Dynamics of Fiber Bragg Grating Formation with Femtosecond Laser Radiation

Abstract

1. Introduction

1.1. Physical Mechanisms of FBG Inscription

1.2. Relevance

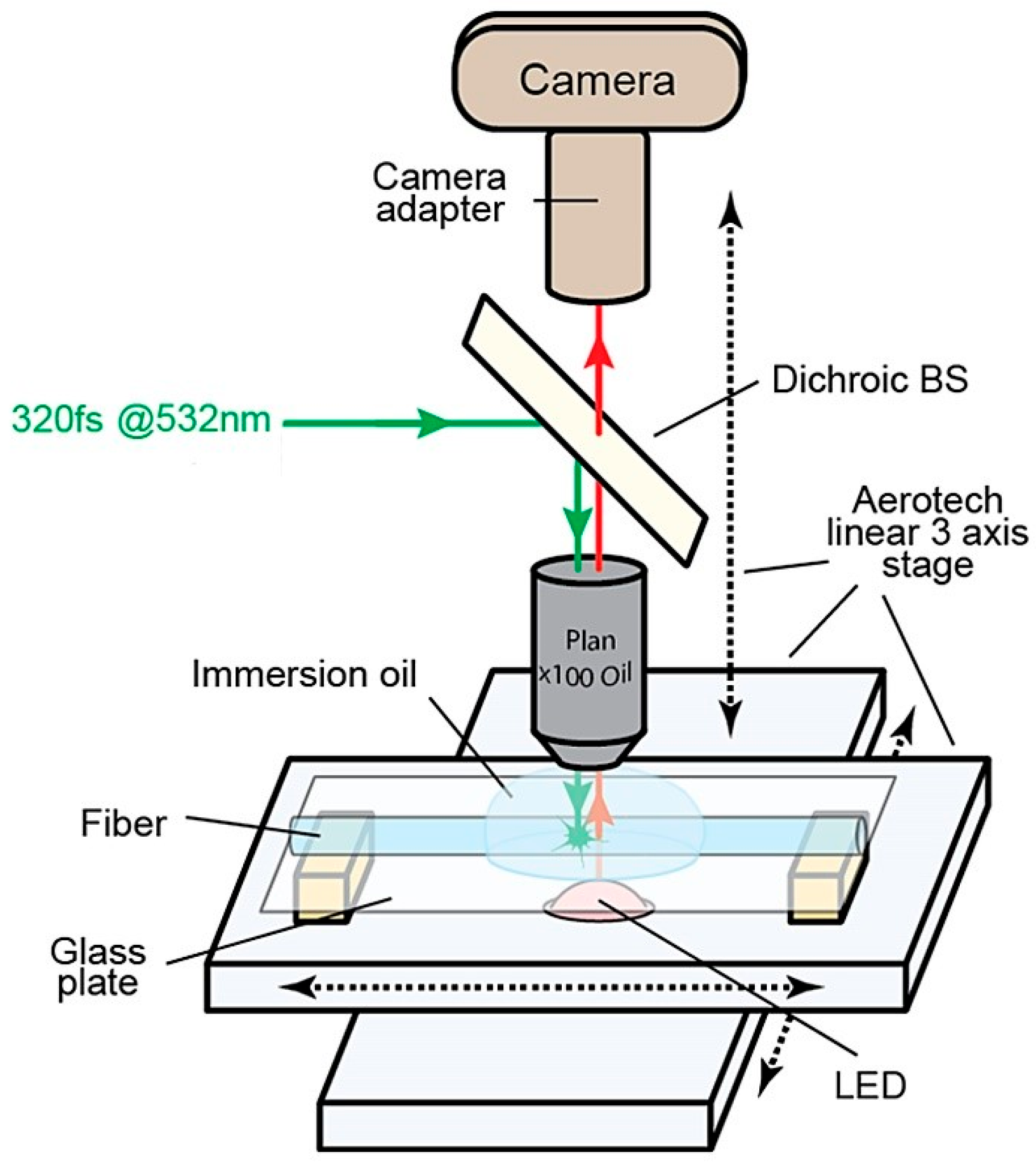

2. Materials and Methods

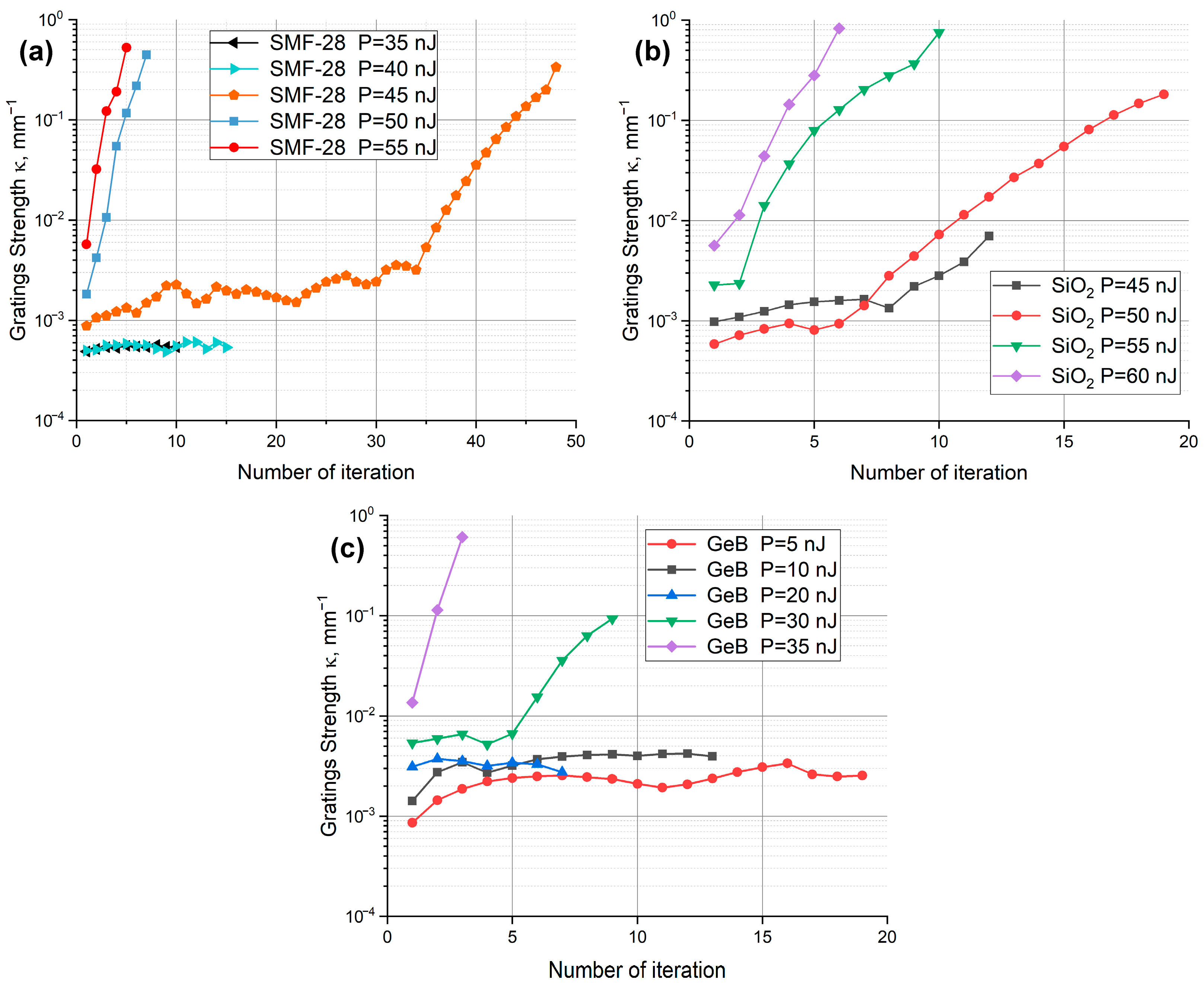

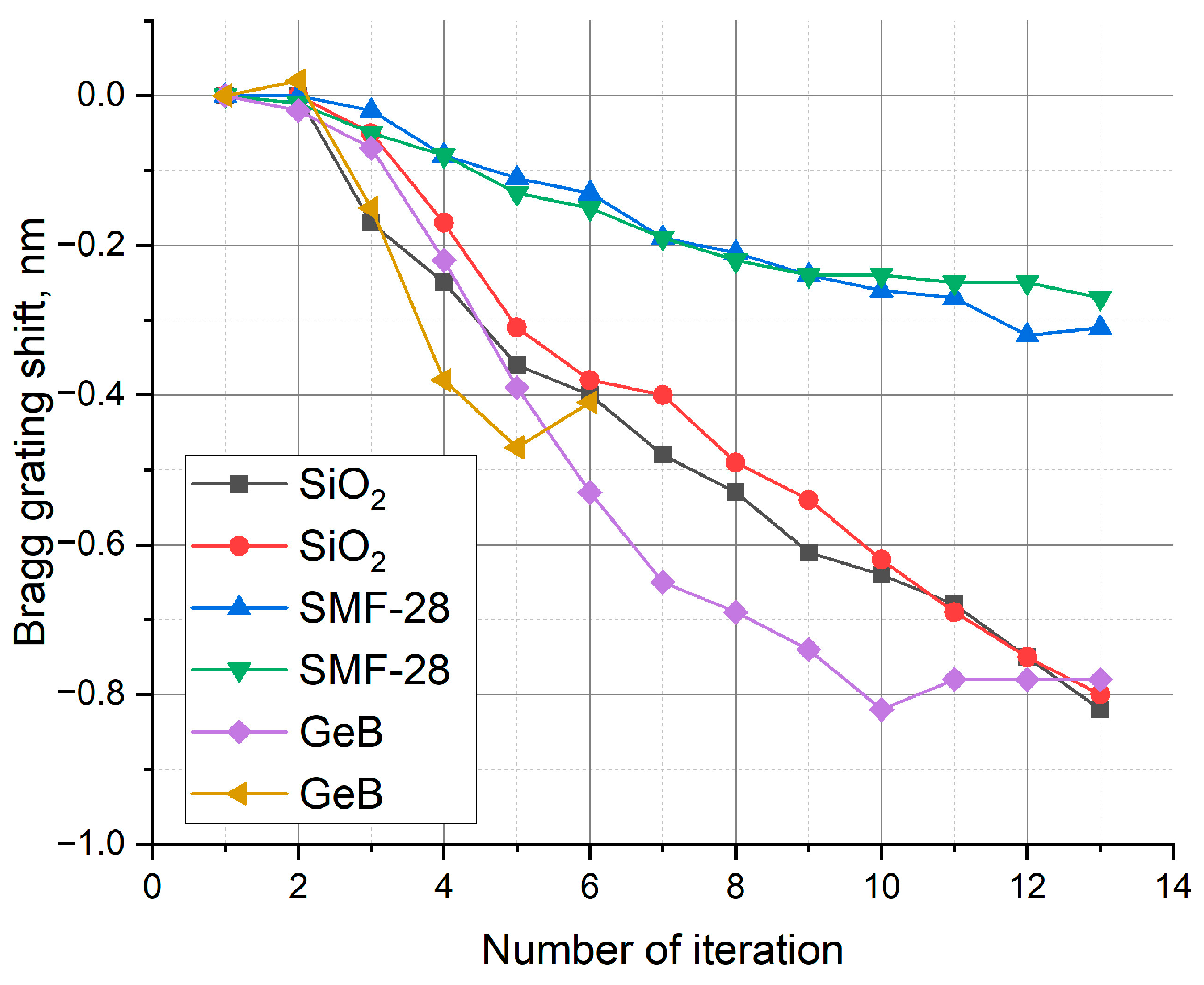

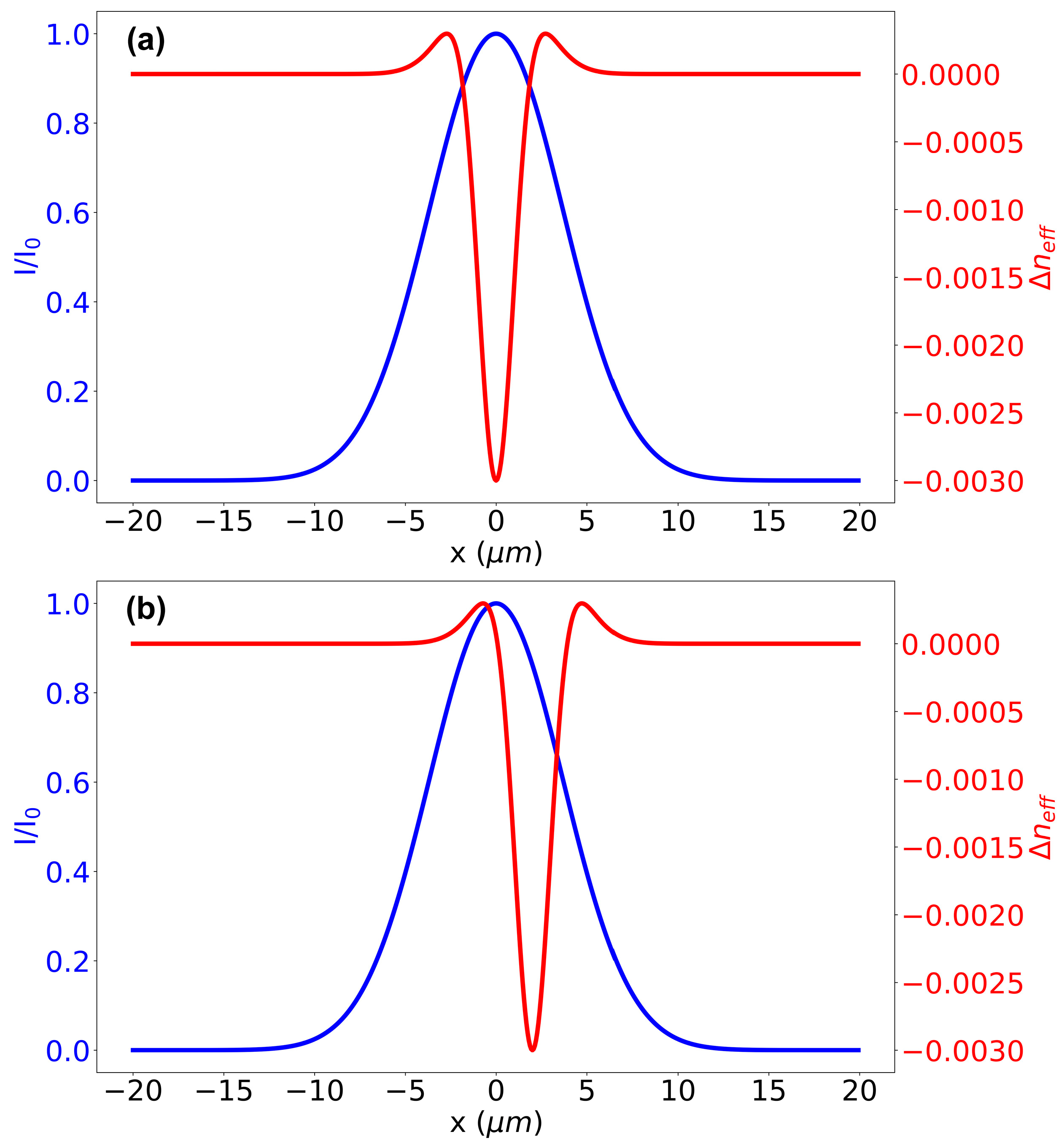

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hill, K.O.; Fujii, Y.; Johnson, D.C.; Kawasaki, B.S. Photosensitivity in optical fiber waveguides: Application to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647–649. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings; Academic Press: Cambridge, MA, USA, 2009. [Google Scholar]

- Othonos, A. Fiber bragg gratings. Rev. Sci. Instrum. 1997, 68, 4309–4341. [Google Scholar] [CrossRef]

- Vasil’ev, S.A.; Medvedkov, O.I.; Korolev, I.G.E.; Bozhkov, A.S.; Kurkov, A.S.; Dianov, E.M. Fibre gratings and their applications. Quantum Electron. 2005, 35, 1085. [Google Scholar] [CrossRef]

- Krohn, D.A.; MacDougall, T.; Mendez, A. Fiber Optic Sensors: Fundamentals and Applications; Spie Press: Bellingham, WA, USA, 2014. [Google Scholar]

- Cusano, A.; Cutolo, A.; Albert, J. Fiber Bragg Grating Sensors: Recent Advancements, Industrial Applications and Market Exploitation; Bentham Science Publishers: Singapore, 2011. [Google Scholar]

- Smirnov, A.M.; Bazakutsa, A.P.; Chamorovskiy, Y.K.; Nechepurenko, I.A.; Dorofeenko, A.V.; Butov, O.V. Thermal switching of lasing regimes in heavily doped Er3+ fiber lasers. ACS Photonics 2018, 5, 5038–5046. [Google Scholar] [CrossRef]

- Hill, K.O.; Malo, B.; Bilodeau, F.; Johnson, D.C.; Albert, J. Bragg gratings fabricated in monomode photosensitive optical fiber by UV exposure through a phase mask. Appl. Phys. Lett. 1993, 62, 1035–1037. [Google Scholar] [CrossRef]

- de Groot, P.J.; de Lega, X.C.; Dawson, J.W.; MacDougall, T.W.; Lu, M.; Troll, J.R. Interferometer Design for Writing Bragg Gratings in Optical Fibers; Interferometry XI: Techniques and Analysis, 2002; International Society for Optics and Photonics: Bellingham, WA, USA, 2002; pp. 31–38. [Google Scholar]

- Meltz, G.; Morey, W.W.; Glenn, W.H. Formation of Bragg gratings in optical fibers by a transverse holographic method. Opt. Lett. 1989, 14, 823–825. [Google Scholar] [CrossRef] [PubMed]

- Pissadakis, S.; Reekie, L. An elliptical Talbot interferometer for fiber Bragg grating fabrication. Rev. Sci. Instrum. 2005, 76, 066101. [Google Scholar] [CrossRef]

- Lemaire, P.J.; Atkins, R.; Mizrahi, V.; Reed, W. High pressure H2 loading as a technique for achieving ultrahigh UV photosensitivity and thermal sensitivity in GeO2 doped optical fibres. Electron. Lett. 1993, 29, 1191–1193. [Google Scholar] [CrossRef]

- Patrick, H.; Gilbert, S.L.; Lidgard, A.; Gallagher, M.D. Annealing of Bragg gratings in hydrogen-loaded optical fiber. J. Appl. Phys. 1995, 78, 2940–2945. [Google Scholar] [CrossRef]

- Bazakutsa, A.P.; Rybaltovsky, A.A.; Butov, O.V. Effect of hydrogen loading and UV irradiation on the gain of Er3+-doped fibers. JOSA B 2019, 36, 2579–2586. [Google Scholar] [CrossRef]

- Bazakutsa, A.; Rybaltovsky, A.; Umnikov, A.; Butov, O. Photobleaching of UV-induced defects in Er/Al-doped glasses for fiber lasers. Opt. Mater. Express 2020, 10, 2669–2678. [Google Scholar] [CrossRef]

- Martinez, A.; Dubov, M.; Khrushchev, I.; Bennion, I. Direct writing of fibre Bragg gratings by femtosecond laser. Electron. Lett. 2004, 40, 1170–1172. [Google Scholar] [CrossRef]

- Dostovalov, A.V.; Wolf, A.A.; Babin, S.A. Femtosecond Point-By-Point Inscription of Fiber Bragg Gratings Through the Polyimide Coating. In Proceedings of the 2014 International Conference Laser Optics, Saint Petersburg, Russia, 30 June–4 July 2014; IEEE: New York, NY, USA, 2014; p. 1. [Google Scholar]

- Dostovalov, A.; Wolf, A.; Parygin, A.; Zyubin, V.; Babin, S. Femtosecond point-by-point inscription of Bragg gratings by drawing a coated fiber through ferrule. Opt. Express 2016, 24, 16232–16237. [Google Scholar] [CrossRef] [PubMed]

- Fuerbach, A.; Bharathan, G.; Ams, M. Grating inscription into fluoride fibers: A review. IEEE Photonics J. 2019, 11, 1–11. [Google Scholar] [CrossRef]

- Xu, X.; He, J.; He, J.; Xu, B.; Chen, R.; Yang, K.; Liao, C.; Yang, Y.; Wang, Y. Slit beam shaping for femtosecond laser point-by-point inscription of high-quality fiber Bragg gratings. J. Light. Technol. 2021, 39, 5142–5148. [Google Scholar] [CrossRef]

- Pallarés-Aldeiturriaga, D.; Roldán-Varona, P.; Rodríguez-Cobo, L.; López-Higuera, J.M. Optical fiber sensors by direct laser processing: A review. Sensors 2020, 20, 6971. [Google Scholar] [CrossRef]

- Zhou, K.; Dubov, M.; Mou, C.; Zhang, L.; Mezentsev, V.K.; Bennion, I. Line-by-line fiber Bragg grating made by femtosecond laser. IEEE Photonics Technol. Lett. 2010, 22, 1190–1192. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X. In Line-By-Line Inscription of Phase-Shifted Fiber Bragg Gratings with Femtosecond Laser. In Proceedings of the Asia Communications and Photonics Conference, Hong Kong, China, 19–23 November 2015; Optica Publishing Group: Washington, DC, USA, 2015; p. ASu2A. 60. [Google Scholar]

- Mihailov, S.J.; Hnatovsky, C.; Abdukerim, N.; Walker, R.B.; Lu, P.; Xu, Y.; Bao, X.; Ding, H.; De Silva, M.; Coulas, D. Ultrafast laser processing of optical fibers for sensing applications. Sensors 2021, 21, 1447. [Google Scholar] [CrossRef]

- Lu, P.; Mihailov, S.J.; Ding, H.; Grobnic, D.; Walker, R.B.; Coulas, D.; Hnatovsky, C.; Naumov, A.Y. Plane-by-plane inscription of grating structures in optical fibers. J. Light. Technol. 2018, 36, 926–931. [Google Scholar] [CrossRef]

- Williams, R.J.; Krämer, R.G.; Nolte, S.; Withford, M.J. Femtosecond direct-writing of low-loss fiber Bragg gratings using a continuous core-scanning technique. Opt. Lett. 2013, 38, 1918–1920. [Google Scholar] [CrossRef]

- Antipov, S.; Ams, M.; Williams, R.J.; Magi, E.; Withford, M.J.; Fuerbach, A. Direct infrared femtosecond laser inscription of chirped fiber Bragg gratings. Opt. Express 2016, 24, 30–40. [Google Scholar] [CrossRef]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Light. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Saliminia, A.; Bérubé, J.-P.; Vallée, R. Refractive index-modified structures in glass written by 266 nm fs laser pulses. Opt. Express 2012, 20, 27410–27419. [Google Scholar] [CrossRef]

- Martinez, A.; Dubov, M.; Khrushchev, I.; Bennion, I. Photoinduced modifications in fiber gratings inscribed directly by infrared femtosecond irradiation. IEEE Photonics Technol. Lett. 2006, 18, 2266–2268. [Google Scholar] [CrossRef]

- Neustruev, V.B. Colour centres in germanosilicate glass and optical fibres. J. Phys. Condens. Matter 1994, 6, 6901. [Google Scholar] [CrossRef]

- Nishii, J.; Kitamura, N.; Yamanaka, H.; Hosono, H.; Kawazoe, H. Ultraviolet-radiation-induced chemical reactions through one-and two-photon absorption processes in GeO2–SiO2 glasses. Opt. Lett. 1995, 20, 1184–1186. [Google Scholar] [CrossRef] [PubMed]

- Golant, K.; Butov, O.; Denisov, A.; Mashinsky, V.; Sazhin, O.; Smith, C.; Muraviov, S. Oxygen deficient centres in germanosilicate glassy films synthesised by hydrogen free plasmachemical deposition. Phys. Chem. Glas. 2004, 43, 131–136. [Google Scholar]

- Saito, K.; Ikushima, A. Absorption edge in silica glass. Phys. Rev. B 2000, 62, 8584. [Google Scholar] [CrossRef]

- Weinberg, Z.; Rubloff, G.; Bassous, E. Transmission, photoconductivity, and the experimental band gap of thermally grown SiO2 films. Phys. Rev. B 1979, 19, 3107. [Google Scholar] [CrossRef]

- Butov, O.V.; Przhiialkovskii, D.V.; Lopunov, A.I.; Pnev, A.B. Strength properties of femtosecond-induced defects and weak Bragg gratings for distributed optical fiber sensors. Opt. Laser Technol. 2023, 162, 109271. [Google Scholar] [CrossRef]

- Kitamura, N.; Fukumi, K.; Nishii, J.; Ohno, N. Relationship between refractive index and density of synthetic silica glasses. J. Appl. Phys. 2007, 101, 123533. [Google Scholar] [CrossRef]

- Tan, C.; Arndt, J.; Xie, H. Optical properties of densified silica glasses. Phys. B Condens. Matter 1998, 252, 28–33. [Google Scholar] [CrossRef]

- Kitamura, N.; Toguchi, Y.; Funo, S.; Yamashita, H.; Kinoshita, M. Refractive index of densified silica glass. J. Non-Cryst. Solids 1993, 159, 241–245. [Google Scholar] [CrossRef]

- Smelser, C.W.; Mihailov, S.J.; Grobnic, D. Formation of Type I-IR and Type II-IR gratings with an ultrafast IR laser and a phase mask. Opt. Express 2005, 13, 5377–5386. [Google Scholar] [CrossRef] [PubMed]

- Smelser, C.W.; Mihailov, S.J.; Grobnic, D. Hydrogen loading for fiber grating writing with a femtosecond laser and a phase mask. Opt. Lett. 2004, 29, 2127–2129. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Xu, B.; Xu, X.; Liao, C.; Wang, Y. Review of femtosecond-laser-inscribed fiber Bragg gratings: Fabrication technologies and sensing applications. Photonic Sens. 2021, 11, 203–226. [Google Scholar] [CrossRef]

- Itoh, K.; Watanabe, W.; Nolte, S.; Schaffer, C.B. Ultrafast processes for bulk modification of transparent materials. MRS Bull. 2006, 31, 620–625. [Google Scholar] [CrossRef]

- Shimotsuma, Y.; Kazansky, P.G.; Qiu, J.; Hirao, K. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys. Rev. Lett. 2003, 91, 247405. [Google Scholar] [CrossRef]

- Schaffer, C.B.; Brodeur, A.; Mazur, E. Laser-induced breakdown and damage in bulktransparent materials induced by tightly focused femtosecond laserpulses. Meas. Sci. Technol. 2001, 12, 1784. [Google Scholar] [CrossRef]

- Rudenko, A.; Colombier, J.P.; Itina, T.E.; Stoian, R. Genesis of nanogratings in silica bulk via multipulse interplay of ultrafast photo-excitation and hydrodynamics. Adv. Opt. Mater. 2021, 9, 2100973. [Google Scholar] [CrossRef]

- Canning, J.; Lancry, M.; Cook, K.; Weickman, A.; Brisset, F.; Poumellec, B. Anatomy of a femtosecond laser processed silica waveguide. Opt. Mater. Express 2011, 1, 998–1008. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Y.; Peng, Y.; Lv, R.-q.; Zhao, Q. Review of femtosecond laser direct writing fiber-optic structures based on refractive index modification and their applications. Opt. Laser Technol. 2022, 146, 107473. [Google Scholar] [CrossRef]

- Przhiialkovskii, D.V.; Butov, O.V. High-precision point-by-point fiber Bragg grating inscription. Results Phys. 2021, 30, 104902. [Google Scholar] [CrossRef]

- Li, Y.; Liao, C.; Wang, D.; Sun, T.; Grattan, K. Study of spectral and annealing properties of fiber Bragg gratings written in H2-free and H2-loaded fibers by use of femtosecond laser pulses. Opt. Express 2008, 16, 21239–21247. [Google Scholar] [CrossRef]

- Liao, C.; Li, Y.; Wang, D.; Sun, T.; Grattan, K. Morphology and Thermal Stability of Fiber Bragg Gratings for Sensor Applications Written in H2-Free and H2-Loaded Fibers by Femtosecond Laser. IEEE Sens. J. 2010, 10, 1675–1681. [Google Scholar] [CrossRef]

- Becker, M.; Bergmann, J.; Brückner, S.; Franke, M.; Lindner, E.; Rothhardt, M.W.; Bartelt, H. Fiber Bragg grating inscription combining DUV sub-picosecond laser pulses and two-beam interferometry. Opt. Express 2008, 16, 19169–19178. [Google Scholar] [CrossRef]

- Canning, J.; Lancry, M.; Cook, K.; Poumellec, B. New Theory of Femtosecond Induced Changes and Nanopore Formation. In Proceedings of the Third Asia Pacific Optical Sensors Conference, Sydney, Australia, 30 January 2012; SPIE: Bellingham, WA, USA, 2012; pp. 572–578. [Google Scholar]

- Skorobogatiy, M. Nanostructured and Subwavelength Waveguides: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

| Fiber Type | Co-Doping | Core/Cladding RI Difference, 10−3 | Core Diameter, μm | Mode Field Diameter, μm |

|---|---|---|---|---|

| SMF-28 | Ge | 5 | 8.5 | 10.4 |

| SiO2 | - | 16 | 5.0 | 5.9 |

| GeB | Ge, B | 17 | 4.0 | 5.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butov, O.V.; Przhiialkovskii, D.V.; Chubchev, E.D.; Pnev, A.B. Dynamics of Fiber Bragg Grating Formation with Femtosecond Laser Radiation. Sensors 2025, 25, 6138. https://doi.org/10.3390/s25196138

Butov OV, Przhiialkovskii DV, Chubchev ED, Pnev AB. Dynamics of Fiber Bragg Grating Formation with Femtosecond Laser Radiation. Sensors. 2025; 25(19):6138. https://doi.org/10.3390/s25196138

Chicago/Turabian StyleButov, Oleg V., Dmitrii V. Przhiialkovskii, Eugeny D. Chubchev, and Alexey B. Pnev. 2025. "Dynamics of Fiber Bragg Grating Formation with Femtosecond Laser Radiation" Sensors 25, no. 19: 6138. https://doi.org/10.3390/s25196138

APA StyleButov, O. V., Przhiialkovskii, D. V., Chubchev, E. D., & Pnev, A. B. (2025). Dynamics of Fiber Bragg Grating Formation with Femtosecond Laser Radiation. Sensors, 25(19), 6138. https://doi.org/10.3390/s25196138