A Review on Pipeline In-Line Inspection Technologies

Abstract

1. Introduction

2. Research Status

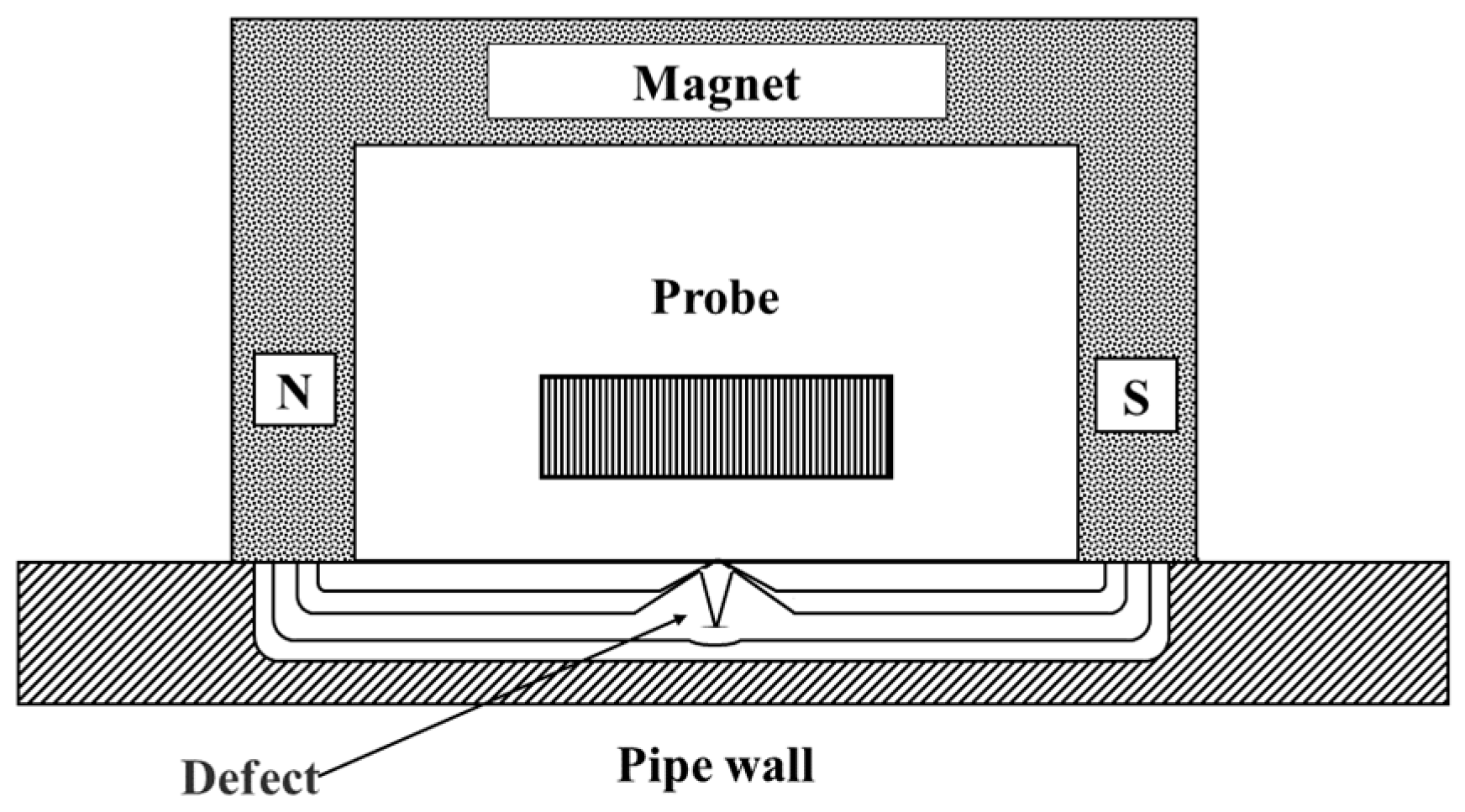

2.1. Electromagnetic Inspection Technologies

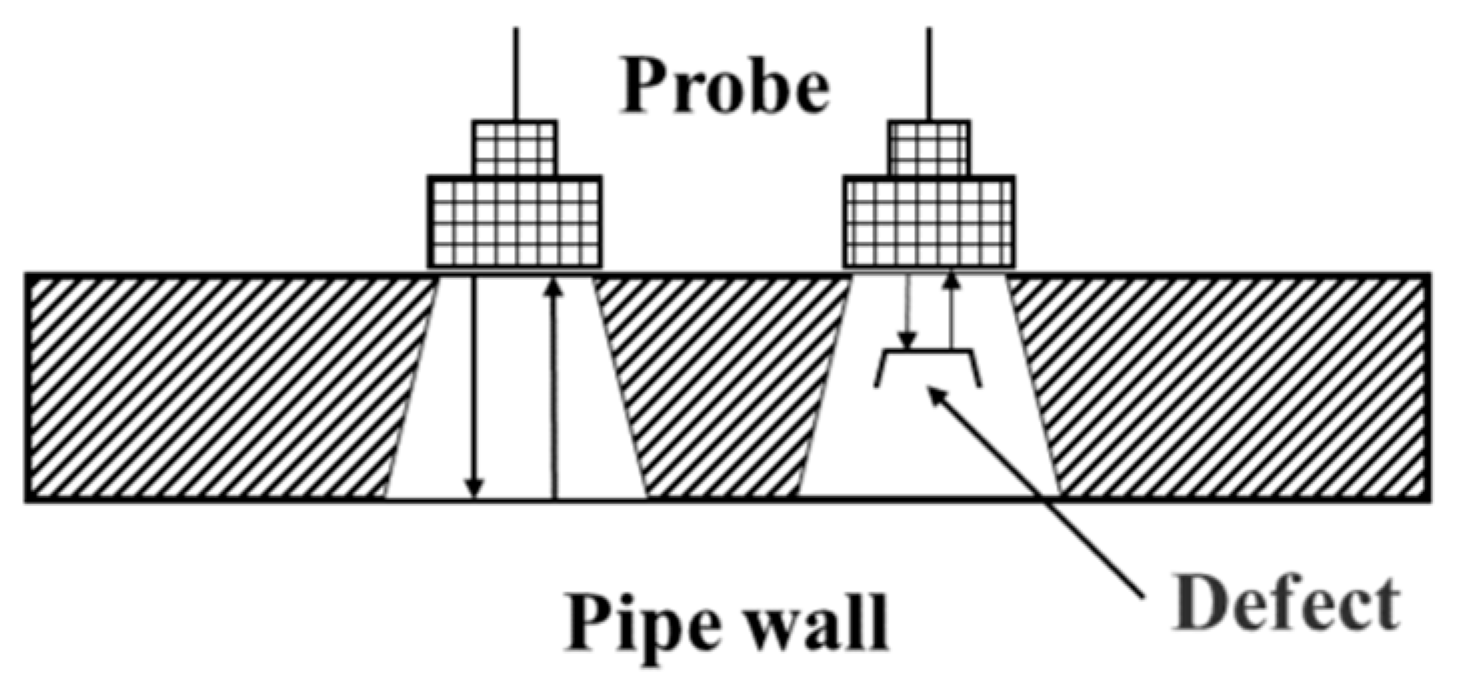

2.2. Acoustic Inspection Technologies

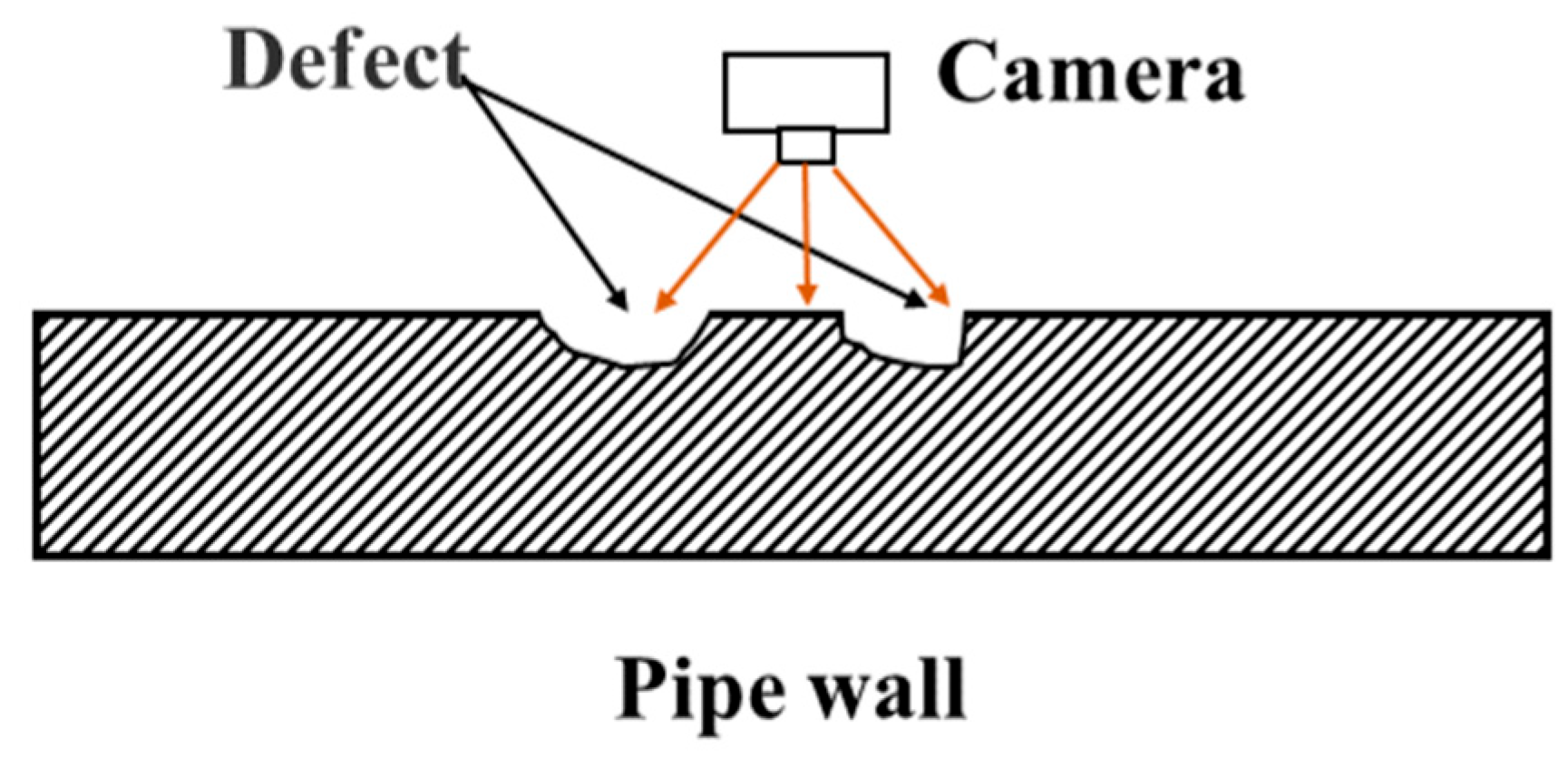

2.3. Optical Inspection Technologies

2.4. Robotic Technology

2.5. Multi-Technology Integration and Special Applications

3. Challenges and Future Perspectives

3.1. Current Challenges

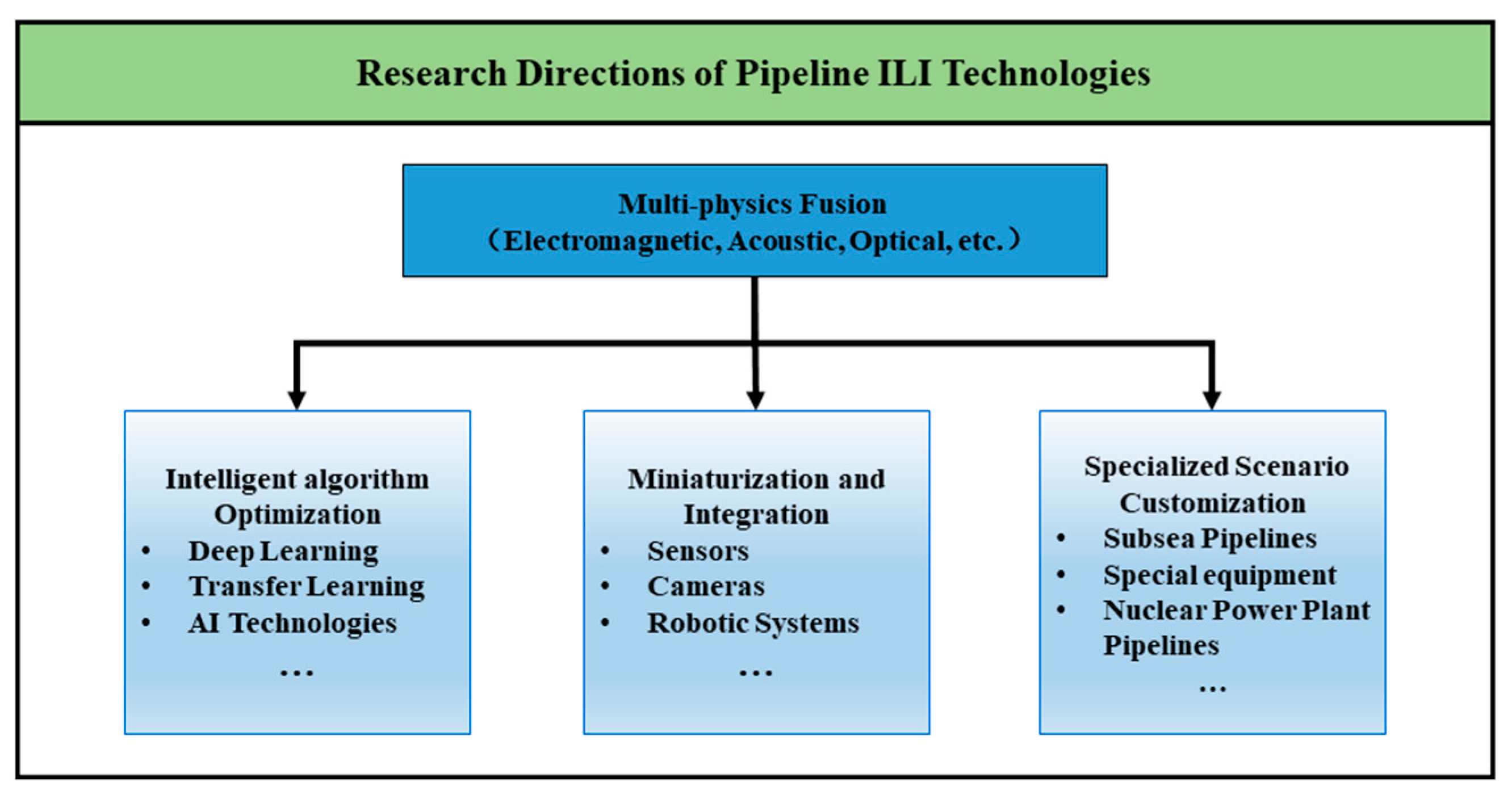

3.2. Future Directions

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Niu, A.; Guo, K.; Dong, C.; Gao, J. Research Status of Inspection Technologies for Long-Distance Oil and Gas Pipelines. Pet. Eng. Constr. 2023, 49, 1–8. [Google Scholar]

- Wang, H.; Zhang, Y.; Gong, Y.; Ma, Y.; An, C. Research Progress in Internal Inspection Technology for Small and Medium-Diameter Gathering Pipelines. China Spec. Equip. Saf. 2025, 41, 3–8. [Google Scholar]

- Xin, J.; Chen, J.; Li, X.; Wang, C.; Zhang, X.; Zhu, H. Research Frontiers in Internal Inspection Technology for Oil and Gas Pipelines. Pet. Mach. 2022, 50, 119–126. [Google Scholar]

- Han, C.; Liu, R.; Liu, G.; Duan, W.; Yan, Y.; Zhao, H. Research on Artillery Barrel Bore Inspection Method Based on Laser Circumferential Scanning and Centering Correction. Ordnance Ind. Autom. 2024, 43, 65–68. [Google Scholar]

- Zhang, J.; Wang, X.; Shi, W.; Dong, Z.; Deng, H. Detection Method for Internal Chamber Cracks of Large-Caliber Artillery Barrels Using Electromagnetic Ultrasonic Surface Horizontal Shear Waves. Acta Armamentarii 2021, 42, 1763–1770. [Google Scholar]

- Fan, X.; Chai, N.; Shi, Y.; Chen, Y.; Chen, F.; Ye, W. Application and Progress of Electromagnetic Testing Technology in Weld Defect Detection for Oil and Gas Pipelines. Nondestruct. Test. 2025, 47, 79–85. [Google Scholar]

- Wu, Y.; Guo, B.; Hu, P.; Chen, J. Internal Inspection Technology for Low-Pressure Natural Gas Pipelines. China Spec. Equip. Saf. 2023, 39, 17–22. [Google Scholar]

- Jian, Q.; Wang, B.; Zhao, J.; Ai, Z. Comparison of Methods for Distinguishing Internal and External Defects in Steel Pipes Based on Magnetic Flux Leakage Principle. Mech. Electr. Technol. 2013, 36, 163–166. [Google Scholar]

- Li, J. The Discrimination Methods of the Inside and Outside Defects in the Ferromagnetic Tubular Products During Magnetic Flux Leakage Testing; Huazhong University of Science and Technology: Wuhan, China, 2009. [Google Scholar]

- Hong, Y.; Liu, Y.; Wang, J.; Wu, S.; Ruan, J. Relationship Between Coincidence of Internal/External Defects in Ferromagnetic Components and Magnetic Flux Leakage Signals. Nondestruct. Test. 2024, 46, 24–31. [Google Scholar]

- Long, Y.; Huang, S.; Peng, L.; Wang, W.; Wang, S.; Zhao, W. Internal and External Defects Discrimination of Pipelines Using Composite Magnetic Flux Leakage Detection. In Proceedings of the 2021 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Glasgow, UK, 17–20 May 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Li, Y.; Hu, P.; Chen, J. Application of Magnetic Flux Leakage Internal Inspection Technology in Gathering Pipeline Detection. China Spec. Equip. Saf. 2023, 39, 28–32. [Google Scholar]

- Saha, S.; Mukherjee, D.; Chandra, Y.; Ramrane, S.C.; Lahiri, S.K.; Marathe, P.P. Development of Sectored External Pipeline Inspection Gauge for Health Monitoring of Industrial Carbon Steel Pipelines. In Advances in Non-Destructive Evaluation, Proceedings of NDE 2019—Conference & Exhibition, Bengaluru, India, 5–7 December 2019; Mukhopadhyay, C., Mulaveesala, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 85–96. [Google Scholar]

- Dong, S.; Tian, Z.; Lai, S.; Wang, T.; Song, Z.; Peng, D.; Liu, G.; Wei, H. Development and Application of New-Generation Ultra-High-Definition Submillimeter-Level Pipeline Internal Inspection Technology. Oil Gas Storage Transp. 2022, 41, 34–41. [Google Scholar]

- Qi, G.; Fan, X.; Zhang, H.; Xu, B.; Zhang, Y.; Sun, W.; Wang, H.; Zhang, J. Detection Technology and Application of Submarine Pipeline. Pipeline Tech. Equip. 2020, 5, 29–31. [Google Scholar]

- Morris, R.D.; Barker, T. Hydrogen Pipeline In-Line Inspection Case Study. In Proceedings of the CORROSION 2021, Virtual, 19–30 April 2021. [Google Scholar]

- Lynch, A.J. Magnetic Flux Leakage Robotic Pipe Inspection: Internal and External Methods. Master’s Thesis, Rice University, Houston, TX, USA, 2009. [Google Scholar]

- Wang, J.; Wang, N.; Xu, J.; Cao, Y.; Cao, Y.; Huang, P. Composite Detection Method for Subsurface Defects in Gas Gathering Station Pipelines Using Eddy Current and Ultrasonic Techniques. In Proceedings of the 2023 China Automation Congress (CAC), Chongqing, China, 17–19 November 2023; pp. 2949–2953. [Google Scholar] [CrossRef]

- Yang, L.; Guo, X.; Gao, S. Eddy Current Testing Method for Internal Surface Defects of Pipelines. Instrum. Tech. Sens. 2014, 10, 78–81. [Google Scholar]

- Abdul Halim, M.F.; Sahadan, S.N. Effectiveness of Portable Eddy Current Inspection on Welding Pipeline. In Proceedings of the Engineering Technology International Conference (ETIC 2022), Kuantan, Malaysia, 7–8 September 2023; Volume 2022, pp. 12–18. [Google Scholar]

- Lu, Y.; Lei, H. Planar L-Shaped Eddy Current Sensor for Pipeline Inspection. Instrum. Tech. Sens. 2025, 1, 1–6. [Google Scholar]

- Chen, S.; Feng, B.; Zhang, M.; Kang, Y. Quantitative Measurement of Carburization Layer Thickness in Furnace Tubes Based on Eddy Current Sensor Impedance Analysis. Instrum. Tech. Sens. 2024, 27, 12–15. [Google Scholar]

- Dong, S.; Zhang, Y.; Wu, Q.; Tong, P.; Han, Z. Online Inspection System for Tube Array Eddy Current Testing. Instrum. Tech. Sens. 2024, 65, 57–61. [Google Scholar]

- Kumar, D.; Kalra, S.; Jha, M.S. A Concise Review on Degradation of Gun Barrels and Its Health Monitoring Techniques. Eng. Fail. Anal. 2022, 142, 106791. [Google Scholar] [CrossRef]

- Wu, Y.; Xin, H.; Shao, W.; Chen, J. A Comparative Study on Eddy Current and Magnetic Flux Leakage Inline Inspection Technology in Long-Distance Oil and Gas Pipelines. In Proceedings of the 2023 3rd International Conference on Energy, Power and Electrical Engineering (EPEE), Wuhan, China, 15–17 September 2023; pp. 416–420. [Google Scholar] [CrossRef]

- Xie, H.; Yao, W.; Ye, Y.; Lu, S. Design and research of pipeline inner inspection robot based on pulsed eddy current inspection system. China Meas. Test 2025, 51, 136–146. [Google Scholar]

- Zhao, F.; Tang, X.; Wang, J.; Pu, Z. Pulsed Eddy Current Detection System for Internal and External Defects of Metal Pipelines. Nondestruct. Test. 2020, 42, 58–62. [Google Scholar]

- Wang, C.; Wu, S.; Xin, J.; He, R.; Chen, J.; Wan, D. Numerical Simulation of Oil and Gas Pipeline Crack Detection Based on Pulsed Eddy Current Testing Technology. In Proceedings of the 2021 4th International Conference on Electron Device and Mechanical Engineering (ICEDME), Guangzhou, China, 19–21 March 2021; pp. 46–50. [Google Scholar] [CrossRef]

- Yang, C.; Sun, H.; Tang, C. Research on Metal Pipeline Defect Detection Using Electromagnetic Pulsed Eddy Current Testing. J. Electron. Meas. Instrum. 2025, 39, 132–140. [Google Scholar]

- Tao, A.; Yang, F.; Fu, Y.; Huang, W.; Xing, R.; Tang, C.; Cao, A. Characteristics of Focusing Probe in Pulsed Eddy Current Detection of Water-Wall Tube Corrosion. J. Vib. 2025, 45, 367–375+416–417. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Su, B.; Wang, R.; Jia, P.; Chen, Z. Pulsed Eddy Current Detection Method for Internal Corrosion Defects of In-Service Oil Tubes. Sens. Microsyst. 2024, 43, 122–125. [Google Scholar]

- Chen, T.; Yin, Y.; Lü, C.; Song, X.; Deng, Z.; Liao, C. Review of Pulsed Eddy Current Defect Detection Theory and Technology. J. Electron. Meas. Instrum. 2024, 38, 1–10. [Google Scholar]

- Pan, Y.; Cheng, X.; Li, J.; Li, J.; Xie, J.; Yin, Z.; Miao, C.; Zhao, Q. Analysis and Suggestions on Oil-Water Pipeline Inspection Methods for Compensators. Electr. Power Equip. Manag. 2024, 7, 269–271. [Google Scholar]

- Cao, J.; Ji, B.; Ji, W. Laser Ultrasonic Detection Method and Experiment for Internal Surface Cracks in X80 Pipelines. Oil Gas Storage Transp. 2021, 40, 1365–1369. [Google Scholar]

- Skjelvareid, M.H.; Birkelund, Y.; Larsen, Y. Internal Pipeline Inspection Using Virtual Source Synthetic Aperture Ultrasound Imaging. NDT E Int. 2013, 54, 151–158. [Google Scholar] [CrossRef]

- Yang, P. Application of Ultrasonic Guided Wave Testing Technology in Pressure Pipeline Inspection. Chem. Enterp. Manag. 2021, 30, 67–68. [Google Scholar]

- Okamoto, J.; Adamowski, J.C.; Tsuzuki, M.S.G.; Buiochi, F.; Camerini, C.S. Autonomous System for Oil Pipelines Inspection. Mechatronics 1999, 9, 731–743. [Google Scholar] [CrossRef]

- Mehd, Z.A.; Ibrahim, R.I.; Oudah, M.K. Oil Pipelines Inspection Using Guided-Wave Transducer. In Proceedings of the 3rd International Conference on Electromechanical Engineering & Its Applications (ICEMEA-2022), Baghdad, Iraq, 19–20 July 2022; AIP Publishing: Melville, NY, USA, 2024; Volume 3002, p. 040004. [Google Scholar] [CrossRef]

- Shi, H.; Hou, W. Structural Design of Pipeline Inspection Robots. Mach. Manuf. 2022, 60, 64–66. [Google Scholar]

- Wang, Y.; Song, D.; Li, B.; Qi, J. Review of Acoustic Emission Leak Detection in Gas Pipelines. J. Saf. Environ. 2024, 24, 1114–1127. [Google Scholar]

- Yang, L.; Tan, K.; Wu, J. Application of Acoustic Emission Nondestructive Testing Technology in Pipeline Fault Detection. Intern. Combust. Engine Parts 2023, 13, 90–92. [Google Scholar]

- Yoshida, K.; Matsukawa, S.; Okuda, T.; Hazama, M.; Kurokawa, S.; Murata, H. Microwave Time-Domain Analysis for Non-Destructive Inspection of FRPM Pipelines Using Electro-Optic Sensor. In Proceedings of the 2020 International Topical Meeting on Microwave Photonics (MWP), Matsue, Japan, 24–26 November 2020; pp. 260–263. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, D.; Ding, Z.; Lu, S.; Wang, Q.; Wu, J.; Qian, S.; Kong, F. Feasibility Study on Online Acoustic Emission Detection of Main Steam Pipelines of High-Temperature Boiler. Hot Work. Technol. 2024, 1–7. [Google Scholar] [CrossRef]

- Bai, C.; Bai, Y. Corrosion Detection Test of In-Service Pipelines Based on Acoustic Emission Technology. Chem. Eng. Mach. 2023, 50, 307–312+342. [Google Scholar]

- Liu, W.; Yang, J.; Lu, Y.; Zhou, Z.; Guo, J.; Yao, L.; Du, Y.; Zhang, C. Review of Acoustic Emission Testing Technology for Composite Material Diagnosis. Insul. Mater. 2024, 57, 9–16. [Google Scholar]

- Huang, M. Research on Machine Vision-Based Polyethylene Pipeline Internal Surface Defect Detection System. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2024. [Google Scholar] [CrossRef]

- Li, J. Research and Design of Gas Pipeline Internal Surface Crack Detection System. Master’s Thesis, Xihua University, Chengdu, China, 2023. [Google Scholar]

- Liu, R.; Shao, Z.; Sun, Q.; Yu, Z. Defect Detection and 3D Reconstruction of Complex Urban Underground Pipeline Scenes for Sewer Robots. Sensors 2024, 24, 7557. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Yan, R.; Xu, Y.; Qiao, J.; Yang, F. Enhanced Visual Pipeline Defect Detection Using Partial Convolution Image Restoration. In Proceedings of the 2021 International Conference on Signal Processing and Machine Learning (CONF-SPML), Stanford, CA, USA, 14 November 2021; pp. 139–144. [Google Scholar] [CrossRef]

- Durai, M.; Hsu, Y.M.; Chang, H. In-Line Inspection of Pipeline Defects Detection Using Ring-Type Laser. World J. Eng. Technol. 2021, 9, 589–603. [Google Scholar] [CrossRef]

- Jacintha, V.; Subramanian, S.; Sundarambal, B.; Karthikeyini, C.; Bommi, R.M. An Image Processing Based Fault Detection in Industrial Pipelines Using FCM and Kurtosis Process. In Proceedings of the 2022 6th International Conference on Devices, Circuits and Systems (ICDCS), Coimbatore, India, 21–22 April 2022; pp. 263–267. [Google Scholar] [CrossRef]

- Fahimipirehgalin, M.; Trunzer, E.; Odenweller, M.; Vogel-Heuser, B. Automated Visual Leak Detection and Localization for Chemical Plant Pipelines Using Machine Vision. Engineering 2021, 7, 123–161. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Y.; Dong, S.; Zhao, Z.; Chen, Q. Quantitative Detection Technology for Pipeline Damage Based on Laser Point Cloud Data. Bull. Surv. Mapp. 2024, 1, 120–125. [Google Scholar]

- Li, Y.; Dong, S.; Shi, Y.; Chen, Q. Quantitative Detection Technology for Deformation Defects in Drainage Pipelines Based on Laser Point Cloud Data. Chin. J. Eng. Geophys. 2024, 21, 54–61. [Google Scholar]

- Sun, Y.; Bao, J. Improved ICP Algorithm Based on k-Neighborhood Fast Search for Pipeline Inspection. J. Test Meas. Technol. 2019, 33, 99–103. [Google Scholar]

- Zhou, J. Research on Structured-Light-Based Internal Surface Defect Detection Technology for Pipelines. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2022. [Google Scholar]

- Wang, Y.; Shao, C. Application of Solid-State Area-Array LiDAR in Drainage Pipeline Inspection. Mod. Electron. Tech. 2023, 46, 1–6. [Google Scholar]

- Silva, W.; Lopes, R.; Zscherpel, U.; Meinel, D.; Ewert, U. X-Ray Imaging Techniques for Inspection of Composite Pipelines. Micron 2021, 145, 103033. [Google Scholar] [CrossRef]

- Xie, R.; Lu, Z.; Yi, Y. Review of Online Detection and Control Technology for Laser Metal Forming Defects. Foundry 2017, 66, 33–37. [Google Scholar]

- Qiu, X.; Zhang, F.; Sun, Z.; Jia, Q.; Li, M.; Song, C.; He, C. Combined Detection Method for Pipeline Damage Based on Distributed Optical Fiber Sensing Technology. Oil Gas Storage Transp. 2021, 40, 888–894. [Google Scholar]

- Yin, H.; Wu, W.; Hu, Y.; Wei, Q.; Qi, H. Sewage Pipeline Inspection Method Based on Fiber Optic Temperature Measurement and Wavelet Denoising. J. Tongji Univ. Nat. Sci. Ed. 2024, 52, 1947–1954. [Google Scholar]

- Li, X.; Liu, X.; Zhang, Y.; Guo, F.; Wang, X.; Feng, Y. Application and Progress of Distributed Optical Fiber Acoustic Sensing in Oil and Gas Well Engineering Monitoring. Pet. Drill. Prod. Technol. 2022, 44, 309–320. [Google Scholar]

- Baballe, M.A. Robotic Inspection Monitoring System for Pipelines. J. Artif. Intell. Syst. 2022, 4, 50–64. [Google Scholar] [CrossRef]

- Ciszewski, M.; Giergiel, M.; Buratowski, T.; Małka, P. Robotic Inspection of Pipelines. In Modeling and Control of a Tracked Mobile Robot for Pipeline Inspection; Mechanisms and Machine Science; Ciszewski, M., Giergiel, M., Buratowski, T., Małka, P., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Zhang, W.; Miao, S.; Li, X.; Zhao, D.; Cheng, J.; Jin, G. Research Progress of Internal Inspection Robot Technology for Urban Polyethylene Gas Pipelines. Pipeline Tech. Equip. 2024, 2, 42–51+62. [Google Scholar]

- Sawabe, H.; Nakajima, M.; Tanaka, M.; Tanaka, K.; Matsuno, F. Control of an articulated wheeled mobile robot in pipes. Adv. Robot. 2019, 33, 1072–1086. [Google Scholar] [CrossRef]

- Mao, L.; Wang, G. Research on Adaptive Internal Inspection Robot for Small-Diameter Pipelines. Mach. Des. Manuf. 2021, 10, 229–232. [Google Scholar]

- Zang, Y.; Liang, X.; Zhao, Y. Design of Probe Mechanism for Pipeline Inspection Gauges. J. North China Inst. Aerosp. Eng. 2023, 33, 4–6. [Google Scholar]

- Ding, R.; Wei, Z.; Yan, W.; Yang, F.; Chen, Y.; Xun, W. Application of Acoustic Detector-Based Internal Inspection Technology in Product Oil Pipelines. Pipeline Tech. Equip. 2023, 2, 12–18. [Google Scholar]

- Li, S.; Yue, Z.; Zhang, Z. Development Status and Key Technologies of Heating Pipeline Inspection Robots. Sci. Technol. Innov. 2024, 16, 62–64. [Google Scholar]

- Ma, Y.; Shang, Z.; Zheng, J.; Zhou, B.; Mu, S.; Yang, X.; Song, H.; Jiang, X. Research Progress in Oil and Gas Pipeline Robots. Sci. Technol. Eng. 2025, 25, 3089–3101. [Google Scholar]

- Rajendran, S.E. Developments in Inpipe Inspection Robot: A Review. J. Mech. Contin. Math. Sci. 2020, 15, 238–248. [Google Scholar]

- Lilge, S.; Nuelle, K.; Childs, J.A.; Wen, K.; Rucker, D.C.; Burgner-Kahrs, J. Parallel-Continuum Robots: A Survey. IEEE Transactions on Robotics 2024, 40, 3252–3270. [Google Scholar] [CrossRef]

- Fu, H.; Yang, Y.; Zou, Y.; Chen, S.; Gao, F. Development and Application of All-Terrain Pipeline Inspection Robots. China Sci. Technol. Achiev. 2024, 25, 21–23, 27. [Google Scholar]

- Mishra, D.; Agrawal, K.K.; Abbas, A.; Srivastava, R.; Yadav, R.S. PIG [Pipe Inspection Gauge]: An Artificial Dustman for Cross Country Pipelines. Procedia Comput. Sci. 2019, 152, 333–340. [Google Scholar] [CrossRef]

- Atalla, M.A.; Trauzettel, F.; van Gelder, S.P.; Breedveld, P.; Wiertlewski, M.; Sakes, A. Mechanically-Inflatable Bio-Inspired Locomotion for Robotic Pipeline Inspection. In Proceedings of the 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft), San Diego, CA, USA, 15–18 April 2024; pp. 586–592. [Google Scholar] [CrossRef]

- Li, W.; Zhou, M. Development of a Fully Pneumatic Pipeline Inspection Robot. Hydraul. Pneum. 2020, 8, 161–166. [Google Scholar]

- Rayhana, R.; Jiao, Y.; Bahrami, Z.; Liu, Z.; Wu, A.; Kong, X. Valve Detection for Autonomous Water Pipeline Inspection Platform. IEEE/ASME Trans. Mechatron. 2022, 27, 1070–1080. [Google Scholar] [CrossRef]

- Botteghi, N.; Grefte, L.; Poel, M.; Sirmacek, B.; Brune, C.; Dertien, E.; Stramigioli, S. Towards Autonomous Pipeline Inspection with Hierarchical Reinforcement Learning. In Robot Intelligence Technology and Applications 6, Proceedings of International Conference on Intelligent Robotics (IROS), Daejeon, Republic of Korea, 16–17 December 2021; Kim, J., Englot, B., Park, H.-W., Choi, H.-L., Myung, H., Kim, J., Kim, J.-H., Eds.; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Sun, J.; Qi, F.; Zhang, H.; Li, X.; Lin, J.; Feng, J. Master-Slave Control of Continuum Robots for Pipeline Inspection. Mach. Tool Hydraul. 2024, 52, 36–42. [Google Scholar]

- Dai, T.; Jia, Z.; Ren, L.; Li, H. Multi-Source Data Fusion Method for Structural Strength Assessment of Cracked Components. Eng. Mech. 2023, 40, 20–28. [Google Scholar]

- Huang, S.; Jia, X. Application of Multi-Sensor Data Fusion Technology in Pipeline Nondestructive Testing. Nondestruct. Test. 2024, 46, 69–73, 86. [Google Scholar]

- Ou, Z.; Han, Z.; Cen, J.; Li, X. Current Status and Prospects of Buried Pipeline Inspection Technology. Meas. Control. Technol. 2023, 42, 1–9. [Google Scholar]

- Cao, J.; Zhong, J.; Li, J.; Luo, Z.; Zhang, H.; Wang, Q. Laser Ultrasonic Pipeline Detection System Based on LabVIEW. China Meas. Test. 2017, 43, 80–85. [Google Scholar]

- Zhou, X.; Huang, X.; Hou, D. Laser Ultrasonic Visualization for Internal Pipeline Defects. Laser Optoelectron. Prog. 2021, 58, 240–245. [Google Scholar]

- Mazraeh, A.A.; Ismail, F.B.; Khaksar, W.; Sahari, K.S.M. Development of Ultrasonic Crack Detection System on Multi-Diameter PIG Robots. Procedia Comput. Sci. 2017, 105, 282–288. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, J. Reliability Assessment of Pulsed Eddy Current-Electromagnetic Ultrasonic Composite Detection Method. Ordnance Mater. Sci. Eng. 2024, 47, 130–137. [Google Scholar]

- Sun, X. Application of QV-Based Pipeline Inspection Data in Information Systems. Guangxi Water Resour. Hydropower Eng. 2025, 1, 66–69. [Google Scholar]

- Wu, D.; Zhang, Y.; Cui, M.; Pei, H.; Yan, R. Research Progress in Drainage Pipeline Inspection Robots. Smart City 2023, 9, 19–22. [Google Scholar]

- Gower, S.A.; Lardeux, M.; Gilmour, B.; Ling, D. Subsea Robotics—AUV Pipeline Inspection Development Project. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022. OTC-31733-MS. [Google Scholar] [CrossRef]

- Rumson, A.G. The Application of Fully Unmanned Robotic Systems for Inspection of Subsea Pipelines. Ocean Eng. 2021, 235, 109214. [Google Scholar] [CrossRef]

- Passucci, C.; Wolicki, R.D.; Morodei, F.; Arca, S.; D’Alessandro, E.; Leoni, A.; Barile, G.; Stornelli, V.; Bajocco, M. DeepSense—A Novel Easy Way for Pipeline Inspection. In Proceedings of the OMC Med Energy Conference and Exhibition, Ravenna, Italy, 13–15 April 2025. OMC-2025-XXXX. [Google Scholar]

- Zeng, W.; Wang, H.; Li, C.; Ma, X.; Xu, D.; Wang, B.; Zhou, J. Application of Non-Contact Magnetic Stress Testing in Natural Gas Pipeline Inspection. Chem. Eng. Mach. 2021, 48, 622–625. [Google Scholar]

- Al-Ammari, W.A.; Sleiti, A.K.; Rahman, M.A.; Rezaei-Gomari, S.; Hassan, I.; Hassan, R. Digital Twin for Leak Detection and Fault Diagnostics in Gas Pipelines: A Systematic Review, Model Development, and Case Study. Alex. Eng. J. 2025, 123, 91–111. [Google Scholar] [CrossRef]

- Cao, Y.; Zheng, L.; Zhu, J. A Review of Gun Barrel Observation and Detection System. In Proceedings of the 2017 5th International Conference on Frontiers of Manufacturing Science and Measuring Technology (FMSMT 2017), Taiyuan, China, 24–25 June 2017; Atlantis Press: Dordrecht, The Netherlands, 2017; pp. 810–813. [Google Scholar]

- Zhao, K. Research on Laser Detection and 3D Reconstruction Methods for Artillery Bore. Master’s Thesis, Shenyang Ligong University, Shenyang, China, 2023. [Google Scholar] [CrossRef]

- Lu, Z.; Jiang, J. Design and Research of Artillery Barrel Bore Surface Defect Detection System. J. Ordnance Equip. Eng. 2022, 43, 112–118. [Google Scholar]

- Chang, J. Research on Automatic Detection Method for Artillery Barrel Bore Surface. Master’s Thesis, Shenyang Ligong University, Shenyang, China, 2022. [Google Scholar] [CrossRef]

- Iureva, R.A.; Kremlev, A.S.; Subbotin, V.; Kolesnikova, D.V.; Andreev, Y.S. Digital Twin Technology for Pipeline Inspection. In Intelligent Decision Technologies, Proceedings of the 12th KES International Conference on Intelligent Decision Technologies (KES-IDT 2020), Virtual conference, 17–19 June 2020; Czarnowski, I., Howlett, R., Jain, L., Eds.; Springer: Singapore, 2020; Volume 193. [Google Scholar] [CrossRef]

- Hassan, S.; Wang, J.; Kontovas, C.; Bashir, M. Modified FMEA Hazard Identification for Cross-Country Petroleum Pipeline Using Fuzzy Rule Base and Approximate Reasoning. J. Loss Prev. Process Ind. 2022, 74, 104616. [Google Scholar] [CrossRef]

- Ali, A.; Xinhua, W.; Razzaq, I. Optimizing Acoustic Signal Processing for Localization of Precise Pipeline Leakage Using Acoustic Signal Decomposition and Wavelet Analysis. Digit. Signal Process. 2025, 157, 104890. [Google Scholar] [CrossRef]

- Roy, A.M.; Bhaduri, J. DenseSPH-YOLOv5: An Automated Damage Detection Model Based on DenseNet and Swin-Transformer Prediction Head-Enabled YOLOv5 with Attention Mechanism. Adv. Eng. Inform. 2023, 56, 102007. [Google Scholar] [CrossRef]

- Samavati, T.; Soryani, M. Deep Learning-Based 3D Reconstruction: A Survey. Artif. Intell. Rev. 2023, 56, 9175–9219. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Zhu, J.; Du, J.; Du, Z. Multi-Head Attention-Driven Fault Diagnosis Method for High-Speed Aviation Bearings. J. Vib. Shock. 2023, 42, 295–305. [Google Scholar]

- Gong, W.; Chen, H.; Wang, D. Fast Fault Diagnosis Method for Ship Rotating Machinery Based on Improved LSTM-SVM and Multi-Sensor Data. J. Ship Mech. 2021, 25, 1239–1250. [Google Scholar]

- Jiang, S.; Ma, Y.; Li, Q.; Jiang, W.; Guo, B.; Wang, L. Parallel SfM 3D Reconstruction Method for Unordered UAV Images. Acta Geod. Cartogr. Sin. 2024, 53, 946–958. [Google Scholar]

- Ibrahimli, N.; Ledoux, H.; Kooij, J.F.P.; Nan, L. DDL-MVS: Depth Discontinuity Learning for Multi-View Stereo Networks. Remote Sens. 2023, 15, 2970. [Google Scholar] [CrossRef]

- Fan, H.; Ouyang, Z.; Chen, Q.; Hu, D. Database Index Structure Construction for Special Vehicle Status Monitoring and Fault Diagnosis. J. Ordnance Equip. Eng. 2021, 42, 178–184. [Google Scholar]

- Ullah, K.; Ahsan, M.; Hasanat, S.M.; Haris, M.; Yousaf, H.; Raza, S.F. Short-Term Load Forecasting: A Comprehensive Review and Simulation Study with CNN-LSTM Hybrids Approach. IEEE Access 2024, 12, 111858–111881. [Google Scholar] [CrossRef]

- Samadzadegan, F.; Toosi, A.; Dadrass Javan, F. A Critical Review on Multi-Sensor and Multi-Platform Remote Sensing Data Fusion Approaches: Current Status and Prospects. Int. J. Remote Sens. 2025, 46, 1327–1402. [Google Scholar] [CrossRef]

- Liu, J.; An, J.; Chen, R.; Tan, Z.; Gong, X.; Zheng, H.; Xiong, J.; Wang, Z.; Guan, S.; Yang, J.; et al. Key Technologies and Applications of AI-Fused Multi-Sensor Intelligent Inspection Robots for Drainage Pipelines; Technical Report for Wuhan University; Wuhan University: Wuhan, China, 2024. [Google Scholar]

- Shanthamallappa, M.; Puttegowda, K.; Hullahalli Nannappa, N.K.; Vasudeva Rao, S.K. Robust Automatic Speech Recognition Using Wavelet-Based Adaptive Wavelet Thresholding: A Review. SN Comput. Sci. 2024, 5, 248. [Google Scholar] [CrossRef]

- Deluxni, N.; Sudhakaran, P.; Kitmo; Ndiaye, M.F. A Review on Image Enhancement and Restoration Techniques for Underwater Optical Imaging Applications. IEEE Access 2023, 11, 111715–111737. [Google Scholar] [CrossRef]

- Szafarczyk, A.; Toś, C. The Use of Green Laser in LiDAR Bathymetry: State of the Art and Recent Advancements. Sensors 2023, 23, 292. [Google Scholar] [CrossRef]

| Technology | Advantages | Disadvantages |

|---|---|---|

| MFL | High efficiency for volumetric defects in ferromagnetic pipes; Strong contamination resistance; Suitable for large-diameter pipelines | Limited to ferromagnetic materials; Low sensitivity to axial cracks; Requires measurable wall loss |

| ECT | High-precision surface crack detection; No couplant required; Rapid response | Limited to conductive materials; Shallow penetration depth; Susceptible to lift-off effects |

| PECT | Capable of inspecting through insulation layers; Non-removal of coatings; Non-contact | Restricted to carbon steel/ferromagnetic materials; Low resolution; Vulnerable to electromagnetic interference |

| UT | Accurate thickness measurement; Internal defect detection; Applicable to multi-material pipes | Requires coupling medium; Highly affected by surface roughness; Limited in high-temperature environments |

| AET | Real-time dynamic monitoring; Large coverage; No active scanning required | Detects only active defects; poor localization accuracy; Noise interference susceptibility |

| Machine Vision | Direct visualization of defects; High-resolution imaging; Comprehensive digital records | Dependent on illumination/surface cleanliness; Lens contamination vulnerability; Significant blind spots |

| Laser | Sub-millimeter 3D mapping; Non-contact; High-precision corrosion quantification | Extremely high cost; Requires reflective surfaces; Slow scanning speed |

| DFOS | Long-distance real-time monitoring; Multi-parameter measurement (temp/vibration/strain); EMI immunity | Low spatial resolution (meter-level); Insensitive to micro-leaks; Complex installation |

| Wheeled/ Tracked Robots | High payload capacity; Extended operation time; Suitable for straight/gentle-bend pipes | Poor obstacle negotiation (e.g., tees/reducers); Limited terrain adaptability; Prone to jamming |

| Continuum Robots | Exceptional maneuverability (elbows/valves); ideal for small-diameter/complex networks | Extremely high cost; Complex control; Short endurance; Limited tether length |

| Technology | Quantitative Defect Analysis Capability | Qualitative Defect Analysis Capability |

|---|---|---|

| MFL | Yes (Wall loss, corrosion depth) | Limited (Volumetric defects only) |

| ECT | Semi-quantitative (Crack length/depth estimation) | Yes (Crack/pitting classification) |

| PECT | Yes (Average wall thinning rate) | No (Defect type identification unavailable) |

| UT | Yes (Wall thickness ±0.1 mm, defect sizing) | Yes (Internal/external defect differentiation) |

| AET | No (Intensity grading only) | Yes (Defect activity typification) |

| Machine Vision | No (Requires calibration) | Yes (Surface defect morphology identification) |

| Laser | Yes (3D topography) | Yes (Corrosion/deformation pattern discrimination) |

| DFOS | Yes (Temperature/strain quantification) | Yes (Event-type recognition: leaks/third-party damage) |

| Wheeled/Tracked Robots | Contingent on integrated sensors | Contingent on integrated sensors |

| Continuum Robots | Contingent on integrated sensors | Contingent on integrated sensors |

| Technology | Application Scope | Limitations |

|---|---|---|

| MFL | Ferromagnetic pipelines (oil/gas/water); volumetric defects (pits, wall thinning). | Ferromagnetic materials only; insensitive to axial cracks; requires clean surfaces; speed-dependent accuracy. |

| ECT | Surface defects in conductive pipelines (petrochemical/nuclear); cracks, pitting corrosion. | Conductive materials only; shallow penetration; lift-off effect limitations; proximity to surface required. |

| PECT | Corrosion inspection under insulation/cladding without removal. | Ferromagnetic substrates only; low resolution; insensitive to micro-defects; EMI susceptibility. |

| UT | Wall thickness measurement, internal/external corrosion, crack detection in metallic/non-metallic pipes (chemical/power). | Requires couplant (water/gel); surface roughness compromises accuracy; unsuitable for high temperatures; limited for thin-walled pipes. |

| AET | Real-time monitoring of active defects (e.g., stress corrosion cracking, leaks); structural integrity assessment. | Detects dynamic defects only; low positioning accuracy; background noise interference; requires permanent sensors. |

| Machine Vision Inspection | Visual surface defects (cracks, deformation, deposits); weld inspection. | Lighting-dependent; lenses vulnerable to dirt/moisture; limited to line-of-sight areas; high computational load. |

| Laser Scanning | High-precision 3D topography (deformation, dents); internal wall corrosion imaging. | High cost; requires clean surfaces; slow scanning speed; unsuitable for high-curvature pipes. |

| DFOS | Long-distance leak monitoring; third-party intrusion warning; temperature/strain distribution. | Limited spatial resolution; positioning errors; complex installation/maintenance; low micro-leak sensitivity. |

| Wheeled/ Tracked Robots | Medium-large diameter pipes (>200 mm) with straight/gentle bends; multi-sensor payload (MFL/UT/cameras). | Poor obstacle negotiation (T-joints/diameter changes); limited traction; weak geometric adaptability. |

| Continuum Robots | Small-diameter (≥75 mm), multi-branch, vertical pipes; modular design navigates valves. | Extremely high cost; complex control algorithms; limited communication range; short battery endurance. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Liang, W.; Zhou, P. A Review on Pipeline In-Line Inspection Technologies. Sensors 2025, 25, 4873. https://doi.org/10.3390/s25154873

Ma Q, Liang W, Zhou P. A Review on Pipeline In-Line Inspection Technologies. Sensors. 2025; 25(15):4873. https://doi.org/10.3390/s25154873

Chicago/Turabian StyleMa, Qingmiao, Weige Liang, and Peiyi Zhou. 2025. "A Review on Pipeline In-Line Inspection Technologies" Sensors 25, no. 15: 4873. https://doi.org/10.3390/s25154873

APA StyleMa, Q., Liang, W., & Zhou, P. (2025). A Review on Pipeline In-Line Inspection Technologies. Sensors, 25(15), 4873. https://doi.org/10.3390/s25154873