Toward Field Deployment: Tackling the Energy Challenge in Environmental Sensors

Abstract

1. Introduction

2. Active Sensors

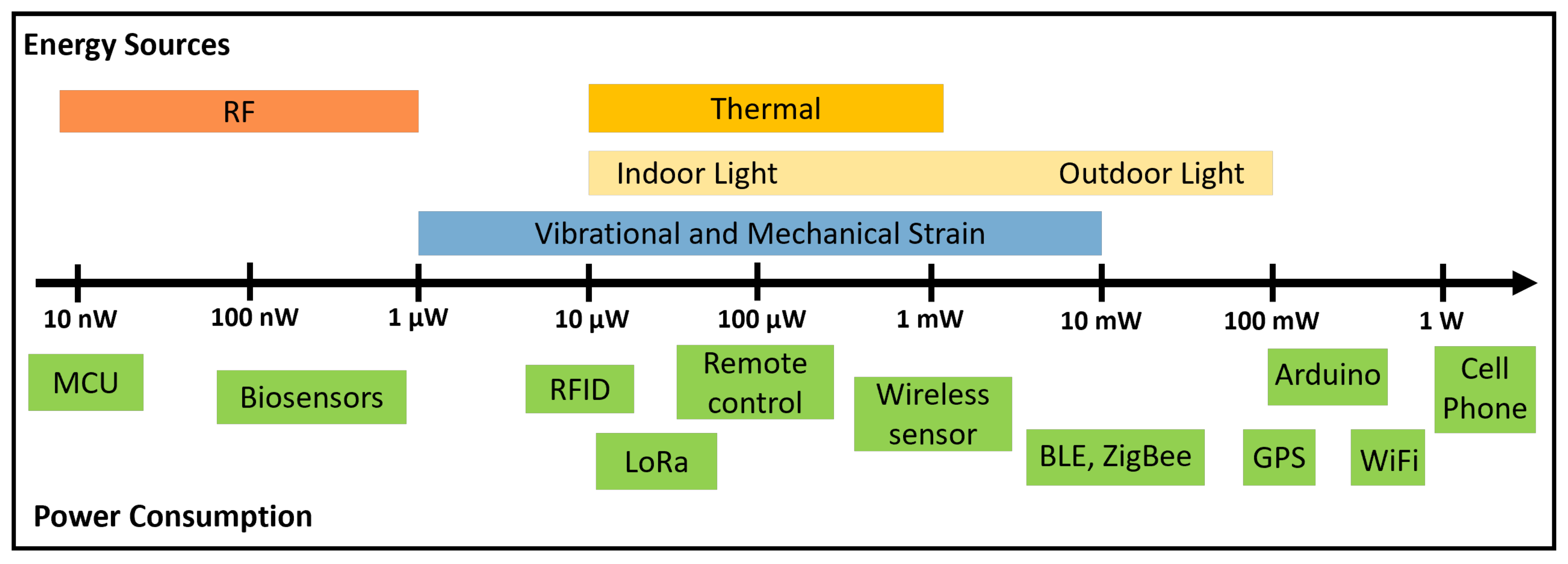

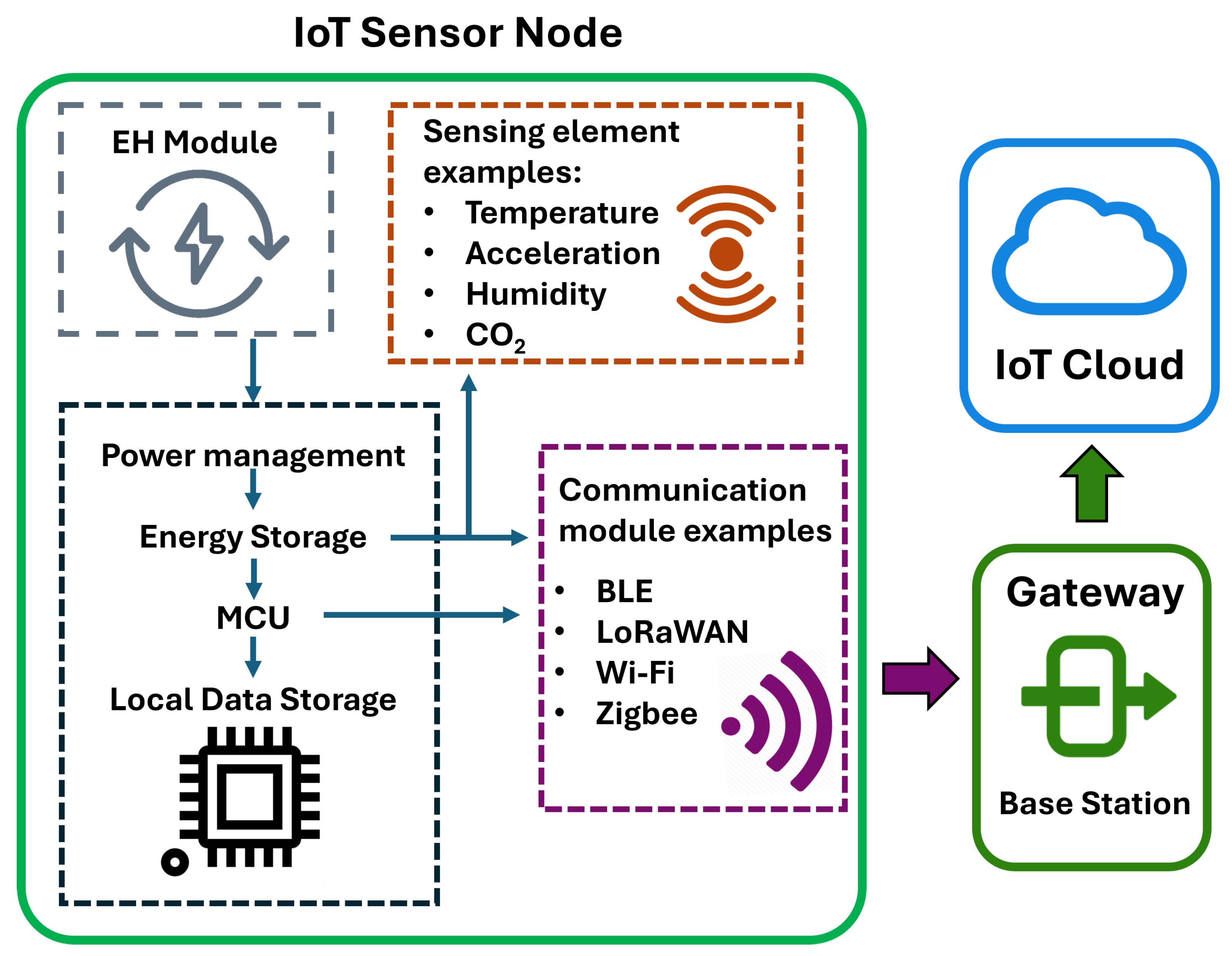

2.1. Autonomy Through Energy Harvesting and Power Management

2.2. Triboelectric Nanogenerator (TENG)

2.2.1. Working Principle

2.2.2. Applications

2.3. Electrochemical Sensors

2.3.1. Working Principle

2.3.2. Applications

2.4. Active Optical Sensors

2.5. Other Non-Optical Sensors

3. Passive Sensors

3.1. Passive Optical Sensors

Applications

3.2. Passive RF Sensors

3.2.1. LC and RFID

Working Principle

- Chipless RFID: the physical structure of the tag acts as both the sensor and the identifier. The tag is generally designed with multiple resonators to have a unique spectral signature (a specific pattern of resonances across different frequencies) and, like LC sensors, some of these resonators can be engineered to be sensitive to an environmental parameter. Sensor data is therefore analogically encoded into the reflected signal.

- Chip-based passive RFID: these tags incorporate an IC and use RF harvesting: a small fraction of the energy from the reader’s RF signal is converted into DC power by a rectifier circuit to operate the tag’s components [129]. These tags can be divided into the following [122]:

- −

- Electromagnetic: the antenna itself is the sensor, similarly to a chipless or an LC sensor.

- −

- Electronic: the sensing and communication functions are separate. The tag consists of an antenna, an IC and a sensor, and sensor data is therefore digitally encoded in the backscattered signal.

Applications

3.2.2. Surface Acoustic Wave Sensors

Working Principle

- Delay Line: In this architecture, the wave can travel to a second, separate IDT for conversion back to an RF signal. Alternatively, in a reflective delay line, it is reflected back to the original IDT. By introducing multiple reflectors to create a unique pattern of reflected signals, a SAW device can also function as a time-encoded RFID tag [125]. Delay line sensors operate by measuring changes in the signal’s time delay or magnitude.

- Resonators: This design uses reflective gratings (Bragg reflectors) to trap the wave in an acoustic cavity between the reflectors. This creates a device with a very sharp and stable resonant frequency, and sensing is mainly achieved by measuring shifts in this frequency.

Applications

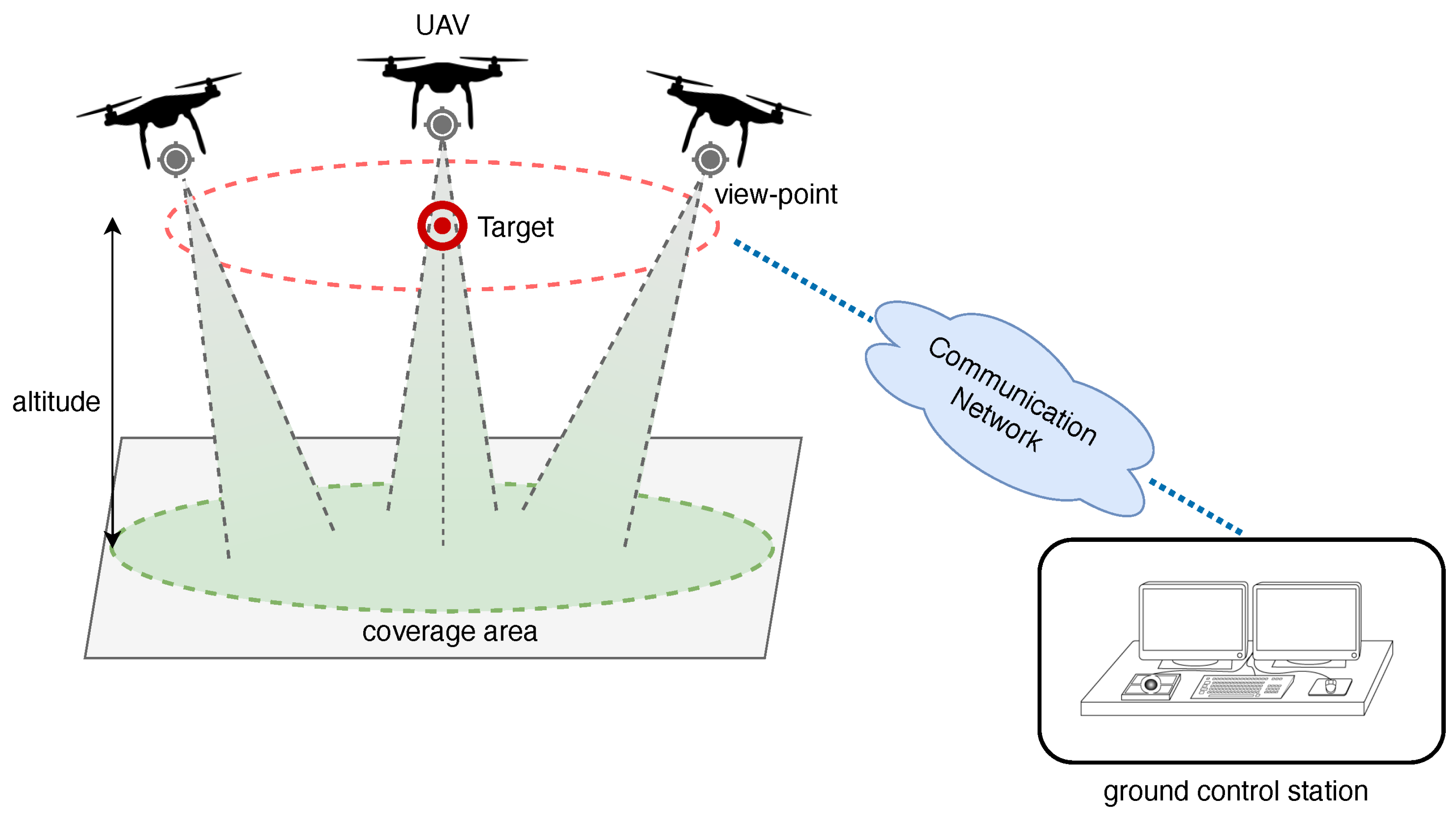

4. Remote Sensing via Drone-Mounted Sensors and AI-Assisted Decisions

5. Discussion and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Yi, W.Y.; Lo, K.M.; Mak, T.; Leung, K.S.; Leung, Y.; Meng, M.L. A Survey of Wireless Sensor Network Based Air Pollution Monitoring Systems. Sensors 2015, 15, 31392–31427. [Google Scholar] [CrossRef] [PubMed]

- Mao, F.; Khamis, K.; Krause, S.; Clark, J.; Hannah, D.M. Low-Cost Environmental Sensor Networks: Recent Advances and Future Directions. Front. Earth Sci. 2019, 7, 221. [Google Scholar] [CrossRef]

- University of California Agriculture and Natural Resources. Roses and Vineyards—Friends or Foe? 2022. Available online: https://ucanr.edu/blog/napa-master-gardener-column/article/roses-and-vineyards-friends-or-foe (accessed on 27 July 2025).

- Guo, Y.; Canning, J.; Chaczko, Z. Towards a bionic IoT: Environmental monitoring using smartphone interrogated plant sensors. PLoS ONE 2023, 18, e0265856. [Google Scholar] [CrossRef] [PubMed]

- Rosa, R.L.; Boulebnane, L.; Pagano, A.; Giuliano, F.; Croce, D. Towards Mass-Scale IoT with Energy-Autonomous LoRaWAN Sensor Nodes. Sensors 2024, 24, 4279. [Google Scholar] [CrossRef]

- Moiş, G.D.; Sanislav, T.; Folea, S.C.; Zeadally, S. Performance Evaluation of Energy-Autonomous Sensors Using Power-Harvesting Beacons for Environmental Monitoring in Internet of Things (IoT). Sensors 2018, 18, 1709. [Google Scholar] [CrossRef]

- Kumar, M.; Khamis, K.; Stevens, R.; Hannah, D.M.; Bradley, C. In-situ optical water quality monitoring sensors—Applications, challenges, and future opportunities. Front. Water 2024, 6, 1380133. [Google Scholar] [CrossRef]

- Hou, L.; Duan, J.; Xiong, F.; Carraro, C.; Shi, T.; Maboudian, R.; Long, H. Low Power Gas Sensors: From Structure to Application. ACS Sens. 2024, 9, 6327–6357. [Google Scholar] [CrossRef]

- Rajab, H.; Al-Amaireh, H.; Bouguera, T.; Cinkler, T. Evaluation of energy consumption of LPWAN technologies. EURASIP J. Wirel. Commun. Netw. 2023, 2023, 118. [Google Scholar] [CrossRef]

- Al-Amri, A.M. Printed Sensors for Environmental Monitoring: Advancements, Challenges, and Future Directions. Chemosensors 2025, 13, 285. [Google Scholar] [CrossRef]

- Ávila, B.Y.L.; Vázquez, C.A.G.; Baluja, O.P.; Cotfas, D.T.; Cotfas, P.A. Energy harvesting techniques for wireless sensor networks: A systematic literature review. Energy Strategy Rev. 2025, 57, 101617. [Google Scholar] [CrossRef]

- Zahedi, A.; Liyanapathirana, R.; Thiyagarajan, K. Biodegradable and Renewable Antennas for Green IoT Sensors: A Review. IEEE Access 2024, 12, 189749–189775. [Google Scholar] [CrossRef]

- Slabov, V.; Kopyl, S.; Soares dos Santos, M.P.; Kholkin, A.L. Natural and Eco-Friendly Materials for Triboelectric Energy Harvesting. Nano-Micro Lett. 2020, 12, 42. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, T.; Zhang, D. Using the internet of things in smart energy systems and networks. Sustain. Cities Soc. 2021, 68, 102783. [Google Scholar] [CrossRef]

- Gljušćić, P.; Zelenika, S.; Blažević, D.; Kamenar, E. Kinetic energy harvesting for wearable medical sensors. Sensors 2019, 19, 4922. [Google Scholar] [CrossRef]

- Roy, S.; Azad, A.W.; Baidya, S.; Alam, M.K.; Khan, F. Powering solutions for biomedical sensors and implants inside the human body: A comprehensive review on energy harvesting units, energy storage, and wireless power transfer techniques. IEEE Trans. Power Electron. 2022, 37, 12237–12263. [Google Scholar] [CrossRef]

- Hwang, S.; Yasuda, T. Indoor photovoltaic energy harvesting based on semiconducting π-conjugated polymers and oligomeric materials toward future IoT applications. Polym. J. 2023, 55, 297–316. [Google Scholar] [CrossRef]

- La Rosa, R.; Dehollain, C.; Burg, A.; Costanza, M.; Livreri, P. An energy-autonomous wireless sensor with simultaneous energy harvesting and ambient light sensing. IEEE Sens. J. 2021, 21, 13744–13752. [Google Scholar] [CrossRef]

- Clementi, G.; Cottone, F.; Di Michele, A.; Gammaitoni, L.; Mattarelli, M.; Perna, G.; López-Suárez, M.; Baglio, S.; Trigona, C.; Neri, I. Review on Innovative Piezoelectric Materials for Mechanical Energy Harvesting. Energies 2022, 15, 6227. [Google Scholar] [CrossRef]

- Elfrink, R.; Kamel, T.; Goedbloed, M.; Matova, S.; Hohlfeld, D.; Van Andel, Y.; Van Schaijk, R. Vibration energy harvesting with aluminum nitride-based piezoelectric devices. J. Micromech. Microeng. 2009, 19, 094005. [Google Scholar] [CrossRef]

- Clementi, G.; Costanza, M.; Ouhabaz, M.; Bartasyte, A.; Dulmet, B.; Margueron, S. 2D+ 1 degree of freedom equivalent circuit model for LiNbO3/metal/LiNbO3 bimorph bending cantilever. Sens. Actuators A Phys. 2023, 362, 114606. [Google Scholar] [CrossRef]

- Sukumaran, S.; Chatbouri, S.; Rouxel, D.; Tisserand, E.; Thiebaud, F.; Ben Zineb, T. Recent advances in flexible PVDF based piezoelectric polymer devices for energy harvesting applications. J. Intell. Mater. Syst. Struct. 2021, 32, 746–780. [Google Scholar] [CrossRef]

- Clementi, G.; Lombardi, G.; Margueron, S.; Suarez, M.A.; Lebrasseur, E.; Ballandras, S.; Imbaud, J.; Lardet-Vieudrin, F.; Gauthier-Manuel, L.; Dulmet, B.; et al. LiNbO3 films–A low-cost alternative lead-free piezoelectric material for vibrational energy harvesters. Mech. Syst. Signal Process. 2021, 149, 107171. [Google Scholar] [CrossRef]

- Panayanthatta, N.; Clementi, G.; Ouhabaz, M.; Costanza, M.; Margueron, S.; Bartasyte, A.; Basrour, S.; Bano, E.; Montes, L.; Dehollain, C.; et al. A self-powered and battery-free vibrational energy to time converter for wireless vibration monitoring. Sensors 2021, 21, 7503. [Google Scholar] [CrossRef]

- Yahya Alkhalaf, H.; Yazed Ahmad, M.; Ramiah, H. Self-sustainable biomedical devices powered by RF energy: A review. Sensors 2022, 22, 6371. [Google Scholar] [CrossRef] [PubMed]

- Paterova, T.; Prauzek, M.; Konecny, J.; Ozana, S.; Zmij, P.; Stankus, M.; Weise, D.; Pierer, A. Environment-monitoring IoT devices powered by a TEG which converts thermal flux between air and near-surface soil into electrical energy. Sensors 2021, 21, 8098. [Google Scholar] [CrossRef] [PubMed]

- Shirvanimoghaddam, M.; Shirvanimoghaddam, K.; Abolhasani, M.M.; Farhangi, M.; Barsari, V.Z.; Liu, H.; Dohler, M.; Naebe, M. Towards a green and self-powered Internet of Things using piezoelectric energy harvesting. IEEE Access 2019, 7, 94533–94556. [Google Scholar] [CrossRef]

- Kanoun, O.; Bradai, S.; Khriji, S.; Bouattour, G.; El Houssaini, D.; Ben Ammar, M.; Naifar, S.; Bouhamed, A.; Derbel, F.; Viehweger, C. Energy-aware system design for autonomous wireless sensor nodes: A comprehensive review. Sensors 2021, 21, 548. [Google Scholar] [CrossRef]

- Javaid, S.; Fahim, H.; Zeadally, S.; He, B. Self-powered sensors: Applications, challenges, and solutions. IEEE Sens. J. 2023, 23, 20483–20509. [Google Scholar] [CrossRef]

- Shaukat, H.; Ali, A.; Ali, S.; Altabey, W.A.; Noori, M.; Kouritem, S.A. Applications of sustainable hybrid energy harvesting: A review. J. Low Power Electron. Appl. 2023, 13, 62. [Google Scholar] [CrossRef]

- Brusa, E.; Carrera, A.; Delprete, C. A review of piezoelectric energy harvesting: Materials, design, and readout circuits. Actuators 2023, 12, 457. [Google Scholar] [CrossRef]

- Chéour, R.; Jmal, M.W.; Khriji, S.; El Houssaini, D.; Trigona, C.; Abid, M.; Kanoun, O. Towards hybrid energy-efficient power management in wireless sensor networks. Sensors 2021, 22, 301. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, S.; Giwa, A. Advances in real-time water quality monitoring using triboelectric nanosensors. J. Mater. Chem. A 2025, 13, 11134–11158. [Google Scholar] [CrossRef]

- He, C.; Zhu, W.; Gu, G.Q.; Jiang, T.; Xu, L.; Chen, B.D.; Han, C.B.; Li, D.; Wang, Z.L. Integrative square-grid triboelectric nanogenerator as a vibrational energy harvester and impulsive force sensor. Nano Res. 2018, 11, 1157–1164. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Jiang, Y.; Liang, X.; Jiang, T.; Wang, Z.L. Advances in Triboelectric Nanogenerators for Blue Energy Harvesting and Marine Environmental Monitoring. Engineering 2024, 33, 204–224. [Google Scholar] [CrossRef]

- Wu, J.; Zheng, Y.; Li, X. Recent progress in self-powered sensors based on triboelectric nanogenerators. Sensors 2021, 21, 7129. [Google Scholar] [CrossRef]

- Bai, Y.; Xu, L.; He, C.; Zhu, L.; Yang, X.; Jiang, T.; Nie, J.; Zhong, W.; Wang, Z.L. High-performance triboelectric nanogenerators for self-powered, in-situ and real-time water quality mapping. Nano Energy 2019, 66, 104117. [Google Scholar] [CrossRef]

- Liu, W.; Xu, L.; Bu, T.; Yang, H.; Liu, G.; Li, W.; Pang, Y.; Hu, C.; Zhang, C.; Cheng, T. Torus structured triboelectric nanogenerator array for water wave energy harvesting. Nano Energy 2019, 58, 499–507. [Google Scholar] [CrossRef]

- Wang, X.; Niu, S.; Yin, Y.; Yi, F.; You, Z.; Wang, Z.L. Triboelectric Nanogenerator Based on Fully Enclosed Rolling Spherical Structure for Harvesting Low-Frequency Water Wave Energy. Adv. Energy Mater. 2015, 5, 1501467. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Ning, A. Optimization of a Rolling Triboelectric Nanogenerator Based on the Nano-Micro Structure for Ocean Environmental Monitoring. ACS Omega 2021, 6, 21059–21065. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, J.; Bian, C.; Tong, J.; Xia, S. A MEMS-based multi-parameter integrated chip and its portable system forwater quality detection. Micromachines 2020, 11, 63. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.H.; Zhu, G.; Zhou, Y.S.; Yang, Y.; Bai, P.; Chen, J.; Wang, Z.L. A self-powered triboelectric nanosensor for mercury ion detection. Angew. Chem.—Int. Ed. 2013, 52, 5065–5069. [Google Scholar] [CrossRef] [PubMed]

- Bhaduri, A.; Ha, T.J. Biowaste-Derived Triboelectric Nanogenerators for Emerging Bioelectronics. Adv. Sci. 2024, 11, 2405666. [Google Scholar] [CrossRef] [PubMed]

- Troncoso, O.P.; Corman-Hijar, J.I.; Torres, F.G. Lignocellulosic Biomass for the Fabrication of Triboelectric Nano-Generators (TENGs)—A Review. Int. J. Mol. Sci. 2023, 24, 15784. [Google Scholar] [CrossRef]

- Du, T.; Chen, Z.; Dong, F.; Cai, H.; Zou, Y.; Zhang, Y.; Sun, P.; Xu, M. Advances in Green Triboelectric Nanogenerators. Adv. Funct. Mater. 2024, 34, 2313794. [Google Scholar] [CrossRef]

- Luo, Y.; Cao, X.; Wang, Z.L. Self-powered smart agriculture sensing using triboelectric nanogenerators based on living plant leaves. Nano Energy 2023, 107, 108097. [Google Scholar] [CrossRef]

- Zhang, R.; Hummelgård, M.; Örtegren, J.; Song, M.; Olsen, M.; Andersson, H.; Blomquist, N.; Olin, H. High performance single material-based triboelectric nanogenerators made of hetero-triboelectric half-cell plant skins. Nano Energy 2022, 94, 106959. [Google Scholar] [CrossRef]

- Panda, S.; Jeong, H.; Hajra, S.; Rajaitha, P.M.; Hong, S.; Kim, H.J. Biocompatible polydopamine based triboelectric nanogenerator for humidity sensing. Sens. Actuators B Chem. 2023, 394, 134384. [Google Scholar] [CrossRef]

- Liu, H.; Wang, H.; Fan, Y.; Lyu, Y.; Liu, Z. A triboelectric nanogenerator based on white sugar for self-powered humidity sensor. Solid-State Electron. 2020, 174, 107920. [Google Scholar] [CrossRef]

- Zhang, R.; Xia, R.; Cao, X.; Wang, N. Nutshell Powder-Based Green Triboelectric Nanogenerator for Wind Energy Harvesting. Adv. Mater. Interfaces 2022, 9, 2200293. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, X.; Wu, Y.; Zhang, H.; Lin, Z.; Meng, K.; Lin, Z.; He, Q.; Sun, C.C.; Yang, J.; et al. Wireless self-powered sensor networks driven by triboelectric nanogenerator for in-situ real time survey of environmental monitoring. Nano Energy 2018, 53, 501–507. [Google Scholar] [CrossRef]

- Gu, G.; Gu, G.; Shang, W.; Zhang, Z.; Zhang, W.; Wang, C.; Fang, D.; Cheng, G.; Du, Z. The self-powered agricultural sensing system with 1.7 km wireless multichannel signal transmission using a pulsed triboelectric nanogenerator of corn husk composite film. Nano Energy 2022, 102, 107699. [Google Scholar] [CrossRef]

- Zhao, H.; Xu, M.; Shu, M.; An, J.; Ding, W.; Liu, X.; Wang, S.; Zhao, C.; Yu, H.; Wang, H.; et al. Underwater wireless communication via TENG-generated Maxwell’s displacement current. Nat. Commun. 2022, 13, 3325. [Google Scholar] [CrossRef]

- Ge, H.; Zhao, S.; Dai, B.; Chen, S.; Pan, Y.; Lu, Y.; Xie, Y.; Jiang, C. Acoustic triboelectric nanogenerator for underwater acoustic communication. Nano Energy 2025, 136, 110738. [Google Scholar] [CrossRef]

- Zhang, C.; Hao, Y.; Yang, J.; Su, W.; Zhang, H.; Wang, J.; Wang, Z.L.; Li, X. Recent Advances in Triboelectric Nanogenerators for Marine Exploitation. Adv. Energy Mater. 2023, 13, 2300387. [Google Scholar] [CrossRef]

- Popoola, O.A.; Stewart, G.B.; Mead, M.I.; Jones, R.L. Development of a baseline-temperature correction methodology for electrochemical sensors and its implications for long-term stability. Atmos. Environ. 2016, 147, 330–343. [Google Scholar] [CrossRef]

- Biyani, M.; Biyani, R.; Tsuchihashi, T.; Takamura, Y.; Ushijima, H.; Tamiya, E.; Biyani, M. DEP-On-gO for simultaneous sensing of multiple heavy metals pollutants in environmental samples. Sensors 2017, 17, 45. [Google Scholar] [CrossRef]

- Baranwal, J.; Barse, B.; Gatto, G.; Broncova, G.; Kumar, A. Electrochemical Sensors and Their Applications: A Review. Chemosensors 2022, 10, 363. [Google Scholar] [CrossRef]

- Zhu, C.; Yang, G.; Li, H.; Du, D.; Lin, Y. Electrochemical sensors and biosensors based on nanomaterials and nanostructures. Anal. Chem. 2015, 87, 230–249. [Google Scholar] [CrossRef]

- Nazemi, H.; Joseph, A.; Park, J.; Emadi, A. Advanced micro-and nano-gas sensor technology: A review. Sensors 2019, 19, 1285. [Google Scholar] [CrossRef]

- Dincer, C.; Bruch, R.; Costa-Rama, E.; Fernández-Abedul, M.T.; Merkoçi, A.; Manz, A.; Urban, G.A.; Güder, F. Disposable Sensors in Diagnostics, Food, and Environmental Monitoring. Adv. Mater. 2019, 31, 1806739. [Google Scholar] [CrossRef]

- Mastouri, H.; Remaidi, M.; Ennawaoui, A.; Derraz, M.; Ennawaoui, C. Advanced Self-Powered Sensor for Carbon Dioxide Monitoring Utilizing Surface Acoustic Wave (SAW) Technology. Energies 2025, 18, 3082. [Google Scholar] [CrossRef]

- Díaz-González, M.; Gutiérrez-Capitán, M.; Niu, P.; Baldi, A.; Jiménez-Jorquera, C.; Fernández-Sánchez, C. Electrochemical devices for the detection of priority pollutants listed in the EU water framework directive. TrAC—Trends Anal. Chem. 2016, 77, 186–202. [Google Scholar] [CrossRef]

- Khanmohammadi, A.; Ghazizadeh, A.J.; Hashemi, P.; Afkhami, A.; Arduini, F.; Bagheri, H. An overview to electrochemical biosensors and sensors for the detection of environmental contaminants. J. Iran. Chem. Soc. 2020, 17, 2429–2447. [Google Scholar] [CrossRef]

- Hanafi, R.; Mayasari, R.D.; Masmui; Agustanhakri; Raharjo, J.; Nuryadi, R. Electrochemical sensor for environmental monitoring system: A review. In AIP Conference Proceedings; American Institute of Physics Inc.: New York, NY, USA, 2019; Volume 2169. [Google Scholar] [CrossRef]

- Moro, G.; Wael, K.D.; Moretto, L.M. Challenges in the electrochemical (bio)sensing of nonelectroactive food and environmental contaminants. Curr. Opin. Electrochem. 2019, 16, 57–65. [Google Scholar] [CrossRef]

- Donar, Y.O.; Bilge, S.; Bayramoğlu, D.; Özoylumlu, B.; Ergenekon, S.; Sınağ, A. Recent developments and modification strategies in electrochemical sensors based on green nanomaterials for catechol detection. Trends Environ. Anal. Chem. 2024, 41, e00223. [Google Scholar] [CrossRef]

- Koyappayil, A.; Seok, H.; Choi, G.H.; Chavan, S.; Yeon, S.; Son, S.; Go, A.; Lee, J.; Kim, K.W.; Lee, D.; et al. Mesoporous WO3-Dot-Decorated Flexible Electrodes for the Determination of Industrial Pollutants. Energy Environ. Mater. 2025, 8, e12842. [Google Scholar] [CrossRef]

- Lee, J.; Kim, M.C.; Soltis, I.; Lee, S.H.; Yeo, W. Advances in Electrochemical Sensors for Detecting Analytes in Biofluids. Adv. Sens. Res. 2023, 2, 2200088. [Google Scholar] [CrossRef]

- Benjamin, S.R.; Júnior, E.J.M.R. Graphene-Based electrochemical sensors for detection of environmental pollutants. Curr. Opin. Environ. Sci. Health 2022, 29, 100381. [Google Scholar] [CrossRef]

- Maduraiveeran, G.; Jin, W. Nanomaterials based electrochemical sensor and biosensor platforms for environmental applications. Trends Environ. Anal. Chem. 2017, 13, 10–23. [Google Scholar] [CrossRef]

- Tajik, S.; Beitollahi, H.; Nejad, F.G.; Dourandish, Z.; Khalilzadeh, M.A.; Jang, H.W.; Venditti, R.A.; Varma, R.S.; Shokouhimehr, M. Recent developments in polymer nanocomposite-based electrochemical sensors for detecting environmental pollutants. Ind. Eng. Chem. Res. 2021, 60, 1112–1136. [Google Scholar] [CrossRef]

- Wang, L.; Ma, W.; Xu, L.; Chen, W.; Zhu, Y.; Xu, C.; Kotov, N.A. Nanoparticle-based environmental sensors. Mater. Sci. Eng. R Rep. 2010, 70, 265–274. [Google Scholar] [CrossRef]

- Sailapu, S.K.; Menon, C. Engineering Self-Powered Electrochemical Sensors Using Analyzed Liquid Sample as the Sole Energy Source. Adv. Sci. 2022, 9, 2203690. [Google Scholar] [CrossRef]

- Grattieri, M.; Minteer, S.D. Self-Powered Biosensors. ACS Sens. 2018, 3, 44–53. [Google Scholar] [CrossRef]

- del Campo, F.J. Self-powered electrochemical sensors. Curr. Opin. Electrochem. 2023, 41, 101356. [Google Scholar] [CrossRef]

- Naik, S.; Jujjavarapu, S.E. Self-powered and reusable microbial fuel cell biosensor for toxicity detection in heavy metal polluted water. J. Environ. Chem. Eng. 2021, 9, 105318. [Google Scholar] [CrossRef]

- Sailapu, S.K.; Sabaté, N.; Bakker, E. Self-Powered Potentiometric Sensors with Memory. ACS Sens. 2021, 6, 3650–3656. [Google Scholar] [CrossRef]

- Sheikhyousefi, P.R.; Esfahany, M.N.; Colombo, A.; Franzetti, A.; Trasatti, S.P.; Cristiani, P. Investigation of different configurations of microbial fuel cells for the treatment of oilfield produced water. Appl. Energy 2017, 192, 457–465. [Google Scholar] [CrossRef]

- Sandsten, J. Development of Infrared Spectroscopy Techniques for Environmental Monitoring. Ph.D. Thesis, Lund University, Lund, Sweden, 2000. [Google Scholar]

- Kim, K.J.; Culp, J.T.; Ellis, J.E.; Reeder, M.D. Real-time monitoring of gas-phase and dissolved CO2 using a mixed-matrix composite integrated fiber optic sensor for carbon storage application. Environ. Sci. Technol. 2022, 56, 10891–10903. [Google Scholar] [CrossRef]

- Rolle, F.; Cara, E.; Romeo, C.; Fretto, M.; Angelini, A.; Bonino, V.; Gatti, G.; Cossi, M.; Marchese, L.; Durbiano, F.; et al. Development of miniaturised sensors for methane detection at trace levels for environmental monitoring applications. Meas. Sens. 2025, 38, 101766. [Google Scholar] [CrossRef]

- Fu, B.; Zhang, C.; Lyu, W.; Sun, J.; Shang, C.; Cheng, Y.; Xu, L. Recent progress on laser absorption spectroscopy for determination of gaseous chemical species. Appl. Spectrosc. Rev. 2022, 57, 112–152. [Google Scholar] [CrossRef]

- Zeng, Y.; Hao, D.; Huete, A.; Dechant, B.; Berry, J.; Chen, J.M.; Joiner, J.; Frankenberg, C.; Bond-Lamberty, B.; Ryu, Y.; et al. Optical vegetation indices for monitoring terrestrial ecosystems globally. Nat. Rev. Earth Environ. 2022, 3, 477–493. [Google Scholar] [CrossRef]

- Haque, M.A.; Reza, M.N.; Ali, M.; Karim, M.R.; Ahmed, S.; Lee, K.D.; Khang, Y.H.; Chung, S.O. Effects of environmental conditions on vegetation indices from multispectral images: A review. Korean J. Remote Sens. 2024, 40, 319–341. [Google Scholar] [CrossRef]

- Ma, J.; Ma, R.; Pan, Q.; Liang, X.; Wang, J.; Ni, X. A global review of progress in remote sensing and monitoring of marine pollution. Water 2023, 15, 3491. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, J.; Cao, Y.; Fu, J.; Li, B.; Sun, G.; Zhang, X.; Xu, C. Leaf reflectance and functional traits as environmental indicators of urban dust deposition. BMC Plant Biol. 2021, 21, 533. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, X.; Wang, Z.; Jiang, M.; Zhou, Z.; Xu, M.; Han, J.; Yang, B.; Fan, X. On-line measurement of ultralow mass concentration particulate based on light scattering coupled with beta ray attenuation method. Fuel 2022, 329, 125461. [Google Scholar] [CrossRef]

- Han, J.; Liu, X.; Jiang, M.; Wang, Z.; Xu, M. A novel light scattering method with size analysis and correction for on-line measurement of particulate matter concentration. J. Hazard. Mater. 2021, 401, 123721. [Google Scholar] [CrossRef]

- Bandeliuk, O.; Assaf, A.; Bittel, M.; Durand, M.J.; Thouand, G. Development and automation of a bacterial biosensor to the targeting of the pollutants toxic effects by Portable Raman Spectrometer. Sensors 2022, 22, 4352. [Google Scholar] [CrossRef]

- Liu, Y.; Paris, J.; Vrekoussis, M.; Antoniou, P.; Constantinides, C.; Desservettaz, M.; Keleshis, C.; Laurent, O.; Leonidou, A.; Philippon, C.; et al. Improvements of a low-cost CO2 commercial nondispersive near-infrared (NDIR) sensor for unmanned aerial vehicle (UAV) atmospheric mapping applications. Atmos. Meas. Tech. 2022, 15, 4431–4442. [Google Scholar] [CrossRef]

- Tinivelli, P.; Cardellini, C.; Clementi, G.; Fanò, L.; Mattarelli, M.; Neri, I.; Turrioni, C.; Cottone, F. An Autonomous Sensing System for Monitoring Dissolved Carbon Dioxide of Naturl Water for Geochemical Applications. In Proceedings of the IEEE 2022 21st International Conference on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS), Salt Lake City, UT, USA, 12–15 December 2022; pp. 294–297. [Google Scholar] [CrossRef]

- Chen, A.; Wang, S.; Liu, Y.; Yan, S.; Zeng, J.; Deng, T. Light scattering intensity field imaging sensor for in situ aerosol analysis. ACS Sens. 2020, 5, 2061–2066. [Google Scholar] [CrossRef]

- Molaie, S.; Lino, P. Review of the newly developed, mobile optical sensors for real-time measurement of the atmospheric particulate matter concentration. Micromachines 2021, 12, 416. [Google Scholar] [CrossRef]

- Xu, C.; Nie, W.; Peng, H.; Li, H.; Wan, J. Enhancing dust concentration monitoring in high particulate matter environments: A dual-light source particulate matter sensor approach based on Mie scattering. Sens. Actuators A Phys. 2025, 387, 116348. [Google Scholar] [CrossRef]

- Kim, D.; Kang, H.; Ryu, J.Y.; Jun, S.C.; Yun, S.T.; Choi, S.; Park, S.; Yoon, M.; Lee, H. Development of Raman lidar system for remote sensing of CO2 leakage at a carbon capture and storage site. Remote Sens. 2018, 10, 1439. [Google Scholar] [CrossRef]

- Mazumder, J.T.; Jha, R.K.; Kim, H.W.; Kim, S.S. Capacitive Toxic Gas Sensors Based on Oxide Composites: A Review. IEEE Sens. J. 2023, 23, 17842–17853. [Google Scholar] [CrossRef]

- Chiappini, A.; Tran, L.T.N.; Trejo-García, P.M.; Zur, L.; Lukowiak, A.; Ferrari, M.; Righini, G.C. Photonic Crystal Stimuli-Responsive Chromatic Sensors: A Short Review. Micromachines 2020, 11, 290. [Google Scholar] [CrossRef] [PubMed]

- Supian, A.B.M.; Asyraf, M.R.M.; Syamsir, A.; Najeeb, M.I.; Alhayek, A.; Al-Dala’ien, R.N.; Manar, G.; Atiqah, A. Thermochromic Polymer Nanocomposites for the Heat Detection System: Recent Progress on Properties, Applications, and Challenges. Polymers 2024, 16, 1545. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Pyo, M.; Lee, S.H.; Kim, J.; Ra, M.; Kim, W.Y.; Park, B.J.; Lee, C.W.; Kim, J.M. Hydrochromic conjugated polymers for human sweat pore mapping. Nat. Commun. 2014, 5, 3736. [Google Scholar] [CrossRef]

- Lee, S.; Lee, E.H.; Lee, S.W. A Flexible and Attachable Colorimetric Film Sensor for the Detection of Gaseous Ammonia. Biosensors 2022, 12, 664. [Google Scholar] [CrossRef]

- Campanella, C.E.; Cuccovillo, A.; Campanella, C.; Yurt, A.; Passaro, V.M.N. Fibre Bragg Grating based strain sensors: Review of technology and applications. Sensors 2018, 18, 3115. [Google Scholar] [CrossRef]

- Li, T.; Liu, G.; Kong, H.; Yang, G.; Wei, G.; Zhou, X. Recent advances in photonic crystal-based sensors. Coord. Chem. Rev. 2023, 475, 214909. [Google Scholar] [CrossRef]

- Liu, B.; Zhuang, J.; Wei, G. Recent advances in the design of colorimetric sensors for environmental monitoring. Environ. Sci. Nano 2020, 7, 2195–2213. [Google Scholar] [CrossRef]

- Butt, M.A.; Voronkov, G.S.; Grakhova, E.P.; Kutluyarov, R.V.; Kazanskiy, N.L.; Khonina, S.N. Environmental Monitoring: A Comprehensive Review on Optical Waveguide and Fiber-Based Sensors. Biosensors 2022, 12, 1038. [Google Scholar] [CrossRef]

- Jung, S.H.; Lee, H.T.; Park, M.J.; Lim, B.; Park, B.C.; Jung, Y.J.; Kong, H.; Hwang, D.H.; Lee, H.i.; Park, J.M. Precisely Tunable Humidity Color Indicator Based on Photonic Polymer Films. Macromolecules 2021, 54, 621–628. [Google Scholar] [CrossRef]

- Yi, H.; Lee, S.H.; Kim, D.; Jeong, H.E.; Jeong, C. Colorimetric Sensor Based on Hydroxypropyl Cellulose for Wide Temperature Sensing Range. Sensors 2022, 22, 886. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, S.H.; Girma, H.G.; Jeon, S.; Lim, B.; Jung, S.H. Dual Responsive Dependent Background Color Based on Thermochromic 1D Photonic Crystal Multilayer Films. Polymers 2022, 14, 5330. [Google Scholar] [CrossRef]

- Kim, S.; Han, S.G.; Koh, Y.G.; Lee, H.; Lee, W. Colorimetric Humidity Sensor Using Inverse Opal Photonic Gel in Hydrophilic Ionic Liquid. Sensors 2018, 18, 1357. [Google Scholar] [CrossRef]

- Sobhanimatin, M.B.; Pourmahdian, S.; Tehranchi, M.M. Colorimetric monitoring of humidity by opal photonic hydrogel. Polym. Test. 2021, 98, 106999. [Google Scholar] [CrossRef]

- Nettey-Oppong, E.E.; Muhammad, R.; Yoo, D.; Hwang, S.H.; Ali, A.; Mwita, C.S.; Jeong, H.W.; Kim, S.W.; Seok, Y.S.; Choi, S.H. The Use of Biomass-Derived Chitosan for Colorimetric pH Detection. Photonics 2025, 12, 231. [Google Scholar] [CrossRef]

- Choi, H.; Seo, J.H.; Weon, S. Visualizing indoor ozone exposures via o-dianisidine based colorimetric passive sampler. J. Hazard. Mater. 2023, 460, 132510. [Google Scholar] [CrossRef]

- Cencillo-Abad, P.; Mastranzo-Ortega, P.; Appavoo, D.; Guo, T.; Zhai, L.; Sanchez-Mondragon, J.; Chanda, D. Reusable Structural Colored Nanostructure for Powerless Temperature and Humidity Sensing. Adv. Opt. Mater. 2023, 11, 2300300. [Google Scholar] [CrossRef]

- Urbano, B.F.; Bustamante, S.; Palacio, D.A.; Vera, M.; Rivas, B.L. Polymer-based chromogenic sensors for the detection of compounds of environmental interest. Polym. Int. 2021, 70, 1202–1208. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Shi, J.; Huang, X.; Sun, Z.; Zhang, D.; Zou, X.; Sun, Y.; Zhang, J.; Holmes, M.; et al. A colorimetric hydrogen sulfide sensor based on gellan gum-silver nanoparticles bionanocomposite for monitoring of meat spoilage in intelligent packaging. Food Chem. 2019, 290, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Chemla, Y.; Levin, I.; Fan, Y.; Johnson, A.A.; Coley, C.W.; Voigt, C.A. Hyperspectral reporters for long-distance and wide-area detection of gene expression in living bacteria. Nat. Biotechnol. 2025. [Google Scholar] [CrossRef] [PubMed]

- He, D.; Cui, Y.; Ming, F.; Wu, W. Advancements in Passive Wireless Sensors, Materials, Devices, and Applications. Sensors 2023, 23, 8200. [Google Scholar] [CrossRef]

- Dimitrov, K.C.; Song, S.; Chang, H.; Lim, T.; Lee, Y.; Kwak, B.J. Interdigital Capacitor-Based Passive LC Resonant Sensor for Improved Moisture Sensing. Sensors 2020, 20, 6306. [Google Scholar] [CrossRef]

- Mulloni, V.; Donelli, M. Chipless RFID Sensors for the Internet of Things: Challenges and Opportunities. Sensors 2020, 20, 2135. [Google Scholar] [CrossRef]

- Costa, F.; Genovesi, S.; Borgese, M.; Michel, A.; Dicandia, F.A.; Manara, G. A Review of RFID Sensors, the New Frontier of Internet of Things. Sensors 2021, 21, 3138. [Google Scholar] [CrossRef]

- Huang, Q.A.; Dong, L.; Wang, L.F. LC Passive Wireless Sensors Toward a Wireless Sensing Platform: Status, Prospects, and Challenges. J. Microelectromech. Syst. 2016, 25, 822–841. [Google Scholar] [CrossRef]

- Masud, M.; Vazquez, P.; Rehman, M.R.U.; Elahi, A.; Wijns, W.; Shahzad, A. Measurement Techniques and Challenges of Wireless LC Resonant Sensors: A Review. IEEE Access 2023, 11, 95235–95252. [Google Scholar] [CrossRef]

- Finkenzeller, K. RFID Handbook: Fundamentals and Applications in Contactless Smart Cards, Radio Frequency Identification and near-Field Communication, 3rd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Stockman, H. Communication by Means of Reflected Power. Proc. IRE 1948, 36, 1196–1204. [Google Scholar] [CrossRef]

- Smolders, A.B.; Visser, H.J.; Johannsen, U. Modern Antennas and Microwave Circuits—A Complete Master-Level Course. arXiv 2022. [Google Scholar] [CrossRef]

- Barbot, N.; Rance, O.; Perret, E. Classical RFID Versus Chipless RFID Read Range: Is Linearity a Friend or a Foe? IEEE Trans. Microw. Theory Tech. 2021, 69, 4199–4208. [Google Scholar] [CrossRef]

- Akan, O.B.; Isik, M.T.; Baykal, B. Wireless Passive Sensor Networks. IEEE Commun. Mag. 2009, 47, 92–99. [Google Scholar] [CrossRef]

- Azarfar, A.; Barbot, N.; Perret, E. Chipless RFID Based on Micro-Doppler Effect. IEEE Trans. Microw. Theory Tech. 2022, 70, 766–778. [Google Scholar] [CrossRef]

- Ye, Z.; Yang, M.; Ren, Y.; Hung, C.H.J.; Wu, C.T.M.; Chen, P.Y. Review on Recent Advances and Applications of Passive Harmonic RFID Systems. IEEE J. Radio Freq. Identif. 2023, 7, 118–133. [Google Scholar] [CrossRef]

- Barbot, N.; Perret, E. Linear Time-Variant Chipless RFID Sensor. IEEE J. Radio Freq. Identif. 2022, 6, 104–111. [Google Scholar] [CrossRef]

- Brinker, K.R.; Zoughi, R. A Review of Chipless RFID Measurement Methods, Response Detection Approaches, and Decoding Techniques. IEEE Open J. Instrum. Meas. 2022, 1, 1–31. [Google Scholar] [CrossRef]

- Liu, V.; Parks, A.; Talla, V.; Gollakota, S.; Wetherall, D.; Smith, J.R. Ambient Backscatter: Wireless Communication out of Thin Air. In Proceedings of the ACM SIGCOMM 2013 Conference on SIGCOMM (SIGCOMM ’13), Hong Kong, China, 12–16 August 2013; pp. 39–50. [Google Scholar] [CrossRef]

- Van Huynh, N.; Hoang, D.T.; Lu, X.; Niyato, D.; Wang, P.; Kim, D.I. Ambient Backscatter Communications: A Contemporary Survey. IEEE Commun. Surv. Tutor. 2018, 20, 2889–2922. [Google Scholar] [CrossRef]

- Jamshed, M.A.; Haq, B.; Mohsin, M.A.; Nauman, A.; Yanikomeroglu, H. Artificial Intelligence, Ambient Backscatter Communication and Non-Terrestrial Networks: A 6G Commixture. IEEE Internet Things Mag. 2025, 8, 88–94. [Google Scholar] [CrossRef]

- Chan, Y.J.; Carr, A.R.; Roy, S.; Washburn, C.M.; Neihart, N.M.; Reuel, N.F. Positionally-Independent and Extended Read Range Resonant Sensors Applied to Deep Soil Moisture Monitoring. Sens. Actuators A Phys. 2022, 333, 113227. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Waimin, J.; Raghunathan, N.; Bagchi, S.; Shakouri, A.; Rahimi, R. Battery-Less Wireless Chipless Sensor Tag for Subsoil Moisture Monitoring. IEEE Sens. J. 2021, 21, 6071–6082. [Google Scholar] [CrossRef]

- Dey, S.; Amin, E.M.; Karmakar, N.C. Paper Based Chipless RFID Leaf Wetness Detector for Plant Health Monitoring. IEEE Access 2020, 8, 191986–191996. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Waimin, J.; Zareei, A.; Sedaghat, S.; Raghunathan, N.; Shakouri, A.; Rahimi, R. A Biodegradable Chipless Sensor for Wireless Subsoil Health Monitoring. Sci. Rep. 2022, 12, 8011. [Google Scholar] [CrossRef] [PubMed]

- Sakabe, K.; Kan, T.; Onoe, H. Entirely Biodegradable Wireless pH Sensor with Split-Ring Resonators for Soil pH Monitoring. Adv. Mater. Technol. 2024, 9, 2400038. [Google Scholar] [CrossRef]

- Hasan, A.; Bhattacharyya, R.; Sarma, S. Towards Pervasive Soil Moisture Sensing Using RFID Tag Antenna-Based Sensors. In Proceedings of the 2015 IEEE International Conference on RFID Technology and Applications (RFID-TA), Tokyo, Japan, 16–18 September 2015; pp. 165–170. [Google Scholar] [CrossRef]

- Cappelli, I.; Fort, A.; Mugnaini, M.; Panzardi, E.; Pozzebon, A.; Tani, M.; Vignoli, V. Battery-Less HF RFID Sensor Tag for Soil Moisture Measurements. IEEE Trans. Instrum. Meas. 2021, 70, 1–13. [Google Scholar] [CrossRef]

- Deng, F.; Zuo, P.; Wen, K.; Wu, X. Novel Soil Environment Monitoring System Based on RFID Sensor and LoRa. Comput. Electron. Agric. 2020, 169, 105169. [Google Scholar] [CrossRef]

- Zhou, S.; Deng, F.; Yu, L.; Li, B.; Wu, X.; Yin, B. A Novel Passive Wireless Sensor for Concrete Humidity Monitoring. Sensors 2016, 16, 1535. [Google Scholar] [CrossRef]

- Johann, S.; Strangfeld, C.; Müller, M.; Mieller, B.; Bartholmai, M. RFID Sensor Systems Embedded in Concrete—Requirements for Long–Term Operation. Mater. Today Proc. 2017, 4, 5827–5832. [Google Scholar] [CrossRef]

- Lu, D.; Yan, Y.; Deng, Y.; Yang, Q.; Zhao, J.; Seo, M.H.; Bai, W.; MacEwan, M.R.; Huang, Y.; Ray, W.Z.; et al. Bioresorbable Wireless Sensors as Temporary Implants for In Vivo Measurements of Pressure. Adv. Funct. Mater. 2020, 30, 2003754. [Google Scholar] [CrossRef]

- Luo, M.; Martinez, A.W.; Song, C.; Herrault, F.; Allen, M.G. A Microfabricated Wireless RF Pressure Sensor Made Completely of Biodegradable Materials. J. Microelectromech. Syst. 2014, 23, 4–13. [Google Scholar] [CrossRef]

- Palmroth, A.; Salpavaara, T.; Vuoristo, P.; Karjalainen, S.; Kääriäinen, T.; Miettinen, S.; Massera, J.; Lekkala, J.; Kellomäki, M. Materials and Orthopedic Applications for Bioresorbable Inductively Coupled Resonance Sensors. ACS Appl. Mater. Interfaces 2020, 12, 31148–31161. [Google Scholar] [CrossRef] [PubMed]

- Clementi, G.; Neri, I.; Cottone, F.; Di Michele, A.; Mattarelli, M.; Sforna, L.; Chiappalupi, S.; Sorci, G.; Michelucci, A.; Catacuzzeno, L.; et al. Self-powered temperature sensors harnessing membrane potential of living cells. Nano Energy 2024, 121, 109211. [Google Scholar] [CrossRef]

- Wu, S.Y.; Hsu, W. Design and Characterization of LC Strain Sensors with Novel Inductor for Sensitivity Enhancement. Smart Mater. Struct. 2013, 22, 105015. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Q.; Zhang, L.; Lin, B.; Li, M.; Fan, Z. Wireless Passive LC Temperature and Strain Dual-Parameter Sensor. Micromachines 2020, 12, 34. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, S.; Zhang, X. A Flexible Chipless RFID Strain Sensor with High Sensitivity Based on Laser-Induced Graphene. Sens. Actuators A Phys. 2025, 382, 116144. [Google Scholar] [CrossRef]

- Nesser, H.; Mahmoud, H.A.; Lubineau, G. High-Sensitivity RFID Sensor for Structural Health Monitoring. Adv. Sci. 2023, 10, 2301807. [Google Scholar] [CrossRef]

- Shaterian, Z.; Horestani, A.K.; Martín, F.; Mrozowski, M. Design of Novel Highly Sensitive Sensors for Crack Detection in Metal Surfaces: Theoretical Foundation and Experimental Validation. Sci. Rep. 2023, 13, 18540. [Google Scholar] [CrossRef]

- Marindra, A.M.J.; Tian, G.Y. Chipless RFID Sensor Tag for Metal Crack Detection and Characterization. IEEE Trans. Microw. Theory Tech. 2018, 66, 2452–2462. [Google Scholar] [CrossRef]

- Kuhn, M.; Breier, G.; Dias, A.; Clarke, T. A Novel RFID-Based Strain Sensor for Wireless Structural Health Monitoring. J. Nondestruct. Eval. 2018, 37, 22. [Google Scholar] [CrossRef]

- He, Y.; Li, M.M.; Wan, G.C.; Tong, M.S. A Passive and Wireless Sensor Based on RFID Antenna for Detecting Mechanical Deformation. IEEE Open J. Antennas Propag. 2020, 1, 426–434. [Google Scholar] [CrossRef]

- Zhang, B.; Lyu, Y.; Lee, Y.c. Passive Wireless Strain and Crack Sensing Using a RFID-based Patch Antenna. J. Phys. Conf. Ser. 2022, 2198, 012018. [Google Scholar] [CrossRef]

- Kalansuriya, P.; Bhattacharyya, R.; Sarma, S. RFID Tag Antenna-Based Sensing for Pervasive Surface Crack Detection. IEEE Sens. J. 2013, 13, 1564–1570. [Google Scholar] [CrossRef]

- Wang, P.; Dong, L.; Wang, H.; Li, G.; Di, Y.; Xie, X.; Huang, D. Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring. Sensors 2021, 21, 882. [Google Scholar] [CrossRef]

- Suresh, S.; Chakaravarthi, G. A Novel Passive Wireless RFID Sensor for Localized Surface Crack Characterization on Metals. Measurement 2024, 231, 114651. [Google Scholar] [CrossRef]

- Ma, M.; Khan, H.; Shan, W.; Wang, Y.; Ou, J.Z.; Liu, Z.; Kalantar-zadeh, K.; Li, Y. A Novel Wireless Gas Sensor Based on LTCC Technology. Sens. Actuators B Chem. 2017, 239, 711–717. [Google Scholar] [CrossRef]

- Liu, Z.; Shen, Y.; Zhao, S.; Bai, J.; Ma, R.; Gao, S.; Liu, W.; Zhao, Q. A Novel-Structure LC Resonant Passive Wireless Sensor for NO2 Sensing. Chemosensors 2023, 11, 359. [Google Scholar] [CrossRef]

- Shen, S.; Fan, Z.; Deng, J.; Guo, X.; Zhang, L.; Liu, G.; Tan, Q.; Xiong, J. An LC Passive Wireless Gas Sensor Based on PANI/CNT Composite. Sensors 2018, 18, 3022. [Google Scholar] [CrossRef] [PubMed]

- Vena, A.; Sydänheimo, L.; Tentzeris, M.M.; Ukkonen, L. A Novel Inkjet Printed Carbon Nanotube-Based Chipless RFID Sensor for Gas Detection. In Proceedings of the 2013 European Microwave Conference, Nuremberg, Germany, 6–10 October 2013; pp. 9–12. [Google Scholar] [CrossRef]

- Shen, X.; Shi, G.; Cheng, L.; Gu, L.; Rao, Y.; He, Y. Chipless RFID-inspired Sensing for Smart Agriculture: A Review. Sens. Actuators A Phys. 2023, 363, 114725. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Surman, C. A Passive Radio-Frequency Identification (RFID) Gas Sensor with Self-Correction against Fluctuations of Ambient Temperature. Sens. Actuators B Chem. 2013, 185, 587–593. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, Y.; Deng, F.; Wei, B.; Wu, X. Methane Gas Density Monitoring and Predicting Based on RFID Sensor Tag and CNN Algorithm. Electronics 2018, 7, 69. [Google Scholar] [CrossRef]

- Qin, L.; Shen, D.; Wei, T.; Tan, Q.; Luo, T.; Zhou, Z.; Xiong, J. A Wireless Passive LC Resonant Sensor Based on LTCC under High-Temperature/Pressure Environments. Sensors 2015, 15, 16729–16739. [Google Scholar] [CrossRef] [PubMed]

- Tan, Q.; Luo, T.; Xiong, J.; Kang, H.; Ji, X.; Zhang, Y.; Yang, M.; Wang, X.; Xue, C.; Liu, J.; et al. A Harsh Environment-Oriented Wireless Passive Temperature Sensor Realized by LTCC Technology. Sensors 2014, 14, 4154–4166. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Tan, Q.; Lin, B.; Xiong, J. A Novel Temperature and Pressure Measuring Scheme Based on LC Sensor for Ultra-High Temperature Environment. IEEE Access 2019, 7, 162747–162755. [Google Scholar] [CrossRef]

- Kubina, B.; Schüßler, M.; Mandel, C.; Mehmood, A.; Jakoby, R. Wireless High-Temperature Sensing with a Chipless Tag Based on a Dielectric Resonator Antenna. In Proceedings of the 2013 IEEE SENSORS, Baltimore, MD, USA, 3–6 November 2013; pp. 1–4. [Google Scholar] [CrossRef]

- Gu, T.; Wang, B. Design of a Metamaterial Chipless RFID Sensor Tag for High Temperature. In Proceedings of the 2022 International Conference on Frontiers of Communications, Information System and Data Science (CISDS), Guangzhou, China, 25–27 November 2022; pp. 160–164. [Google Scholar] [CrossRef]

- Tedjini, S.; Palazzi, V. Wireless Identification and Sensing Systems for Harsh and Severe Environments, 1st ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2025. [Google Scholar] [CrossRef]

- Zarifi, M.H.; Deif, S.; Daneshmand, M. Wireless Passive RFID Sensor for Pipeline Integrity Monitoring. Sens. Actuators A Phys. 2017, 261, 24–29. [Google Scholar] [CrossRef]

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820. [Google Scholar] [CrossRef]

- Mc Gee, K.; Anandarajah, P.; Collins, D. A Review of Chipless Remote Sensing Solutions Based on RFID Technology. Sensors 2019, 19, 4829. [Google Scholar] [CrossRef]

- Tang, Z.; Wu, W.; Yang, P.; Luo, J.; Fu, C.; Han, J.C.; Zhou, Y.; Wang, L.; Wu, Y.; Huang, Y. A Review of Surface Acoustic Wave Sensors: Mechanisms, Stability and Future Prospects. Sens. Rev. 2024, 44, 249–266. [Google Scholar] [CrossRef]

- Panneerselvam, G.; Thirumal, V.; Pandya, H. Review of Surface Acoustic Wave Sensors for the Detection and Identification of Toxic Environmental Gases/Vapours. Arch. Acoust. 2018, 43, 357–367. [Google Scholar] [CrossRef]

- Buiculescu, V.; Dinu, L.A.; Veca, L.M.; Pârvulescu, C.; Mihai, M.; Brîncoveanu, O.; Comănescu, F.; Brașoveanu, C.; Stoian, M.; Baracu, A.M. The Development of Sensitive Graphene-Based Surface Acoustic Wave Sensors for NO2 Detection at Room Temperature. Microchim. Acta 2024, 191, 323. [Google Scholar] [CrossRef]

- Vanotti, M.; Theron, C.; Poisson, S.; Quesneau, V.; Naitana, M.; Soumann, V.; Brandès, S.; Desbois, N.; Gros, C.; Tran-Thi, T.H.; et al. Surface Acoustic Wave Sensors for the Detection of Hazardous Compounds in Indoor Air. Proceedings 2017, 1, 444. [Google Scholar] [CrossRef]

- Cui, B.; Ren, Z.; Wang, W.; Cheng, L.; Gao, X.; Huang, L.; Hu, A.; Hu, F.; Jin, J. Review of Surface Acoustic Wave-Based Hydrogen Sensor. Sens. Actuators Rep. 2024, 7, 100197. [Google Scholar] [CrossRef]

- Paschke, B.; Wixforth, A.; Denysenko, D.; Volkmer, D. Fast Surface Acoustic Wave-Based Sensors to Investigate the Kinetics of Gas Uptake in Ultra-Microporous Frameworks. ACS Sens. 2017, 2, 740–747. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Yan, C.; Gao, X.; Yang, J.; Guo, T.; Zhang, L.; Wang, W. A Passive Wireless Surface Acoustic Wave (SAW) Sensor System for Detecting Warfare Agents Based on Fluoroalcohol Polysiloxane Film. Microsyst. Nanoeng. 2024, 10, 4. [Google Scholar] [CrossRef]

- Aslam, M.Z.; Zhang, H.; Sreejith, V.S.; Naghdi, M.; Ju, S. Advances in the Surface Acoustic Wave Sensors for Industrial Applications: Potentials, Challenges, and Future Directions: A Review. Measurement 2023, 222, 113657. [Google Scholar] [CrossRef]

- Ghosh, A.; Zhang, C.; Shi, S.Q.; Zhang, H. High-Temperature Gas Sensors for Harsh Environment Applications: A Review. CLEAN—Soil Air Water 2019, 47, 1800491. [Google Scholar] [CrossRef]

- Devkota, J.; Ohodnicki, P.R.; Greve, D.W. SAW Sensors for Chemical Vapors and Gases. Sensors 2017, 17, 801. [Google Scholar] [CrossRef]

- Piro, L.; Lamanna, L.; Guido, F.; Balena, A.; Mariello, M.; Rizzi, F.; Vittorio, M.D. Flexible SAW Microfluidic Devices as Wearable pH Sensors Based on ZnO Nanoparticles. Nanomaterials 2021, 11, 1479. [Google Scholar] [CrossRef]

- Li, X.; Tan, Q.; Qin, L.; Yan, X.; Liang, X. Novel Surface Acoustic Wave Temperature–Strain Sensor Based on LiNbO3 for Structural Health Monitoring. Micromachines 2022, 13, 912. [Google Scholar] [CrossRef]

- Gruber, C.; Hammer, R.; Gänser, H.P.; Künstner, D.; Eck, S. Use of Surface Acoustic Waves for Crack Detection on Railway Track Components—Laboratory Tests. Appl. Sci. 2022, 12, 6334. [Google Scholar] [CrossRef]

- Perry, M.; Mckeeman, I.; Saafi, M.; Niewczas, P. Wireless Surface Acoustic Wave Sensors for Displacement and Crack Monitoring in Concrete Structures. Smart Mater. Struct. 2016, 25, 035035. [Google Scholar] [CrossRef]

- Fascista, A. Toward integrated large-scale environmental monitoring using WSN/UAV/Crowdsensing: A review of applications, signal processing, and future perspectives. Sensors 2022, 22, 1824. [Google Scholar] [CrossRef]

- Doerenbecher, A.; Basdevant, C.; Drobinski, P.; Durand, P.; Fesquet, C.; Bernard, F.; Cocquerez, P.; Verdier, N.; Vargas, A. Low-atmosphere drifting balloons: Platforms for environment monitoring and forecast improvement. Bull. Am. Meteorol. Soc. 2016, 97, 1583–1599. [Google Scholar] [CrossRef]

- Boubrima, A.; Shaikhanov, Z.; Knightly, E.W. Toward accurate environmental mapping using balloon-based UAVs. In Proceedings of the 2024 IEEE 21st consumer communications & networking conference (CCNC), Las Vegas, NV, USA, 6–9 January 2024; pp. 135–142. [Google Scholar] [CrossRef]

- Fawcett, D.; Panigada, C.; Tagliabue, G.; Boschetti, M.; Celesti, M.; Evdokimov, A.; Biriukova, K.; Colombo, R.; Miglietta, F.; Rascher, U.; et al. Multi-scale evaluation of drone-based multispectral surface reflectance and vegetation indices in operational conditions. Remote Sens. 2020, 12, 514. [Google Scholar] [CrossRef]

- Bolch, E.A.; Hestir, E.L.; Khanna, S. Performance and feasibility of drone-mounted imaging spectroscopy for invasive aquatic vegetation detection. Remote Sens. 2021, 13, 582. [Google Scholar] [CrossRef]

- Meivel, S.; Maheswari, S. Remote sensing analysis of agricultural drone. J. Indian Soc. Remote Sens. 2021, 49, 689–701. [Google Scholar] [CrossRef]

- Wang, C.; Morris, J.T.; Smith, E.M. A lidar biomass index of tidal marshes from drone lidar point cloud. Remote Sens. 2024, 16, 1823. [Google Scholar] [CrossRef]

- Shokirov, S.; Jucker, T.; Levick, S.R.; Manning, A.D.; Bonnet, T.; Yebra, M.; Youngentob, K.N. Habitat highs and lows: Using terrestrial and UAV LiDAR for modelling avian species richness and abundance in a restored woodland. Remote Sens. Environ. 2023, 285, 113326. [Google Scholar] [CrossRef]

- Tak, W.; Jun, K.; Kim, S.; Lee, H. Using drone and LiDAR to assess coastal erosion and shoreline change due to the construction of coastal structures. J. Coast. Res. 2020, 95, 674–678. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Cheema, M.; Zaman, Q.; Shaheen, A.; Aslam, B.; Zhu, W.; Ajmal, M.; Faheem, M.; Hussain, S.; et al. UAV-based remote sensing in plant stress imagine using high-resolution thermal sensor for digital agriculture practices: A meta-review. Int. J. Environ. Sci. Technol. 2023, 20, 1135–1152. [Google Scholar] [CrossRef]

- Beaver, J.T.; Baldwin, R.W.; Messinger, M.; Newbolt, C.H.; Ditchkoff, S.S.; Silman, M.R. Evaluating the use of drones equipped with thermal sensors as an effective method for estimating wildlife. Wildl. Soc. Bull. 2020, 44, 434–443. [Google Scholar] [CrossRef]

- Nithyavathy, N.; Kumar, S.A.; Rahul, D.; Kumar, B.S.; Shanthini, E.; Naveen, C. Detection of fire prone environment using Thermal Sensing Drone. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1055, p. 012006. [Google Scholar] [CrossRef]

- Maes, W.H.; Huete, A.R.; Steppe, K. Optimizing the processing of UAV-based thermal imagery. Remote Sens. 2017, 9, 476. [Google Scholar] [CrossRef]

- Yan, X.; Fu, T.; Lin, H.; Xuan, F.; Huang, Y.; Cao, Y.; Hu, H.; Liu, P. UAV detection and tracking in urban environments using passive sensors: A survey. Appl. Sci. 2023, 13, 11320. [Google Scholar] [CrossRef]

- Bhattacherjee, U.; Ozturk, E.; Ozdemir, O.; Guvenc, I.; Sichitiu, M.L.; Dai, H. Experimental study of outdoor UAV localization and tracking using passive RF sensing. In Proceedings of the 15th ACM Workshop on Wireless Network Testbeds, Experimental Evaluation & Characterization, New Orleans, LA, USA, 4 February 2022; pp. 31–38. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Boyle, D.; Kkelis, G.; Yates, D.; Saenz, J.A.; Aldhaher, S.; Yeatman, E. Energy-autonomous sensing systems using drones. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Alotaibi, E.; Nassif, N. Artificial intelligence in environmental monitoring: In-depth analysis. Discov. Artif. Intell. 2024, 4, 84. [Google Scholar] [CrossRef]

- Wani, A.K.; Rahayu, F.; Ben Amor, I.; Quadir, M.; Murianingrum, M.; Parnidi, P.; Ayub, A.; Supriyadi, S.; Sakiroh, S.; Saefudin, S.; et al. Environmental resilience through artificial intelligence: Innovations in monitoring and management. Environ. Sci. Pollut. Res. 2024, 31, 18379–18395. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, L.; Lee, C. Recent advances in artificial intelligence sensors. Adv. Sens. Res. 2023, 2, 2200072. [Google Scholar] [CrossRef]

- Neri, I.; Caponi, S.; Bonacci, F.; Clementi, G.; Cottone, F.; Gammaitoni, L.; Figorilli, S.; Ortenzi, L.; Aisa, S.; Pallottino, F.; et al. Real-Time AI-Assisted Push-Broom Hyperspectral System for Precision Agriculture. Sensors 2024, 24, 344. [Google Scholar] [CrossRef]

- Falcioni, R.; Gonçalves, J.V.F.; Oliveira, K.M.d.; Oliveira, C.A.d.; Demattê, J.A.; Antunes, W.C.; Nanni, M.R. Enhancing pigment phenotyping and classification in lettuce through the integration of reflectance spectroscopy and AI algorithms. Plants 2023, 12, 1333. [Google Scholar] [CrossRef]

- Samaras, S.; Diamantidou, E.; Ataloglou, D.; Sakellariou, N.; Vafeiadis, A.; Magoulianitis, V.; Lalas, A.; Dimou, A.; Zarpalas, D.; Votis, K.; et al. Deep learning on multi sensor data for counter UAV applications—A systematic review. Sensors 2019, 19, 4837. [Google Scholar] [CrossRef]

- Pajares, G. Overview and current status of remote sensing applications based on unmanned aerial vehicles (UAVs). Photogramm. Eng. Remote Sens. 2015, 81, 281–330. [Google Scholar] [CrossRef]

- Fei, S.; Hassan, M.A.; Xiao, Y.; Su, X.; Chen, Z.; Cheng, Q.; Duan, F.; Chen, R.; Ma, Y. UAV-based multi-sensor data fusion and machine learning algorithm for yield prediction in wheat. Precis. Agric. 2023, 24, 187–212. [Google Scholar] [CrossRef]

- Semenyuk, V.; Kurmashev, I.; Lupidi, A.; Alyoshin, D.; Kurmasheva, L.; Cantelli-Forti, A. Advances in UAV detection: Integrating multi-sensor systems and AI for enhanced accuracy and efficiency. Int. J. Crit. Infrastruct. Prot. 2025, 49, 100744. [Google Scholar] [CrossRef]

- Hua, H.; Li, Y.; Wang, T.; Dong, N.; Li, W.; Cao, J. Edge computing with artificial intelligence: A machine learning perspective. ACM Comput. Surv. 2023, 55, 1–35. [Google Scholar] [CrossRef]

- Hawkinson, J.; Ramesh, S.M.; Raj, A.S.; Gomathy, B. Optimizing WSN Network Lifetime With Federated Learning–Based Routing. Int. J. Commun. Syst. 2025, 38. [Google Scholar] [CrossRef]

- Luvisi, A.; Panattoni, A.; Materazzi, A. RFID temperature sensors for monitoring soil solarization with biodegradable films. Comput. Electron. Agric. 2016, 123, 135–141. [Google Scholar] [CrossRef]

| Technology | Parameters | Energy Req. | Environmental Sustainability | TRL | Maintenance | Reliability | Commercialization Barriers | References |

|---|---|---|---|---|---|---|---|---|

| NDIR | CO2 concentration | Medium (multi-circuit, not autonomous) | Low: high footprint (electronics, optics) | 4–6 | Medium: UAV-mounted, temperature and pressure dependance | N.A.* | High cost, UAV integration | [93] |

| Multi-sensors | dCO2, temp., humidity | 10 mWh (EH modules) | Low: EH partly mitigates battery impact | 4–6 | Low: EH-assisted prototype | Unknown: prototype stage | Prototype stage, integration challenges | [94] |

| Light scattering | Particulate pollutants | Not autonomous | Low: high e-waste risk from electronics and optics | 3–5 | N.A. | N.A. | Low TRL, complex optics, cost | [95,97] |

| Raman | Molecular pollutants | High energy requirements (laser source) | Low: very high cost, energy intensive | 3–5 | High: potential frequent recalibration | High: 99.89% accuracy | High cost, complex optics | [98] |

| Electrochemical | Gases, pesticides, metals | Medium-high (potentiostat) | Moderate: electrode waste, metal disposal issues | 5–7 | Medium: electrode fouling common | Medium–High: proven in lab, field-dependent | Cost of nanomaterials, calibration needs | [60,76,78] |

| SPES | Metals, pH, pollutants | Low (biofuel/galvanic/ photo cells) | High: eco-friendly, biocompatible, reduced e-waste | 3–5 | Low–Medium: reduced recalibration needs | Promising: early validation | Low maturity, reproducibility, certification | [76,79] |

| TENG-based | Water quality, humidity, waves | Low–medium (µW–mW) | High: biodegradable options available; moderate otherwise | 4–6 | Medium: materials degrade with use | Medium | Durability, reproducibility | [13,34,45,47,57] and references therein |

| SAW-active | CO2 concentration | Low (piezo EH integrated) | Moderate: piezo materials face recycling challenges | 4–6 | Medium: substrate issues | Medium | Packaging, piezo material cost | [64] |

| Technology | Parameters | Energy req. | Environmental sustainability | TRL | Maintenance | Reliability | Commercialization barriers | References |

|---|---|---|---|---|---|---|---|---|

| Photonic crystals | Humidity, temperature, analytes | None (ambient light) | High: biodegradable (cellulose/HPC); moderate otherwise | up to 9 | Low: simple optical readout | High: proven in lab, limited field stability | Nanofabrication cost, scalability | [108,109,110,112] |

| Chromogenic | pH, gases, pollutants | None (ambient light) | High: biomass-based films, low e-waste | 3–5 | Low: recalibration sometimes needed | Medium: dye stability issues | Material reproducibility, dye stability | [113,114,115] |

| Plasmonic | Trace pollutants, gases | None (ambient light) | Moderate: nanoparticle recycling challenges | 3–5 | Low–Medium: some film degradation | Medium: NP degradation possible | NP cost, regulatory issues | [117] |

| Passive LC | Temperature, humidity, moisture, gases, strain, cracks | None (inductive RF) | High: No silicon chip, biodegradable LC substrates possible | 5–9 | Low: Recalibration and sensitive film replacement may be needed | High: robust sensor, sensitive readout | Read range, calibration | [124] |

| Chipless RFID | Temperature, humidity, moisture, gases, strain, cracks | None (ambient RF) | High: biodegradable tags (paper/PLA) | 4–6 | Low: Recalibration and sensitive film replacement may be needed | Medium: limited by range, interference | Weak signals, interference, low TRL | [121,139,141] |

| Chip-based RFID | Temperature, humidity, moisture, gases, strain, cracks | None (RF rectification) | Moderate: IC adds e-waste risk | 4–9 | Low: Recalibration and sensitive film replacement may be needed | High: predictable standardized performance due to IC | Reader dependence, certification | [122,125,143] |

| SAW (passive) | Temperature, humidity, moisture, gases, strain, cracks | None (RF backscatter) | Moderate: conventional substrates not recyclable | 4–9 | Medium: substrate durability limits | High: robust field validation | Substrate cost, harsh env. packaging | [177,179] |

| Living sensors | Soil conditions (bio-signature) | None (biological metabolism) | Very High: eco-compatible, naturally biodegradable | 3–5 | Low: self-maintaining | Low–Medium: still experimental | Certification, acceptance hurdles | [118] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paccoia, V.D.; Bonacci, F.; Clementi, G.; Cottone, F.; Neri, I.; Mattarelli, M. Toward Field Deployment: Tackling the Energy Challenge in Environmental Sensors. Sensors 2025, 25, 5618. https://doi.org/10.3390/s25185618

Paccoia VD, Bonacci F, Clementi G, Cottone F, Neri I, Mattarelli M. Toward Field Deployment: Tackling the Energy Challenge in Environmental Sensors. Sensors. 2025; 25(18):5618. https://doi.org/10.3390/s25185618

Chicago/Turabian StylePaccoia, Valentin Daniel, Francesco Bonacci, Giacomo Clementi, Francesco Cottone, Igor Neri, and Maurizio Mattarelli. 2025. "Toward Field Deployment: Tackling the Energy Challenge in Environmental Sensors" Sensors 25, no. 18: 5618. https://doi.org/10.3390/s25185618

APA StylePaccoia, V. D., Bonacci, F., Clementi, G., Cottone, F., Neri, I., & Mattarelli, M. (2025). Toward Field Deployment: Tackling the Energy Challenge in Environmental Sensors. Sensors, 25(18), 5618. https://doi.org/10.3390/s25185618