1. Introduction

In the face of accelerating technological advancement, scientists are actively developing innovative energy solutions to address climate change and resource depletion [

1]. Rapid industrialization and population growth have intensified urban development, creating challenges in achieving sustainable and livable environments [

2]. Transportation, as a core component of modern society, significantly influences both economic efficiency and sustainable development [

3]. While automobiles, airplanes, and trains provide essential mobility, their growing energy demands have led to increased greenhouse gas emissions and concerns over depleting resources [

4,

5]. This escalating energy demand has prompted nations to reevaluate their energy strategies, promote environmental technologies, and pursue sustainable energy use [

6]. Key efforts include expanding renewable energy, improving energy efficiency, and advancing green transportation technologies [

7]. As a result, energy management in the transportation sector has become a focal point of innovation and sustainability [

8]. Future vehicle development will concentrate on battery electric vehicles (BEVs), hybrid electric vehicles (HEVs), and hydrogen fuel cell electric vehicles (FCEVs) [

9], with BEVs emerging as a major global focus. In response, automotive manufacturers are shifting toward new energy technologies, reshaping industry competitiveness and demonstrating a commitment to sustainability [

10]. The transition from internal combustion engines to hybrid systems marks a key trend, with HEVs combining engines and electric motors for dual power output [

11,

12]. These systems adapt to varying conditions, improving performance, extending the range, and reducing fuel consumption, bringing them closer to the goals of clean mobility [

13]. The optimization of energy and power systems focuses on energy conservation and cost reduction. Energy management strategies are central to this goal, enabling the efficient use of multiple energy sources and reducing environmental impacts [

14]. In parallel, power system design—including component selection and the system architecture—ensures optimal system coordination and performance [

15,

16].

The power systems of BEVs can be divided into two main configurations: (1) single-motor drive and (2) multi-motor drive. The single-motor configuration features a simplified structure and the use of high-performance electric motors, which makes it more challenging to balance vehicle performance with improved energy efficiency [

17]. Multi-motor drive systems can be further categorized into two types based on the number of motors: (1) four-motor distributed drive and (2) dual-motor coupled powertrain [

18]. The four-motor distributed drive system features individual motors assigned to each wheel, with each wheel delivering power independently through separate reducers or drive shafts, or, alternatively, integrating motors directly into the wheels as hub motors [

19]. In contrast, the dual-motor coupled powertrain employs two motors to achieve multiple driving modes. Through an ingeniously designed mechanical coupling mechanism, the system efficiently allocates power between the two motors, significantly enhancing motor utilization. Compared to conventional single-motor setups, this configuration achieves superior overall performance [

20]. Therefore, the development of dual-motor electric vehicles not only enhances overall vehicle performance and operational flexibility but also contributes to the realization of high-efficiency, low-emission transportation solutions. It plays a crucial role in advancing green mobility and the development of intelligent vehicle technologies.

HEVs and dual-motor electric vehicles exhibit significant differences in their power distribution control strategies, primarily in terms of energy sources, control objectives, and the complexity of strategies. Specifically, HEVs convert motor electricity consumption into an equivalent fuel consumption measure, whereas dual-motor electric vehicles calculate the minimum motor electricity consumption directly. Despite these differences, the two vehicle types share similarities in their energy distribution control methodologies, allowing for the application of analogous power distribution control strategies. According to previous studies, the optimization of a vehicle’s energy management system primarily aims at reducing the overall energy consumption and lowering the costs to enhance the overall efficiency and system performance. Energy management system strategies can mainly be categorized into two types: (1) rule-based (RB) strategies and (2) optimization-based strategies [

21]. Rule-based strategies can be further divided into two main types: (1) deterministic rules and (2) fuzzy logic rules [

22]. Deterministic rules involve predefined control strategies based on engineering experience to manage switching between different operational modes of the powertrain and distributing power among various energy sources [

23]. In contrast, fuzzy logic rules employ a set of predetermined yet flexible control strategies, allowing the more adaptable handling of uncertainties and complexities within the system. Decisions and controls are executed through fuzzy logic, enabling dynamic adjustments to operational modes and power allocation between different energy sources [

24]. Optimization-based strategies can be mainly classified into two categories: (1) real-time optimization and (2) global optimization [

25]. Real-time optimization involves dynamically allocating power between the engine and electric motor based on the current power demands, ensuring the minimum equivalent consumption and minimal power losses at each moment. An example of this approach is global grid search (GGS) [

26]. Global optimization utilizes optimal control principles to improve fuel consumption and power loss across an entire driving cycle, dynamically optimizing power allocation among energy sources to achieve overall optimal vehicle performance. Examples include methods such as dynamic programming (DP) [

27] and genetic algorithms (GAs) [

28]. To thoroughly investigate vehicle energy efficiency, this research primarily focuses on two main areas: the powertrain system and the control strategy. Regarding powertrain design, recent commercially available vehicles exhibit highly similar system architectures, with multi-power-source configurations emerging as the mainstream design. In terms of control strategies, theory-based controls have already achieved considerable success in various engineering applications. Currently, bio-inspired heuristic algorithms, such as the whale optimization algorithm (WOA), are gradually becoming a popular trend in the field of optimization methods [

29]. The WOA, compared with other heuristic algorithms, demonstrates superior problem-solving capabilities and computational efficiency. It is feasible for energy management involving multiple control variables, thereby enhancing the performance of hybrid power systems and showcasing its significant potential in vehicle control applications [

30]. In addition, hierarchical reinforcement learning (HRL) algorithms can be effectively applied to vehicle energy management. Specifically, in dual-motor or hybrid electric vehicles, HRL can determine overarching vehicle power objectives, such as energy-saving mode or power mode, while simultaneously managing detailed controls for individual motors or power sources. These detailed controls include the front and rear motor torque distribution, generator operation, and battery charge–discharge management. By employing hierarchical management, HRL significantly reduces the complexity involved in designing vehicle control strategies, thereby enabling the rapid and efficient determination of optimal control solutions [

31].

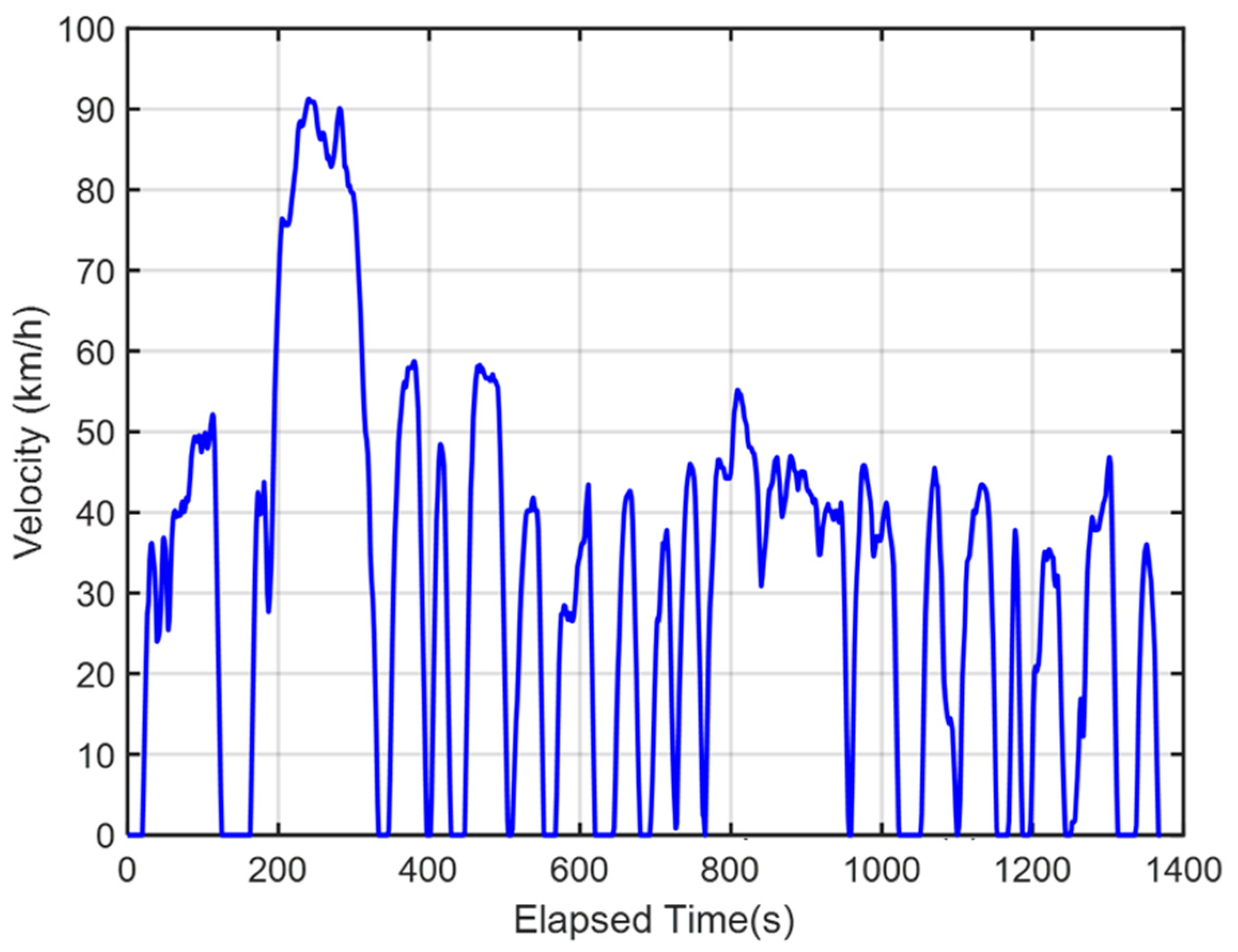

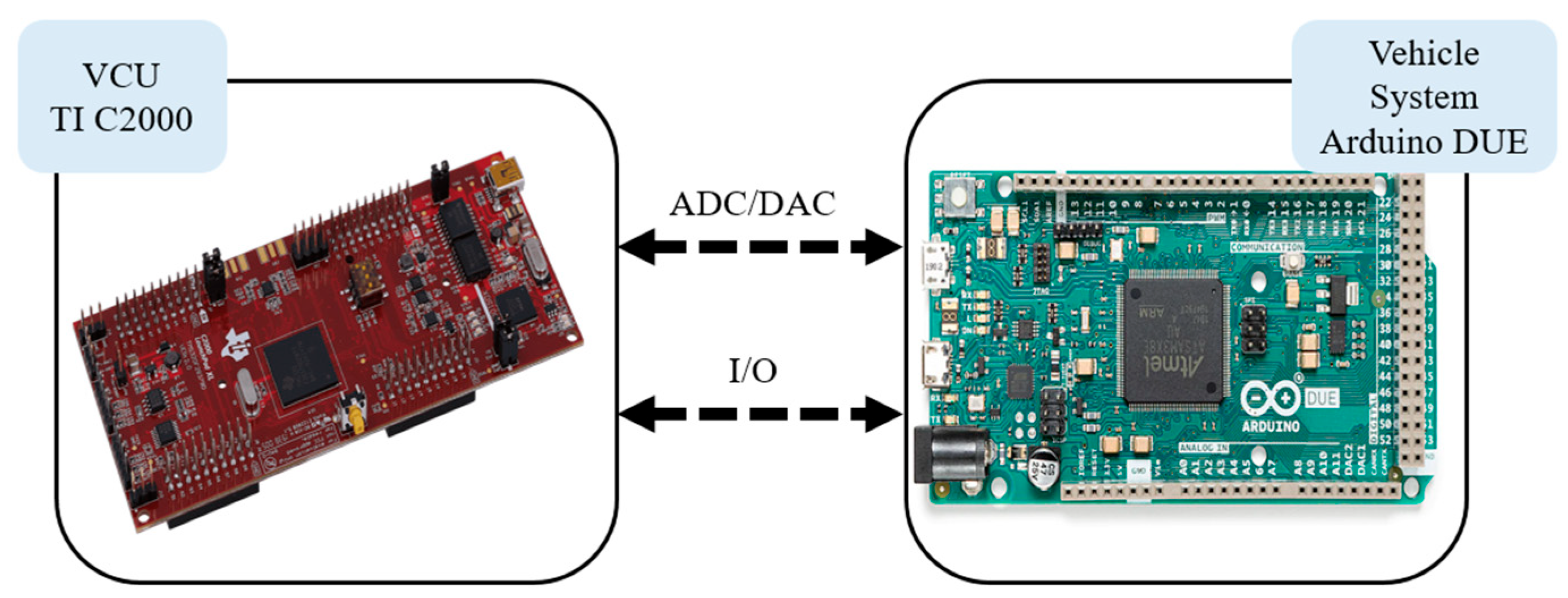

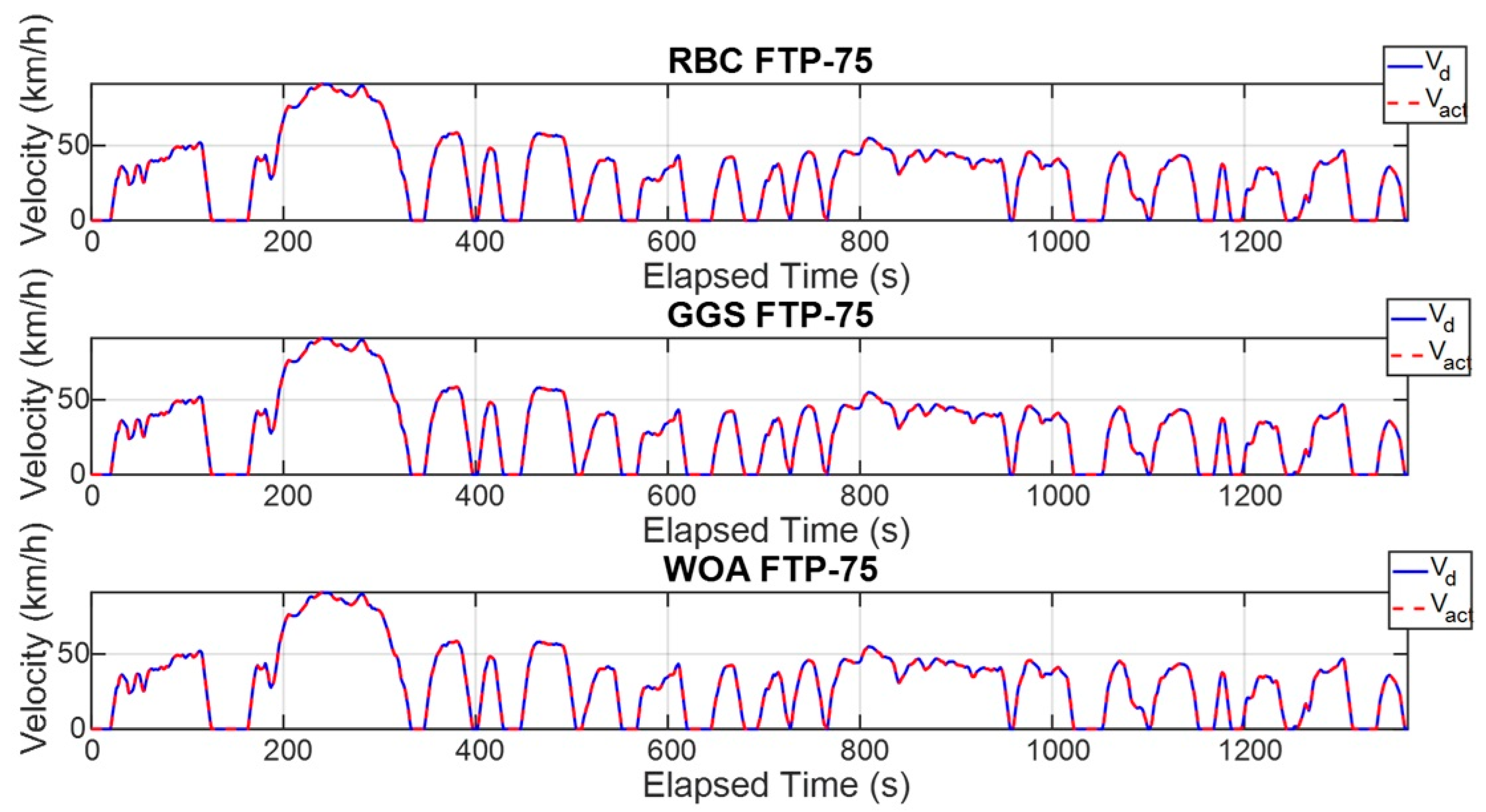

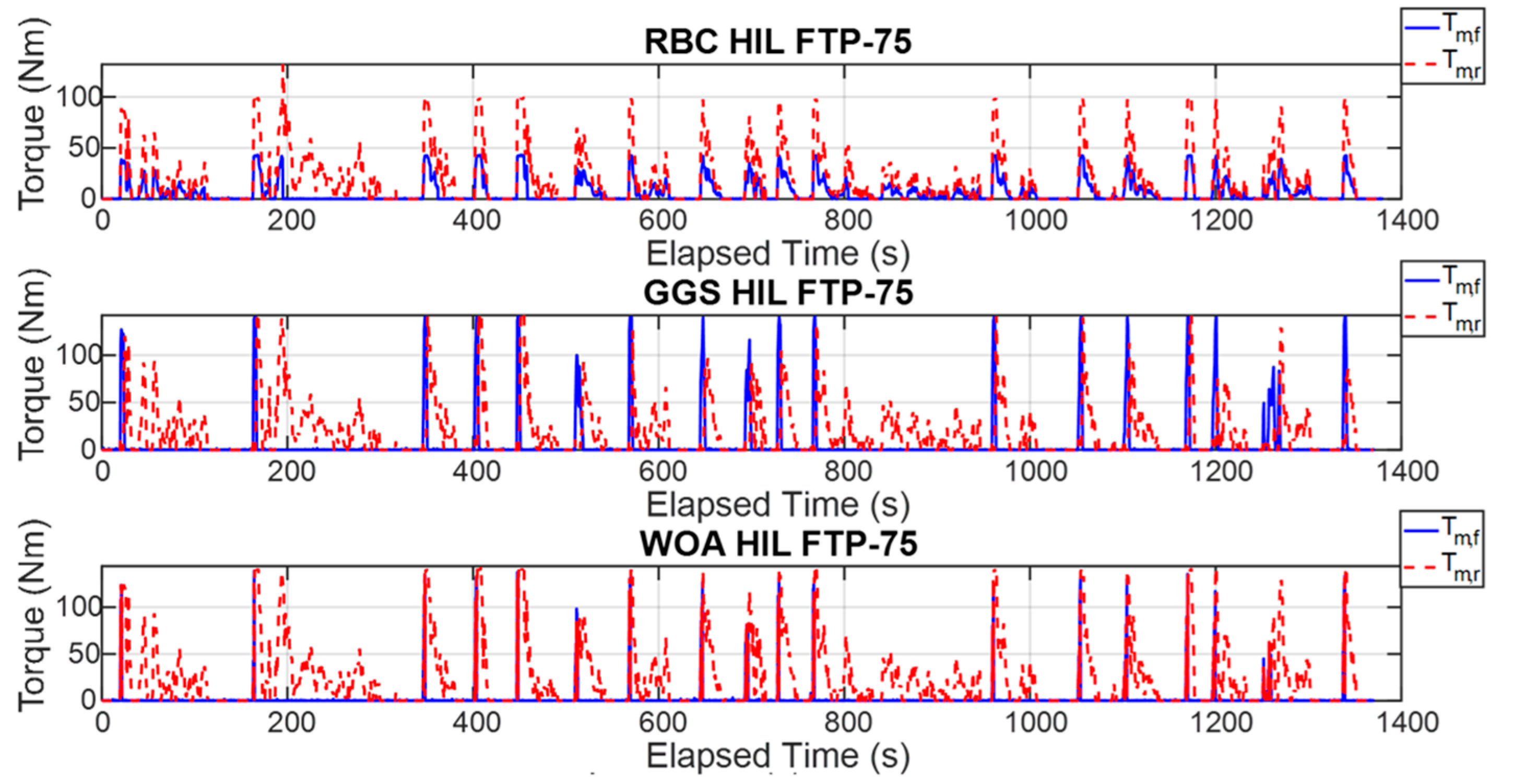

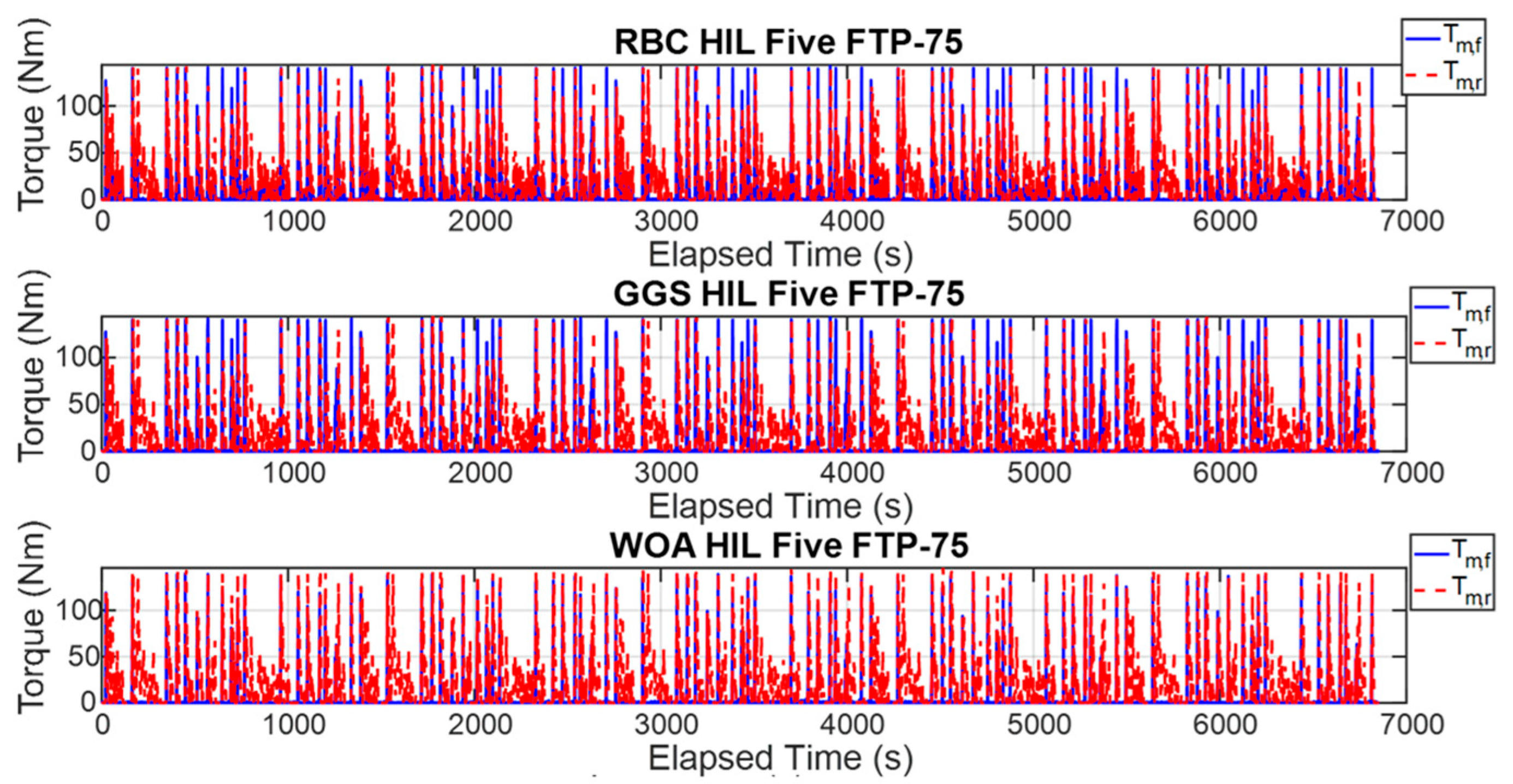

To effectively validate the practical operation of the energy management system, a HIL system is utilized to perform real-time computation, bridging the gap between the simulation phase and actual vehicle implementation. This approach helps to identify data errors and enhances the system’s fault tolerance. In this research, the dual-motor drive simulation platform is divided into two parts: the vehicle control unit (VCU) and the vehicle platform. An Arduino DUE microcontroller and a Ti C2000 microcontroller are employed to construct a hardware-in-the-loop (HIL) platform, enabling analog and digital input/output signal conversions through signal processing. The Federal Test Procedure 75 (FTP-75) driving cycle is used as a basis for the analysis of the performance characteristics and inter-system response relationships, including the torque, rotational speed, optimization management, and overall vehicle energy efficiency.

3. Energy Management Strategy

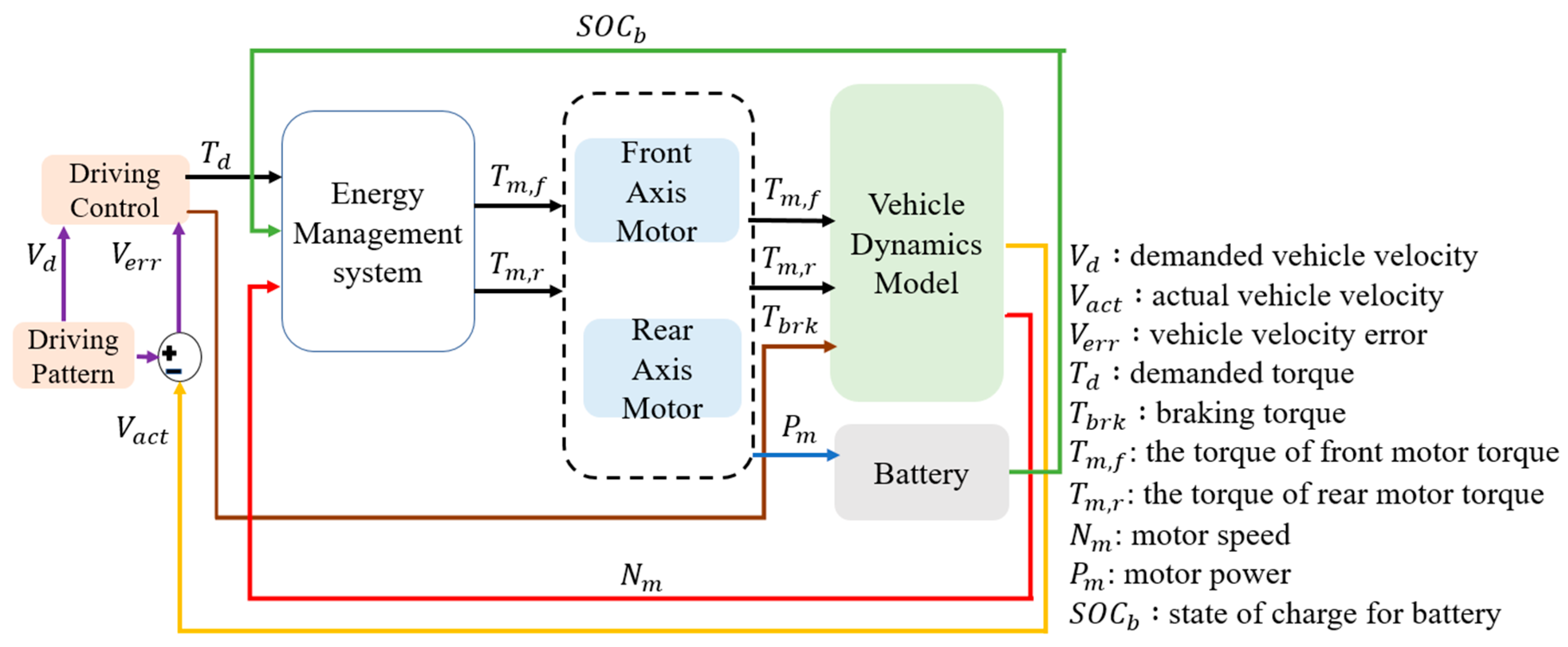

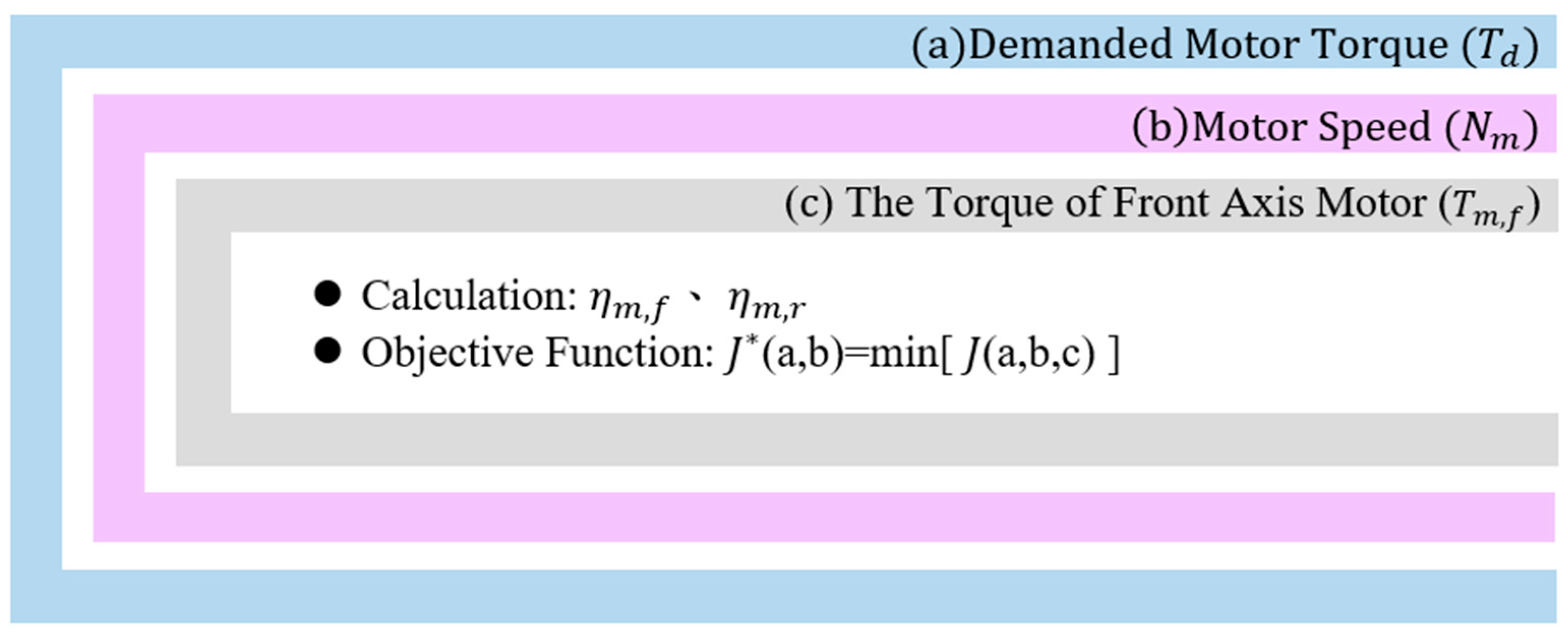

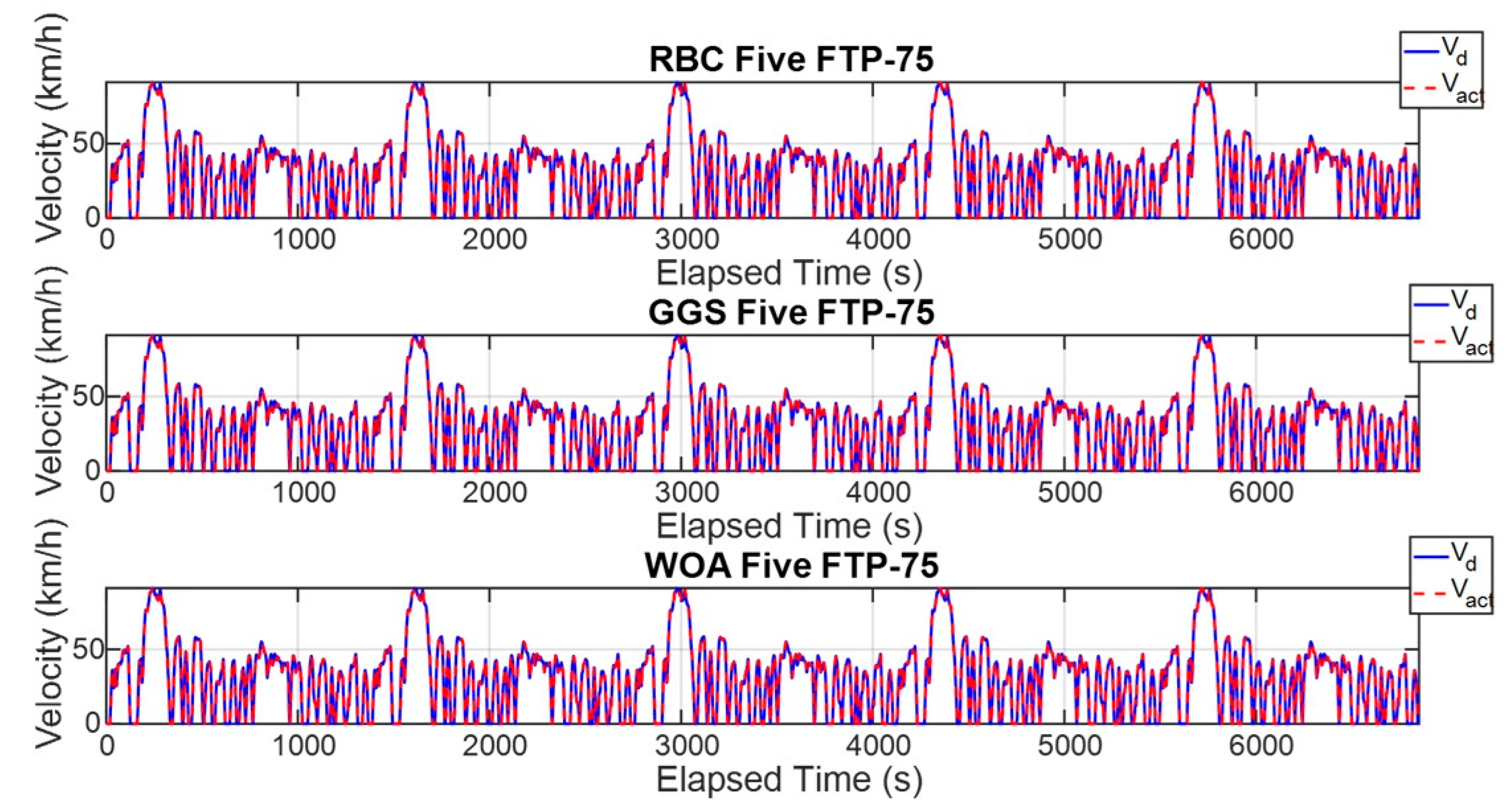

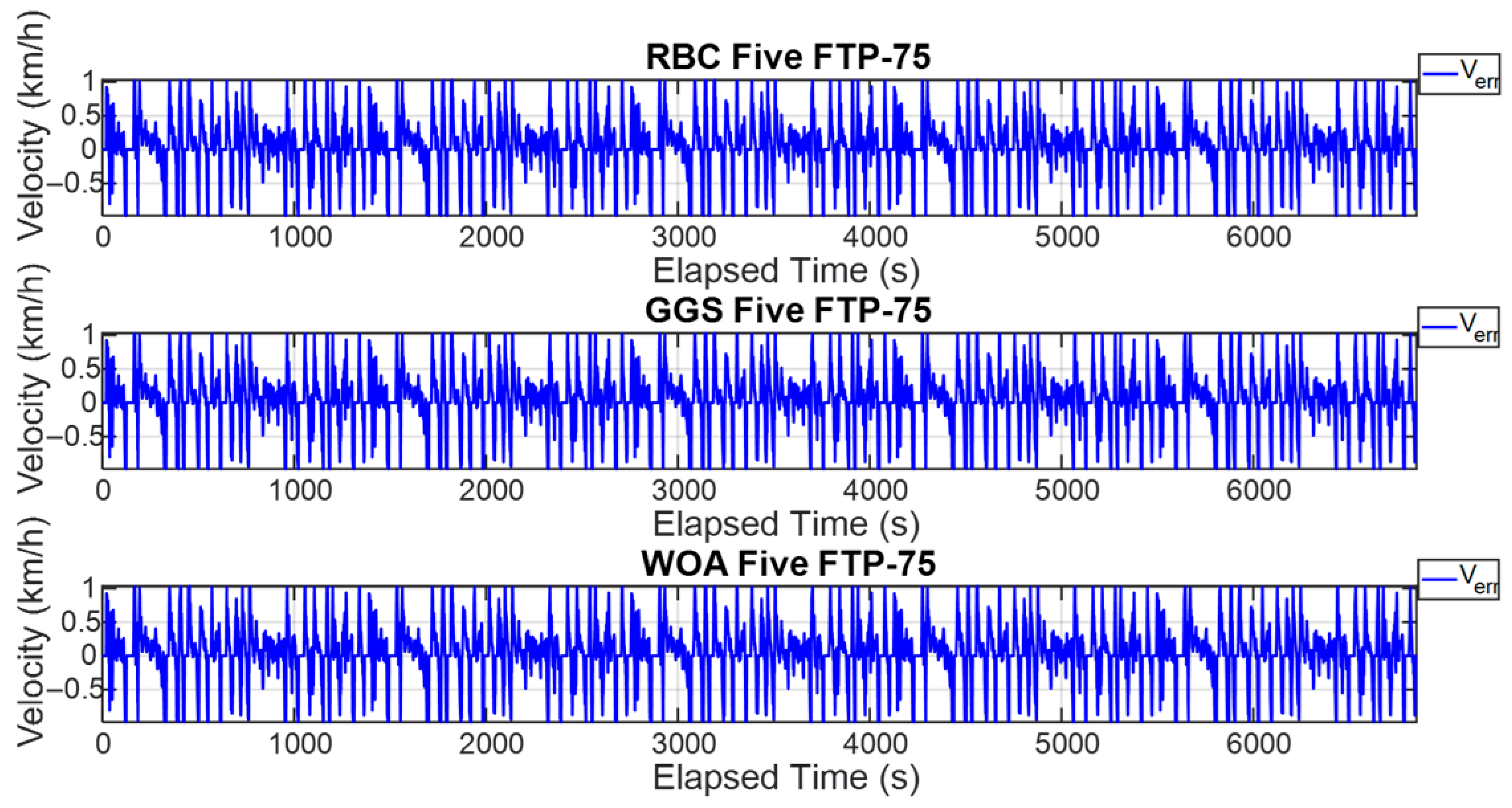

This study adopts an energy management strategy to calculate the optimal motor efficiency range and determine the best power distribution ratio. Simulation verification is conducted using the FTP-75 driving cycle, and the control architecture of the energy management system is illustrated in

Figure 6. First, the driving cycle model provides the target vehicle velocity for simulation. The actual vehicle velocity is then calculated through the vehicle dynamics model. The vehicle velocity error, obtained by subtracting the actual velocity from the demanded vehicle velocity, is used as the input to the PI controller. The PI controller outputs the demanded torque, which is sent to the energy management model to determine the power distribution between the dual drive motors. Meanwhile, the braking torque is used to command the braking force and is sent to the vehicle dynamics model to perform vehicle braking. The energy management model uses the actual motor speed from the vehicle dynamics model to calculate the optimal torque distribution, sending control commands to the front- and rear-axis motors for execution. Finally, the motor outputs are integrated into the vehicle dynamics model to compute the actual vehicle velocity.

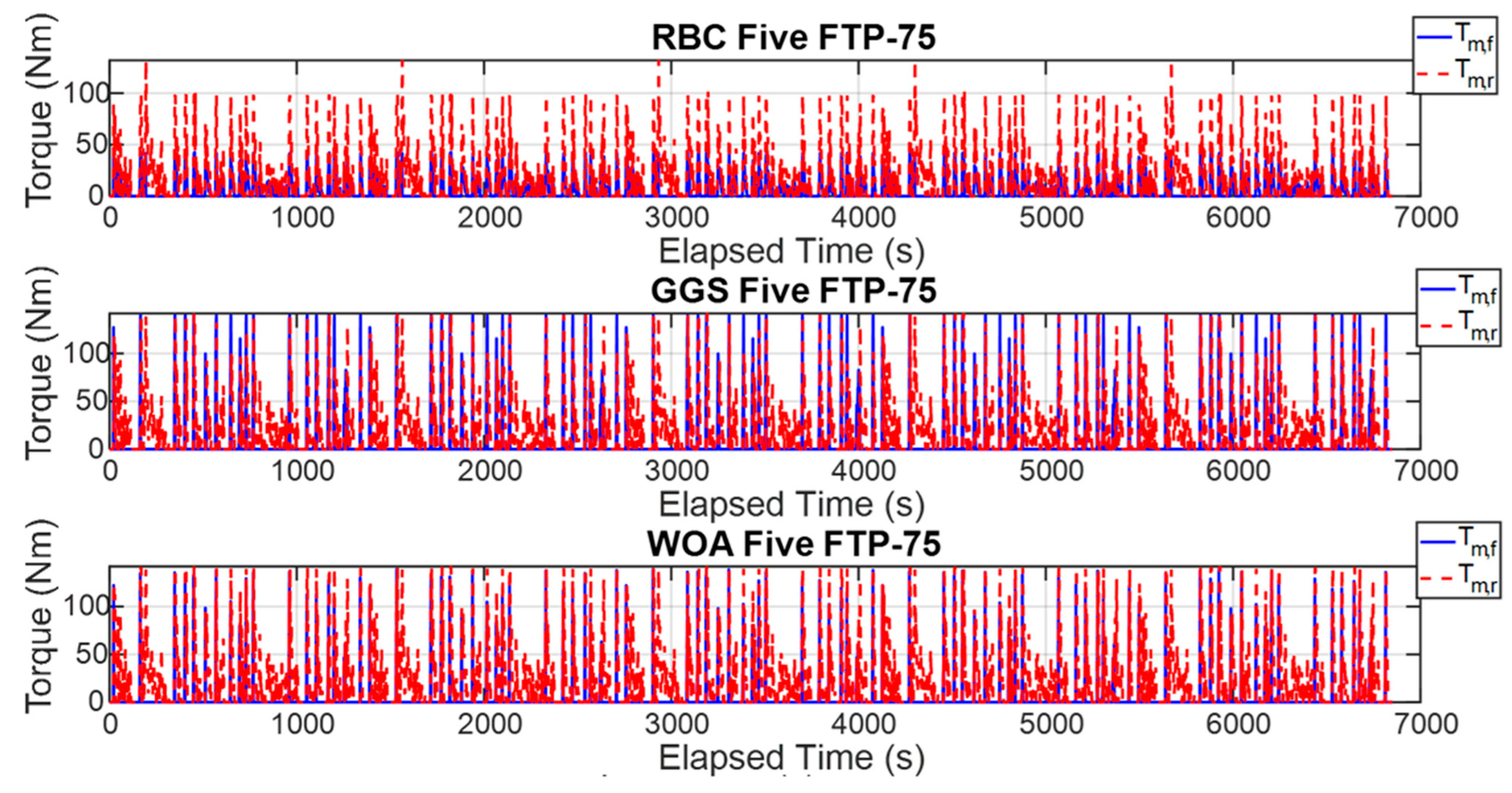

The energy management system dynamically allocates the output torque of the front- and rear-axle motors based on the current driving conditions, summing their contributions to generate the total driving torque. However, the actual wheel driving force is primarily determined by the vehicle’s load conditions, including the acceleration demand, rolling resistance, and aerodynamic drag. The total driving torque is fed back to the control system through the vehicle dynamics module, forming a closed-loop control architecture that enables real-time adjustment and energy optimization. Consequently, this torque distribution strategy directly influences the overall energy efficiency. Although the front- and rear-axle motors are of identical specifications, their operating speeds and output torques differ during actual operation, resulting in variations in their individual energy conversion efficiencies. Therefore, by dynamically adjusting the torque split parameter () within the energy management system, it is possible to optimize the operating points of each motor according to their efficiency maps. This approach minimizes the total energy consumption and extends the driving range. In addition, the model incorporates a vehicle dynamics module to calculate the required wheel driving force under different operating modes. As the load increases, the system can dynamically modify the torque distribution between the front and rear axles to enhance the traction performance and driving response. Thus, even when using motors of the same specifications, an appropriate torque distribution strategy can achieve an optimal energy efficiency and performance balance under various driving conditions. This demonstrates that the proposed distribution strategy in this study holds practical significance and real-world applicability.

3.1. Rule-Based Control Strategy

Rule-based control (RBC) is implemented using the Stateflow model in MATLAB/Simulink

® to develop the energy management strategy. Based on different driving demands, corresponding power distribution modes are established, as detailed in

Table 3. When the input signals meet the predefined state conditions, the system outputs the corresponding power distribution results. These rules are primarily formulated based on the researcher’s engineering experience and the operational efficiency of individual components, enabling control over mode switching under various driving conditions [

38]. In this study, the RBC strategy defines four operating modes, as shown in

Table 3. The mode determination is based on the demanded vehicle velocity, demanded torque, and battery SOC. The modes are defined as follows.

- ➢

System Ready Mode: When the driver’s demanded torque is 0 Nm, the system enters the ready mode, and the commanded motor torque output is also set to 0 Nm.

- ➢

Low-Load Mode: When the demanded torque is greater than or equal to 0.1 Nm, the vehicle enters the low-load mode. In this mode, the demanded torque is shared between the front- and rear-axis motors with a distribution ratio of 3:7.

- ➢

High-Load Mode: When the actual vehicle velocity exceeds 50 km/h, the system switches to high-load mode. In this mode, the demanded torque is allocated to the rear-axis motor, which primarily propels the vehicle.

- ➢

Safety Mode: When the demanded torque is 0 Nm and the battery SOC reaches 0, the system enters the safety mode.

- ➢

These control rules ensure appropriate power allocation and system responses under various operating conditions.

Since dual-motor electric vehicles share a single battery system, the system will automatically enter a protection mode and reduce the power output when the battery SOC is low. This study focuses on the torque distribution between the front and rear motors under normal operating conditions, based on the actual vehicle speed, and therefore does not take the battery SOC into account. An SOC value of zero indicates either a fully depleted battery (activating the battery’s built-in protection mechanism) or a disconnection, both of which trigger system safety protocols. These conditions must be considered in practical applications.

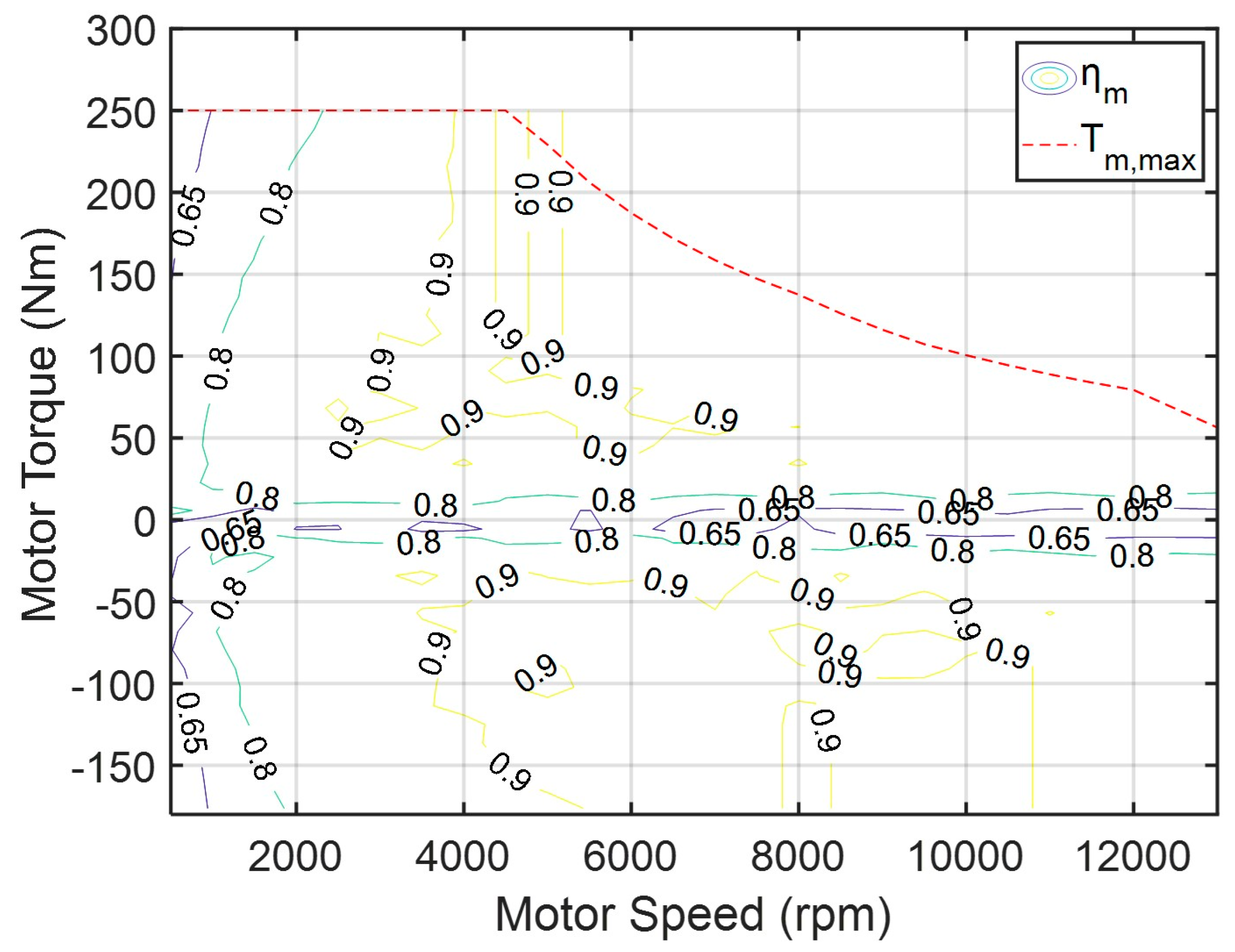

3.2. Global Grid Search Method

In the computational process, system model parameters such as the total demanded power, motor speed, and physical constraints are established to construct an optimized power distribution model for control system parameter analysis. This approach effectively simplifies the control model to meet the real-time computing requirements of the HIL system. To obtain the optimal control model parameters, a GGS method is used to find the best parameter solution. By first inputting the necessary parameters, such as the demanded torque and drive motor speed, and performing discretization, an objective function is defined to identify the optimal power distribution algorithm. The goal is to minimize the power consumption, and the minimum value is determined as expressed in Equation (9):

where

is the efficiency of the front-axis motor;

is the efficiency of the rear-axis motor;

is the input power of the front-axis motor;

is the input power of the rear-axis motor;

is the optimal cost function; and

is a penalty value. The output powers of the front- and rear-axle motors are calculated as shown in Equations (10) and (11):

By substituting Equations (10) and (11), the result is as shown in Equation (12):

Here,

represents the penalty value; when the conditions of grid search exceed the physical constraints, a large penalty value is assigned:

In studies related to the front and rear motor power ratio, it has been observed that, when electric vehicles require more acceleration and high-speed operation, the importance of the front-axle motor may increase [

39,

40]. The GGS method selects the optimal power distribution by minimizing the power consumption based on the vehicle’s real-time operating status and control variables, while also taking the vehicle performance requirements into account. This enables the vehicle to achieve the most efficient energy management at different operating points, thereby improving overall energy utilization. The strategy process is as follows:

- ➢

The GGS search method involves three nested loops used to globally search discretized values of the demanded torque and motor speed;

- ➢

The program uses “if–then–else” conditional statements to evaluate various possible operating modes and then calculates parameters such as the efficiency and torque of the front- and rear-axis motors;

- ➢

Based on the concept of minimum power consumption, the power consumption under different conditions is calculated—for a fixed motor speed and demanded torque, the minimum power consumption under different dual-motor torque distributions can be used to determine the optimal power distribution ratio.

Table 4 lists the relevant parameters for the front- and rear-axle motors. Based on the design of the optimal objective function, the power distribution ratios are defined according to Equations (14) and (15):

where

is the power distribution ratio (0~1).

Under the same minimum motor power consumption strategy, the optimal motor power consumption is identified using the optimal power distribution loop shown in

Figure 7. The discretized variables include the required torque, the motor speed, and the front- and rear-axle motor power distribution ratio α, which are used to perform a global search. By calculating the electric power consumption of the front- and rear-axis motors under different variable conditions, an optimal two-dimensional power distribution map can be derived. The calculation is expressed in Equation (16) and (17):

In the energy management system of this study, the demanded torque serves as the primary input parameter, determined by the accelerator pedal position, reflecting the driver’s demanded torque. The battery SOC affects the motor output torque, imposing limitations at lower SOC levels based on the battery capabilities. The rotational speeds of the front and rear motors are calculated according to the current vehicle velocity and the drivetrain characteristics, such as the tire radius and final gear ratio. Subsequently, a nested loop calculation is conducted, considering the motor speed range, torque limits, maximum torque capabilities, and motor efficiency maps, enabling the selection of an optimal operating point under all conditions to minimize the overall energy consumption and achieve global energy efficiency optimization. Consequently, this optimization procedure determines the torque distribution ratio between the front and rear motors.

3.3. Whale Optimization Algorithm

In this study, a heuristic optimization algorithm inspired by the foraging behavior of whales is utilized. The WOA simulates the process by which whales search for food, perceiving information such as sounds and scents in their surroundings to determine the direction and distance of prey and then taking corresponding actions. The algorithm mimics these behaviors to search for optimal solutions [

41]. One of the most remarkable features of whales is their unique hunting method, known as the bubble-net feeding method. This feeding behavior typically occurs near the ocean surface, where whales create bubbles to trap prey. They form these bubble nets along circular or figure-of-eight-shaped paths. During the upward spiral, a whale dives to a depth of approximately 12 m and begins creating spiral-shaped bubbles around the prey, eventually swimming upward to capture it. The dual-spiral strategy involved in this behavior includes three distinct stages: spiral ascent, surface tail slapping, and the capture cycle. Bubble-net feeding is a unique and specialized behavior among whales, and the WOA is modeled after this spiral bubble-net hunting strategy to achieve optimization objectives [

42]. The strategy process is as follows.

- (1)

Initialization: In this stage, the initial parameters are set and the initial positions of the whales are generated. To prevent the algorithm from falling into local optima, the whales are uniformly distributed throughout the search space. The initial positions are defined by Equation (18):

where

is the lower bound of the control variable being searched;

is the upper bound of the control variable being searched;

is the dimensional size of the control variable.

- (2)

Surround prey: The whale identifies the position of the prey and encircles it. In the WOA, it is assumed that the current best solution is the target prey or is close to the optimal solution [

43]. Once the best search formula is defined, other search agents will attempt to update their positions toward the best one. This behavior can be expressed by the following equation:

where

is the current number of iterations;

is the step coefficient;

is the weighting coefficient;

is the spatial vector between the whale and the current best prey position;

is the position of the current best solution;

is the current position. Whenever a better solution appears during each iteration, an update is required.

,

, and

are calculated as follows:

where

decreases linearly from 2 to 0 during the iteration process;

is the current iteration number;

is the maximum number of iterations;

is a random vector within the range [0, 1].

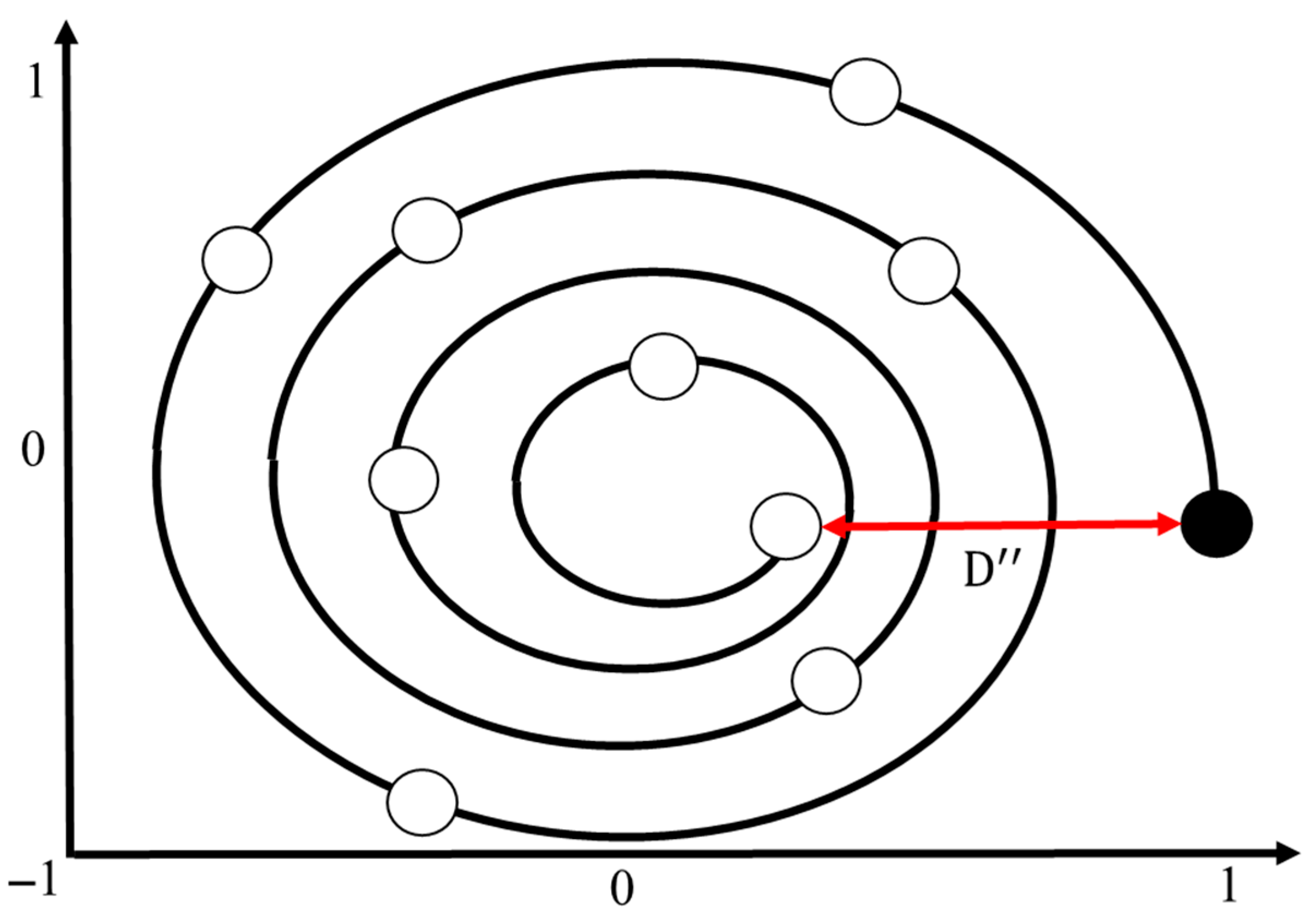

- (3)

Bubble-net attacking method: There are two methods of modeling the whale’s bubble-net feeding behavior: (1) the shrinking surround mechanism and (2) the spiral position update [

44]. As shown in Equation (21), this behavior is achieved by gradually decreasing the value of

. It is important to note that the range of

also decreases along with a, where

is a random value within the interval [−

,

]. By setting

as a random number between −1 and 1, the new position of a search agent can lie anywhere between its original location and the current best position. When

, it illustrates all possible locations in the 2D space between (X, Y) and (X*, Y*), which essentially simulates the behavior of surrounding and hunting prey. Whales generate spiral-shaped bubble nets through their blowholes to trap prey, making it difficult for the prey to escape. They then move along this spiral bubble path to complete the hunt [

45]. Based on the position of the best-identified prey, the whale generates a spiral bubble pattern and updates its position accordingly using Equation (23), as shown in

Figure 8. The spiral position update is expressed by Equation (24):

where

is the spatial vector between the whale and the current best prey position;

is a constant that defines the shape of the spiral bubble net, and it is set to 1 in this study;

is a random number within [−1, 1].

- (4)

Search for prey: In addition to using the bubble-net method, whales also exhibit random prey-searching behavior during foraging, as illustrated in

Figure 9. This behavior is based on a variable

vector, where whales perform random searches relative to each other’s positions. In this method, when

is greater than 1 or less than −1, it drives the search to move away from the current location. Unlike the bubble-net method, this search mechanism does not rely on the best solution found so far, but rather updates the positions based on randomly selected search agents [

46]. This mechanism involves an

vector magnitude greater than 1, as represented in Equations (25) and (26):

where

is the current random position of the whale population;

is the position vector between the whale and a randomly selected prey.

- (5)

Record the current highest profit until the search stopping condition is met: The WOA continuously updates the optimal solution through iterative searching (i.e., minimizing the objective function defined in this study). Once the search stopping condition is met, the algorithm outputs the optimal solution; otherwise, it returns to steps (2), (3), and (4) to continue the computation until the stopping condition is satisfied or the computation is complete [

47].

This study introduces two optimization methods for control strategies. Although the core computations differ in terms of the mathematical equations used during their respective search processes, both aim to optimize the same objective function, and the control variables used are identical to those in the GGS approach, as referenced in the GGS power distribution ratio formula. In the WOA, key control parameters typically include the population size and the number of iterations. These parameters significantly affect the algorithm’s performance and convergence speed. In general, their values are adjusted according to the characteristics and requirements of the problem being addressed. In this study, vehicle energy efficiency simulations are conducted using MATLAB/Simulink

®, with a sampling time of 0.01 s. The main focus is to compare the impacts of different control strategies on the vehicle energy efficiency, rather than on the optimization of the algorithm parameters themselves. Based on the simulation results, using a larger population size yields better outcomes. The parameter settings are shown in

Table 5.

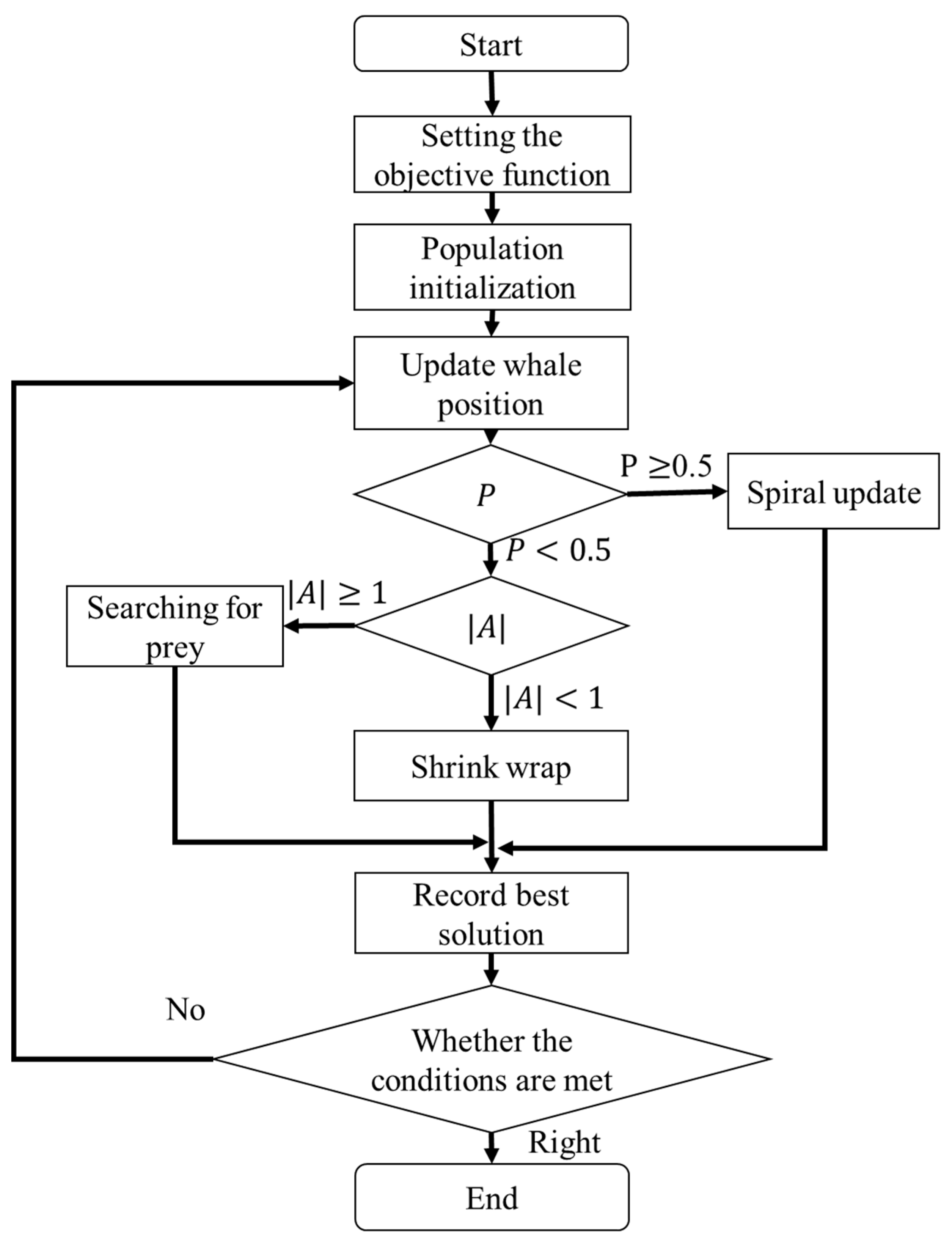

In this study, the defined parameters are applied to the WOA for computation. The process begins with Step 1, which involves initializing the whale population, calculating the fitness, updating the whale positions, handling boundary conditions, and generating initial positions. In Step 2, the algorithm checks whether the maximum number of iterations has been reached. If not, it proceeds to Step 3, where a probability-based decision is made. Based on the value of

, the algorithm selects a behavior mode: if

0.5, the spiral position update is performed; if

0.5, it proceeds to Step 4. In Step 4, the algorithm determines the step coefficient based on the relative distance between the whale and the prey using the value of

. If

1, the whale performs a search for prey; if

1, the whale engages in shrinking surround behavior. Finally, the best solution is selected based on the optimal fitness value, and the process returns to Step 2 to continue the iterations until the stopping condition is met. The WOA flow is illustrated in

Figure 10. The core functionality of the WOA is to identify an optimal set of control parameters that achieves a defined optimization objective. Inspired by the hunting behavior of humpback whales, the algorithm continuously updates its search position within a specified range, emphasizing extensive exploratory behavior initially. As the iterations progress and the search narrows, the WOA transitions to intensified local optimization. Based on these iterative optimization results, the WOA ultimately determines the torque distribution ratio between the motors.