Network-Wide GIS Mapping of Cycling Vibration Comfort: From Methodology to Real-World Implementation

Abstract

1. Introduction

2. Experiments

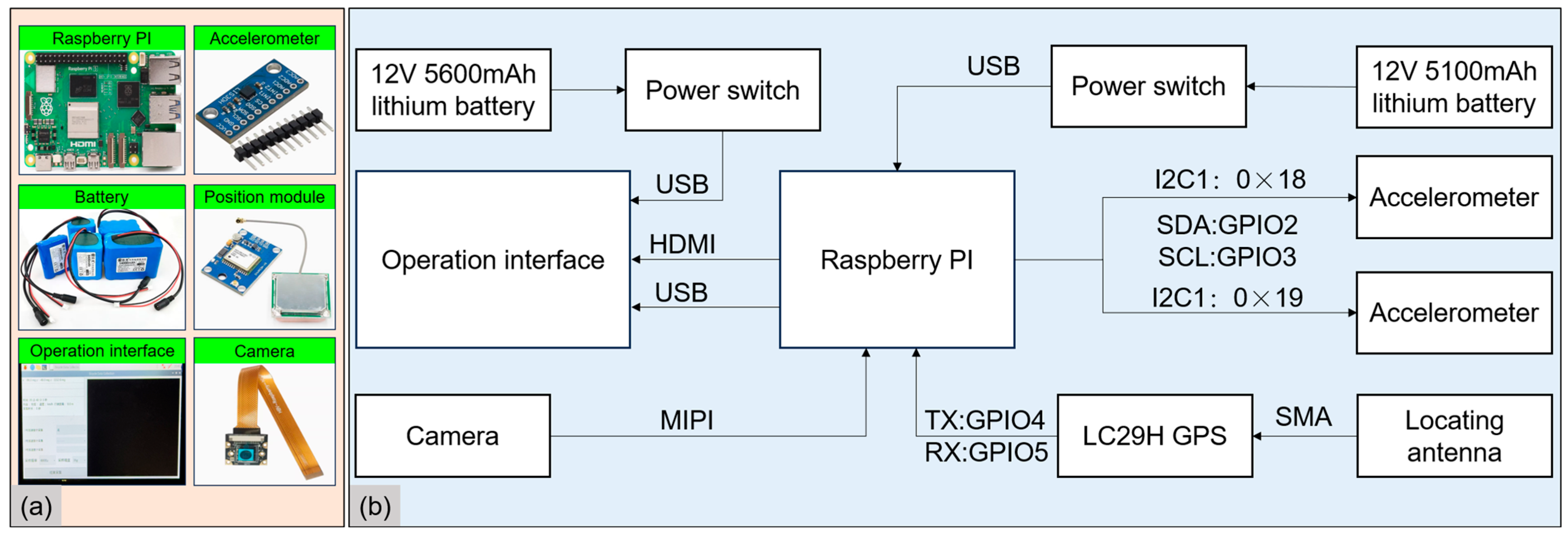

2.1. Cycling Vibration Dynamic Testing Hardware System

2.1.1. System Composition

2.1.2. Module Parameters

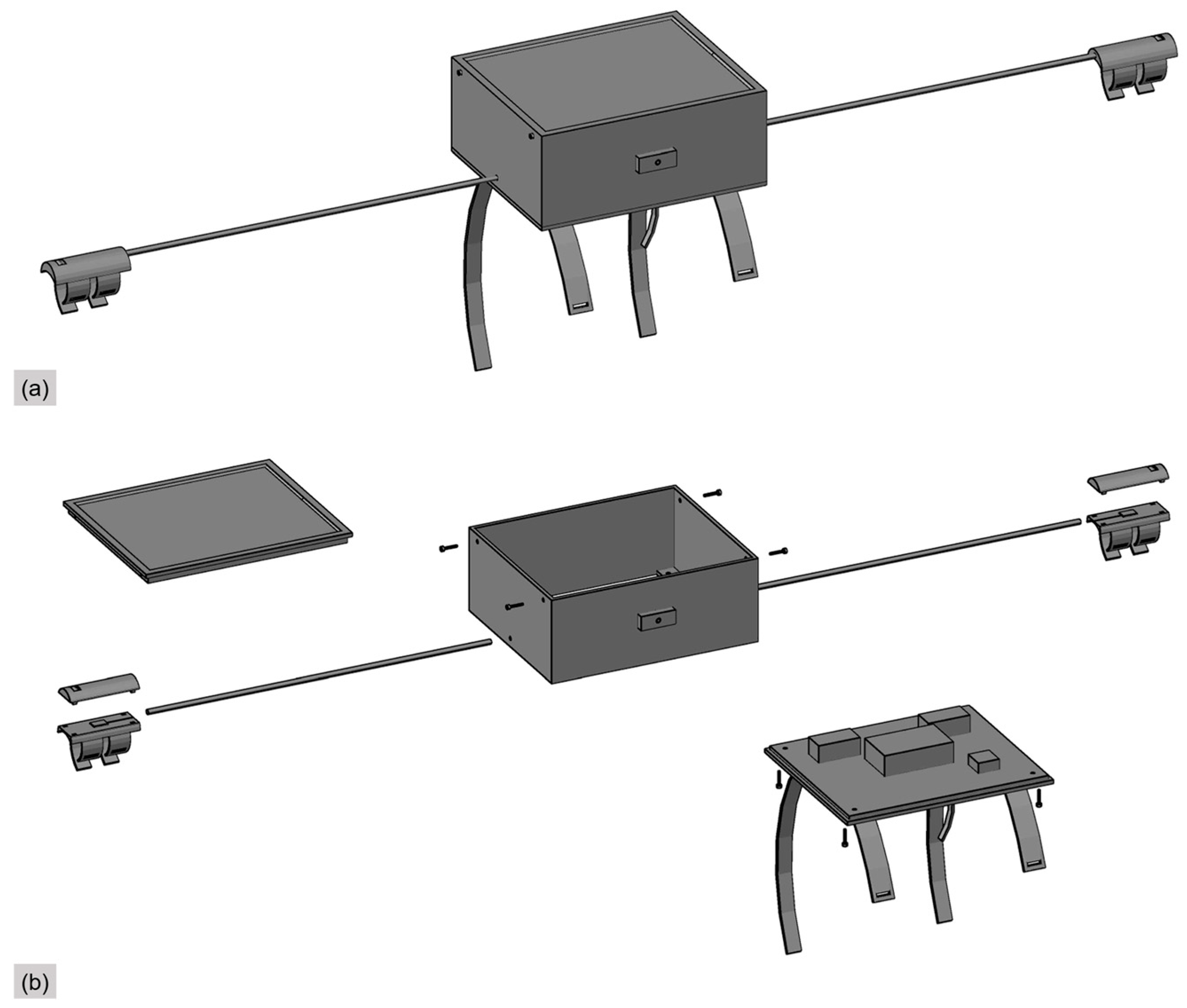

2.2. Cycling Vibration Test

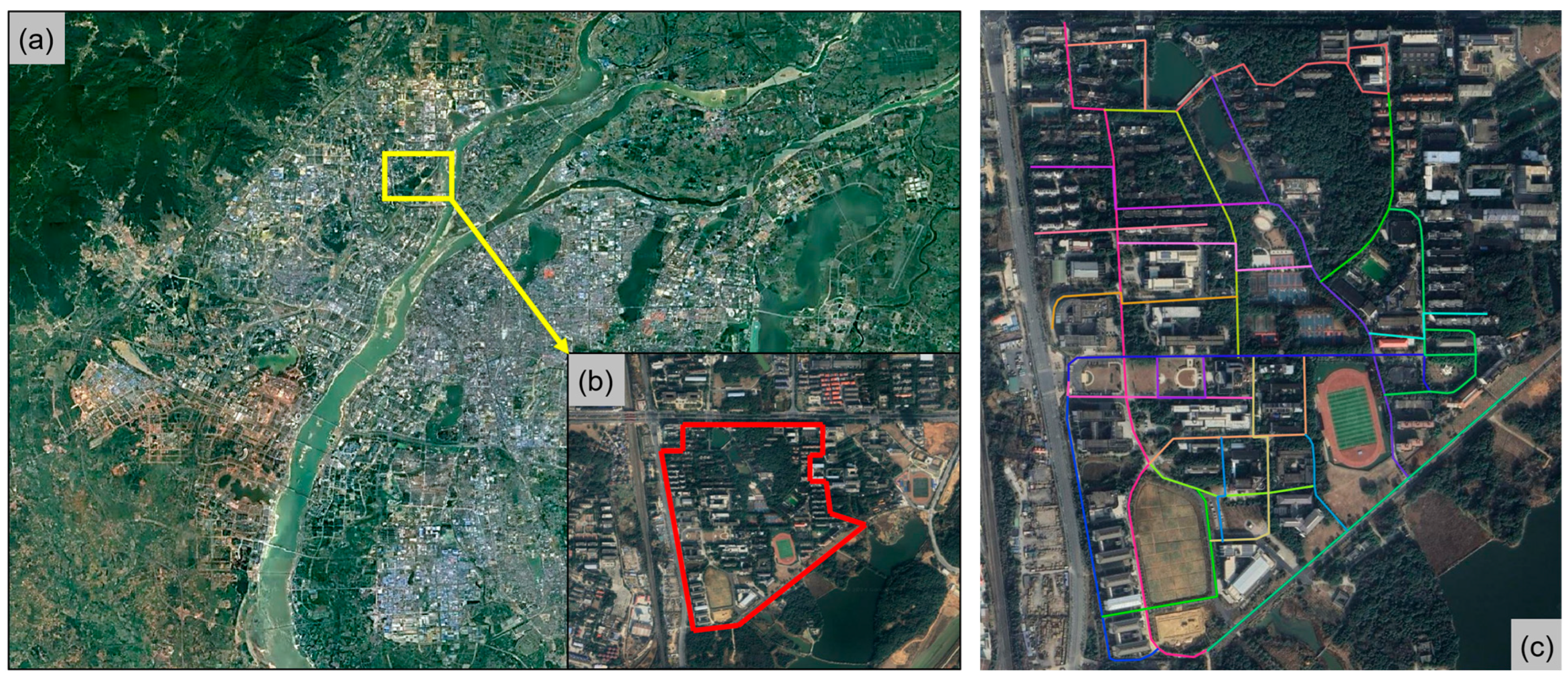

2.2.1. Study Area

2.2.2. Test Procedure

2.2.3. Data Processing

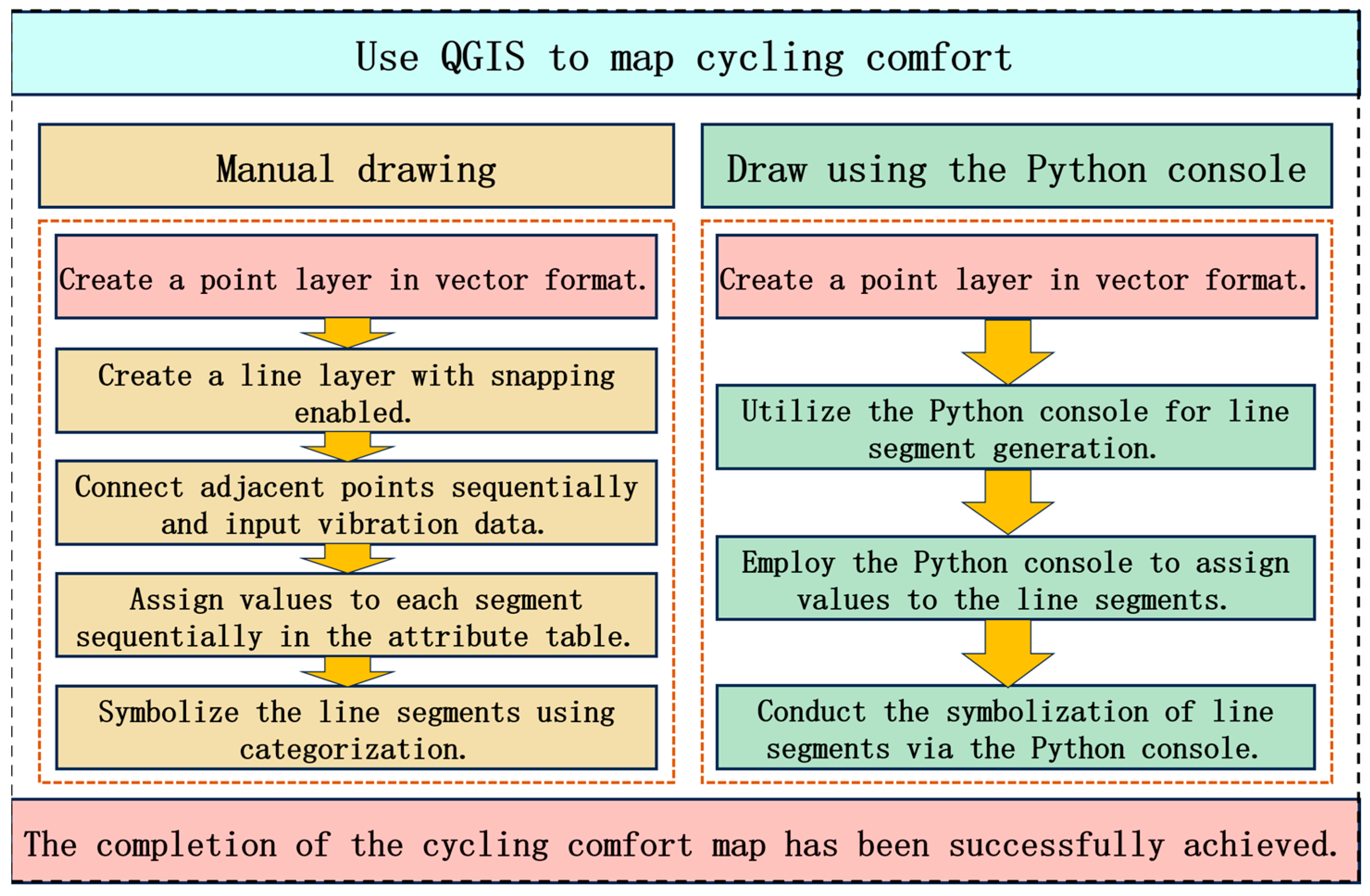

2.3. Comfort Mapping for Cycling

2.3.1. Comfort Level Classification

2.3.2. Map Generation

3. Results and Discussion

3.1. Reliability Verification

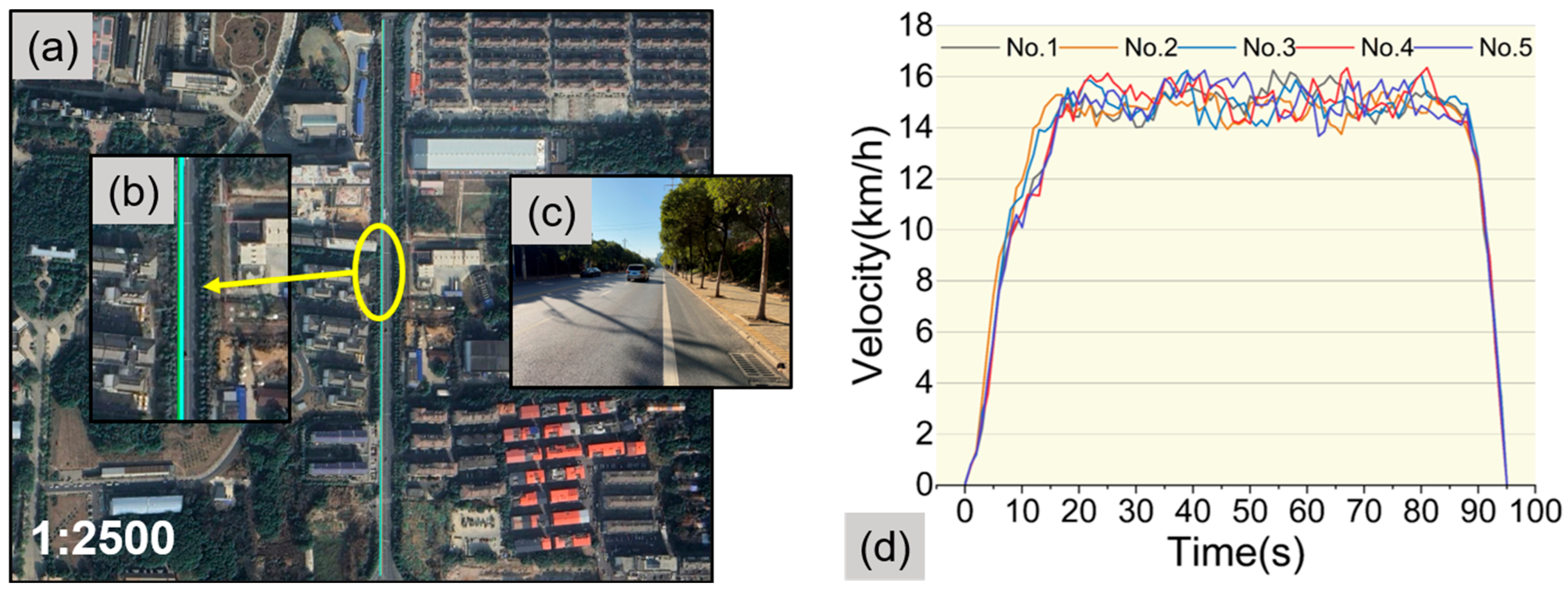

3.1.1. Cycling Trajectory and Speed Validation

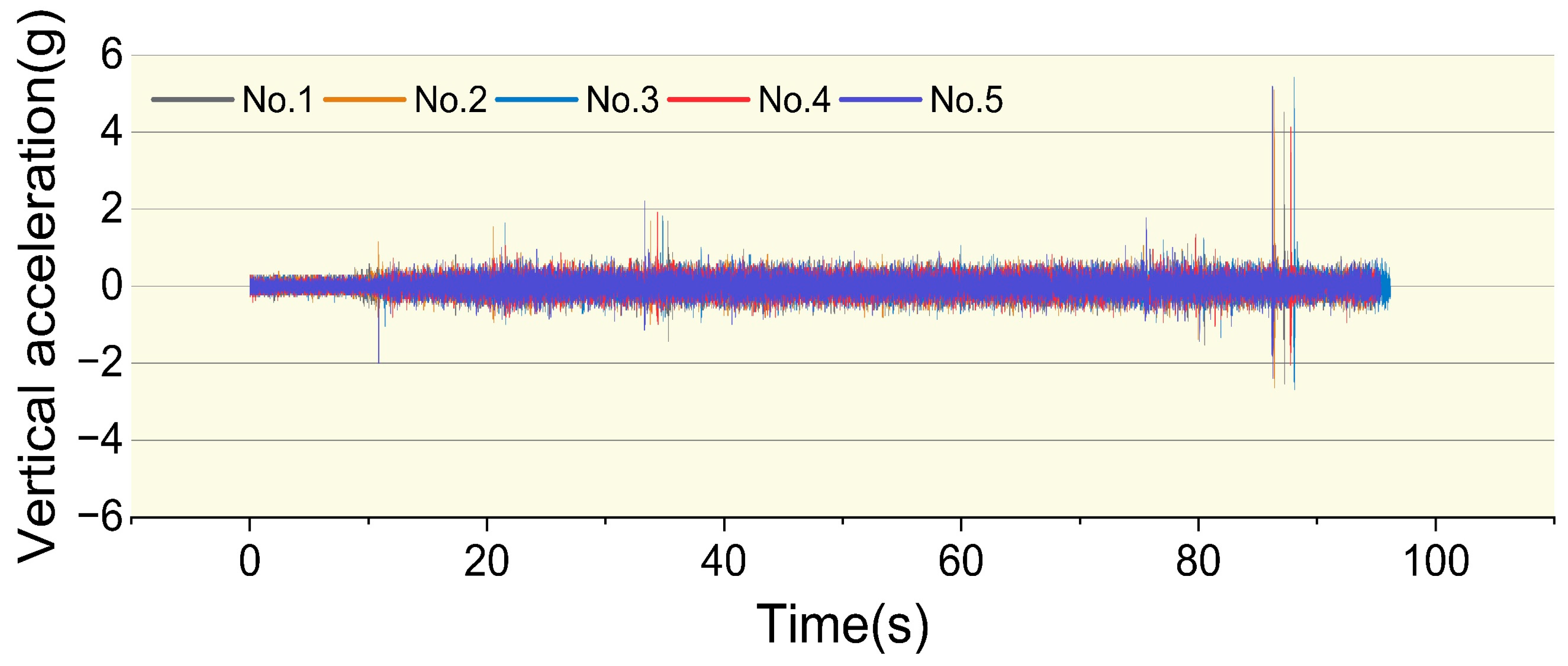

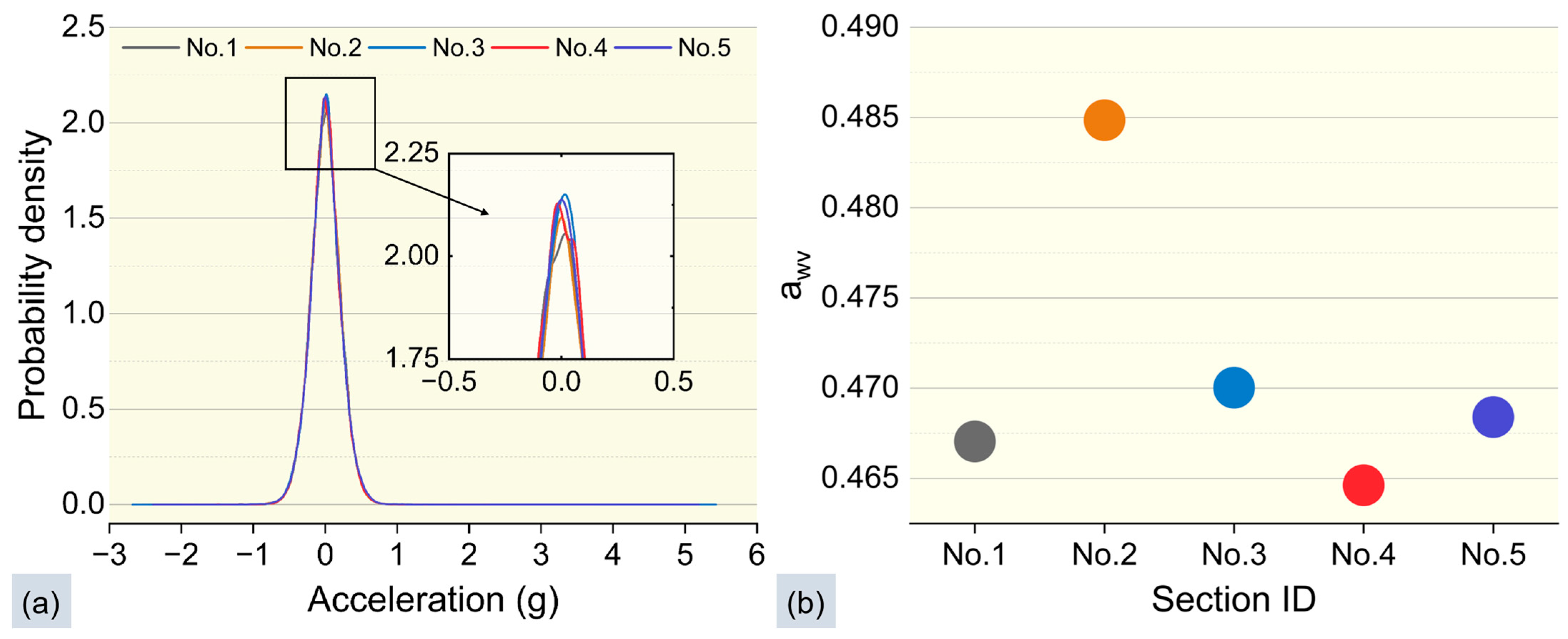

3.1.2. Vibration Stability Verification

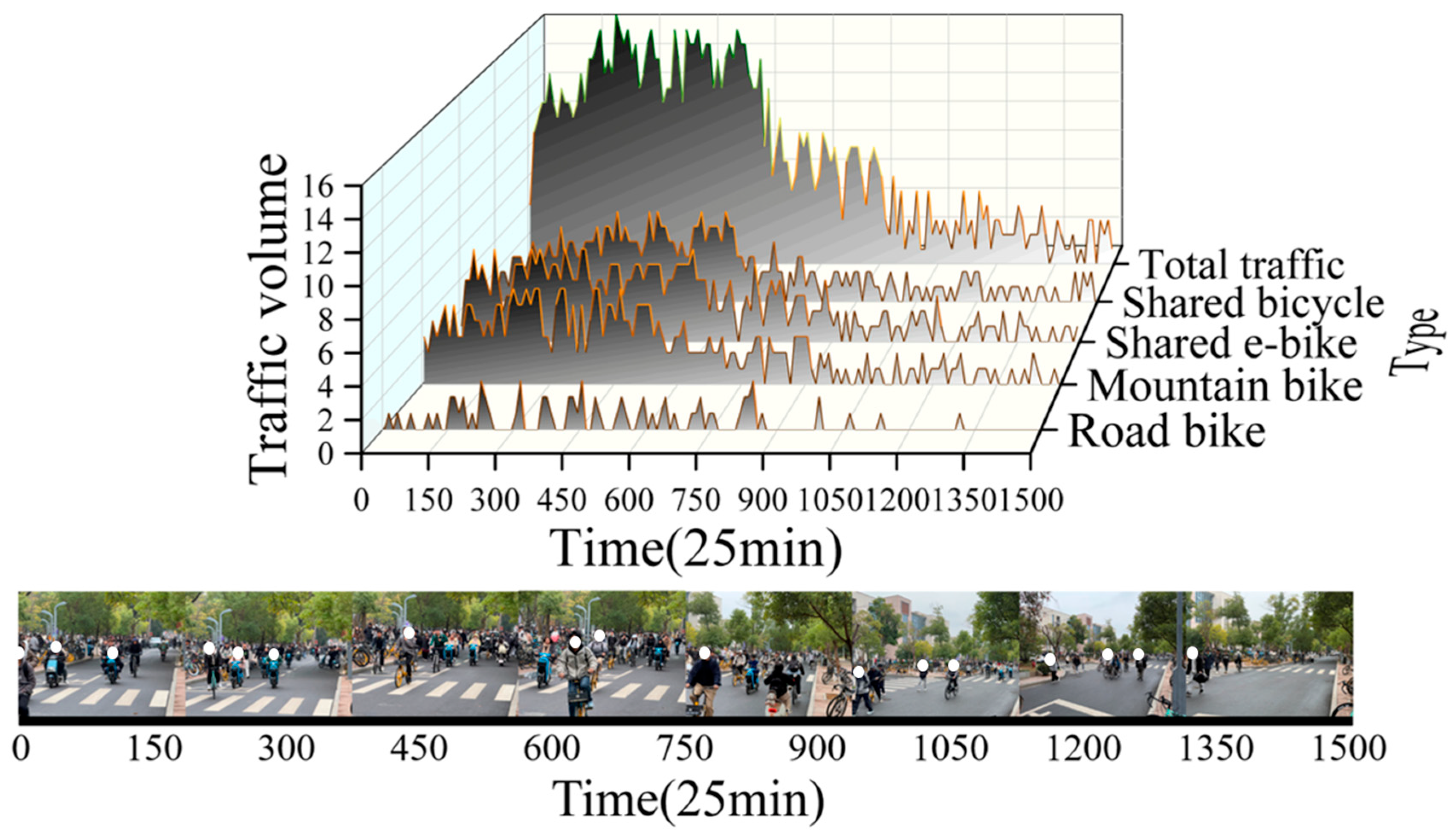

3.2. Field Testing

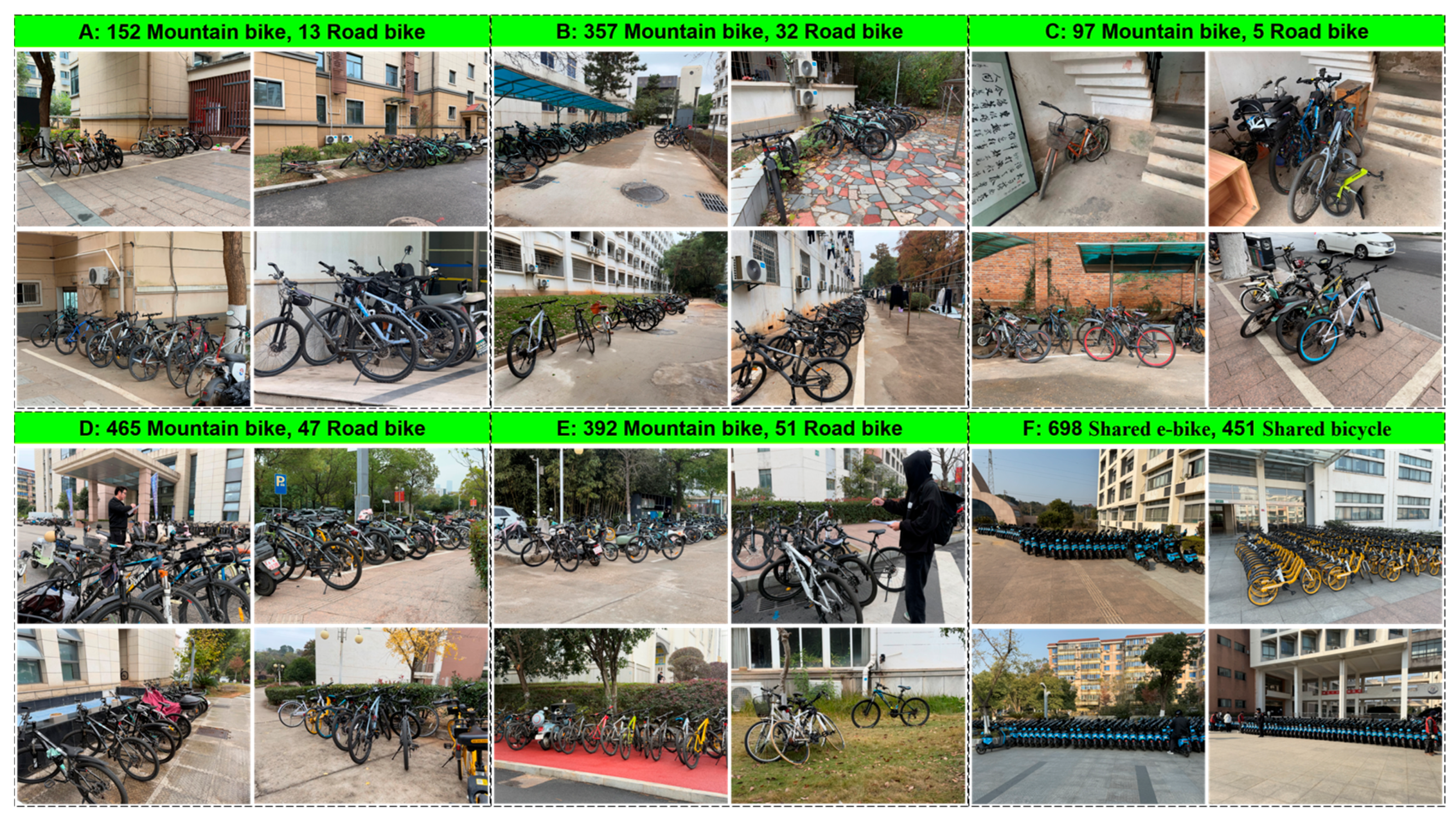

3.2.1. Road Conditions and Environment

3.2.2. Test Vehicle

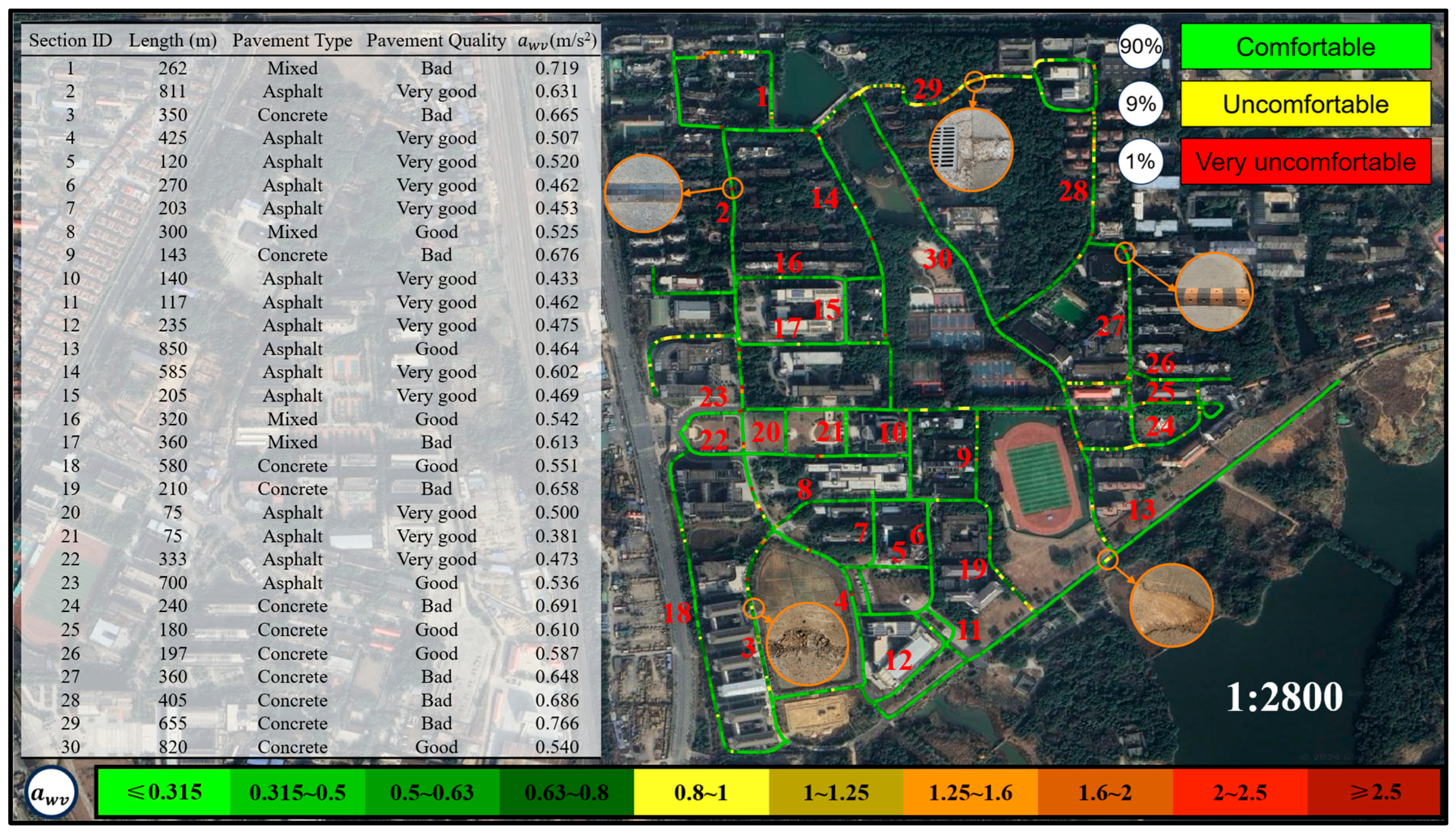

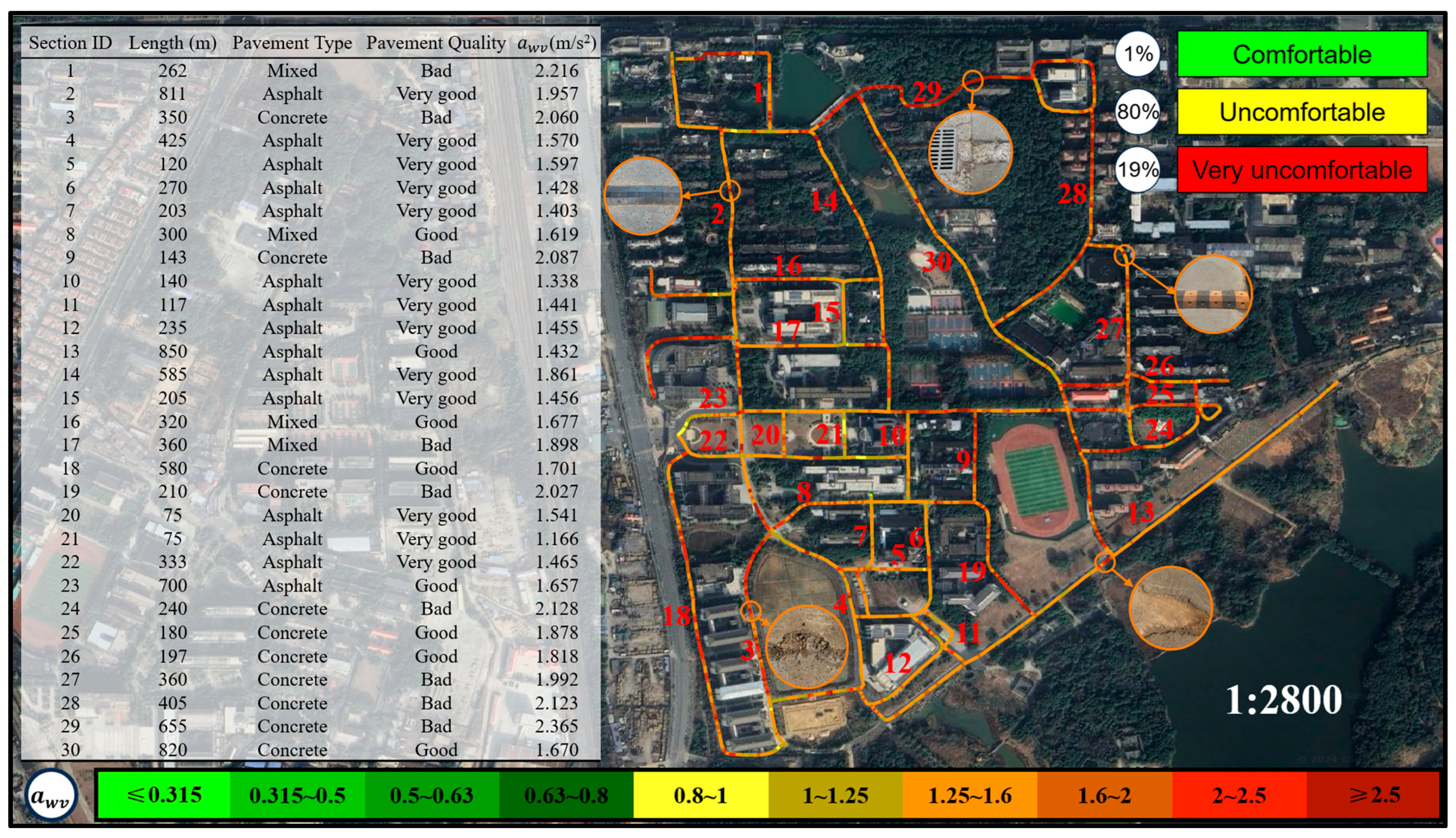

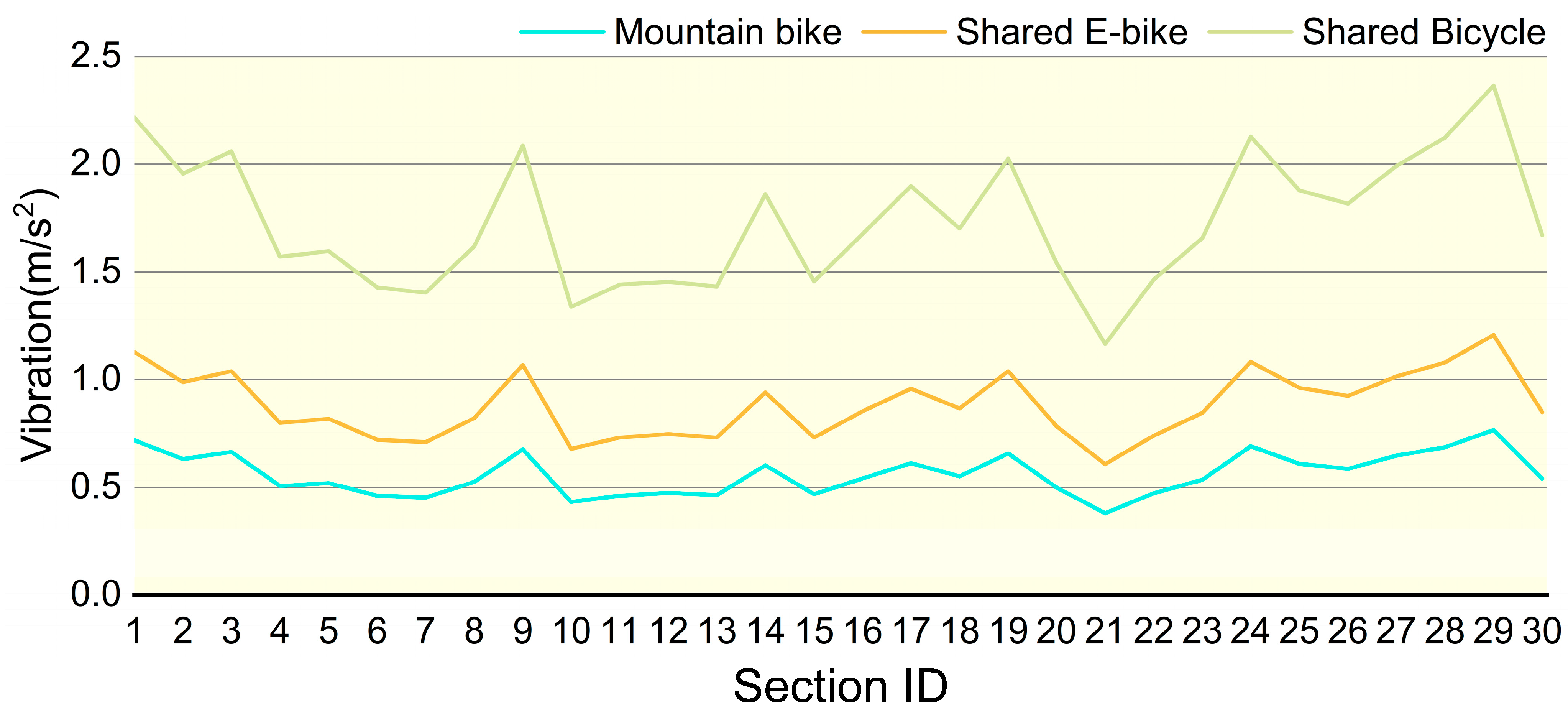

3.3. Cycling Comfort Map for Three Types of Vehicles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hongfei, C.; Yuxin, L.; Mengyuan, C. How to Make Carbon Reduction Compatible with Economic Growth: An Empirical Study Based on the New Energy Demonstration City Policy. Financ. Res. 2024, 50, 126–140. [Google Scholar]

- Gao, J.; Sha, A.; Huang, Y.; Liu, Z.; Hu, L.; Jiang, W.; Yun, D.; Tong, Z.; Wang, Z. Cycling comfort on asphalt pavement: Influence of the pavement-tyre interface on vibration. J. Clean. Prod. 2019, 223, 323–341. [Google Scholar] [CrossRef]

- Hölzel, C.; Höchtl, F.; Senner, V. Cycling comfort on different road surfaces. Procedia Eng. 2012, 34, 479–484. [Google Scholar] [CrossRef]

- Hunt, J.D.; Abraham, J.E. Influences on bicycle use. Transportation 2007, 34, 453–470. [Google Scholar] [CrossRef]

- Fan, M.; Lv, J.; Yu, C.; Guo, Y.; Bian, Z.; Yang, S.; Yang, L.; Chen, Y.; Huang, Y.; Chen, B.; et al. Association Between Active Commuting and Incident Cardiovascular Diseases in Chinese: A Prospective Cohort Study. J. Am. Heart Assoc. 2019, 8, e012556. [Google Scholar] [CrossRef]

- Maizlish, N.; Woodcock, J.; Co, S.; Ostro, B.; Fanai, A.; Fairley, D. Health cobenefits and transportation-related reductions in greenhouse gas emissions in the San Francisco Bay area. Am. J. Public Health 2013, 103, 703–709. [Google Scholar] [CrossRef]

- Budd, D.; Holness, D.L. Raising awareness of hand-arm vibration syndrome (HAVS) using posters. Work 2018, 61, 3–10. [Google Scholar] [CrossRef]

- Olieman, M.; Marin-Perianu, R.; Marin-Perianu, M. Measurement of dynamic comfort in cycling using wireless acceleration sensors. Procedia Eng. 2012, 34, 568–573. [Google Scholar] [CrossRef]

- Gao, J.; Sha, A.; Huang, Y.; Hu, L.; Tong, Z.; Jiang, W. Evaluating the cycling comfort on urban roads based on cyclists’ perception of vibration. J. Clean. Prod. 2018, 192, 531–541. [Google Scholar] [CrossRef]

- Ayachi, F.S.; Dorey, J.; Guastavino, C. Identifying factors of bicycle comfort: An online survey with enthusiast cyclists. Appl. Ergon. 2015, 46, 124–136. [Google Scholar] [CrossRef]

- Lépine, J.; Champoux, Y.; Drouet, J. The relative contribution of road bicycle components on vibration induced to the cyclist. Sports Eng. 2015, 18, 79–91. [Google Scholar] [CrossRef]

- Petrone, N.; Giubilato, F. Development of a Test Method for the Comparative Analysis of Bicycle Saddle Vibration Transmissibility. Procedia Eng. 2013, 60, 288–293. [Google Scholar] [CrossRef]

- Arellana, J.; Saltarín, M.; Larrañaga, A.M.; González, V.I.; Henao, C.A. Developing an urban bikeability index for different types of cyclists as a tool to prioritise bicycle infrastructure investments. Transp. Res. Part A Policy Pract. 2020, 139, 310–334. [Google Scholar] [CrossRef]

- Akar, G.; Clifton, K.J. Influence of Individual Perceptions and Bicycle Infrastructure on Decision to Bike. Transport Res. Rec. 2009, 2140, 165–172. [Google Scholar] [CrossRef]

- Pérez-Zuriaga, A.M.; Llopis-Castelló, D.; Just-Martínez, V.; Fonseca-Cabrera, A.S.; Alonso-Troyano, C.; García, A. Implementation of a Low-Cost Data Acquisition System on an E-Scooter for Micromobility Research. Sensors 2022, 22, 8215. [Google Scholar] [CrossRef]

- Zhu, S.; Zhu, F. Cycling comfort evaluation with instrumented probe bicycle. Transp. Res. Part A Policy Pract. 2019, 129, 217–231. [Google Scholar] [CrossRef]

- Segadilha, A.B.P.; Sanches, S.D.P. Analysis of Bicycle Commuter Routes Using GPSs and GIS. Procedia-Soc. Behav. Sci. 2014, 162, 198–207. [Google Scholar] [CrossRef]

- Menghini, G.; Carrasco, N.; Schüssler, N.; Axhausen, K.W. Route choice of cyclists in Zurich. Transp. Res. Part A Policy Pract. 2010, 44, 754–765. [Google Scholar] [CrossRef]

- Ambrož, M. Raspberry Pi as a low-cost data acquisition system for human powered vehicles. Measurement 2017, 100, 7–18. [Google Scholar] [CrossRef]

- Vanwalleghem, J.; Mortier, F.; De Baere, I.; Loccufier, M.; Van Paepegem, W. Design of an instrumented bicycle for the evaluation of bicycle dynamics and its relation with the cyclist’s comfort. Procedia Eng. 2012, 34, 485–490. [Google Scholar] [CrossRef]

- Bíl, M.; Andrášik, R.; Kubeček, J. How comfortable are your cycling tracks? A new method for objective bicycle vibration measurement. Transp. Res. Part C Emerg. Technol. 2015, 56, 415–425. [Google Scholar] [CrossRef]

- Nuñez, J.Y.M.; Bisconsini, D.R.; Rodrigues Da Silva, A.N. Combining environmental quality assessment of bicycle infrastructures with vertical acceleration measurements. Transp. Res. Part A Policy Pract. 2020, 137, 447–458. [Google Scholar] [CrossRef]

- Doria, A.; Marconi, E.; Munoz, L.; Polanco, A.; Suarez, D. An experimental-numerical method for the prediction of on-road comfort of city bicycles. Veh. Syst. Dyn. 2021, 59, 1376–1396. [Google Scholar] [CrossRef]

- Ahmed, T.; Pirdavani, A.; Wets, G.; Janssens, D. Evaluating Bicycle Path Roughness: A Comparative Study Using Smartphone and Smart Bicycle Light Sensors. Sensors 2024, 24, 7210. [Google Scholar] [CrossRef]

- Yamanaka, H.; Pan, X.; Sanada, J. Evaluation Models for Cyclists’ Perception Using Probe Bicycle System. J. East. Asia Soc. Transp. Stud. 2013, 10, 1413–1425. [Google Scholar]

- Anjum, M.T.; Tabassum, S.; Alqubaysi, T.; Saleemi, H.; Sahar, U.U.; Alanazi, F. Accessibility enhancement of mass transit system through GIS based modeling of feeder routes. J. Urban Manag. 2024, 13, 755–771. [Google Scholar] [CrossRef]

- Haery, S.; Mahpour, A.; Vafaeinejad, A. Forecasting urban travel demand with geo-AI: A combination of GIS and machine learning techniques utilizing uber data in New York City. Environ. Earth Sci. 2024, 83, 594. [Google Scholar] [CrossRef]

- ISO 2631-1; Mechanical Vibration and Shock-Evaluation of Human Exposure to Whole-Body Vibration—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 1997.

- Li, Z.; Wang, W.; Liu, P.; Ragland, D.R. Physical environments influencing bicyclists’ perception of comfort on separated and on-street bicycle facilities. Transp. Res. Part D Transp. Environ. 2012, 17, 256–261. [Google Scholar] [CrossRef]

- Polanco, A.; Marconi, E.; Muñoz, L.; Suárez, D.; Doria, A. Effect of Rider Posture on Bicycle Comfort. In Proceedings of the ASME 2019 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019. [Google Scholar]

| Module Name | Parameters | Functions |

|---|---|---|

| Raspberry PI 5 | Operating memory: 4 GB LPDDR4-3200 SDRAM; Interface: 2 × USB3.0, 2 × USB2.0; Connection: WIFI6, Bluetooth 5.0; System: Raspberry Pi OS. Manufacturer: Changsha yaomai Intelligent Technology Co., Ltd. (Changsha, China) | Responsible for executing the instructions and computations necessary for the proper operation of the system, ensuring efficient data acquisition and writing by the hardware. |

| Accelerometer | Model: Lis3dh; Range: ±2 g, ±4 g, ±8 g, ±16 g; Test setting range: ±16 g; Sampling frequency: 400 Hz. Manufacturer: STMicroelectronics (Geneva, Switzerland) | Acquires triaxial vibration acceleration data. |

| Position module | Model: LC29H; Positioning system: GPS, Beidou; Update frequency: 1 Hz; Latitude and longitude format: NMEA0183; Positioning accuracy: ±1 m. Manufacturer: Quectel (Shanghai, China) | Acquires data such as latitude, longitude, cycling speed, and cycling distance. |

| Camera | Pixel: 8 million. Manufacturer: Sony (Tokyo, Japan) | Performs real-time recording of the test road environment to facilitate retrospective analysis and comparison. |

| Operation interface | Size: 7 inches; Resolution: 1024 × 600 pixels; Principle: Touch; Interfaces: USB, HDMI, Power port. Manufacturer: MAKEROBOT (New York, NY, USA) | This system is employed during the data acquisition process to facilitate human–machine interaction, enabling test personnel to monitor in real-time and adjust equipment parameters as necessary. |

| Power Supply | Specifications: 12 V 5100 mAh, 12 V 5600 mAh. Manufacturer: WHEELTEC (Tampa, FL, USA) | It is utilized to power the Raspberry Pi and the display screen. |

| Vibration Intensity (m/s2) | Potential Comfort Level |

|---|---|

| Below 0.315 | Very comfortable |

| 0.315~0.63 | Slight uncomfortable |

| 0.5~1 | Uncomfortable |

| 0.8~1.6 | Very uncomfortable |

| 1.25~2.5 | Quite uncomfortable |

| Above 2.5 | Extremely uncomfortable |

| Vibration Intensity (m/s2) | Comfort Level | Line Colour (HEX) | Assignment |

|---|---|---|---|

| Below 0.315 | Very comfortable | #8DFF01 | 1 |

| 0.315~0.5 | Slight uncomfortable | #32C800 | 2 |

| 0.5~0.63 | Slight uncomfortable or Uncomfortable | #2A9E00 | 3 |

| 0.63~0.8 | Uncomfortable | #006813 | 4 |

| 0.8~1 | Uncomfortable or Very uncomfortable | #FFFF47 | 5 |

| 1~1.25 | Very uncomfortable | #B4A200 | 6 |

| 1.25~1.6 | Very Uncomfortable or Quite uncomfortable | #FF9501 | 7 |

| 1.6~2 | Quite uncomfortable | #C45F00 | 8 |

| 2~2.5 | Quite uncomfortable or Extremely uncomfortable | #FF2701 | 9 |

| Above 2.5 | Extremely uncomfortable | #A01D00 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Wu, X.; Xie, Z.; Song, L.; Fang, S. Network-Wide GIS Mapping of Cycling Vibration Comfort: From Methodology to Real-World Implementation. Sensors 2025, 25, 6185. https://doi.org/10.3390/s25196185

Gao J, Wu X, Xie Z, Song L, Fang S. Network-Wide GIS Mapping of Cycling Vibration Comfort: From Methodology to Real-World Implementation. Sensors. 2025; 25(19):6185. https://doi.org/10.3390/s25196185

Chicago/Turabian StyleGao, Jie, Xixian Wu, Zijie Xie, Liang Song, and Shandong Fang. 2025. "Network-Wide GIS Mapping of Cycling Vibration Comfort: From Methodology to Real-World Implementation" Sensors 25, no. 19: 6185. https://doi.org/10.3390/s25196185

APA StyleGao, J., Wu, X., Xie, Z., Song, L., & Fang, S. (2025). Network-Wide GIS Mapping of Cycling Vibration Comfort: From Methodology to Real-World Implementation. Sensors, 25(19), 6185. https://doi.org/10.3390/s25196185