1. Introduction

DTS is a fiber-optic technique that measures temperature based on Raman scattering within the fiber [

1]. In this process, photons interacting with molecular vibrations are scattered in two forms: Stokes and anti-Stokes [

2]. While Stokes scattering produces lower-energy photons, anti-Stokes scattering generates higher-energy photons whose intensity strongly depends on temperature [

3]. By analyzing the ratio between these two signals, the temperature distribution along the fiber can be determined. Most DTS systems employ optical time-domain reflectometry (OTDR), where short light pulses are sent through the fiber and the backscattered signal is recorded [

4]. The time delay of the returning signal indicates the location of the scattering event, allowing temperature to be mapped along the fiber length [

1]. DTS has become an essential technology in upstream oil and gas applications, enabling real-time downhole measurement for monitoring and optimizing well performance [

5]. More recently, it has drawn particular attention to geothermal energy development, where downhole temperature profiling provides critical insights into subsurface heat transfer and overall well performance.

Wellbore fluid temperature modeling has advanced significantly since the pioneering study of Ramey [

6], who introduced a single-phase vertical flow model incorporating a time-dependent function and an effective heat transfer coefficient. While sufficiently accurate for long-term steady-state condition, this approach could not capture short-term transients. Subsequent studies extended Ramey’s framework to account for multiphase flow, well deviation, and variable thermal properties [

7,

8,

9]. A major step forward came in the mid-1990s, when Hasan and co-workers proposed simplified analytical models that enabled direct calculation of circulating fluid temperatures [

10,

11], and later developed fully coupled wellbore–reservoir simulators capable of analyzing both pressure-transient and temperature behavior in single- and two-phase flow systems [

12,

13]. Collectively, these developments have greatly expanded the ability to model complex thermal and flow processes across a wide range of wellbore and reservoir conditions.

Despite these advances, existing wellbore heat transfer models still face key limitations. Many rely on steady-state thermal assumptions and therefore cannot adequately represent transient temperature responses, while fully coupled mass–momentum–energy simulators, although comprehensive, are mathematically demanding and computationally intensive. Previous studies have also examined transient responses from field observations. For example, one study interpreted the propagation of thermal slugs detected by fiber-optic systems in the Utah FORGE 16B producer. Apparently, they considered the thermal slug velocities as equal to the fluid velocities in the wellbore [

14]. This interpretation has offered a practical basis for flow profiling in fractured wells and has been applied in geothermal developments [

15,

16,

17,

18], particularly in Enhanced Geothermal Systems (EGS) [

14,

19]. However, this assumption inherently oversimplifies the underlying heat transfer processes, highlighting the need for a more rigorous understanding of thermal conduction and propagation in relation to fluid velocity.

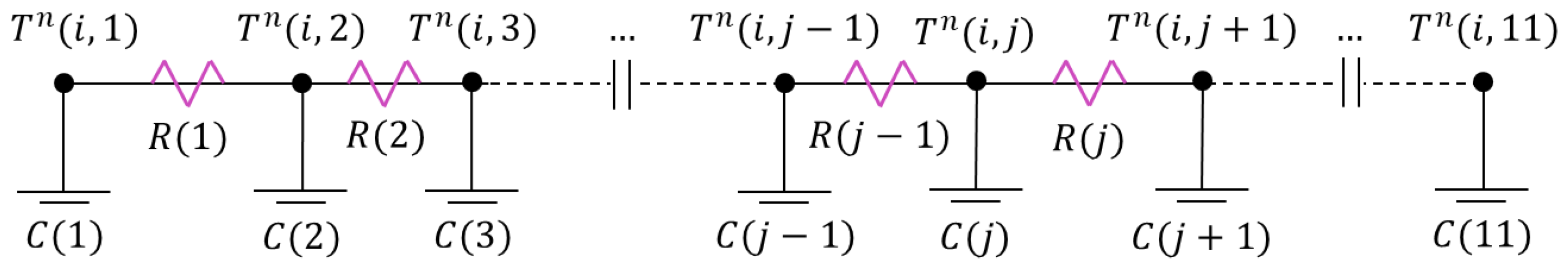

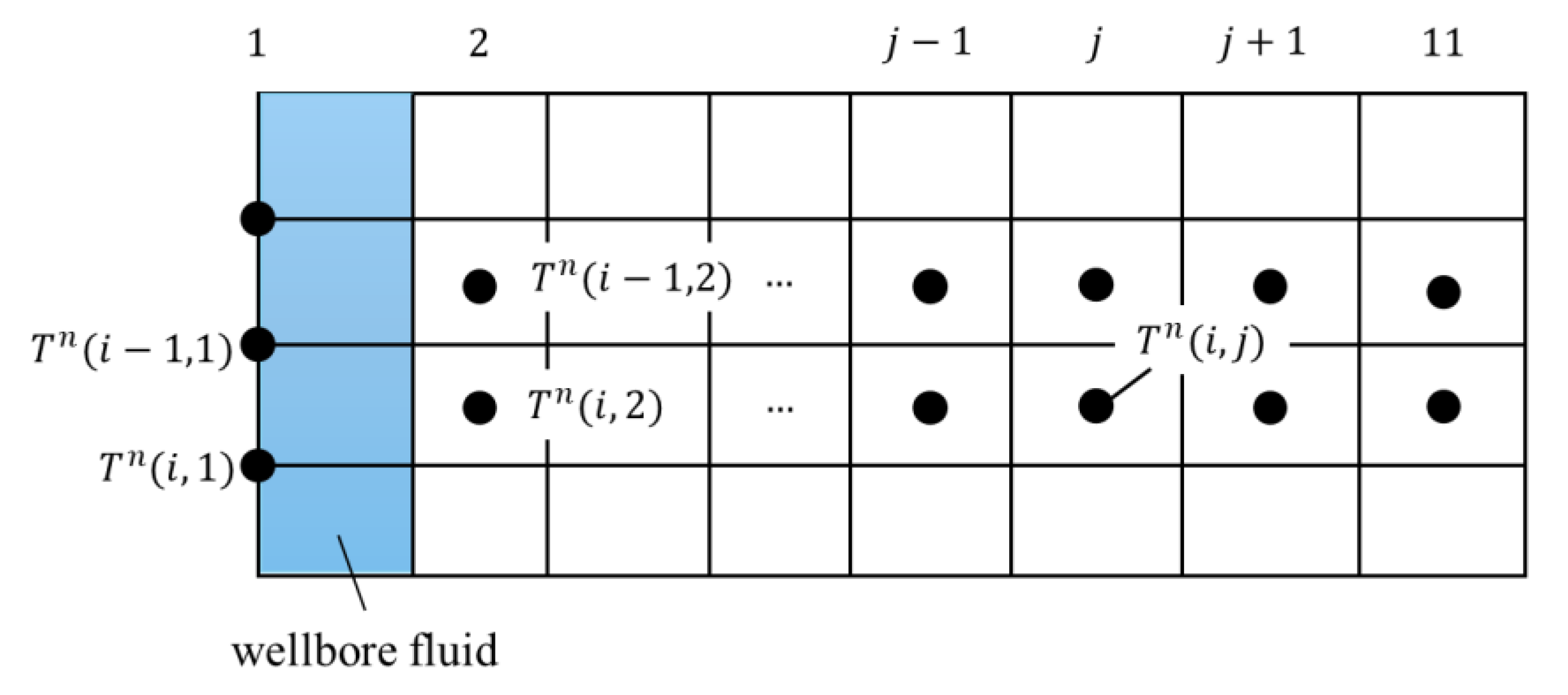

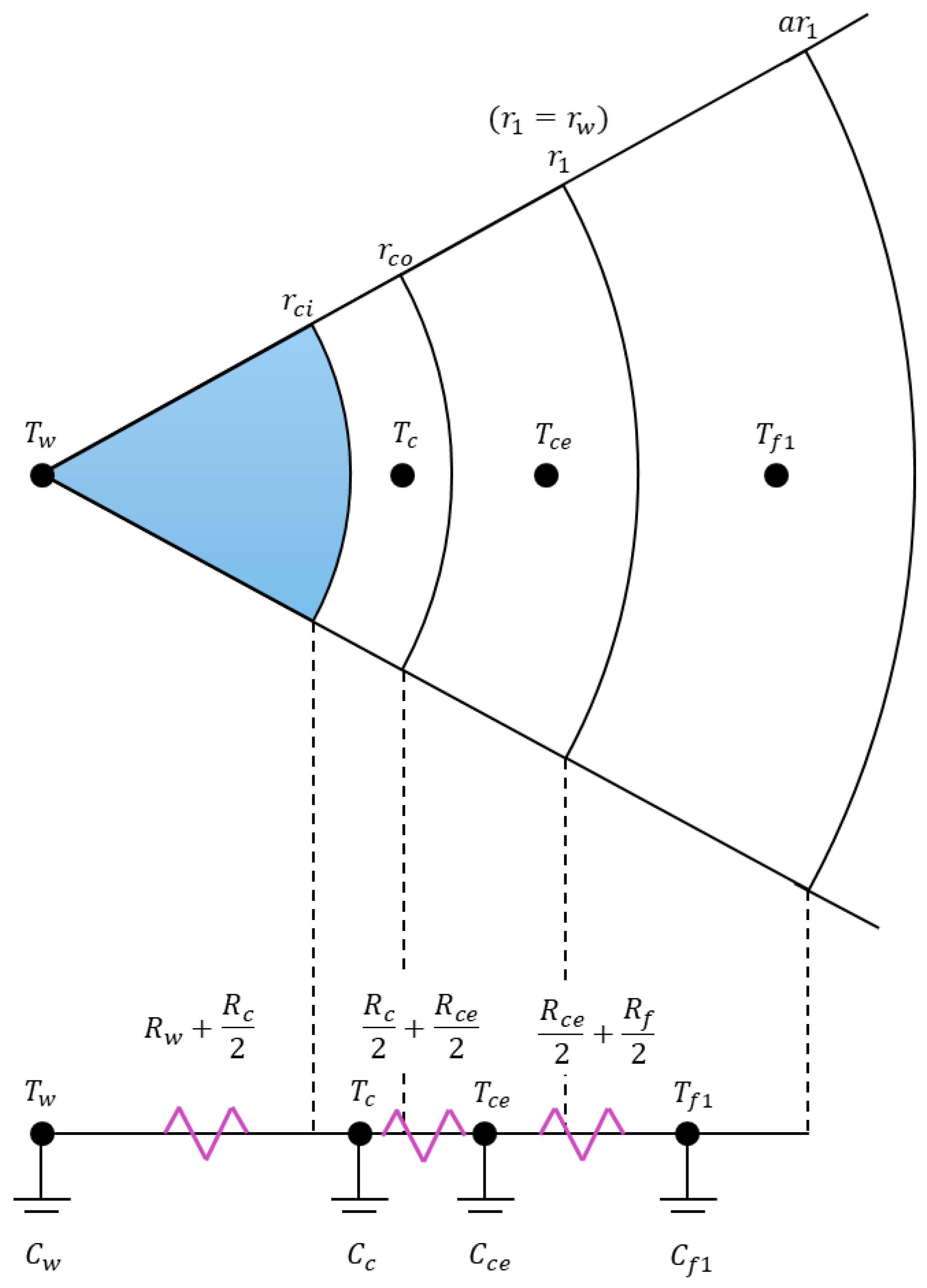

To overcome the above limitations, this study employs a thermal-analogy approach for modeling transient wellbore heat transfer, drawing on the methodology proposed by Eickmeier et al. [

20]. This approach provides three key advantages. First, it enables reliable prediction of temperature changes under both steady and transient conditions, during both heating and cooling phases. Second, by treating fluid flow in the wellbore as steady, it avoids solving transient mass and momentum equations, while still capturing the essential unsteady thermal behavior. Third, it naturally accounts for heat conduction into the surrounding formation without requiring a reservoir flow model, thereby reducing computational effort.

Accordingly, this study has three main objectives: (i) to develop a transient wellbore heat transfer model capable of accurately predicting temperature profiles with a relatively simple mathematical approach, (ii) to validate the model against field observations by comparing temperature profiles and thermal slug velocities between them, and (iii) to enhance the understanding of transient temperature behavior by investigating and comparing fluid and thermal slug velocities. The remainder of this paper is organized as follows.

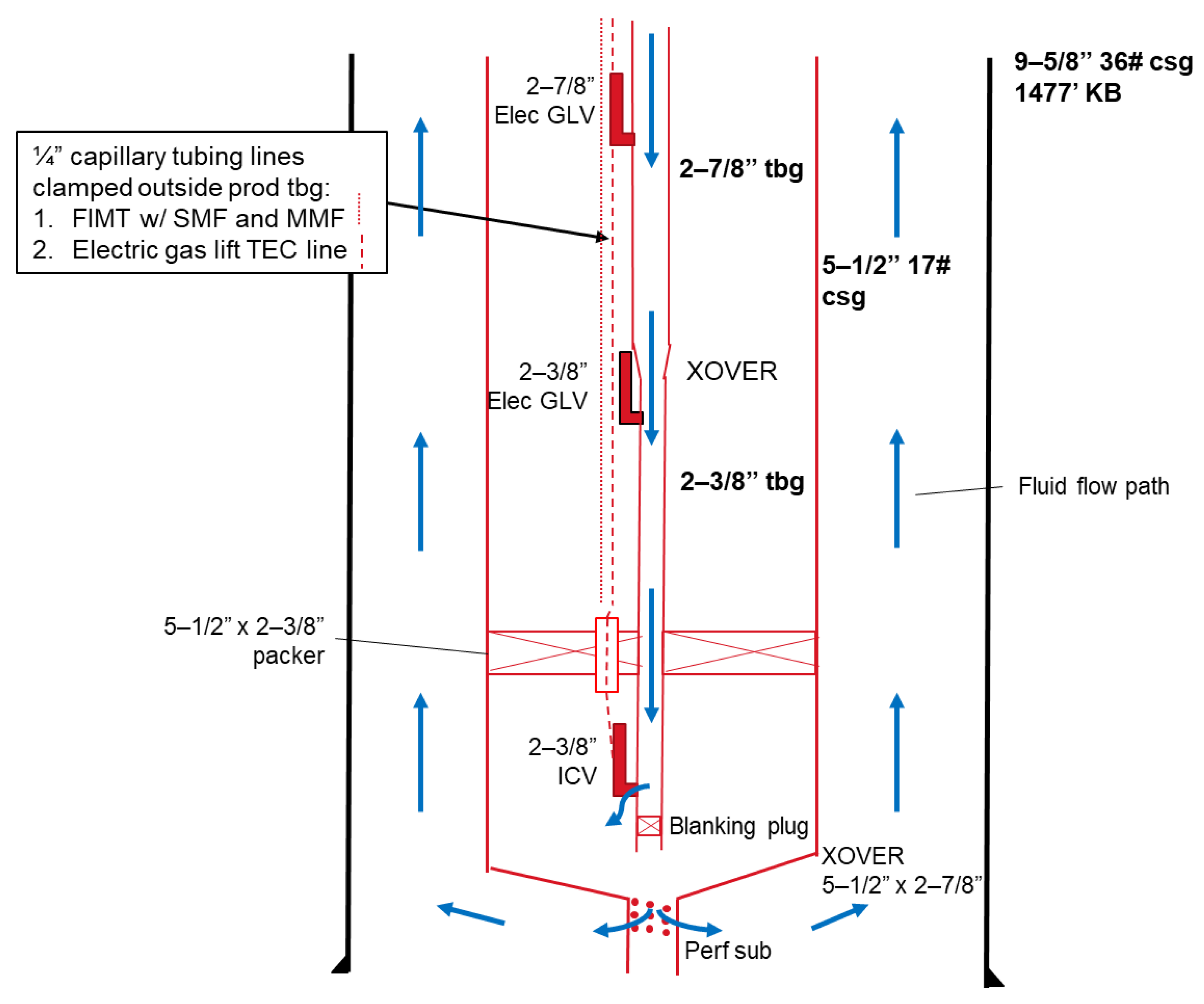

Section 2 details the methodology of the developed numerical model and the experimental design of the fluid circulation test, from which most of the input parameters for the numerical simulation were determined.

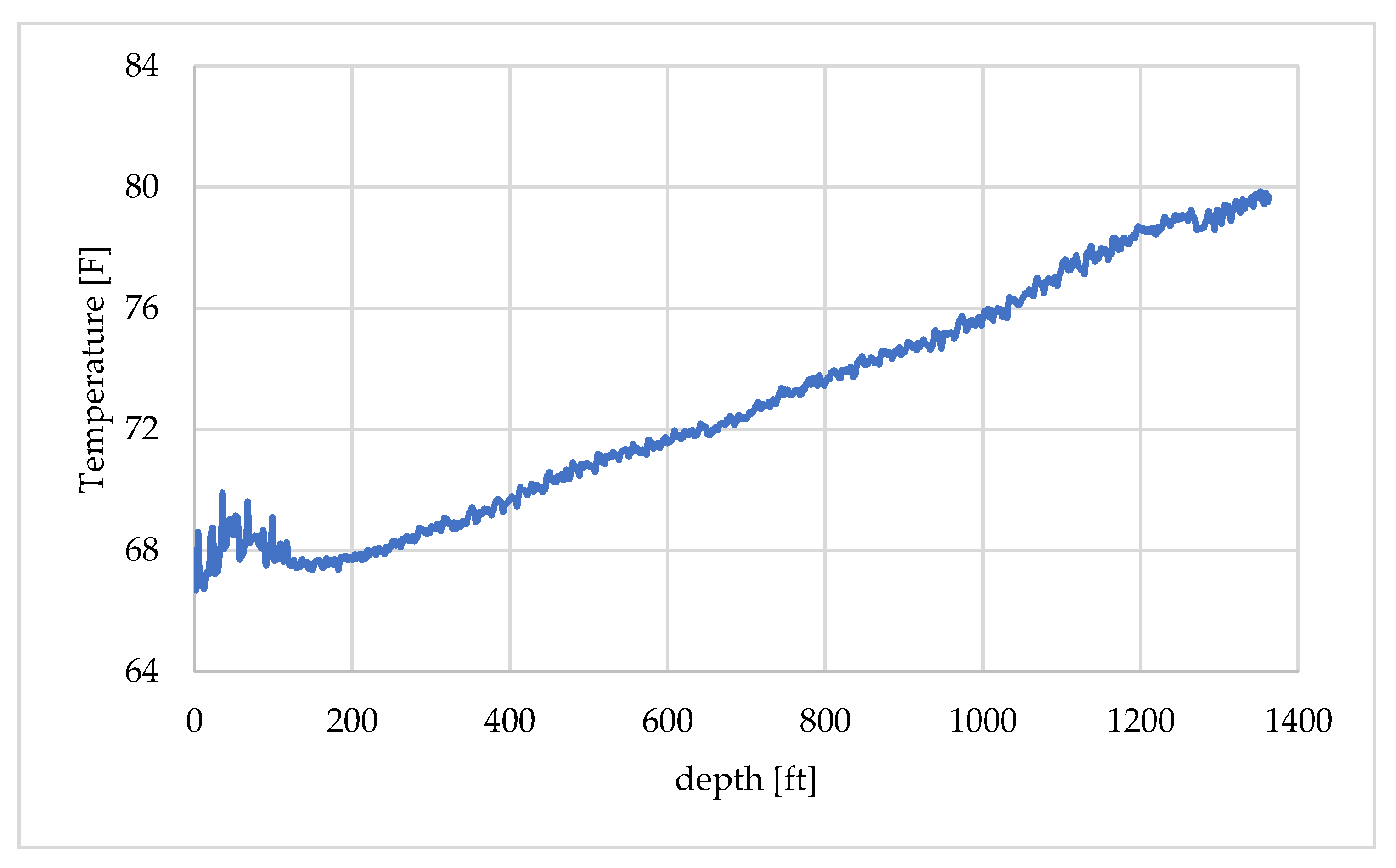

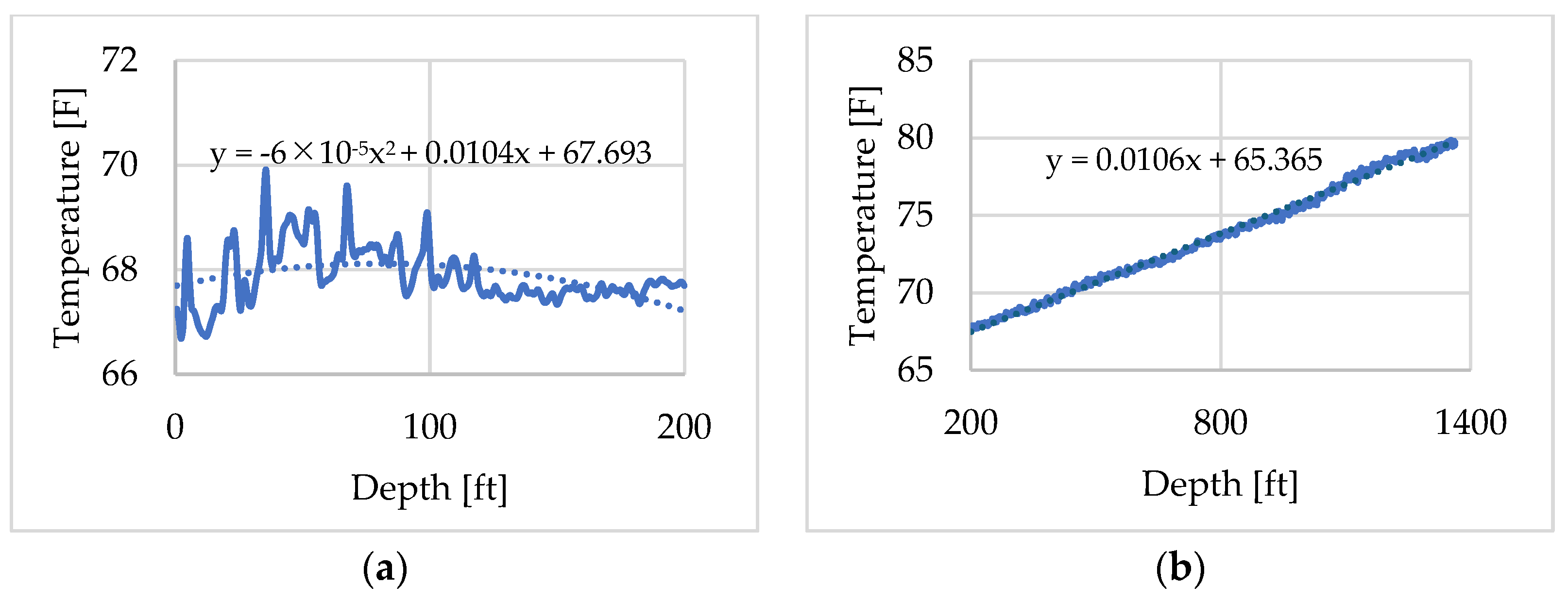

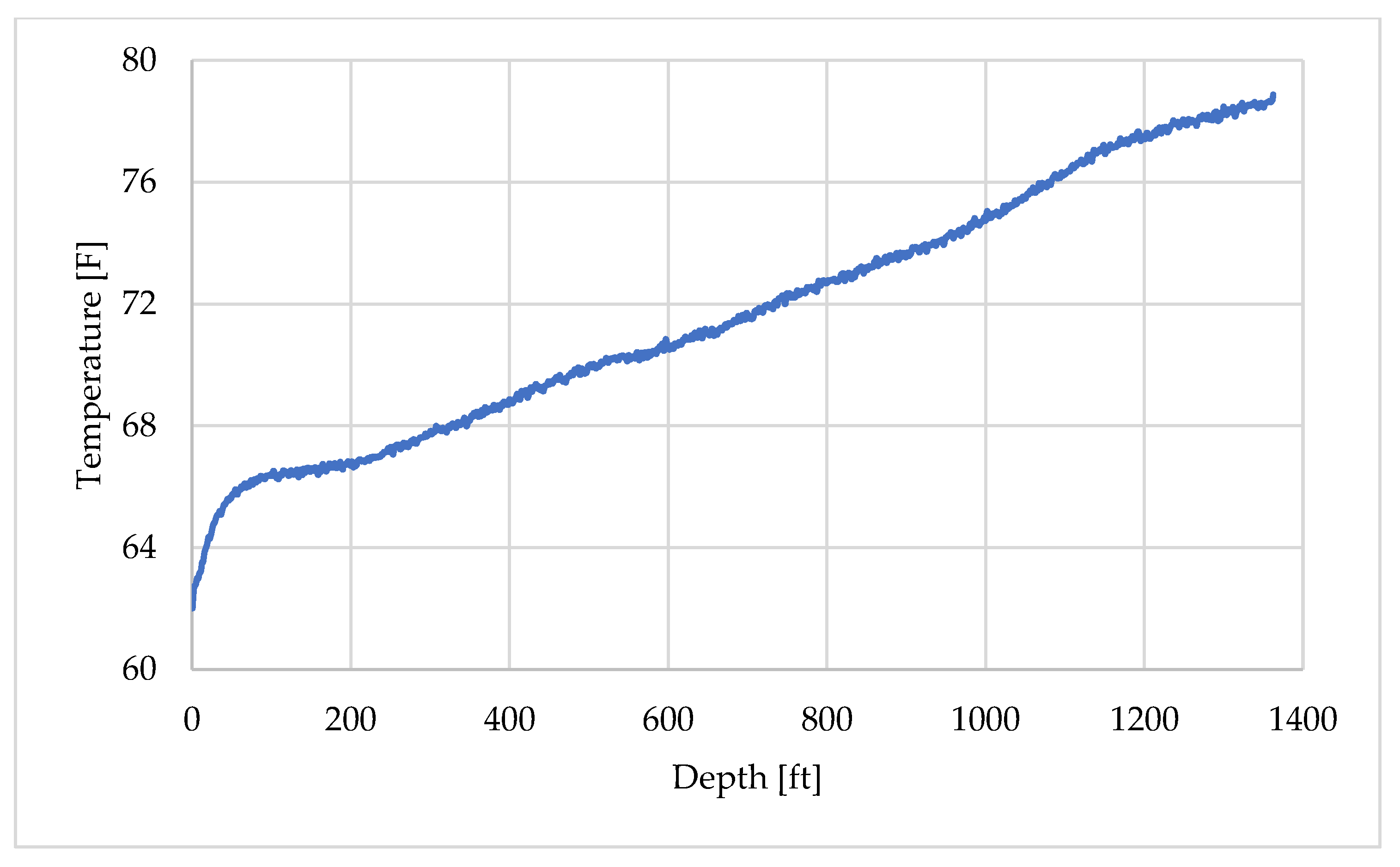

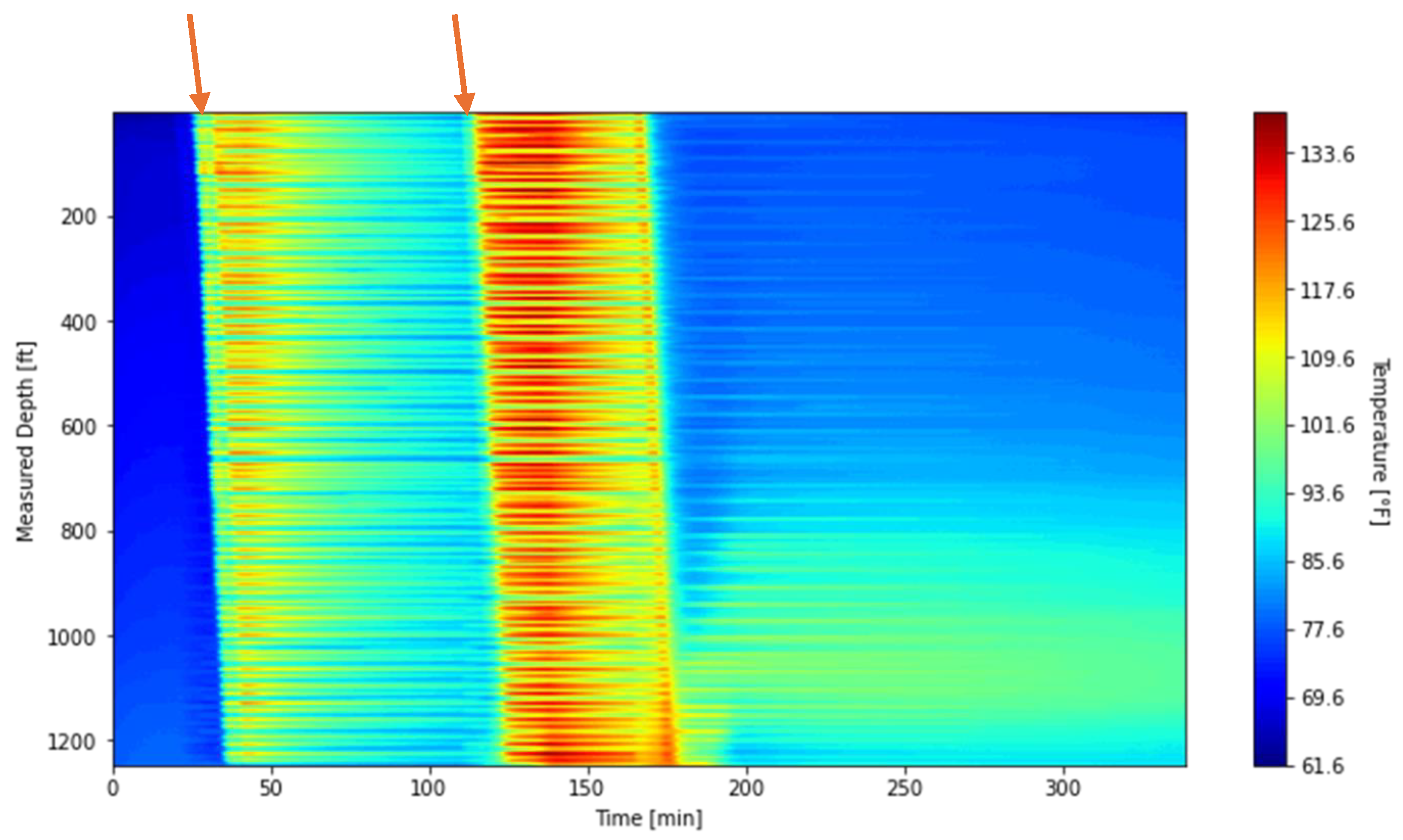

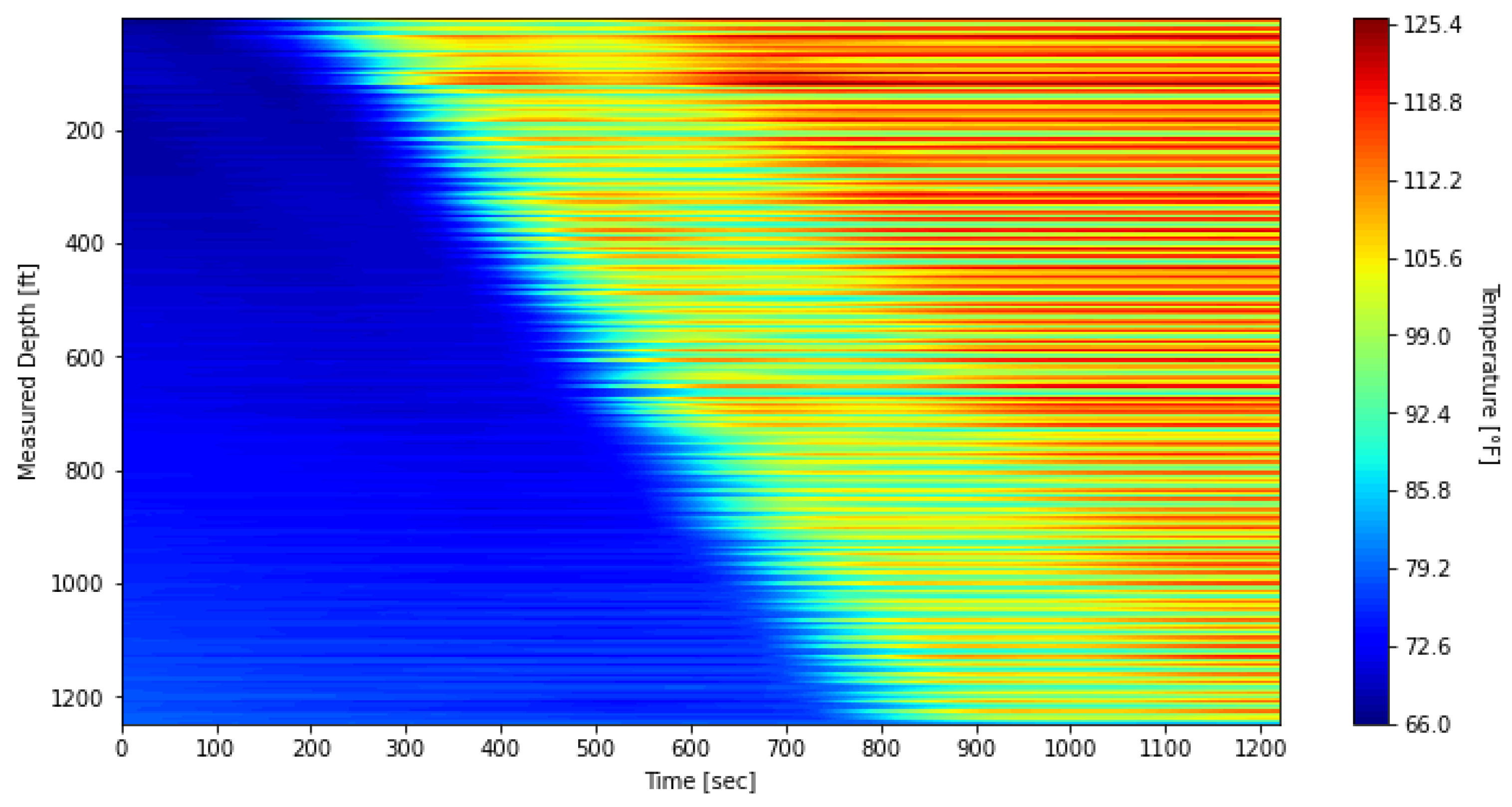

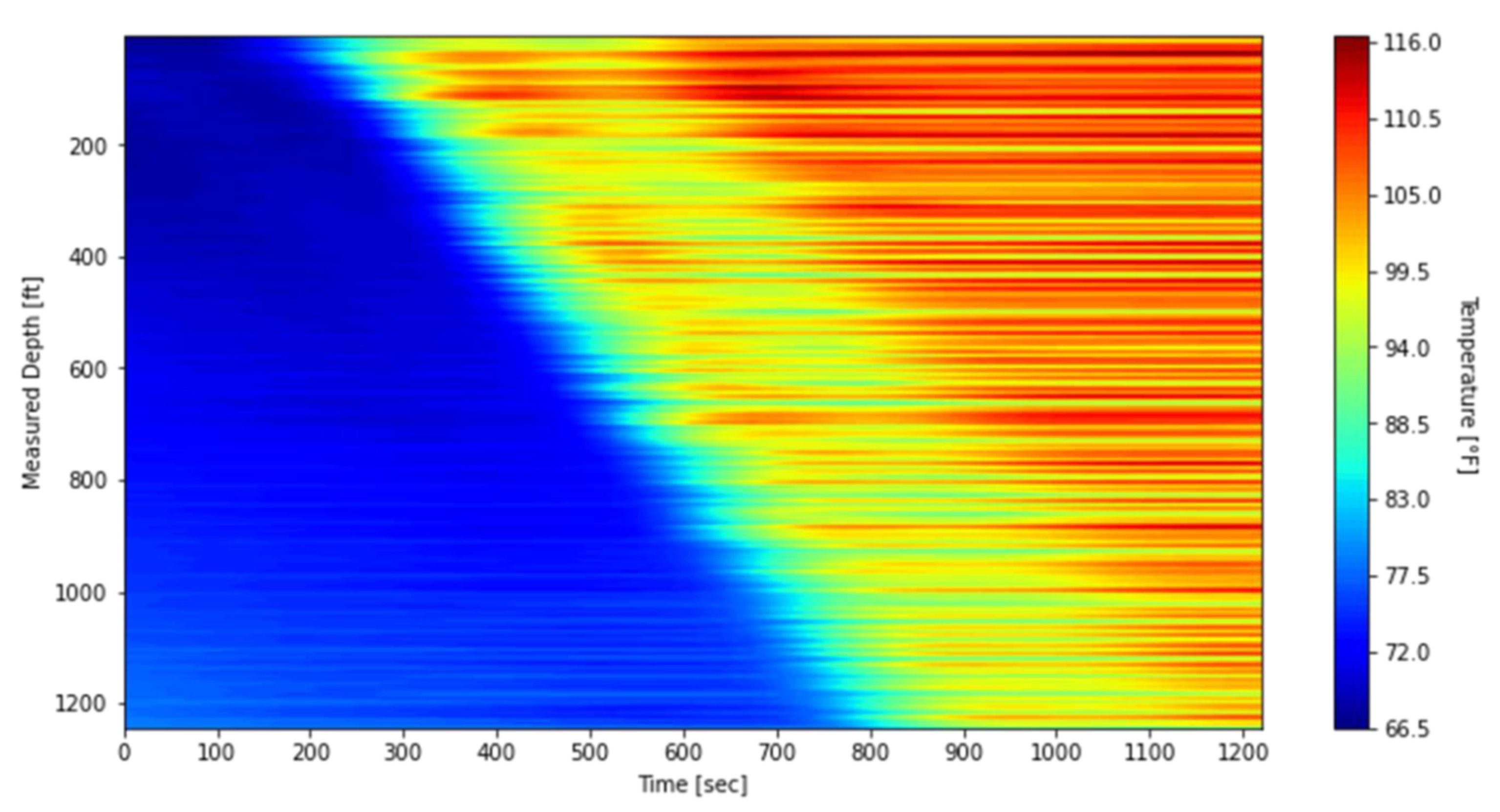

Section 3 presents the DTS results obtained from the circulation test and provides a detailed description of the validation procedure and interpretation of the results. Finally,

Section 4 concludes the study and highlights potential directions for future research.

4. Conclusions

In this study, we confirmed that the thermal slug velocity is lower than the fluid velocity. This finding provides new insight into heat transfer dynamics, showing that the thermal front propagates more slowly than the fluid front because heat transfer within the fluid is not instantaneous. The analysis highlighted strong completion effects, as the presence or absence of banding affected the DTS temperature profile and demonstrated the importance of accounting for completion design in data interpretation.

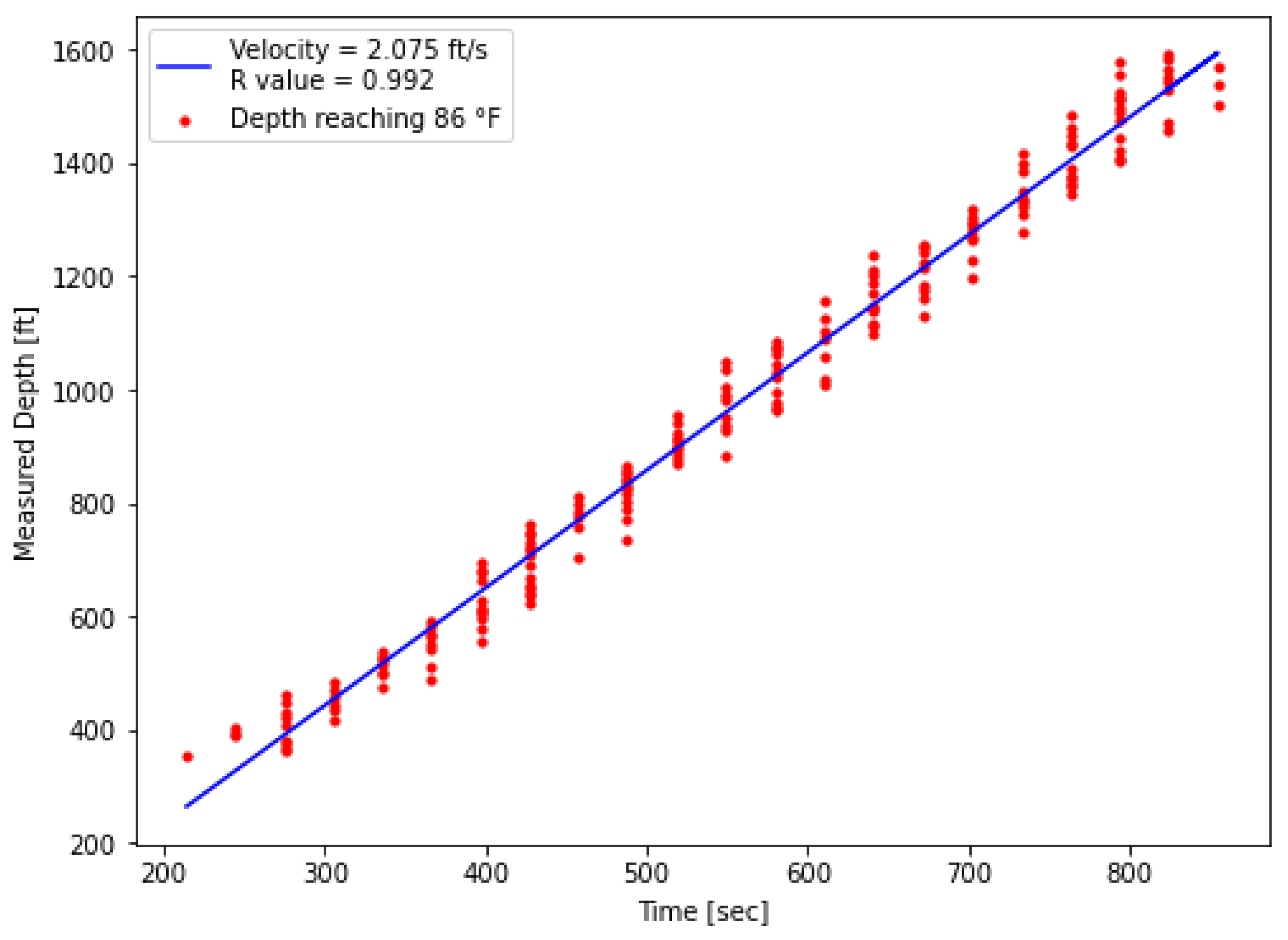

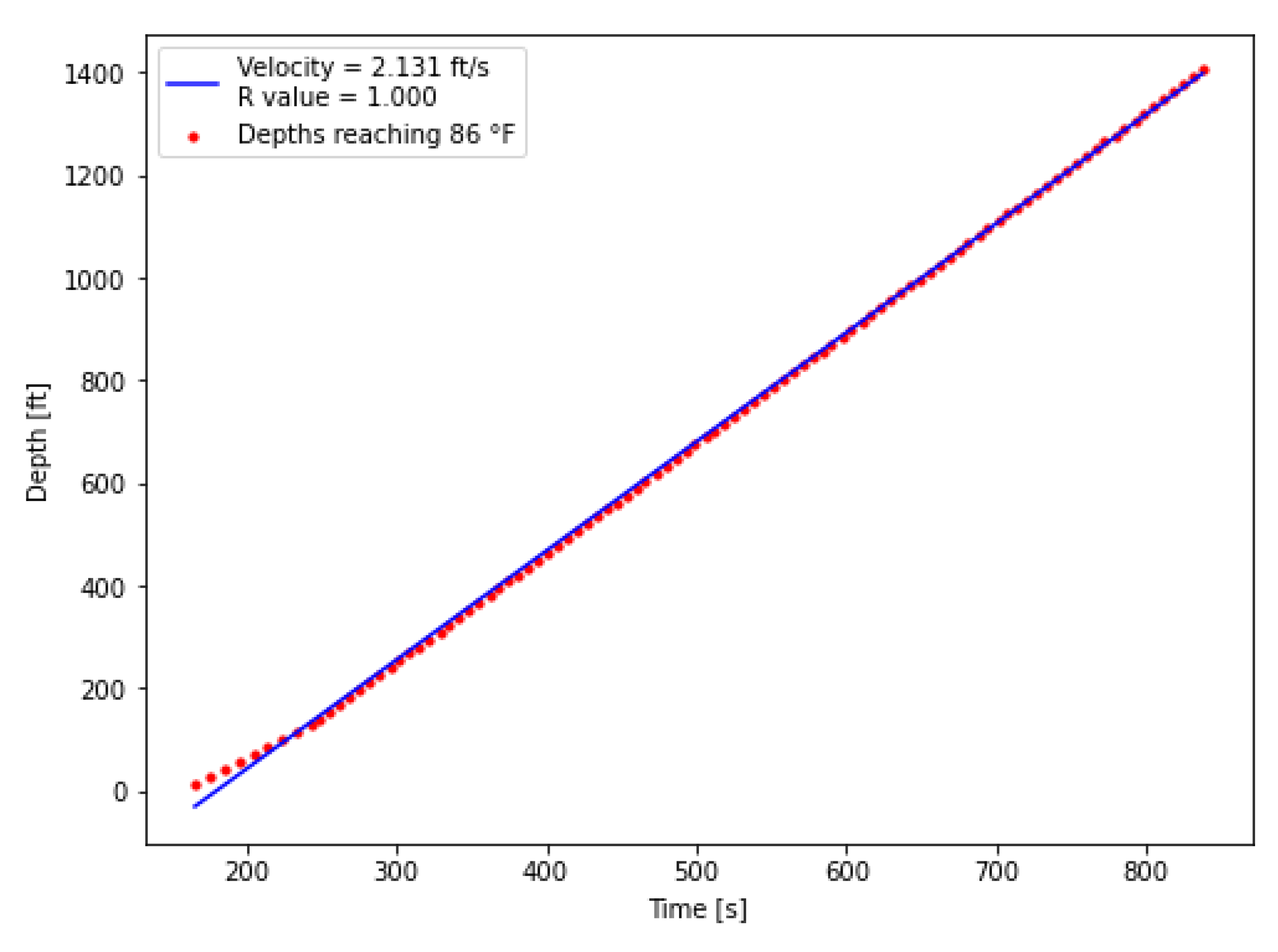

These findings were obtained by developing a transient wellbore heat transfer model and validating its predictions against DTS measurements. As part of this process, we introduced a threshold-temperature method to determine the thermal slug velocity in a non-arbitrary manner. When measurement points exceed the threshold at a given depth and time, they are recorded and plotted on time–depth diagrams. Linear regression is then applied to these points to calculate the velocity. This systematic approach removes the arbitrariness of conventional methods and yields consistent, reproducible velocity estimates. Model validation against DTS observations, including both waterfall plots and thermal slug velocities, showed close agreement, with velocity errors of less than 2.7%. In addition to its methodological advantages, the threshold method is practical and can be readily integrated into commercial DTS analysis platforms for automated velocity evaluation. Overall, the results demonstrate that the model reliably captures the dominant unsteady thermal behavior while retaining a simple framework and computational efficiency.

Looking ahead, future work will extend this approach to identify fracture locations from fiber-optic measurements and to quantify flow communication between injection and production wells in EGS. These developments will deepen the understanding of complex transient heat transfer in geothermal reservoirs and further enhance the role of fiber-optic sensing technology in geothermal development.