Automated Building Monitoring System Based on Reflectorless Measurements: A Case Study of the IMSGeo System

Abstract

Highlights

- The IMSGeo system demonstrated high measurement repeatability and accuracy across five surface types, with maximum point coordinate differences not exceeding 5 mm and a surface change detection accuracy reaching up to 97%.

- The use of normal vectors for surface change analysis proved more reliable than direct point-to-point comparisons, especially for unsignaled, reflectorless measurements.

- The IMSGeo system enables cost-effective, automated, and reliable geodetic monitoring in real-time, even under varying surface conditions and without the need for signalized targets.

- Proper configuration of measurement parameters, such as point density and field size for normal vector analysis, is crucial for accurately detecting structural deformations and minimizing false alerts.

Abstract

1. Introduction

Automatic Monitoring System—IMSGeo

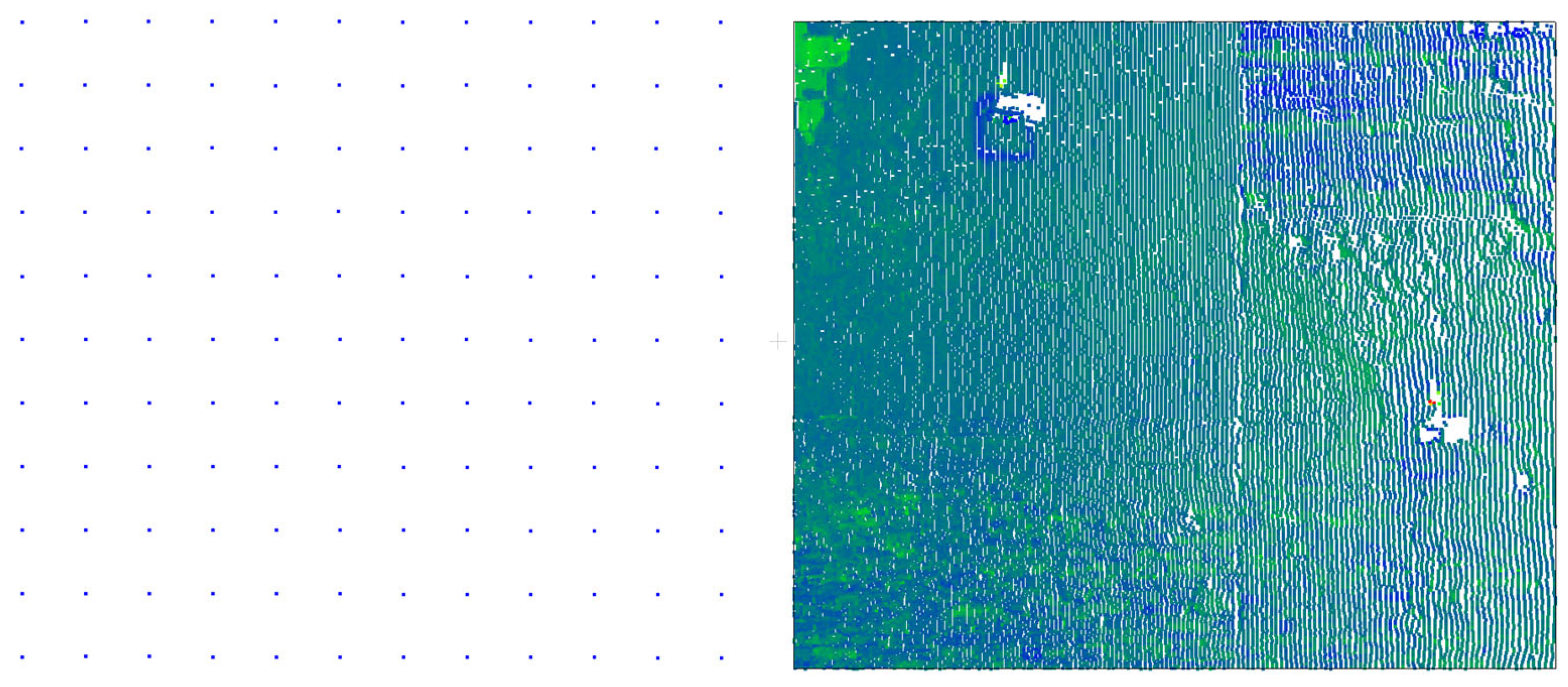

- The range of the scanned surface is determined based on the measurement of points with known coordinates;

- The distances between the measured points on the object are defined before the measurement; thus, their density is adjusted to the expected magnitude of change, which significantly reduces the size of the data sets;

- The points are measured in a regular grid;

- The point cloud is linked to a network of reference points and control points and thus is automatically oriented in the object/external coordinate system;

- The measurement to points is more accurate because it is performed using a motorized total station.

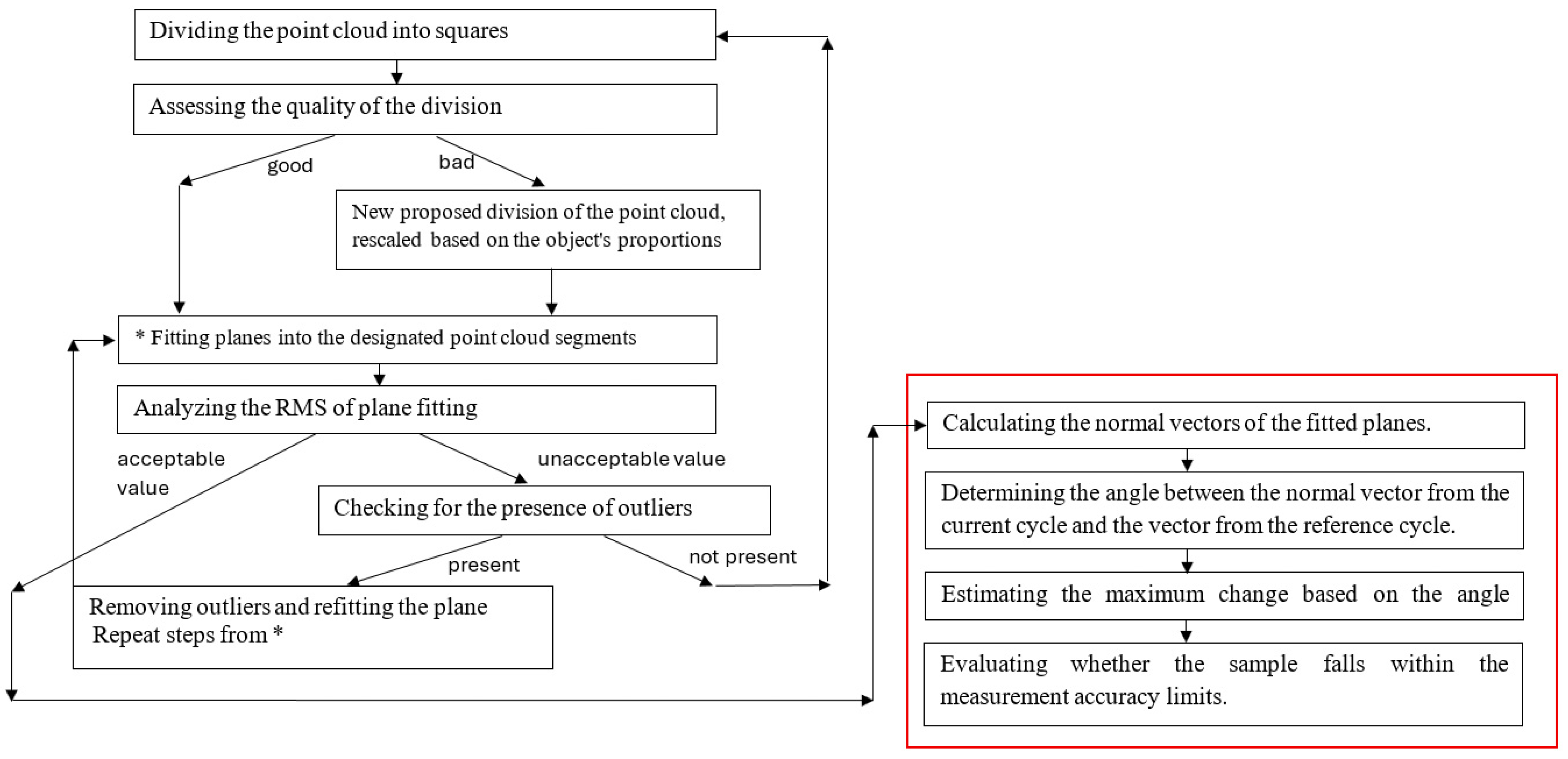

- Measuring a deforming surface without a reflector, we will not always measure exactly at the same point;

- In some measurement cycles, we may not register all points in each field;

- The change based on normal vectors is very quickly determined and is used for the indication of a trend/situation in which something is happening on a given wall; we process data in groups, but we store each point in the database.

2. Materials and Methods

- Selection of the reference measurement (initial “zero” measurement or another measurement cycle we take as reference).

- Determination of the coordinate differences dXi = Xr − Xi, dYi = Yr − Yi, and dZi = Zr − Zi, where Xr, Yr, and Zr are coordinates from the reference cycle, and Xi, Yi, and Zi are coordinates from the compared measurement cycle, as well as the difference in point distances .

- Determination of measurement error values according to the parameters of the instrument used and determination of the value of the mdi (distance measurement error) depending on the target length.

- Determination of the mean error values of the measured points for the individual components , , and and the point position error value based on the formulas:

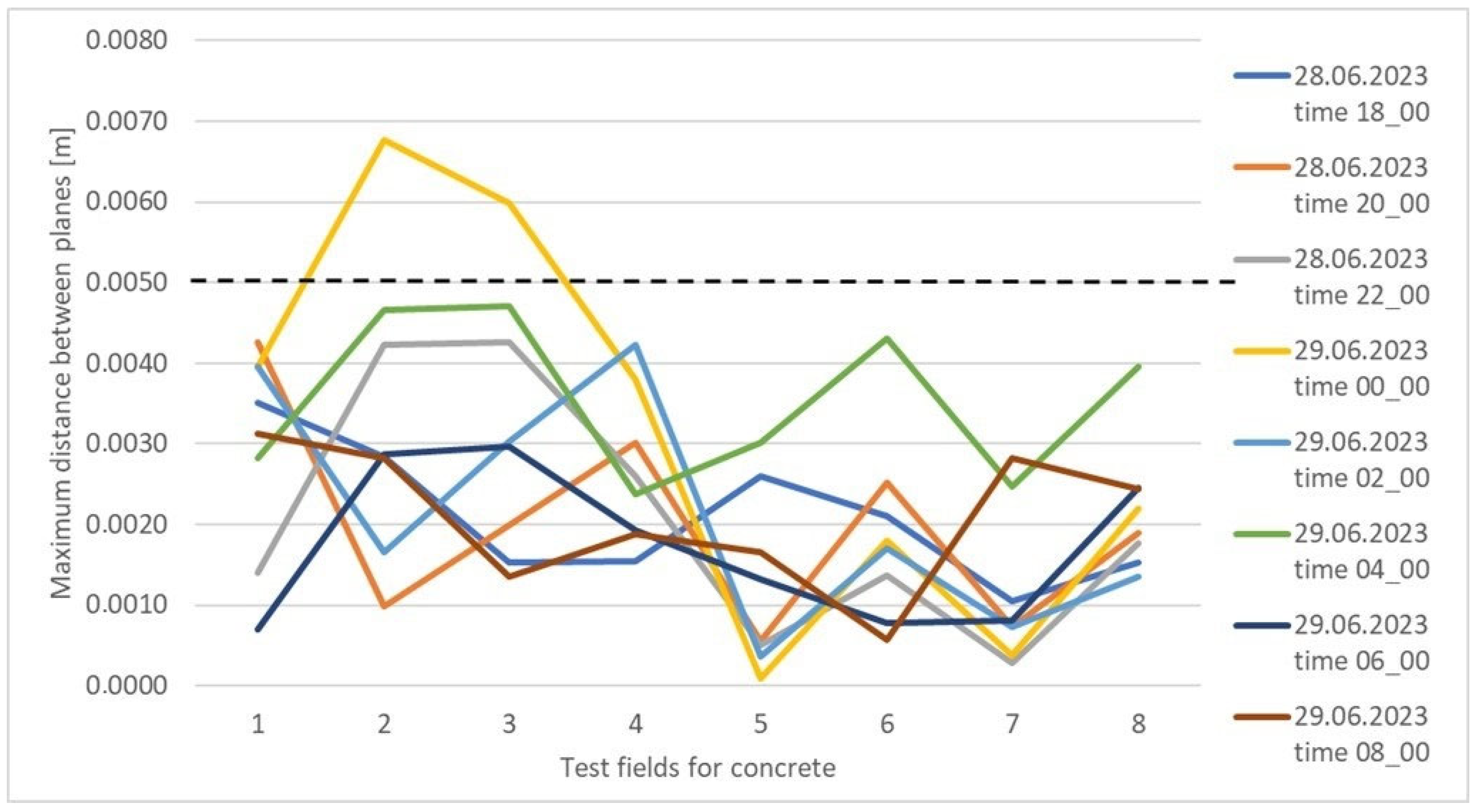

3. Results

3.1. Verification of Measurement Result Repeatability

3.2. Verification of Result Repeatability Using the Clustering Algorithm

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ALS | Airborne Laser Scanning |

| GNSS | Global Navigation Satellite System |

| IMSGeo | Intelligent Monitoring System for Threatened Objects based on Automatic Non-invasive Measurements |

| RMS | Root Mean Square |

| RTS | Robotic Total Stations |

| SHM | Structural Health Monitoring |

| TLS | Terrestrial Laser Scanning |

| UAV | Unmanned Aerial Vehicle |

References

- Garbrecht, G. Wasserspeicher (Talsperren) in der Antike. In Antike Welt; Antiker Wasserbau; Raggi-Verlag: Feldmeilen, Switzerland, 1986; pp. 51–64. [Google Scholar]

- Bauer, P.; Lienhart, W. 3D concept creation of permanent geodetic monitoring installations and the a priori assessment of systematic effects using Virtual Reality. J. Appl. Geod. 2023, 17, 1–13. [Google Scholar] [CrossRef]

- Bąk, M. The use of automatic measurement techniques in the geotechnical monitoring system of PGE GiEK S.A., KWB Turów branch. Int. J. Coal Sci. Technol. 2022, 9, 89. [Google Scholar] [CrossRef]

- Lubej, S.; Kovačič, B. A Comparative Study of Signal Processing Methods for Contactless Geodetic Monitoring. Appl. Sci. 2021, 11, 11276. [Google Scholar] [CrossRef]

- Wiget, A.; Sievers, B.; Walser, F. Contributions of geodesy to the safety of dams in Switzerland. In Role of Dams and Reservoirs in a Successful Energy Transition; CRC Press: Boca Raton, FL, USA, 2023; pp. 80–88. [Google Scholar]

- Li, Y.; Liu, P.; Li, H.; Huang, F. A Comparison Method for 3D Laser Point Clouds in Displacement Change Detection for Arch Dams. ISPRS Int. J. Geo-Inf. 2021, 10, 184. [Google Scholar] [CrossRef]

- Qian, H. Design of Tunnel Automatic Monitoring System Based on BIM and IOT. J. Phys. Conf. Ser. 2021, 1982, 012073. [Google Scholar] [CrossRef]

- Zhou, J.; Xiao, H.; Jiang, W.; Bai, W.; Liu, G. Automatic subway tunnel displacement monitoring using robotic total station. Measurement 2020, 151, 107251. [Google Scholar] [CrossRef]

- Hu, D.; Zhou, R.; Xiao, L.; Liang, X.; Li, Y.; Yang, X. A Supershallow Buried Large-Span Rectangular Pipe Jacking Tunnel Undercrossing an Expressway: Construction Method, Monitoring Results, and Numerical Simulation. Int. J. Civ. Eng. 2024, 22, 757–771. [Google Scholar] [CrossRef]

- Zaczek-Peplinska, J.; Kowalska, M.E. Application of non-contact geodetic measurement techniques in dam monitoring. Arch. Civ. Eng. 2022, 63, 49–70. [Google Scholar] [CrossRef]

- Zaczek-Peplinska, J.; Podawca, K.; Karsznia, K. Reliability of geodetic control measurements of high dams as a guarantee of safety of the construction and the natural environment. Bull. Pol. Acad. Sci. Tech. Sci. 2018, 66, 87–98. [Google Scholar] [CrossRef]

- Karsznia, K.; Zaczek-Peplinska, J.; Łapiński, S.; Odziemczyk, W.; Piasta, Ł.; Saloni, L. The functionality assessment of geodetic monitoring systems for analyzing structural elements. In Proceedings of the XXVII FIG Congress “Volunteering for the Future—Geospatial Excellence for a Better Living”, Warsaw, Poland, 11–15 September 2022. [Google Scholar]

- Galan-Martin, D.; Marchamalo, M.; Martínez, R.; Sanchez Sobrino, J. Geomatics applied to dam safety DGPS real time monitoring. Int. J. Civ. Eng. 2013, 11, 134–141. [Google Scholar]

- Teng, J.; Shi, Y.; Wang, H.; Wu, J. Review on the Research and Applications of TLS in Ground Surface and Constructions Deformation Monitoring. Sensors 2022, 22, 9179. [Google Scholar] [CrossRef] [PubMed]

- Keyvanfar, A.; Shafaghat, A.; Awanghamat, M.A. Optimization and Trajectory Analysis of Drone’s Flying and Environmental Variables for 3D Modelling the Construction Progress Monitoring. Int. J. Civ. Eng. 2022, 20, 363–388. [Google Scholar] [CrossRef]

- Arif, F.; Khan, W.A. Smart Progress Monitoring Framework for Building Construction Elements Using Videography–MATLAB–BIM Integration. Int. J. Civ. Eng. 2021, 19, 717–732. [Google Scholar] [CrossRef]

- Ren, D.; Kang, C.; Peng, T.; Li, Y.; Wang, J. Deformation Behavior of a Large-Scale Excavation and the Effect of an Adjacent Foundation Pit on the Excavation. Int. J. Civ. Eng. 2024, 22, 1493–1505. [Google Scholar] [CrossRef]

- Kawajiri, S.; Hikichi, S.; Kondo, K.; Kagamihara, S.; Abe, Y.; Koizumi, K. Observation of Pier Inclination Caused by Scouring Phenomenon of Foundation Ground Using a Large-Scale Open Channel and Development of Its Monitoring System. Int. J. Civ. Eng. 2023, 21, 1477–1493. [Google Scholar] [CrossRef]

- Zacchei, E.; Lyra, P.H.C.; Lage, G.E.; Antonine, E.; Soares, A.B.; Caruso, N.C.; de Assis, C.S. Structural Health Monitoring and Mathematical Modelling of a Site-Specific Concrete Bridge Under Moving Two-Axle Vehicles. Int. J. Civ. Eng. 2023, 21, 427–443. [Google Scholar] [CrossRef]

- Pasternak, G.; Zaczek-Peplinska, J.; Pasternak, K.; Jóźwiak, J.; Pasik, M.; Koda, E.; Vaverková, M.D. Surface Monitoring of an MSW Landfill Based on Linear and Angular Measurements, TLS, and LIDAR UAV. Sensors 2023, 23, 1847. [Google Scholar] [CrossRef] [PubMed]

- Jäger, R.; González, F. GNSS/LPS Based Online Control and Alarm System (GOCA)—Mathematical Models and Technical Realization of a System for Natural and Geotechnical Deformation Monitoring and Hazard Prevention. In Geodetic Deformation Monitoring: From Geophysical to Engineering Roles; Springer: Berlin/Heidelberg, Germany, 2006; pp. 293–303. [Google Scholar]

- Zayats, O. Automated System of Geodetic Monitoring. Available online: https://lpnu.ua/en/scientific-developments-directory/automated-system-geodetic-monitoring (accessed on 20 July 2025).

- Leica Geosystems AG Leica GeoMoS Monitoring Solution. Available online: https://leica-geosystems.com/en-gb/products/total-stations/software/leica-geomos (accessed on 20 July 2025).

- Topcon Delta LINK. Available online: https://www.topconpositioning.com/solutions/infrastructure/building-construction/monitoring (accessed on 20 July 2025).

- Trimble Inc. Trimble 4D Control. Available online: https://geospatial.trimble.com/en/products/software/trimble-4d-control (accessed on 20 July 2025).

- Kowalska, M.; Zaczek-Peplinska, J.; Piasta, Ł. Determining the trend of geometrical changes of a hydrotechnical object based on data in the form of LiDAR point clouds. Arch. Civ. Eng. 2024, 70, 305–323. [Google Scholar] [CrossRef]

- Fawzy, H.E. Evaluate the accuracy of reflector-less total station. Int. J. Civ. Eng. Technol. 2015, 6, 23–30. [Google Scholar]

- Ford, J. Effect of Environmental Surroundings on Accuracy and Precision of Total Station Measurements. In Proceedings of the Engineering and Built Environment Project Conference 2015, Toowoomba, Australia, 21–25 September 2015. [Google Scholar]

- Mohammed, S.I. Important methods measurements to exam the accuracy and reliability of reflector-less total station measurements. J. Phys. Conf. Ser. 2021, 1895, 012007. [Google Scholar] [CrossRef]

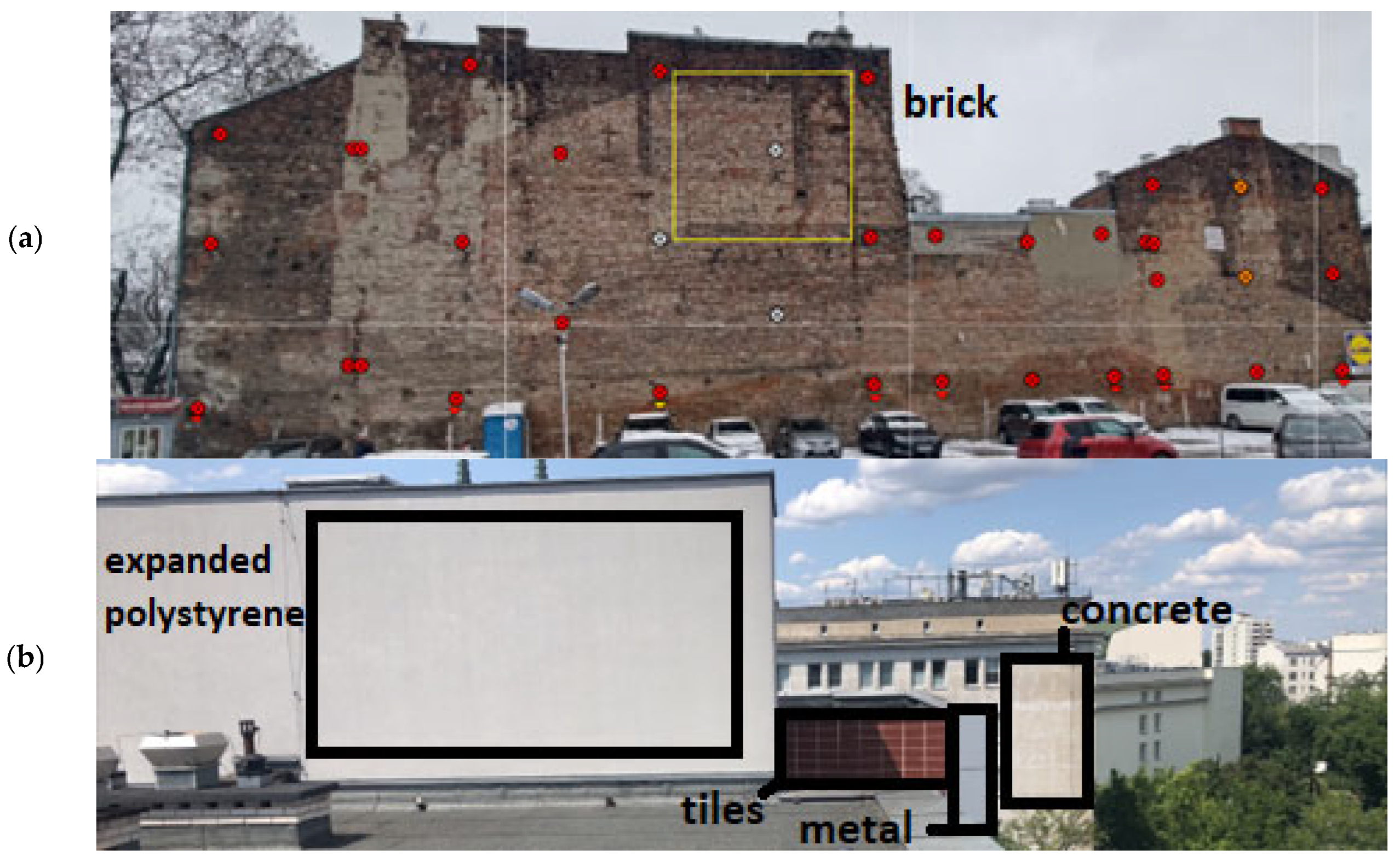

| Surface Type | Number of Measurement Cycles/Time Interval Between Cycles | Distance Between Measurement Points | Surface Dimension: In Vertical and Horizontal Direction | Distance from Which the Measurement was Taken | Number of Measured Points in the Set |

|---|---|---|---|---|---|

| Brick | 10/1 h | 0.400 m | 7.6 m/8.0 m | 63 m | 420 |

| Metal | 8/1 h | 0.055 m | 0.5 m/0.5 m | 16 m | 109 |

| Tiles | 12/1 h | 0.080 m | 0.7 m/2.3 m | 16 m | 300 |

| Expanded polystyrene | 11/1 h | 0.140 m | 1.7 m /2.2 m | 15 m | 285 |

| Concrete | 9/2 h | 0.095 m | 1.8 m/1.3 m | 63 m | 275 |

| Repeatability [%] | Xi | Yi | Zi | Di |

|---|---|---|---|---|

| Brick | 100% | 9–99% | 100% | 100% |

| Metal | 100% | 8–99% | 100% | 100% |

| Tiles | 97–100% | 1–100% | 98–100% | 98–100% |

| Expanded polystyrene | 96–100% | 80–100% | 94–100% | 96–100% |

| Concrete | 97% | 4–100% | 100% | 99–100% |

| Tiles | |||||||

| Repeatability % | 100 | 100 | 100 | 100 | 100 | 100 | 97 |

| Max [m] | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 |

| Min [m] | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | −0.001 |

| Repeatability % | 97 | 7 | 1 | 98 | |||

| Max [m] | 0.001 | 0.001 | 0.002 | 0.001 | |||

| Min [m] | −0.001 | 0.001 | 0.001 | −0.001 | |||

| Brick | |||||||

| Repeatability % | 97 | 99 | 98 | 98 | 98 | 51 | 89 |

| Max [m] | −0.001 | −0.001 | 0.002 | 0.002 | 0.002 | 0.003 | 0.003 |

| Min [m] | −0.002 | −0.002 | −0.002 | 0.002 | −0.001 | 0.001 | 0.001 |

| Repeatability % | 28 | 9 | |||||

| Max [m] | 0.004 | 0.005 | |||||

| Min [m] | 0.001 | 0.001 | |||||

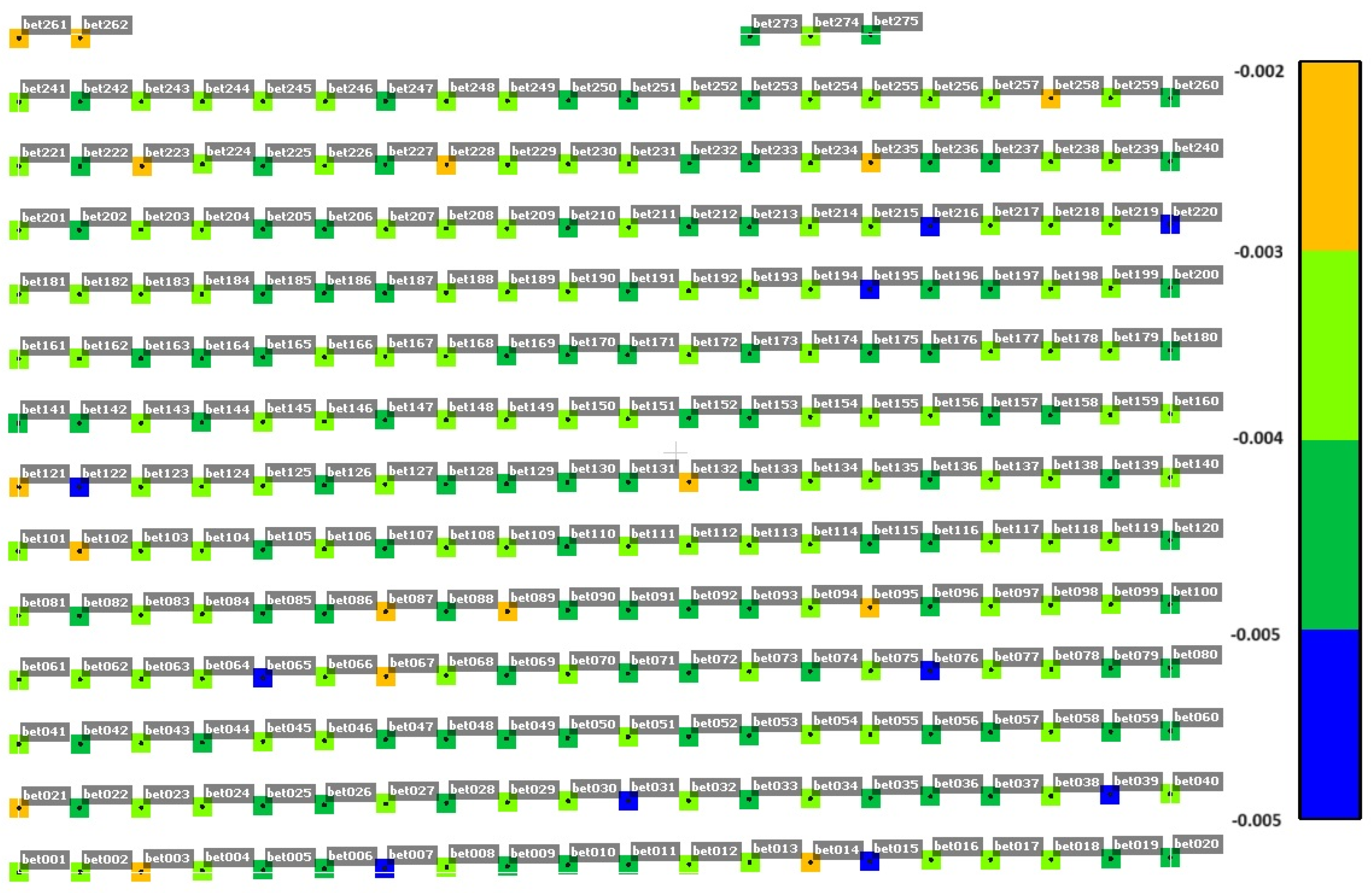

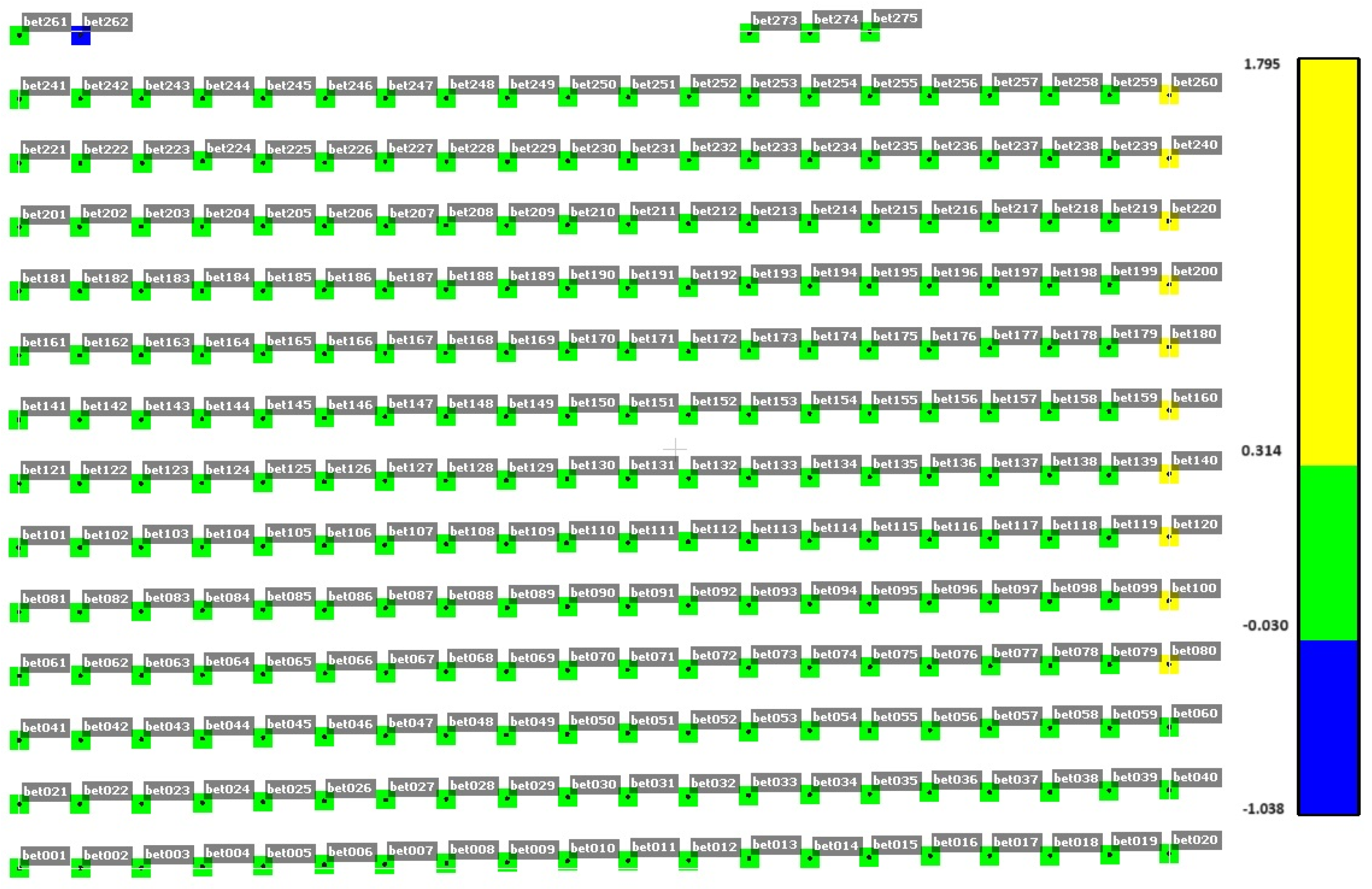

| Concrete | |||||||

| Repeatability % | 4 | 26 | 96 | 84 | 33 | 95 | 64 |

| Max [m] | −0.002 | −0.001 | 0.002 | −0.001 | −0.001 | −0.001 | −0.001 |

| Min [m] | −0.005 | −0.004 | −0.002 | −0.003 | −0.003 | −0.002 | −0.003 |

| Repeatability % | 4 | ||||||

| Max [m] | 1.795 | ||||||

| Min [m] | −1.038 | ||||||

| Metal | |||||||

| Repeatability % | 99 | 8 | 12 | 8 | 9 | 8 | 99 |

| Max [m] | −0.001 | 0.002 | 0.001 | 0.002 | 0.001 | 0.002 | 0.001 |

| Min [m] | −0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Expanded polystyrene | |||||||

| Repeatability % | 100 | 100 | 100 | 100 | 100 | 99 | 80 |

| Max [m] | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | −0.002 | −0.003 |

| Min [m] | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | −0.002 | −0.004 |

| Repeatability % | 100 | 100 | 93 | ||||

| Max [m] | 0.000 | 0.000 | −0.002 | ||||

| Min [m] | 0.000 | 0.000 | −0.003 | ||||

| Type of Surface | Max [m] |

|---|---|

| Expanded polystyrene | 0.009 |

| Metal | 0.004 |

| Concrete | 0.009 (1.797—outlier) |

| Brick | 0.011 |

| Tiles | 0.022 |

| Type of Surface | Percentage of Test Fields for Which the Given Criterion Was Met |

|---|---|

| Brick | 100% did not exceed 2 mm |

| Metal | 100% did not exceed 2 mm |

| Tiles | 84% did not exceed 2 mm |

| Expanded polystyrene | 89% did not exceed 2 mm |

| Concrete | 97% did not exceed 5 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalska, M.E.; Zaczek-Peplinska, J.; Łapiński, S.; Piasta, Ł. Automated Building Monitoring System Based on Reflectorless Measurements: A Case Study of the IMSGeo System. Sensors 2025, 25, 5327. https://doi.org/10.3390/s25175327

Kowalska ME, Zaczek-Peplinska J, Łapiński S, Piasta Ł. Automated Building Monitoring System Based on Reflectorless Measurements: A Case Study of the IMSGeo System. Sensors. 2025; 25(17):5327. https://doi.org/10.3390/s25175327

Chicago/Turabian StyleKowalska, Maria E., Janina Zaczek-Peplinska, Sławomir Łapiński, and Łukasz Piasta. 2025. "Automated Building Monitoring System Based on Reflectorless Measurements: A Case Study of the IMSGeo System" Sensors 25, no. 17: 5327. https://doi.org/10.3390/s25175327

APA StyleKowalska, M. E., Zaczek-Peplinska, J., Łapiński, S., & Piasta, Ł. (2025). Automated Building Monitoring System Based on Reflectorless Measurements: A Case Study of the IMSGeo System. Sensors, 25(17), 5327. https://doi.org/10.3390/s25175327