A Multivariate Blaschke-Based Mode Decomposition Approach for Gear Fault Diagnosis

Abstract

1. Introduction

- (1)

- A multivariate signal decomposition method, MBMD, is proposed. MBMD treats multivariate vibration signals as the observed responses of a gear system in different dimensions. It is the first to introduce the SAFD theory into the mechanical fault diagnosis field, inverting the gear system and representing multivariate vibration signals using a unified Blaschke product, thereby achieving multivariate information fusion. Its decomposition mechanism is completely different from existing multivariate signal decomposition methods.

- (2)

- The concept of the Blaschke multi-spectra is proposed, representing multivariate signals in the form of a Blaschke multi-spectra. Building on this, a joint spectral segmentation approach is introduced. This strategy divides the Blaschke multi-spectra into several segments with concentrated energy, enabling the subsequent decomposition results to be organized on the same Blaschke product scale. This lays the groundwork for multivariate decomposition and ensures modal alignment.

- (3)

- A voting filter bank is proposed to extract mechanical fault feature components, accurately eliminating noise interference.

2. Multivariate Blaschke-Based Mode Decomposition

2.1. SAFD and Blaschke Multi-Spectra

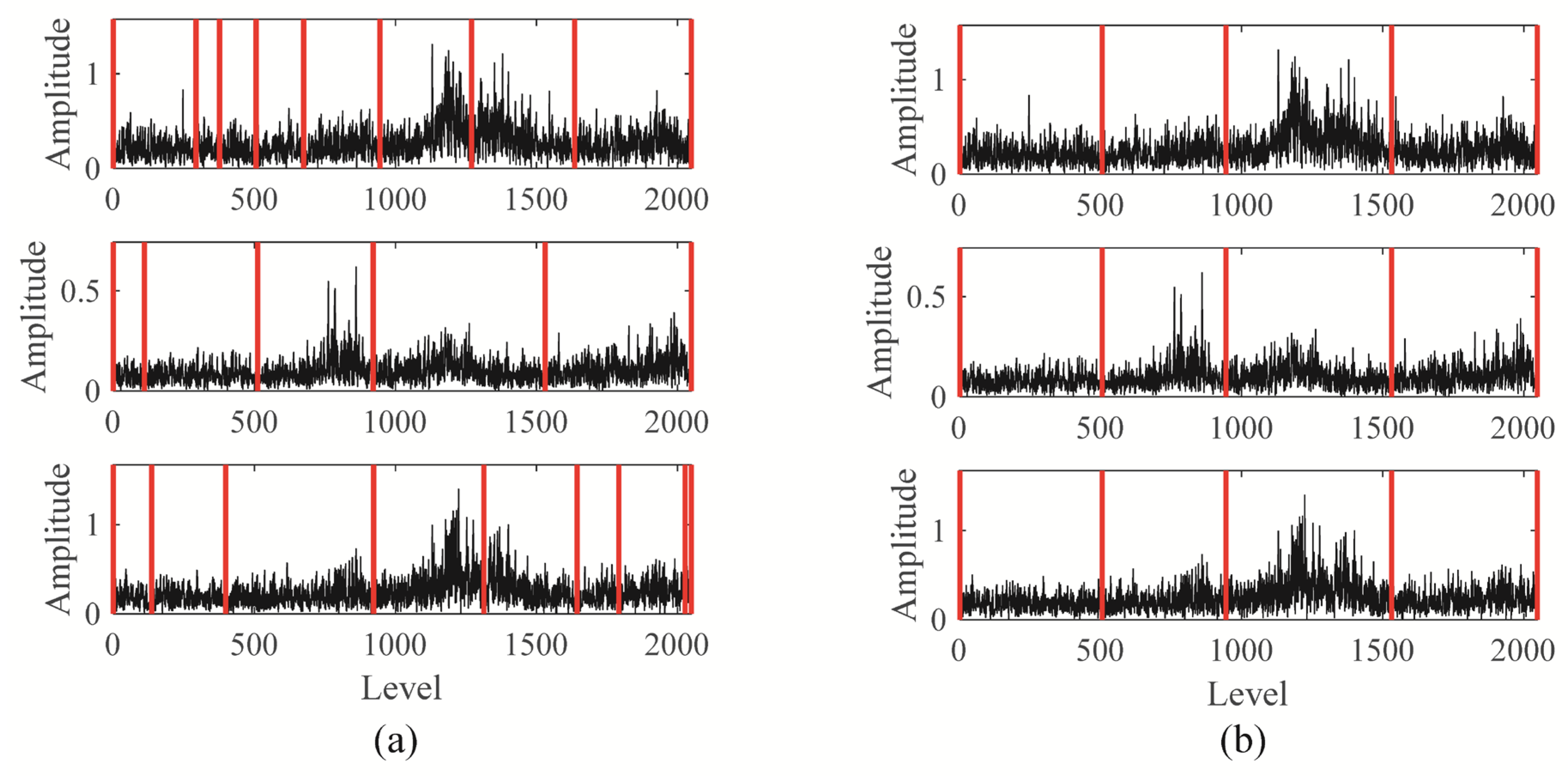

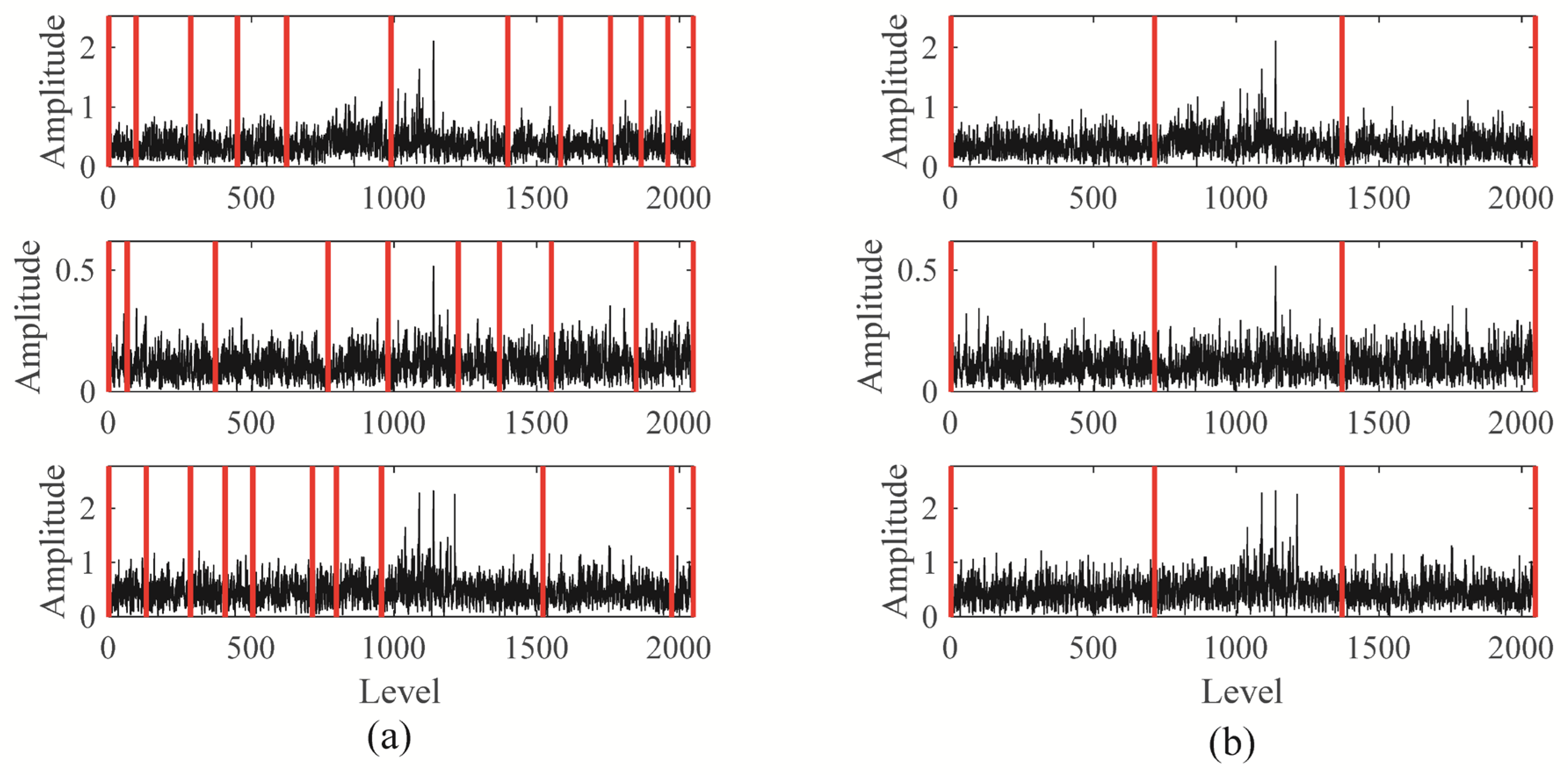

2.2. Joint Spectrum Segmentation

- The Blaschke multi-spectra can be divided into K spectral segments, each sharing the same Blaschke product.

- There exist K + 1 shared spectral lines, such that the K segmented spectral segments exhibit a distinct energy concentration trend.

- (a)

- Unimodal interval

- (b)

- Alignment

2.3. MBMD for Gear Fault Diagnosis

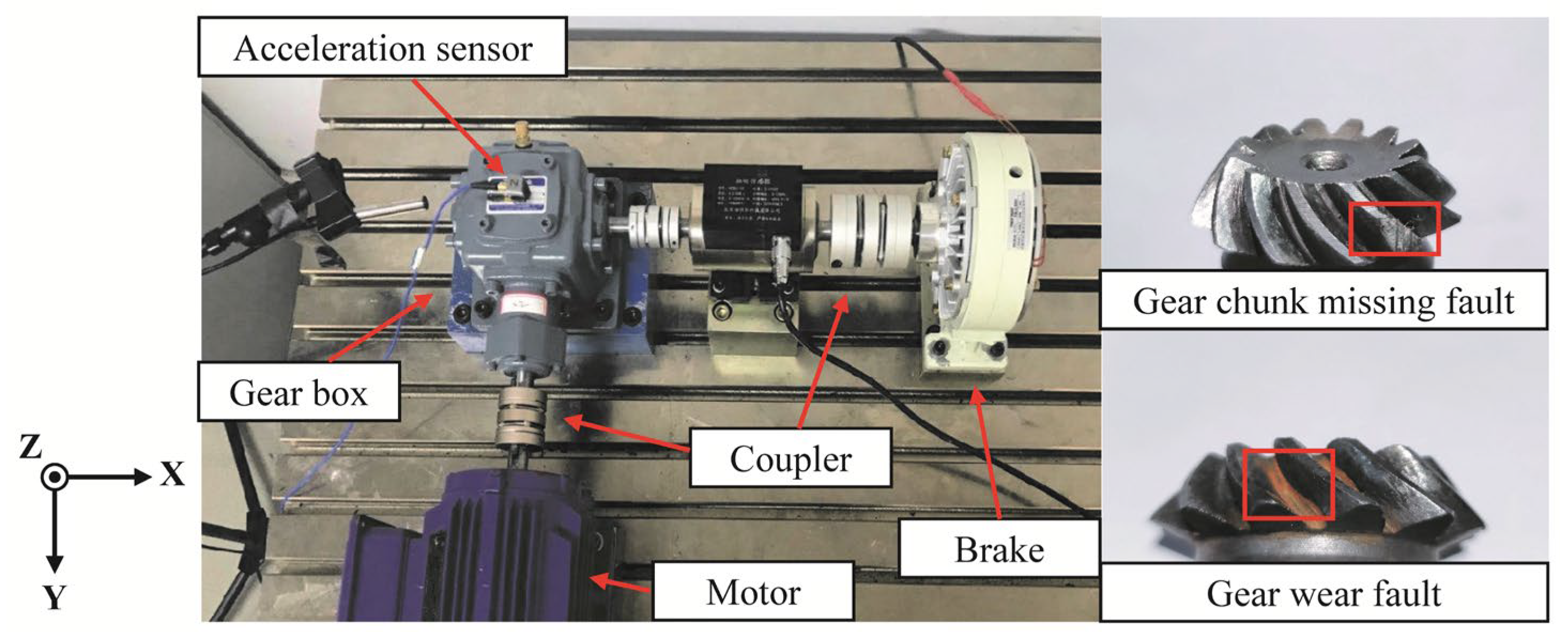

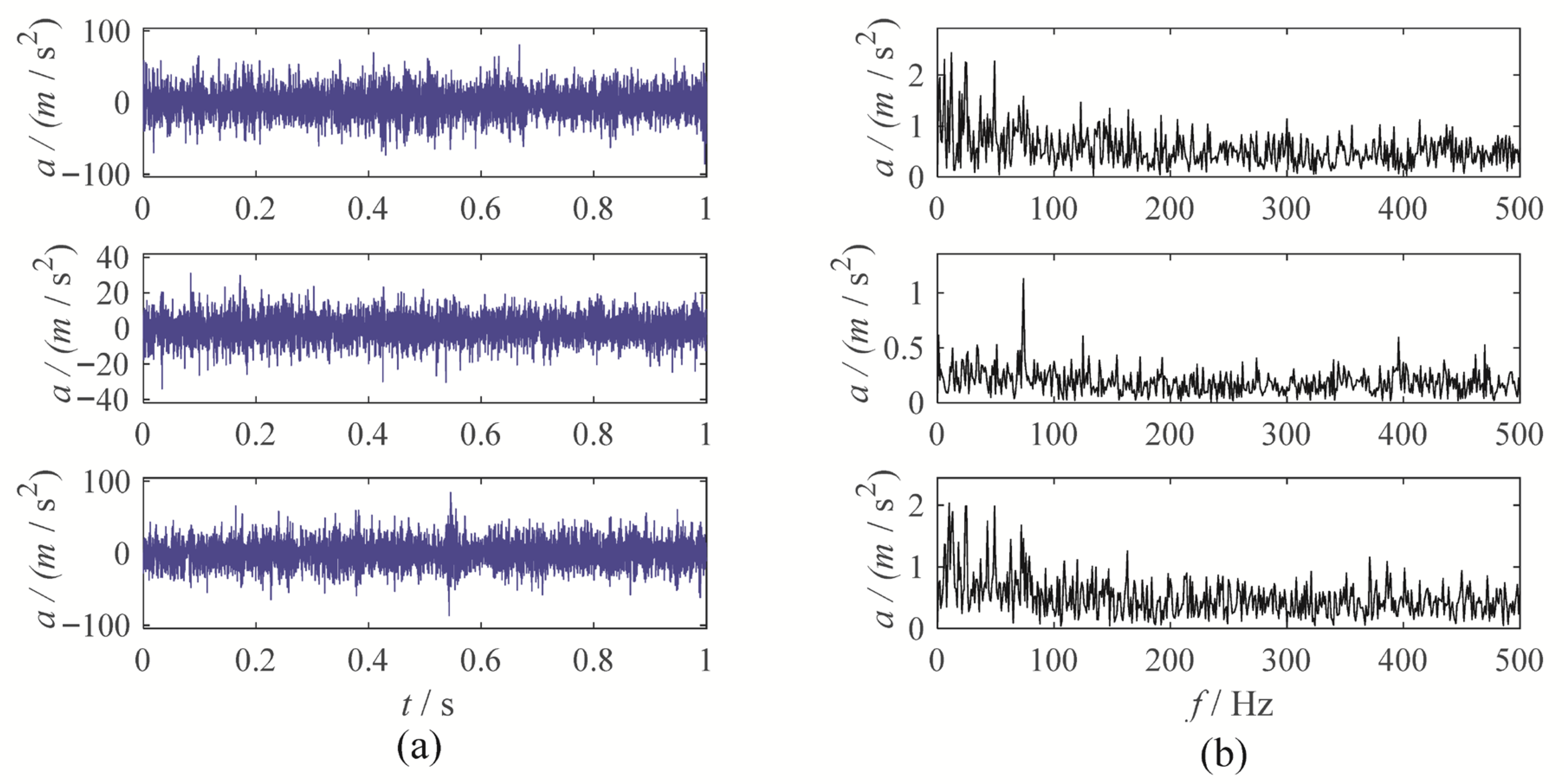

3. Gear Vibration Signal Experiment

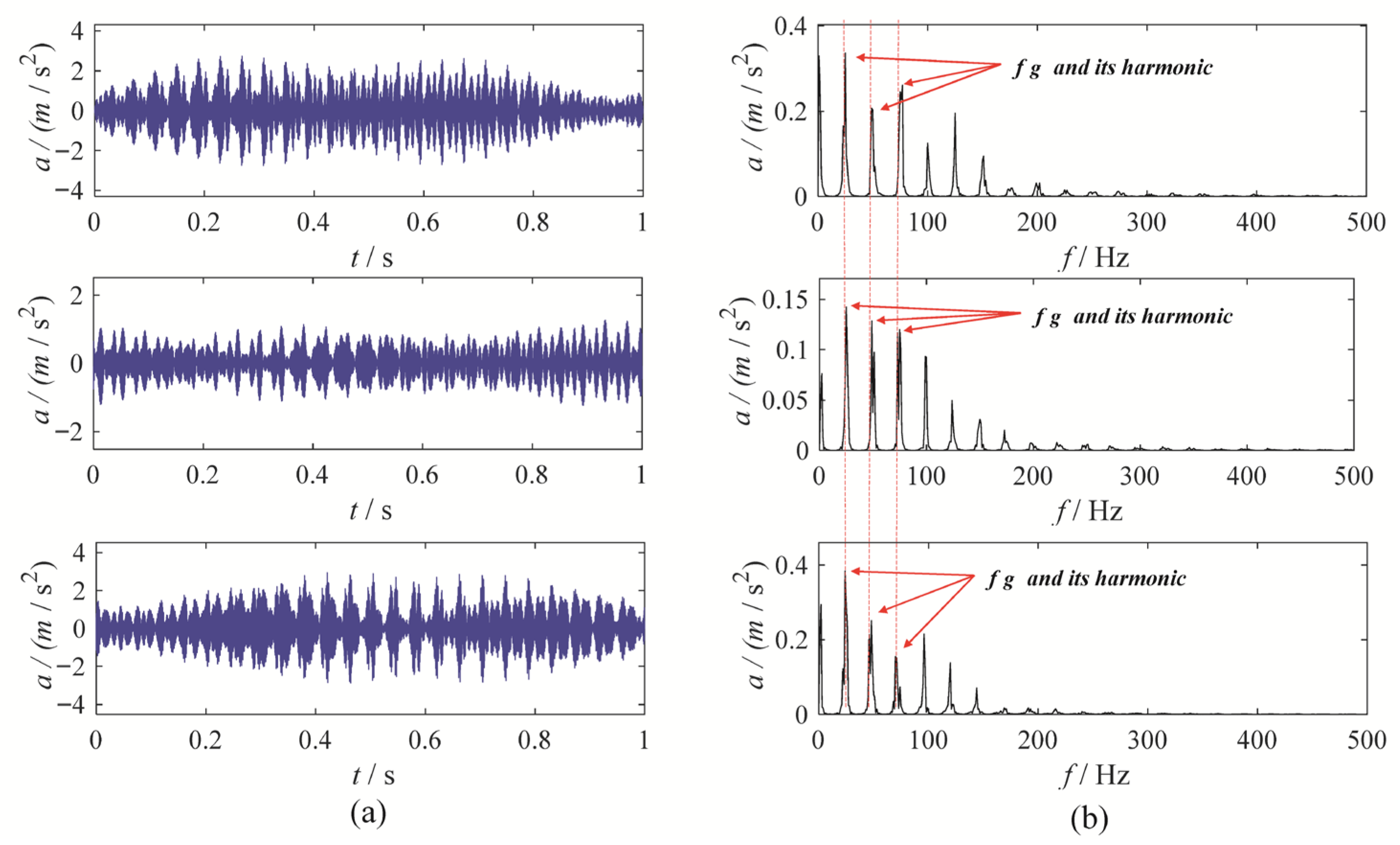

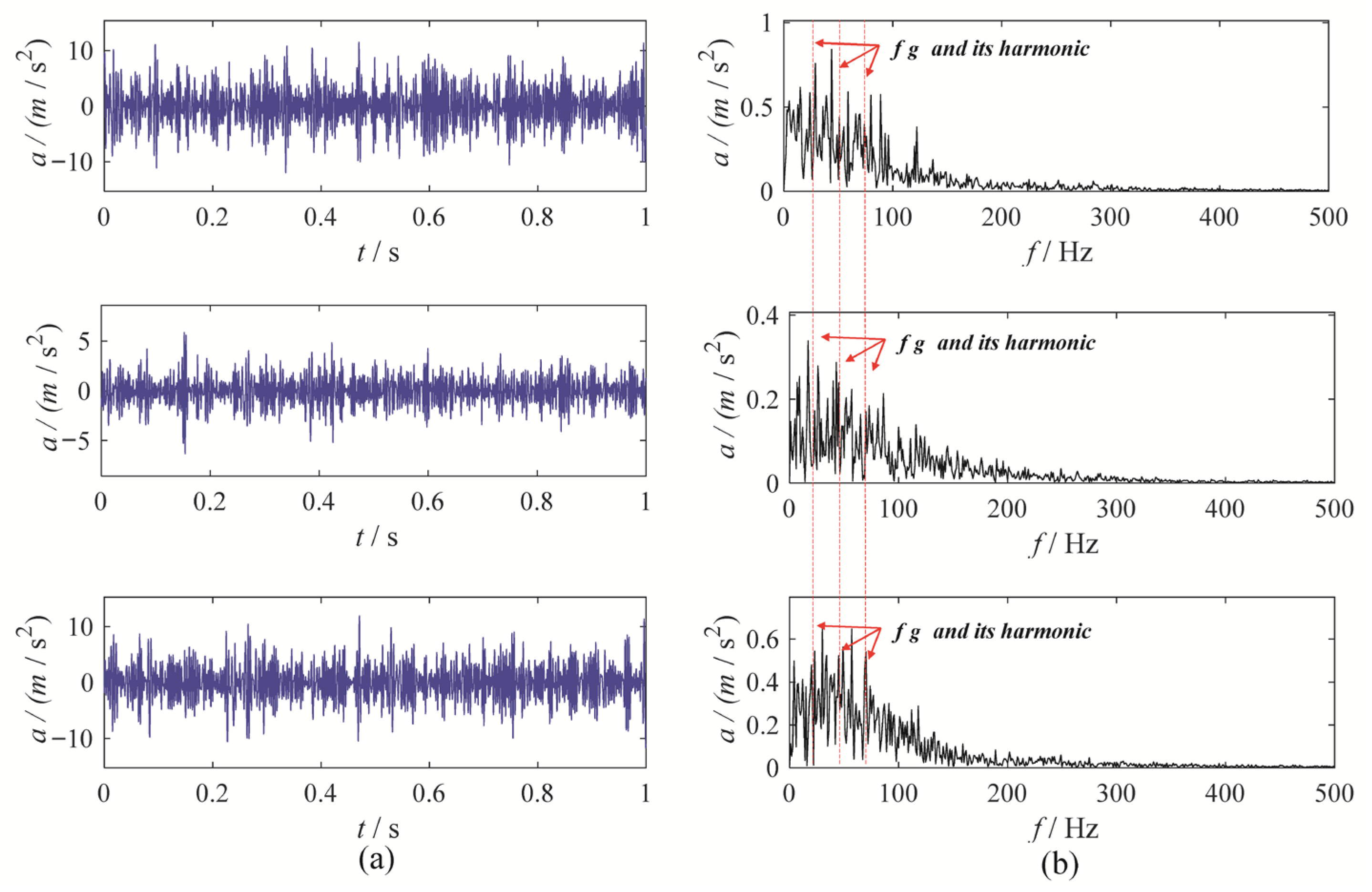

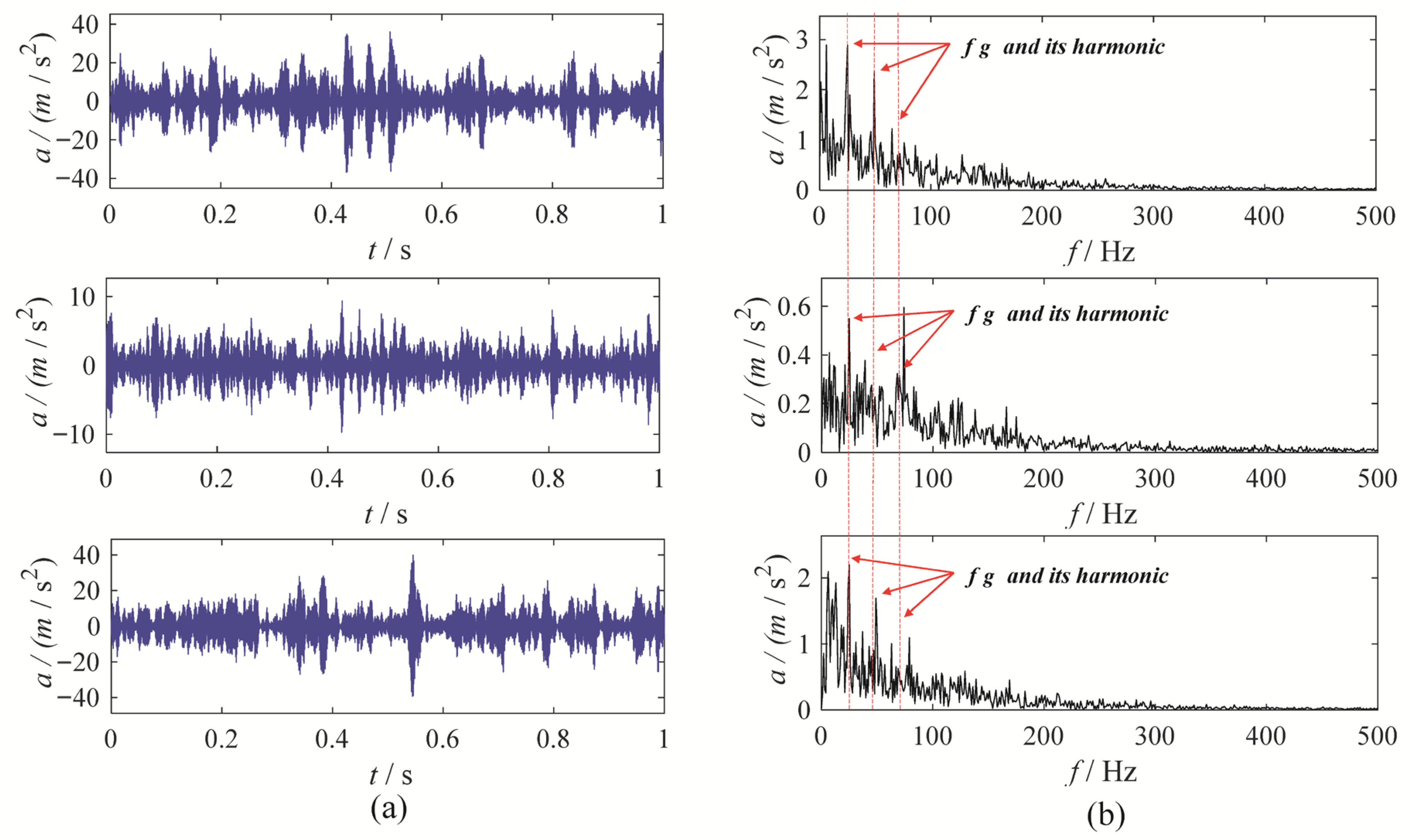

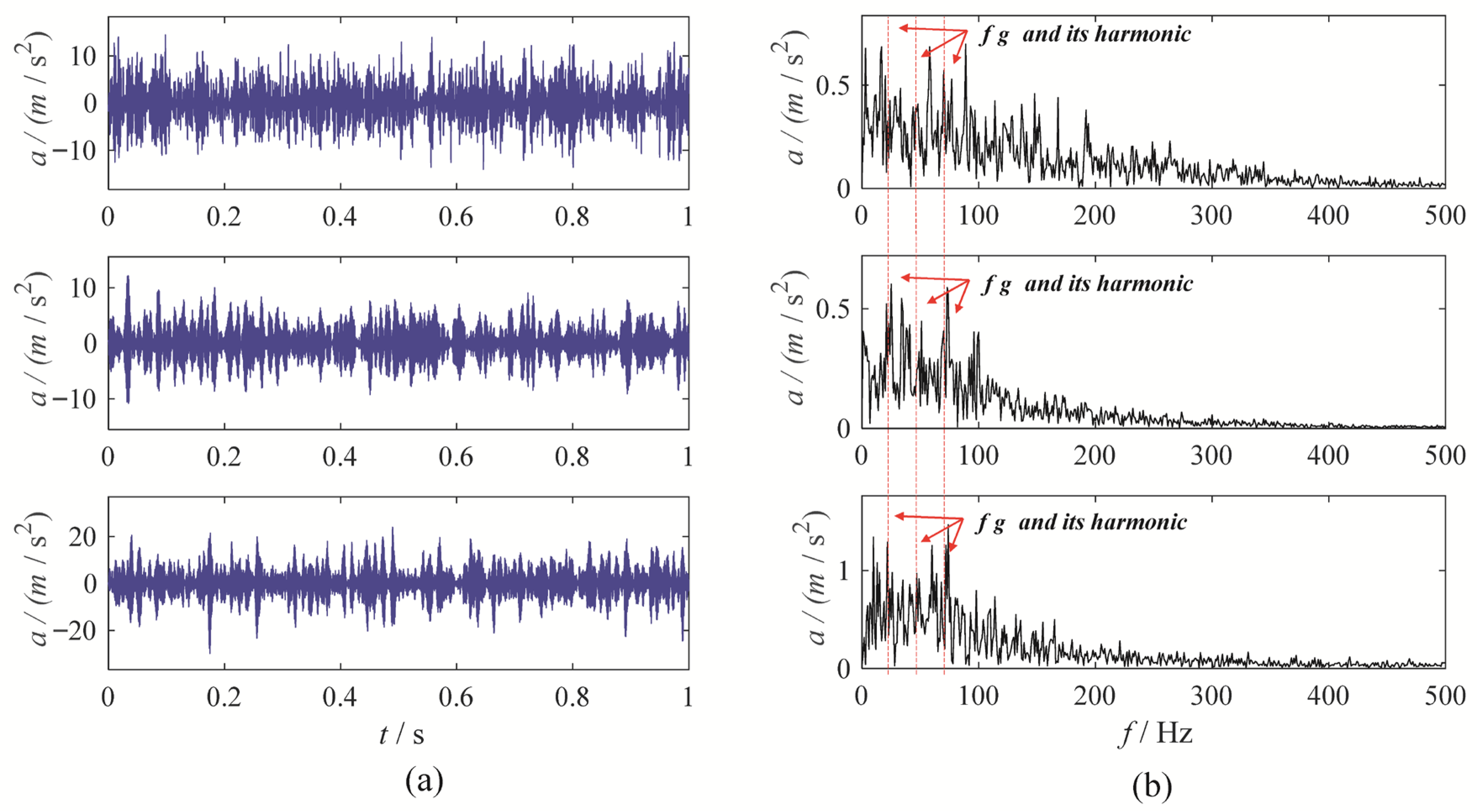

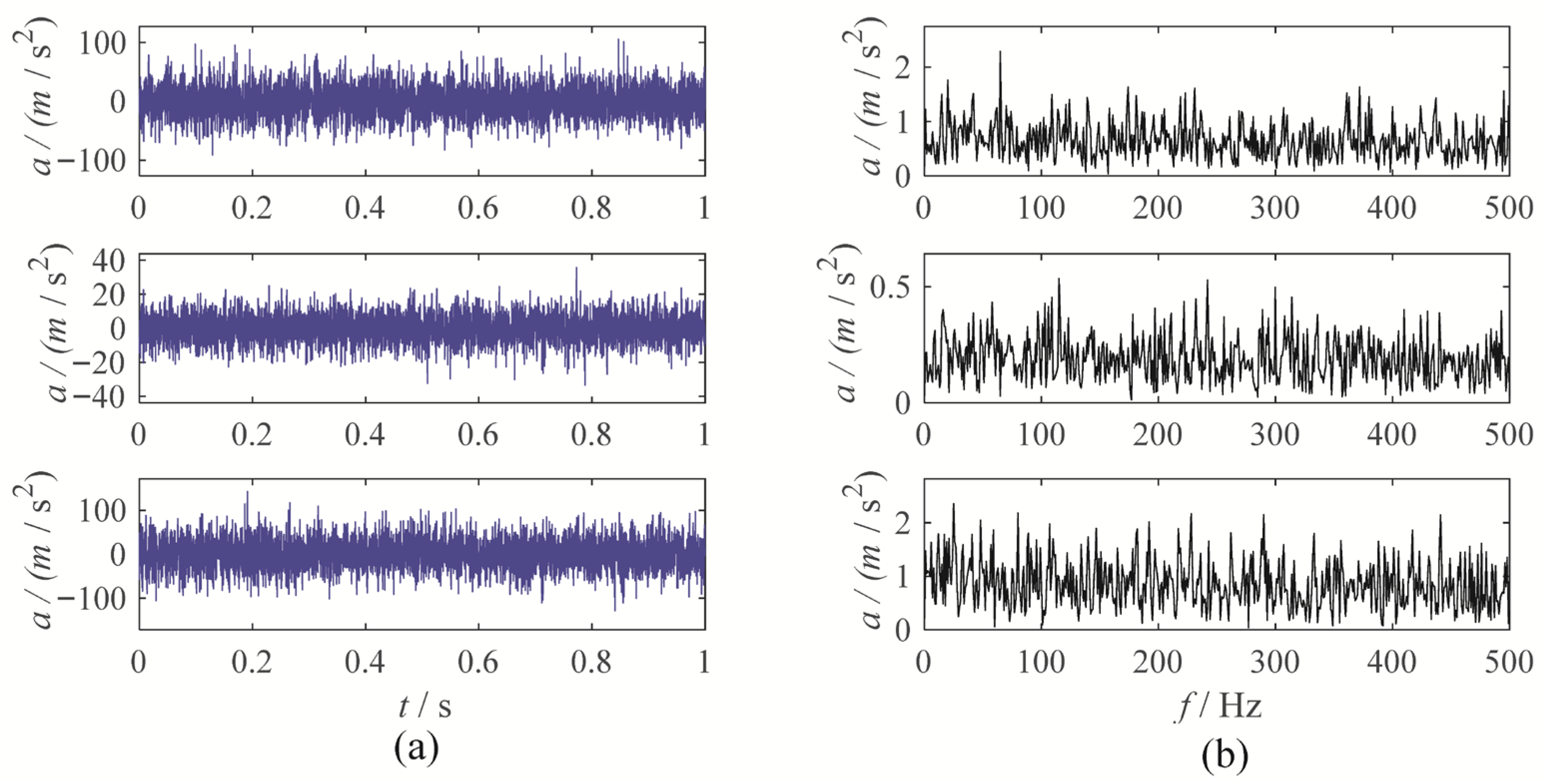

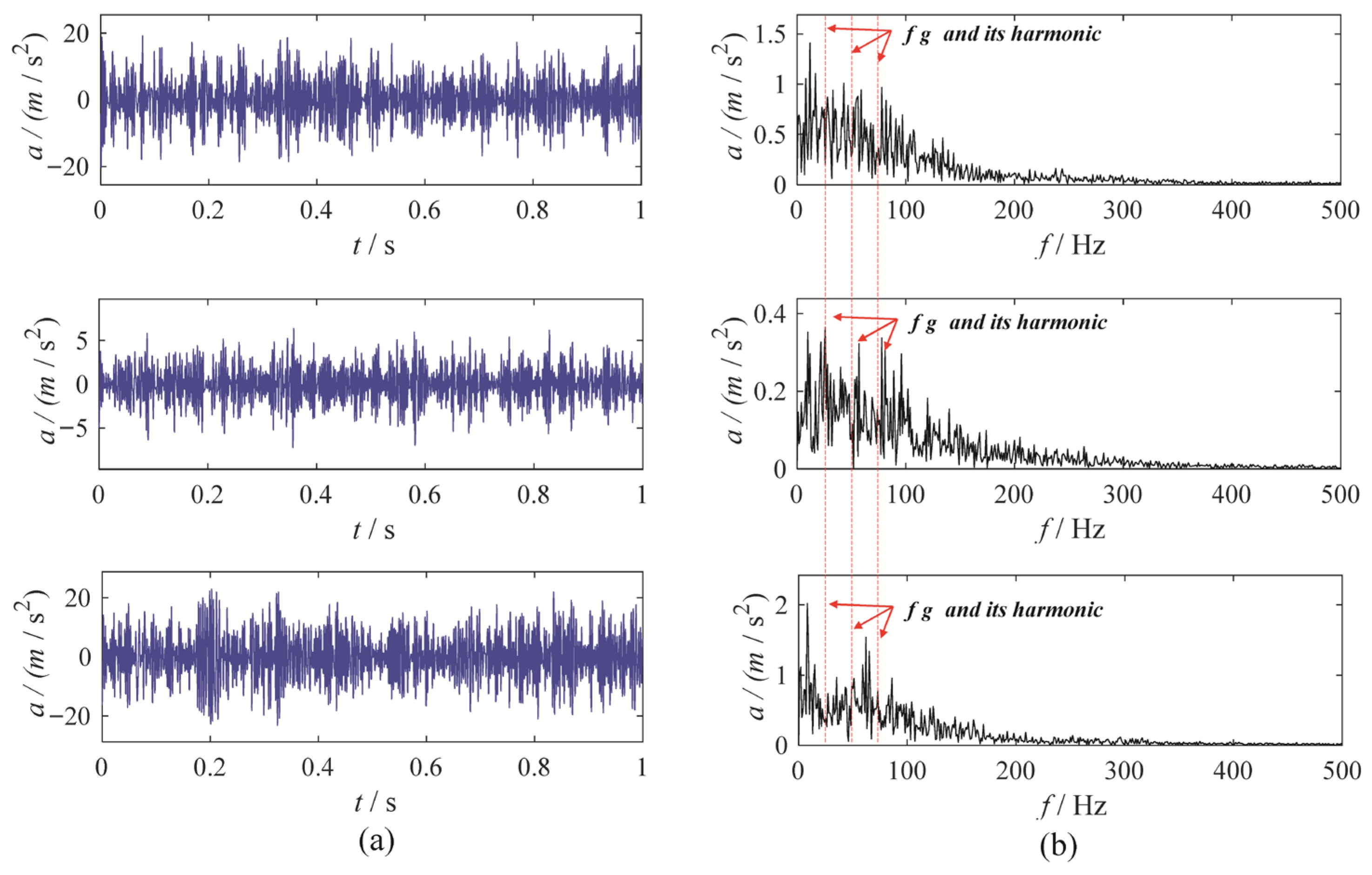

3.1. Gear Chunk Missing Fault Experiment

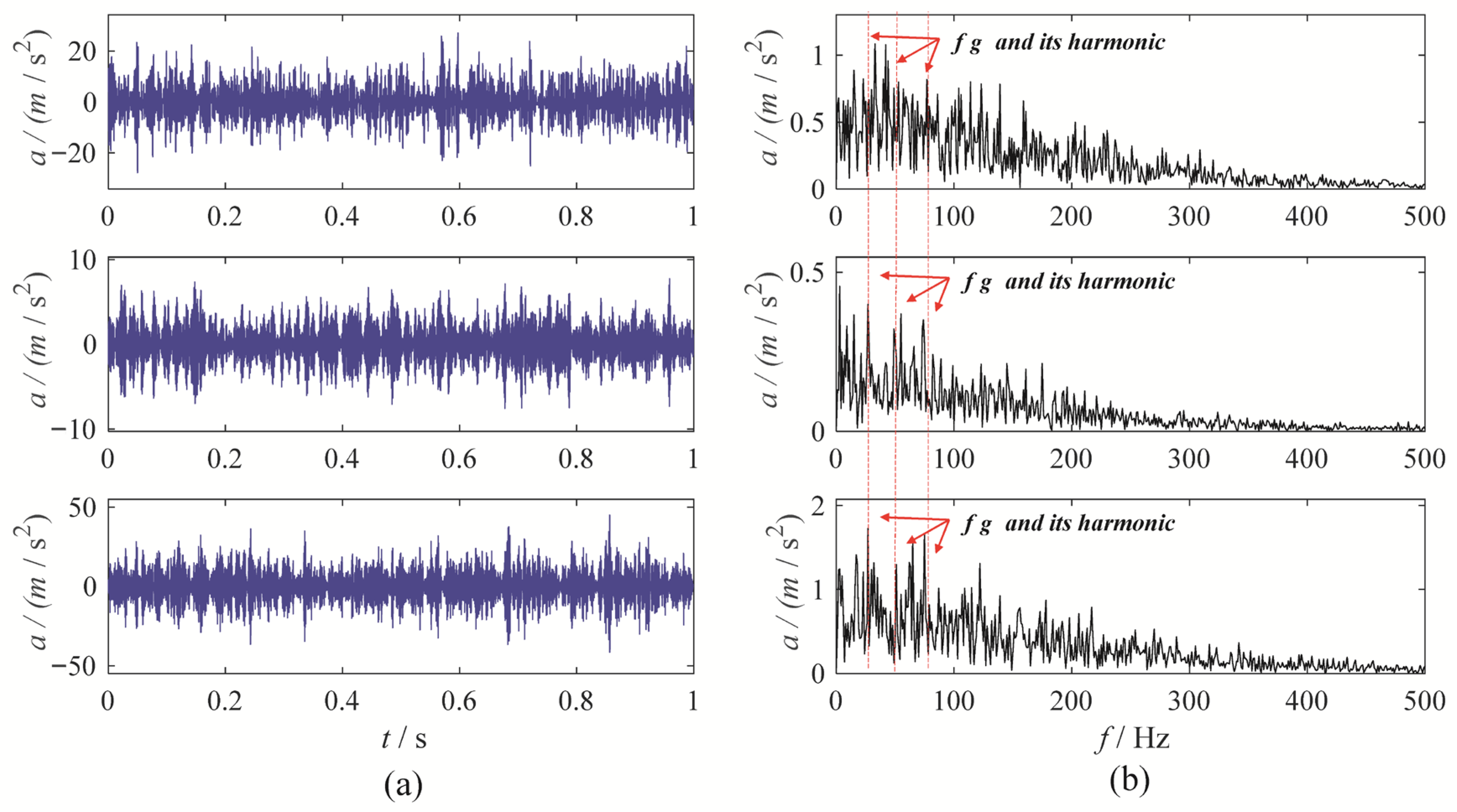

3.2. Gear Wear Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, H.; Li, Z.; Chen, X. Gear fault diagnosis based on continuous wavelet transform. Mech. Syst. Signal Process. 2002, 16, 447–457. [Google Scholar] [CrossRef]

- Lei, Y.; Zuo, M.J.; He, Z.; Zi, Y. A multidimensional hybrid intelligent method for gear fault diagnosis. Expert Syst. Appl. 2010, 37, 1419–1430. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, J.; Wang, E.; Zhang, H.; Gu, M.; Pirttikangas, S. State of the art on vibration signal processing towards data-driven gear fault diagnosis. IET Collab. Intell. Manuf. 2022, 4, 249–266. [Google Scholar] [CrossRef]

- Mohammed, O.D.; Rantatalo, M.; Aidanpää, J.O.; Kumar, U. Vibration signal analysis for gear fault diagnosis with various crack progression scenarios. Mech. Syst. Signal Process. 2013, 41, 176–195. [Google Scholar] [CrossRef]

- Cheng, J.; Pan, H.Y.; Zheng, J.D. Maximum Ramanujan spectrum signal-to-noise ratio deconvolution method: Algorithm and applications. IEEE Trans. Ind. Inform. 2024, 20, 11977–11986. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, Z.H.; Pan, H.Y.; Zheng, J.; Tong, J. An adaptive ultra-narrow band filtering method based on flexible sliding band segmentation. Mech. Syst. Signal Process. 2025, 229, 112560. [Google Scholar] [CrossRef]

- Sharma, V.; Parey, A. A review of gear fault diagnosis using various condition indicators. Procedia Eng. 2016, 144, 253–263. [Google Scholar] [CrossRef]

- Wu, H.; Cheng, J.; Nie, Y.; Wang, J.; Yang, Y. Multivariate complex modulation model decomposition and its application to gear fault diagnosis. Digit. Signal Process. 2023, 135, 103940. [Google Scholar] [CrossRef]

- Miao, Y.; Hu, S.; Liu, Y.; Hua, J. Angle-domain feature mode decomposition for fault diagnosis under speed-varying condition. IEEE Trans. Instrum. Meas. 2025, 74, 3506909. [Google Scholar] [CrossRef]

- Xue, S.; Howard, I. Torsional vibration signal analysis as a diagnostic tool for planetary gear fault detection. Mech. Syst. Signal Process. 2018, 100, 706–728. [Google Scholar] [CrossRef]

- Li, C.; Liang, M. Time–frequency signal analysis for gearbox fault diagnosis using a generalized synchrosqueezing transform. Mech. Syst. Signal Process. 2012, 26, 205–217. [Google Scholar] [CrossRef]

- Yang, K.; Xu, T.; Pan, D.; Zhang, Z.; Wang, H.; Kong, X. Multi-channel MCG signals filtering method based on multivariate variational mode decomposition. Biomed. Signal Process. Control 2025, 99, 106806. [Google Scholar] [CrossRef]

- Wang, Z.; Wong, C.M.; Rosa, A.; Qian, T.; Wan, F. Adaptive Fourier decomposition for multi-channel signal analysis. IEEE Trans. Signal Process. 2022, 70, 903–918. [Google Scholar] [CrossRef]

- Rehman, N.; Mandic, D.P. Multivariate empirical mode decomposition. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 1291–1302. [Google Scholar] [CrossRef]

- Fleureau, J.; Kachenoura, A.; Albera, L.; Nunes, J.-C.; Senhadji, L. Multivariate empirical mode decomposition and application to multichannel filtering. Signal Process. 2011, 91, 2783–2792. [Google Scholar] [CrossRef]

- Yan, X.; Yan, W.-J.; Xu, Y.; Yuen, K.-V. Machinery multi-sensor fault diagnosis based on adaptive multivariate feature mode decomposition and multi-attention fusion residual convolutional neural network. Mech. Syst. Signal Process. 2023, 202, 110664. [Google Scholar] [CrossRef]

- Fu, X.; Fang, Y.; Xu, Y.; Xu, H.; Ma, G.; Peng, N. Current status of research on fault diagnosis using machine learning for gear transmission systems. Machines 2024, 12, 679. [Google Scholar] [CrossRef]

- ur Rehman, N.; Aftab, H. Multivariate variational mode decomposition. IEEE Trans. Signal Process. 2019, 67, 6039–6052. [Google Scholar] [CrossRef]

- Liu, S.; Yu, K. Successive multivariate variational mode decomposition. Multidimens. Syst. Signal Process. 2022, 33, 917–943. [Google Scholar] [CrossRef]

- Daepp, U.; Gorkin, P.; Shaffer, A.; Sokolowsky, B.; Voss, K. Decomposing finite Blaschke products. J. Math. Anal. Appl. 2015, 426, 1201–1216. [Google Scholar] [CrossRef]

- Tan, C.; Zhang, L.; Wu, H. A novel Blaschke unwinding adaptive-Fourier-decomposition-based signal compression algorithm with application on ECG signals. IEEE J. Biomed. Health Inform. 2018, 23, 672–682. [Google Scholar] [CrossRef]

- Qian, T.; Zhang, L.; Li, Z. Algorithm of adaptive Fourier decomposition. IEEE Trans. Signal Process. 2011, 59, 5899–5906. [Google Scholar] [CrossRef]

- Zheng, X.; Cheng, Z.; Cheng, J.; Yang, Y.; Yang, X. Blaschke mode decomposition: Algorithm and application. Struct. Health Monit. 2025. [Google Scholar] [CrossRef]

- Qian, T.; Zhang, Y.; Liu, W.; Qu, W. Adaptive Fourier decomposition-type sparse representations versus the Karhunen–Loève expansion for decomposing stochastic processes. Math. Methods Appl. Sci. 2023, 46, 14007–14025. [Google Scholar] [CrossRef]

- Qian, T. Sparse representations of random signals. Math. Methods Appl. Sci. 2022, 45, 4210–4230. [Google Scholar] [CrossRef]

- Delon, J.; Desolneux, A.; Lisani, J.L.; Petro, A.B. A nonparametric approach for histogram segmentation. IEEE Trans. Image Process. 2006, 16, 253–261. [Google Scholar] [CrossRef]

- Desolneux, A.; Moisan, L.; More, J.M. A grouping principle and four applications. IEEE Trans. Pattern Anal. Mach. Intell. 2003, 25, 508–513. [Google Scholar] [CrossRef]

- Zheng, X.; Yang, Y.; Hu, N.; Cheng, Z.; Cheng, J. Blaschke transform-based Weight Soft Voting Denoise Method and its applications in gear fault diagnosis. Mech. Syst. Signal Process. 2024, 214, 111400. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, X.; Cheng, Z.; Cheng, J.; Yang, Y. A Multivariate Blaschke-Based Mode Decomposition Approach for Gear Fault Diagnosis. Sensors 2025, 25, 6302. https://doi.org/10.3390/s25206302

Zheng X, Cheng Z, Cheng J, Yang Y. A Multivariate Blaschke-Based Mode Decomposition Approach for Gear Fault Diagnosis. Sensors. 2025; 25(20):6302. https://doi.org/10.3390/s25206302

Chicago/Turabian StyleZheng, Xianbin, Zhengyang Cheng, Junsheng Cheng, and Yu Yang. 2025. "A Multivariate Blaschke-Based Mode Decomposition Approach for Gear Fault Diagnosis" Sensors 25, no. 20: 6302. https://doi.org/10.3390/s25206302

APA StyleZheng, X., Cheng, Z., Cheng, J., & Yang, Y. (2025). A Multivariate Blaschke-Based Mode Decomposition Approach for Gear Fault Diagnosis. Sensors, 25(20), 6302. https://doi.org/10.3390/s25206302