | 3 | |

| v5 | 0.138 | 5.50 | 0.76 | 66.60 | 87.747 | 2 | |

| EI | Ranking Fd’/EI (M) | Ranking Fd’/EI (O) | Ranking Fd’/EI (VAL) | |

|---|---|---|---|---|

| Variant | ||||

| v1 | 3 | 5 | 5 | |

| v2 | 1 | 1 | 1 | |

| v3 | 2 | 3 | 4 | |

| v4 | 5 | 4 | 3 | |

| v5 | 4 | 2 | 2 | |

| Film Variant | Film Thickness (µm) | EI(M) [N g−1] ± 95% CI | EI(O) [J g−1] ± 95% CI | EI(VAL) [a.u.] ± 95% CI | Comment |

|---|---|---|---|---|---|

| v1 | 15 | 0.308 ± 0.012 | 0.214 ± 0.010 | 1.00 ± 0.05 | Highest normalized efficiency; non-overlapping CI vs. v2/v3 |

| v2 | 17 | 0.279 ± 0.015 | 0.201 ± 0.011 | 0.92 ± 0.06 | Intermediate; overlaps with v3 (not significant, α = 0.05) |

| v3 | 23 | 0.266 ± 0.016 | 0.198 ± 0.012 | 0.89 ± 0.07 | Lowest normalized efficiency; statistically similar to v2 |

| Variant | Fd′ (N) | VAL Baseline (PLN) | Efficiency Fd′/VAL (N/PLN) | Fd′/VA −20% Price | Fd′/VAL +20% Price | Rank (Baseline/−20%/+20%) |

|---|---|---|---|---|---|---|

| v1 | 42.70 | 0.58 | 73.88 | 92.03 | 61.35 | 5/5/5 |

| v2 | 53.60 | 0.48 | 110.63 | 139.58 | 93.06 | 1/1/1 |

| v3 | 65.95 | 0.87 | 76.07 | 94.74 | 63.17 | 4/4/4 |

| v4 | 42.80 | 0.56 | 77.05 | 95.54 | 63.69 | 3/3/3 |

| v5 | 66.60 | 0.76 | 87.75 | 109.54 | 73.03 | 2/2/2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tkaczyk, S.; Jagelčák, J.; Szpotański, M.; Sędrowicz, R. Pilot Study of Stretch Film for Securing Palletized Loads. Sensors 2025, 25, 6883. https://doi.org/10.3390/s25226883

Tkaczyk S, Jagelčák J, Szpotański M, Sędrowicz R. Pilot Study of Stretch Film for Securing Palletized Loads. Sensors. 2025; 25(22):6883. https://doi.org/10.3390/s25226883

Chicago/Turabian StyleTkaczyk, Sławomir, Juraj Jagelčák, Mariusz Szpotański, and Radosław Sędrowicz. 2025. "Pilot Study of Stretch Film for Securing Palletized Loads" Sensors 25, no. 22: 6883. https://doi.org/10.3390/s25226883

APA StyleTkaczyk, S., Jagelčák, J., Szpotański, M., & Sędrowicz, R. (2025). Pilot Study of Stretch Film for Securing Palletized Loads. Sensors, 25(22), 6883. https://doi.org/10.3390/s25226883