1. Introduction

Frictional vibration is a significant issue for various systems subjected to friction, such as doors, brakes, and seats. The unstable vibration caused by friction leads to noise, thereby causing emotional quality problems. Considering noise is directly related to the stability of a system, its root cause should be analyzed. The vibration caused by friction in a brake is typically classified into groan noise, which occurs near a low frequency of 500 Hz, and squeal noise, which occurs at a higher frequency [

1,

2,

3]. Considering that automotive brakes are directly related to safety, relatively unstable vibration is the main cause of many customer complaints and overall automotive quality issues.

Research on brake noise has been conducted using various methods, including experimental methods using dynamometers, theoretical verification methods for obtaining complete solutions, and complex eigenvalue analysis based on the finite element method (FEM). Because squeal noise is the most sensitive in the audible frequency range (20 Hz–20 kHz), many studies have been conducted to identify its causes [

4]. Brake squeal is well known as frictional self-excited vibration, and many studies have applied theoretical approaches to investigate the dynamic instability of brake systems [

5,

6,

7]. Mode-coupling instability, known as the main cause of brake squeal, can be described using a spring-mass model. In this model, mode-coupling instability is caused by frictional coupling in the critical region [

8,

9]. Mathematical approaches can directly express the mechanism of mode-coupling instability based on complete solutions; however, reflecting geometric elements is difficult. Sinou et al. [

10] derived characteristic equations by the linearization of nonlinear systems and analyzed the stability of friction systems using stability theory. The stability analysis was conducted based on complex eigenvalue analysis and the Routh–Hurwitz criterion, and mode-coupling instability for damping elements was analyzed. Kang [

11] identified the relationship between mode-merged vibration and the stick-slip limit cycle by building single-degree-of-freedom and coupled oscillator models. Another study by the author conducted a complex stability analysis that included gyroscopic, negative slope, and mode-coupling mechanisms for understanding the dynamic instability of disc brakes [

12].

Improved mathematical approaches may reflect some geometric elements by expressing the equations of motion at contact points using a semi-analytical model; however, accurately expressing the equations of motion is extremely difficult and time-consuming. Nam et al. [

13] investigated the instability caused by the negative slope and mode-coupling mechanisms by describing the equations of motion for a pin-on-disc at the contact points. The equations of motion could be expressed relatively simply as they were described at the contact points, and they could be rapidly implemented because the conditions for dynamic instability were clear. The rail pad model examined the fundamental squeal mode of dynamic instability occurring in the brake pad using refined equations of motion [

14]. Kang et al. [

15] analyzed the effect of dynamic instability on the contact span by representing physical models based on the vibration modes of the finite element models of a disc and a pad.

Recently, machine learning has been applied to various fields, including the classification and prediction of vibration signals [

16]. Signals generated by dynamic instability can be visualized using a range of signal-processing techniques and subsequently classified using algorithms that analyze visual patterns, such as convolutional neural networks (CNNs) [

17]. Since machine learning relies on data rather than analytical models, it does not require complex equations of motion or detailed physical modeling. However, its practical application remains challenging, as reliable estimation and classification demand large volumes of squeal data.

FEM-based analytical methods can predict the dynamic instability caused by friction based on algorithms defined in commercial software programs and models. Previously, their use was difficult owing to the considerable computation time and cost required; however, advances in hardware and software have made these methods relatively easily accessible. Ouyang et al. [

18] introduced transient and complex eigenvalue analyses as numerical approaches for obtaining disc brake squeal and described the squeal mechanism and various parameters. Massi et al. [

19] identified the cause and mechanism of the noise generated in thin plates by linear and nonlinear numerical approaches. Obert et al. [

20] predicted squeal in the time domain by representing nonlinear models as finite element models to improve the reliability of existing linear stability analysis. The nonlinear time-domain analysis revealed instability even in the pad mode, which was not found by the existing mode-coupling instability analysis, and emphasized instability for the intermittency route type.

In recent years, various approaches have been adopted for studying brake squeal. By integrating various parameters and mechanisms, research can effectively simulate practical phenomena and elucidate distinct characteristics through traditional methodologies. Meehan et al. [

21] analyzed the causes of brake noise by integrating various mechanisms that had been studied individually into a single model. The proposed model was used for a closed-form analysis of brake squeal occurrence. They also analyzed squeal characteristics in the time domain. Qi et al. [

22] analyzed the mechanism of brake squeal that occurs in railway vehicles and its influencing factors, and defined squeal parameters by nonlinear analysis. They defined the brake pressure as the most important cause of brake noise, and based on experimental and analysis results, verified that the probability of brake squeal further increases with an increase in brake pressure.

Brake squeal, which results from relative motion caused by friction, is generated by self-excited vibration. The main factors of dynamic instability are known to be pressure, variations in friction coefficient, contact area, and damping—all of which are directly related to friction force. Although the stiffness and nonlinear stiffness behavior of the brake pad are important factors in determining dynamic instability, many classical studies have investigated these aspects through contact stiffness [

11,

12,

15]. While contact stiffness is a critical factor influencing squeal in brake systems, it is difficult to define physically, and in actual brake systems, squeal frequently occurs due to physical factors other than the main parameters of friction force.

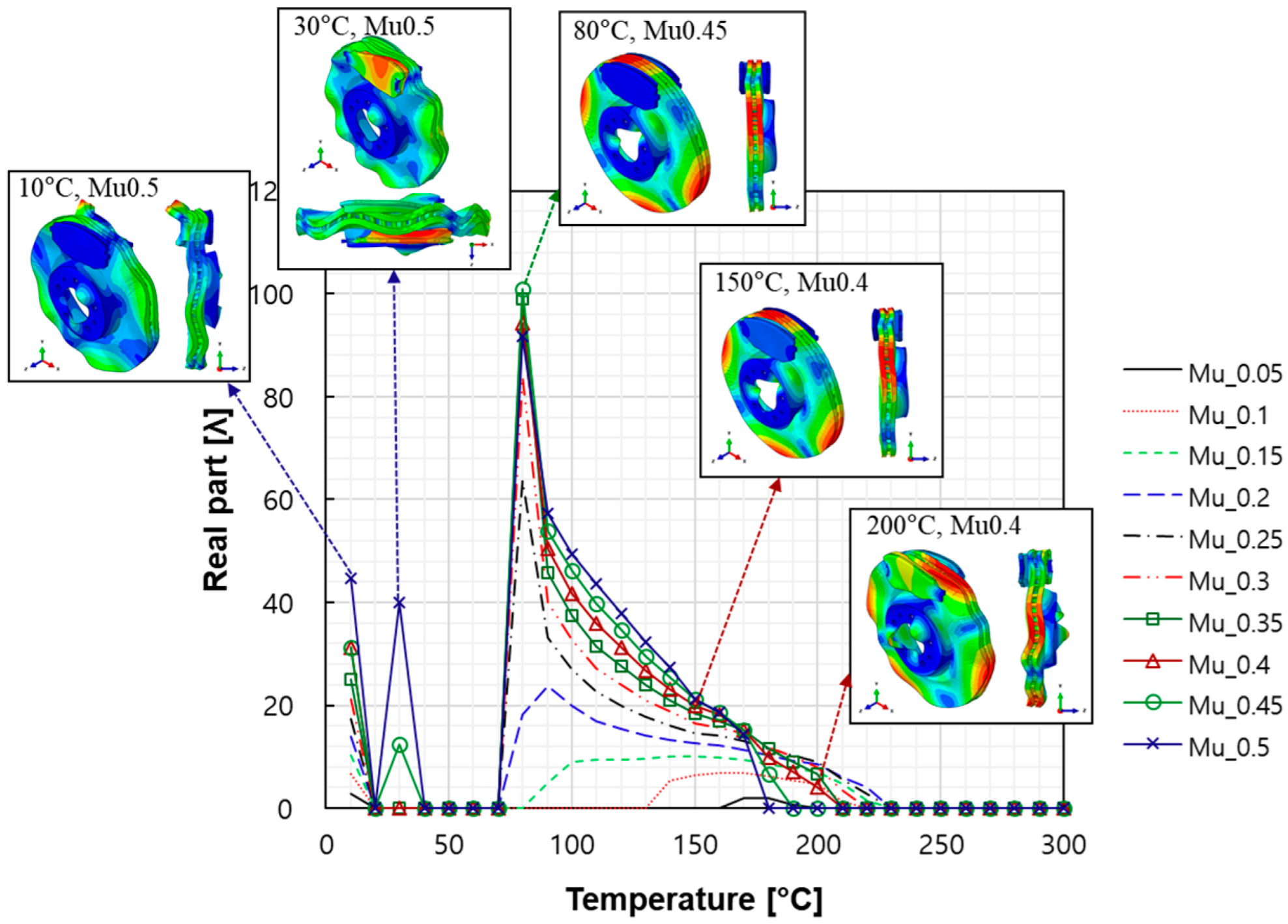

In complex eigenvalue analysis, when the friction coefficient is defined as a function of velocity, an increase in velocity coupled with a decrease in the friction coefficient leads to an increase in the positive real part of the eigenvalue, indicating enhanced instability. Temperature variations affect both velocity and the friction coefficient, leading to the development of corresponding dynamic instability conditions. Mortazavi et al. [

23] theoretically investigated the conditions under which frictional sliding becomes unstable when the coefficient of friction varies with temperature. They demonstrated that friction generates heat, and if the coefficient of friction increases with temperature, a positive feedback loop is formed between heat generation and friction, potentially leading to system instability. Xiao et al. [

24] analyzed the friction and wear characteristics of brake materials. Their study reported that during the initial phase of braking, the coefficient of friction may remain stable or slightly increase with rising temperature; however, once a certain threshold temperature is exceeded, significant degradation of the friction coefficient occurs due to physical and chemical changes at the contact surface. Balotin et al. [

25] conducted an analysis that considered the temperature dependency of the coefficient of friction. They described that frictional heating is strongly influenced by material properties, and materials whose friction coefficients increase with temperature tend to generate more frictional heat. They also predicted that assuming a constant friction coefficient in FEM simulations can result in the underestimation of brake temperature. Although various studies have addressed the thermal and frictional behavior of brake systems, the trends vary significantly depending on the material and operating conditions, making it challenging to generalize a model.

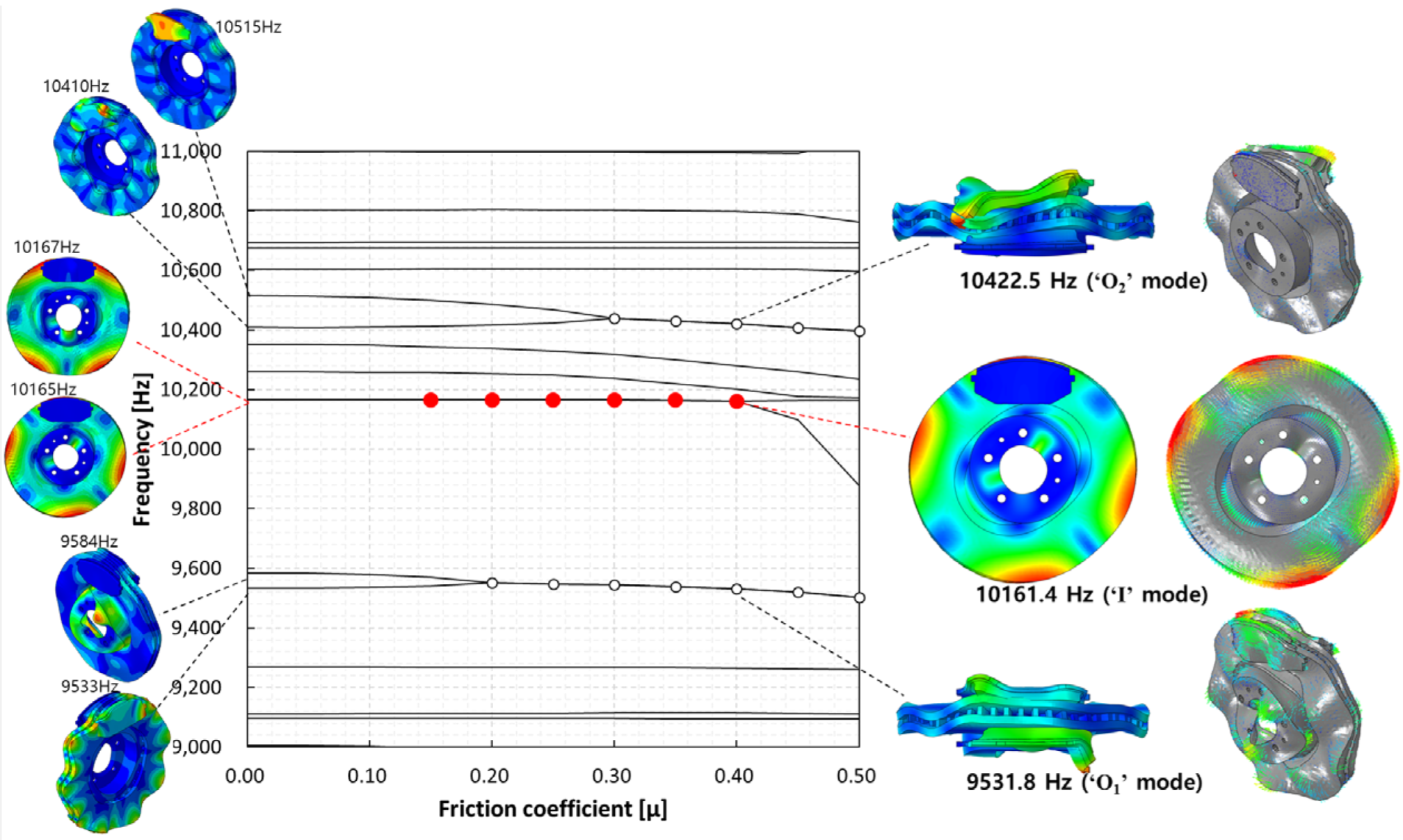

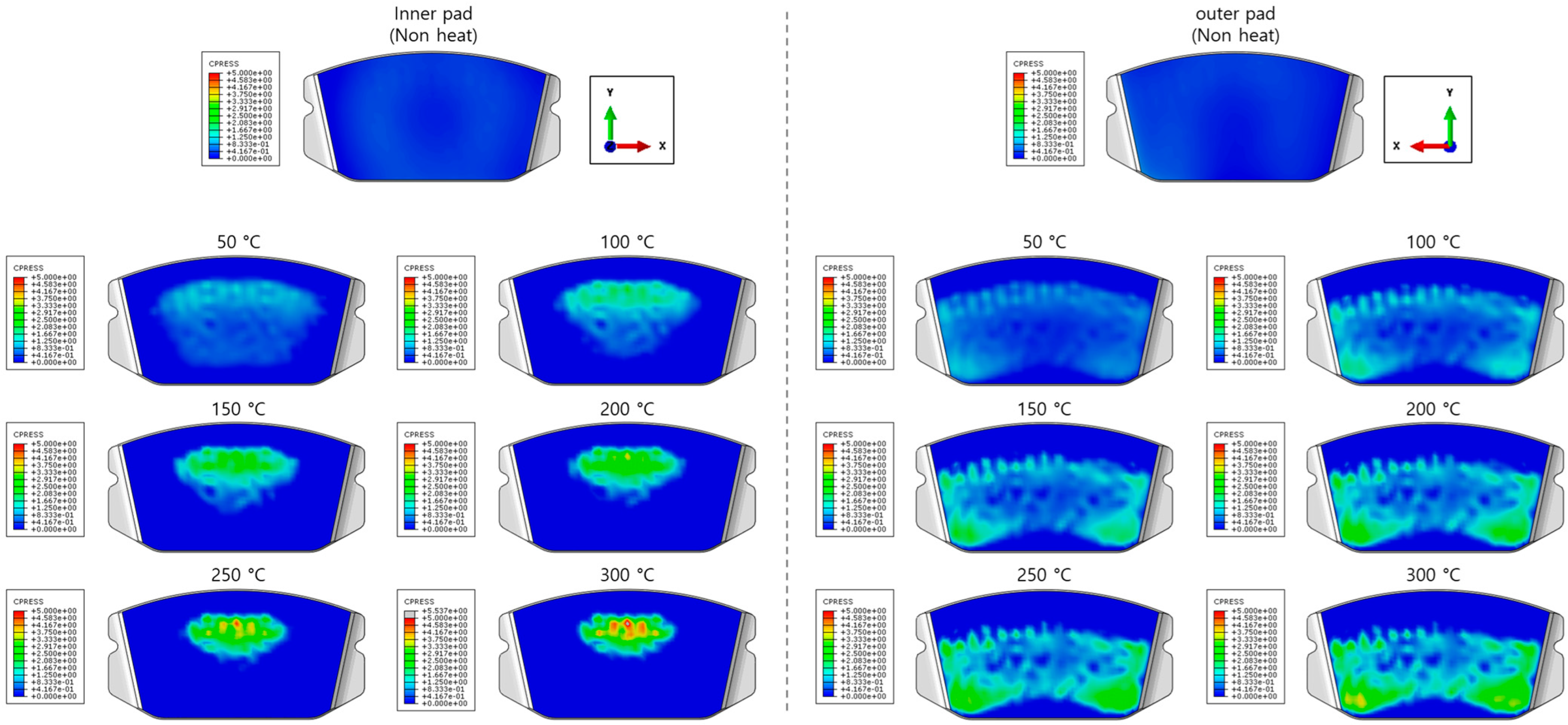

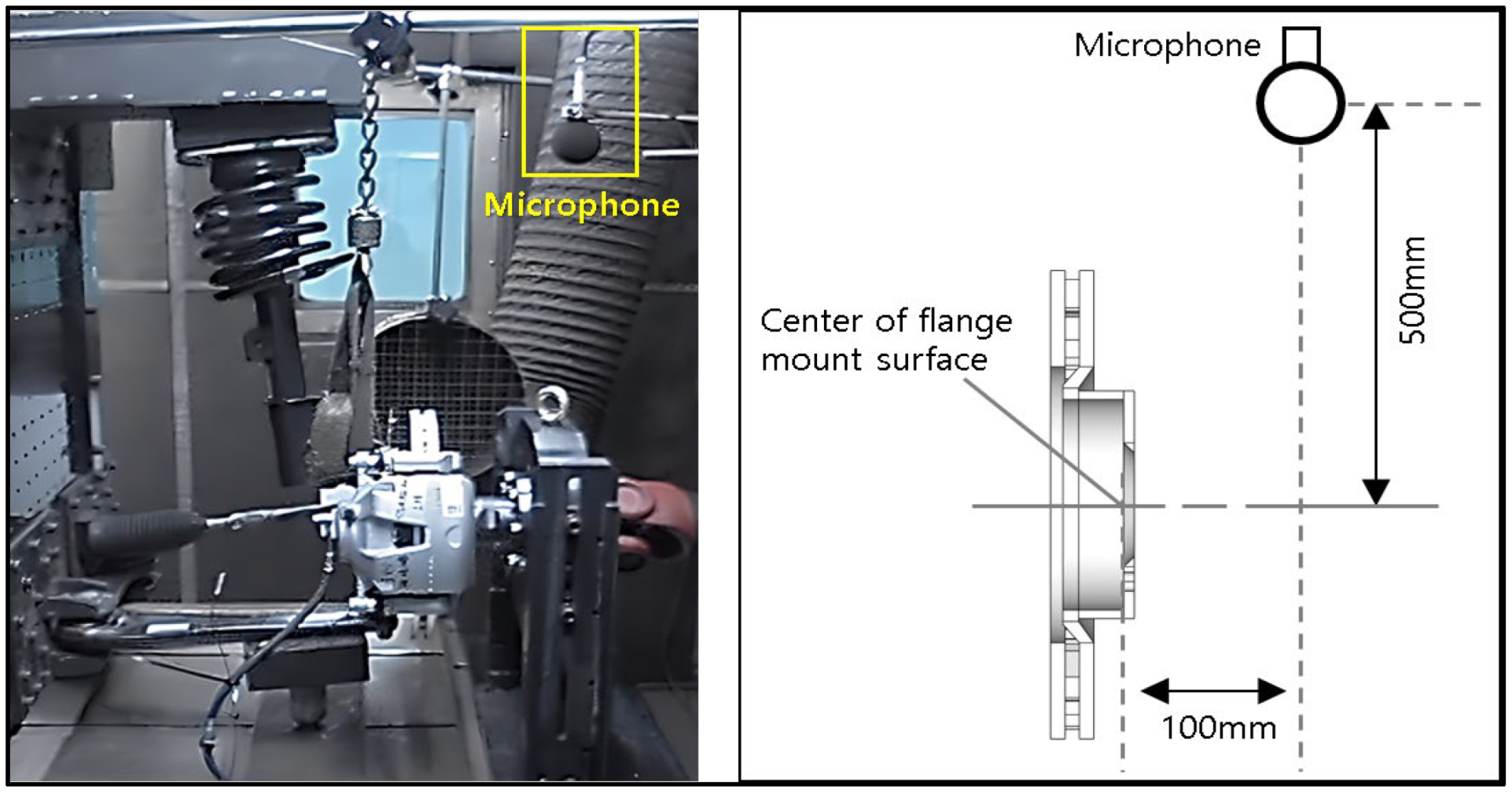

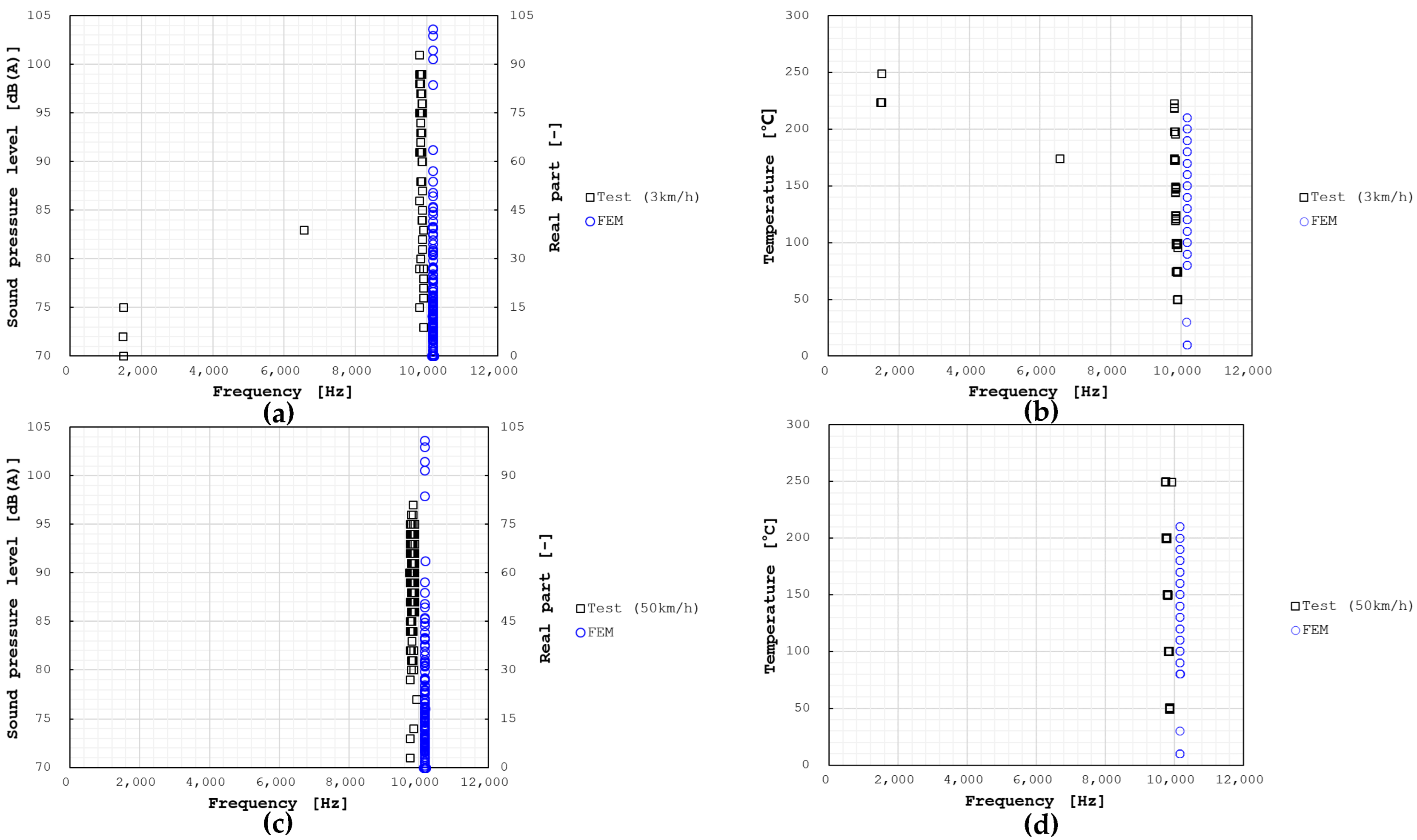

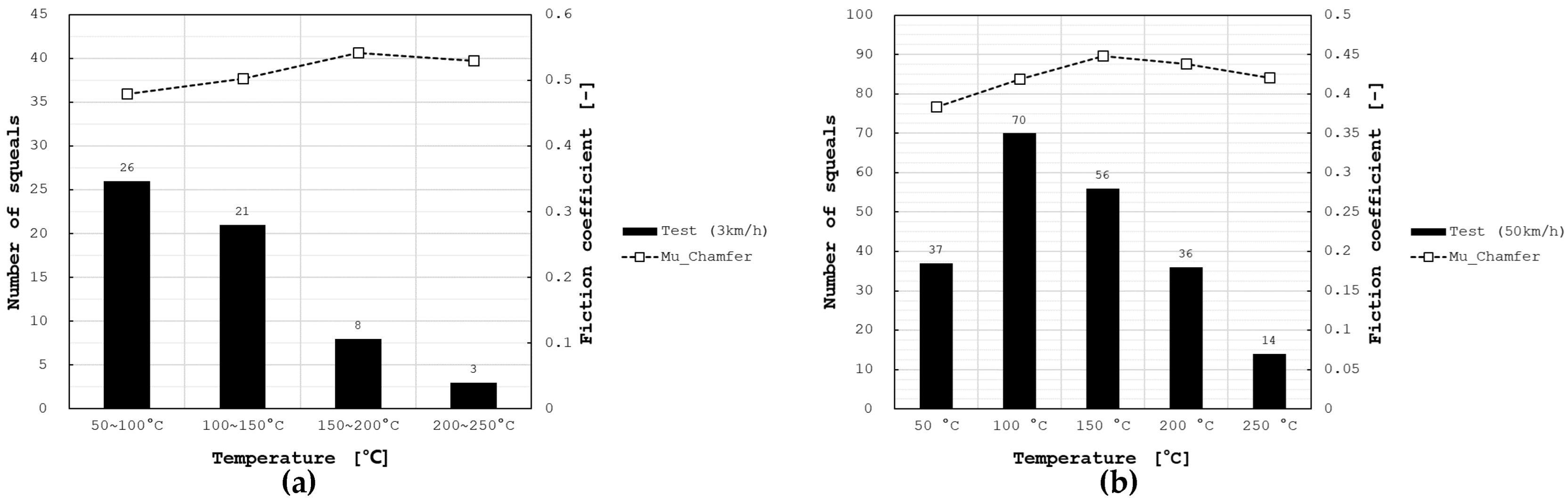

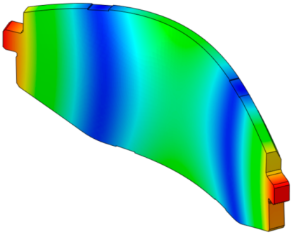

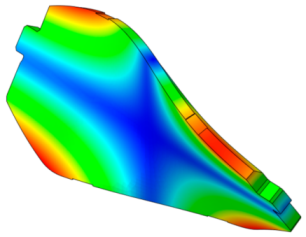

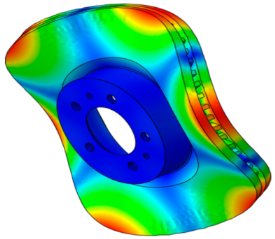

Therefore, this study defines the contact characteristics according to temperature variations of the pad in a disc brake system and aims to investigate the characteristics of squeal noise in the in-plane mode, which is the main instability mode triggered by temperature change. Brake squeal research has primarily focused on the out-of-plane modes (doublet modes) of the disc. However, in the experimental results of the present study, dynamic instability did not occur in the out-of-plane mode of the disc. To evaluate instability modes, complex eigenvalue analysis using the finite element method (FEM) was conducted to represent all geometric characteristics. The pad temperature was set from 50 °C to 300 °C, and the corresponding instability modes were analyzed. Finally, brake dynamometer tests were conducted to verify the reproducibility of squeal noise in the disc’s in-plane mode, and the squeal characteristics were analyzed according to the pad geometry and temperature to validate the suitability of the FEM model.

2. Method

2.1. Complex Eigenvalue Analysis Using FEM

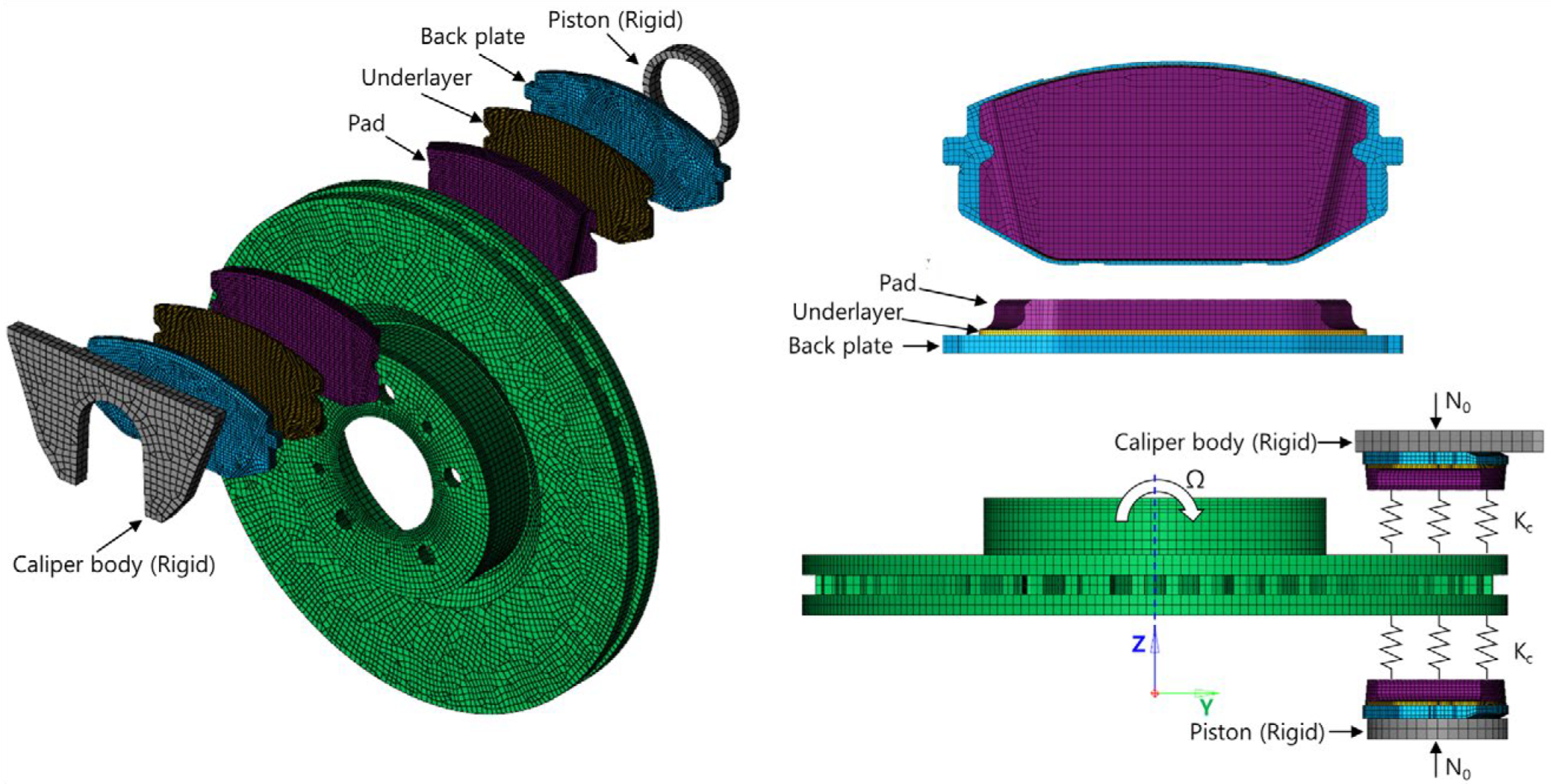

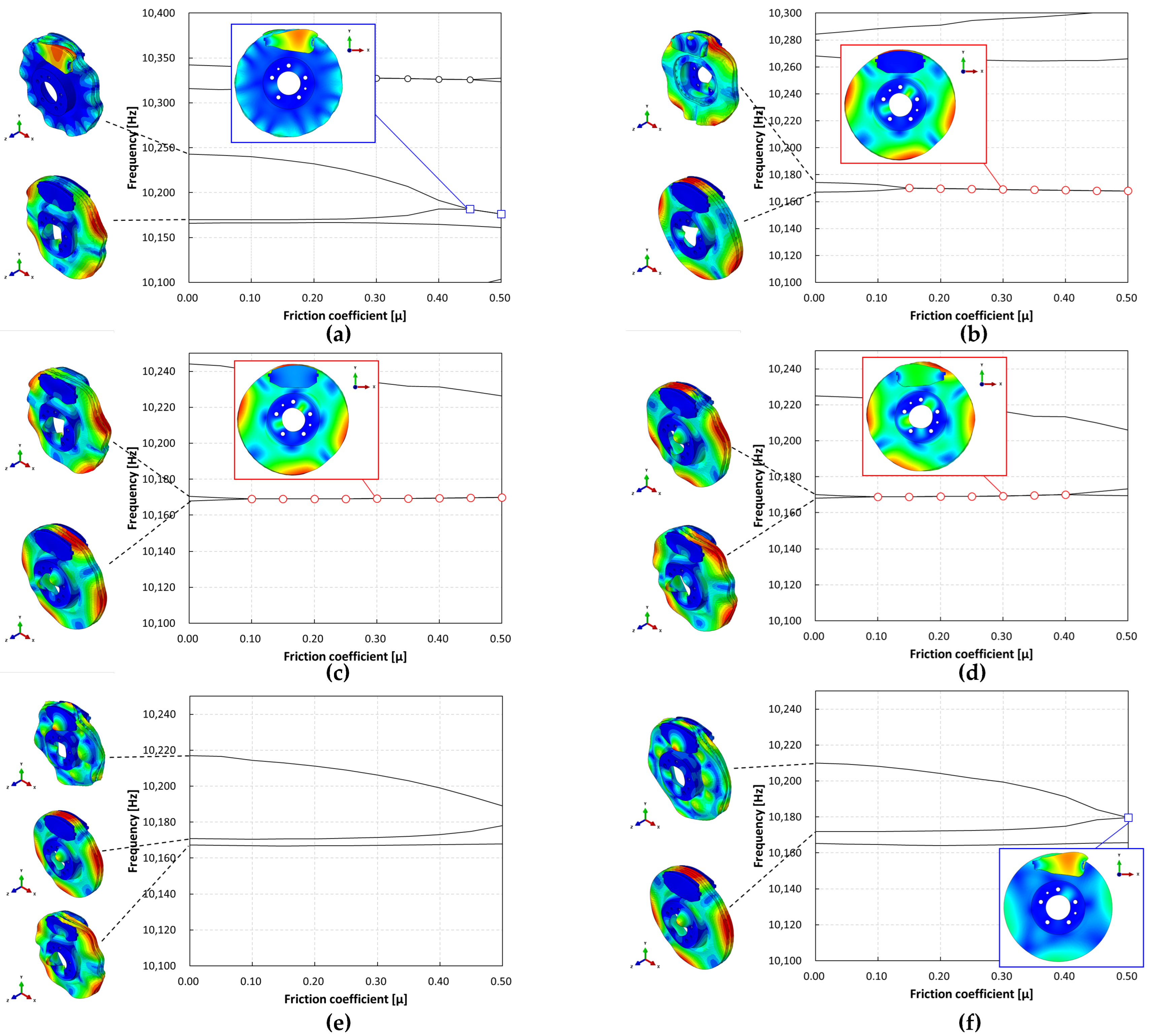

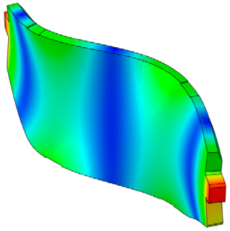

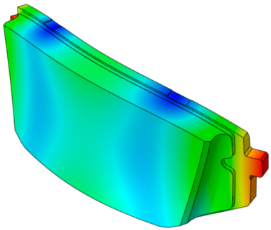

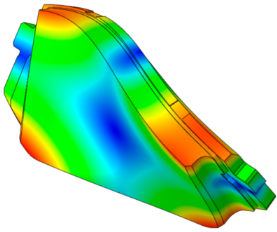

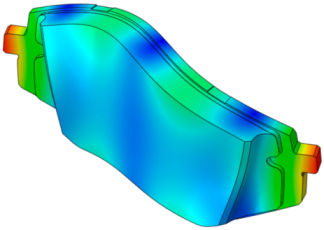

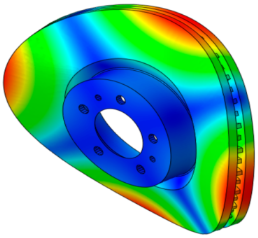

As shown in

Figure 1, the finite element model of the disc brake system of a mid-size van is composed of a disc, a pad, an underlayer, and a backplate. The piston and caliper body, which transmit pressure to the pad, are simplified as rigid bodies. The pseudo-rotation [

13] state, in which the disc rotates at a constant speed (Ω) with respect to the z-axis, is assumed. The pad is subjected to pressure under a constant load (N0) by the piston, resulting in a friction force that is caused by the relative motion between the disc and the pad on the contact surface. The contact pressure can be expressed by the static pressure (N0) and contact stiffness. For contact coupling, the contact stiffness between the disc and the pad, kc, was modeled using the penalty method. A caliper applies pressure with one piston, and the surface symmetrical to the piston is the caliper body. In this study, complex eigenvalue analysis was conducted using ABAQUS/Standard 2024. This method provides solutions for the real and imaginary parts of the eigenvalues and the damping ratio. The simulation model consists of a total of 112,776 hexahedral elements, and the material properties are summarized in

Table 1. Since this study focuses on squeal instability due to temperature variation in the brake pad, the stiffness of the friction material was assumed to be linear.

The equation of motion of the brake system is as follows:

where

is the mass matrix,

is the damping matrix,

is the stiffness matrix, and

is a displacement vector.

The characteristic equation can be written as:

where

denotes the eigenvalue and

represents the corresponding eigenvector. According to the definition of modal analysis, the damping matrix is neglected, and the stiffness matrix is assumed to be symmetric. For such symmetric systems, the resulting eigenvalues are purely imaginary and can be expressed as

. Thus, the undamped eigenvalue problem is given by:

where

is the symmetric stiffness matrix and

is the circular frequency. To analyze the stability of the system due to friction, the eigenvectors obtained from the modal analysis are projected onto a reduced subspace, leading to the following complex eigenvalue problem:

The projected stiffness matrix

can be expressed as:

Here, is the friction-coupling matrix, which includes the effects of contact stiffness and friction forces. This asymmetric component of the stiffness matrix is responsible for inducing dynamic instabilities, such as squeal.

The complex eigenvalue problem is solved using the QZ method, and the eigenvectors of the original system are reconstructed as:

The eigenvalue

is a complex number consisting of a real and an imaginary part, as shown below:

The real part of the eigenvalue determines the dynamic stability of the system. A positive real part indicates dynamic instability, which is characteristic of brake squeal phenomena.

In the complex eigenvalue analysis, the mounting holes for fastening the disc to the hub with bolts were fully constrained. For the pad, a tie condition (full coupling) was applied to the contact surfaces between the pad, underlayer, and backplate to prevent any relative displacement or rotation among the components. A pressure of 20 MPa was applied to the inner back plate using a piston to represent the pressure acting on the inner pad. For the outer pad, the caliper body was fully constrained to allow pressure transmission. The rotational speed of the disc was set to 2.49 rad/s, corresponding to a vehicle speed of approximately 3 km/h. As mentioned earlier, disc rotation in complex eigenvalue analysis is defined as pseudo-rotation, and the applied pressure—when not considering velocity-dependent terms—affects only the equilibrium state, assuming constant contact stiffness. Therefore, the applied pressure was defined as the maximum pressure that may occur in a typical automotive brake system.

2.2. Material Properties

For the pad used in this study, materials with an iron content of 50% or higher, which are classified as semi-metallic, were used. The disc was made of gray cast iron and was similar in size to the discs of typical passenger cars. The physical properties of the disc and pad were corrected based on the modal test results after conducting FEM modal analysis using the elastic modulus, Poisson’s ratio, and density measured in advance. To implement the free-free boundary condition, a flexible elastic sound-absorbing material was used in the modal test, and the frequency response of each component was measured using an impact hammer based on the impact excitation technique. The impact was applied to the backplate, which has a dominant influence on the bending mode of the pad. The modal test was conducted using a uniaxial accelerometer, and the average value was obtained from five repeated measurements. The natural frequencies were validated by coherence, and the mode shapes were estimated by numerical analysis. The accelerometer was attached to the end of the backplate, where a large displacement was expected, based on the prediction of the first bending mode.

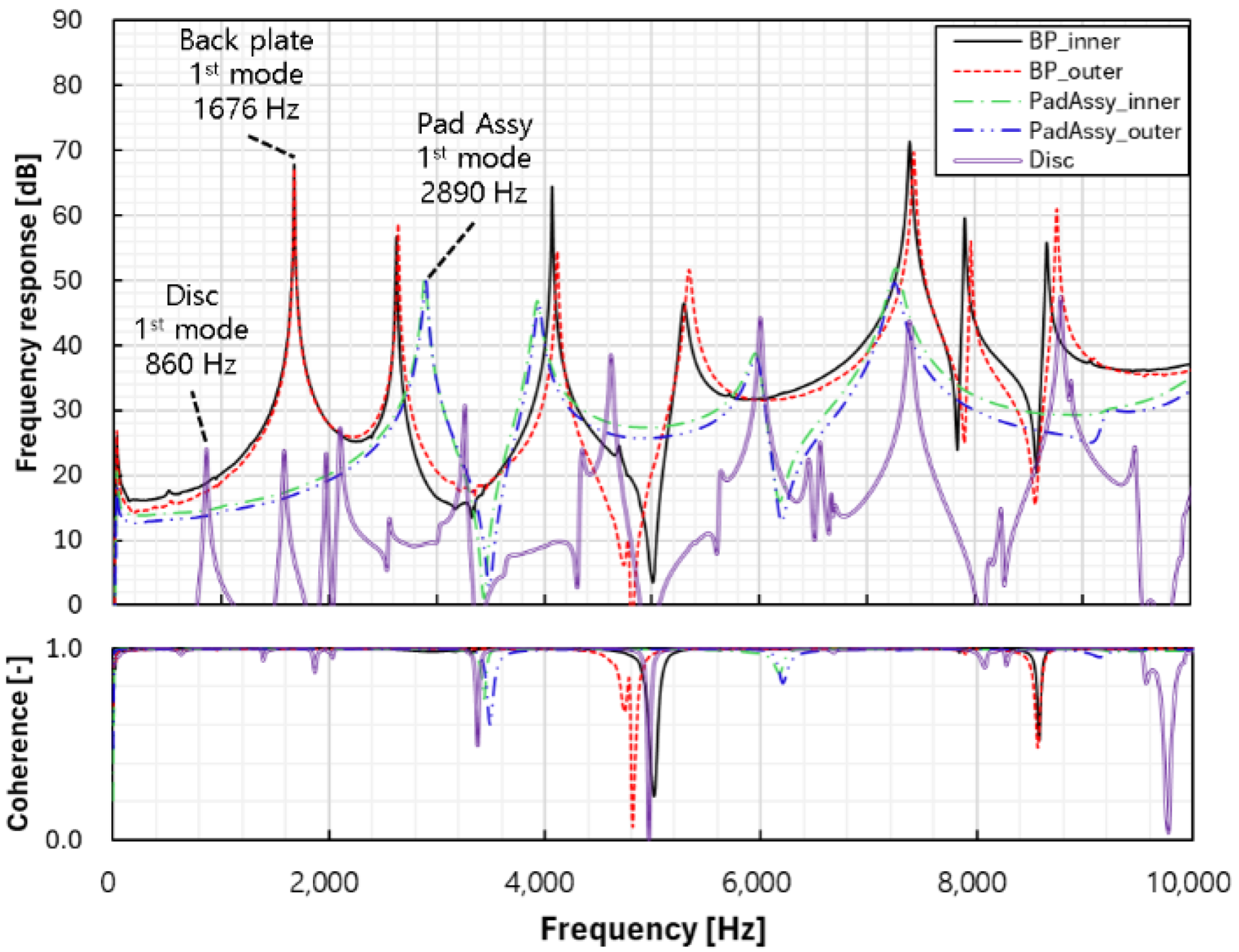

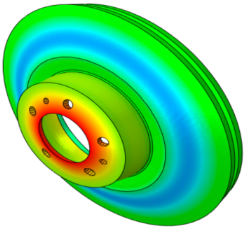

Figure 2 shows the frequency response curve measured in the modal test. The primary and secondary natural frequencies (bending and torsional modes, respectively) identified from the backplate and pad assembly were used as factors to correct the elastic modulus and Poisson’s ratio, respectively. For the disc, the mode shape was the second nodal diametrical mode for the primary natural frequency and the nodal circle axial mode for the secondary natural frequency. The elastic modulus and Poisson’s ratio were corrected using the primary and secondary modes.

Table 2,

Table 3 and

Table 4 compare the FEM analysis and test results for the natural frequencies of each component. The error rate for up to the tertiary mode was found to be less than 5%.

Contact stiffness, i.e., the change in contact pressure per unit length (as expressed in (9)), was estimated from the elastic modulus corrected from the modal test. The calculated contact stiffness of the pad was

, and complex eigenvalue analysis was conducted by applying this value as a contact stiffness factor in the finite element analysis as follows:

where

is the maximum contact pressure and

is the maximum deformation.

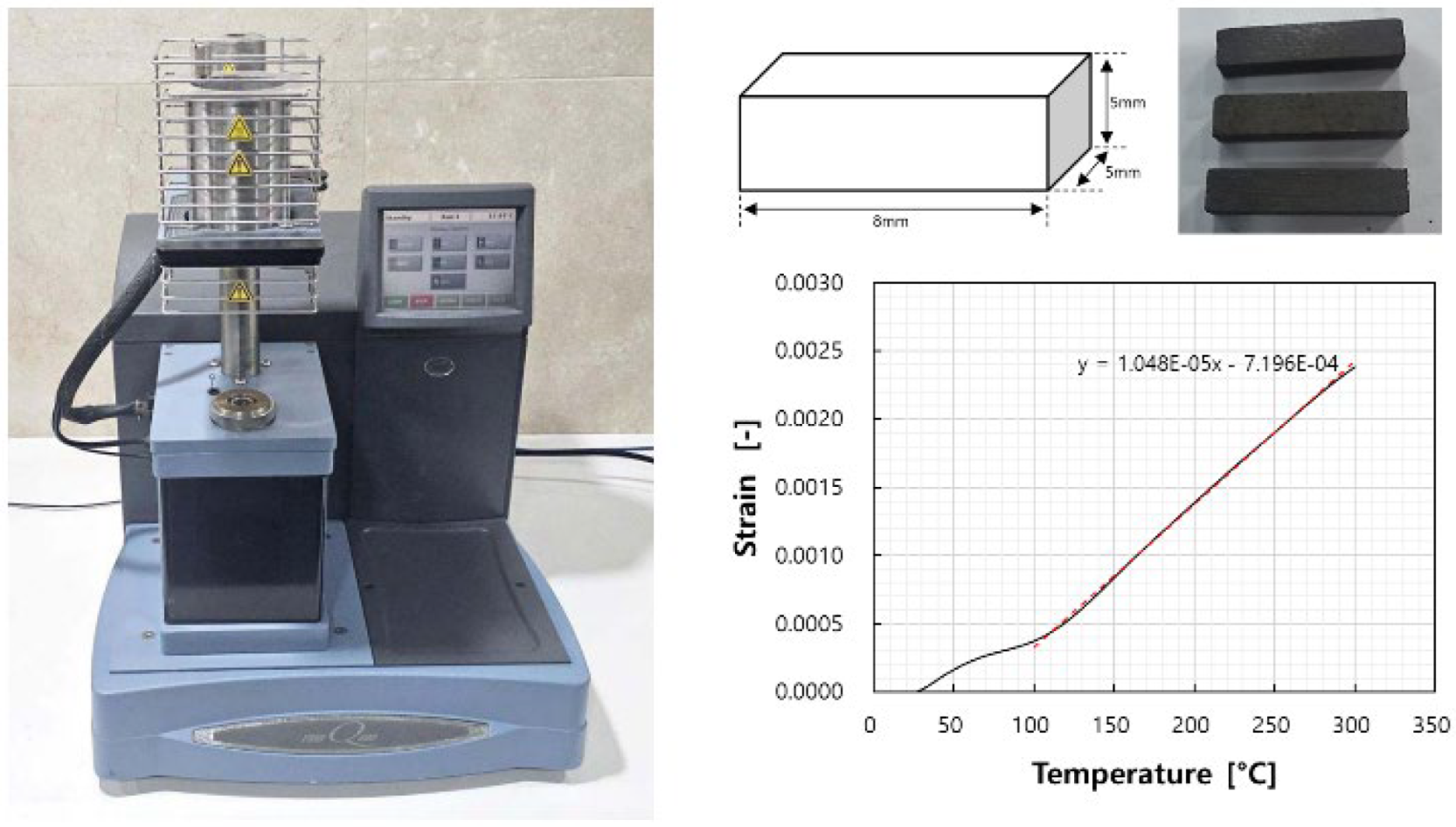

To reflect the thermal deformation characteristics of the brake pad, the coefficient of thermal expansion is measured by collecting specimens, as shown in

Figure 3. Thermal expansion represents the change in the volume of the material due to the temperature change. As expressed in (10), the thermal strain,

, is proportional to the temperature as follows:

where

is the thermal strain [−], α is the coefficient of linear expansion [/°C], and ΔT is the temperature change [°C].

In this study, the coefficient of linear expansion was used to reflect the thermal deformation characteristics. In the test, the coefficient of linear expansion was measured using a thermomechanical analyzer (TMA Q400 model, TA Instruments, New Castle, DE, USA). For the test, three specimens were precisely cut from one brake pad by selecting the x-axis direction as the longitudinal direction. Their sizes were set as 5 mm (width) × 5 mm (height) × 8 mm (length). The initial load was 0.1 N, and the temperature was increased from 27 °C to 300 °C at a rate of 5 °C/min. The thermal deformation of the pad according to the temperature was found to exhibit strong linearity after 100 °C, and the coefficient of linear expansion was calculated for the straight slope in the range of 100 to 300 °C. The coefficient of linear expansion of the pad was found to be /°C. For the disc, the coefficient of linear expansion of typical cast iron (/°C) was selected and used in the finite element analysis.

4. Conclusions

This study investigated the squeal noise characteristics of the in-plane mode of the disc of a disc brake system according to the temperature of the brake pad. The instability before and after applying thermal deformation of the pad was analyzed using finite element analysis. The instability mode generated from the in-plane mode of the disc changed into an out-of-plane mode by the z-axis deformation of the pad. In addition, the analysis of the change in the magnitude of the real part of the in-plane mode according to the temperature revealed that near 80 °C was the most sensitive region for instability. Finally, squeal noise characteristics according to the pad geometry, temperature, pressure, and rotation speed were analyzed using a brake dynamometer to verify the reliability of the finite element analysis. The main frequency of squeal noise was approximately 10,000 Hz, which was derived to result from the instability of the in-plane mode derived from the analysis. In particular, the frequency of squeal noise was highest near 100 °C, whereas squeal noise disappeared after 250 °C. This tendency was largely consistent with the results of the finite element analysis, thereby verifying the reliability of the analysis.

In future research, we plan to develop a refined squeal model that more accurately reflects thermal effects by integrating mathematical modeling at the contact interface with machine learning techniques. This approach aims to establish a systematic methodology for the precise prediction of brake squeal behavior.