DUA-MQTT: A Distributed High-Availability Message Communication Model for the Industrial Internet of Things

Abstract

1. Introduction

- (1)

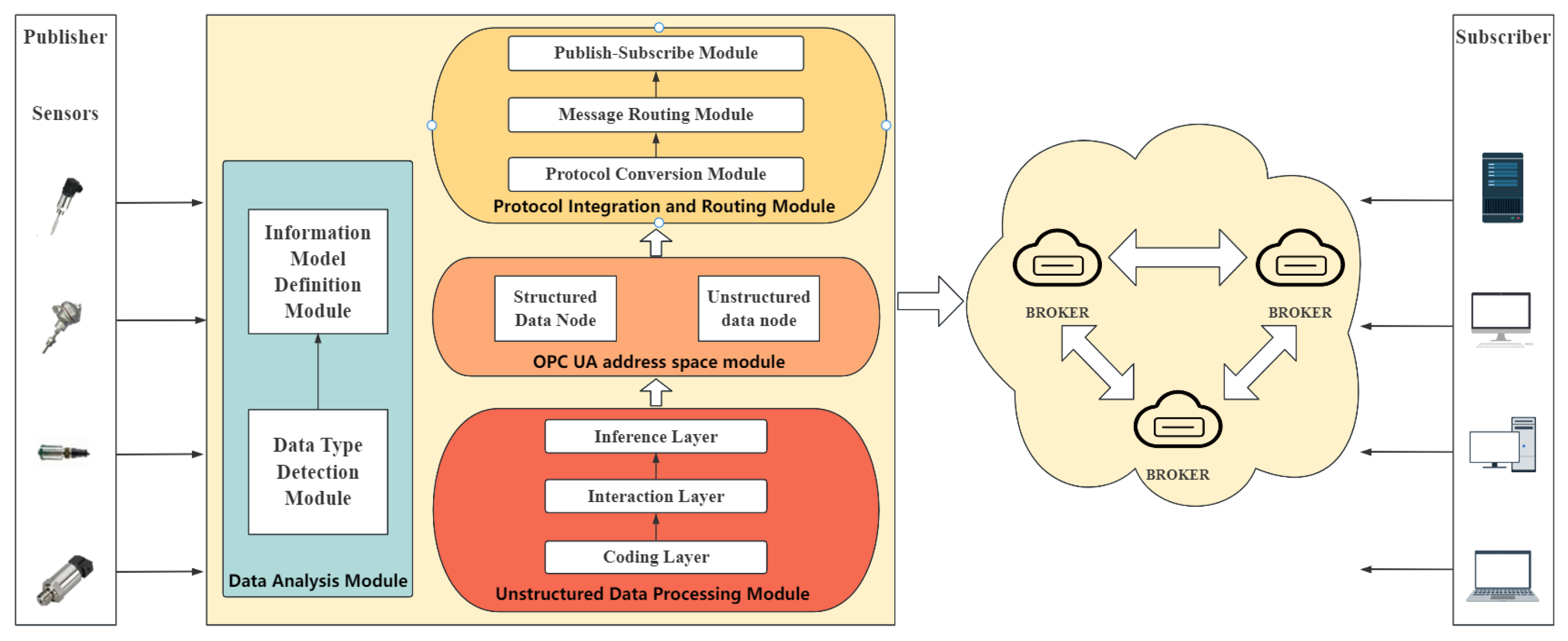

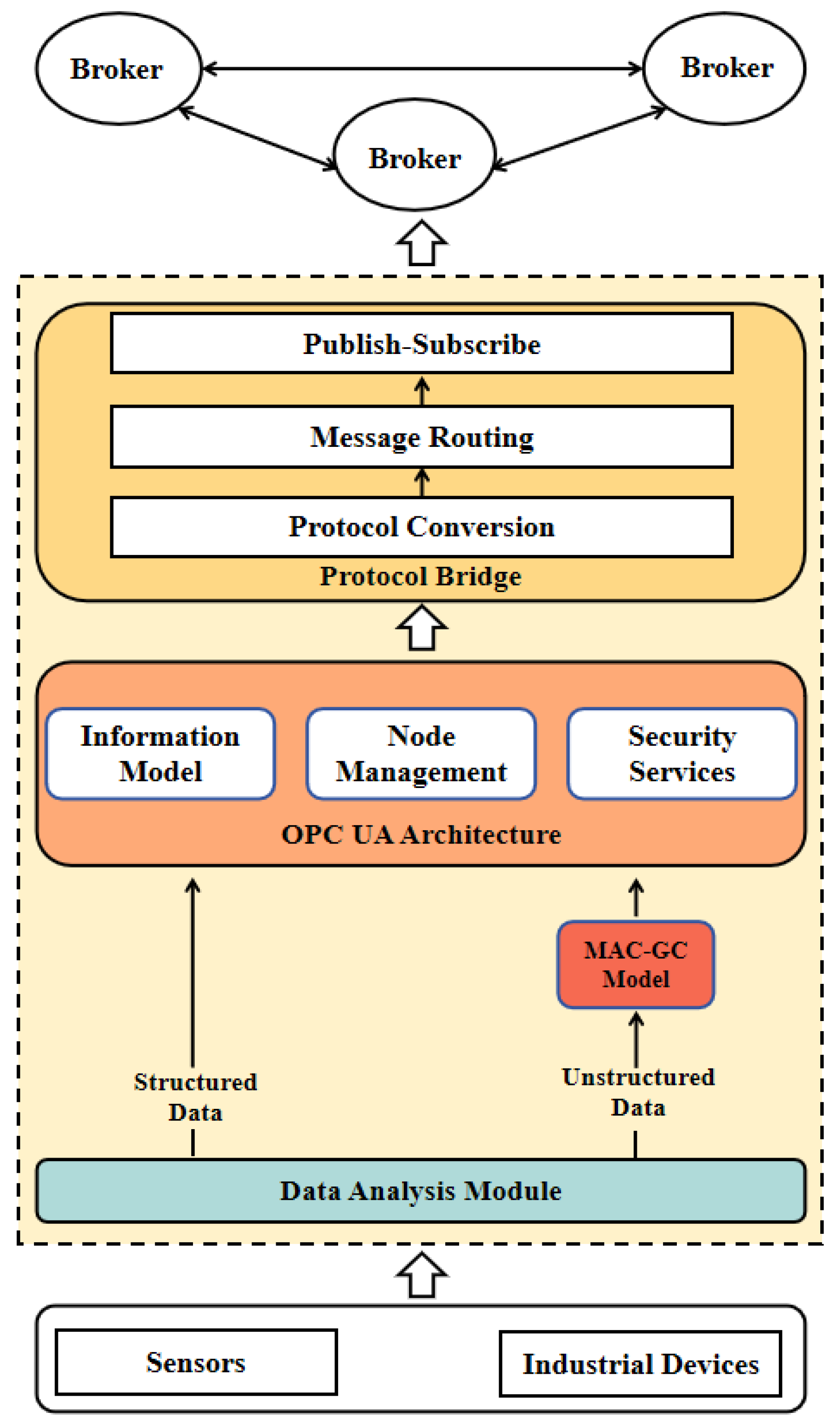

- Based on the traditional client/server communication architecture, this paper proposes the DUA-MQTT distributed communication model, which introduces a multi-agent collaboration mechanism and the distributed MQTT protocol, to achieve efficient communication among heterogeneous devices. This model adopts a multi-agent mechanism to optimize resource utilization, combines load-balancing strategies to enhance system scalability and fault tolerance, effectively reduces communication latency, and improves transmission efficiency in high-concurrency environments.

- (2)

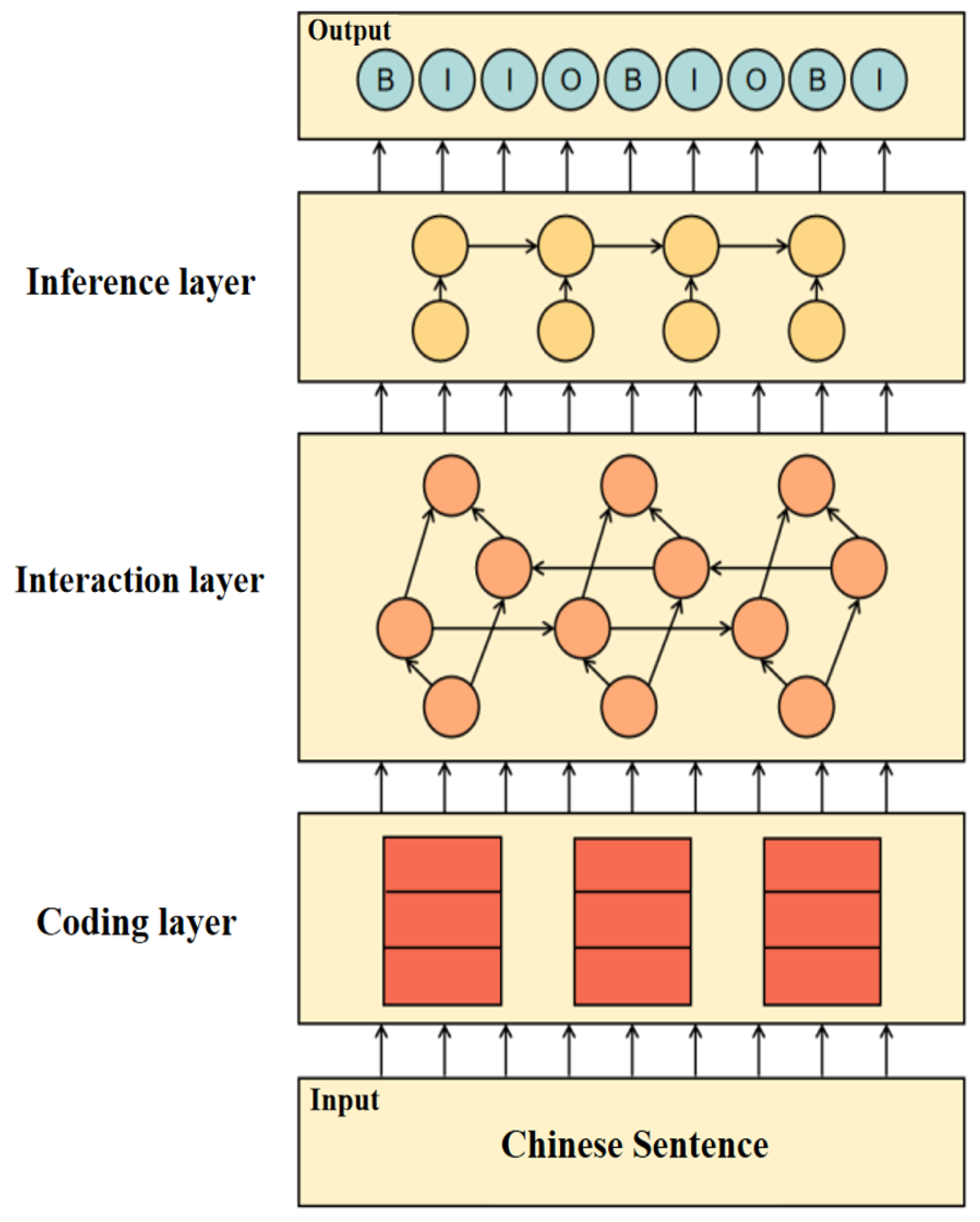

- To address the challenge of modeling unstructured text data in industrial scenarios, this paper proposes the MAC-GC modeling model, which is used to achieve high-quality semantic expression, context feature capture, and label sequence decoding. This model can accurately extract key entities and attribute information from industrial texts and construct information model nodes that conform to the OPC UA standard, significantly enhancing the expression ability and modeling accuracy of unstructured data.

- (3)

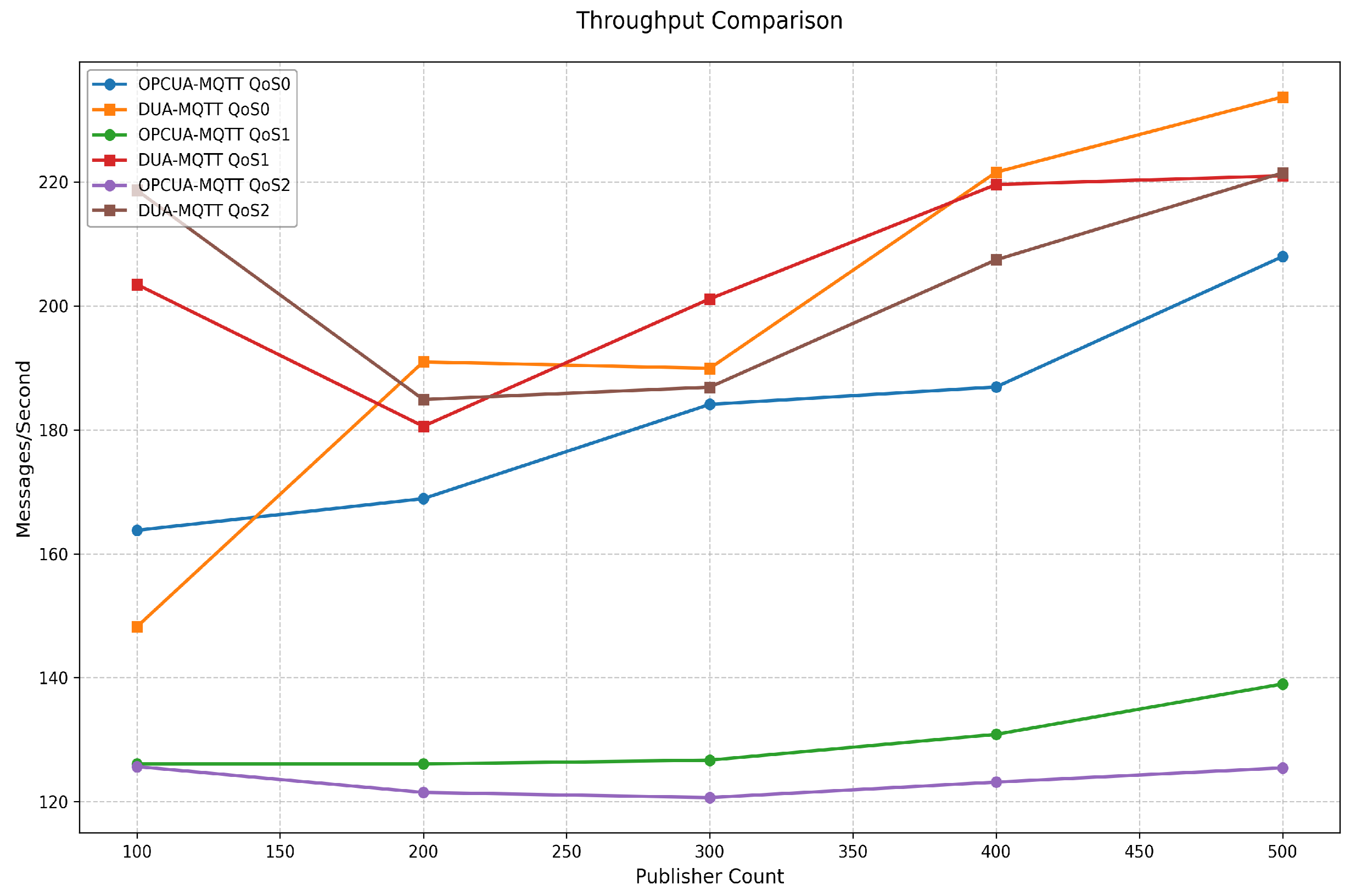

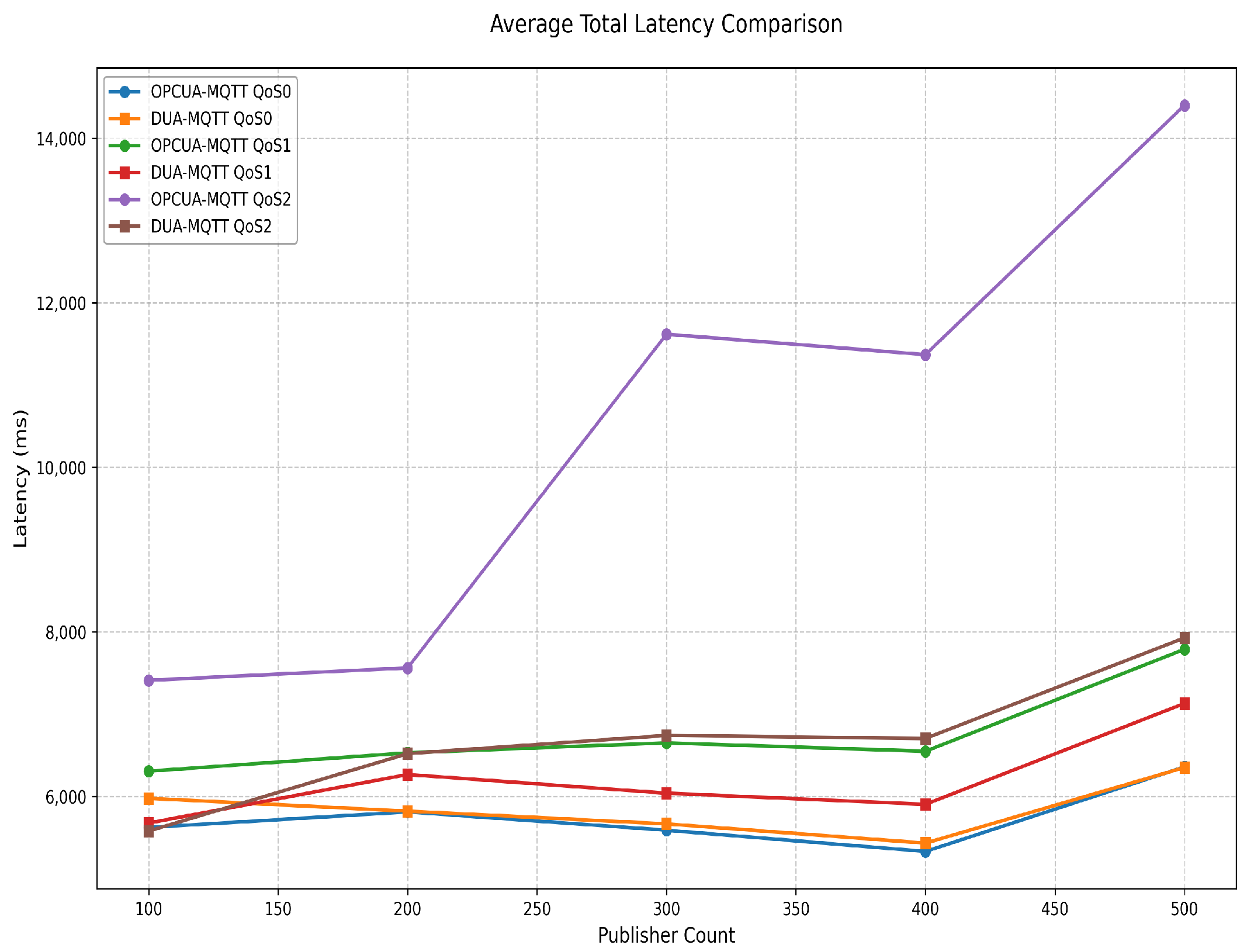

- The DUA-MQTT model has been experimentally verified to possess a superior concurrent transmission performance in high-load, large-scale industrial Internet of Things environments. The distributed architecture significantly enhances system throughput and reduces end-to-end communication latency. Meanwhile, the MAC-GC model demonstrates higher processing efficiency and semantic understanding capabilities in information-modeling tasks involving unstructured data.

2. Related Work

3. Distributed and Highly Available Messaging and Communication Model for Industrial IoT

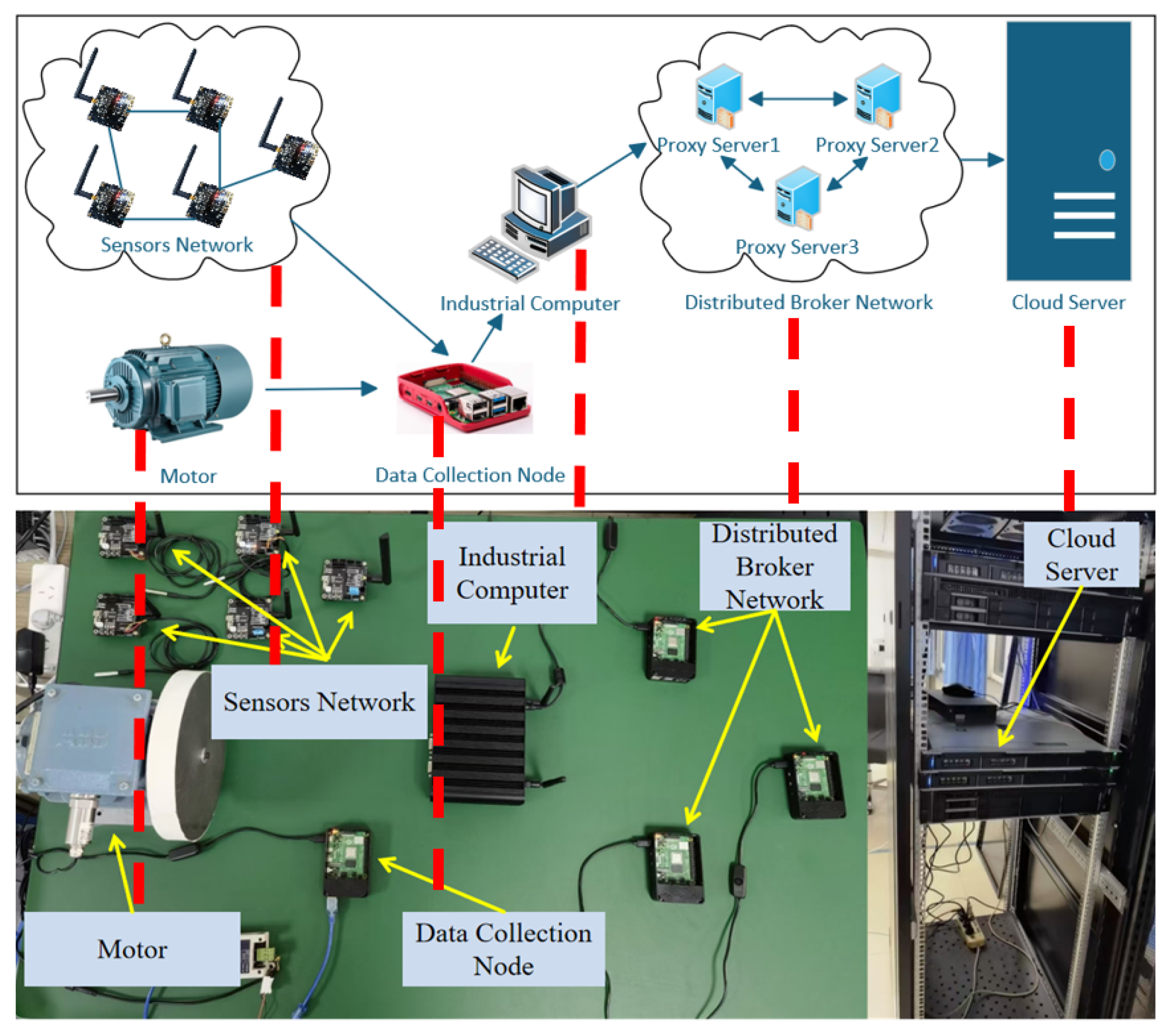

3.1. Overall Architecture

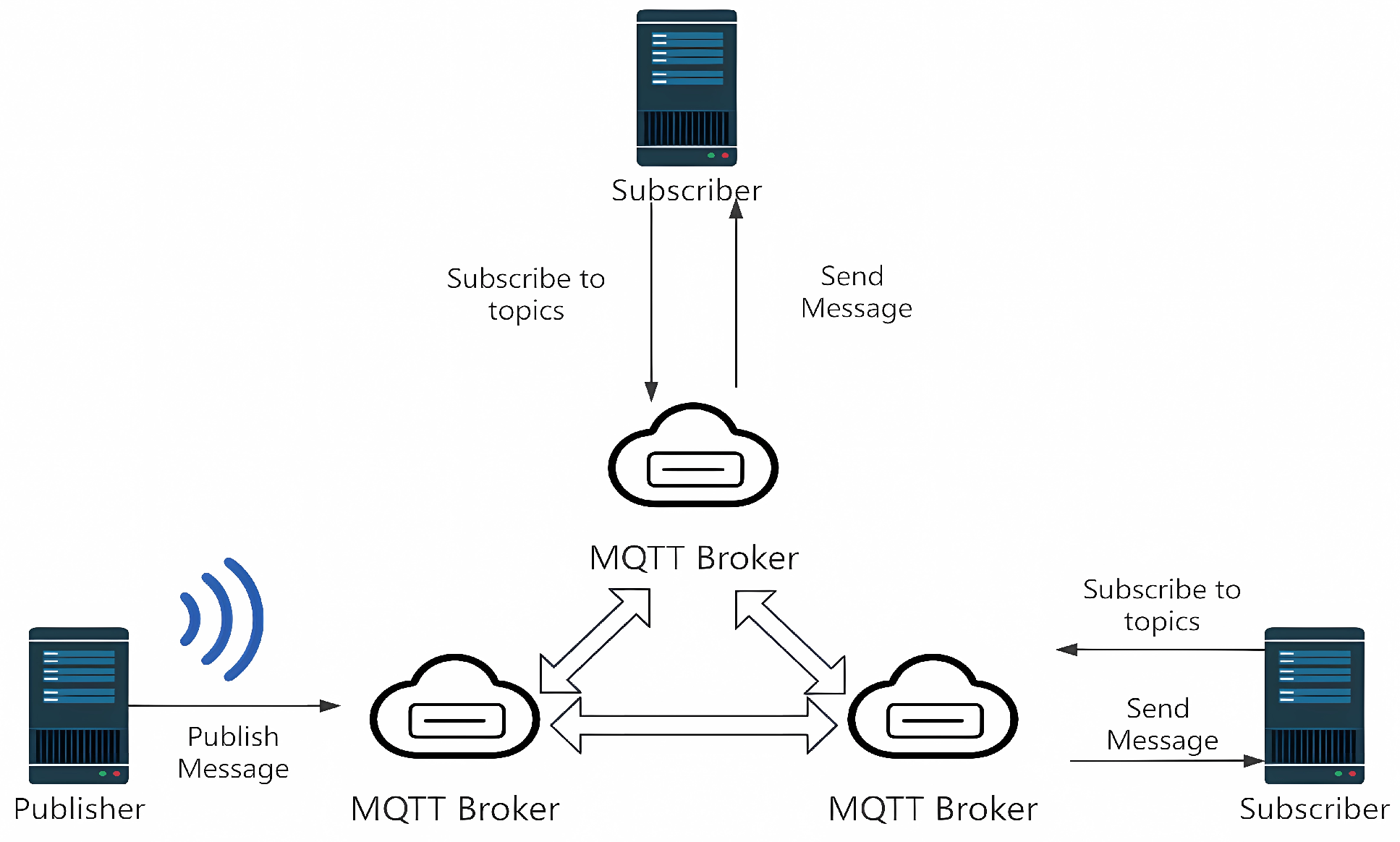

3.2. Distributed Multi-Agent Collaborative Communication Strategy Based on MQTT

3.3. Information-Modeling Method Based on Industrial Unstructured Text Data

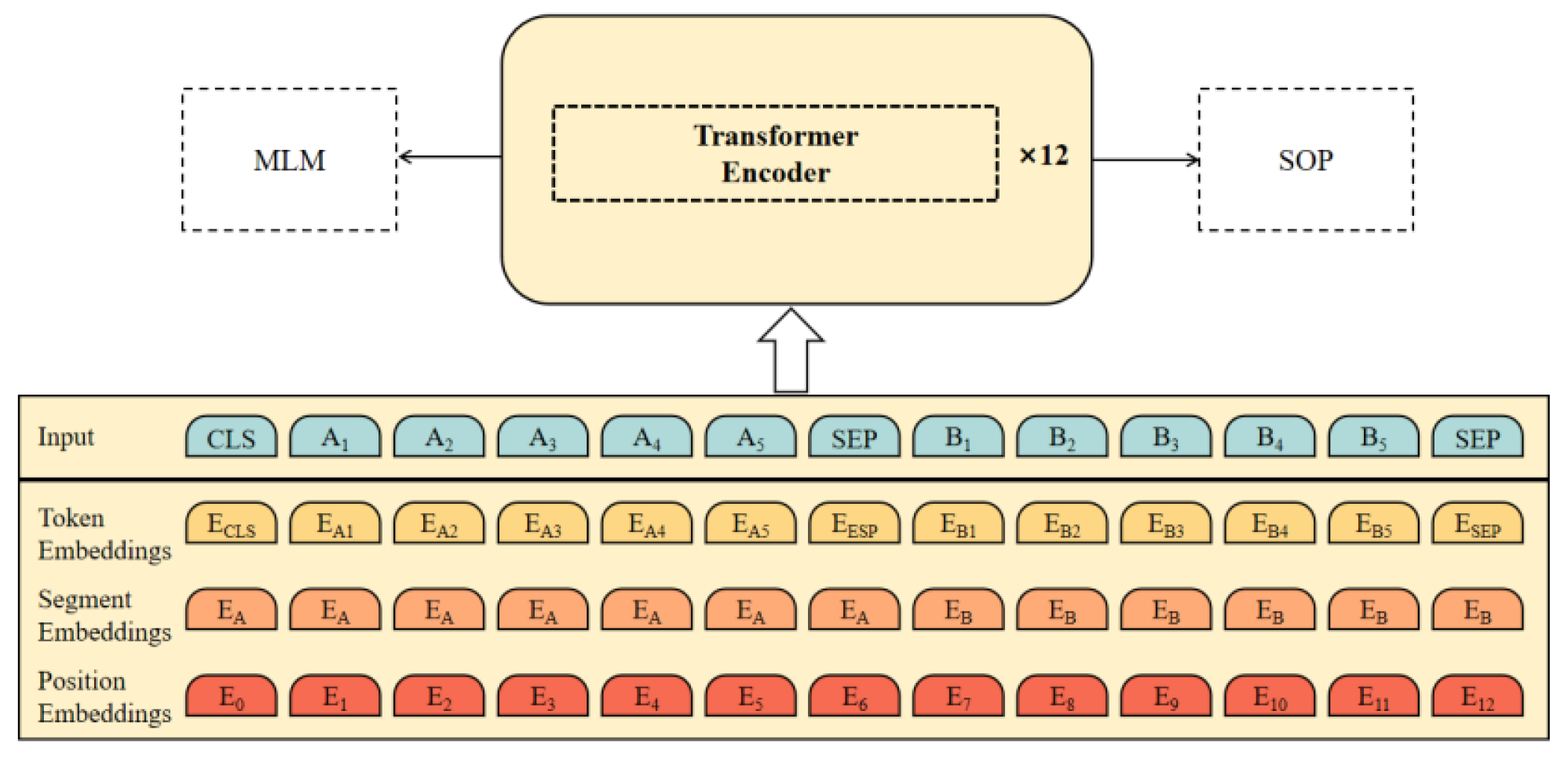

3.3.1. Encoding Layer

3.3.2. Interaction Layer

3.3.3. Inference Layer

4. Experimental Results and Discussion

4.1. Communication Performance Analysis

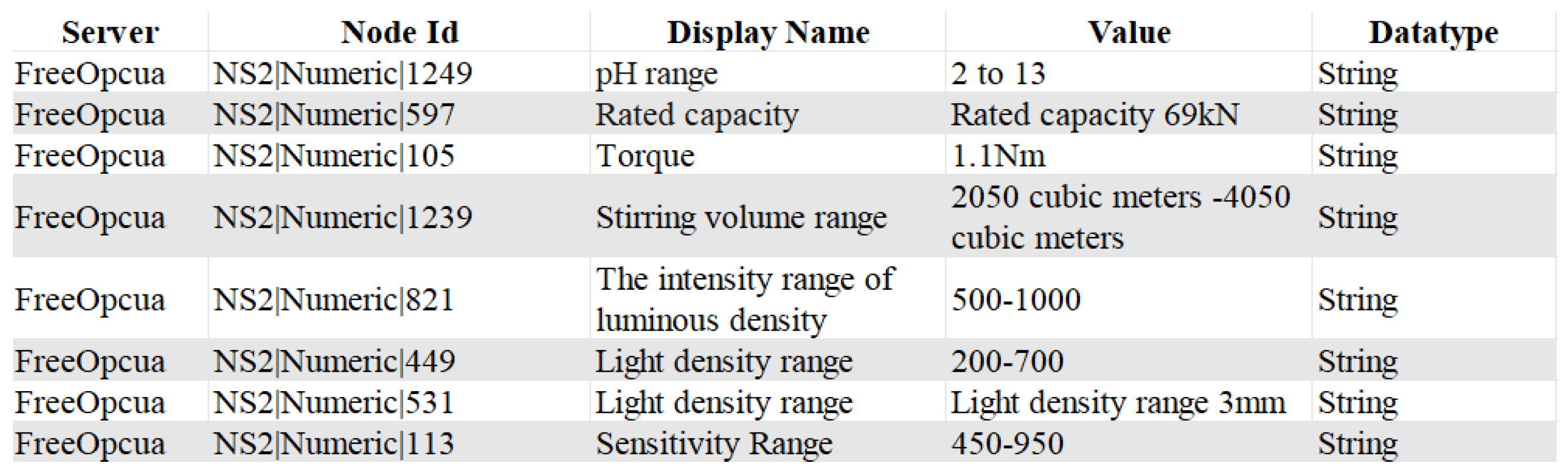

4.2. Information Modeling Capability Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Algorithm A1 DUA-MQTT Network Construction and Message Forwarding |

Input: Root agent selection criteria (CPU speed, memory size), Non-root agent resources Output: Updated network topology, routing decisions, QoS levels, LWT messages

|

References

- Huang, M.; Peng, Q.; Zhu, X.; Deng, T.; Cao, R.; Liu, W. Ensuring Trustworthy and Secure IoT: Fundamentals, Threats, Solutions, and Future Hotspots. Comput. Netw. 2025, 263, 111218. [Google Scholar] [CrossRef]

- Serror, M.; Hack, S.; Henze, M.; Schuba, M.; Wehrle, K. Challenges and Opportunities in Securing the Industrial Internet of Things. IEEE Trans. Ind. Inform. 2021, 17, 2985–2996. [Google Scholar] [CrossRef]

- Afrin, S.; Rafa, S.J.; Kabir, M.; Farah, T.; Alam, M.S.B.; Lameesa, A.; Ahmed, S.F.; Gandomi, A.H. Industrial Internet of Things: Implementations, Challenges, and Potential Solutions across Various Industries. Comput. Ind. 2025, 170, 104317. [Google Scholar] [CrossRef]

- Anjum, N.; Latif, Z.; Chen, H. Security and Privacy of Industrial Big Data: Motivation, Opportunities, and Challenges. J. Netw. Comput. Appl. 2025, 237, 104130. [Google Scholar] [CrossRef]

- Hazra, A.; Adhikari, M.; Amgoth, T.; Srirama, S.N. A comprehensive survey on interoperability for IIoT: Taxonomy, standards, and future directions. ACM Comput. Surv. 2021, 55, 9:1–9:35. [Google Scholar] [CrossRef]

- Sun, D.; Xi, Y.; Yaqot, A.; Hellbrück, H.; Wu, H. Throughput maximization using deep complex networks for industrial Internet of Things. Sensors 2023, 23, 951. [Google Scholar] [CrossRef]

- Zou, L.; Wang, Z.; Hu, J.; Liu, Y.; Liu, X. Communication-protocol-based analysis and synthesis of networked systems: Progress, prospects and challenges. Int. J. Syst. Sci. 2021, 52, 3013–3034. [Google Scholar] [CrossRef]

- Shin, S.-J. An OPC UA-compliant interface of data analytics models for interoperable manufacturing intelligence. IEEE Trans. Ind. Inform. 2021, 17, 3588–3598. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Jiang, P.; Deng, M.; Wang, X.V.; Yin, C. Knowledge Graph Based OPC UA Information Model Automatic Construction Method for Heterogeneous Devices Integration. Robot. Comput.-Integr. Manuf. 2024, 88, 102736. [Google Scholar] [CrossRef]

- Chai, A.; Ma, Y.; Yin, Z.; Li, M. Real-time communication model based on OPC UA wireless network for intelligent production line. IEEE Access 2021, 9, 102312–102326. [Google Scholar] [CrossRef]

- Fukushima, Y.; Tsunamoto, H.; Sakai, K.; Sun, M.-T.; Ku, W.-S. An Analysis of Anonymous MQTT for Publish-Subscribe-Based IoT Networks. IEEE Trans. Netw. Sci. Eng. 2025, 12, 3206–3220. [Google Scholar] [CrossRef]

- Jesus, B.; Lins, F.; Laranjeiro, N. An Approach to Assess Robustness of MQTT-Based IoT Systems. Internet Things 2025, 31, 101590. [Google Scholar] [CrossRef]

- Bartoli, C.; Bonanni, M.; Chiti, F.; Pierucci, L. The Alliance of SDN and MQTT for the Web of Industrial Things. IEEE Trans. Ind. Inform. 2025, 21, 4367–4376. [Google Scholar] [CrossRef]

- Gil, S.; Zapata-Madrigal, G.D.; García-Sierra, R.; Cruz Salazar, L.A. Converging IoT protocols for the data integration of automation systems in the electrical industry. J. Electr. Syst. Inf. Technol. 2022, 9, 1. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Li, Y.; Fan, X.; Xiao, S.; Hu, L. A review of the technology standards for enabling digital twin. Digit. Twin 2022, 2, 4. [Google Scholar] [CrossRef]

- Xia, D.; Jiang, C.; Wan, J.; Jin, J.; Leung, V.C.M.; Martínez-García, M. Heterogeneous network access and fusion in smart factory: A survey. ACM Comput. Surv. 2022, 55, 113:1–113:31. [Google Scholar] [CrossRef]

- Mileva, A.; Velinov, A.; Hartmann, L.; Wendzel, S.; Mazurczyk, W. Comprehensive analysis of MQTT 5.0 susceptibility to network covert channels. Comput. Secur. 2021, 104, 102207. [Google Scholar] [CrossRef]

- Liu, Z.; Bellot, P. A configuration tool for MQTT based OPC UA PubSub. In Proceedings of the 2020 RIVF International Conference on Computing and Communication Technologies (RIVF), Ho Chi Minh City, Vietnam, 14–15 October 2020; pp. 1–6. [Google Scholar]

- Nast, M.; Raddatz, H.; Golatowski, F.; Haubelt, C. A novel OPC UA PubSub protocol binding using MQTT for sensor networks (MQTT-SN). In Proceedings of the 2024 IEEE 29th International Conference on Emerging Technologies and Factory Automation (ETFA), Padova, Italy, 10–13 September 2024; pp. 1–4. [Google Scholar]

- Longo, E.; Redondi, A.E.C.; Cesana, M.; Manzoni, P. BORDER: A benchmarking framework for distributed MQTT brokers. IEEE Internet Things J. 2022, 9, 17728–17740. [Google Scholar] [CrossRef]

- Buccafurri, F.; de Angelis, V.; Lazzaro, S. MQTT-A: A broker-bridging P2P architecture to achieve anonymity in MQTT. IEEE Internet Things J. 2023, 10, 15443–15463. [Google Scholar] [CrossRef]

- Shi, H.; Niu, L.; Sun, J. Construction of industrial internet of things based on MQTT and OPC UA protocols. In Proceedings of the 2020 IEEE International Conference on Artificial Intelligence and Computer Applications (ICAICA), Dalian, China, 27–29 June 2020; pp. 1263–1267. [Google Scholar]

- Sheng, C.; Zhou, W.; Han, Q.-L.; Ma, W.; Zhu, X.; Wen, S.; Xiang, Y. Network Traffic Fingerprinting for IIoT Device Identification: A Survey. IEEE Trans. Ind. Inform. 2025, 21, 3541–3554. [Google Scholar] [CrossRef]

- Feng, X.; Zhu, X.; Han, Q.-L.; Zhou, W.; Wen, S.; Xiang, Y. Detecting Vulnerability on IoT Device Firmware: A Survey. IEEE/CAA J. Autom. Sin. 2023, 10, 25–41. [Google Scholar] [CrossRef]

- Bauer, H.; Höppner, S.; Iatrou, C.; Charania, Z.; Hartmann, S.; Rehman, S.U.; Dixius, A.; Ellguth, G.; Walter, D.; Uhlig, J.; et al. Hardware implementation of an OPC UA server for industrial field devices. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2021, 29, 1998–2002. [Google Scholar] [CrossRef]

- Cho, A.; Kim, T.; Kim, C.K.; Choi, S.; Lee, S. IoT data dissemination scheme for reducing delay in multi-broker environments. Internet Things 2024, 25, 101025. [Google Scholar] [CrossRef]

- Chai, A.; Li, M.; Yang, H.; Guo, C. EMD-EmLSTM: A QoS analysis and prediction method for industrial internet of things. IEEE Internet Things J. 2024, 11, 32730–32744. [Google Scholar] [CrossRef]

- Yang, H.; Guo, C.; Chai, A.; Jia, Z.; Liang, X. A energy efficiency optimization routing processing method for Linear Wireless Sensor Networks. Internet Things 2024, 27, 101285. [Google Scholar] [CrossRef]

- Ji, T.; Xu, X. Exploring the integration of cloud manufacturing and cyber-physical systems in the era of industry 4.0–An OPC UA approach. Robot. Comput.-Integr. Manuf. 2025, 93, 102927. [Google Scholar] [CrossRef]

- Gide, A.I.; Mu’azu, A.A. A Real-Time Intrusion Detection System for DoS/DDoS Attack Classification in IoT Networks Using KNN-Neural Network Hybrid Technique. Babylon. J. Internet Things 2024, 2024, 60–69. [Google Scholar] [CrossRef]

- Cavalieri, S.; Salafia, M.G.; Scroppo, M.S. Towards interoperability between OPC UA and OCF. J. Ind. Inf. Integr. 2019, 15, 122–137. [Google Scholar] [CrossRef]

- Wang, R.; Gu, C.; He, S.; Chen, J. Text2UA: Automatic OPC UA Information Modeling from Textual Data with Large Language Model. IEEE/CAA J. Autom. Sin. 2025, 1–3. [Google Scholar] [CrossRef]

- Muniraj, S.P.; Xu, X. An implementation of OPC UA for machine-to-machine communications in a smart factory. Procedia Manuf. 2021, 53, 52–58. [Google Scholar] [CrossRef]

- Dai, W.; Zhang, Y.; Zhang, Y.; Kang, J.; Huang, D. Automatic information model generation for industrial edge applications based on IEC 61499 and OPC UA. IEEE Trans. Ind. Inform. 2023, 19, 6093–6104. [Google Scholar] [CrossRef]

- Busboom, A. Automated generation of OPC UA information models—A review and outlook. J. Ind. Inf. Integr. 2024, 39, 100602. [Google Scholar] [CrossRef]

- Martins, A.; Lucas, J.; Costelha, H.; Neves, C. CNC machines integration in smart factories using OPC UA. J. Ind. Inf. Integr. 2023, 34, 100482. [Google Scholar] [CrossRef]

- Wang, B.; Xie, Q.; Pei, J.; Chen, Z.; Tiwari, P.; Li, Z.; Fu, J. Pre-trained Language Models in Biomedical Domain: A Systematic Survey. ACM Comput. Surv. 2023, 56, 55:1–55:52. [Google Scholar] [CrossRef]

- Lee, J.; Yoon, W.; Kim, S.; Kim, D.; Kim, S.; So, C.H.; Kang, J. BioBERT: A pre-trained biomedical language representation model for biomedical text mining. Bioinformatics 2020, 36, 1234–1240. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Che, W.; Liu, T.; Qin, B.; Yang, Z. Pre-training with whole word masking for Chinese BERT. IEEE/ACM Trans. Audio Speech Lang. Process. 2021, 29, 3504–3514. [Google Scholar] [CrossRef]

| QoS Level | Description |

|---|---|

| QoS 0 | The message is sent without acknowledgment, which may lead to message loss. |

| QoS 1 | Ensures that the message is delivered at least once, but duplicates may occur. |

| QoS 2 | Guarantees that the message is delivered exactly once through a strict acknowledgment mechanism. |

| Parameter | Value |

|---|---|

| Transformer layers | 12 |

| Hidden layer dimension | 768 |

| Epochs | 20 |

| Learning rate | |

| Batch size | 8 |

| Dropout | 0.5 |

| GRU dimension | 128 |

| Model | P | R | F1 |

|---|---|---|---|

| BiGRU–CRF | 0.8671 | 0.8599 | 0.8635 |

| MacBERT–CRF | 0.9355 | 0.9238 | 0.9294 |

| MAC–GC | 0.9701 | 0.9601 | 0.9651 |

| Model | P | R | F1 |

|---|---|---|---|

| BERT–CRF | 0.9030 | 0.9032 | 0.9028 |

| BERT–BiLSTM–CRF | 0.9237 | 0.9151 | 0.9194 |

| RoBERTa–BiLSTM–CRF | 0.9377 | 0.9258 | 0.9317 |

| MAC–GC | 0.9701 | 0.9601 | 0.9651 |

| Label Type | Information Model Node Type |

|---|---|

| Objects: OBJ | Object type node |

| Components: COM | Reference type node |

| Attributes: ATT | Variable node |

| Attribute values: VAL | Variable node value |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, A.; Yin, W.; Lian, M.; Sun, Y.; Guo, C.; Wang, L.; Fang, Z. DUA-MQTT: A Distributed High-Availability Message Communication Model for the Industrial Internet of Things. Sensors 2025, 25, 5071. https://doi.org/10.3390/s25165071

Chai A, Yin W, Lian M, Sun Y, Guo C, Wang L, Fang Z. DUA-MQTT: A Distributed High-Availability Message Communication Model for the Industrial Internet of Things. Sensors. 2025; 25(16):5071. https://doi.org/10.3390/s25165071

Chicago/Turabian StyleChai, Anying, Wanda Yin, Mengjia Lian, Yunpeng Sun, Chenyang Guo, Lei Wang, and Zhaobo Fang. 2025. "DUA-MQTT: A Distributed High-Availability Message Communication Model for the Industrial Internet of Things" Sensors 25, no. 16: 5071. https://doi.org/10.3390/s25165071

APA StyleChai, A., Yin, W., Lian, M., Sun, Y., Guo, C., Wang, L., & Fang, Z. (2025). DUA-MQTT: A Distributed High-Availability Message Communication Model for the Industrial Internet of Things. Sensors, 25(16), 5071. https://doi.org/10.3390/s25165071