Comparative Study of Hops Moisture Content and the Relative Humidity of the Drying Environment in a Hop Belt Dryer

Abstract

1. Introduction

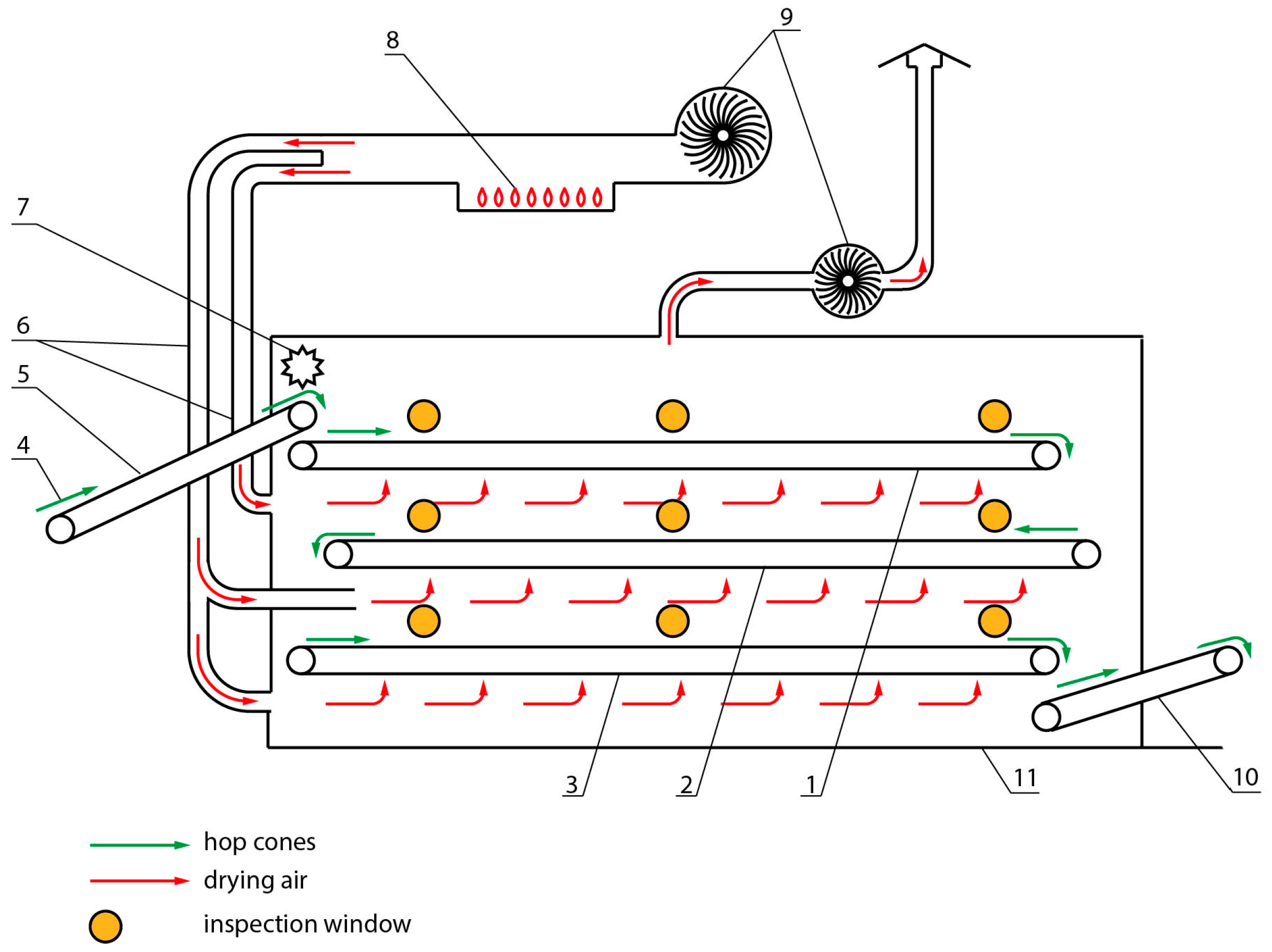

2. Materials and Methods

- By measuring with embedded data loggers (DL 1–3) VOLTCRAFT DL-121-TH (Conrad Electronic);

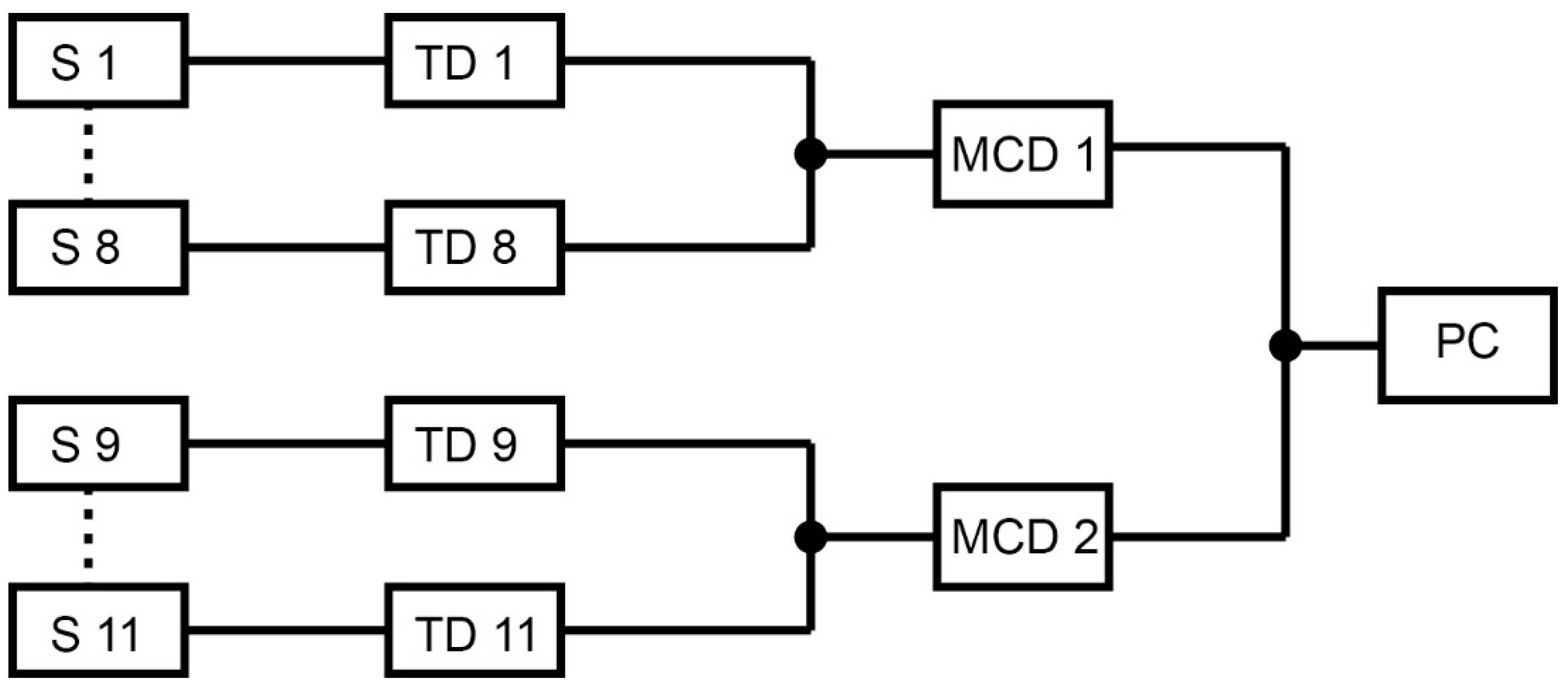

- Measurement using Comet T3419 fixed sensors (FS) and the Comet MS6D measuring centre;

- Laboratory analysis (LAB) of samples obtained on a halogen moisture analyser HE43 from Mettler-Toledo.

2.1. Measurements Using Data Loggers (DL 1–3)

2.2. Measurements Using Fixed Sensors (FS)

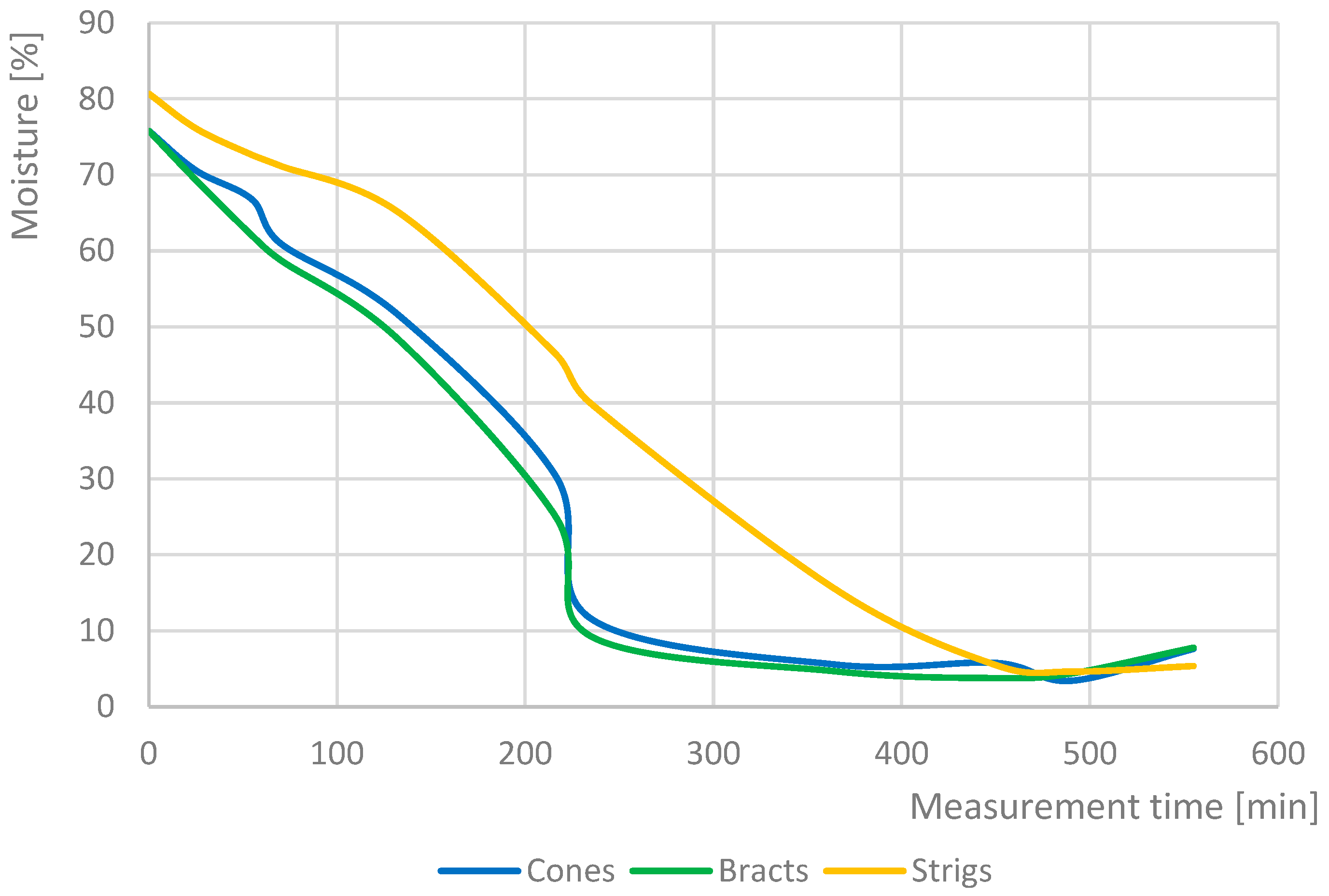

2.3. The Laboratory Analyses of the Acquired Samples (LAB)

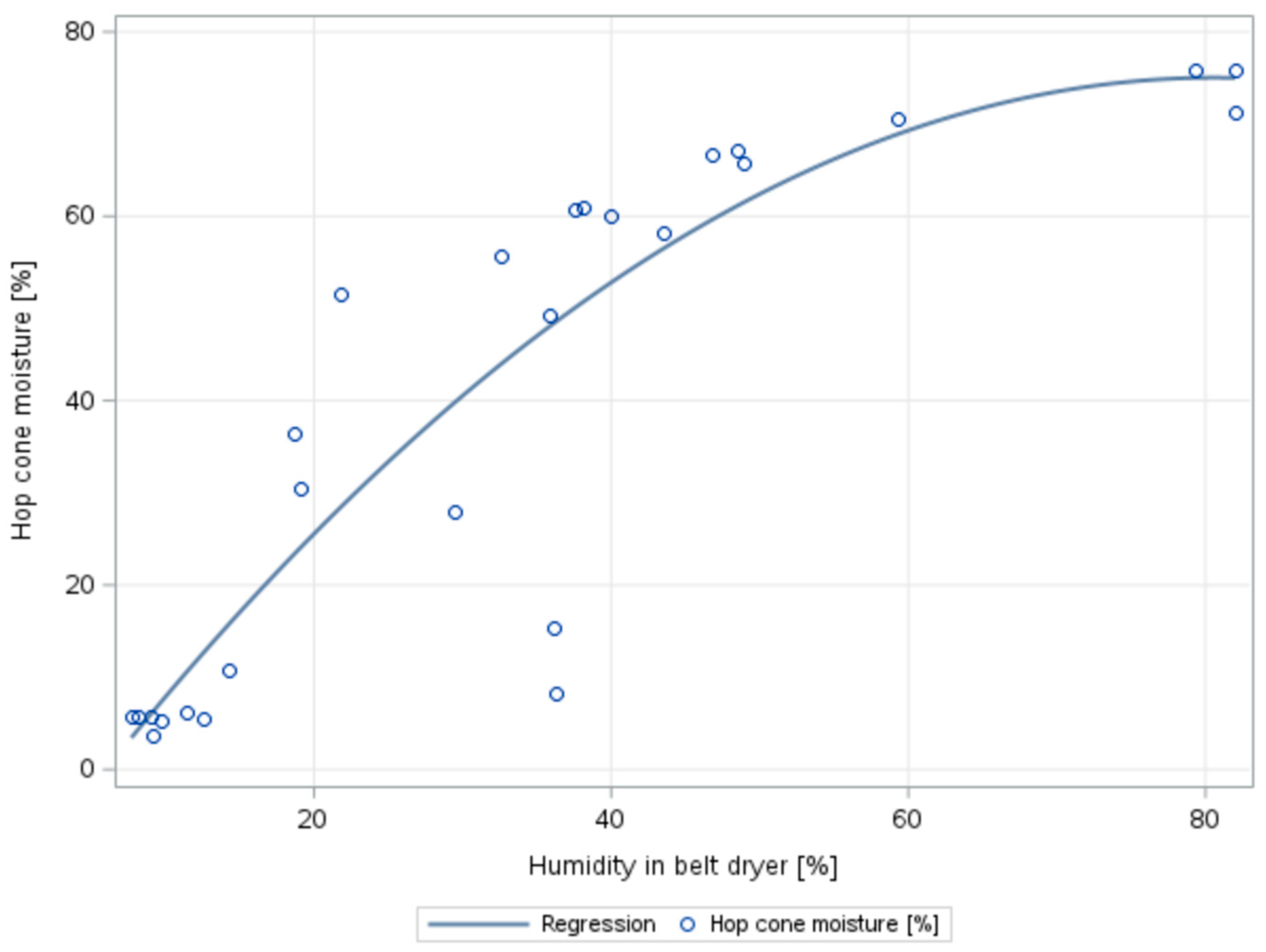

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Co., Ltd. | Company Limited |

| CZU | Czech University of Life Sciences Prague |

| DL | data logger |

| F | parameter of statistical method |

| LAB | laboratory analysis |

| LED | light-emitting diode |

| MCD | multi-channel data logger |

| NAZV | National Agricultural Research Agency |

| PC | personal computer |

| PCHB | type of belt dryer from the manufacturer Vzduchotechnika, Nové Město nad Váhom, Slovak Republic |

| FS | fixed sensor |

| p-value | parameter of statistical method |

| R | parameter of statistical method |

| S | sensor |

| SAAZ | traditional Czech hop variety |

| SAS studio version 9.4 | statistical software |

| t | parameter of statistical method |

| TD | transmitter and display |

| t-test | type of statistical analysis |

| USB | universal serial bus, the system for connecting other pieces of equipment to a computer |

| Χ | parameter of statistical method |

References

- Zanoli, P.; Zavatti, M. Pharmacognostic and Pharmacological Profile of Humulus lupulus L. J. Ethnopharmacol. 2008, 116, 383–396. [Google Scholar] [CrossRef] [PubMed]

- Holubková, A.; Mošovská, S.; Baloghová, B.; Šturdík, E. Hop Pellets as an Interesting Source of Antioxidant Active Compounds. Potravin. Slovak J. Food Sci. 2013, 7, 53–57. [Google Scholar] [CrossRef] [PubMed]

- Formato, A.; Gallo, M.; Ianniello, D.; Montesano, D.; Naviglio, D. Supercritical Fluid Extraction of α- and β-Acids from Hops Compared to Cyclically Pressurized Solid–Liquid Extraction. J. Supercrit. Fluids 2013, 84, 113–120. [Google Scholar] [CrossRef]

- Hrnčič, M.K.; Španinger, E.; Košir, I.J.; Knez, Ž.; Bren, U. Hop Compounds: Extraction Techniques, Chemical Analyses, Antioxidative, Antimicrobial, and Anticarcinogenic Effects. Nutrients 2019, 11, 257. [Google Scholar] [CrossRef] [PubMed]

- Rettberg, N.; Biendl, M.; Garbe, L.A. Hop Aroma and Hoppy Beer Flavor: Chemical Backgrounds and Analytical Tools—A Review. J. Am. Soc. Brew. Chem. 2018, 76, 1–20. [Google Scholar] [CrossRef]

- Schönberger, C.; Kostelecky, T. 125th Anniversary Review: The Role of Hops in Brewing. J. Inst. Brew. 2011, 117, 259–267. [Google Scholar] [CrossRef]

- Bailey. The Influence of Hop Harvest Date on Hop Aroma in Dry-Hopped Beers. Tech. Q. 2009. [Google Scholar] [CrossRef]

- Matsui, H.; Inui, T.; Oka, K.; Fukui, N. The Influence of Pruning and Harvest Timing on Hop Aroma, Cone Appearance, and Yield. Food Chem. 2016, 202, 15–22. [Google Scholar] [CrossRef] [PubMed]

- Probasco, G.; Murphey, J.M. The Development of Brewing Quality Characteristics in Hops during Maturation. Master Brew. Assoc. Am. Tech. Q. 1996, 33, 149–159. [Google Scholar]

- Tarhan, S.; Telci, I.; Tuncay, M.T.; Polatci, H. Peppermint Drying Performance of Contact Dryer in Terms of Product Quality, Energy Consumption, and Drying Duration. Dry. Technol. 2011, 29, 642–651. [Google Scholar] [CrossRef]

- Henderson, S.M.; Miller, G.E. Hop Drying–Unique Problems and Some Solutions. J. Agric. Eng. Res. 1972, 17, 281–287. [Google Scholar] [CrossRef]

- Lincoln, T. Plant Physiology and Development, 6th ed.; Sinauer Associates: Sunderland, MA, USA, 2015. [Google Scholar]

- Doe, P.E.; Menary, R.C. Optimization of the Hop Drying Process with Respect to Alpha Acid Content. J. Agric. Eng. Res. 1979, 24, 233–248. [Google Scholar] [CrossRef]

- Ma, X.; Driscoll, R.H.; Srzednicki, G. Development of In-Store Dryer Model for Corn for Varying Inlet Conditions. Agron. Res. 2015, 13, 202–211. [Google Scholar]

- Rybka, A.; Heřmánek, P.; Honzík, I.; Krofta, K. Parameters of the Drying Medium and Dried Hops in Belt Dryer. Res. Agr. Eng. 2017, 63, S24–S32. [Google Scholar] [CrossRef]

- Aboltins, A.; Palabinskis, J. Fruit Drying Process Investigation in Infrared Film Dryer. Agron. Res. 2016, 14, 5–13. [Google Scholar]

- Kudra, T. Energy Aspects in Drying. Dry. Technol. 2004, 22, 917–932. [Google Scholar] [CrossRef]

- Lewicki, P.P. Design of Hot Air Drying for Better Foods. Trends Food Sci. Technol. 2006, 17, 153–163. [Google Scholar] [CrossRef]

- Mujumdar, A. Principles, Classification, and Selection of Dryers. In Handbook of Industrial Drying, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Bernášek, K.; Hanousek, B.; Rybka, A.; Kvíz, Z. Drying Curves Shape for Hop Cones and Energy Consumption during Different Drying Air Flow Rate and Drying Temperature. In 3rd International Conference Trends in Agricultural Engineering; Libra, M., Ed.; Czech University of Life Sciences: Prague, Czech Republic, 2007; pp. 57–60. [Google Scholar]

- Bohner, M.; Barfuss, I.; Heindl, A.; Muller, J. Uniformity and Energy Consumption of a Parsley (Petroselinum Crispum) Band Drying Process. Z. Fur Arznei Gewurzpflanzen 2009, 14, 126–131. [Google Scholar]

- Jech, J.; Artim, J.; Angelovičová, M.; Angelovič, M.; Bernášek, K.; Honzík, I.; Kvíz, Z.; Mareček, J.; Krčálová, E.; Polák, P.; et al. Machines for Crop Production 3: Machinery and Equipment for Post-Harvesting and Treatment of Plant Material; Profi Press Co., Ltd.: Prague, Czech Republic, 2011. [Google Scholar]

- Mellmann, J.; Fürll, C. Drying facilities for medicinal and aromatic plants - Specific energy consumption and potential for optimisation. Z. Fur Arznei Gewurzpflanzen 2008, 13, 127–133. [Google Scholar]

- Chokphoemphun, S.; Chokphoemphun, S. Moisture Content Prediction of Paddy Drying in a Fluidized-Bed Drier with a Vortex Flow Generator Using an Artificial Neural Network. Appl. Therm. Eng. 2018, 145, 630–636. [Google Scholar] [CrossRef]

- Youssefi, S.; Emam-Djomeh, Z.; Mousavi, S.M. Comparison of Artificial Neural Network (ANN) and Response Surface Methodology (RSM) in the Prediction of Quality Parameters of Spray-Dried Pomegranate Juice. Dry. Technol. 2009, 27, 910–917. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Barroca, M.J.; Gonçalves, F.J.; Alves, M.; Oliveira, S.; Mendes, M. Artificial Neural Network Modelling of the Antioxidant Activity and Phenolic Compounds of Bananas Submitted to Different Drying Treatments. Food Chem. 2015, 168, 454–459. [Google Scholar] [CrossRef] [PubMed]

- Şahïnbaşkan, T.; Köse, E. Modelling of Time Related Drying Changes on Matte Coated Paper with Artificial Neural Networks. Expert. Syst. Appl. 2010, 37, 3140–3144. [Google Scholar] [CrossRef]

- Kırbaş, İ.; Tuncer, A.D.; Şirin, C.; Usta, H. Modeling and Developing a Smart Interface for Various Drying Methods of Pomelo Fruit (Citrus Maxima) Peel Using Machine Learning Approaches. Comput. Electron. Agric. 2019, 165, 104928. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Martynenko, A.; Janaszek-Mańkowska, M.; Trajer, J. Multi-Objective Optimization of Convective Drying of Apple Cubes. Comput. Electron. Agric. 2018, 145, 341–348. [Google Scholar] [CrossRef]

- Kaveh, M.; Rasooli Sharabiani, V.; Amiri Chayjan, R.; Taghinezhad, E.; Abbaspour-Gilandeh, Y.; Golpour, I. ANFIS and ANNs Model for Prediction of Moisture Diffusivity and Specific Energy Consumption Potato, Garlic and Cantaloupe Drying under Convective Hot Air Dryer. Inf. Process. Agric. 2018, 5, 372–387. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, H.; Yang, S.X. A Neuro-Fuzzy Decoupling Approach for Real-Time Drying Room Control in Meat Manufacturing. Expert. Syst. Appl. 2015, 42, 1039–1049. [Google Scholar] [CrossRef]

- Kořen, J.; Ciniburg, V.; Podsednik, J.; Rybka, A.; Veselý, F. Sušení Chmele na Komorových Sušárnách; Hop Research Institute Co., Ltd.: Žatec, Czech Republic, 2008. [Google Scholar]

- Kořen, J.; Ciniburk, V.; Podsedník, J.; Rybka, A.; Veselý, F. Sušení Chmele na Pásových Sušárnách; Hop Research Institute Co., Ltd.: Žatec, Czech Republic, 2008. [Google Scholar]

- International Hop Growers’ Convention (IHGC). Souhrnná Zpráva Ekonomické Komise; IHGC: Freising, Germany, 2025. [Google Scholar]

- Hebák, P. Statistical Thinking and Data Analysis Tools; Informatorium: Prague, Czech Republic, 2013. [Google Scholar]

- Cipra, T. Financial Econometrics, 2nd ed.; Ekopress: Prague, Czech Republic, 2008. [Google Scholar]

- Münsterer, J. Drying and Conditioning of Hops, Trockung Und Konditionierung von Hopfen; Bayerische Landesanstalt für Landwirtschaft (LfL): Freising, Germany, 2020. [Google Scholar]

- Sturm, B.; Raut, S.; Kulig, B.; Münsterer, J.; Kammhuber, K.; Hensel, O.; Crichton, S.O.J. In-Process Investigation of the Dynamics in Drying Behavior and Quality Development of Hops Using Visual and Environmental Sensors Combined with Chemometrics. Comput. Electron. Agric. 2020, 175, 105547. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heřmánek, P.; Rybka, A.; Honzík, I.; Hlavsa, T.; Marčan, J. Comparative Study of Hops Moisture Content and the Relative Humidity of the Drying Environment in a Hop Belt Dryer. Sensors 2025, 25, 4526. https://doi.org/10.3390/s25154526

Heřmánek P, Rybka A, Honzík I, Hlavsa T, Marčan J. Comparative Study of Hops Moisture Content and the Relative Humidity of the Drying Environment in a Hop Belt Dryer. Sensors. 2025; 25(15):4526. https://doi.org/10.3390/s25154526

Chicago/Turabian StyleHeřmánek, Petr, Adolf Rybka, Ivo Honzík, Tomáš Hlavsa, and Jiří Marčan. 2025. "Comparative Study of Hops Moisture Content and the Relative Humidity of the Drying Environment in a Hop Belt Dryer" Sensors 25, no. 15: 4526. https://doi.org/10.3390/s25154526

APA StyleHeřmánek, P., Rybka, A., Honzík, I., Hlavsa, T., & Marčan, J. (2025). Comparative Study of Hops Moisture Content and the Relative Humidity of the Drying Environment in a Hop Belt Dryer. Sensors, 25(15), 4526. https://doi.org/10.3390/s25154526