Graphene-Based, Flexible, Wearable Piezoresistive Sensors with High Sensitivity for Tiny Pressure Detection

Abstract

1. Introduction

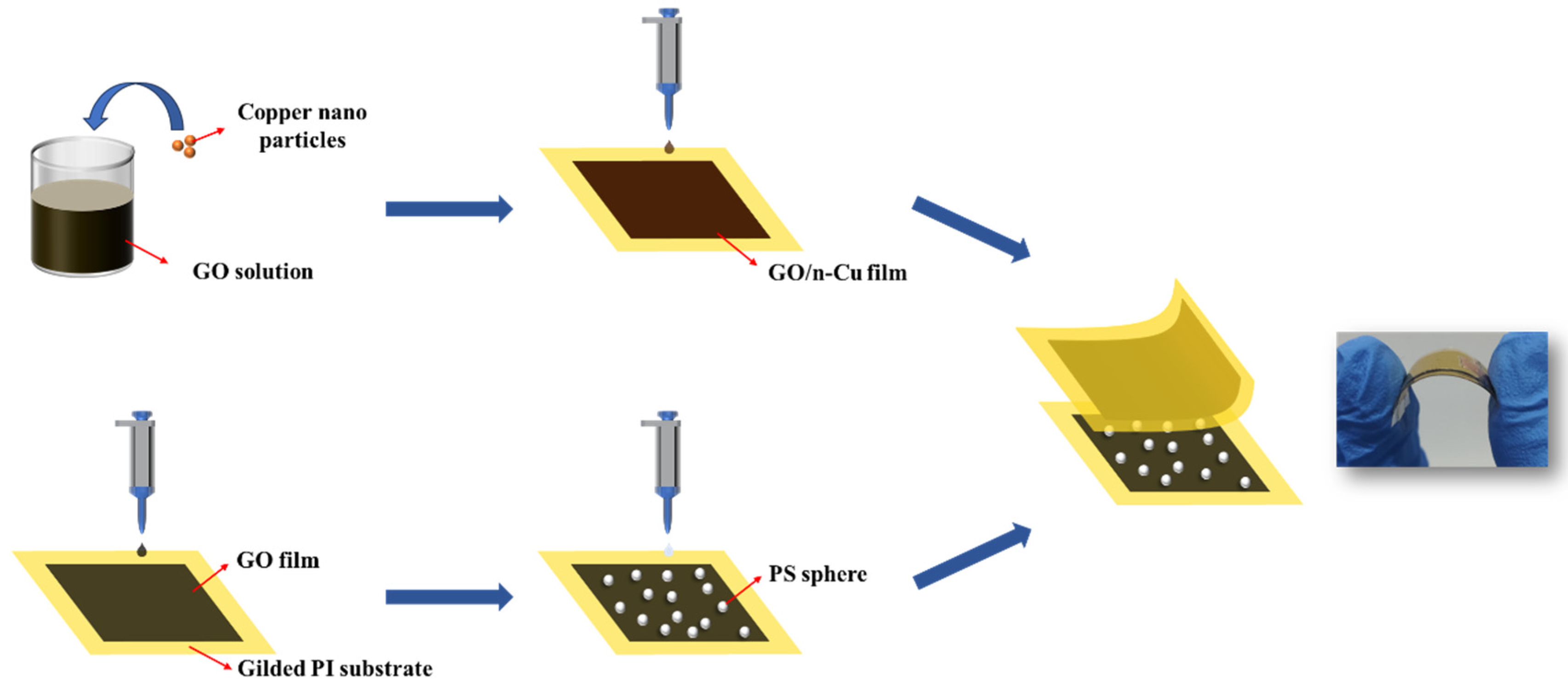

2. Experimental Section

2.1. Materials

2.2. Preparation of n-Cu/GO Solution

2.3. Preparation of the Sensor

2.4. Principle Analysis and Characterization

2.5. Measurement Instruments

3. Results

3.1. Piezoresistive Performance

3.2. Applications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, W.; He, T.; Zhao, W.; Li, W.; Liu, Y.; Li, C.; Luo, Q.; Zhao, W.; Yan, J.; Sun, J. Robust and tunable hydrogels strengthened by dynamic amphiphilic ionic domains. Chem. Eng. J. 2024, 4948, 153136. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, Y.Z.; Fang, S.; Liu, C.; Niu, J.; Li, G.; Li, F.; Li, X.; Cheng, T.; Lai, W.Y. Artificial intelligent optoelectronic skin with anisotropic electrical and optical responses for multi-dimensional sensing. Appl. Phys. Rev. 2022, 9, 021403. [Google Scholar] [CrossRef]

- Chen, S.; Qi, J.; Fan, S.; Qiao, Z.; Yeo, J.C.; Lim, C.T. Flexible Wearable Sensors for Cardiovascular Health Monitoring. Adv. Healthc. Mater. 2021, 10, 2100116. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Bick, M.; Xiao, X.; Chen, G.; Nashalian, A.; Chen, J. Leveraging triboelectric nanogenerators for bioengineering. Matter 2021, 4, 845–887. [Google Scholar] [CrossRef]

- Pang, Y.; Tian, H.; Tao, L.; Li, Y.; Wang, X.; Deng, N.; Yang, Y.; Ren, T.L. Flexible, Highly Sensitive, and Wearable Pressure and Strain Sensors with Graphene Porous Network Structure. ACS Appl. Mater. Interfaces 2016, 8, 26458–26462. [Google Scholar] [CrossRef] [PubMed]

- Hammock, M.L.; Chortos, A.; Tee, B.C.K.; Tok, J.B.H.; Bao, Z. 25th Anniversary Article: The Evolution of Electronic Skin (E-Skin): A Brief History, Design Considerations, and Recent Progress. Adv. Mater. 2013, 25, 5997–6038. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Yu, R.; Xia, T.; Wu, B.; Yuan, J.; Ma, L.; Cheng, G.J.; Liu, F. Highly Sensitive Flexible Piezoresistive Sensor with 3D Conductive Network. ACS Appl. Mater. Interfaces 2020, 12, 35291–35299. [Google Scholar] [CrossRef]

- Wen, J.; Zhang, L.; Wang, Y.Z.; Guo, X. Artificial Tactile Perception System Based on Spiking Tactile Neurons and Spiking Neural Networks. ACS Appl. Mater. Interfaces 2023, 16, 998–1004. [Google Scholar] [CrossRef]

- Huang, J.; Li, D.; Zhao, M.; Ke, H.; Mensah, A.; Lv, P.; Tian, X.; Wei, Q. Flexible electrically conductive biomass-based aerogels for piezoresistive pressure/strain sensors. Chem. Eng. J. 2019, 373, 1357–1366. [Google Scholar] [CrossRef]

- Duan, L.; D’ Hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Li, N.; Gao, S.; Li, Y.; Liu, J.; Song, W.; Shen, G. Multi-attribute wearable pressure sensor based on multilayered modulation with high constant sensitivity over a wide range. Nano Res. 2023, 16, 7583–7592. [Google Scholar] [CrossRef]

- Yang, T.; Deng, W.; Chu, X.; Wang, X.; Hu, Y.; Fan, X.; Song, J.; Gao, Y.; Zhang, B.; Tian, G.; et al. Hierarchically Microstructure-Bioinspired Flexible Piezoresistive Bioelectronics. ACS Nano 2021, 15, 11555–11563. [Google Scholar] [CrossRef]

- Das, K.; Mathew, A.K.; Assumi, K.; Sudhakar, G.V.S. Loupe Assisted Thyroidectomy: A Tool for Reducing Complications. Indian J. Otolaryngol. Head Neck Surg. 2021, 74, 5543–5547. [Google Scholar] [CrossRef]

- Hirschberg, J.; Dejonckere, P.H.; Hirano, M.; Mori, K.; Schultz-Coulon, H.J.; Vrtička, K. Voice disorders in children. Int. J. Pediatr. Otorhinolaryngol. 1995, 32, S109–S125. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Zhang, L.; Li, H.; Lai, X.; Zeng, X. Skin-inspired flexible and high-performance MXene@polydimethylsiloxane piezoresistive pressure sensor for human motion detection. J. Colloid Interface Sci. 2022, 617, 478–488. [Google Scholar] [CrossRef]

- Jing, M.; Zhou, J.; Zhang, P.; Hou, D.; Shen, J.; Tian, J.; Chen, W. Porous AgNWs/Poly (vinylidene fluoride) Composite-Based Flexible Piezoresistive Sensor with High Sensitivity and Wide Pressure Ranges. ACS Appl. Mater. Interfaces 2022, 14, 55119–55129. [Google Scholar] [CrossRef]

- Li, L.; Cheng, Y.; Cao, H.; Liang, Z.; Liu, Z.; Yan, S.; Li, L.; Jia, S.; Wang, J.; Gao, Y. MXene/rGO/PS spheres multiple physical networks as high-performance pressure sensor. Nano Energy 2022, 95, 106986. [Google Scholar] [CrossRef]

- Li, M.; Wang, T.; Han, C.; Yang, H.; Huang, Y.; Hu, J.; Li, L.; Jiang, J.; Huang, M.; Fan, Y.; et al. A novel piezoresistive sensor with rectification properties. Mater. Des. 2024, 239, 112782. [Google Scholar] [CrossRef]

- Liu, C.; Tan, Q.; Deng, Y.; Ye, P.; Kong, L.; Ma, X.; Xu, L.; Xu, Y.; Qiang, Q.; Chen, W.; et al. Highly sensitive and stable 3D flexible pressure sensor based on carbon black and multi-walled carbon nanotubes prepared by hydrothermal method. Compos. Commun. 2022, 32, 101178. [Google Scholar] [CrossRef]

- Berry, D.A.; Chhetri, D.K.; Neubauer, J. Observations of phonation threshold pressure and fundamental frequency in the in vivo canine larynx using graded neuromuscular stimulation. J. Acoust. Soc. Am. 2012, 131, 3347. [Google Scholar] [CrossRef]

- Titze, I.R.; Schmidt, S.S.; Titze, M.R. Phonation threshold pressure in a physical model of the vocal fold mucosa. J. Acoust. Soc. Am. 1995, 97, 3080–3084. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, H.; Liang, X.; Deng, H.; Zhang, X.; Heidari, H.; Ghannam, R.; Zhang, X. Speech Recognition Using Intelligent Piezoresistive Sensor Based on Polystyrene Sphere Microstructures. Adv. Intell. Syst. 2023, 5, 2200427. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Li, Y.; Zhao, Y.; Wang, W.; Li, S.; Huang, L. Flexible Piezoresistive Sensor with the Microarray Structure Based on Self-Assembly of Multi-Walled Carbon Nanotubes. Sensors 2019, 19, 4985. [Google Scholar] [CrossRef]

- Teng, F.R.; Ren, Q.; Lai, T.C.; Liu, C.; Li, A.D. A stretchable petal patterned strain sensor comprising Ir nanoparticles-modified multi-walled carbon nanotubes for human-motion detection. J. Phys. D Appl. Phys. 2020, 53, 505402. [Google Scholar] [CrossRef]

- Yan, J.; Ma, Y.; Jia, G.; Zhao, S.; Yue, Y.; Cheng, F.; Zhang, C.; Cao, M.; Xiong, Y.; Shen, P.; et al. Bionic MXene based hybrid film design for an ultrasensitive piezoresistive pressure sensor. Chem. Eng. J. 2022, 431, 133458. [Google Scholar]

- Zhu, Y.; Hartel, M.C.; Yu, N.; Garrido, P.R.; Kim, S.; Lee, J.; Bandaru, P.; Guan, S.; Lin, H.; Emaminejad, S.; et al. Epidermis-Inspired Wearable Piezoresistive Pressure Sensors Using Reduced Graphene Oxide Self-Wrapped Copper Nanowire Networks. Small Methods 2021, 6, 2100900. [Google Scholar] [CrossRef]

- Liu, C.; Xu, L.; Kong, L.; Xu, Y.; Zhou, W.; Qiang, Q.; Tian, L.; Chen, W.; Cai, M.; Lang, T.; et al. High-performance piezoresistive flexible pressure sensor based on wrinkled microstructures prepared from discarded vinyl records and ultra-thin, transparent polyaniline films for human health monitoring. J. Mater. Chem. C 2022, 10, 13064–13073. [Google Scholar] [CrossRef]

- Lv, Y.; Min, L.; Niu, F.; Qin, Z.; Zhang, M.; Zhao, B.; Liu, Y.; Pan, K. Conductive Nanomaterials with Different Dimensions for Flexible Piezoresistive Sensors: From Selectivity to Applications. Adv. Mater. Technol. 2023, 8, 2200427. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [PubMed]

- Sofer, Z.; Wang, X.; Yu, M. MXene Chemistry and Applications. Small Methods 2023, 7, 2300778. [Google Scholar] [CrossRef]

- Li, Y. Carbon Nanotube Research in Its 30th Year. ACS Nano 2021, 15, 9197–9200. [Google Scholar] [CrossRef]

- Feng, J.; Tian, Y.; Wang, S.; Xiao, M.; Hui, Z.; Hang, C.; Duley, W.W.; Zhou, Y.N. Femtosecond laser irradiation induced heterojunctions between carbon nanofibers and silver nanowires for a flexible strain sensor. J. Mater. Sci. Technol. 2021, 84, 139–146. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef]

- The rise and rise of graphene. Nat. Nanotechnol. 2010, 5, 755. [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Huang, Y.; Qiang, Y.; Yi, R.; Wang, S.; Liang, S.; Chen, L. “Network-trapped engineering” of graphene oxide membrane with stable structure. J. Membr. Sci. 2025, 715, 123473. [Google Scholar] [CrossRef]

- Castro Neto, A.H.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Gibney, E. Graphene conducts electricity ten times better than expected. Nature 2014, 2, 2–4. [Google Scholar] [CrossRef]

- Zhong, H.; Xu, K.; Liu, Z.; Xu, G.; Shi, L.; Fan, Y.; Wang, J.; Ren, G.; Yang, H. Charge transport mechanisms of graphene/semiconductor Schottky barriers: A theoretical and experimental study. J. Appl. Phys. 2014, 115, 013701. [Google Scholar] [CrossRef]

- Chen, L.; Shi, G.; Shen, J.; Peng, B.; Zhang, B.; Wang, Y.; Bian, F.; Wang, J.; Li, D.; Qian, Z.; et al. Ion sieving in graphene oxide membranes via cationic control of interlayer spacing. Nature 2017, 550, 380–383. [Google Scholar] [CrossRef] [PubMed]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 208, 1334–1339. [Google Scholar] [CrossRef]

- Yu, T.; Koh, T.; Lim, B. Synthesis of Copper Nanoparticles with Controlled Sizes by Reverse Micelle Method. J. Nanosci. Nanotechnol. 2013, 13, 3250–3253. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Song, Z.; Liu, S.; Liu, Z.; Li, W.; Kong, H.; Li, C.; Bao, Y.; Zhang, W.; Niu, L. Iontronic tactile sensory system for plant species and growth-stage classification. Device 2024, 3, 100615. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, L.; Xue, C.; Zhang, X.; Meng, X.; Li, X. Bubbles-Induced Porous Structure-Based Flexible Piezoresistive Sensors for Speech Recognition. ACS Appl. Mater. Interfaces 2024, 16, 9532–9543. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, D.; Zhang, R.; Zhang, J.; Zhao, Q.; He, H.; Huang, H.; Yang, L.; Xu, Y. Novel Polyurethane Based, Fully Flexible, High-Performance Piezoresistive Sensor for Real-Time Pressure Monitoring. ACS Appl. Mater. Interfaces 2024, 16, 25422–25431. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Zhang, T.; Wang, Z.; Zhang, H.; Yan, Z.; Li, X.; Hong, W.; Zhang, A.; Qian, Z.; Zhang, X.; et al. Tactile corpuscle-inspired piezoresistive sensors based on (3-aminopropyl) triethoxysilane-enhanced CNPs/carboxylated MWCNTs/cellulosic fiber composites for textile electronics. J. Colloid Interface Sci. 2024, 660, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, H.; Lai, X.; Gao, T.; Liao, X.; Chen, W.; Zeng, X. Carbonized cotton fabric-based multilayer piezoresistive pressure sensors. Cellulose 2019, 26, 5001–5014. [Google Scholar] [CrossRef]

- Wang, F.; Su, D.; Ma, K.; Qin, B.; Li, B.; Li, J.; Zhang, C.; Xin, Y.; Huang, Z.; Yang, W.; et al. Reliable and Scalable Piezoresistive Sensors with an MXene/MoS2 Hierarchical Nanostructure for Health Signals Monitoring. ACS Appl. Mater. Interfaces 2023, 15, 44001–44011. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, D.; Wang, D.; Xu, Z.; Zhang, H.; Chen, X.; Wang, Z.; Xia, H.; Cai, H. Efficient Fabrication of TPU/MXene/Tungsten Disulfide Fibers with Ultra-Fast Response for Human Respiratory Pattern Recognition and Disease Diagnosis via Deep Learning. ACS Appl. Mater. Interfaces 2023, 15, 37946–37956. [Google Scholar] [CrossRef]

- Ren, J.; Huang, X.; Han, R.; Chen, G.; Zhou, Z.; Li, Q. An extreme condition-resistant superelastic silica nanofiber/MXene composite aerogel for synchronous sensing and thermal management. J. Mater. Chem. A 2023, 11, 10396–10412. [Google Scholar] [CrossRef]

- Li, Z.; Feng, D.; Li, B.; Zhao, W.; Xie, D.; Mei, Y.; Liu, P. Ultra-Wide Range, High Sensitivity Piezoresistive Sensor Based on Triple Periodic Minimum Surface Construction. Small 2023, 19, 2301378. [Google Scholar] [CrossRef] [PubMed]

| Sensitivity (kPa−1) | Response | Recovery | Stability | Ref. |

| 27.6 (1–1.5 kPa) | 800 (μs) | 800 (μs) | 10,000 | [46] |

| 7.023 (0–0.1 kPa) | 60 (ms) | 80 (ms) | 80,000 | [47] |

| 1.0005 (0–0.1 kPa) | 40 (ms) | 40 (ms) | 500 | [48] |

| 13.89 (0–6 kPa) | 64 (ms) | 165 (ms) | 500 | [49] |

| 0.42 (0−1.5 kPa) | 36 (ms) | 36 (ms) | 10,000 | [50] |

| 45.81 (0–0.5 kPa) | 18 (ms) | 36 (ms) | 5000 | [51] |

| 0.33 (0–1.9 kPa) | 72 (ms) | 99 (ms) | 5000 | [52] |

| 132 (0–5.7 MPa) | --- | --- | 10,000 | [53] |

| 2.65 (0–0.3 kPa) | 80 (ms) | 80 (ms) | 5000 | [25] |

| 20.33 | 186 (ms) | 242 (ms) | 9000 | [26] |

| 403.46 (10–18 kPa) | 105.3 (ms) | 99.3 (ms) | 12,000 | [27] |

| 0.24 (0–2.2 kPa) | 15 (ms) | 20 (ms) | 7000 | [29] |

| 0.144 (0–1 kPa) | 150 (ms) | 150 (ms) | 1000 | [28] |

| 232.5 (0–0.2 kPa) | 45 (ms) | 36 (ms) | 2800 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Hu, J.; Li, Y.; Huang, Y.; Wang, L.; Huang, M.; Wang, Z.; Chen, J.; Fan, Y.; Chen, L. Graphene-Based, Flexible, Wearable Piezoresistive Sensors with High Sensitivity for Tiny Pressure Detection. Sensors 2025, 25, 423. https://doi.org/10.3390/s25020423

Li R, Hu J, Li Y, Huang Y, Wang L, Huang M, Wang Z, Chen J, Fan Y, Chen L. Graphene-Based, Flexible, Wearable Piezoresistive Sensors with High Sensitivity for Tiny Pressure Detection. Sensors. 2025; 25(2):423. https://doi.org/10.3390/s25020423

Chicago/Turabian StyleLi, Rui, Jiahao Hu, Yalong Li, Yi Huang, Lin Wang, Mohan Huang, Zhikun Wang, Junlang Chen, Yan Fan, and Liang Chen. 2025. "Graphene-Based, Flexible, Wearable Piezoresistive Sensors with High Sensitivity for Tiny Pressure Detection" Sensors 25, no. 2: 423. https://doi.org/10.3390/s25020423

APA StyleLi, R., Hu, J., Li, Y., Huang, Y., Wang, L., Huang, M., Wang, Z., Chen, J., Fan, Y., & Chen, L. (2025). Graphene-Based, Flexible, Wearable Piezoresistive Sensors with High Sensitivity for Tiny Pressure Detection. Sensors, 25(2), 423. https://doi.org/10.3390/s25020423