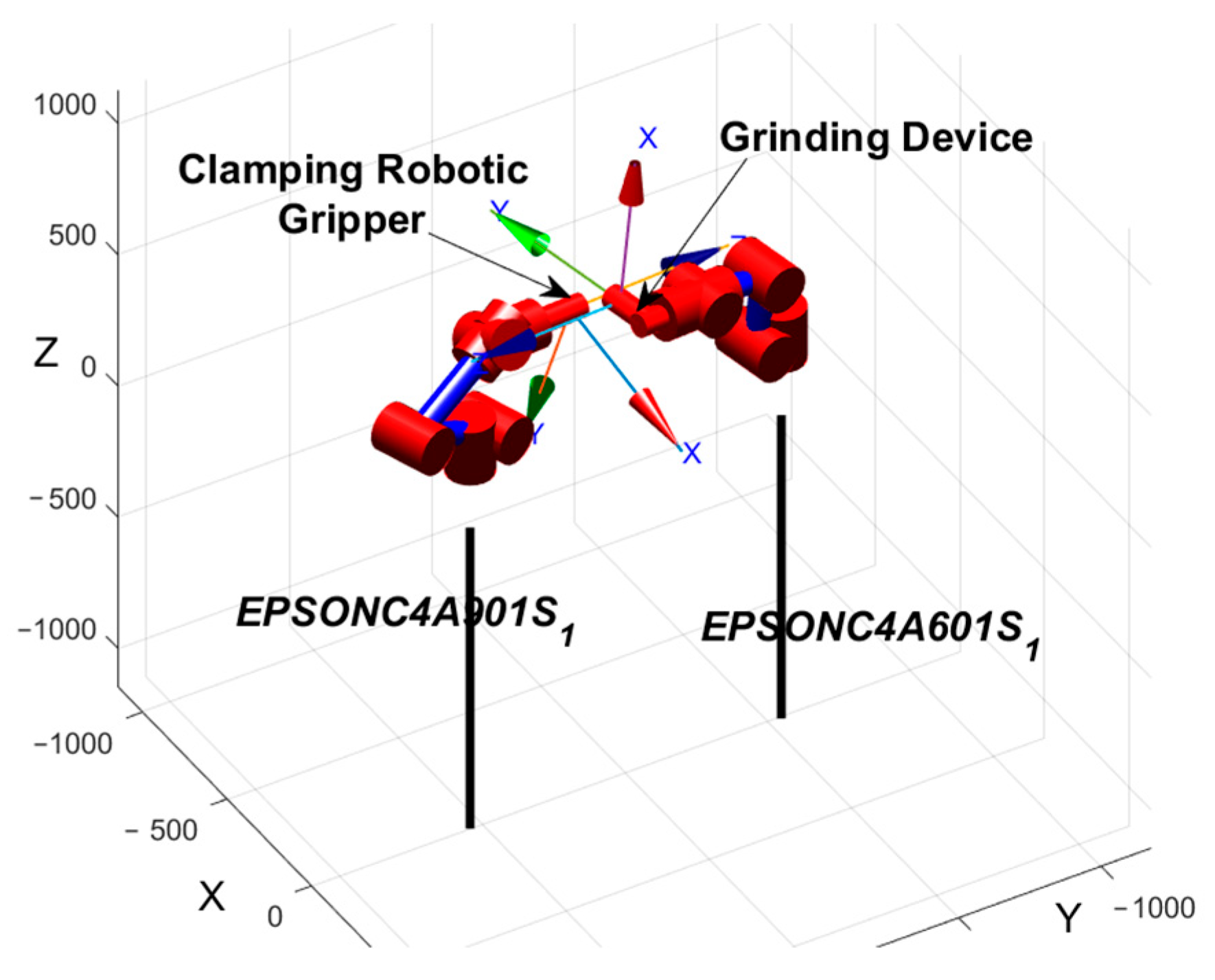

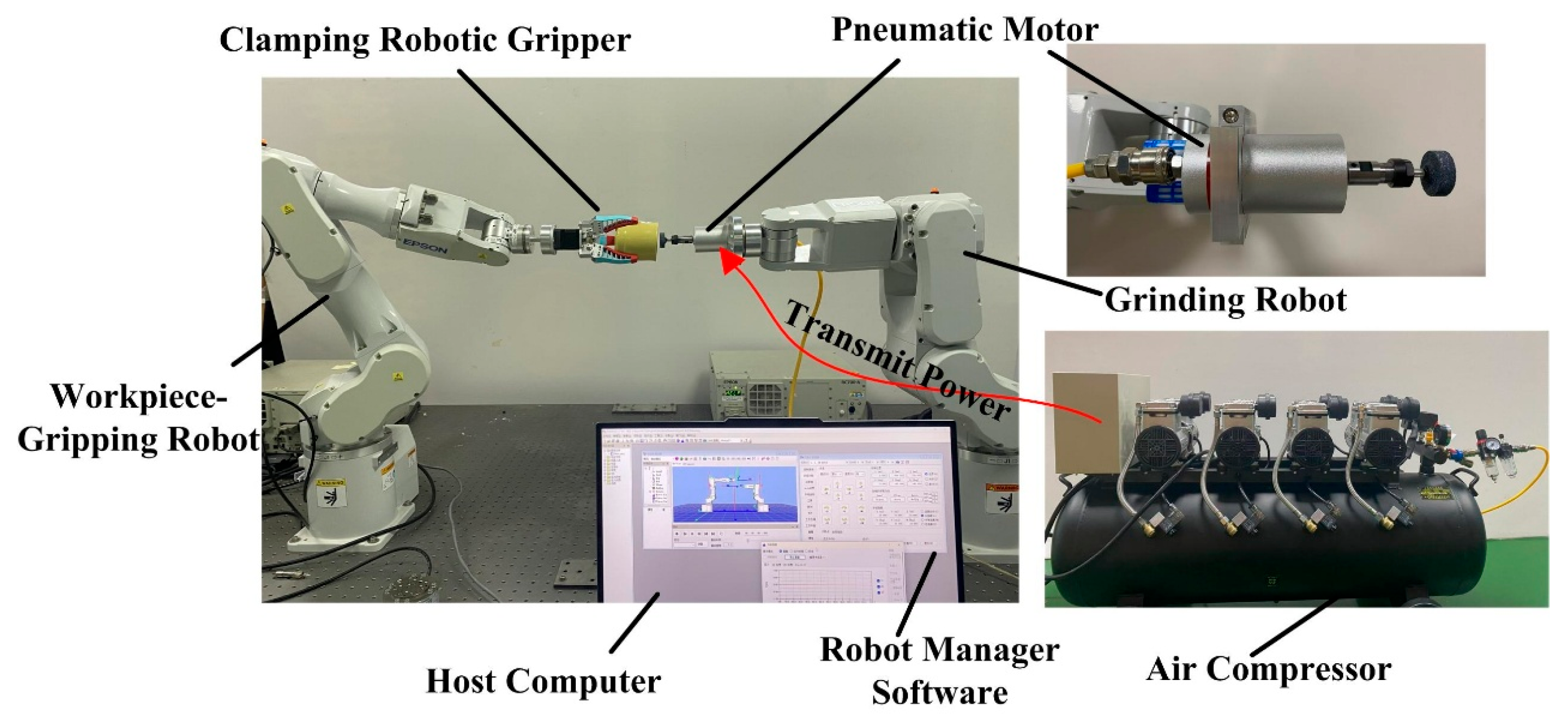

In this study, an EPSON C4 series robotic system is employed, where the EPSON C4-A601S—selected for its high joint motion velocity and positioning accuracy—is equipped with a grinding module to function as the grinding robot, while the EPSON C4-A901 serves as the workpiece-holding robot.

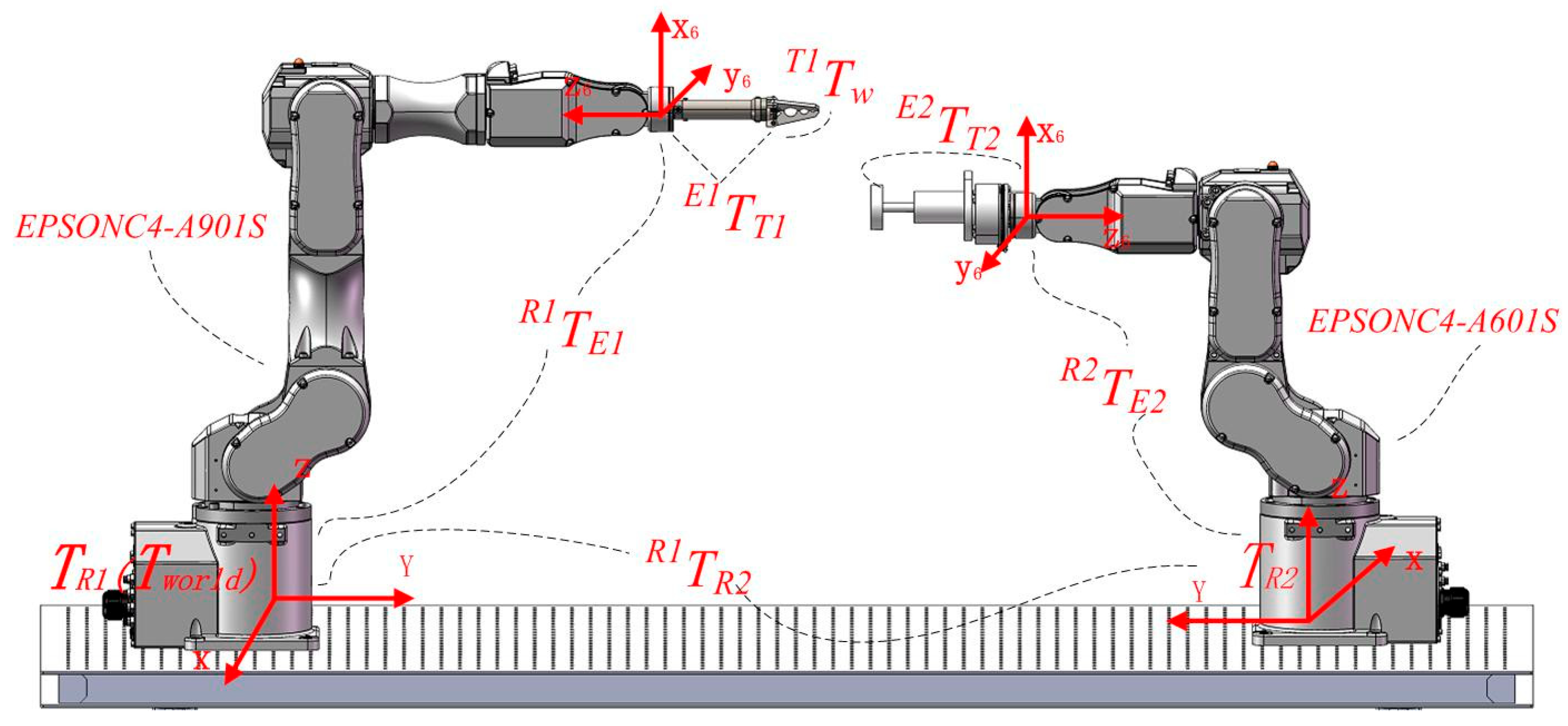

Figure 1 illustrates the coordinate system relationship within the dual-robot grinding and polishing system. In the figure, [R

i] denotes the robot base coordinate system, [E

i] represents the end-effector coordinate system of the robotic arm, and [T

i] indicates the tool coordinate system of the robotic arm, where

i = 1 corresponds to the EPSON C4-A901S robot and

i = 2 refers to the EPSON C4-A601S robot, while [w] signifies the workpiece coordinate system. When the grinding tool establishes contact with the workpiece, the dual-robot system forms a closed kinematic chain. Based on the master–slave control strategy for system decoupling, the constraint equations of the system can be derived as follows:

where

R1Tw represents the transformation matrix from the workpiece coordinate system to the master robot’s base coordinate system. Upon specification of the grinding task requirements and the determination of the tool path trajectory, this transformation matrix becomes fully defined and serves as a known parameter in the system;

E1TT1 and

E2TT2 denote the transformation matrices from the gripping tool to the master robot and from the grinding tool to the slave robot, respectively. While both matrices are structurally defined by the mechanical assembly,

E2TT2 must be calibrated owing to the unique properties of the grinding tool, resulting in a constant matrix post-calibration. The homogeneous transformation matrix

R1TR2 defines the spatial relationship between the base frames of both robotic systems, which is determined through calibration procedures and remains invariant during operation. The homogeneous transformation matrix

T1Tw defines the spatial relationship between the workpiece frame and the gripping tool frame. This matrix is structurally determined by the mechanical assembly configuration, where the workpiece maintains a fixed pose relative to the gripping tool, resulting in a time-invariant transformation. The homogeneous transformation matrix

T2Tw defines the dynamic spatial relationship between the workpiece frame and the grinding device frame. As the grinding tool must maintain persistent contact with the target point throughout the process, this matrix becomes path-dependent and exhibits time-varying characteristics [

16].

The equation establishes a closed-loop constraint relationship of “master robot motion—base frame transformation—slave robot motion”, rigorously maintaining time-invariant relative poses between master–slave end-effectors. This constraint equation provides the theoretical foundation for integrating the Handshake Method and the seven-point method. The Handshake Method derives the base frame transformation matrix

R1TR2 to establish a global coordinate mapping for the dual-robot system, ensuring coordinated motion under a unified reference frame. The seven-point method computes the tool frame transformation matrix

E2TT2 to compensate for end-effector installation errors. When orientation error Δ

R exists in

R1TR2 and position error Δ

P occurs in

E2TT2, the constraint equation transforms into (3). This constraint equation resolves the coupling between Δ

R and Δ

P, enabling error convergence through iterative optimization.

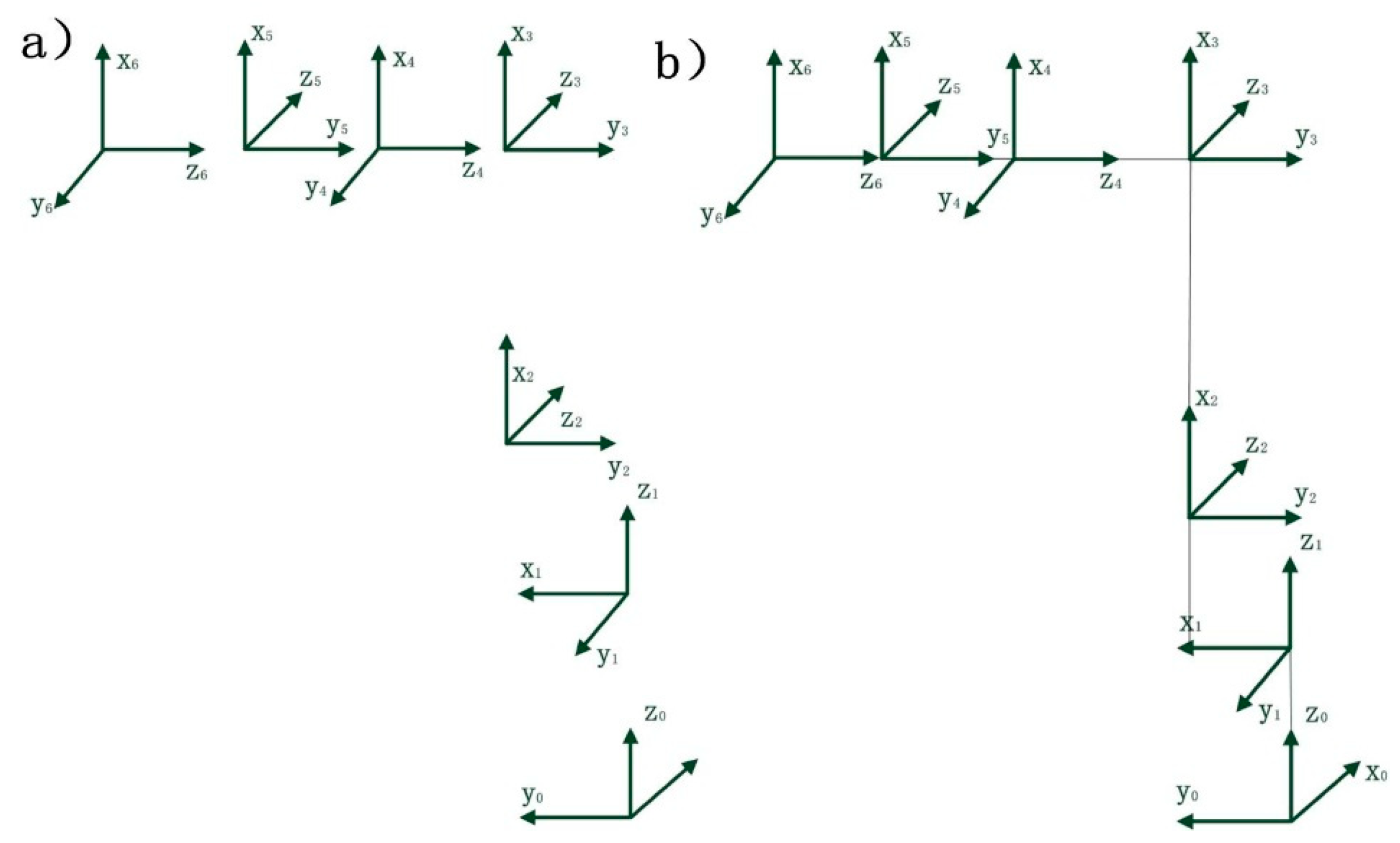

2.2. Dual-Robot Base Frame Calibration

Kinematic analysis of the dual-robot system indicates that the calibration of R1TR2 is essential for establishing accurate inter-robot spatial relationships. Since this relative pose relationship serves as the fundamental basis for dual-robot collaborative operation, its precise measurement is imperative. The calibration of dual-robot base frames aims to determine the transformation matrix between coordinate systems R1 and R2. This study employs a calibration method in which two EPSON robots are each equipped with a calibration needle at their end-effectors. The calibration procedure involves controlling the robots to bring their needle tips into contact at four spatially distinct positions, with the critical condition that these four contact points must not lie on the same plane. Based on the coordinate relationships obtained from these non-coplanar contact points, the calibration matrix between the two robot systems is then mathematically determined. This experimental method enables direct determination of the coordinate transformation relationship between the two robotic base frames without requiring auxiliary measurement tools.

The calibration procedure is conducted as follows:

(1) Coordinate system definition and notation specification: The world coordinate system, base frames (R1 and R2 for Robot 1 and Robot 2, respectively), and tool frames (T1, T2) are explicitly defined. With calibration needles mounted on each robot’s end-effector, both manipulators are controlled to establish four non-coplanar contact points (P1–P4) within their shared workspace. The corresponding coordinates of each contact point are recorded in both robot base frames as R1Pk and R2Pk (k = 1, 2, 3, 4).

(2) Rotation matrix computation: Assuming the world coordinate system coincides with Robot 1’s base frame, we obtain

Substituting the coordinates of the four contact points into the above equations, subtracting point coordinates, and reformulating them in matrix form yields

To ensure the solvability of

R1RR2, the selected four points must be non-coplanar (the determinant of the matrix on the right-hand side of the equation must be non-zero), from which the rotation matrix is derived as follows:

(3) Compute the translation matrix: Substitute the rotation matrix

R1RR2 into

(4) Orthonormalization of the rotation matrix: Due to computational errors, the derived rotation matrix

R1RR2 may violate orthonormality constraints. To reconcile the discrepancies between matrices while preserving geometric validity, we optimize the solution using the Frobenius norm criterion. The specific formulation is given as follows:

Define the objective function as

Constraints:

The optimized orthonormalized rotation matrix

is obtained when the objective function J reaches its minimum.

Base coordinate system calibration experiment:

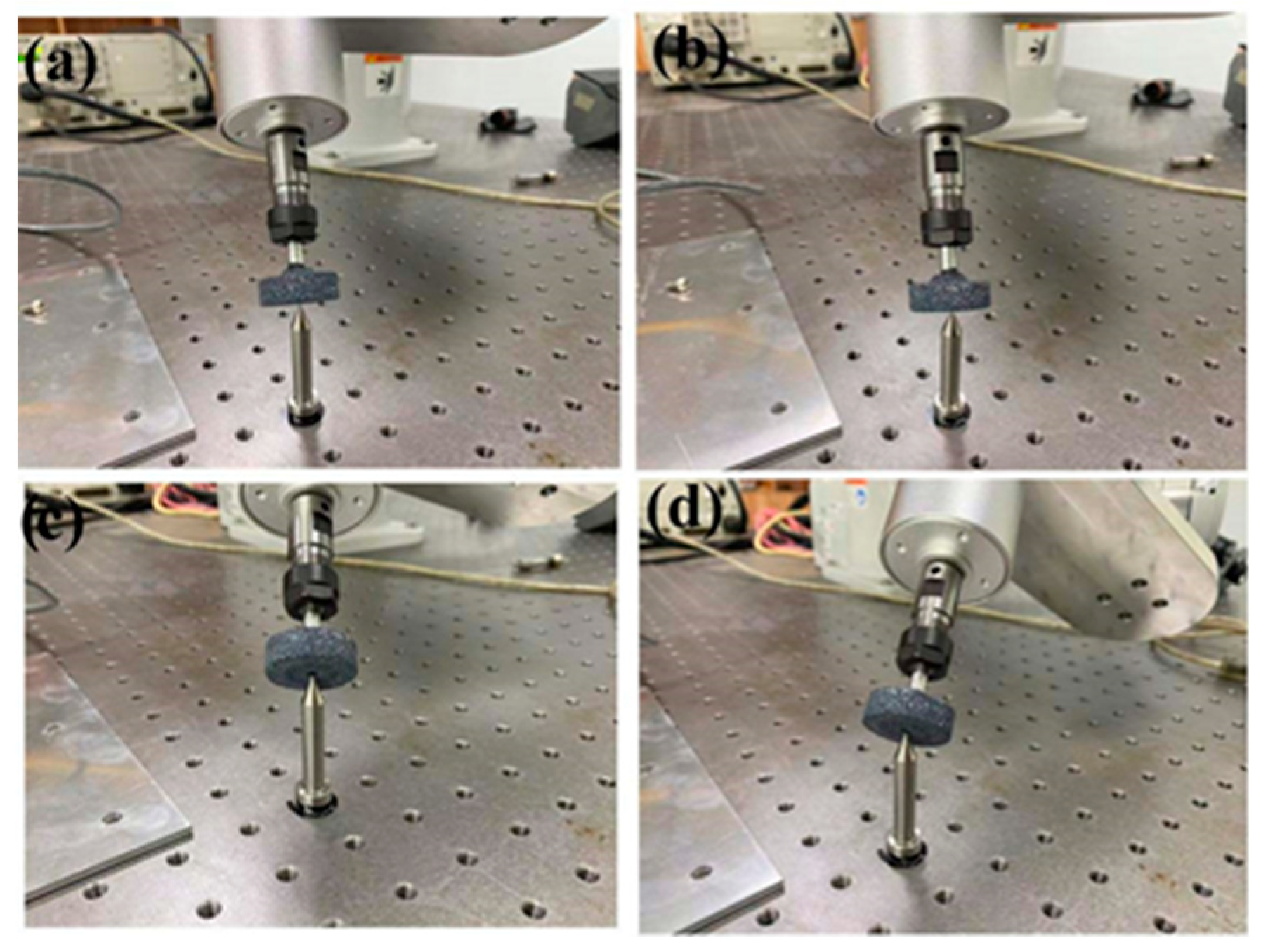

The calibration experimental platform consists of an RC700-A controller with a host computer, two robotic manipulators, and a calibration probe, as illustrated in

Figure 2. Following the experimental procedure, a dual-robot base frame calibration was conducted, with the coordinate data of key points for both the master and slave robots recorded in

Table 2 and

Table 3, respectively.

The rotation matrix

R1RR2 is derived from Equation (6).

The translation matrix

R1PR2 is derived from Equation (7).

After orthonormalization, the transformation matrix between the base frames of the two robots is obtained as

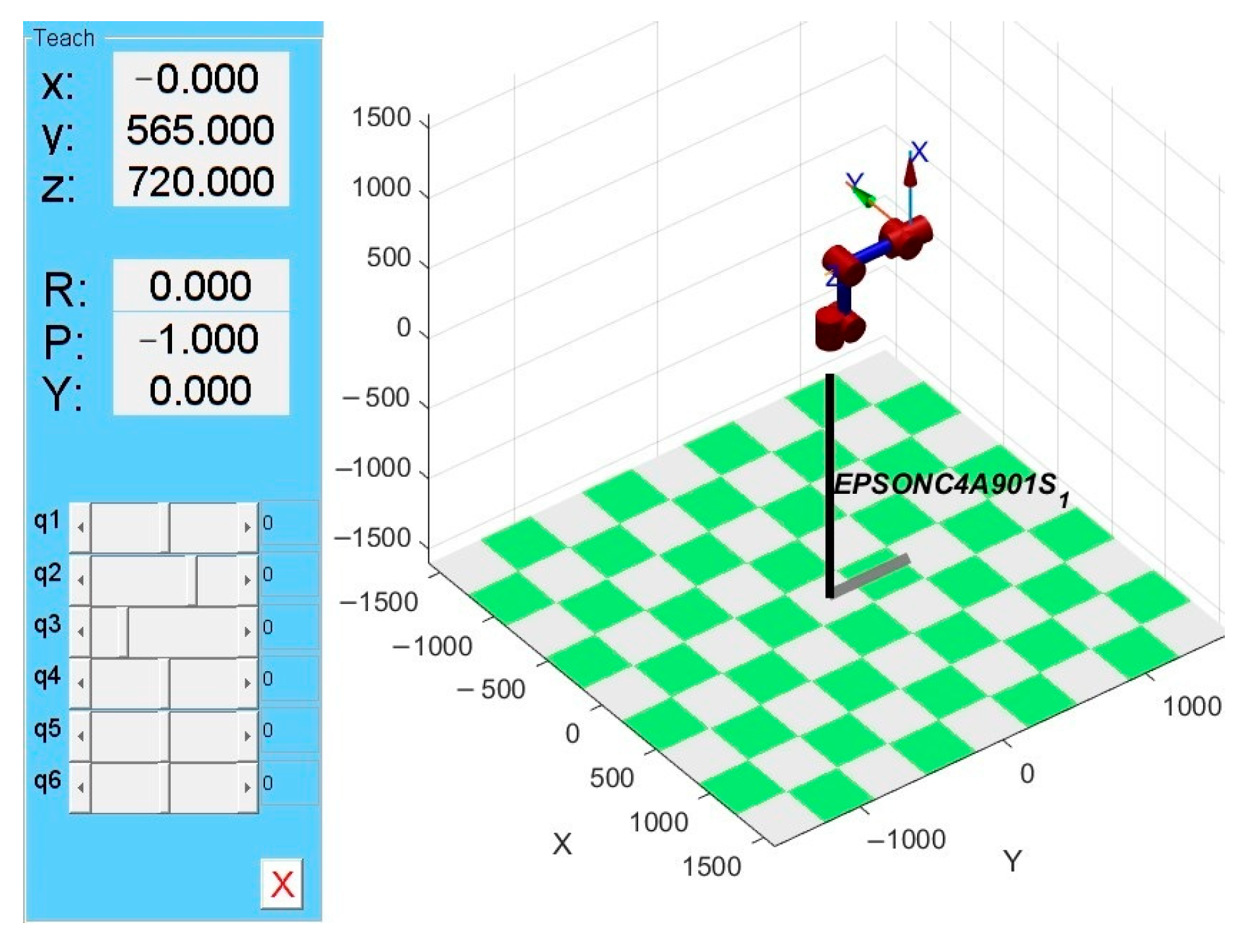

2.3. TCP Calibration

This paper adopts the seven-point method for Tool Center Point (TCP) calibration.

The calibration procedure is as follows:

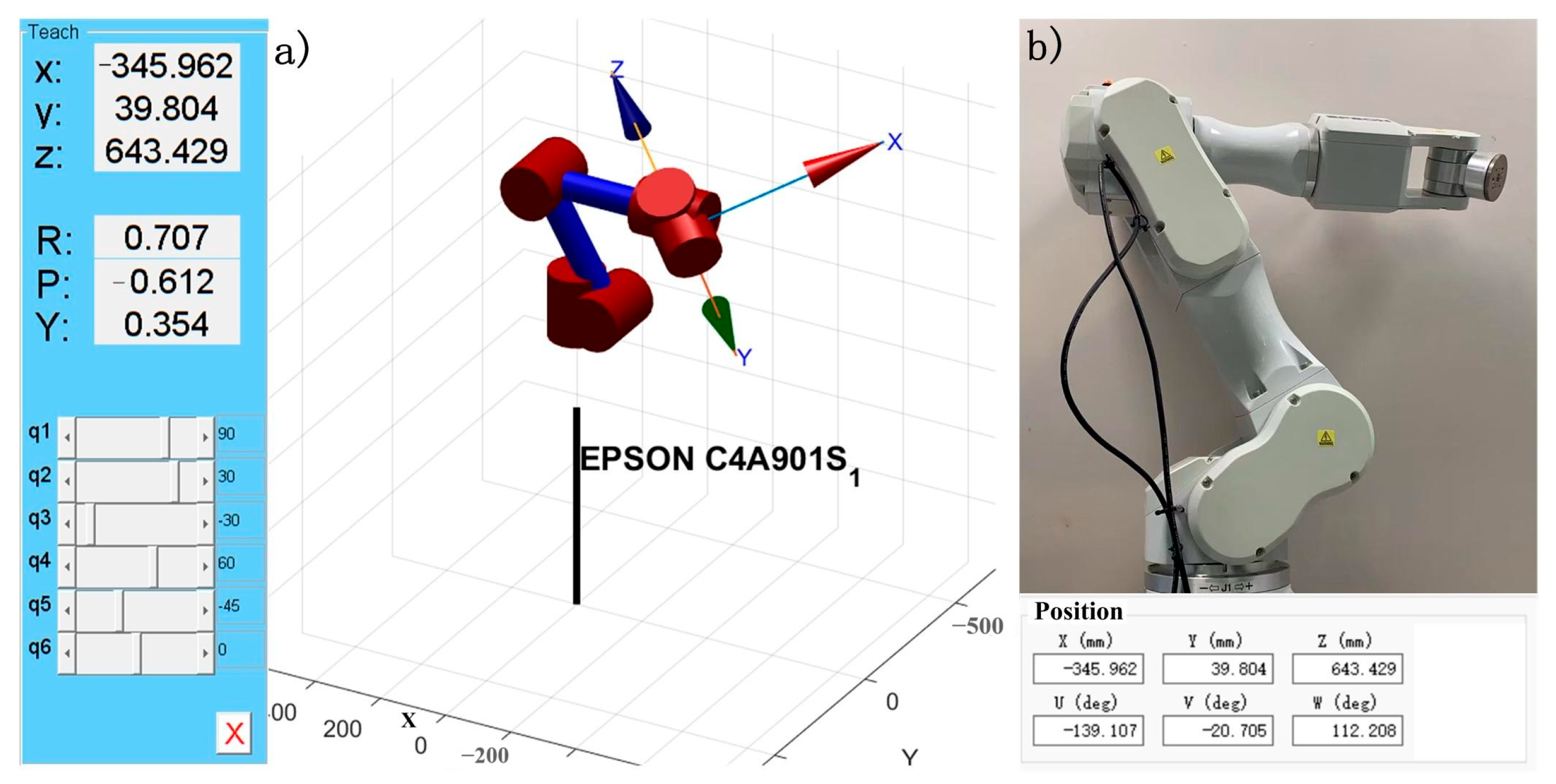

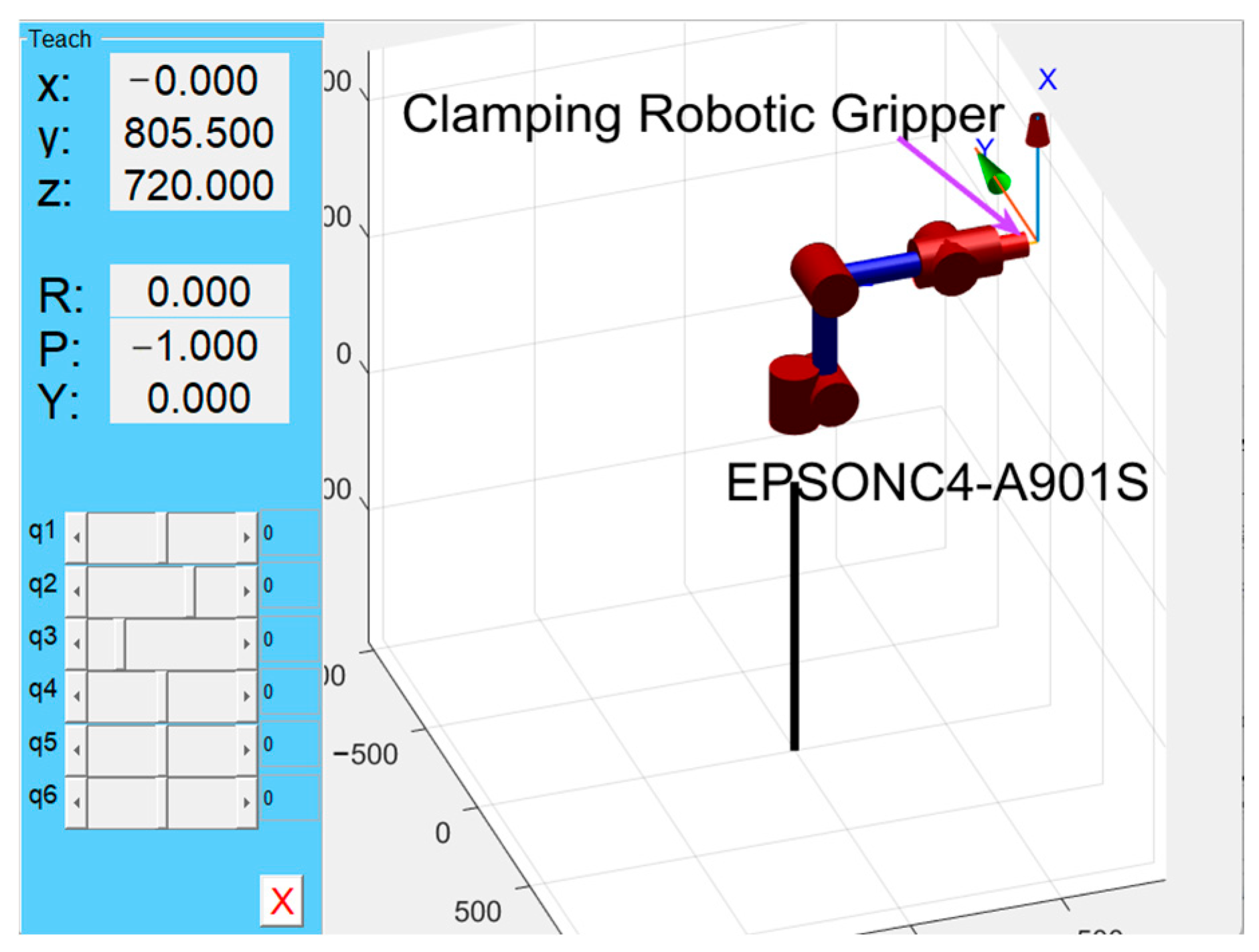

(1) Determine calibration points: A calibration needle is fixed on the optical platform, with its tip position designated as P. Control the robot to position the tool end-effector at point P with four distinct orientations, as illustrated in

Figure 3, while recording its pose relative to the base coordinate frame.

(2) Formulate the system of equations: Applying coordinate transformation principles yields the relevant equations. Since the tool end-effector reaches the same position four times, simultaneous elimination of point P coordinates gives the following matrix:

where matrix

A is composed of differences between rotation matrices of the flange end coordinate system under different orientations, matrix

B consists of corresponding positional differences, and

X represents the Tool Center Point (TCP) position in the end-effector coordinate system (

E2PT).

(3) Solve using the least squares method: Obtain

E2PT2 by applying the least squares principle:

(4) Initial position adjustment and recording: Move the robot near the origin point, adjust the joints to align the tool coordinate system’s X and Z axes parallel to the corresponding axes of the base coordinate system, and then record the data parameters (for the 5th calibration point).

(5) Motion position recording: Maintaining the current orientation, move from Point 5 along the X and Y axes of the base coordinate system by specified distances, respectively, and then record the parameters for Points 6 and 7, as illustrated in

Figure 4.

(6) Direction vector determination:

(7) Transformation matrix computation: Orthonormalize PX, PY, and PZ, and substitute to obtain

Combining the obtained

E2PT2, we derive

E2TT2:

TCP Calibration Experiment:

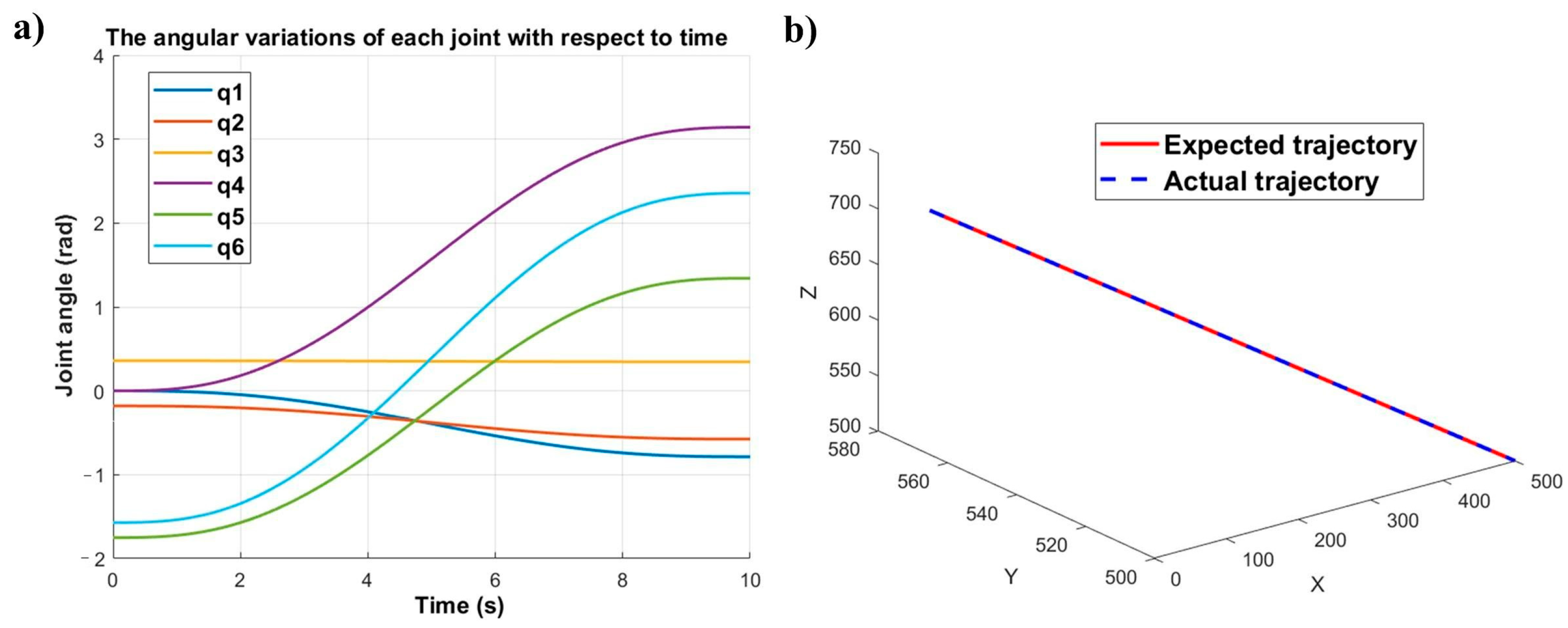

By operating the Epson C4-A601S robot through its controller, the tool end-effector was repeatedly positioned at the same target point in four distinct spatial orientations (as illustrated in

Figure 5). The end-effector pose data for each repetition were recorded. The experimental dataset is shown in

Table 4.

The position matrix

E2PT2 is obtained according to Equation (15):

Furthermore, since the

Y-axis,

Z-axis, and

X-axis of the tool coordinate system are parallel to the

X-axis,

Y-axis, and

Z-axis of the base coordinate system, respectively, PX and PY represent the directional vectors of the

Y-axis and

Z-axis in the tool coordinate system. The robot was controlled to move 50 mm along the

X-axis and 50 mm along the

Y-axis of the base coordinate system, with the data shown in

Table 5.

The matrices

R2RT2 and

E2TT2 are computed using (18) and (19).