Abstract

This paper presents a state-of-the-art review on the integration of digital twins and artificial intelligence to advance the circular economy and the 10R principles implementation in high-speed train rolling stock. Rolling stock generates substantial waste at the end of its service life, yet the application of the circular economy and the 10R principles (Refuse, Rethink, Reduce, Reuse, Repair, Refurbish, Remanufacture, Repurpose, Recycle, and Recover) in this domain remains limited compared with infrastructure. The review analyses 47 studies retrieved from Web of Science and IEEE Xplore, focusing on digital twin applications in railway infrastructure and rolling stock, and machine learning techniques. Findings reveal that most studies concentrate on data management and efficiency improvement, while only a few explicitly address the circular economy and 10R principles. A comparative analysis of high-waste components against current machine learning applications further highlights critical gaps. To address these, an automated workflow is proposed, incorporating digital twins, artificial intelligence, and the 10R principles to support condition monitoring and sustainable resource management. The study provides insights and research directions to enhance sustainability in railway asset management.

1. Introduction

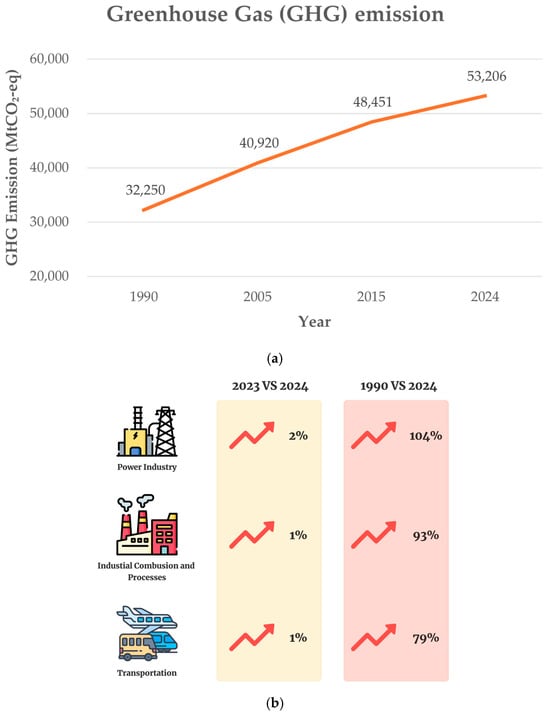

Climate changes refer to long-term changes in temperatures and weather patterns. Since the 1800s, human activities have been the main cause of climate change, mostly because of burning fossil fuels. Fossil fuels combustion produces greenhouse gas emissions. The main greenhouse gases responsible for climate change are carbon dioxide and methane. Carbon dioxide and methane come from using gasoline for driving a car or burning coal for heating a building. Agriculture, oil, and gas operations are major sources of methane emissions. Energy, industry, transport, buildings, agriculture, and land use are among the main sectors that cause greenhouse gases Nations [1]. According to the European Commission’s 2025 report on GHG Emissions of all countries, global GHG emissions have shown a substantial upward trend since 1990. Over the past 34 years, total GHG have increased by nearly 20,000 Mt CO2-equivalent, reaching over 50,000 Mt CO2-equivalent in 2024. Among all sectors, the power industry, industrial combustion and processes, and transportation have been identified as the top three contributors to this increase, together accounting for the largest share of global GHG growth between 1990 and 2024 [2], as shown in Figure 1.

Figure 1.

Global greenhouse gas (GHG) emission trends [2]. (a) The trend of global GHG emissions from 1990 to 2024 shows a significant increase of nearly 20,000 Mt CO2eq over the past 34 years. (b) Comparison of GHG emission growth rates among the three highest-emitting sectors, power industry, industrial combustion and processes, and transportation, between 1990–2024 and 2023–2024.

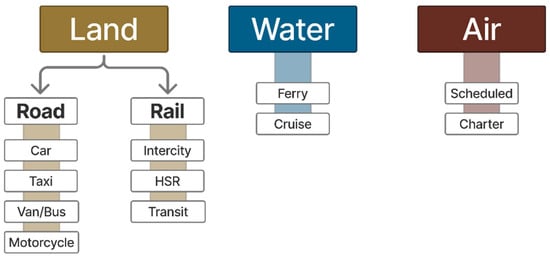

As mentioned, human activities, particularly transportation, are part of the cause of climate change. To comprehend its environmental impact, it is important to identify the modes of transport, generally categorised as land, water, and air. Each mode is characterised by technical, operational, and commercial attributes. Technical characteristics refer to features such as speed, capacity, and technology, while operational characteristics relate to the context in which modes operate, including speed limit, safety conditions, and operating hours [3]. An overview of the modes of transport is provided in Figure 2, and a comparison of CO2 emissions, one of the key greenhouse gases, among different transportation modes is provided in Figure 3 [4].

Figure 2.

Modes of transport, adapted from Rodrigue [3].

Figure 3.

Share of CO2 emissions by transportation mode (adapted from Ritchie [4]).

In terms of greenhouse gas emissions, automobiles contribute 20%, whereas railways, despite carrying 11% of goods across European countries, only contribute less than 0.6% of emissions [5]. Although this appears small compared to automobiles, according to data from the European Environment Agency, CO2 emissions from the railway industry in the EU-27 are estimated at approximately 3.3 million tonnes, a significant consideration for greenhouse gas contributions from the transportation sector [6]. Globally, rail transport is widely used, with the total passenger travel distance amounting to approximately 2.47 trillion passenger-kilometres (Pkm) in 2022 [7]. Asia, which includes several developed and developing countries such as China, Japan, Thailand, Laos, and other Southeast Asian nations, contains the largest part at 1.79 trillion (Pkm), driven by the need to increase capacity and reduce traffic congestion. Furthermore, Thailand is developing the high-speed train system to create a connectivity route with other nations, both locally and globally, in accordance with the Belt and Road Initiative (BRI) supported by the Government of the People’s Republic of China [8]. While the high-speed railway system developments offer substantial benefits for mobility and economic growth, environmental concerns are also raised regarding the management of high-speed train rolling stock.

Rolling stock’s improper end-of-life management results in significant waste generation, generally more than other vehicle types. Only 75% of the end-of-life rolling stocks were made of recyclable metals. It means that the rest of the end-of-life rolling stock will be wasted in a landfill [9]. Since train rolling stock is a resource-intensive system, a large quantity of materials is required for its manufacturing and assembly. The total mass of freight train rolling stock can reach approximately 8,000,000 kg, passenger train (Electric Diesel) is 168,373.5 kg, and high-speed train rolling stock is 265,000 kg [10]. Most of the mass comes from steel and aluminium alloys, which are among the most resource-demanding but recyclable materials used in transport manufacturing. These figures illustrate the substantial material input associated with rolling stock production and highlight the importance of implementing sustainable resource management strategies in the railway industry. In the process of ore smelting, the current challenge does not stem from insufficient availability of resources but rather from the declining quality of ores. Lower ore grades require greater extraction and processing, which increases the consumption of energy, water, and land. This intensifies the environmental burden, leading to higher GHG emissions [11].

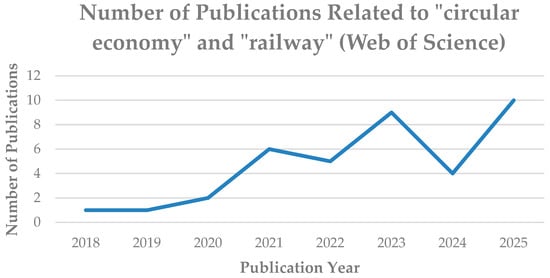

Consequently, many initiatives seeking not only to lower landfill use but also to reduce carbon emissions during vehicle operations have started to support the recycling and reuse of vehicle waste. This approach aligns with the concepts of the circular economy. The circular economy plays a crucial role in reducing greenhouse gas emissions by reducing waste and maximizing material reuse. Circular economy helps to reduce demand for new resources by extending the lifespan of materials in rolling stock, therefore supporting environmental sustainability [12]. Moreover, the circular economy is applied through the reuse of in-situ materials in the subgrade, achieving approximately 30% reduction in carbon emissions [13], while in the sub-ballast layer, the integration of reclaimed asphalt pavement and end-of-life tire rubber contributes to a 20–40% reduction in global warming [14]. To highlight the importance of applying the circular economy in the railway industry, the amount of research implementing the circular economy concept in the railway sector has been increasing, as illustrated in Figure 4.

Figure 4.

Publications trend on “circular economy” and “railway” (Web of Science, 2018–2025).

In today’s world, where digitalisation is increasingly used and the Fourth Industrial Revolution is coming, the implementation of tools such as digital twins has gained growing attention. Digital twins refer to virtual representations of physical assets, enabling bidirectional transfer or sharing of data between the physical and virtual models. Digital twins can perform across multiple sectors, such as conducting in-depth analysis of physical twins, simulating health conditions of physical twins, tracking the status throughout the lifecycle, predicting the performance, and facilitating real-time control of the physical twins [15]. However, the adoption of digital twins in high-speed train rolling stock, especially in the area of the circular economy, remains limited. To enable the circulation and utilisation of materials in high-speed train rolling stock and to extend their retention within ‘ material lifecycle in alignment with circular economy principles, this study conducts a state-of-the-art literature review to identify research gaps for future research.

This state-of-the-art review is organised as follows: In Section 2, the circular economy and 10R principles are demonstrated, and the instances of research that have implemented these concepts within the railway sector are discussed. This section also provides an overview of digital twins technology to illustrate the potential of digital twins in enhancing the implementation of the circular economy and 10R principles in the railway sector. Section 3 contains the methodology for selecting relevant studies based on the chosen keywords, including the search strategy, databases used, and inclusion/exclusion criteria for the state-of-the-art review. Section 4 includes the results of applications of digital twins and machine learning in rolling stock and a discussion on how these applications can enhance the implementation of the circular economy in high-speed train rolling stock. This section also proposes an automated workflow to enable circular economy and condition monitoring for the assets. Lastly, Section 5 presents a conclusion and outlines directions for future studies.

2. Sustainability in the Railway Industry

2.1. Circular Economy and 10R Principles

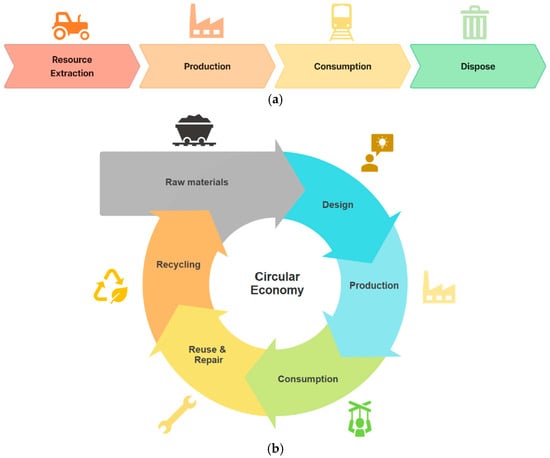

The utilisation of raw materials has adhered to a linear economy model, a ‘take-make-dispose’, wherein material is introduced into the production process but are finally discarded at the end-of-life of the finished product, rather than being reused or recycled (as shown in Figure 5a). However, in recent years, the circular economy (as shown in Figure 5b), which advocate reducing raw material consumption, have gained significant attention. Particularly since the introduction of the United Nations’ Sustainable Development Goals (SDGs), the circular economy has been increasingly promoted as a global agenda.

Figure 5.

Linear and Circular Economy Models: (a) the Linear Economy model, where resources flow in a straight line from extraction to disposal; (b) the Circular Economy model, where resources are continuously reused, repaired, and recycled to minimise waste.

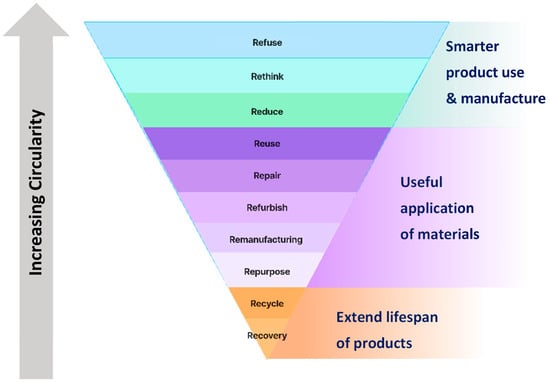

According to José Potting [16] the Policy Report, circularity is categorized into three categories, referred to as the 10Rs, as seen in Figure 6.

Figure 6.

The 10R principles for circular economy [16].

To enhance the understanding of the 10R principles, the meaning of each “R” is described, starting from the strategies that exhibit the highest degree of circularity, as follows:

- Refuse: Make a product redundant by abandoning its function or by offering the same function through a radically different product.

- Rethink: Make product use more intensive through design or service innovation.

- Reduce: Increase efficiency in product manufacture or use by consuming fewer natural resources and materials.

- Reuse: Allow another consumer to reuse a discarded product that is still in good condition and fulfils its original function.

- Repair: Conduct repair and maintenance of a defective product so it can continue to be used with its original function.

- Refurbish: Restore an old product and bring it up to date to meet current standards.

- Remanufacture: Use parts of discarded products in a new product with the same function.

- Repurpose: Use a discarded product or its parts in a new product with a different function.

- Recycle: Process materials to obtain the same or lower quality for reuse.

- Recover: Perform incineration of materials with energy recovery.

In previous studies, the circular economy and the 10R principles have been partially implemented in the railway sector. To illustrate the examples of the application of circular economy in the railway sector, Table 1 presents examples of relevant studies identified through a Web of Science search engine using the keywords “circular economy” and “railway”. The table demonstrates that the implementation of the circular economy and 10R principles in the railway sector is predominantly concentrated on infrastructure rather than rolling stock.

Table 1.

Examples of the implementation of the circular economy in the railway industry.

Table 1 illustrates that Circular Economy applications in the railway sector mostly emphasise infrastructure, while research on rolling stock is very scarce. This disparity might be attributed to the structural complexity of rolling stock systems, including multiple components and subsystems. The implementation of a circular economy, such as reuse, remanufacturing, or recycling, is further limited by the variety of materials utilised in manufacturing.

To better understand material-related challenges, the following section provides an overview of the main components and materials that constitute rolling stock systems. The analysis focuses particularly on high-speed train rolling stock, which forms the primary scope of this study.

2.2. Material Analysis of High-Speed Train Rolling Stock

This state-of-the-art review, as mentioned in Section 1, concentrates on high-speed train rolling stock. To offer a general overview of rolling stocks, as specified by Silva and Kaewunruen [22], this section briefly presents the types of train rolling stock. Following this, the materials and components of high-speed train rolling stock are detailed.

2.2.1. Types of Train Rolling Stock

This subsection will present the types of rolling stock that are classified according to their functions and services. According to European Practice, rolling stock can be classified into several types. However, in this study, rolling stocks will be divided into 3 types.

- Passenger Trains

Passenger trains, such as a metro, tram, light rail, or urban rail vehicle, are designed to transport passengers and typically consist of elongated carriages meant to operate at higher speeds. It can be a self-propelled railcar or a combination of one or more locomotives and one or more trailers. The primary function of passenger trains is to facilitate passenger transportation between stations. They adhere to fixed schedules and generally accommodate more passengers than other types of trains.

- Freight Trains

Freight trains consist of locomotives and freight wagons or freight cars, facilitating the transportation of materials and goods. Utilizing trains for freight transportation can offer significant economic benefits and efficiency compared to road transport.

- High-speed Trains

High-speed trains fall within the category of long-distance passenger trains. These trains can achieve speeds surpassing 250 km/h and operate on specially designated tracks engineered to accommodate high speeds. Japan’s Shinkansen is the pioneering example of a successful high-speed passenger rail system. In Thailand, the high-speed rail system project connecting Thailand and China, which is officially titled “The Project on Bangkok–Nong Khai HSR Development,” has commenced. The construction in Thailand began with Section 1: Bangkok-Nakhon Ratchasima, covering 250.77 km, which is currently 45.56% complete [8]. As mentioned in Section 1, the development of a high-speed rail system not only enhances mobility and economic growth but also potentially presents environmental impacts arising from the waste generated by high-speed train rolling stock. So, to enable the application of circular economy and 10R principles, the materials and components of high-speed train rolling stock are detailed in the following section.

2.2.2. Material Analysis of High-Speed Train Rolling Stock

Material Analysis of rolling stock components provides insight into their potential for 10R principles, which are key considerations for the circular economy. In the study conducted by Kaewunruen, et al. [10], a summary of the total weight, recyclability rate (%), and recoverability rate (%) of rolling stock was provided in Table 2, comparing three different types of rolling stock.

Table 2.

Summary of total weight of rolling stocks (kg), recyclability rate (%), and recoverability rate (%) comparing with three types of rolling stocks.

2.2.3. Circularity Potential of Key Components

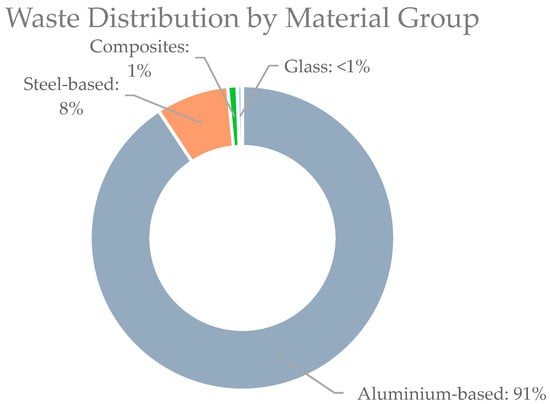

As mentioned in the previous sections, the components of high-speed trains are divided according to the weight of waste generated, ranked from the highest to the lowest in terms of weight (in kilograms). From the 36 components identified in Table 3, the 15 components with the highest waste weight are presented in Table 3, enabling a more practical and effective evaluation of circularity. Following the identification of the top 15 waste-generating components, the waste was categorised by material type into four categories: Aluminium-based, Steel-based, Composites, and Glass, as illustrated in Figure 7.

Table 3.

Top 15 components ranked by waste generated (in kilograms).

Figure 7.

Waste distribution by material group from the top 15 waste-generating components of the high-speed train.

Following the material classification, a circularity assessment is conducted for each group with specific attention to the 10R principle.

- Aluminium

As shown in Table 3, aluminium-based materials constitute the primary component of waste generated from high-speed train rolling stock. The material possesses a lightweight property that minimizes weight by approximately 10%. Furthermore, the recyclability and recovery rate could exceed 95% [10]. According to Passarini et al. [23] a significant portion of recycled aluminium, up to 75%, in Europe is utilized within the transportation sector.

- Steel

Steel is recognized for its potential to be recycled up to 100% for the production of new steel products. If steel maintains its qualities, it can be recycled. As shown in Table 3, components that are made of steel-based materials include wheels, bogie frame, main transformer, bogie transom, motor suspension coil, and gearbox.

- Glass

Apart from aluminium and steel, glass represents almost 1% of the overall waste. In the context of the circular economy and 10R principles, glass is a reusable material. Used glass is processed into cullet, which is subsequently combined with sand, soda, and limestone before being returned to the manufacturing process [10]. As shown in Table 3, the waste weight of glass amounts to 490.3 kg. Glass can be recycled into various products, such as aggregates in concrete, ceramic sanitary ware, fiberglass insulation products, and recycled glass countertops [10,24].

2.3. Digital Twins Technology

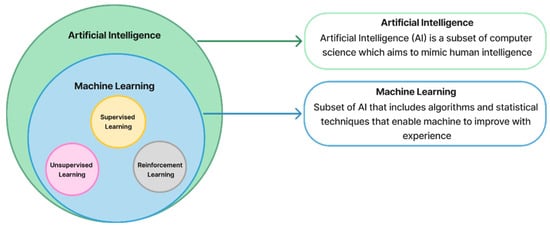

Before the emergence of digital twin technology, Artificial Intelligence (AI), officially introduced during the 1956 Dartmouth Conference, has since evolved significantly, driving advancements in computational power, machine learning, and big data analytics. These advancements have established the foundations for transformational technologies such as digital twins [25,26]. Machine learning and Deep learning, which are considered essential subsets of AI, play a particularly important role in this evolution (as shown in Figure 8).

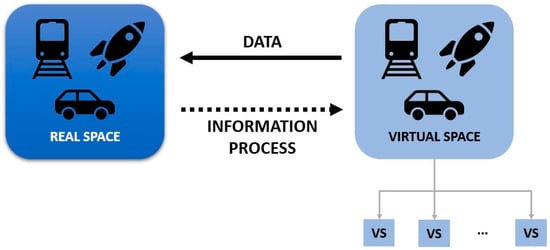

The emergence of digital twins has been largely driven by advancements in Artificial Intelligence (AI). Digital twins are a virtual representation of physical systems. This kind of technology does simulations based on real data. The concept of digital twins was informally introduced by Michael Grieves in 2002 during his presentation with the title “Conceptual Ideal for Product Lifecycle Management (PLM)”. Grieves’ DT model, later detailed in publications [26], consist of three key components: (1) a real space containing a physical object; (2) a digital space containing a virtual object; and (3) the link for data flow from real space to virtual space, and information flow from virtual space to real space [27] as shown in Figure 9.

Figure 8.

Brief definitions of Artificial Intelligence, machine learning (adopted from Uc Castillo, et al. [28]).

Figure 9.

Conceptual ideal for product lifecycle management (PLM) by Grieves and Vickers [27].

After presenting studies that demonstrate the implementation of circular economy within the railway sector in Section 2.1, Table 4 illustrates how various digital technologies, such as Digital twins and Artificial Intelligence, have been employed across multiple domains to enhance circular economy practices.

Table 4.

Overview of Digital Technology Applications Supporting the Circular Economy Across Multiple Domains.

Table 4.

Overview of Digital Technology Applications Supporting the Circular Economy Across Multiple Domains.

| Domain | Objective | Digital Technology Involved | Circular/Sustainability Relevance | Reference |

|---|---|---|---|---|

| Supply Chain Management | To review and synthesise various Industry 4.0 technologies and their environmental sustainability implications within supply chain management. | DTs, AI, IoT, blockchain, cloud computing | Waste reduction, emission control, traceability, reverse logistics and CE | Challouf, et al. [29] |

| To map the theoretical, contextual, and methodological evolution of net-zero supply chain management and identify research gaps in digital and circular strategies. | DTs, AI, Data Analytics, Life Cycle Assessment Frameworks | Highlights the integration of circular economy and digital transformation themes to support data-informed decarbonisation and sustainable supply chain transitions. | Raman, et al. [30] | |

| Energy Storage | To review modelling and simulation approaches for optimising electrode drying and predicting defect formation. | DTs/ML, etc. | Green solvents and solvent recovery within drying systems | Mujumdar, et al. [31] |

| To explore how digitalisation and digital twins can enable circular and efficient end-of-life management in the lithium-ion battery value chain. | DTs | Battery recycling | Cardenas-Sierra, et al. [32] | |

| Urban system | To propose and validate an integrated SSCC architecture linking digital, governance, and data systems to support circular urban transformations. | DTs, AI, IoT, Drones, Participatory Platforms | Integrated digital and governance frameworks enable circular strategies through waste–energy–information nexus | Velasquez-Mendez, et al. [33] |

| Construction | To review how digital technologies enhance circularity and life cycle management in the construction sector | DTs, BIM, IoT, Blockchain, Big Data | Optimises resource use, improves traceability, and advances circularity in line with EU sustainability standards | Gondak, et al. [34] |

| To develop and validate a predictive digital twin–based system integrating BIM, IoT, and AI for efficient and sustainable construction resource management. | DTs, BIM, IoT, ML | Enhances real-time monitoring and predictive control of site resources, reducing waste and improving efficiency to support circular economy. | Elghaish, et al. [35] | |

| To examine the role and benefits of digital twinning in facilitating the transition to a circular economy in the construction industry | DTs | Waste reduction, resource optimisation | Awodele, et al. [36] | |

| To conceptualise and examine the role of digital twins as enablers of circular economy and sustainable development goals in the construction and manufacturing sectors. | DTs | Demonstrates how DT-driven information enhances recyclability, reusability, and sustainability. | Ali, et al. [37] | |

| Port Energy System | To propose a digital twin–based dynamic optimisation framework for zero-carbon port energy systems integrating renewable management and carbon accountability. | DTs, Federated Learning, Hybrid Quantum–Classical Optimisation, Blockchain, Adversarial Reinforcement Learning | Real-time optimisation for renewable utilisation, carbon reduction, and energy efficiency | Li, et al. [38] |

| Waste Management | To introduce and validate a digital twin–based methodology for optimising organic waste management processes | DTs, Cloud Architecture, IoT-enabled Monitoring | Resource recovery and demomstrating scalable potential for circular economy applications in waste management | Vargas, et al. [39] |

| Manufacturing | To review engineering innovations and technologies advancing PVC recycling and circular manufacturing integration. | DTs, AI, Robotics, Hyperspectral Imaging | Promotes digitally integrated recycling systems supporting circular manufacturing and sustainable polymer reprocessing. | Chidara, et al. [40] |

3. Methodology

3.1. Research Gap Identification Approach

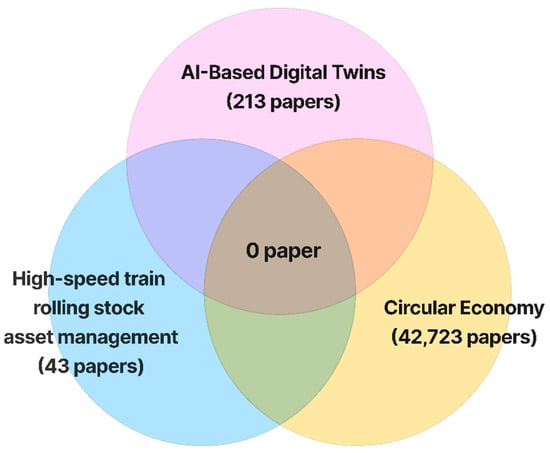

First, to achieve a comprehensive review of the relevant literature, a Venn diagram was created as a visual tool to examine potential gaps between existing research topics, identified through selected keywords, for defining future research directions and their novelty. The keywords used were “AI-based digital twins”, “High-speed Train rolling stock asset management,” and “Circular Economy,” using the Web of Science as a search engine to determine the number of research studies conducted on those fields. The Venn diagram for this study is shown in Figure 10.

Figure 10.

Venn Diagram.

From the results of the Venn Diagram, using these three keywords, it is demonstrated that no previous research has integrated AI-based digital twins, High-speed train rolling stock asset management, and circular economy within the same research scope

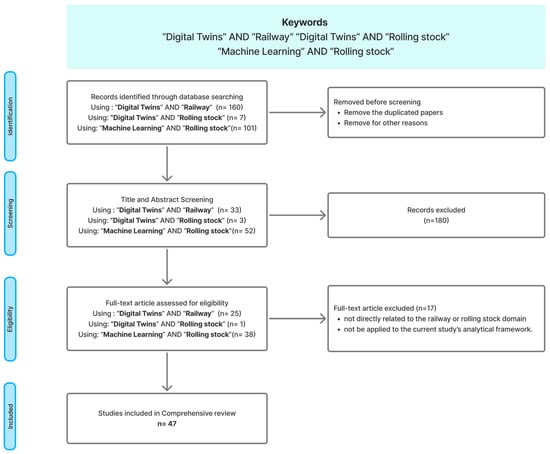

3.2. Paper Screening and Selection

As stated in Section 2.3, machine learning (ML) enables AI and digital twins. Consequently, the publications are selected from both fields: digital twins and machine learning. In the digital twins part, the keywords “Digital twins” AND “Railway” and “Digital twins” AND “Rolling stock” were used to search for studies related to this topic, and in the machine learning domain, the keywords “Machine Learning” AND “Rolling Stock” were used in the screening and selection phase. The review was performed utilising two scholarly databases: Web of Science and IEEE Xplore.

The review process was undertaken in four key steps:

- Retrieve publications from the Web of Science and IEEE Xplore database using the defined keywords.

- Eliminate irrelevant publications by screening abstracts, introductions, and conclusions to ensure alignment with the inclusion criteria.

- Conduct a detailed review of the full content of all relevant publications filtered in step 2.

- Undertake a comprehensive analysis, categorizing the publications based on applications, attributes, and functionalities.

The diagram below (Figure 11) presents the procedure for screening and selecting papers.

Figure 11.

Presents the steps involved in the screening and selection of papers.

Following the initial review process described above, a total of 268 studies were found. After applying the review process, which involved analysing the relevance of each study to the research aim, 47 studies were chosen for comprehensive analysis. These consist of 21 studies under the keyword “Digital twins” AND “Railway”, 1 study under “Digital twins” AND “Rolling stock”, and 25 studies under “Machine Learning” AND “Rolling stock”.

4. Result

4.1. Digital Twins Applications in Railway

4.1.1. Initial Research Insights into Digital Twins for Railway Systems

In this subsection, a selection of notable literature reviews is examined to demonstrate the increasing interest among researchers in the application of digital twins in railway systems. This field of study is still relatively unexplored, although the available literature provides significant insights into ongoing research trends and the developing function of digital twins in the railway sector.

Doubell, et al. [41] Emphasised the increasing trend of digital twins implementation across several industries, driven by the emergence of the Fourth Industrial Revolution. However, the application of digital twins in the railway industry is still limited. The exist-ing studies were reviewed and prospective approaches for using digital twins were suggested in the railway infrastructure data management. These directions include the integration of data from various sources, validation of management paradigms, and the processing of large volumes of data.

Moreover, an additional literature analysis emphasised the growing interest in digital twins [42]; yet, it observed that standardisation in their applications is still lacking. This state-of-the-art literature review employed the PRISMA methodology to investigate the resilience and sustainability of rail and road infrastructure through the implementation of digital twin technologies.

From the reviewed literature, along with the increasing research trend in the field of digital twins, it becomes clear that this area is gaining academic interest. This growing attention has sparked the author’s interest in further examining how digital twins have been utilised within railway systems. In the following subsection, relevant research works will be discussed in detail, categorized into 3 areas: applications related to infrastructure, to rolling stock, and both infrastructures and rolling stock. This categorization is based on the primary focus of each research work, allowing for a clearer understanding of the key areas explored within this domain.

4.1.2. Research on Digital Twins in Railway Infrastructure

From the selected literature, a total of 21 studies were identified that applied digital twins technologies in the context of railway infrastructure. To explain the diverse applications and research directions within this area of study, these papers have been classified into 5 subtopics, each representing a different aspect of digital twins application in railway infrastructure.

Data Management Approaches and Framework for Digital Twins of Railway Infrastructure

This subtopic presents studies that focus on the generation of synthetic data to support railway infrastructure applications and the development of digital twins frameworks. Some works have demonstrated how synthetic data can be used to augment limited datasets and improve model training (Table 5).

Table 5.

Studies on Synthetic Data Generation and Digital Twin Frameworks for Railway Infrastructure.

Digital Twins for Defects Visualisation and Enhancing Inspection

This subtopic presents research that explores the application of DTs for defect visualisation and the enhancement of the inspection process in railway infrastructure. The selected studies demonstrate how DTs can support the 3D model of track defects, predict inspection signals, monitor and visualize the operation of level crossings (LC), and simulate fatigue damage. To better understand these applications, each study is discussed, highlighting how digital twins have been utilised across different visualization and inspection contexts (Table 6).

Table 6.

Applications of Digital Twins in Railway Defect Visualisation and Inspection.

Digital Twins for Sustainability

One study demonstrates the potential of digital twins in supporting sustainability objectives within the PCAT concrete slab track system (Table 7).

Table 7.

Applications of Digital Twins for Sustainability.

Digital Twins for Condition Monitoring

This subtopic highlights the use of DTs for condition monitoring. The reviewed studies demonstrate how DTs have been employed to monitor various aspects, such as weather conditions and the operational status of railway switches. Additionally, there is a study focused on investigating the causes of deterioration as a foundational step toward the future development of digital twins for condition monitoring (Table 8).

Table 8.

Applications of Digital Twins for condition monitoring.

Semantic Segmentation for Developing Digital Twin Models

Semantic Segmentation, which involves pixel-wise classification of images or point cloud data to classify into a specific category or class, is considered a promising approach for enhancing the development of DT models (Table 9).

Table 9.

Applications of Semantic Segmentation in Enhancing Digital Twin Models.

Digital Twins for Prediction

This subtopic highlights the use of DTs for prediction (Table 10). The reviewed studies demonstrate how DTs have been applied to forecast rail surface damage and derailment risks, supporting predictive maintenance, enhancing safety, and improving operational efficiency in railway systems.

Table 10.

Applications of digital twins for prediction.

4.1.3. Research on Digital Twins in Railway Rolling Stock

Following the review of DTs’ application in railway infrastructure, this section focuses on research related to the application of DTs in railway rolling stock (Table 11). Even though the use of digital twins in Train Rolling Stock is not yet widespread, at least there has been research that has started to study the creation of an accurate model of rolling stock, which is a good start to further develop digital twins in the train rolling stock system. Among the several techniques available, laser scanning and vision-based technologies have proven to be successful for capturing detailed structural information.

Table 11.

Applications of digital twins in railway rolling stock.

4.2. Overview of Machine Learning Applications in Rolling Stock

After reviewing the research on DTs in infrastructure and rolling stock, it can be seen that the difference in the amount of research on infrastructure and rolling stock is significant. This shows that the use of DTs in rolling stock systems is still in great demand. Therefore, in this section, the research related to the usage of ML in rolling stock systems will be reviewed.

Rolling stock, including critical elements such as wheelsets, bogies, and traction systems, constitutes the foundation of railway operations. These subsystems are essential for ensuring safety, reliability, and performance in contemporary railway networks. Nonetheless, sustaining and enhancing these components present considerable difficulties, particularly because of the complexity of their interconnections and the large amount of data produced during operation.

Machine Learning (ML) is growing as a powerful technology for addressing these difficulties. Utilising advanced algorithms, machine learning facilitates predictive maintenance, real-time monitoring, and defect identification, essential for minimising downtime, enhancing safety, and decreasing operational expenses. The use of machine learning techniques in rolling stock maintenance operations signifies a crucial advancement towards more intelligent and efficient railway systems.

This section provides studies of the Machine Learning techniques used in rolling stock. It classifies the components and their corresponding machine learning methodologies, highlighting the role of these techniques in prediction, detection, classification, and monitoring.

4.2.1. Predicting

Predictive maintenance is essential for reducing breakdowns and enhancing the operational efficiency of rolling stock. Several machine learning techniques have been employed to predict maintenance requirements, save downtime, and improve component reliability. Linear regression and regularisation techniques were employed to predict the maintenance schedule of wheelsets, as noted in [63]. This method effectively forecasts optimal maintenance times through the analysis of previous data, although it is constrained by its susceptibility to outliers and the necessity for data scaling.

Moreover, research utilising moving averages, ARIMA, and seasonal ARIMA (SARIMA) has demonstrated efficiency in developing dependable forecasting models for traction control units (TCU) [64]. These strategies use expert knowledge to analyse onboard diagnostic data and generate predictions. However, issues remain involving data reliance and seasonality, as changes in train performance might reduce forecasting precision. The manual methodology employed in certain models also adds biases, constraining the automation capabilities of machine learning systems.

A related study on Mean Time to Repair (MTTR) [65] employed regression-based techniques, such as linear regression, polynomial regression, and random forests, to forecast downtime and enhance maintenance models. However, challenges remain in terms of data quality, model complexity, and generalisability across railway systems.

Bayesian models, including Bayesian Factorisation and Expectation-Maximization (EM), have been employed in dynamic risk assessment to identify key risk variables in semi-permanent coupler failures [66]. Although these models yield valuable insights using sensitivity analysis, their dependence on high-quality data and complex integrations presents considerable challenges.

Another study introduces a predictive maintenance approach for rolling stock vehicles utilising Machine Learning Algorithms for Remaining Useful Life estimation [67]. The focus is on reducing uncertainty in maintenance schedules, estimating Remaining Useful Life (RUL), and lowering downtime and expenses by effective maintenance scheduling and multi-tier platform execution. Nonetheless, limitations include its dependence on a singular case study, which minimises generalisability, and data reliance, whereby insufficient data affects predictive accuracy. The study underscores the complexity of implementation due to multi-layer architecture and diagnostic integration, insufficient emphasis on specific components important to diverse vehicle types, and restricted validation metrics, which prevent an accurate evaluation of the technique.

The prediction of technical failures in railway door systems utilises models such as Restricted Boltzmann Machines (RBM) and Echo-State Networks (ESN). These approaches effectively predict failures by employing diagnostic data, although they encounter limitations such as data dependence and the static characteristics of training data [68].

Research utilising Random Forests (RF), Quantile Random Forests (QRF), and Principal Component Regression (PCR) has demonstrated considerable advancements in predictive maintenance for calculating the Remaining Useful Life (RUL) of components [69]. Nonetheless, constraints such as insufficient data, complex feature interactions, and challenges in model interpretability remain in limiting wider use.

Additionally, Random Forests (RF) and Missing Value Imputation methods have been employed to predict failure times of railcar wheels and trucks based on wayside detector data [70]. These methods proficiently manage sensor data and enhance railway safety by reducing inspection and maintenance expenses. Nonetheless, constraints such as dependence on a singular dataset, the intricacy of real-world scenarios, and biases from missing data limit the generalisability of these models.

Another research proposes a data-driven methodology for forecasting the service life of rolling stock components through Random Forest Regression (RFR) and Gradient Boosting Regression (GBR) [71]. The primary focus is on forecasting service longevity, addressing the SGR backlog, calculating long-term replacement expenses, and improving asset management approaches. Nonetheless, limitations encompass the emphasis on minor urban and rural networks, potentially limiting generalisability, as well as data restrictions due to reliance on 2020 vehicle inventory statistics. The model’s exclusion of active vehicles could miss significant patterns, while the study underscores the opportunity for model enhancement through the integration of maintenance records and real-time sensor data to improve accuracy and practical relevance.

Within traction converter systems, Long Short-Term Memory (LSTM) networks have exhibited significant precision in forecasting breakdowns and reducing false alarm rates [72]. Although its accuracy, factors such as dataset specificity and temporal reliance on previous data undermine the model’s robustness.

The prediction of energy consumption in metro trains depends on Neural Networks (NN) and data filtration methods to improve energy efficiency and minimise data noise [73]. Nonetheless, factors such as signal noise, limits of closed environments, and data quality persist in affecting the models’ accuracy.

Finally, to improve rail network velocity with a machine learning methodology for predictive maintenance, [74] concentrating on components including bearings, trucks, wheels, and monitoring systems. Methods such as Support Vector Machines (SVM), Decision Trees (DT), distributed learning, and causal analysis were employed to forecast Level 1 (L1) alarms, reduce false alarm rates, and combine various data sources for predictive maintenance. Primary challenges encompass data quality and availability, as model efficacy depends on extensive detection data, and generalizability, where methods may be confined to specific operational situations. Further limitations include the complexity of real-world scenarios, the attainment of a minimal false alarm rate in practice, and the interpretability of sophisticated models such as SVM, which may limit their practical implementation in decision-making.

4.2.2. Detecting

The study examines variations in waveform distortion in railway pantograph observations through the application of Deep Autoencoder [75], clustering techniques, and Principal Component Analysis (PCA). The techniques concentrate on evaluating waveform distortion, recognising patterns, enhancing power quality, and conducting dynamic analysis through the identification of patterns in the recorded waveforms. Significant limitations encompass sample size and diversity, potentially constraining generalisability, as well as challenges with distinguishing the effects attributable to the static versus dynamic observations of pantographs. The complexity of distortion causes and reliance on data quality underscore possible challenges presented by noise or mistakes that could affect model reliability. Moreover, the study’s restricted analytical scope concentrates mainly on waveform distortion.

Fault detection in rolling stock components is essential for maintaining operating safety and reliability. Diverse machine learning methodologies, encompassing Support Vector Machines (SVM), Deep Learning Networks (DNNs), and Wavelet Transform, have been utilised to identify wheel faults, including flat spots, shelling, and non-roundness [76]. Research has shown early detection abilities; nonetheless, difficulties remain in managing class imbalance within datasets and the intricacies of real-world applications.

Methods such as Sparse Autoencoders (SAE), Mahalanobis Distance, and Cluster Analysis have been investigated for detecting out-of-roundness (OOR) in wheels and evaluating the severity and type of damage [77]. Although these technologies exhibit potential, their dependence on simulation-based validation and controlled failure situations could limit their applicability to actual railway systems.

In the realm of fault detection, Convolutional Neural Networks (CNNs), such as Xception and EfficientNet-B7 architectures, have been used for condition monitoring systems [78]. These algorithms combine defect detection with performance evaluation; however, substantial computational resources and environmental considerations present practical deployment challenges.

Hybrid methodologies integrating Multi-Layer Perceptrons (MLP), Support Vector Machines (SVM), together with other techniques such as Decision Trees (DT) and k-Nearest Neighbours (kNN), have been developed for the detection of wheelset failures [79]. Although it has resilience, factors such as sensor requirements, simulation-exclusive data, and limited fault scenarios prevent its practical application.

Detection methods have also been utilised for unsupported sleepers and integrated railway problems employing deep learning methodologies, including Convolutional Neural Networks (CNN), Recurrent Neural Networks (RNN), and Fully Convolutional Networks (FCN) [80]. These investigations underscore their efficacy in identifying faults and assessing severity; however, issues such as a lack of field data, limited sample variety, and the complexity of real-world situations remain unresolved.

The study focuses on wheel flat detection and severity classification using deep learning techniques such as DNN, CNN, and RNN [81]. It aims to improve predictive models and contribute to preventive maintenance by detecting and classifying the severity of wheel flats. However, limitations include the reliance on simulation-based data instead of real-world data and the lack of real-time testing under operational conditions. Additional challenges involve the risk of overfitting, a limited scope focusing solely on wheel flats, and the potential for incomplete feature selection, which may overlook other influencing factors.

Machine learning models, including DNN, CNN, and RNN, have been used to detect and evaluate the severity of railway problems, particularly dipping joints and settlements, by analysing wheel and axle box acceleration (ABA) data [82]. While effective, the study relies on simulation-based data and simplified features, limiting real-world applicability. It underscores the necessity for additional validation and thorough modelling to address the complex interactions of faults.

Utilising machine learning for fault detection enables railway systems to discover problems early, mitigate operating risks, and enhance predictive maintenance plans. Nonetheless, persistent challenges, including data constraints, model intricacy, and generalisability, necessitate additional enhancement to attain viable and scalable solutions.

4.2.3. Classifying

The research provides a comparative examination of Convolutional Neural Networks (CNN), Vision Transformers (ViT), and Compact Convolutional Transformers (CCT) to create an efficient model for the safety inspection of trains, with particular emphasis on the classification of missing bolts in train components [83]. Although the models achieved high accuracy, the study underscores significant limitations, including sample size, as the dataset lacked information on the number of images, consequently impacting generalisability. Environmental variability was insufficiently examined, potentially affecting model performance in real-world scenarios. The necessity for enhanced interpretability was underscored to foster confidence in model predictions during safety inspections. Furthermore, the study’s concentration on missing bolts limits the relevance of its findings to other defect categories or problems.

The research employs t-Distributed Stochastic Neighbour Embedding (t-SNE) to classify the causes of rail contact fatigue (RCF) and to identify clusters of significant loadings associated with prospective damage areas [84]. The analysed key components consist of wheels, axle load, wheel flange, dynamic masses, and wheel trajectories. The experimental analysis offers interesting insights; nonetheless, the study is limited by its singular crossing focus, measurement limitations, and insufficient model validation. The investigation primarily focuses on high-impact load conditions, possibly ignoring other contributing aspects.

4.2.4. Monitoring

An intelligent IoT sensing system for rail vehicle running states based on artificial neural networks (ANN), sigmoid activation functions, model training and conversion, and offset time window methods is proposed [85]. The system enables real-time detection of the complex operational status, offering advantages including low energy consumption, cost efficiency, data collection and processing, deployment, and visualisation. However, there are significant challenges and limitations to acknowledge. Data dependency influences the model’s accuracy, as it is significantly contingent upon the quality and quantity of the training data. Sensor limitations occur because the study primarily concentrated on acceleration data, overlooking other potentially important inputs that could enhance accuracy and robustness. Generalisability is a concern, as findings may not be universally applicable across many contexts. The limits of real-time processing indicate that processing speed and efficiency may vary based on model complexity and the capabilities of IoT microcontrollers.

Another research [86] aims to improve the accuracy of 3D point clouds using supervised machine learning for the automated inspection of train couplers. Algorithms including Linear Regression Models, Regression Trees, Gaussian Regression Models, Support Vector Machines (SVM), and Ensembles of Trees enhance target localisation precision in dynamic and unstructured situations. Challenges encompass the environmental variables that influence sensor data accuracy, limits of depth sensors, including inadequate precision and resolution, and the necessity for a more extensive and diverse dataset to enhance model resilience. Moreover, reliance on supervised learning presents challenges, as collecting labelled training data can be expensive and labour-intensive, particularly in complex situations.

Finally, the fretting fatigue damage in solid railway axles was evaluated by unsupervised machine learning and non-destructive testing methodologies [87]. An Unsupervised Intelligent Classification System utilising Artificial Neural Networks (ANN) efficiently categorised acoustic emission (AE) data into classifications, including fretting damage and background noise, alongside the application of a k-SOM clustering approach. Significant limitations encompass the utilisation of artificial notches, which may fail to mimic real-world conditions, the testing of a single specimen that impacts generalisability, and the lack of previous studies on structural health monitoring (SHM) for axles. The study emphasises the efficacy of AE and ANN while recommending the investigation of alternative machine learning models and hybrid methodologies. Table 12 presents a comprehensive overview of machine learning (ML) techniques applied to various components of rolling stock across different purposes, including Predicting, Detecting, Classifying, and Monitoring.

Table 12.

Summary of the best Machine Learning Techniques for Rolling Stock Components.

5. Discussion

The applications of DTs in railway systems and machine learning in rolling stock have been explored from multiple perspectives. This section aims to analyse how these technologies could enhance strategies for reducing aluminium and steel waste, which were identified as the highest portion of the material in high-speed train rolling stock waste, particularly in the context of the circular economy and the 10R principles.

5.1. Digital Twins in Railway Systems

The review of 22 research studies on the application of digital Twins technology in railway systems revealed a strong focus on infrastructure management, with 21 of the studies primarily targeting this area. In contrast, only one study was dedicated to rolling stock, indicating a relatively limited application of DTs in this domain. While most studies concentrate on data management and using DTs for improving the system, relatively few address the integration of the circular economy and 10R principles. This imbalance highlights a critical research gap, suggesting the need for further development in applying DTs to support sustainability goals.

5.2. Applications of Machine Learning in Rolling Stock

After reviewing 25 research studies, the applications of Machine Learning in rolling stock can be classified into four primary categories: prediction, detection, classification, and monitoring. Furthermore, insights obtained from Table 5 reveal that these applications have been executed across multiple rolling stock components.

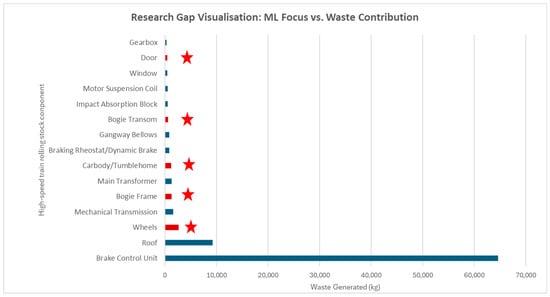

A comparative analysis between the 15 rolling stock components that generate the highest volume of waste, as indicated in Table 3, and the existing applications of Machine Learning (ML) in rolling stock research, reveals a significant research gap. Of the top 15 waste-generating components, only four have been examined in previous studies employing machine learning approaches, as shown in Figure 12, namely in the domains of prediction, detection, and classification. Significantly, none of these studies have concentrated on monitoring, a fundamental function of digital twins essential for enabling monitoring of component degradation and enhancing circular economy and 10R principles to improve sustainability and minimize material waste in high-speed train rolling stock.

Figure 12.

Top 15 rolling stock components ranked by waste generated, ★ indicates components where Machine Learning applications have been identified in existing studies.

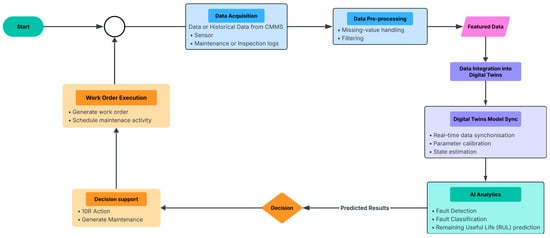

Based on the reviewed studies, it is evident that no current applications of condition monitoring in focused components. To address this limitation, an automated workflow is proposed in this study. This framework (Figure 13) highlights the incorporation of circular economy and 10R principles in component management as a pathway to sustainable resource utilisation. By systematically applying these principles, the framework provides guidance for optimising material flows, reducing unnecessary losses, and advancing railway systems towards a more circular and resilient model.

Figure 13.

Automated Workflow for Condition Monitoring and 10R Integration.

5.3. Quantitative Indicators for Evaluating Circular Economy Performance

To establish a measurable foundation for future research, several quantitative indicators are proposed to assess both the economic and environmental performance of rolling stock systems under Circular Economy (CE) principles. These indicators—Net Present Value (NPV), Embodied Carbon, ISO-based Life Cycle Cost (LCC), and Carbon Accounting—serve as key tools for evaluating sustainability outcomes. Economic indicators such as NPV can be used to assess the long-term financial viability of asset management strategies:

where and represent the revenue and cost at time , and is the discount rate. This formulation helps identify cost-efficient maintenance or refurbishment strategies over the asset lifecycle.

From the environmental perspective, Embodied Carbon is a crucial indicator that quantifies the greenhouse gas (GHG) emissions associated with material production, use, and end-of-life processes:

where is the mass of material and is its emission factor. Integrating these indicators with ISO-based LCC and Carbon Accounting frameworks will provide a more comprehensive understanding of both cost and environmental trade-offs, forming a quantitative basis for evaluating CE-oriented digital twin applications in future studies.

5.4. Potential Challenges of Digital Twins and AI Applications in High-Speed Train Rolling Stock

The integration of digital twins and AI to enhance the implementation of the circular economy in high-speed train rolling stock represents a novel and promising research direction. Nevertheless, several challenges associated with the practical adoption of digital twins and AI remain. These include issues related to data integration, data privacy, and the difficulties of applying AI models to real-world scenarios. As discussed in the following sections.

5.4.1. Data Integration and Interoperability

One of the major challenges in enhancing the circular economy using digital twins and AI for high-speed train rolling stock is the integration of heterogeneous data from multiple sources, including operators and maintenance providers, and multiple components, leading to difficulties in achieving real-time interoperability.

5.4.2. Data Privacy and Governance

Data privacy is another issue, particularly when digital twins involve real-time monitoring. Sensitive operational data, such as component health or maintenance schedules, may raise privacy concerns. Establishing clear data ownership, access control policies, and a secure data-sharing mechanism is essential.

5.4.3. AI Robustness, Bias, and Interpretability Challenges

AI has been successfully and widely adopted across various domains. However, applying AI models to real-world situations still faces several limitations and challenges, both internal and external. The examples of the internal challenges are a biased training dataset or an imbalanced dataset. A biased training dataset or an imbalanced dataset may lead to inaccurate fault detection or misleading sustainability assessments. One prominent issue is the zero-fault dataset. To address this limitation, Chen, et al. [88] proposed a Relation Network with Out-of-Distribution Data Augmentation (OOD-RN) combined with a soft Brownian generator, enabling effective learning and improving the model’s capability to detect faults under zero-fault conditions. Since many components of high-speed train rolling stock operate under rotation motion, the Shrinkage Mamba Relation Network (SMRN) has been introduced to facilitate fault detection in rotation machinery under zero-fault conditions [89]. External factors, on the other hand, involve challenges such as adversarial data. The adversarial data can lead to inaccurate decisions with substantial consequences. Tasneem and Islam [90] addressed this issue by developing an improved adversarial training approach that leverages explainable AI-guided feature and data augmentation techniques to strengthen the AI model.

5.5. Broader Implementation Challenges

Beyond the technical challenges discussed in the previous sections, several broader factors can influence the practical implementation of digital twins and AI applications in high-speed train rolling stock. These include external or regulatory considerations, model validation constraints, and workforce adaptation. While these aspects are not explored in depth within this state-of-the-art review, acknowledging them is essential for understanding the real-world readiness and sustainability of digital twins and AI-based frameworks.

6. Conclusions

This state-of-the-art review has emphasised the transformative potential of new technologies, specifically digital twins and machine learning, in enhancing the circular economy in high-speed train rolling stock. In the field of infrastructure, digital twins have shown effectiveness in improving predictive maintenance and real-time monitoring, thereby dramatically decreasing operational interruptions and maintenance expenses. These characteristics highlight their significance as essential instruments for enhancing resource allocation and augmenting system resilience.

The limited adoption of digital twins in rolling stock indicates a distinct possibility for additional research. Although digital twins applications in infrastructure are extensively documented, the domain of rolling stock is comparatively underexplored, with a limited number of studies addressing this topic. Closing this gap could facilitate enhanced rolling stock performance via sophisticated data integration and real-time monitoring methods.

Machine Learning provides further opportunities for enhancing the prediction, detection, and classification of rolling stock components’ conditions, and especially, increasing monitoring capabilities. This highlights a critical research gap and the need for future studies to explore ML-based monitoring strategies for high-waste components and the integration of machine learning with digital twins to enable real-time system performance monitoring, interdisciplinary data exchange, and sustainable lifecycle management in accordance with circular economy and 10R principles.

Author Contributions

Conceptualization, L.K. and S.K.; methodology, L.K. and S.K.; software, L.K.; validation, L.K. and S.K.; formal analysis, L.K. and S.K.; investigation, L.K.; resources, S.K.; data curation, L.K.; writing—original draft preparation, L.K.; writing—review and editing, L.K. and S.K.; visualization, L.K.; supervision, S.K.; project administration, S.K.; funding acquisition, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Commission, grant number: H2020-MSCA-RISE No. 691135. In addition, the authors wish to thank the European Commission and UKRI Engineering and Physical Science Research Council (EPSRC) for the financial sponsorship of the Re4Rail project (Grant No. EP/Y015401/1). The APC was funded by MDPI’s Invited Paper Initiative.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data supporting the findings of this study are available within the article itself and through the referenced sources.

Acknowledgments

This research was funded by the European Commission, grant number: H2020-MSCA-RISE No. 691135. In addition, the authors wish to thank the European Commission and UKRI Engineering and Physical Science Research Council (EPSRC) for the financial sponsorship of the Re4Rail project (Grant No. EP/Y015401/1). The first author wishes to gratefully thank the Royal Thai Government for the PhD scholarship at the University of Birmingham.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- United Nations. What Is Climate Change? Available online: https://www.un.org/en/climatechange/what-is-climate-change (accessed on 7 November 2024).

- European Commission. GHG Emissions of All World Countries: 2025 Report; European Commission: Luxembourge, 2025; Available online: https://edgar.jrc.ec.europa.eu/report_2025 (accessed on 18 August 2025).

- Rodrigue, J.-P. Transportation modes. In The Geography of Transport Systems; Routledge: London, UK, 2024; pp. 130–177. [Google Scholar]

- Ritchie, H. Cars, Planes, Trains: Where Do CO2 Emissions from Transport Come from? Available online: https://ourworldindata.org/co2-emissions-from-transport (accessed on 14 October 2025).

- Merkisz, J.; Jacyna, M.; Merkisz-Guranowska, A.; Pielecha, J. Exhaust emissions from modes of transport under actual traffic conditions. WIT Trans. Ecol. Environ. 2014, 190, 1139–1150. [Google Scholar] [CrossRef]

- European Commission. Statistical Pocketbook 2024; European Commission: Brussels, Belgium, 2024. [Google Scholar]

- UIC. Rail Transport in the World. Available online: https://uic.org/support-activities/statistics (accessed on 14 August 2025).

- Thailand, T.S.R.o. Thai–Chinese High-Speed Railway (HSR). Available online: https://www.highspeedrail-thai-china.com/en/ (accessed on 14 August 2025).

- Smink, C.K. Vehicle recycling regulations: Lessons from Denmark. J. Clean. Prod. 2007, 15, 1135–1146. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Rungskunroch, P.; Jennings, D. A through-life evaluation of end-of-life rolling stocks considering asset recycling, energy recovering, and financial benefit. J. Clean. Prod. 2019, 212, 1008–1024. (In English) [Google Scholar] [CrossRef]

- Yellishetty, M.; Mudd, G.M.; Ranjith, P.G. The steel industry, abiotic resource depletion and life cycle assessment: A real or perceived issue? J. Clean. Prod. 2011, 19, 78–90. [Google Scholar] [CrossRef]

- European Environment Agency. Capturing the Climate Change Mitigation Benefits of Circular Economy and Waste Sector Policies and Measures. 2024. Available online: https://www.eea.europa.eu/en/analysis/publications/capturing-the-climate-change-mitigation-benefits-of-circular-economy-and-waste-sector-policies-and-measures (accessed on 25 August 2025).

- Chen, A.; Qi, W.; Du, Q.; Hou, S.; Yuan, G.; Ma, Z.; Peng, L.; Wang, T. Laboratory and Field Evaluation of Cement-Stabilized Phyllite for Sustainable Railway Subgrades. Buildings 2025, 15, 3151. (In English) [Google Scholar] [CrossRef]

- Guerrero-Bustamante, O.; Guillen, A.; Moreno-Navarro, F.; Rubio-Gámez, M.C.; Sol-Sánchez, M. Cold Mix Asphalt for sustainable bituminous sub-ballast for railway: Mechanical, vibratory and environmental assessment. J. Clean. Prod. 2025, 520, 18. (In English) [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chains; PBL Netherlands Environmental Assessment Agency: The Hague, The Natherlands, 2017; Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 10 September 2025).

- Koohmishi, M.; Kaewunruen, S.; He, X.; Guo, Y. Advancing railway sustainability: Strategic integration of circular economy principles in ballasted track systems. J. Clean. Prod. 2025, 490, 144713. [Google Scholar] [CrossRef]

- Lenart, S.; Karumanchi, S.R. Deformation properties and performance evaluation of reused ballast with waste tire-derived aggregates. Transp. Geotech. 2025, 52, 101586. [Google Scholar] [CrossRef]

- Huang, Z.; Su, Q.; Liu, T.; Huang, J.; Wang, X.; Kaewunruen, S. Full-Scale Experimental and Field Investigations into Expansion Mechanism of Foamed Polyurethane and its Lifting Behaviors for Repair and Maintenance of Railway Slab Track Systems. Polymers 2024, 16, 404. [Google Scholar] [CrossRef]

- Indraratna, B.; Mehmood, F.; Mishra, S.; Ngo, T.; Rujikiatkamjorn, C. The role of recycled rubber inclusions on increased confinement in track substructure. Transp. Geotech. 2022, 36, 100829. [Google Scholar] [CrossRef]

- Chen, H.-M.; Zhou, R.; Ulianov, C. Numerical Prediction and Corresponding Circular Economy Approaches for Resource Optimisation and Recovery of Underground Structures. Urban Rail Transit 2020, 6, 71–83. [Google Scholar] [CrossRef]

- Silva, R.; Kaewunruen, S. Recycling of Rolling Stocks. Environments 2017, 4, 39. [Google Scholar] [CrossRef]

- Passarini, F.; Ciacci, L.; Santini, A.; Vassura, I.; Morselli, L. Aluminium flows in vehicles: Enhancing the recovery at end-of-life. J. Mater. Cycles Waste Manag. 2013, 16, 39–45. [Google Scholar] [CrossRef]

- Poutos, K.H.; Alani, A.M.; Walden, P.J.; Sangha, C.M. Relative temperature changes within concrete made with recycled glass aggregate. Constr. Build. Mater. 2008, 22, 557–565. [Google Scholar] [CrossRef]

- The Dartmouth College Artificial Intelligence Conference. Dartmouth College. Artificial Intelligence Coined at Dartmouth. Available online: https://home.dartmouth.edu/about/artificial-intelligence-ai-coined-dartmouth (accessed on 15 April 2025).

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. (In English) [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Berlin/Heidelberg, Germany, 2017; Chapter 4; pp. 85–113. [Google Scholar]

- Uc Castillo, J.L.; Marin Celestino, A.E.; Martinez Cruz, D.A.; Tuxpan Vargas, J.; Ramos Leal, J.A.; Moran Ramirez, J. A systematic review of Machine Learning and Deep Learning approaches in Mexico: Challenges and opportunities. Front. Artif. Intell. 2024, 7, 1479855. [Google Scholar] [CrossRef]

- Challouf, K.; Alhloul, A.; Nemeth, N. Mapping the role of industry 4.0 technologies in green supply chain management: A bibliometric and structured text analysis. Discov. Sustain. 2025, 6, 32. (In English) [Google Scholar] [CrossRef]

- Raman, R.; Gunasekaran, A.; Mandal, S. Advancing net-zero supply chain management: A machine learning driven review aligned with the sustainable development goals. Int. J. Logist.-Res. Appl. 2025, 35. (In English) [Google Scholar] [CrossRef]

- Mujumdar, A.S.; Barzigar, A.; Hosseinalipour, S.M.; Edalatpour, A. Critical review of drying processes for electrode materials: Bridging fundamentals and advanced manufacturing for energy storage devices. Dry. Technol. 2025, 26. (In English) [Google Scholar] [CrossRef]

- Cardenas-Sierra, I.; Vijay, U.; Aguesse, F.; Antuñano, N.; Ayerbe, E.; Gold, L.; Naumann, A.; Otaegui, L.; Recham, N.; Stier, S.; et al. Integration of lithium-ion battery recycling into manufacturing through digitalization: A perspective. J. Power Sources 2025, 631, 24. (In English) [Google Scholar] [CrossRef]

- Velasquez-Mendez, A.; Lozoya-Santos, J.D.; Jimenez-Vargas, J.F. Validating a Sustainable, Smart, and Circular City Architecture Through Urban Living Lab Experiments. Urban Sci. 2025, 9, 35. (In English) [Google Scholar] [CrossRef]

- Gondak, M.D.; Hluszko, C.; Moretti, V.; Zeni, G.L.F.; de Francisco, A.C. Guide to digital technologies for circularity in the project lifecycle: Perspective of the EN 15643-3:2012 standard. Constr. Innov.-Engl. 2025, 39. (In English) [Google Scholar] [CrossRef]

- Elghaish, F.; Mohandes, S.R.; Rahimian, F.; Abrishami, S.; Hosseini, M.R. Predictive digital monitoring of construction resources: An integrated digital twin solution. Eng. Constr. Archit. Manag. 2025, 25. (In English) [Google Scholar] [CrossRef]

- Awodele, I.A.; Eze, E.C.; Municio, A.M.G.; Ramabodu, M.S.; Olatunde, N.A. Advancing circular economy transition in the Nigeria construction industry through digital twin technology adoption. Green Technol. Sustain. 2025, 3, 10. (In English) [Google Scholar] [CrossRef]

- Ali, Z.A.; Zain, M.; Hasan, R.; Pathan, M.S.; AlSalman, H.; Almisned, F.A. Digital twins: Cornerstone to circular economy and sustainability goals. Environ. Dev. Sustain. 2025, 42. (In English) [Google Scholar] [CrossRef]

- Li, S.; Fan, X.D.; Qi, Z.Y. A study on the dynamic optimization strategy of energy routers in zero-carbon ports based on digital twin technology. Int. J. Electr. Power Energy Syst. 2025, 170, 11. (In English) [Google Scholar] [CrossRef]

- Vargas, J.M.; Castrillon, O.D.; Giraldo, J.A. Implementation and Field Validation of a Digital Twin Methodology to Enhance Production and Service Systems in Waste Management. Appl. Sci. 2025, 15, 28. (In English) [Google Scholar] [CrossRef]

- Chidara, A.; Cheng, K.; Gallear, D. Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration. Machines 2025, 13, 27. (In English) [Google Scholar] [CrossRef]

- Doubell, G.C.; Kruger, K.; Basson, A.H.; Conradie, P. The Potential for Digital Twin Applications in Railway Infrastructure Management. In 15th WCEAM Proceedings; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2022; Chapter 22; pp. 241–249. [Google Scholar]

- Vieira, J.; Poças Martins, J.; Marques de Almeida, N.; Patrício, H.; Gomes Morgado, J. Towards Resilient and Sustainable Rail and Road Networks: A Systematic Literature Review on Digital Twins. Sustainability 2022, 14, 7060. [Google Scholar] [CrossRef]

- Salierno, G.; Leonardi, L.; Cabri, G. A Big Data Architecture for Digital Twin Creation of Railway Signals Based on Synthetic Data. IEEE Open J. Intell. Transp. Syst. 2024, 5, 342–359. [Google Scholar] [CrossRef]

- Hu, W.; Wang, W.; Liu, X.; Peng, J.; Wang, S.; Ai, C.; Qiu, S.; Wang, W.; Wang, J.; Zaheer, Q.; et al. Hybrid Pixel-Level Crack Segmentation for Ballastless Track Slab Using Digital Twin Model and Weakly Supervised Style Transfer. Struct. Control Health Monit. 2024, 2024, 8846470. [Google Scholar] [CrossRef]

- Adeagbo, M.O.; Wang, S.M.; Ni, Y.Q. Revamping structural health monitoring of advanced rail transit systems: A paradigmatic shift from digital shadows to digital twins. Adv. Eng. Inform. 2024, 61, 102450. [Google Scholar] [CrossRef]

- Vieira, J.; Poças Martins, J.; de Almeida, N.M.; Patrício, H.; Morgado, J. Reshaping the Digital Twin Construct with Levels of Digital Twinning (LoDT). Appl. Syst. Innov. 2023, 6, 114. [Google Scholar] [CrossRef]

- Bondoc, A.E.; Tayefeh, M.; Barari, A. Employing LIVE Digital Twin in Prognostic and Health Management_Identifying Location of the Sensors. IFAC Pap. 2022, 55, 138–143. [Google Scholar]

- Malek, N.G.; Tayefan, M.; Bender, D.; Barari, A. LIVE Digital Twin for Smart Maintenance in Structural Systems. IFAC-Pap. 2021, 54, 1047–1052. [Google Scholar] [CrossRef]

- Kochan, A.; FolĘGa, P.; Skirkus, R.; Bureika, G. Multigraph IS: Part 1. A formal description of railway infrastructure for the digital twin of the ETCS application. Transp. Probl. 2023, 18, 43–52. [Google Scholar] [CrossRef]

- Ahmad, W.; Mutz, M.; Werth, D. Digital Twin of Rail for Defect Analysis. In Proceedings of the 2024 the 8th International Conference on Virtual and Augmented Reality Simulations (ICVARS), Melbourne, Australia, 14–16 March 2024; pp. 53–60. [Google Scholar]

- Djordjević, B.; Krmac, E.; Lin, C.-Y.; Fröidh, O.; Kordnejad, B. An optimisation-based digital twin for automated operation of rail level crossings. Expert Syst. Appl. 2024, 239, 122422. [Google Scholar] [CrossRef]

- Hamarat, M.; Papaelias, M.; Kaewunruen, S. Fatigue damage assessment of complex railway turnout crossings via Peridynamics-based digital twin. Sci. Rep. 2022, 12, 14377. [Google Scholar] [CrossRef]

- Ramatlo, D.A.; Wilke, D.N.; Loveday, P.W. Digital Twin Hybrid Modeling for Enhancing Guided Wave Ultrasound Inspection Signals in Welded Rails. Math. Comput. Appl. 2023, 28, 58. [Google Scholar] [CrossRef]

- Borjigin, A.O.; Sresakoolchai, J.; Kaewunruen, S.; Hammond, J. Digital Twin Aided Sustainability Assessment of Modern Light Rail Infrastructures. Front. Built Environ. 2022, 8, 796388. [Google Scholar] [CrossRef]

- Kampczyk, A.; Dybel, K. The Fundamental Approach of the Digital Twin Application in Railway Turnouts with Innovative Monitoring of Weather Conditions. Sensors 2021, 21, 5757. [Google Scholar] [CrossRef] [PubMed]

- Boschert, S.; Rosen, R. Digital Twin: A Second Life for Engineering Models. ERCIM News 2018, 115, 8–9. [Google Scholar]

- Ekberg, A.; Kabo, E.; Lundén, R. Rail and wheel health management. Wear 2023, 526–527, 204891. [Google Scholar] [CrossRef]

- Avsievich, A.; Avsievich, V.; Avsievich, N.; Ovchinnikov, D.; Ivaschenko, A. Railway Track Stress–Strain Analysis Using High-Precision Accelerometers. Appl. Sci. 2021, 11, 11908. [Google Scholar] [CrossRef]

- Ton, B.; Ahmed, F.; Linssen, J. Semantic Segmentation of Terrestrial Laser Scans of Railway Catenary Arches: A Use Case Perspective. Sensors 2022, 23, 222. [Google Scholar] [CrossRef]

- Ahmad, S.; Spiryagin, M.; Wu, Q.; Bernal, E.; Sun, Y.; Cole, C.; Makin, B. Development of a Digital Twin for prediction of rail surface damage in heavy haul railway operations. Veh. Syst. Dyn. 2023, 62, 41–66. [Google Scholar] [CrossRef]

- Bernal, E.; Wu, Q.; Spiryagin, M.; Cole, C. Augmented digital twin for railway systems. Veh. Syst. Dyn. 2023, 62, 67–83. [Google Scholar] [CrossRef]

- Avizzano, C.A.; Scivoletto, G.; Tripicchio, P. Robust Image Stitching and Reconstruction of Rolling Stocks Using a Novel Kalman Filter With a Multiple-Hypothesis Measurement Model. IEEE Access 2021, 9, 154011–154021. [Google Scholar] [CrossRef]

- Kulikov, Y.M.; Kulikov, M.Y.; Mironenko, N.O.; Mironenko, O.I. Forecasting the Resources of Rolling Stock Elements Using Information Technology. In Proceedings of the 2024 International Conference “Quality Management, Transport and Information Security, Information Technologies” (QM&TIS&IT), Nalchik, Russia, 23–27 September 2024; pp. 162–164. [Google Scholar] [CrossRef]

- Ferdous, R.; Spagnolo, G.; Borselli, A.; Rota, L.; Ferrari, A. Identifying Maintenance Needs with Machine Learning: A Case Study in Railways. In Proceedings of the 2024 IEEE 32nd International Requirements Engineering Conference Workshops (REW), Reykjavik, Iceland, 24–25 June 2024; pp. 22–25. [Google Scholar] [CrossRef]

- Ragala, Z.; Retbi, A.; Bennani, S. MTTR Prediction of railway rolling stock using regression algorithms. In Proceedings of the 2022 International Conference on Intelligent Systems and Computer Vision (ISCV), Fez, Morocco, 18–20 May 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Appoh, F.; Yunusa-Kaltungo, A. Dynamic Hybrid Model for Comprehensive Risk Assessment: A Case Study of Train Derailment Due to Coupler Failure. IEEE Access 2022, 10, 24587–24600. [Google Scholar] [CrossRef]

- Nappi, R.; Cutrera, G.; Vigliotti, A.; Franzè, G. A predictive-based maintenance approach for rolling stocks vehicles. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; pp. 793–798. [Google Scholar] [CrossRef]

- Fink, O.; Zio, E.; Weidmann, U. Fuzzy Classification with Restricted Boltzman Machines and Echo-State Networks for Predicting Potential Railway Door System Failures. IEEE Trans. Reliab. 2015, 64, 861–868. [Google Scholar] [CrossRef]

- Li, Z.; He, Q. Prediction of Railcar Remaining Useful Life by Multiple Data Source Fusion. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2226–2235. [Google Scholar] [CrossRef]

- Li, Z.; He, Q. Predicting failure times of railcar wheels and trucks by using wayside detector signals. In Proceedings of the 2014 IEEE International Conference on Mechatronics and Automation, Tianjin, China, 3–6 August 2014; pp. 1113–1118. [Google Scholar]

- Mistry, D.; Hough, J. Data-Driven Approach to State of Good Repair: Predicting Rolling Stock Service Life with Machine Learning for State of Good Repair Backlog Reduction and Long-Range Replacement Cost Estimation in Small Urban and Rural Transit Systems. Transp. Res. Rec. 2024, 2678, 771–781. [Google Scholar] [CrossRef]

- De Simone, L.; Caputo, E.; Cinque, M.; Galli, A.; Moscato, V.; Russo, S.; Cesaro, G.; Criscuolo, V.; Giannini, G. LSTM-based failure prediction for railway rolling stock equipment. Expert. Syst. Appl. 2023, 222, 119767. [Google Scholar] [CrossRef]