Construction and Experimental Analysis of a Multipurpose Robotic Fin Ray Gripper for Manipulator Robots

Abstract

1. Introduction

1.1. Related Works

1.2. Objectives and Paper Organization

2. Materials and Methods

2.1. FG Development

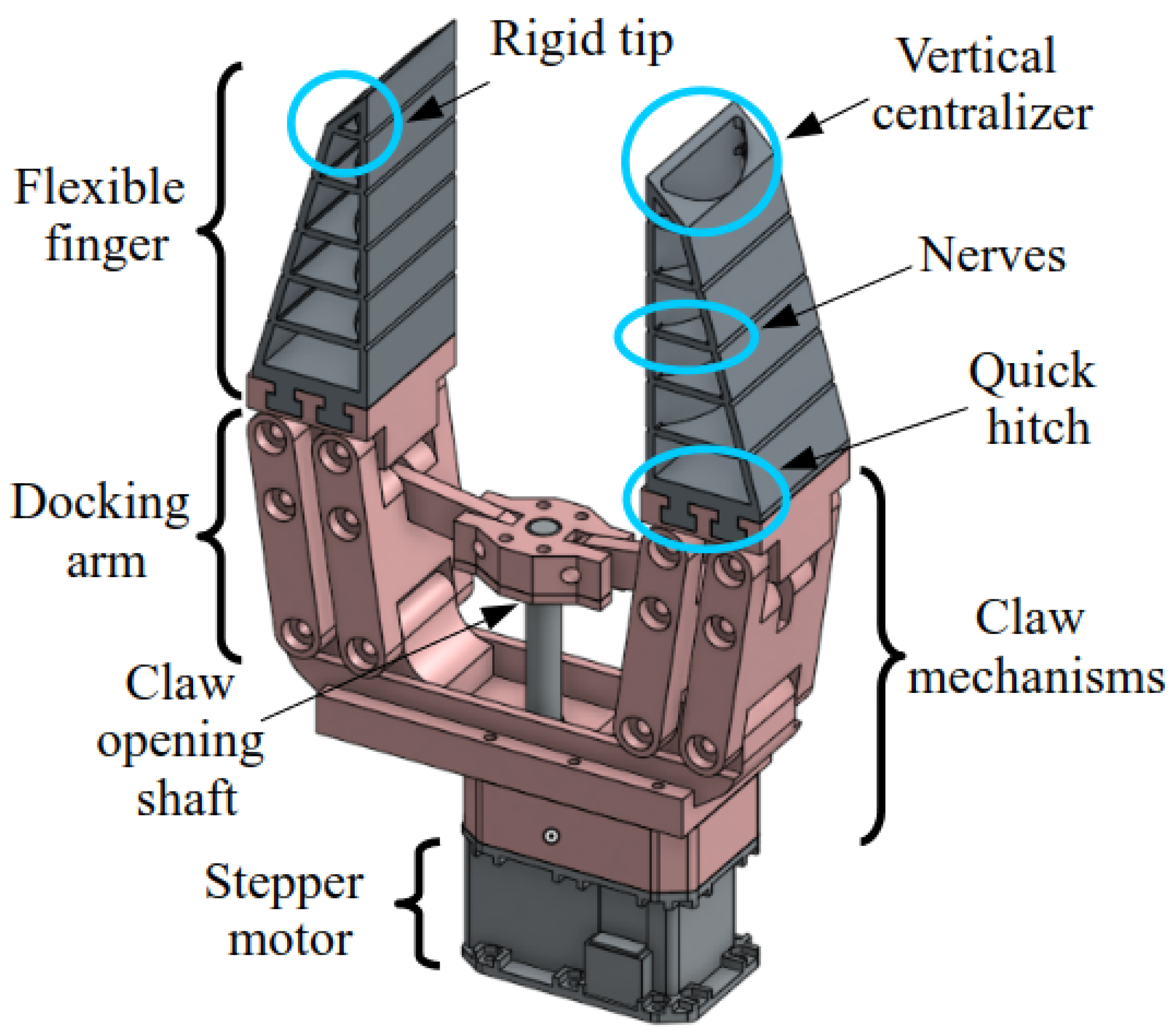

FG Components

2.2. Analysis of the Forces in the FG

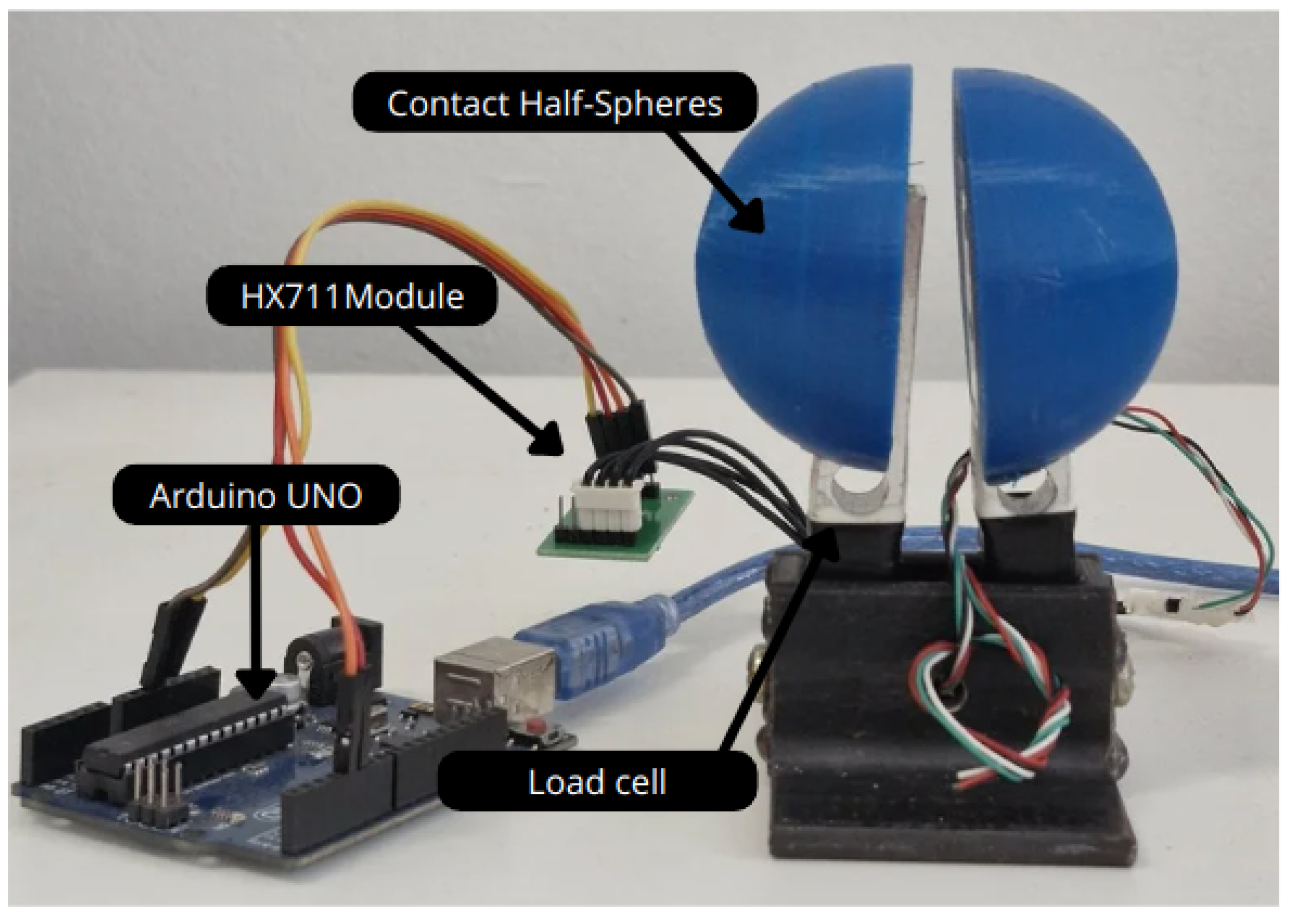

- SAE 1020 steel support for fixing the load cells;

- Two 20 kg nominal load cells, made of aluminum alloy, with an operating voltage of 5 V;

- Two half-spheres printed using 3D technology, made of PETG, serving as contact surfaces between the FG and the load cell;

- An Arduino Uno microcontroller (Arduino, Scarmagno, Italy) with 1 ms reading time and a communication baud rate of 57,600;

- A HX711 module for conditioning the load cell signals, with an analog-to-digital converter for scales;

- A 248 g standard mass for load cell calibration.

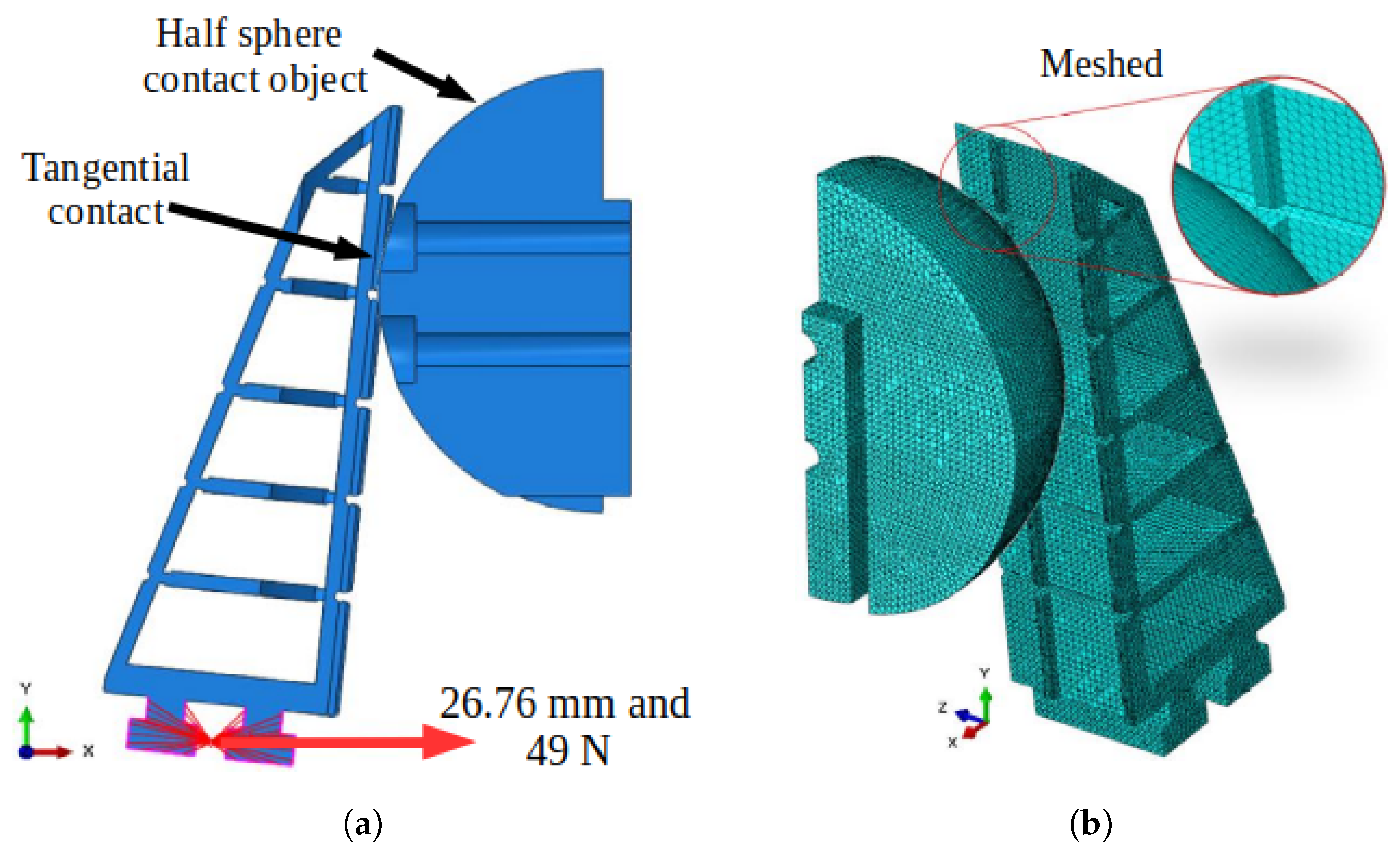

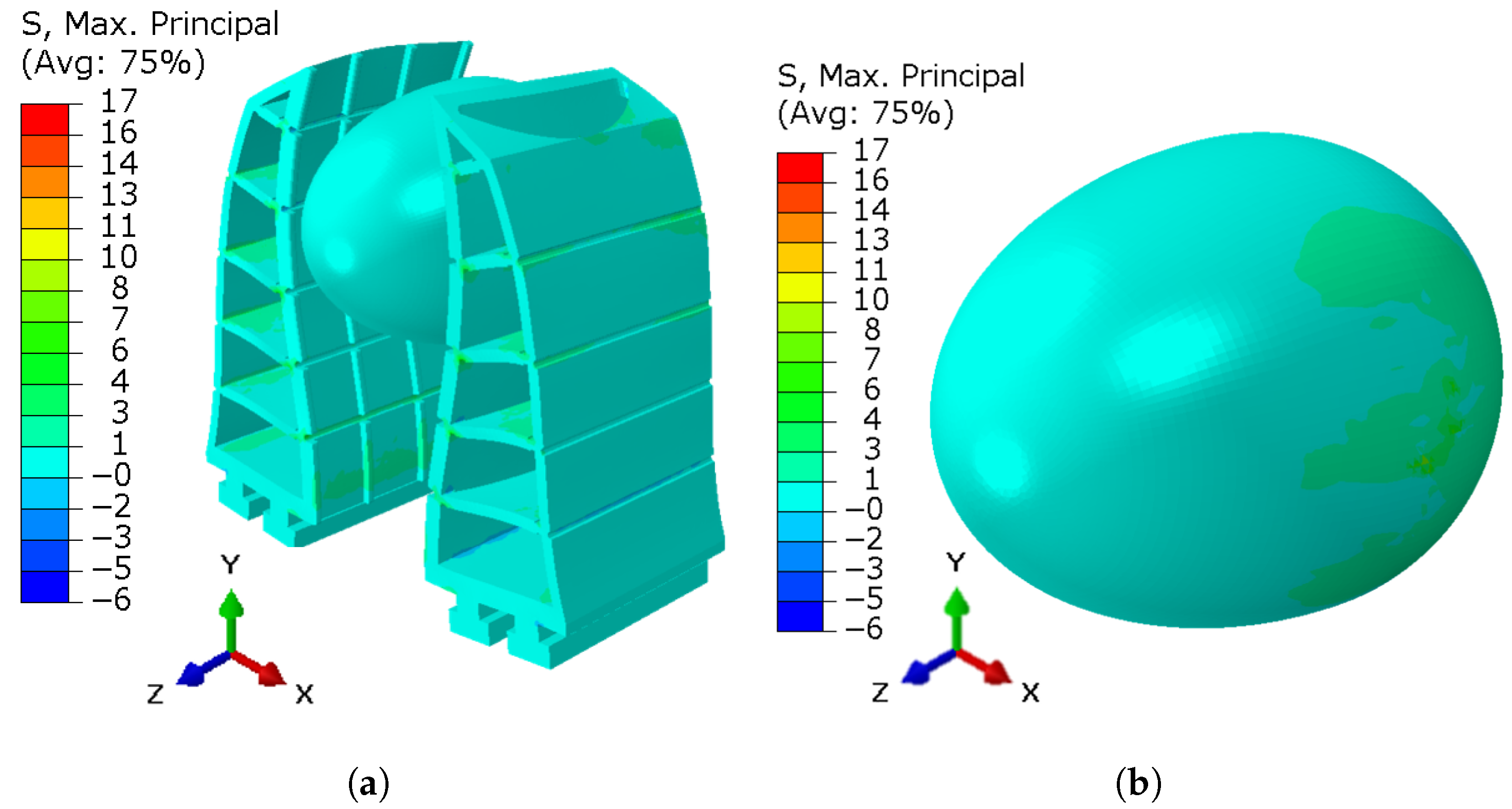

2.3. Analysis by FEM

3. Results

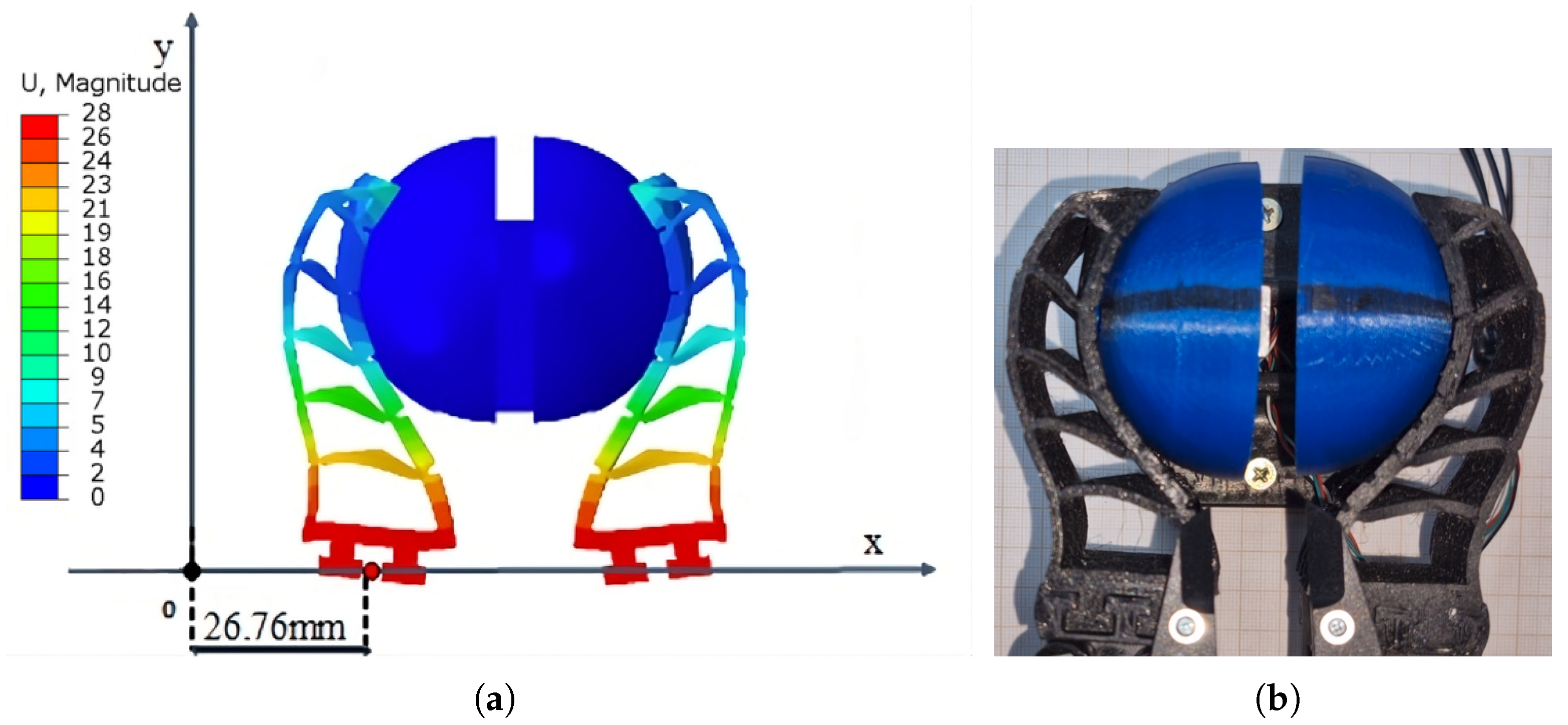

3.1. Validation of the FEM Through Experimental Tests

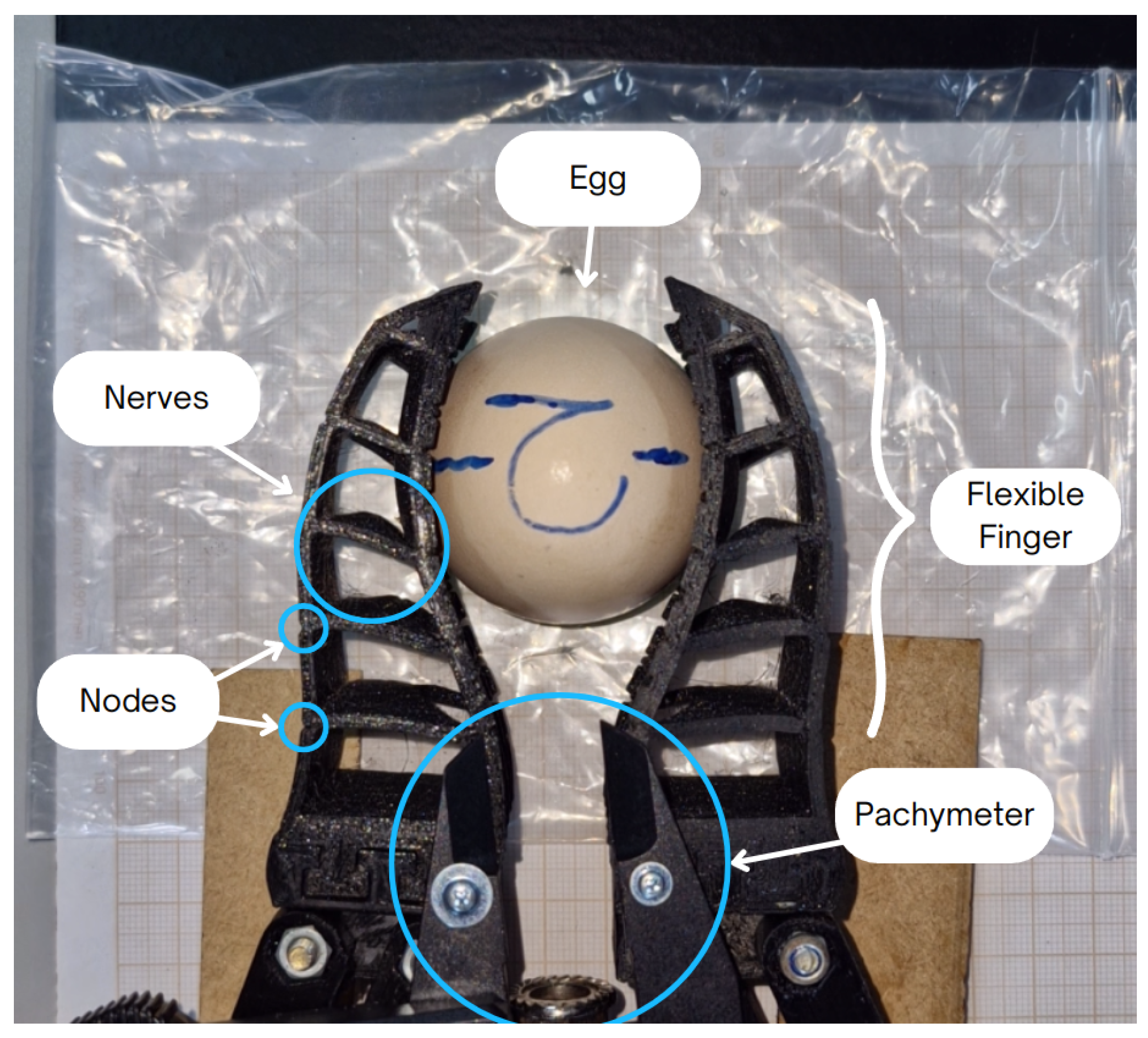

3.2. Analysis of the Forces Exerted by the FG on a Chicken Egg

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Craig, J. Introduction to Robotics, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Romano, V. Robótica Industrial: Aplicação na Indústria de Manufatufatura e de Processos; Edgard Blucher: Santana, Brazil, 2002. [Google Scholar]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Zareinia, K.; Janabi-Sharifi, F. A Brief Review on Robotic Grippers Classifications. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Corporation, K.T. 8 Types of End of Arm Tooling Devices for Automation Projects. 2023. Available online: https://www.kellertechnology.com/blog/8-types-of-end-of-arm-tooling-devices-for-automation-projects (accessed on 6 January 2025).

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft manipulators and grippers: A review. Front. Robot. AI 2016, 3, 69. [Google Scholar] [CrossRef]

- Chen, R.; Song, R.; Zhang, Z.; Bai, L.; Liu, F.; Jiang, P.; Sindersberger, D.; Monkman, G.; Guo, J. Bio-Inspired Shape-Adaptive Soft Robotic Grippers Augmented with Electroadhesion Functionality. Soft Robot. 2019, 6, 701–712. [Google Scholar] [CrossRef]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Nguyen, P.; Dhyan, S.; Mai, V.; Han, B.; Chow, W. Bioinspiration and Biomimetic Art in Robotic Grippers. Micromachines 2023, 14, 1772. [Google Scholar] [CrossRef]

- Ivanov, V.; Andrusyshyn, V.; Pavlenko, I.; Piteľ, J.; Bulej, V. New classification of industrial robotic gripping systems for sustainable production. Sci. Rep. 2024, 14, 295. [Google Scholar] [CrossRef]

- Wang, J.; Chortos, A. Control Strategies for Soft Robot Systems. Adv. Intell. Syst. 2022, 4, 2100165. [Google Scholar] [CrossRef]

- Manoonpong, P.; Rajabi, H.; Larsen, J.; Raoufi, S.; Asawalertsak, N.; Homchanthanakul, J.; Tramsen, H.T.; Darvizeh, A.; Gorb, S. Fin Ray Crossbeam Angles for Efficient Foot Design for Energy-Efficient Robot Locomotion. Adv. Intell. Syst. 2022, 4, 2270001. [Google Scholar] [CrossRef]

- Jiaqiang, Y.; Fang, Y.; Yang, X.; Peiyi, W.; Luquan, L. Design optimization of soft robotic fingers biologically inspired by the fin ray effect with intrinsic force sensing. Mech. Mach. Theory 2023, 191, 105472. [Google Scholar] [CrossRef]

- Crooks, W.; Vukasin, G.; O’Sullivan, M.; Messner, W.; Rogers, C. Fin Ray Effect Inspired Soft Robotic Gripper: From the RoboSoft Grand Challenge Toward Optimization. Front. Robot. AI 2016, 3, 70. [Google Scholar] [CrossRef]

- Ivanov, V.; Aleksandrov, A.; Bdiwi, M.; Popov, A.; Rashid, A.; Pershina, Z.; Kolker, A.; Dimitrov, L. Bin Picking Pneumatic-Mechanical Gripper for Industrial Manipulators. In Proceedings of the 2021 IV International Conference on High Technology for Sustainable Development (HiTech), Sofia, Bulgaria, 7–8 October 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Yuan, S.; Shao, L.; Yako, C.; Gruebele, A.; Salisbury, J. Design and Control of Roller Grasper V2 for In-Hand Manipulation. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020. [Google Scholar] [CrossRef]

- Müller, A.; Aydemir, M.; Glodde, A.; Dietrich, F. Design Approach for Heavy-Duty Soft-Robotic-Gripper. Procedia CIRP 2020, 91, 301–305. [Google Scholar] [CrossRef]

- Elgeneidy, K.; Lightbody, P.; Pearson, S.; Neumann, G. Characterising 3D-printed Soft Fin Ray Robotic Fingers with Layer Jamming Capability for Delicate Grasping. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; pp. 143–148. [Google Scholar]

- Elgeneidy, K.; Fansa, A.; Hussain, I.; Goher, K. Structural Optimization of Adaptive Soft Fin Ray Fingers with Variable Stiffening Capability. In Proceedings of the 3rd IEEE International Conference on Soft Robotics, RoboSoft 2020, New Haven, CT, USA, 5 May–15 July 2020; pp. 779–784. [Google Scholar] [CrossRef]

- Crooks, W.; Rozen-Levy, S.; Trimmer, B.; Rogers, C.; Messner, W. Passive gripper inspired by Manduca sexta and the Fin Ray® Effect. Int. J. Adv. Robot. Syst. 2017, 14, 172988141772115. [Google Scholar] [CrossRef]

- Yang, Y.; Jin, K.; Zhu, H.; Song, G.; Lu, H.; Kang, L. A 3D-Printed Fin Ray Effect Inspired Soft Robotic Gripper with Force Feedback. Micromachines 2021, 12, 1141. [Google Scholar] [CrossRef]

- Patel, V.; Morgan, A.; Dollar, A. Highly Underactuated Radial Gripper for Automated Planar Grasping and Part Fixturing. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 9910–9916. [Google Scholar] [CrossRef]

- Backus, S.; Onishi, R.; Bocklund, A.; Berg, A.; Contreras, E.; Parness, A. Design and testing of the JPL-Nautilus Gripper for deep-ocean geological sampling. J. Field Robot. 2020, 37, 972–986. [Google Scholar] [CrossRef]

- Zhydenko, I.; Permyakov, A.; Kutlubaev, I. Construction basics of adaptive group actuators of anthropomorphic grippers actuating link groups. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Saint Petersburg, Russia, 16–19 May 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Guo Liang, G.; Lyu, Z.; Ariffin, M.; Yeong, W.Y.; Lum, G.; Campolo, D.; Han, B.; Wong, H. 3D Printing of Robotic Soft Grippers: Toward Smart Actuation and Sensing. Adv. Mater. Technol. 2022, 7, 2101672. [Google Scholar] [CrossRef]

- Yao, J.; Fang, Y.; Li, L. Research on effects of different internal structures on the grasping performance of Fin Ray soft grippers. Robotica 2023, 41, 1762–1777. [Google Scholar] [CrossRef]

- Srinivas, G.L.; Javed, A.; Faller, L.M. Versatile 3D-printed fin-ray effect soft robotic fingers: Lightweight optimization and performance analysis. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 382. [Google Scholar] [CrossRef]

- Cong, Q.; Fan, W.; Zhang, D. TacFR-Gripper: A Reconfigurable Fin-Ray-Based Gripper with Tactile Skin for In-Hand Manipulation. Actuators 2024, 13, 521. [Google Scholar] [CrossRef]

- Altuntas, E.; Şekeroğlu, A. Mechanical behavior and physical properties of chicken egg as affected by different egg weights. J. Food Process Eng. 2008, 33, 115–127. [Google Scholar] [CrossRef]

- Mehdizadeh, S.; Nadi, F. Experimental and Numerical Analysis for Prediction of Mechanical Properties of Eggshell. Int. J. Food Eng. 2016, 12, 287–293. [Google Scholar] [CrossRef]

- Hahn, E.; Sherman, V.; Pissarenko, A.; Rohrbach, S.; Fernandes, D. Nature’s technical ceramic: The avian eggshell. J. R. Soc. Interface 2017, 14, 20160804. [Google Scholar] [CrossRef] [PubMed]

- De Barrie, D.; Pandya, M.; Pandya, H.; Hanheide, M.; Elgeneidy, K. A deep learning method for vision based force prediction of a soft fin ray gripper using simulation data. Front. Robot. AI 2021, 8, 631371. [Google Scholar] [CrossRef] [PubMed]

- Ghanizadeh, A.; Ahmadi, A.; Bahrami, A. Multi-Objective Neural Network Assisted Design Optimization of Soft Fin-Ray Grippers for Enhanced Grasping Performance. arXiv 2025, arXiv:2506.00494. [Google Scholar]

- Shan, X.; Birglen, L. Modeling and analysis of soft robotic fingers using the fin ray effect. Int. J. Robot. Res. 2020, 39, 027836492091392. [Google Scholar] [CrossRef]

- Ali, M.; Zhanabayev, A.; Khamzin, S.; Mussin, K. Biologically Inspired Gripper Based on the Fin Ray Effect. In Proceedings of the 2019 5th International Conference on Control, Automation and Robotics (ICCAR), Beijing, China, 19–22 April 2019; pp. 865–869. [Google Scholar] [CrossRef]

- 3DLAB SOLUÇÕES EM IMPRESSÃO 3D. Available online: https://3dlab.com.br/propriedades-dos-materiais-para-impressora-3d/ (accessed on 13 September 2023).

- ASTM International. Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Mercado-Colmenero, J.; La Rubia García, M.; Mata García, E.; Rodriguez-Santiago, M.; Martin-Doñate, C. Experimental and Numerical Analysis for the Mechanical Characterization of PETG Polymers Manufactured with FDM Technology under Pure Uniaxial Compression Stress States for Architectural Applications. Polymers 2020, 12, 2202. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.; Reis, P. Optimization of Printing Parameters to Maximize the Mechanical Properties of 3D-Printed PETG-Based Parts. Polymers 2022, 14, 2564. [Google Scholar] [CrossRef]

- Brancewicz-Steinmetz, E.; Sawicki, J.; Byczkowska, P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials 2021, 14, 6464. [Google Scholar] [CrossRef]

- DIN 53504; Testing of Rubber and Elastomers—Determination of Tear Strength, Tensile Strength, Elongation at Break and Stress Values in a Tensile Test. Deutsches Institut für Normung: Berlin, Germany, 1985.

- ASME. Guide for Verification and Validation in Computational Solid Mechanics; ASME: New York, NY, USA, 2006. [Google Scholar]

- Eom, J.-H.; Jin, C.K.; Ahn, D.-Y.; Babu, J.; Jang, J.-Y.; Lee, M.S. Comparison of FE Simulation and Experiment on Tensile Test of TWB-HPF 22MnB5 Steel. Metals 2024, 14, 1176. [Google Scholar] [CrossRef]

| Experimental Test | FEM Simulation | ||||

|---|---|---|---|---|---|

| Test | Max.

Force [N] |

Max.

Displacement (mm) |

FEM Max.

Force [N] |

FEM

Displacement (mm) |

Error

(%) |

| 1 | 53.65 | 26.80 | 49 | 26.76 | 9.57% |

| 2 | 53.80 | 26.80 | 49 | 26.76 | 9.80% |

| 3 | 52.62 | 26.80 | 49 | 26.76 | 7.35% |

| 4 | 52.08 | 26.80 | 49 | 26.76 | 6.31% |

| 5 | 53.30 | 26.85 | 49 | 26.76 | 8.63% |

| 6 | 53.13 | 26.80 | 49 | 26.76 | 8.43% |

| 7 | 53.29 | 26.85 | 49 | 26.76 | 8.73% |

| 8 | 51.05 | 26.90 | 49 | 26.76 | 4.18% |

| 9 | 51.68 | 25.55 | 49 | 26.76 | 5.47% |

| 10 | 52.15 | 26.90 | 49 | 26.76 | 6.49% |

| 11 | 52.60 | 26.85 | 49 | 26.76 | 7.35% |

| 12 | 51.76 | 26.85 | 49 | 26.76 | 5.63% |

| 13 | 52.47 | 26.75 | 49 | 26.76 | 7.14% |

| 14 | 52.41 | 26.90 | 49 | 26.76 | 7.06% |

| 15 | 53.89 | 26.85 | 49 | 26.76 | 9.98% |

| Average | 52.66 | 26.76 | – | – | 7.14% |

|

Standard Deviation | 0.8117 | 0.3235 | – | – | – |

| Mesh Size [mm] | Force [N] | Relative Error [%] |

|---|---|---|

| 2.00 | 74.72 | – |

| 1.50 | 57.55 | 30.00 |

| 1.25 | 53.03 | 9.00 |

| 1.10 | 50.12 | 6.00 |

| 1.00 | 49.29 | 2.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cukla, A.R.; Crespo Izquierdo, R.; Strapazzon, L.; Taverna, J.E.; Alves Filho, C.R.; Lapczuk, S.O.; Szydlowski, J.A.; Bevilacqua, S.; Tello Gamarra, D.F. Construction and Experimental Analysis of a Multipurpose Robotic Fin Ray Gripper for Manipulator Robots. Sensors 2025, 25, 5782. https://doi.org/10.3390/s25185782

Cukla AR, Crespo Izquierdo R, Strapazzon L, Taverna JE, Alves Filho CR, Lapczuk SO, Szydlowski JA, Bevilacqua S, Tello Gamarra DF. Construction and Experimental Analysis of a Multipurpose Robotic Fin Ray Gripper for Manipulator Robots. Sensors. 2025; 25(18):5782. https://doi.org/10.3390/s25185782

Chicago/Turabian StyleCukla, Anselmo Rafael, Rafael Crespo Izquierdo, Lucas Strapazzon, Joaquín Ezequiel Taverna, Claudenir Rocha Alves Filho, Sergio Omar Lapczuk, Jorge Antonio Szydlowski, Solon Bevilacqua, and Daniel Fernando Tello Gamarra. 2025. "Construction and Experimental Analysis of a Multipurpose Robotic Fin Ray Gripper for Manipulator Robots" Sensors 25, no. 18: 5782. https://doi.org/10.3390/s25185782

APA StyleCukla, A. R., Crespo Izquierdo, R., Strapazzon, L., Taverna, J. E., Alves Filho, C. R., Lapczuk, S. O., Szydlowski, J. A., Bevilacqua, S., & Tello Gamarra, D. F. (2025). Construction and Experimental Analysis of a Multipurpose Robotic Fin Ray Gripper for Manipulator Robots. Sensors, 25(18), 5782. https://doi.org/10.3390/s25185782