Design and Evaluation of an Automated Ultraviolet-C Irradiation System for Maize Seed Disinfection and Monitoring

Abstract

1. Introduction

2. Materials and Methods

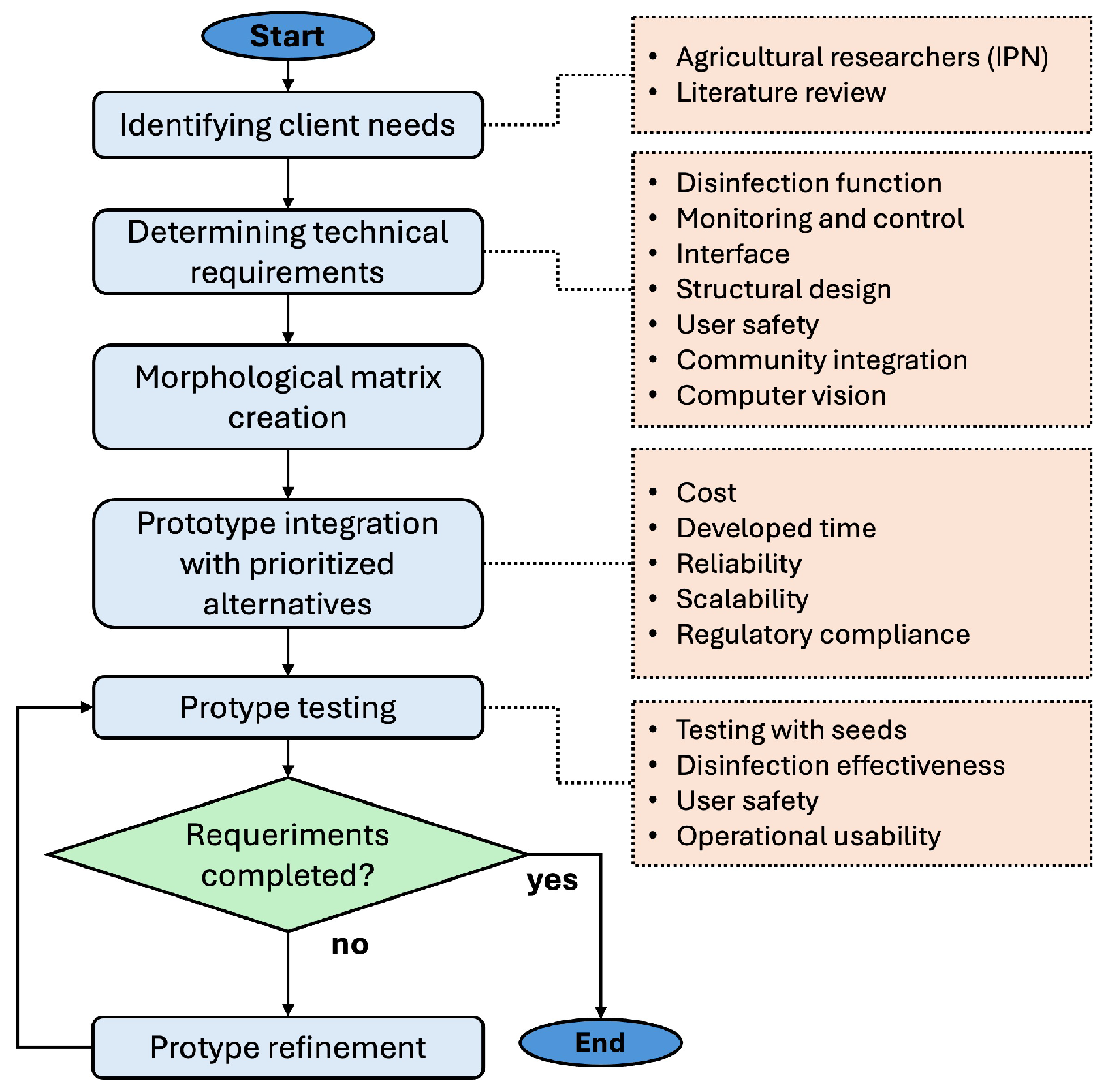

2.1. Prototype Development Methodology

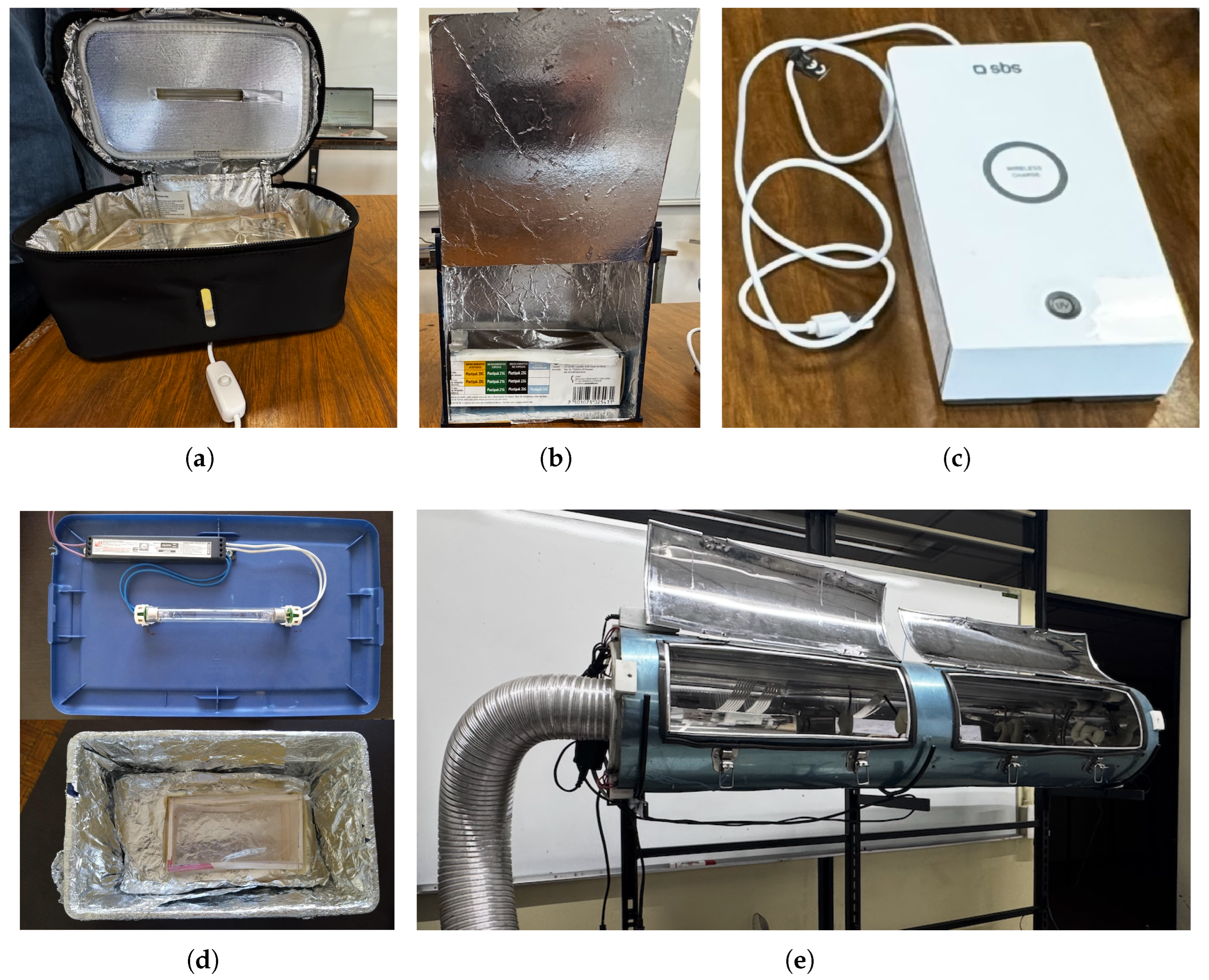

2.2. Design Framework for Determining Prototype Specifications from Previous Work

2.3. Requirements Definition and Morphological Analysis

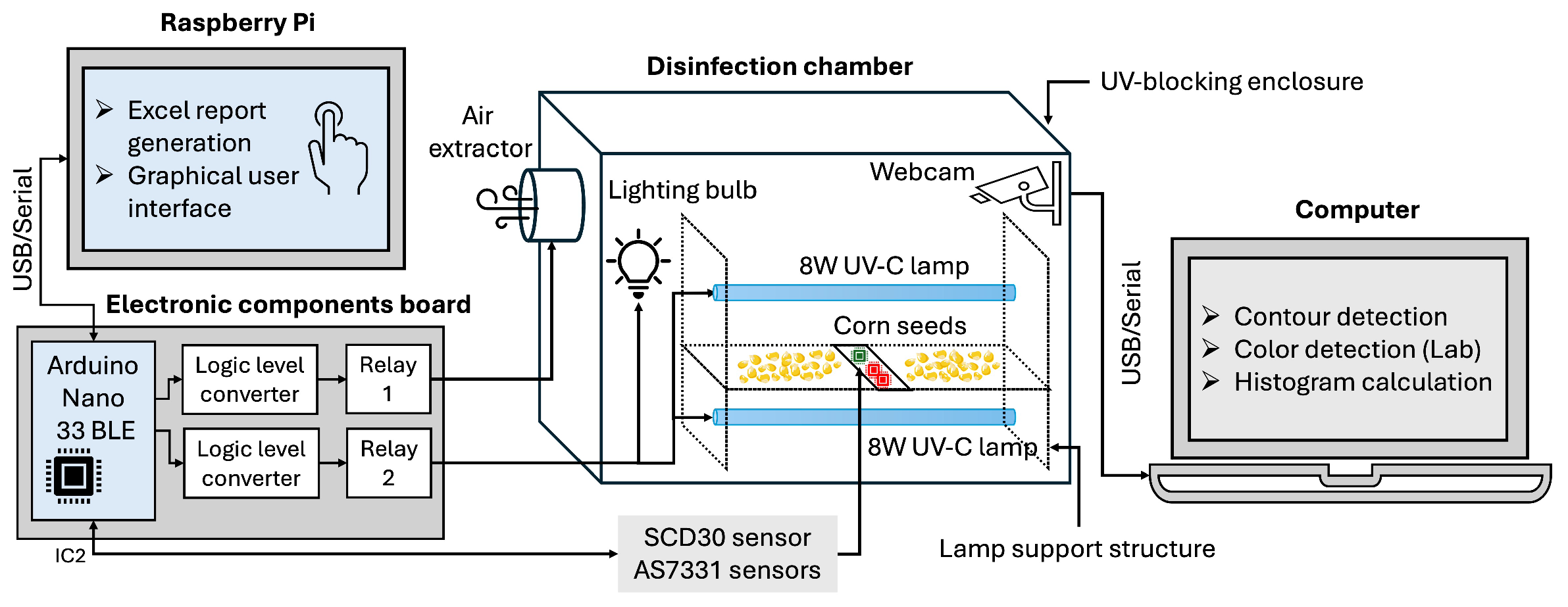

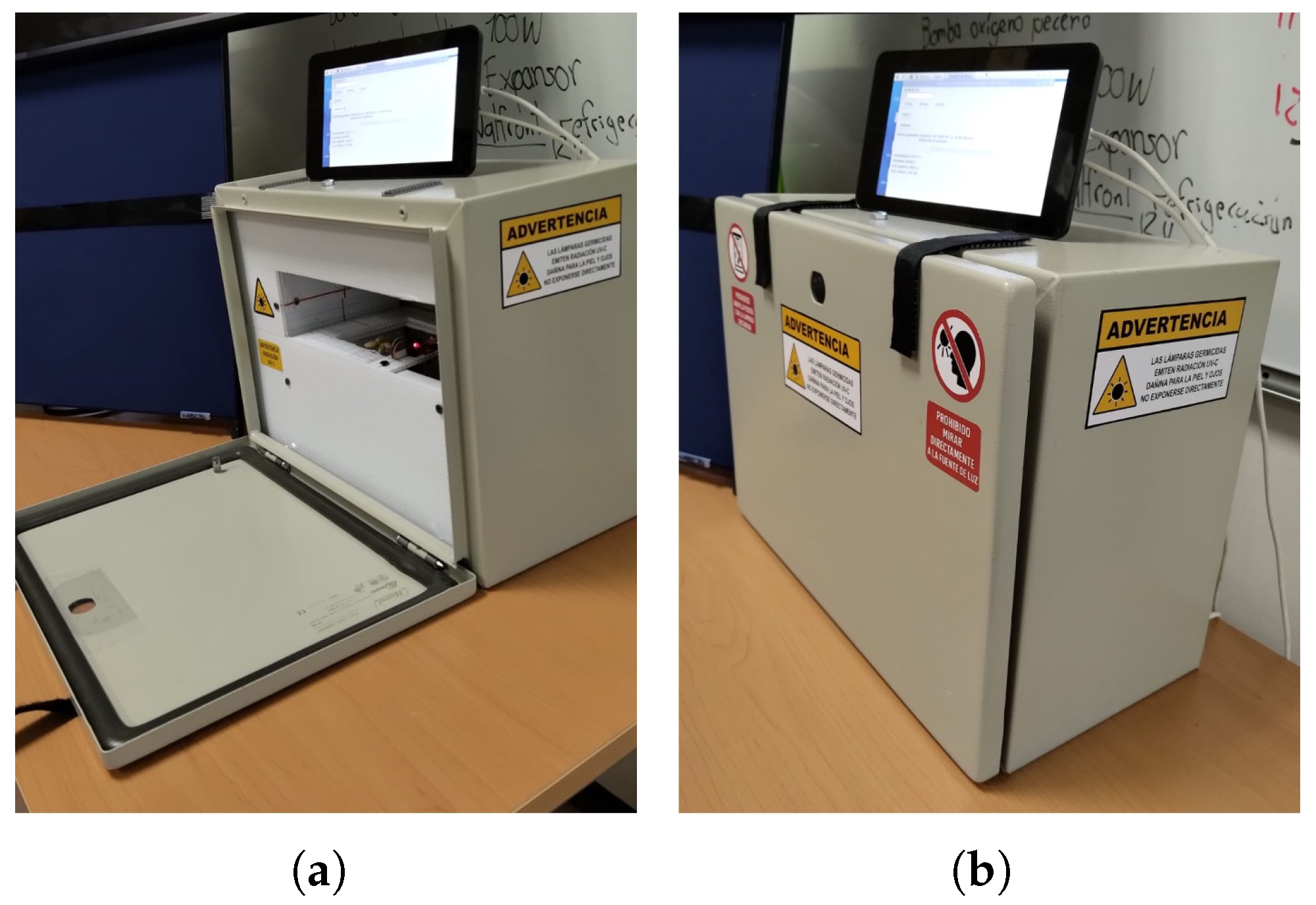

2.4. System Architecture of the Automated UV-C Seed Disinfection Chamber

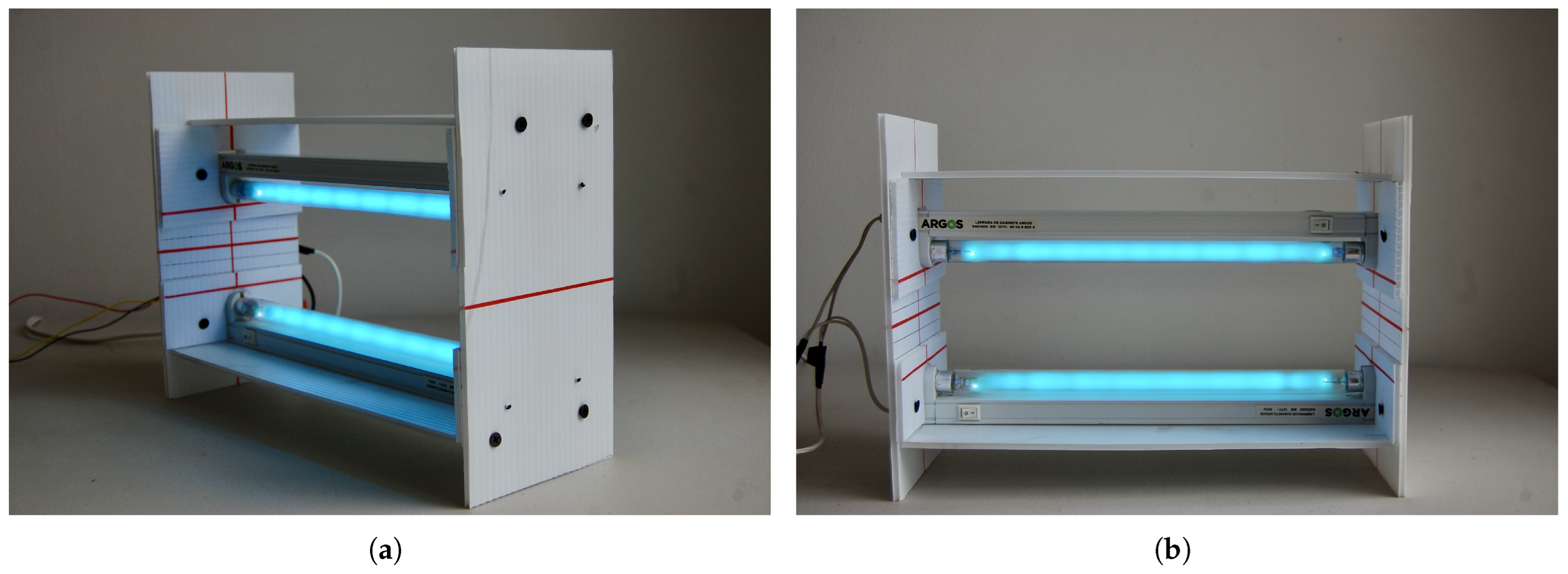

2.4.1. Designed Lamp Support Structure for UV-C Irradiation

2.4.2. Electronic Control and Monitoring System

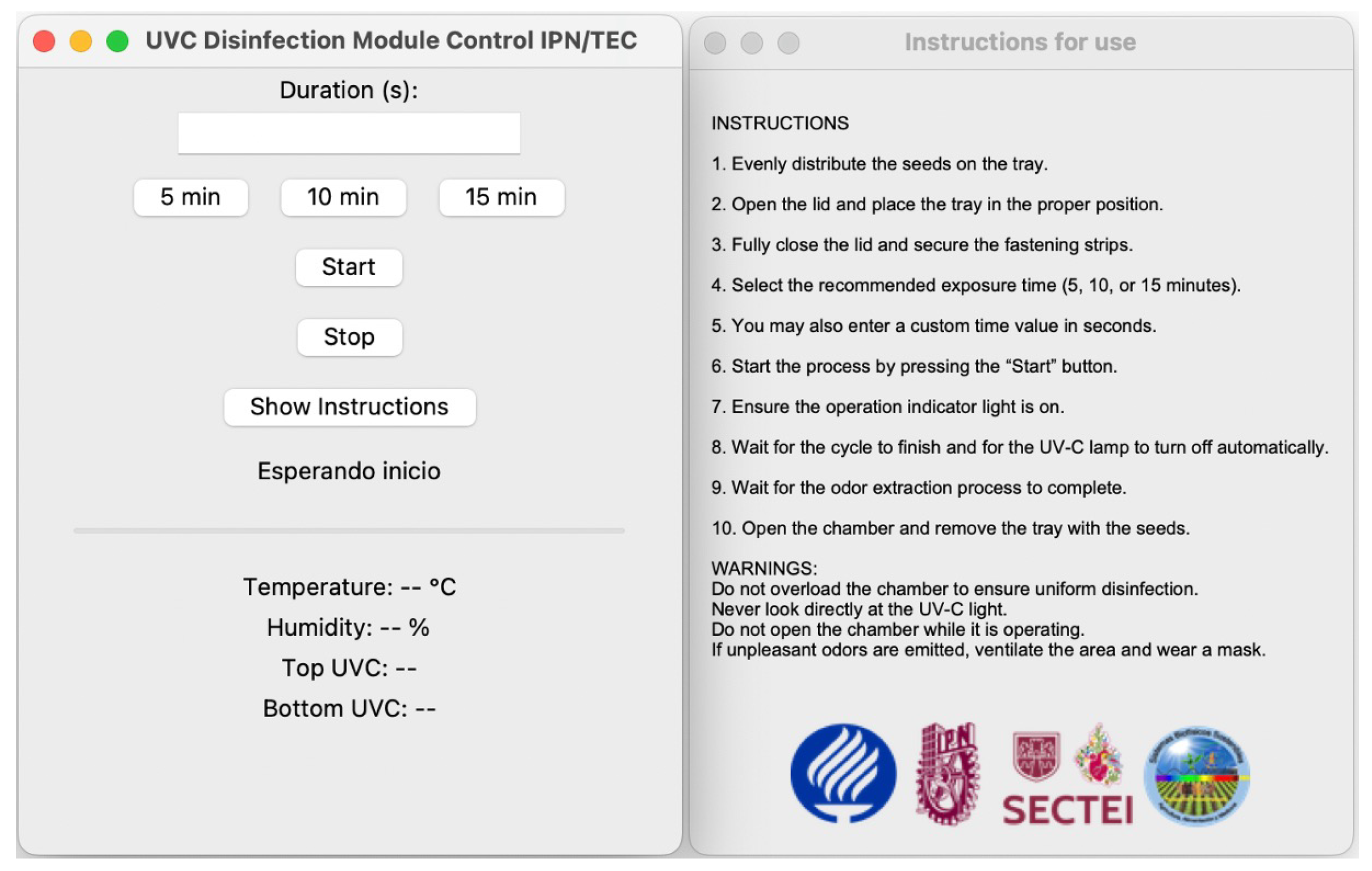

2.4.3. The GUI on the Raspberry Pi

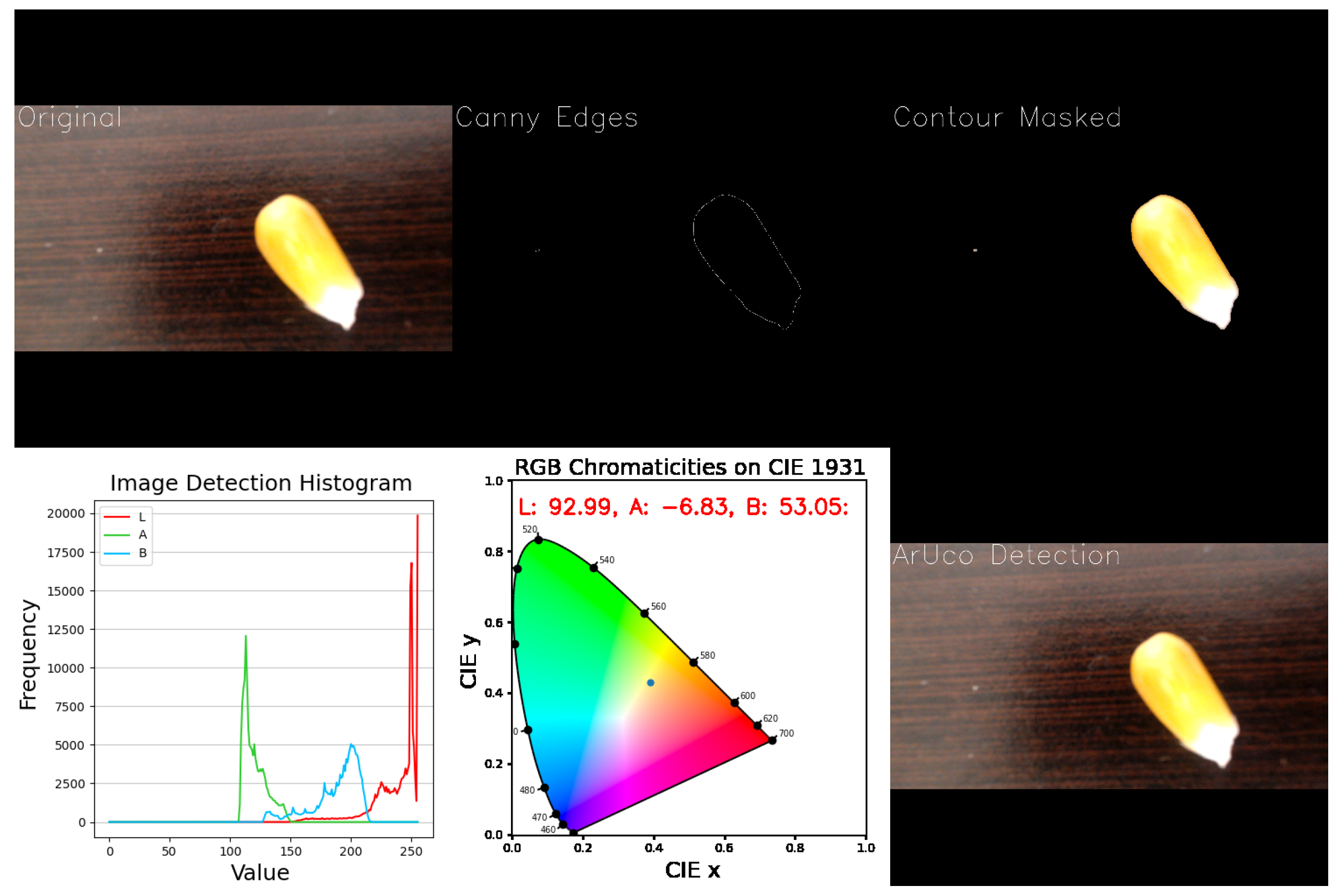

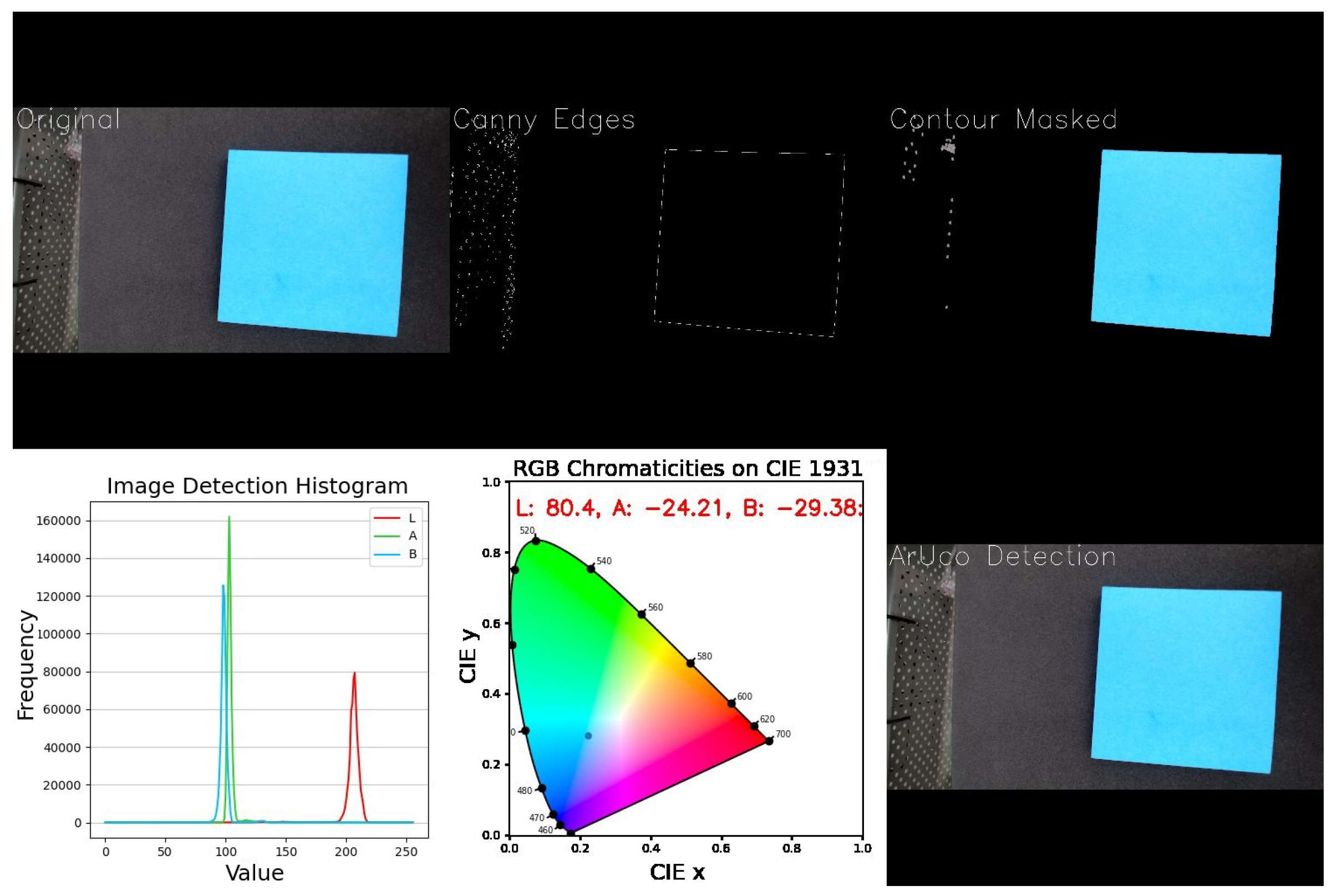

2.4.4. Computer Vision System for Color Monitoring

| Algorithm 1 Computer vision analysis application. | |

| 1: | Start Application |

| 2: | Create GUI window |

| 3: | Initialize video processing thread |

| 4: | Display GUI |

| 5: | Inside VideoThread: |

| 6: | while application is running do |

| 7: | Capture a frame from webcam |

| 8: | Preprocess the image (resize, normalize) |

| 9: | Detect contours and apply mask |

| 10: | Generate LAB color histogram |

| 11: | Update CIE chromaticity diagram |

| 12: | Detect ArUco markers and estimate distance |

| 13: | Combine all visualization images for GUI display |

| 14: | Send final image to GUI |

| 15: | end while |

| 16: | Inside GUI: |

| 17: | Show image on screen |

| 18: | Handle user interactions: |

| • Save image | |

| • Toggle average LAB calculation | |

| • Close application safely | |

2.4.5. Chamber Enclosure and Safety Design Considerations

2.5. Experimental Evaluation and Iterative Refinement

3. Results

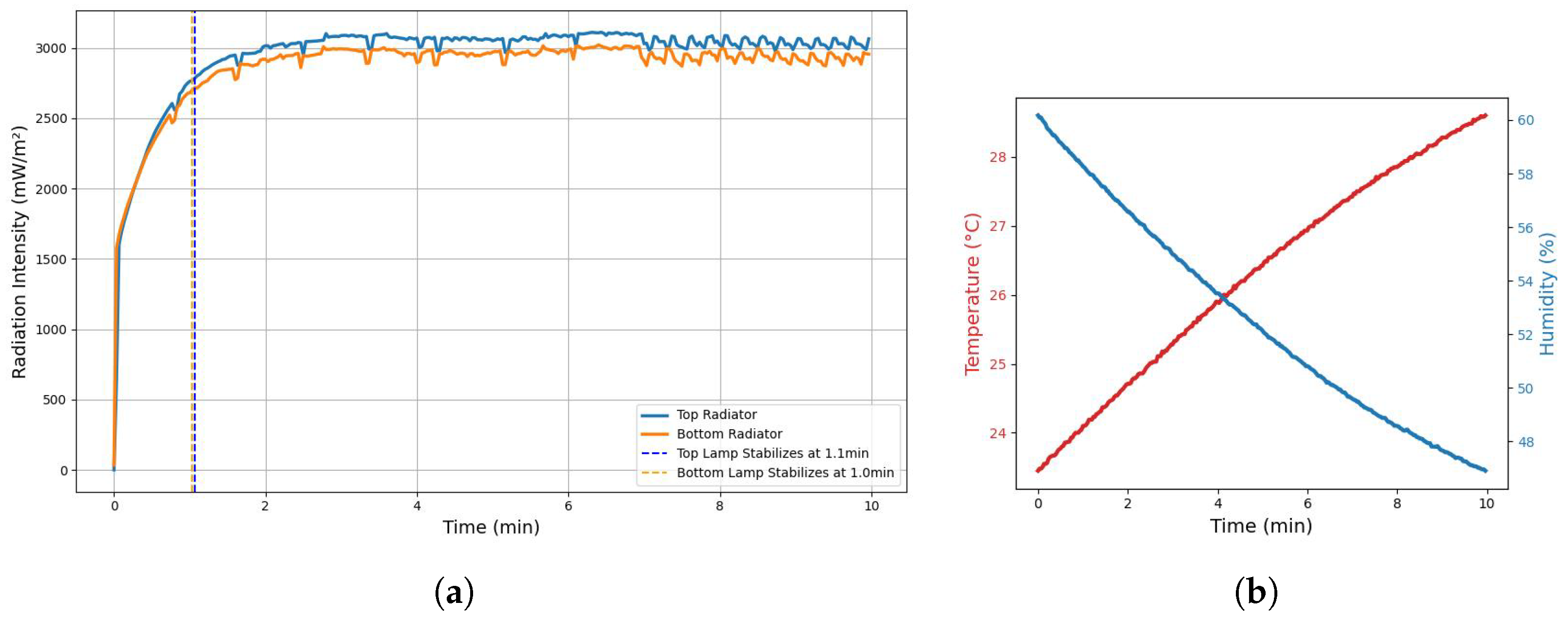

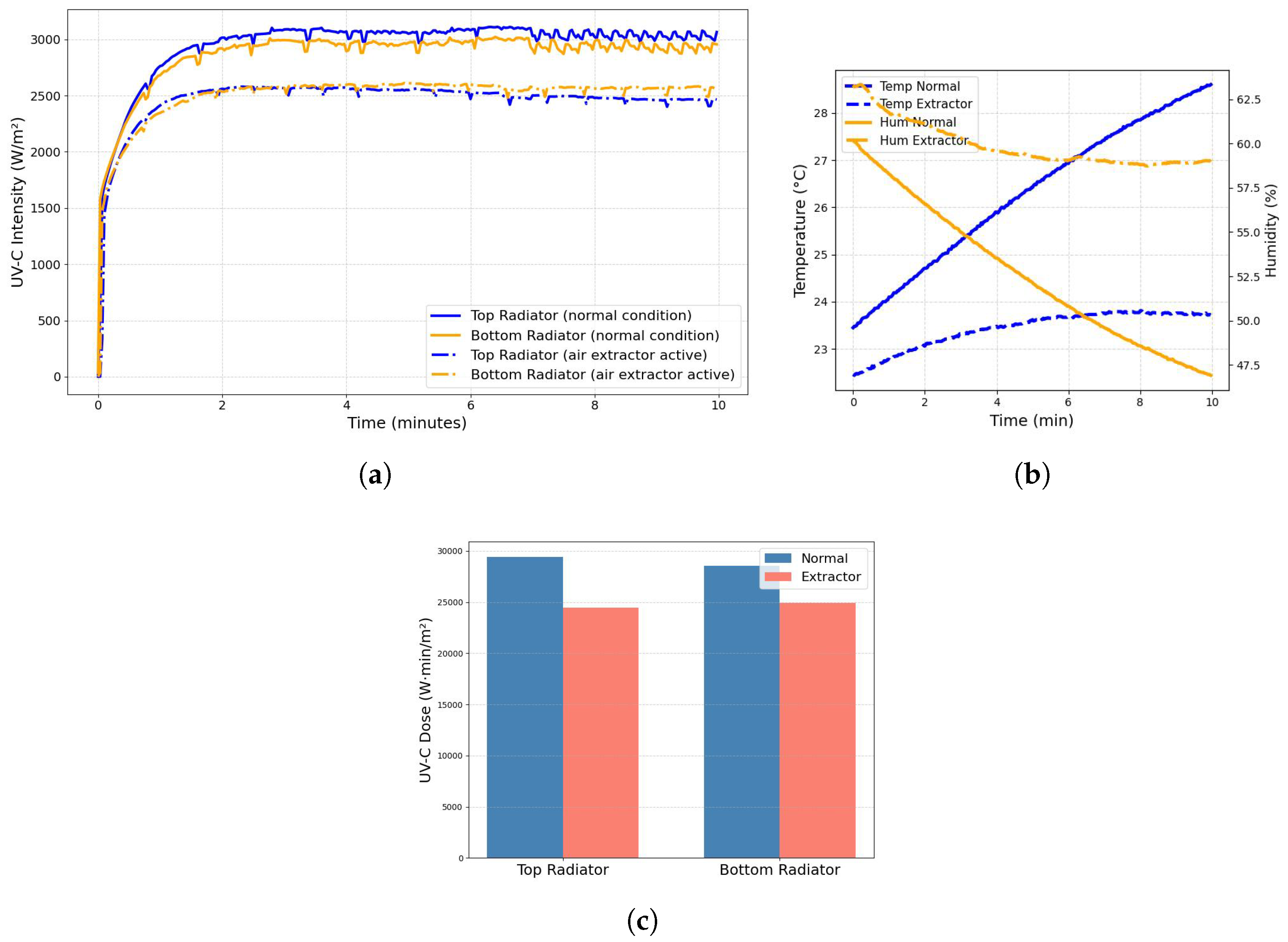

3.1. Monitoring UV-C Irradiation, Temperature, and Humidity During Startup

3.2. Monitoring Variables Under Active Air Extraction Conditions

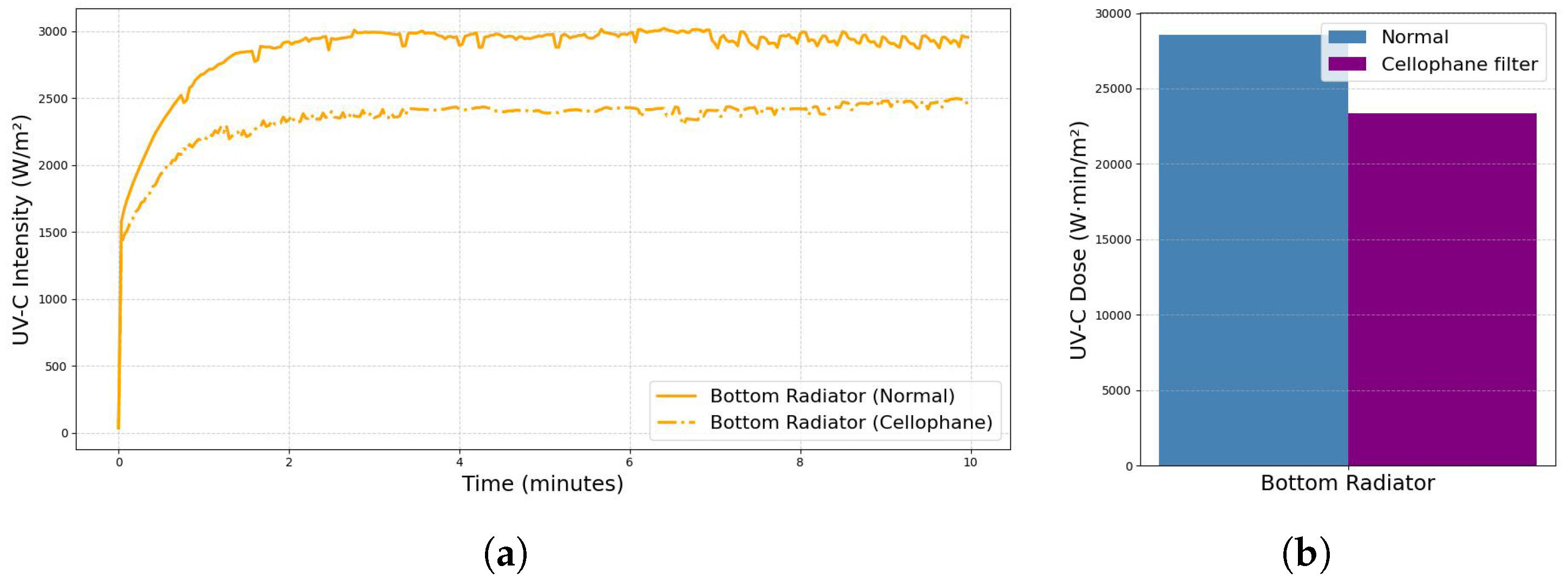

3.3. Monitoring Irradiation Through Cellophane

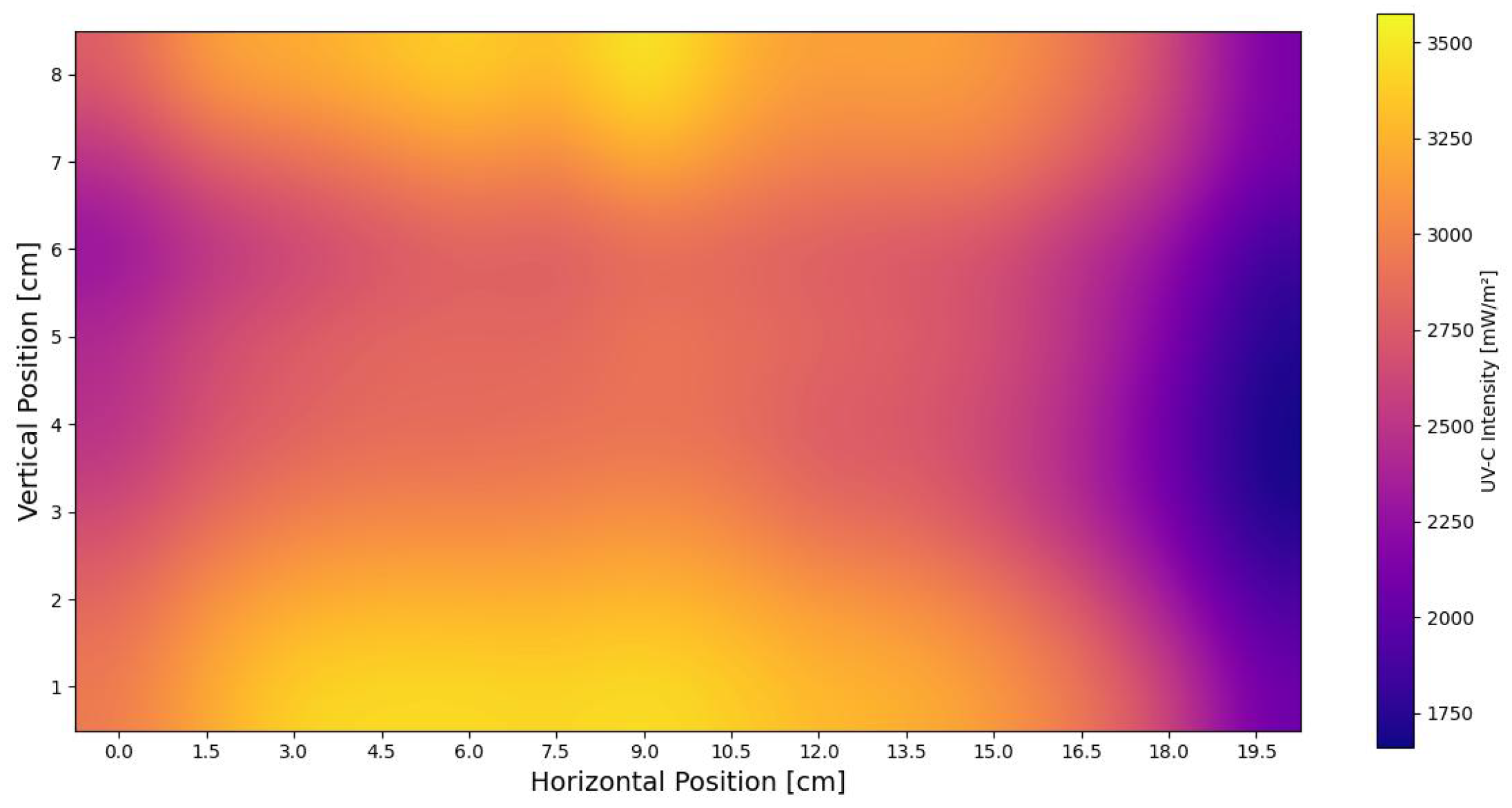

3.4. Uv-C Chamber Irradiation Mapping

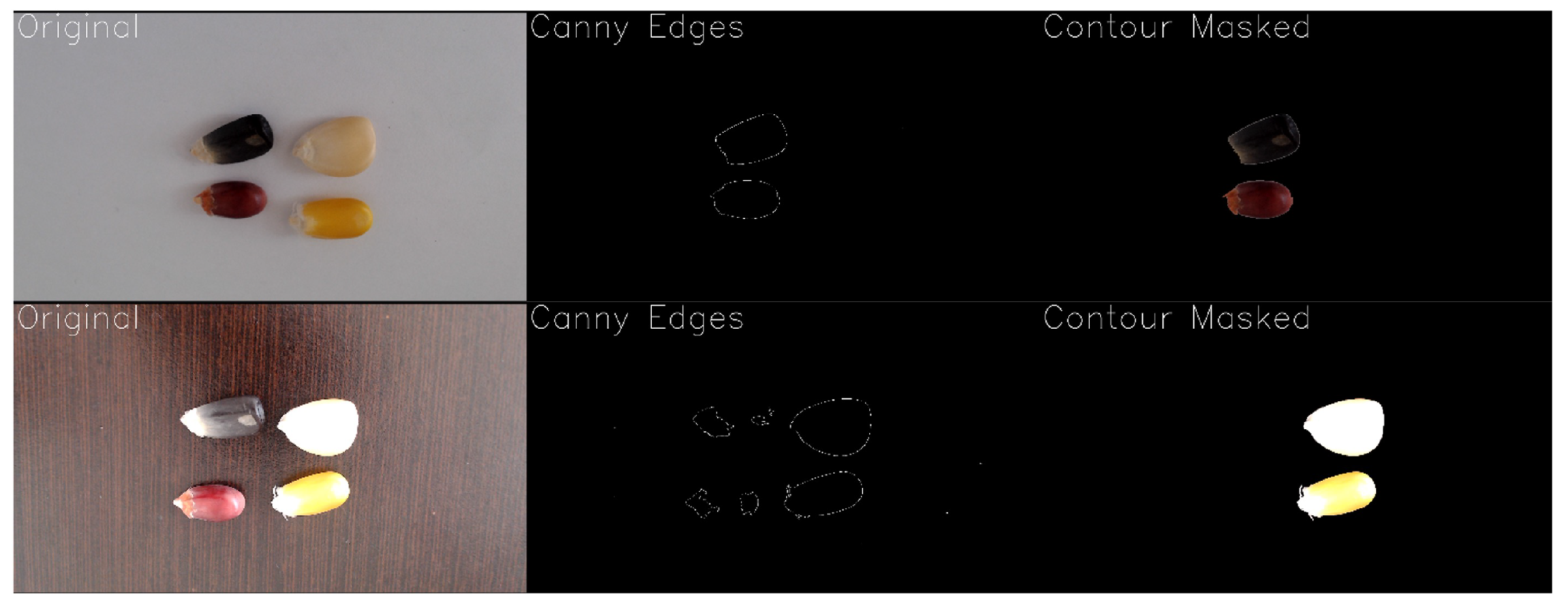

3.5. Evaluation of Computer Vision Performance in Seed Contour and Color Detection

3.6. Experimentation with Maize Seed Samples to Determine the Benefits of the UV-C Radiation Process

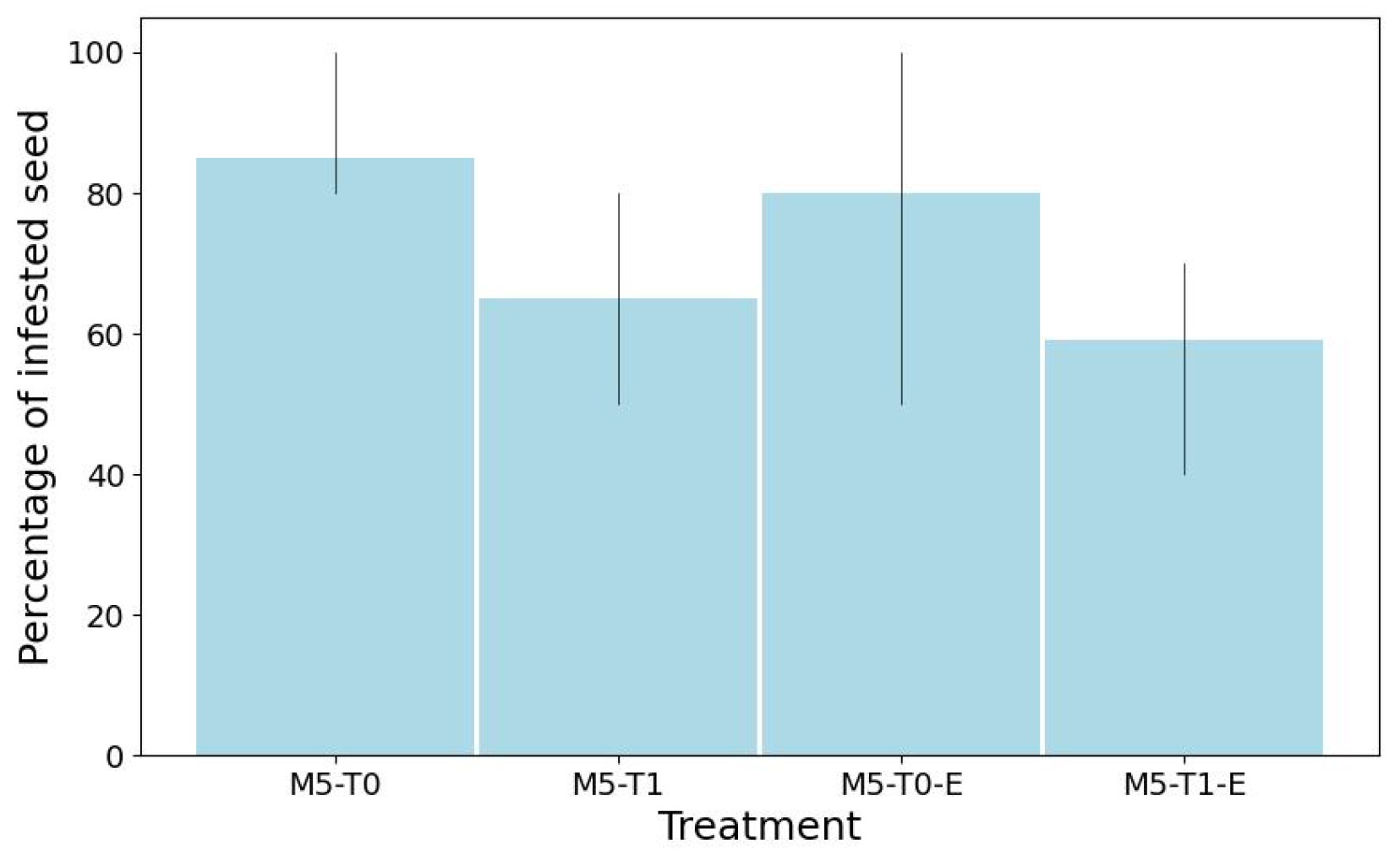

3.6.1. Fungal Infection Assessment (Infested Seed Count)

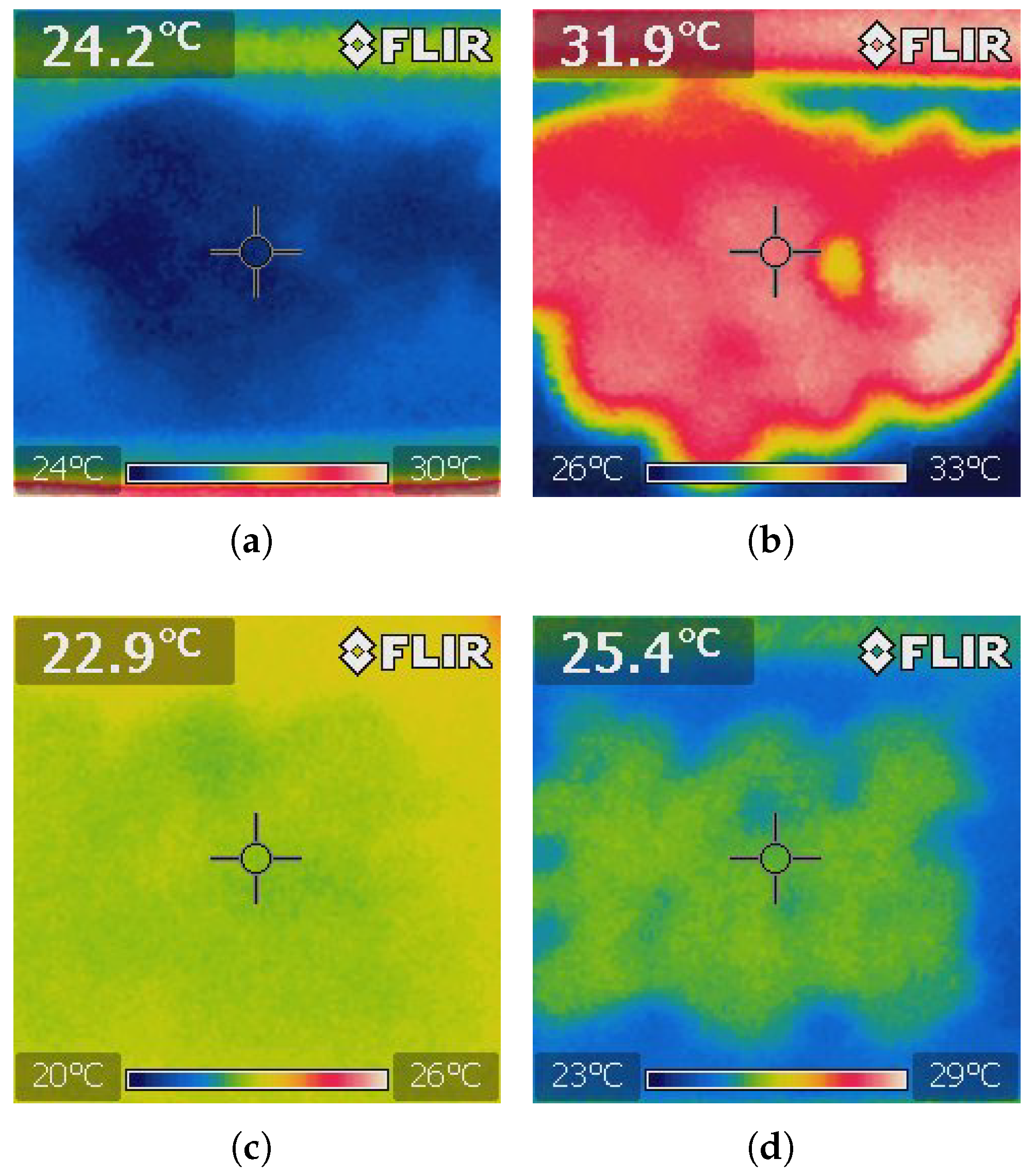

3.6.2. Thermal Effects of UV-C Radiation on Maize Seeds

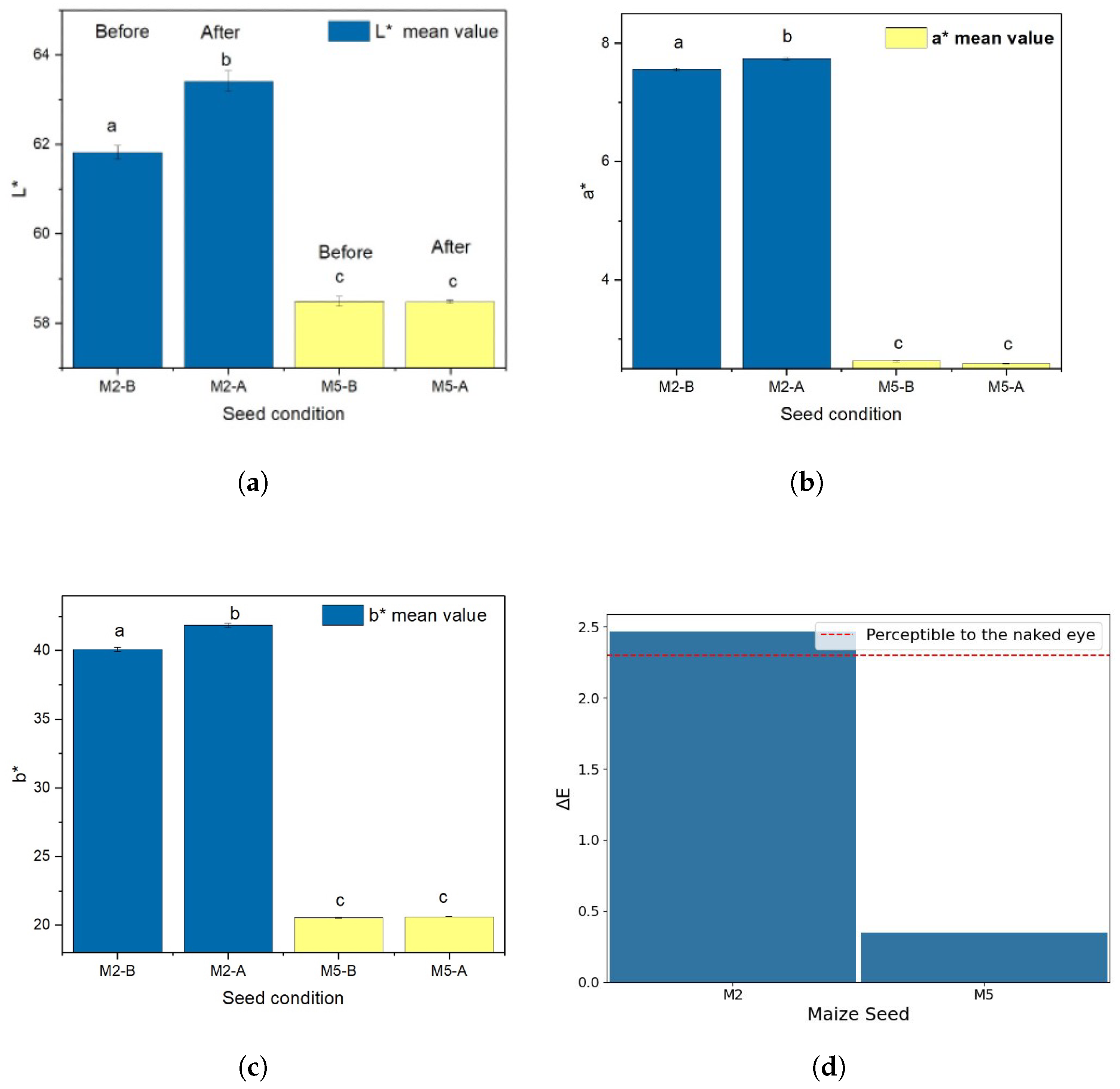

3.6.3. Evaluation of Perceptible Color Differences in Maize Seeds After UV-C Radiation

4. Discussion

4.1. Advancing Prototype Design Through Sensor-Based Feedback

4.2. Computer Vision Proof-of-Concept and Future Integration

4.3. Effectiveness of UV-C Treatment on Fungal Reduction in Maize Seeds

4.4. Future Directions in High-Capacity UV-C Seed Sterilization

4.5. Feedback Control and Regulatory Strategies for UV-C Disinfection

4.6. UV-C Radiation and Its Influence on Seed Surface Appearance and Pigment Degradation

4.7. System Limitations and Pathways for Regulatory-Compliant Improvement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN DESA. The Sustainable Development Goals Report 2024. 2024. Available online: https://unstats.un.org/sdgs/report/2024/ (accessed on 10 February 2025).

- Jha, R.; Zhang, K.; He, Y.; Mendler-Drienyovszki, N.; Magyar-Tábori, K.; Quinet, M.; Germ, M.; Kreft, I.; Meglič, V.; Ikeda, K.; et al. Global nutritional challenges and opportunities: Buckwheat, a potential bridge between nutrient deficiency and food security. Trends Food Sci. Technol. 2024, 145, 104365. [Google Scholar] [CrossRef]

- Kumari, M.; Swati; Priyanka, K. A Comprehensive Review on Sustainable Agricultural Intensification and Ecosystem Services. In Green Equilibrium: Deciphering Earth’s Ecosystems for Sustainable Tomorrow; Gupta, J., Verma, A., Eds.; Springer Nature: Singapore, 2025; pp. 163–178. [Google Scholar] [CrossRef]

- Tolera, A.; Sundstøl, F.; Said, A.N. The effect of stage of maturity on yield and quality of maize grain and stover. Anim. Feed. Sci. Technol. 1998, 75, 157–168. [Google Scholar] [CrossRef]

- Singh, H.; Jassal, R.; Kang, J.; Sandhu, S.; Kang, H.; Grewal, K. Seed priming techniques in field crops—A review. Agric. Rev. 2015, 36, 251–264. [Google Scholar] [CrossRef]

- Dutta, P. Seed Priming: New Vistas and Contemporary Perspectives. In Advances in Seed Priming; Rakshit, A., Singh, H.B., Eds.; Springer: Singapore, 2018; pp. 3–22. [Google Scholar] [CrossRef]

- Amir, M.; Prasad, D.; Khan, F.A.; Khan, A.; Ahamd, B.; Astha. Seed priming: An overview of techniques, mechanisms, and applications. Plant Sci. Today 2024, 11, 553–563. [Google Scholar] [CrossRef]

- Bera, K.; Dutta, P.; Sadhukhan, S. Seed priming with non-ionizing physical agents: Plant responses and underlying physiological mechanisms. Plant Cell Rep. 2022, 41, 53–73. [Google Scholar] [CrossRef] [PubMed]

- Thomas, T.T.D.; Puthur, J.T. UV radiation priming: A means of amplifying the inherent potential for abiotic stress tolerance in crop plants. Environ. Exp. Bot. 2017, 138, 57–66. [Google Scholar] [CrossRef]

- Nik Abdull Halim, N.M.H.; Che Dom, N.; Mat Seleei, N.M.A.S.; Mohd Jamili, A.F.; Precha, N. Radiation effects on dengue vectors: A systematic review. DYSONA-Appl. Sci. 2025, 6, 160–171. [Google Scholar] [CrossRef]

- Urban, L.; Charles, F.; de Miranda, M.R.A.; Aarrouf, J. Understanding the physiological effects of UV-C light and exploiting its agronomic potential before and after harvest. Plant Physiol. Biochem. 2016, 105, 1–11. [Google Scholar] [CrossRef]

- Siddiqui, A.; Dawar, S.; Javed Zaki, M.; Hamid, N. Role of ultra violet (UV-C) radiation in the control of root infecting fungi on groundnut and mung bean. Pak. J. Bot. 2011, 43, 2221–2224. [Google Scholar]

- Ouhibi, C.; Attia, H.; Rebah, F.; Msilini, N.; Chebbi, M.; Aarrouf, J.; Urban, L.; Lachaal, M. Salt stress mitigation by seed priming with UV-C in lettuce plants: Growth, antioxidant activity and phenolic compounds. Plant Physiol. Biochem. 2014, 83, 126–133. [Google Scholar] [CrossRef]

- Mahmood, R.; Ibrahim, M. Testing the effect of ultraviolet C (UV-C) in the germination and growth of local wheat seeds (Triticum aestivum L.). Plant Arch. 2019, 19, 1279–1281. [Google Scholar]

- Popović, V.; Fairbanks, N.; Pierscianowski, J.; Biancaniello, M.; Zhou, T.; Koutchma, T. Feasibility of 3D UV-C treatment to reduce fungal growth and mycotoxin loads on maize and wheat kernels. Mycotoxin Res. 2018, 34, 211–221. [Google Scholar] [CrossRef] [PubMed]

- Stefanello, R.; Puntel, R.T.; da Silva Garcia, W.J.; Strazzabosco Dorneles, L. Mitigating salt stress by conditioning seeds with ultraviolet light (UV-C) in white oats (Avena sativa L.). J. Toxicol. Environ. Health Part A 2024, 87, 533–540. [Google Scholar] [CrossRef]

- Kamel, R.M.; El-kholy, M.M.; Tolba, N.M.; Amer, A.; Eltarawy, A.M.; Ali, L.M. Influence of germicidal ultraviolet radiation UV-C on the quality of Apiaceae spices seeds. Chem. Biol. Technol. Agric. 2022, 9, 89. [Google Scholar] [CrossRef]

- Ali, L.M.; El-kholy, M.M.; Kamel, R.M. Time-dependent changes in quality of Apiaceae spices under synergistic effects of ultraviolet radiation and hermetic storage. J. Appl. Res. Med. Aromat. Plants 2024, 42, 100566. [Google Scholar] [CrossRef]

- El-Beltagi, H.S.; Tawfic, G.A.; Shehata, S.A.; Ali, S.R.; Hamid, O.A.A.; Ahmed, A.E.R.A.; El-Mogy, M.M. The effect of seed priming with UV and gamma rays on the growth, production, and storage ability of cauliflower heads. Not. Bot. Horti Agrobot. Cluj-Napoca 2023, 51, 13264. [Google Scholar] [CrossRef]

- Hernandez-Aguilar, C.; Dominguez-Pacheco, A.; Dominguez-Hernandez, E.; Tsonchev, R.I.; Valderrama-Bravo, M.D.C.; Alvarado-Noguez, M.L. Effects of UV-C light and Spirulina maxima seed conditioning on the germination and the physical and nutraceutical properties of lentils (Lens culinaris). Int. Agrophys. 2023, 37, 15–26. [Google Scholar] [CrossRef]

- Hernandez-Aguilar, C.; Dominguez-Pacheco, A.; Tenango, M.P.; Valderrama-Bravo, C.; Hernández, M.S.; Cruz-Orea, A.; Ordonez-Miranda, J. Characterization of Bean Seeds, Germination, and Phenolic Compounds of Seedlings by UV-C Radiation. J. Plant Growth Regul. 2021, 40, 642–655. [Google Scholar] [CrossRef]

- Scott, G.; Almasrahi, A.; Malekpoor Mansoorkhani, F.; Rupar, M.; Dickinson, M.; Shama, G. Hormetic UV-C seed treatments for the control of tomato diseases. Plant Pathol. 2019, 68, 700–707. [Google Scholar] [CrossRef]

- Chen, X.; Xun, Y.; Li, W.; Zhang, J. Combining discriminant analysis and neural networks for corn variety identification. Comput. Electron. Agric. 2010, 71, S48–S53. [Google Scholar] [CrossRef]

- Javanmardi, S.; Miraei Ashtiani, S.H.; Verbeek, F.J.; Martynenko, A. Computer-vision classification of corn seed varieties using deep convolutional neural network. J. Stored Prod. Res. 2021, 92, 101800. [Google Scholar] [CrossRef]

- Li, J.; Xu, F.; Song, S.; Qi, J. A maize seed variety identification method based on improving deep residual convolutional network. Front. Plant Sci. 2024, 15, 1382715. [Google Scholar] [CrossRef]

- Xu, P.; Tan, Q.; Zhang, Y.; Zha, X.; Yang, S.; Yang, R. Research on Maize Seed Classification and Recognition Based on Machine Vision and Deep Learning. Agriculture 2022, 12, 232. [Google Scholar] [CrossRef]

- Yu, H.; Zhao, J.; Bi, C.G.; Shi, L.; Chen, H. A Lightweight YOLOv5 Target Detection Model and Its Application to the Measurement of 100-Kernel Weight of Corn Seeds. CAAI Trans. Intell. Technol. 2025, 1–14. [Google Scholar] [CrossRef]

- Jocher, G. YOLOv5 by Ultralytics. 2020. Available online: https://github.com/ultralytics/yolov5 (accessed on 9 May 2025). [CrossRef]

- Li, X.; Dai, B.; Sun, H.; Li, W. Corn Classification System Based on Computer Vision. Symmetry 2019, 11, 591. [Google Scholar] [CrossRef]

- Cogan, B. Systems Engineering—Practice and Theory; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Méndez, J.I.; Rojas, M.; Hernández-Aguilar, C.; Domínguez-Pacheco, A.; Valencia-Hernández, J.E.; Ponce, P. Evaluating and Enhancing UV-C Seed Chambers Design for Urban and Peri-Urban Agriculture: A Multi-Criteria Approach using the Penta-S Model. In Proceedings of the SoutheastCon 2025, Concord, NC, USA, 22–30 March 2025; IEEE: New York, NY, USA; pp. 456–462. [Google Scholar]

- Ponce, P.; Rojas, M.; Mendez, J.I.; Anthony, B.; Bradley, R.; Fayek, A.R. Smart City Products and Their Materials Assessment Using the Pentagon Framework. Multimodal Technol. Interact. 2024, 9, 1. [Google Scholar] [CrossRef]

- Santoso, I.; Rau, H.; Choirun, A.; Aprilianto, H.C.; Lestari, K.; A’yuniah, S.; Kusumaningtyas, O.W. Application of QFD in sustainable new product development in the agro-industrial sector: A systematic literature review. Int. J. Sustain. Eng. 2024, 17, 926–944. [Google Scholar] [CrossRef]

- Ma, H.; Chu, X.; Xue, D.; Chen, D. A systematic decision making approach for product conceptual design based on fuzzy morphological matrix. Expert Syst. Appl. 2017, 81, 444–456. [Google Scholar] [CrossRef]

- Gbegbelegbe, S.; Alene, A.; Swamikannu, N.; Frija, A. Multi-dimensional impact assessment for priority setting of agricultural technologies: An application of TOPSIS for the drylands of sub-Saharan Africa and South Asia. PLoS ONE 2024, 19, e0314007. [Google Scholar] [CrossRef]

- Molina, A.; Ponce, P.; Miranda, J.; Cortés, D. Enabling Systems for Intelligent Manufacturing in Industry 4.0: Sensing, Smart and Sustainable Systems for the Design of S3 Products, Processes, Manufacturing Systems, and Enterprises; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Claus, H. Ozone Generation by Ultraviolet Lamps. Photochem. Photobiol. 2021, 97, 471–476. [Google Scholar] [CrossRef]

- Singh, H. Practical Machine Learning and Image Processing: For Facial Recognition, Object Detection, and Pattern Recognition Using Python; Apress: Berkeley, CA, USA, 2019. [Google Scholar] [CrossRef]

- Commission Internationale de l’Éclairage (CIE). Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space; CIE: Vienna, Austria, 1976; Available online: https://cie.co.at/publications/colorimetry-part-4-cie-1976-lab-colour-space-1 (accessed on 9 May 2025).

- Collazo, C.; Lafarga, T.; Aguiló-Aguayo, I.; Marín-Sáez, J.; Abadias, M.; Viñas, I. Decontamination of fresh-cut broccoli with a water–assisted UV-C technology and its combination with peroxyacetic acid. Food Control 2018, 93, 92–100. [Google Scholar] [CrossRef]

- Arcos-Limiñana, V.; Maestre-Pérez, S.; Prats-Moya, M.S. A comprehensive review on ultraviolet disinfection of spices and culinary seeds and its effect on quality. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70076. [Google Scholar] [CrossRef]

- Hernandez, A.C.; Dominguez, P.A.; Cruz, O.A.; Ivanov, R.; Carballo, C.A.; Zepeda, B.R. Laser in agriculture. Int. Agrophys. 2010, 24, 407–422. [Google Scholar]

- Hernández-Aguilar, C.; Domínguez, F.A.P.; Cruz, A.O.; Ivanov, R.T. Thermal effects of laser irradiation on maize seeds. Int. Agrophys. 2015, 29, 147–156. [Google Scholar] [CrossRef]

- Hidaka, Y.; Kubota, K. Study on the Sterilization of Grain Surface Using UV Radiation. Jpn. Agric. Res. Q. JARQ 2006, 40, 157–161. [Google Scholar] [CrossRef]

- Peña Ramos, A.; González Castañeda, F.; Robles Escobedo, F.J. Manejo agronómico para incrementar el rendimiento de grano y forraje en híbridos tardíos de maíz. Rev. Mex. Cienc. Agrícolas 2010, 1, 27–35. [Google Scholar]

- Bang, I.H.; Kim, Y.E.; Lee, S.Y.; Min, S.C. Microbial decontamination of black peppercorns by simultaneous treatment with cold plasma and ultraviolet C. Innov. Food Sci. Emerg. Technol. 2020, 63, 102392. [Google Scholar] [CrossRef]

- Hinds, L.M.; Güçlü, G.; Kelebek, H.; Selli, S.; O’Donnell, C.P.; Tiwari, B.K. Effect of ultraviolet light emitting diode treatments on microbial load, phenolic and volatile profile of black peppercorns. LWT 2021, 152, 112133. [Google Scholar] [CrossRef]

- Xie, J.; Hung, Y.C. Efficacy of pulsed-ultraviolet light for inactivation of Salmonella spp on black peppercorns. J. Food Sci. 2020, 85, 755–761. [Google Scholar] [CrossRef]

- EPA. U.S. Environmental Protection Agency. 2013. Available online: https://www.epa.gov/ (accessed on 9 May 2025).

- IUVA. International Ultraviolet Association. Available online: https://www.iuva.org/ (accessed on 9 May 2025).

- ISO. ISO 15858:2016—UV-C Devices—Safety Information—Permissible Human Exposure. Available online: https://www.iso.org/standard/55553.html (accessed on 9 May 2025).

- Junk-Knievel, D.C.; Vandenberg, A.; Bett, K.E. An Accelerated Postharvest Seed-Coat Darkening—ProQuest. Crop Sci. 2007, 47, 694–700. [Google Scholar] [CrossRef]

- Tekin Kumaş, Y.; Kibar, H.; Soydemir, H.E. Investigating UV-C radiation as a non-chemical method to prevent quality loss in the pea seed during storage. J. Stored Prod. Res. 2025, 111, 102532. [Google Scholar] [CrossRef]

- Virtanen, H.; Vehmas, K.; Erho, T.; Smolander, M. Flexographic printing of Trametes versicolor laccase for indicator applications. Packag. Technol. Sci. 2014, 27, 819–830. [Google Scholar] [CrossRef]

- Erdogdu, S.B.; Ekiz, H.I. Far infrared and ultraviolet radiation as a combined method for surface pasteurization of black pepper seeds. J. Food Eng. 2013, 116, 310–314. [Google Scholar] [CrossRef]

- Dogu-Baykut, E.; Gunes, G. Effect of Ultraviolet (UV-C) Light and Gaseous Ozone on Mocrobial And Color Qualities of Whole Black Pepper Seeds (Piper nigrum L.). Carpathian J. Food Sci. Technol. 2022, 14, 122–131. [Google Scholar] [CrossRef]

| Feature/Solution | Alternative 1 | Alternative 2 | Alternative 3 | |

|---|---|---|---|---|

| 1 | Generate UV-C Radiation Lamps | Low-pressure Mercury | High-pressure Mercury | UV-C LED array |

| 2 | Control Radiation Intensity | PWM dimming | Variable power supply | Lamp distance adjustment |

| 3 | Monitor UV-C Intensity | Photodiode | Digital sensors | Light meter |

| 4 | Monitor Temperature | DHT22 sensor | Thermocouple | Digital sensor |

| 5 | Monitor Humidity | DHT22 sensor | Digital sensor | Capacitive Sensor |

| 6 | UV-blocking enclosure | Full-metal box | Opaque plastic housing | Custom composite material |

| 7 | Provide real-time data interface | Raspberry Pi and Touchscreen LCD | Web dashboard | Mobile app |

| 8 | Enable visual seed analysis | HD webcam | Raspberry Pi camera | Industrial camera |

| 9 | Adjust exposure time | Digital Timer | Manual Knob | Programmable microcontroller |

| 10 | UV-C Lamp support structure | Screwed panels | Snap-fit parts | Magnetic fixtures |

| 11 | Enable Chamber portability | Wheels | Handle and lightweight | Modular compact design |

| 12 | Handle multiple seed samples | Multiple trays | Rotating tray system | Slide-in drawer trays |

| 13 | Facilitate odor extraction | Mini exhaust fan | Charcoal air scrubber | Air filter installation |

| 14 | Adapt to a variety of UV-C enclosures | Modular Mounting frame | Telescopic Sliding Rack Units | Clip-on module panels |

| 15 | Optimize Energy Use | Auto-off function | Low-power electronics | High-efficiency PSU |

| 16 | Ensure affordability | Open-source hardware/software | Standardized off-the-shelf components | Simplified modular design |

| 17 | Community-friendly interface and operation | Large buttons and icons | Simple mobile interface | Multilingual support |

| 18 | Design for easy repair | Quick-swap modular parts | Color-coded internal parts | Snap-fit modular design |

| 19 | Capture images for seed documentation | Periodic image capture | Comparison camera | Integrated logger |

| 20 | Seed detection with computer vision | Blob detection | YOLO-based detection | Edge detection algorithms |

| 21 | Visual/sound indicator of successful treatment | Beep signal | Green indicator LED | End sound and display |

| 22 | User customization options | Adjustable cycle presets | Profile-based settings | Touchscreen wizard setup |

| 23 | Durable, UV- and corrosion-resistant materials | UV-resistant plastics | Anodized aluminium | Stainless steel + coatings |

| 24 | Power supply options | AC mains (110–220V) | Solar panel + inverter | Hybrid system |

| 25 | Automated report generation | Auto-save to connected storage | PDF report generation | Cloud-based reporting |

| 26 | Automatic seed color analysis | RGB camera with calibrated lighting | Multispectral imaging | Open-source vision module |

| Feature | Selected Alternative 1 | Cost | DT | Reliab. | Scalab. | RC |

|---|---|---|---|---|---|---|

| 1 | Low-pressure Mercury | + | + | 0 | 0 | + |

| 2 | Lamp Distance Adjustment | 0 | 0 | + | 0 | + |

| 3 | Digital UV-C sensors | 0 | 0 | + | 0 | + |

| 4 | Digital sensor | 0 | 0 | + | 0 | + |

| 5 | Digital Sensor | 0 | 0 | + | 0 | + |

| 6 | Full metal box | 0 | + | + | + | + |

| 7 | Raspberry Pi and Touchscreen LCD | 0 | 0 | + | 0 | + |

| 8 | HD Webcam | - | 0 | + | 0 | + |

| 9 | Programmable microcontroller | - | 0 | + | + | 0 |

| 10 | Screwed panels | - | - | 0 | 0 | 0 |

| 11 | Handle and lightweight | - | - | + | + | 0 |

| 12 | Multiple trays | - | - | + | + | 0 |

| 13 | Mini exhaust fan | - | - | 0 | + | 0 |

| 14 | Modular mounting frame | 0 | 0 | + | + | + |

| 15 | Low-power electronics | 0 | 0 | + | + | + |

| 16 | Open Source Hardware and Software | + | 0 | 0 | + | 0 |

| 17 | Modular Standard Components | + | 0 | + | + | 0 |

| 18 | Quick-swap modular parts | 0 | - | + | + | 0 |

| 19 | Periodic Image Capture | 0 | 0 | + | + | 0 |

| 20 | Edge Detection algorithms | + | - | 0 | + | 0 |

| 21 | End sound and display | + | + | 0 | + | 0 |

| 22 | Adjustable Cycle Presets | 0 | - | + | + | 0 |

| 23 | Stainless Steel and Coatings | - | 0 | + | 0 | + |

| 24 | AC mains (110–220 V) | + | + | + | + | 0 |

| 25 | Auto-save to connected storage | 0 | 0 | + | + | 0 |

| 26 | Open-source vision module | + | 0 | 0 | + | 0 |

| Object | Colorimeter | Computer Vision | 1 | ||||

|---|---|---|---|---|---|---|---|

| C1 | 71.09 | 22.73 | —16.53 | 74.39 | 21.21 | —4.01 | 13.01 |

| C2 | 75.07 | 45.74 | 54.16 | 78.20 | 19.79 | 57.36 | 26.64 |

| C3 | 78.08 | —21.96 | 38.26 | 79.53 | —17.96 | 31.95 | 7.47 |

| C4 | 90.73 | —2.86 | 59.85 | 98.13 | —11.73 | 38.54 | 24.36 |

| C5 | 65.80 | 53.84 | 2.02 | 71.09 | 43.52 | 16.83 | 20.10 |

| C6 | 63.79 | —25.08 | —22.78 | 80.40 | —24.21 | —29.38 | 17.94 |

| Type | Color (CIELAB) | Dimensions (mm) | ||||

|---|---|---|---|---|---|---|

| Length | Width | Thickness | ||||

| Semi-crystalline | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas, M.; Hernández-Aguilar, C.; Méndez, J.I.; Balderas-Silva, D.; Domínguez-Pacheco, A.; Ponce, P. Design and Evaluation of an Automated Ultraviolet-C Irradiation System for Maize Seed Disinfection and Monitoring. Sensors 2025, 25, 6070. https://doi.org/10.3390/s25196070

Rojas M, Hernández-Aguilar C, Méndez JI, Balderas-Silva D, Domínguez-Pacheco A, Ponce P. Design and Evaluation of an Automated Ultraviolet-C Irradiation System for Maize Seed Disinfection and Monitoring. Sensors. 2025; 25(19):6070. https://doi.org/10.3390/s25196070

Chicago/Turabian StyleRojas, Mario, Claudia Hernández-Aguilar, Juana Isabel Méndez, David Balderas-Silva, Arturo Domínguez-Pacheco, and Pedro Ponce. 2025. "Design and Evaluation of an Automated Ultraviolet-C Irradiation System for Maize Seed Disinfection and Monitoring" Sensors 25, no. 19: 6070. https://doi.org/10.3390/s25196070

APA StyleRojas, M., Hernández-Aguilar, C., Méndez, J. I., Balderas-Silva, D., Domínguez-Pacheco, A., & Ponce, P. (2025). Design and Evaluation of an Automated Ultraviolet-C Irradiation System for Maize Seed Disinfection and Monitoring. Sensors, 25(19), 6070. https://doi.org/10.3390/s25196070