Ventilation Design of an Extra-Long Single-Bore Double-Track Railway Tunnel with High Traffic Density

Abstract

1. Introduction

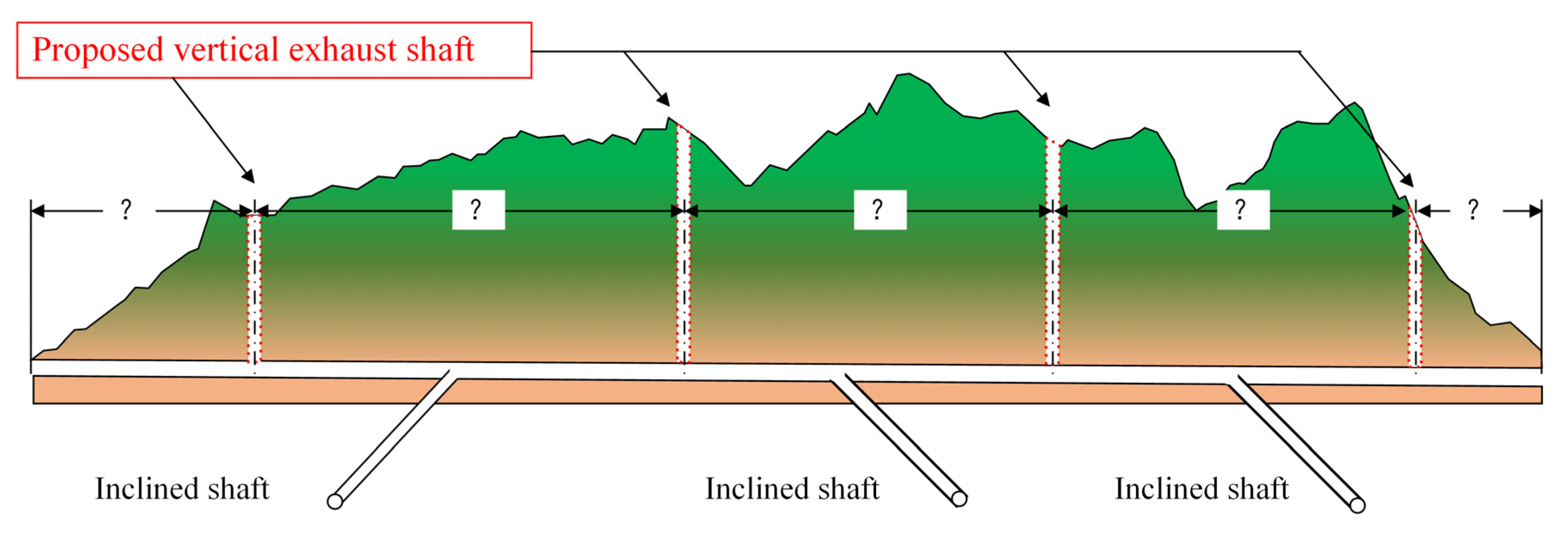

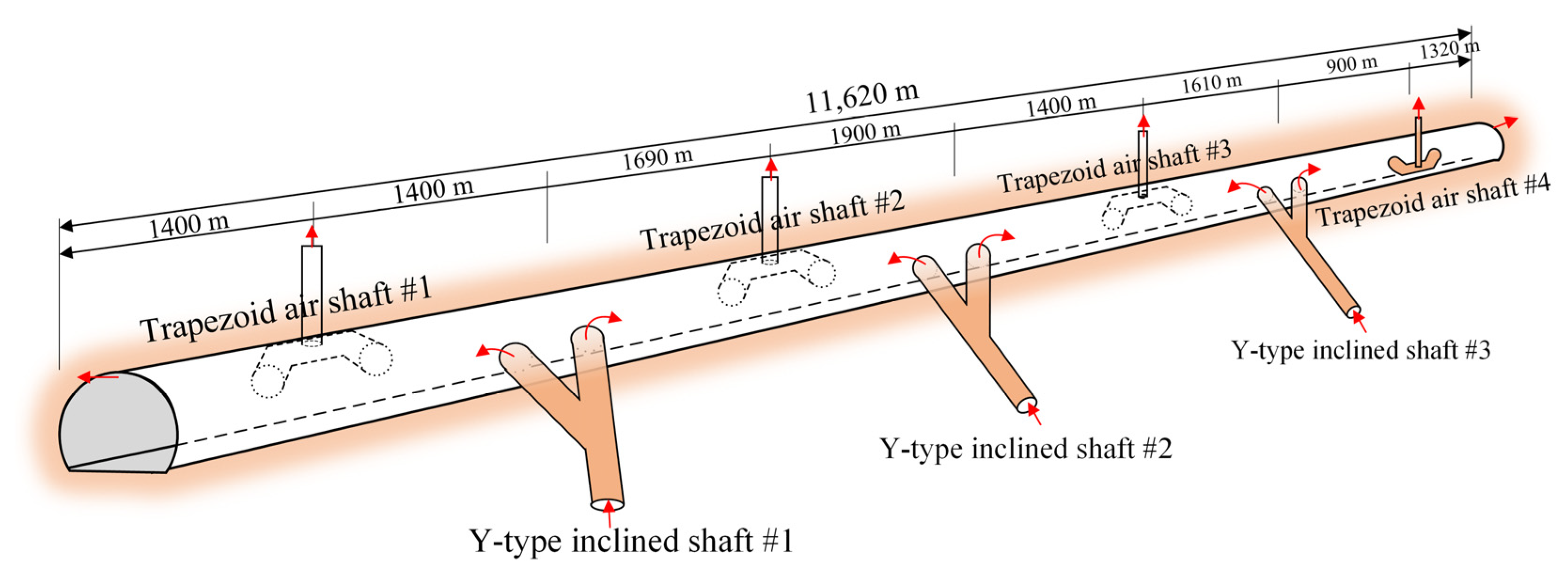

2. Engineering Background

2.1. Tunnel Structures

2.2. Traffic Operation Condition

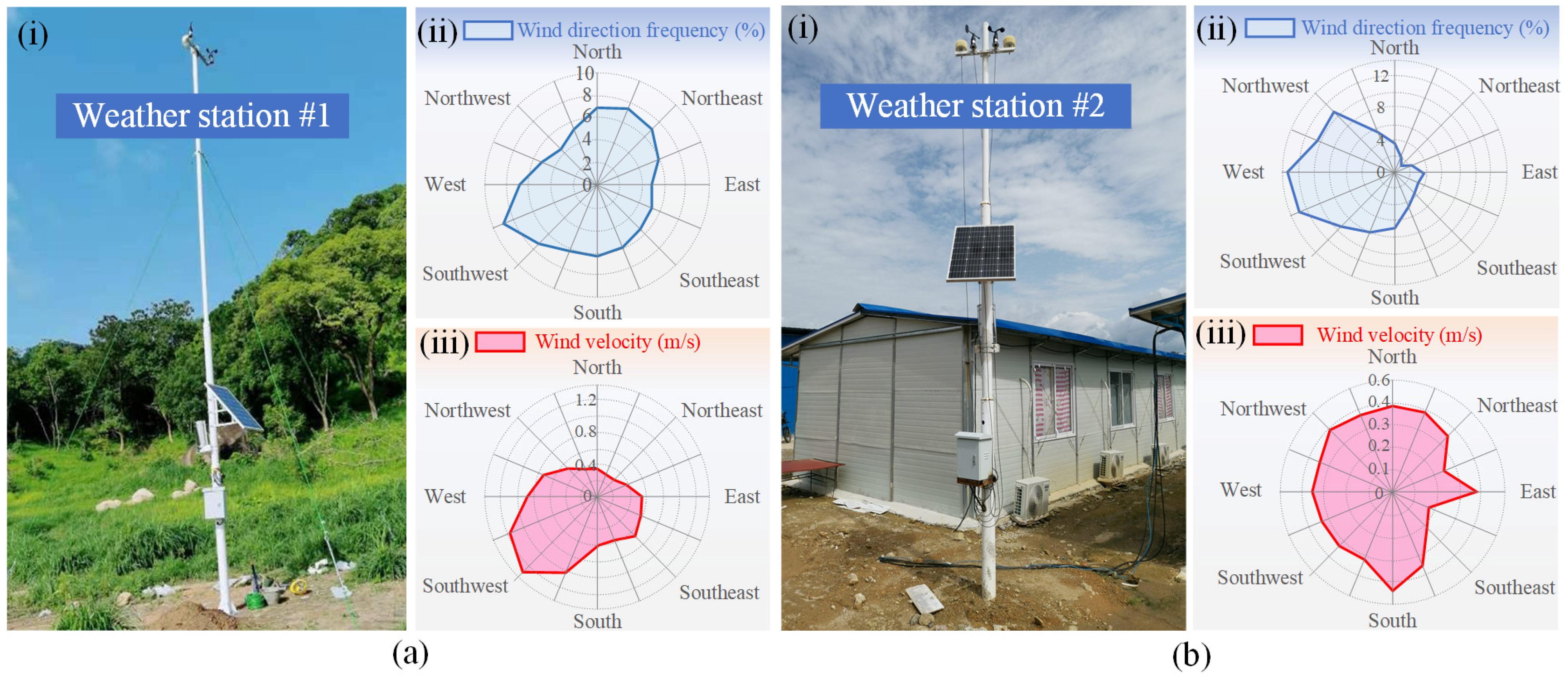

2.3. Natural Wind Condition

2.4. Ventilation Control Standard

- For NOx (expressed as NO2 in this study), the maximum permissible exposure limit is 10 mg/m3, and the average concentration of exhaust gases during any 30 min exposure may not exceed 30 mg/m3.

- For CO, the maximum permissible exposure limit is 40 mg/m3, and the average concentration of exhaust gases during any 30 min exposure may not exceed 100 mg/m3.

3. Harmful Gas Distribution Tests

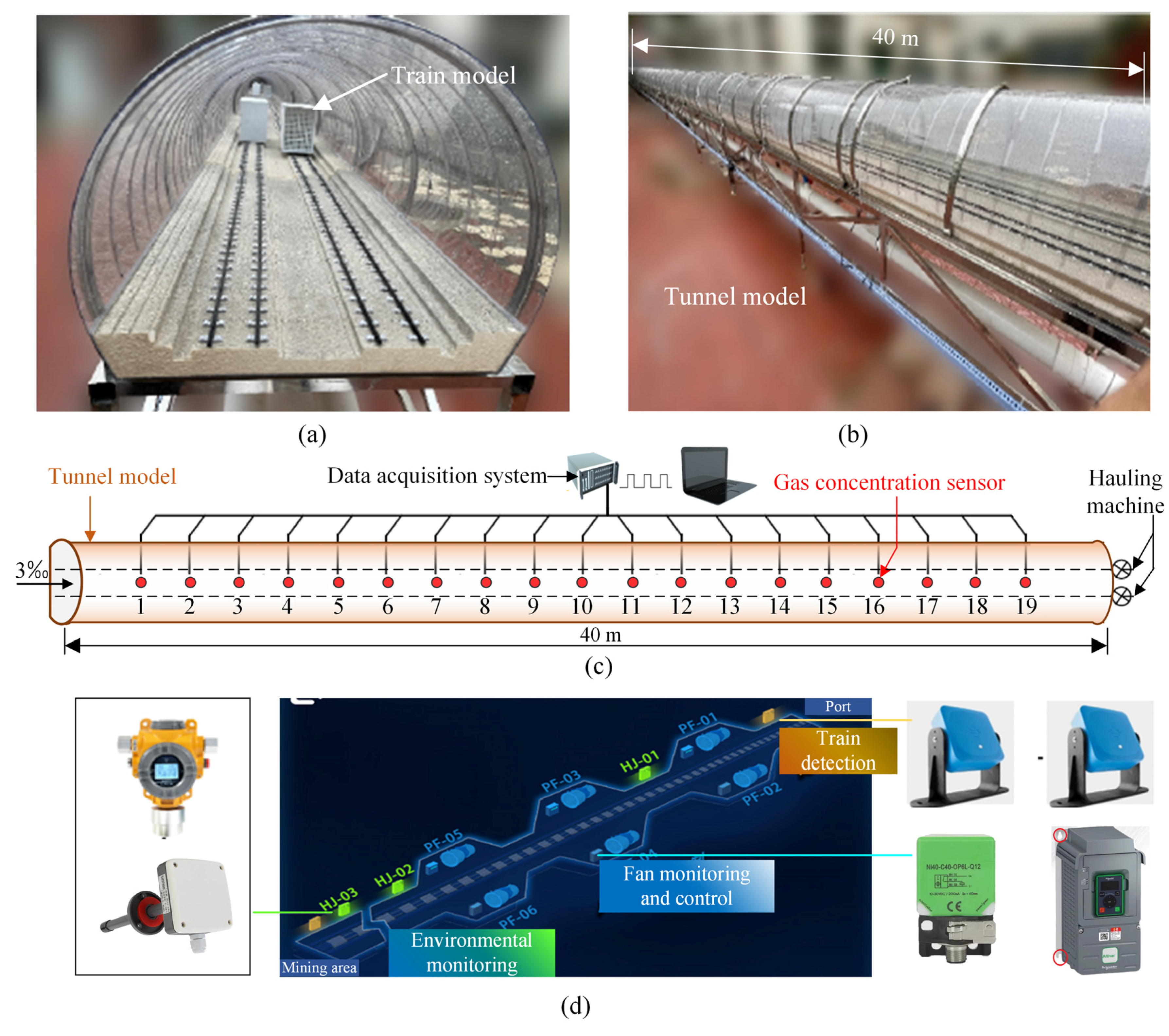

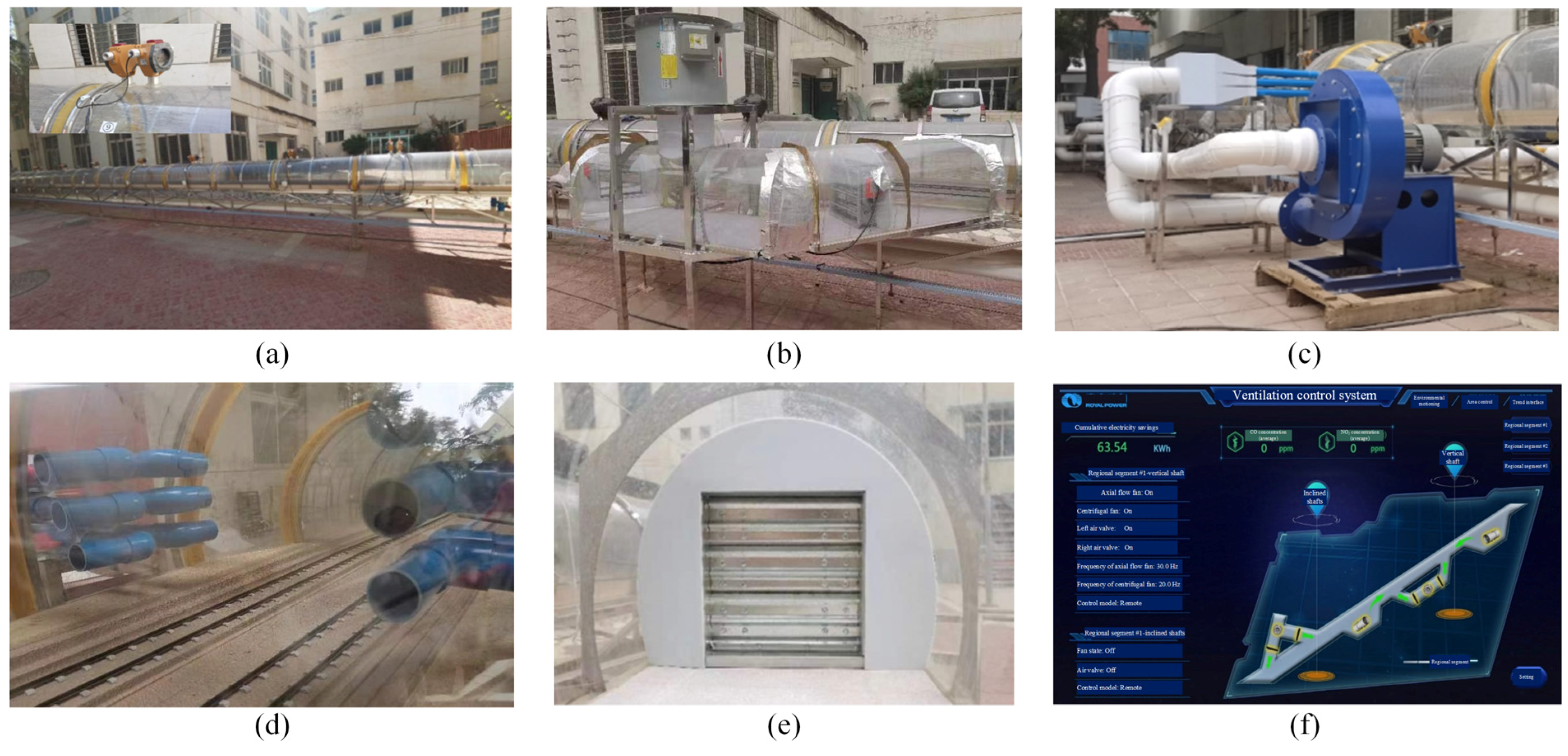

3.1. Scale Model Construction

3.1.1. Tunnel Model Design

3.1.2. Layout of the Gas Concentration Sensors

3.1.3. Test Scheme

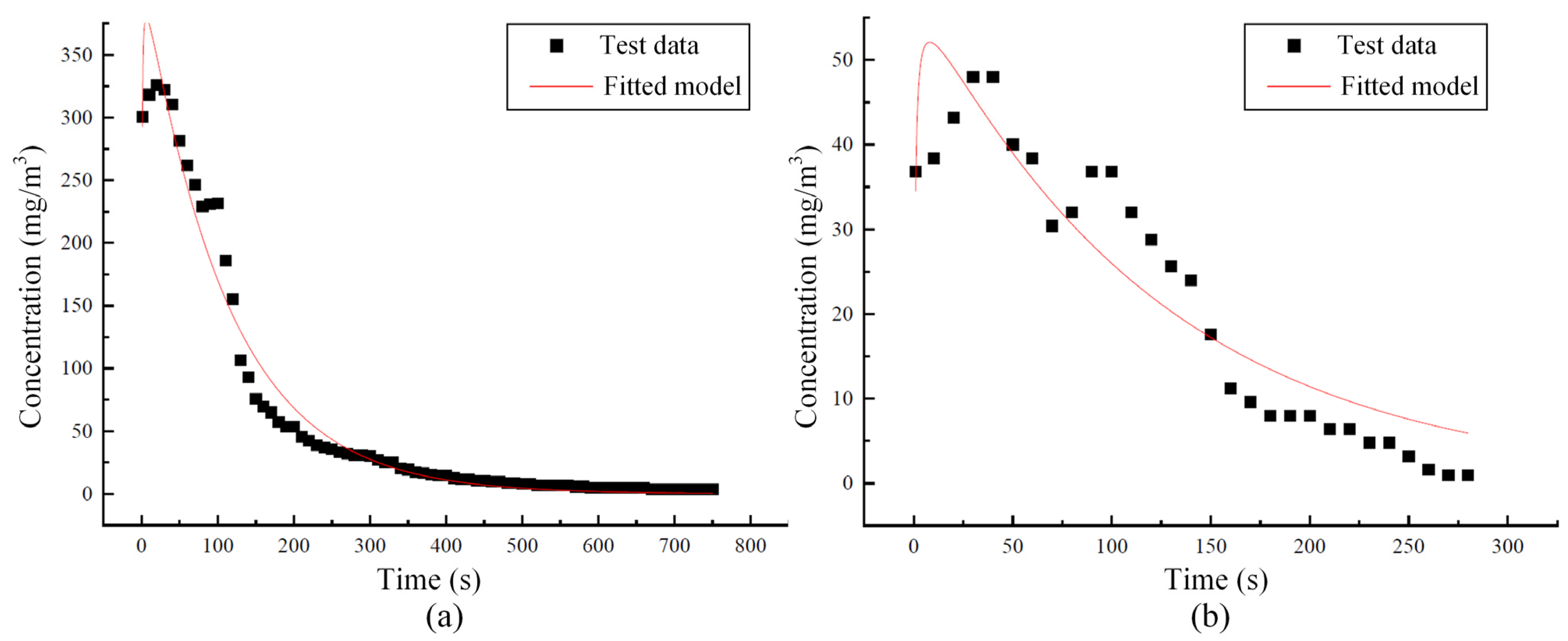

3.2. Tunnel Model Validation

3.2.1. Fundamental Diffusion Theory

3.2.2. Model Validation Results

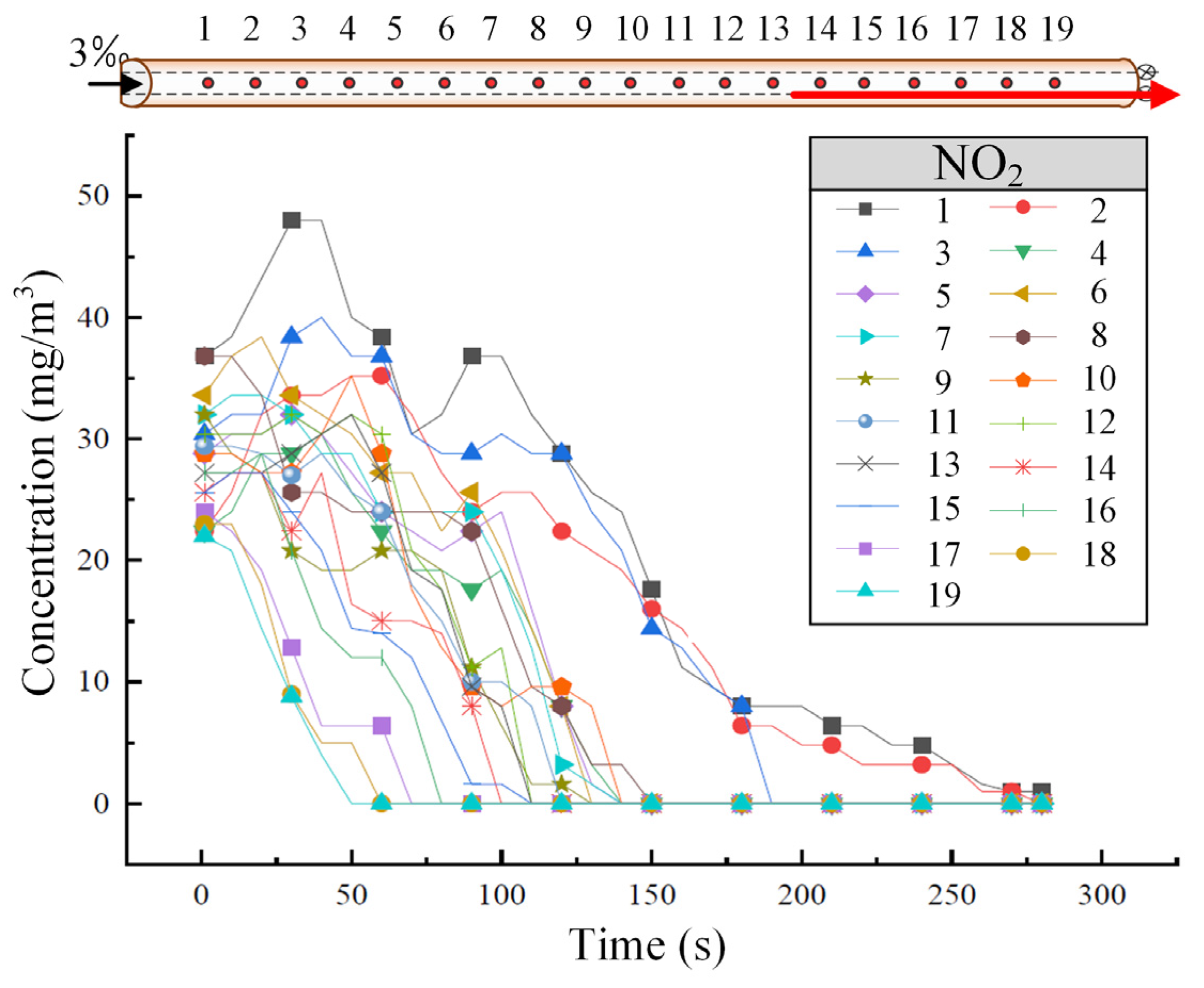

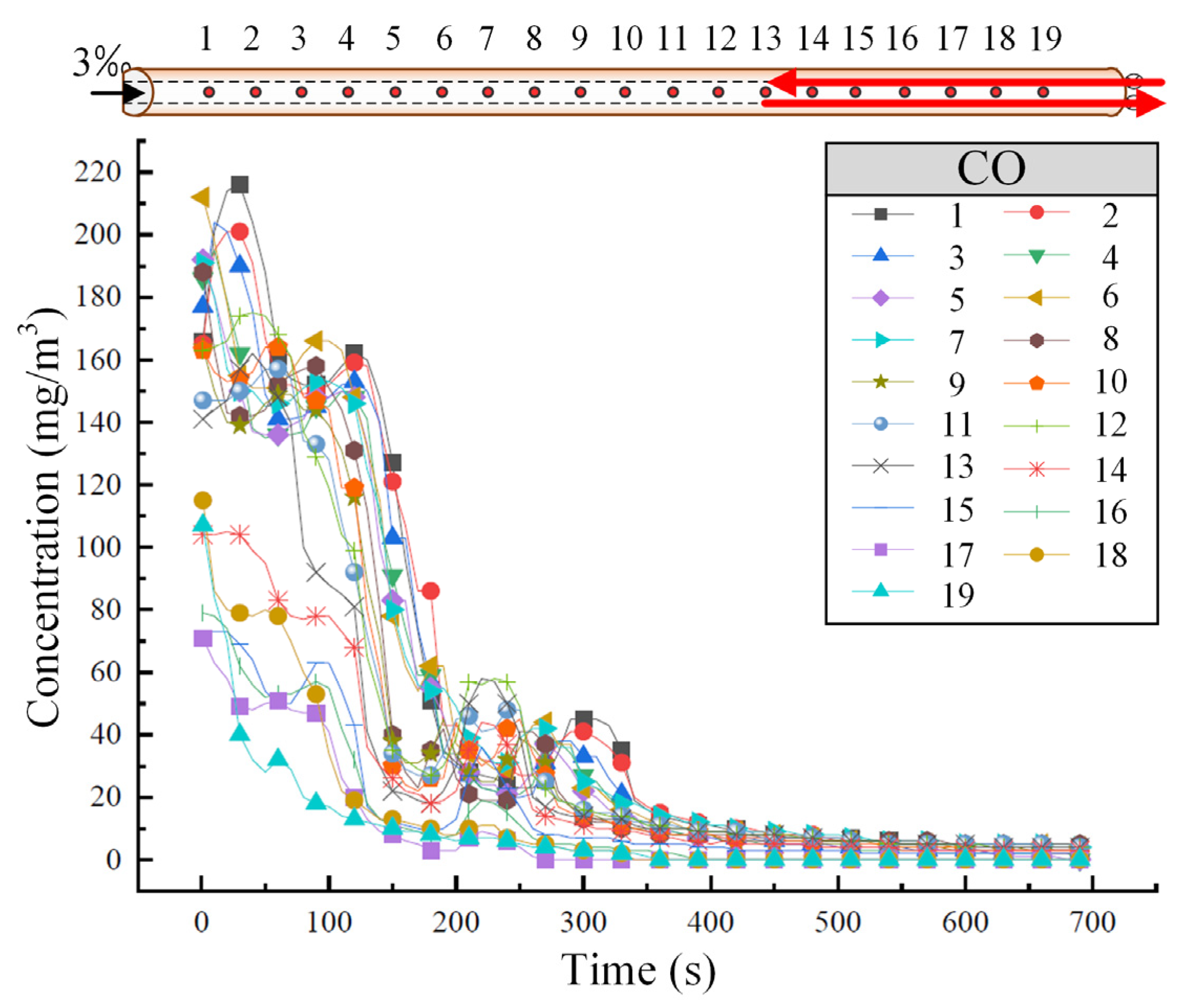

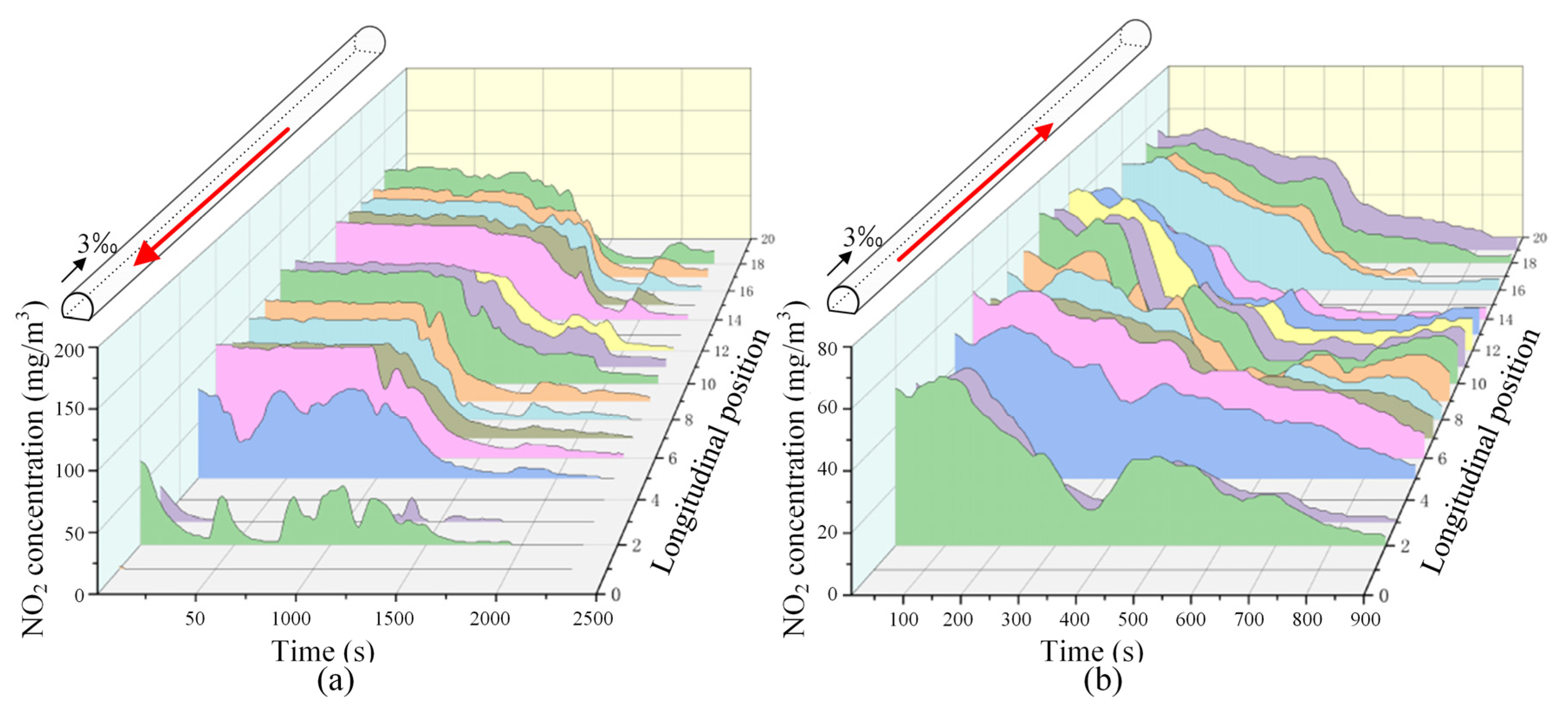

3.3. The Diffusion Law of Harmful Gas Within the Tunnel

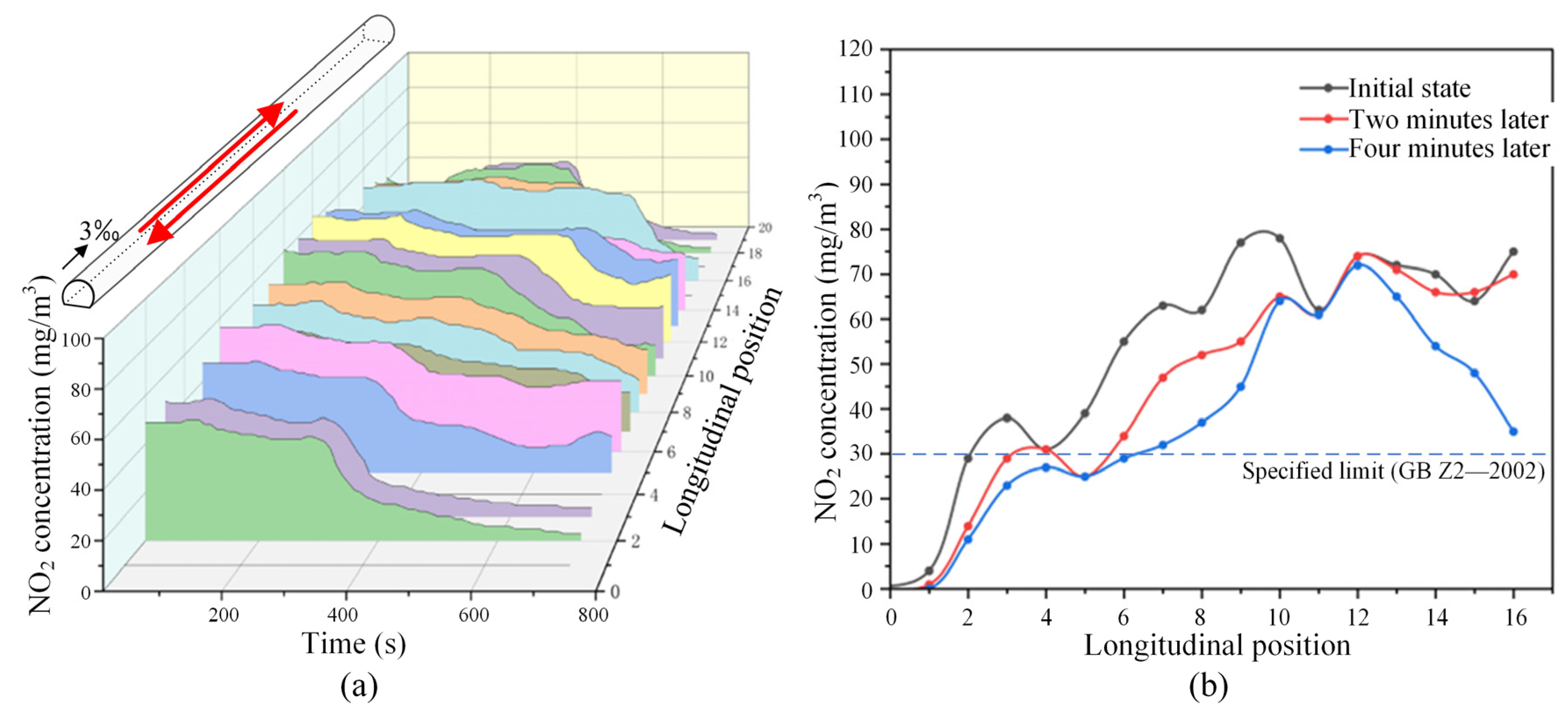

3.3.1. Upward Operating Conditions

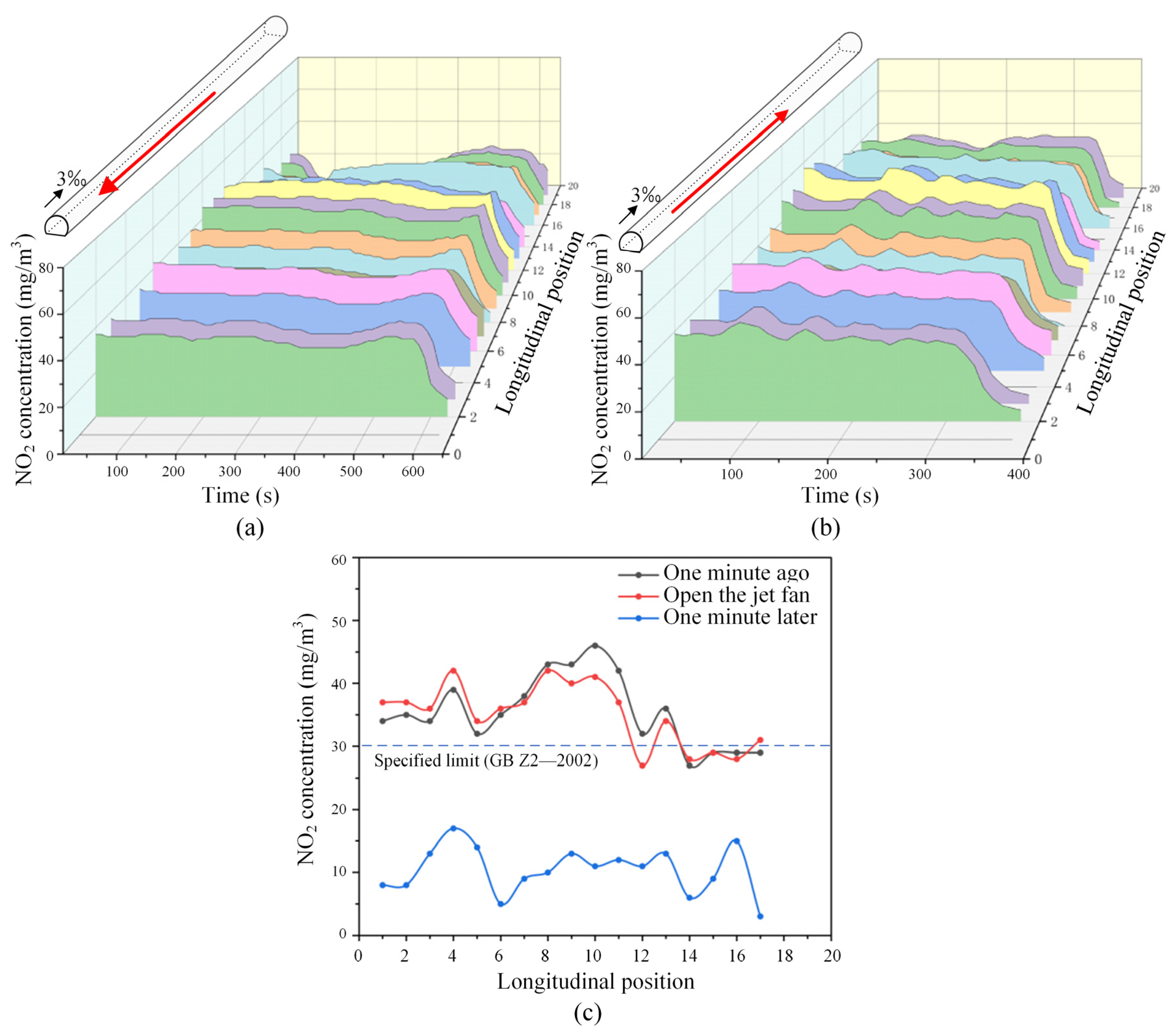

3.3.2. Bidirectional Operating Conditions

4. Design of the Tunnel Ventilation

4.1. Raw Ventilation Scheme of the Tunnel

4.2. Resistance Coefficient Optimization

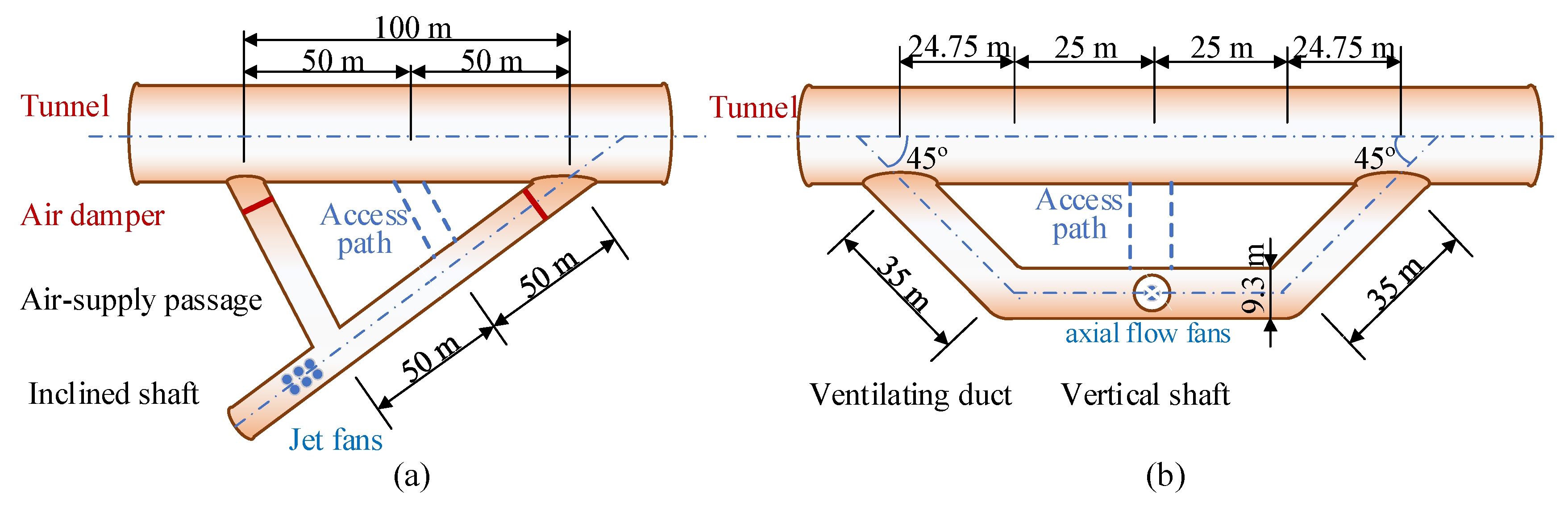

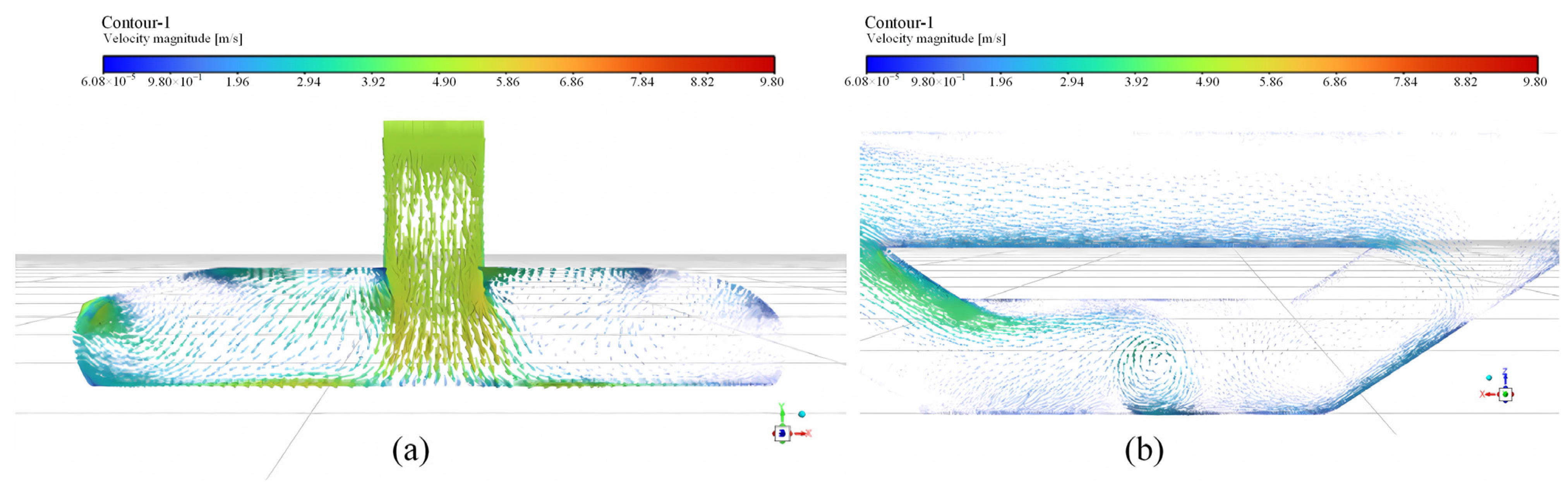

4.2.1. Resistance Optimization for Inclined Shafts

4.2.2. Resistance Optimization for Vertical Shafts

4.2.3. Optimized Ventilation Shafts

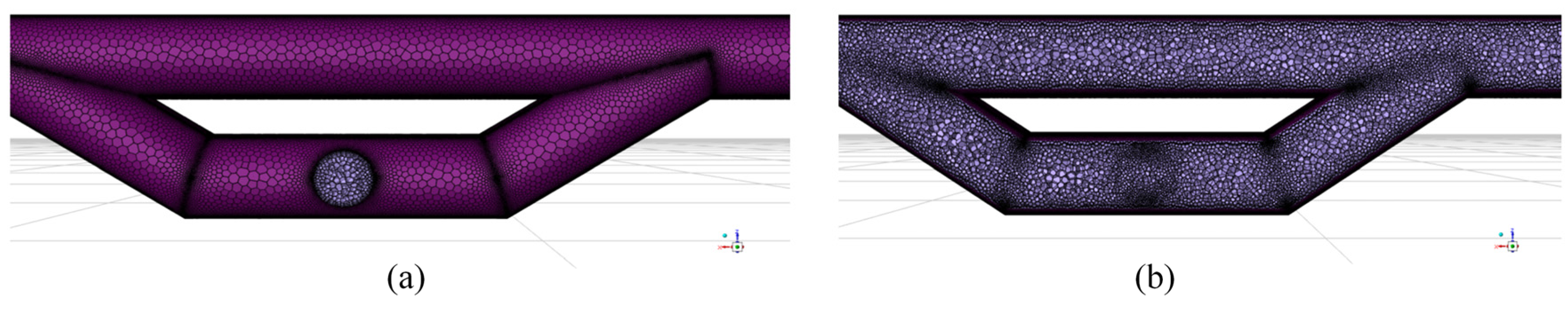

4.3. Validation Results Based on Simulation

- (1)

- Inlet boundary condition: The main tunnel entrance is set as a pressure inlet boundary condition. It is assumed that the pressure at the tunnel exit is equivalent to P2 = 0, and the pressure at the tunnel entrance is equal to the equivalent pressure difference of the computational model, P1 = Pn.

- (2)

- Outlet boundary condition: The tunnel exit is set as a pressure outlet boundary condition. Since the pressure at the tunnel exit is assumed to be equivalent to 0, the pressure at the tunnel exit boundary is set to 0. The fluid temperature at the outlet is set to 20 °C and 25 °C, respectively.

- (3)

- Wall boundary condition: The wall is set as a no-slip, adiabatic wall boundary condition. The wall temperature is set to 15 °C, and the wall roughness is set to 0.008 m.

4.4. Determination of the Ventilation Scheme

4.4.1. Structural Scheme

4.4.2. Energy-Saving Design

- (1)

- Overall design

- (2)

- Primary functions

- (3)

- Main components

- (4)

- Control strategy

- (5)

- Energy saving calculation

- Continuous operation condition at a constant frequency

- 2.

- Operating condition under intelligent variable-frequency control

- (6)

- Energy-saving effect

5. Ventilation Effect Validation

5.1. Validation Process

5.2. Validation Results

5.2.1. Setting Vertical Shafts and Inclined Shafts Without Mechanical Ventilation

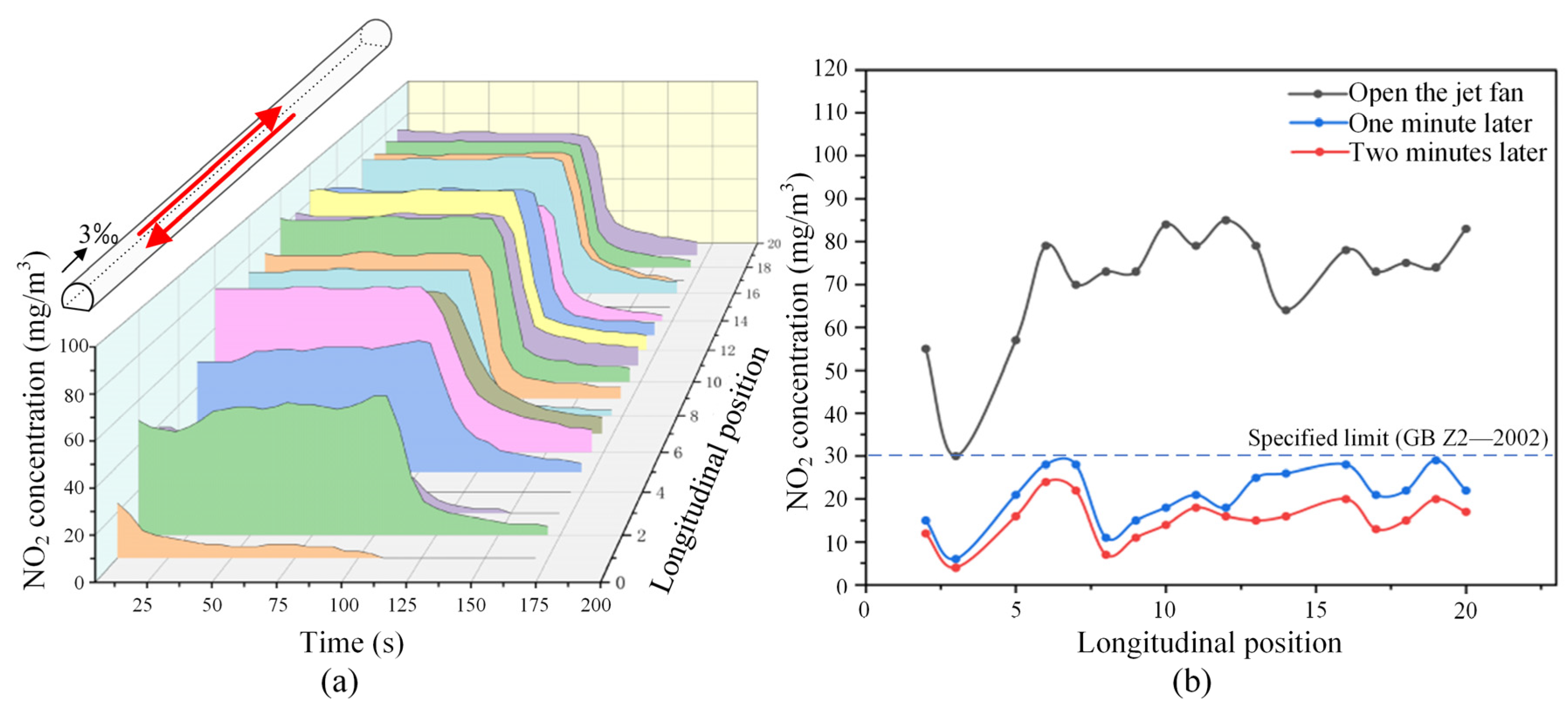

5.2.2. Setting Vertical Shafts and Inclined Shafts with Mechanical Ventilation

6. Conclusions

- If the piston wind effect is only considered, the harmful gases in the tunnel primarily diffuse towards higher areas and are then discharged from the high portal end. In contrast, the gases closer to the low portal end tend to diffuse locally towards the low portal for discharge. Under the same operating conditions, NO2 diffuses more slowly and is more challenging to discharge compared to CO. When designing ventilation systems for railway tunnels under operating scenarios, NO2 can be selected as the key control pollutant for prioritized monitoring and research.

- Based on the optimization theory of the resistance coefficient, for the railway tunnel analyzed in this study, the resistance coefficient of inclined shafts was reduced from 3.00 to 1.65, while that of vertical shafts was decreased from 3.00 to 2.36. This indicates that the application of the resistance-coefficient optimization theory can effectively optimize the traditional inclined and vertical shafts of a tunnel, leading to a notable enhancement in ventilation efficiency.

- Based on the analysis in this study, compared with the traditional operating condition where fans run at full frequency throughout the whole period, the intelligent variable-frequency ventilation control system that adjusts on demand based on the tunnel ventilation sections can achieve precise air supply in different sections. It significantly reduces the ineffective operation time of fan equipment and remarkably cuts down the energy consumption of the ventilation system. The annual energy-saving rate can reach 43.38%.

- Based on the verification results of this study, although the ventilation efficiency of the tunnel has been significantly improved after the optimization of the ventilation ducts, the pollutant concentration inside the tunnel cannot be controlled after four minutes under the most unfavorable operating condition in two directions. After integrating mechanical ventilation, even under the most unfavorable operating conditions, the harmful gases can be reduced below the regulatory safe limits (30 mg/m3) within one minute. This indicates that for railway tunnels with high traffic density, it is necessary to combine the optimization of the tunnel ventilation structure with mechanical ventilation equipment to achieve efficient and safe operational ventilation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El-Fadel, M.; Hashisho, Z. Vehicular Emissions and Air Quality Assessment in Roadway Tunnels: The Salim Slam Tunnel. Transp. Res. Part D Transp. Environ. 2000, 5, 355–372. [Google Scholar] [CrossRef]

- Raaschou-Nielsen, O.; Andersen, Z.J.; Jensen, S.S.; Ketzel, M.; Sørensen, M.; Hansen, J.; Loft, S.; Tjønneland, A.; Overvad, K. Traffic Air Pollution and Mortality from Cardiovascular Disease and All Causes: A Danish Cohort Study. Environ. Health A Glob. Access Sci. Source 2012, 11, 60. [Google Scholar] [CrossRef] [PubMed]

- Hoek, G.; Krishnan, R.M.; Beelen, R.; Peters, A.; Ostro, B.; Brunekreef, B.; Kaufman, J.D. Long-Term Air Pollution Exposure and Cardio-Respiratory Mortality: A Review. Environ. Health A Glob. Access Sci. Source 2013, 12, 43. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, D.; Trinh, X.T.; Takeuchi, W. Assessing the Air Quality Impact of Train Operation at Tokyo Metro Shibuya Station from Portable Sensor Data. Remote Sens. 2025, 17, 235. [Google Scholar] [CrossRef]

- Wang, Z.; Crooks, J.L.; Regan, E.A.; Karimzadeh, M. High-Resolution Estimation of Daily PM2.5 Levels in the Contiguous US Using Bi-LSTM with Attention. Remote Sens. 2025, 17, 126. [Google Scholar] [CrossRef]

- Liu, K.; Guo, J.; Wan, L.; Xu, C. A Model Test Study to Optimize the Ventilation System of a Long Expressway Tunnel. J. Wind Eng. Ind. Aerodyn. 2020, 207, 104393. [Google Scholar] [CrossRef]

- Lai, H.; Wang, X.; Tan, Z.; Zhao, J.; Liu, X. Support Mechanical Response Analysis and Surrounding Rock Pressure Calculation Method for a Shallow Buried Super Large Section Tunnel in Weak Surrounding Rock. Sci. Rep. 2024, 14, 13593. [Google Scholar] [CrossRef]

- Chen, Y.; Geng, X.; Li, J.; Zhang, M.; Zhu, C.; Cai, M.; Zhao, W.; Zhou, X.; Wang, T. Excavation Method Optimization and Mechanical Responses Investigating of a Shallow Buried Super Large Section Tunnels: A Case Study in Zhejiang. Sci. Rep. 2024, 14, 6281. [Google Scholar] [CrossRef]

- Sturm, P.; Fruhwirt, D.; Steiner, H. Impact of Dust Loads in Long Railway Tunnels: In-Situ Measurements and Consequences for Tunnel Facilities and Operation. Tunn. Undergr. Sp. Technol. 2022, 122, 104328. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Liu, C. Enconv1d Model Based on Pseudolite System for Long-Tunnel Positioning. Remote Sens. 2025, 17, 858. [Google Scholar] [CrossRef]

- Qian, C.; Chen, J.; Luo, Y.; Zhao, Z. Monitoring and Analysis of the Operational Environment in an Extra-Long Highway Tunnel with Longitudinal Ventilation. Tunn. Undergr. Sp. Technol. 2019, 83, 475–484. [Google Scholar] [CrossRef]

- Guo, J.; Chen, F.; Xu, C. Traffic Flow Forecasting for Road Tunnel Using PSO-GPR Algorithm with Combined Kernel Function. Math. Probl. Eng. 2017, 2017, 2090783. [Google Scholar] [CrossRef]

- Wang, M.; Tian, Y.; Yu, L.; Wang, X.; Zhang, Z.; Yan, G. Research on the Wind Pressure Coefficient in Natural Wind Calculations for Extra-Long Highway Tunnels with Shafts. J. Wind. Eng. Ind. Aerodyn. 2019, 195, 104020. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Ni, Y.; Liang, Z.; Ding, H.; Liu, L.; Zhang, X.; Wu, K.; Zhang, T. Study on Induced Flow Patterns and Inlet Velocity in Inclined Tunnel Fire with Natural Ventilation. Tunn. Undergr. Sp. Technol. 2025, 155, 106188. [Google Scholar] [CrossRef]

- Chen, T.; Li, Y.; Xu, Z.; Kong, J.; Liang, Y.; Wang, B.; Fan, C. Study of the Optimal Pitch Angle of Jet Fans in Road Tunnels Based on Turbulent Jet Theory and Numerical Simulation. Build. Environ. 2019, 165, 104020. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, G. Research on Ventilation Support Parameters in High Altitude Tunnel Construction. In Civil Engineering and Urban Research; CRC Press: BocaRaton, FL, USA, 2023; Volume 1, pp. 532–536. [Google Scholar]

- Shi, Q.; Chai, J.; Cao, J.; Yang, T. Numerical Simulation Study on Ventilation and Harmful Gas Diffusion during the Construction Period of Shafts. Int. J. Environ. Sci. Technol. 2024, 21, 4789–4806. [Google Scholar] [CrossRef]

- Chang, X.; Chai, J.; Xu, Z.; Qin, Y. Numerical Simulation of Tunnel Ventilation in Jiaoxihe Tunnel, China. Proc. Inst. Civ. Eng. Transp. 2023, 176, 65–77. [Google Scholar] [CrossRef]

- Yuan, C.; Lu, J.; Jiang, Y.; Xiao, J.; Chen, S.; Cui, J.; Qi, Z. Influence of Tunnel Excavation on the Magnitude and Rotation Angle of Principal Stress in Surrounding Rock. Sci. Rep. 2024, 14, 25512. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, S.; Dong, C.; Wang, S.; Guo, Y.; Gao, X.; Sun, B.; Chen, W.; Guo, C. Three-Stage Numerical Simulation of Tunnel Blasting Dust Diffusion Based on Field Monitoring and CFD. Tunn. Undergr. Sp. Technol. 2024, 150, 105830. [Google Scholar] [CrossRef]

- Król, M.; Król, A.; Koper, P.; Wrona, P. Full Scale Measurements of the Operation of Fire Ventilation in a Road Tunnel. Tunn. Undergr. Sp. Technol. 2017, 70, 204–213. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Chen, W. Optimisation of Synergistic Ventilation between Dust and Gas in a Gas Tunnel. Sci. Rep. 2024, 14, 27582. [Google Scholar] [CrossRef] [PubMed]

- Feng, L. Numerical Analysis of Jet Ventilation and Pollutant Concentration in Xinlongmen Tunnel. J. Southwest Jiaotong Univ. 1997, 10, 203–207. [Google Scholar]

- Chen, W. Numerical Simulation of Air Pollution for Yangbajing No. 1 Tunnel of Qinghai-Tibet Railway. Environ. Sci. Technol. 2012, 1, 133–136. [Google Scholar]

- Huang, C.; Li, S.; Zhang, Z.; Yao, T.; Shi, X.; Tian, J.; Hu, Z.; Wang, Y. Influence of Air Intake from Existing Shafts on the Safety of Operating Trains. Sci. Rep. 2024, 14, 12840. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Tan, R.; Hou, W.; Chen, L.; Xing, S.; Li, Z.; Guo, Y.; Han, X. Experimental and Theoretical Study on Ceiling Temperature Distributions in Mountain Tunnel with a Lateral Open Shaft. Sci. Rep. 2025, 15, 280. [Google Scholar] [CrossRef]

- Zhu, J.; Huo, R. Experiment Study on the Influence of Side Opening in the Vertical Shaft. Eng. Mech. 2008, 25, 187–192. [Google Scholar]

- Li, Z.; Liang, X.; Zhang, J. Influence of Shaft on Alleviating Transient Pressure in Tunnel. J. Cent. South Univ. Sci. Technol. 2011, 7, 2514–2519. [Google Scholar]

- Yang, W.; Peng, L.; Shi, C. Analysis on the Action Mechanism and the Influencing Factors of the Tunnel Shaft to the Pressure of the Carbody. China Railw. Sci. 2009, 3, 68–73. [Google Scholar]

- Ji, Y.; Lu, J.; Hong, X.; Zhang, H.; Dong, J.; Huang, F. Optimization of Ventilation Efficiency in Tunnel-Type Underground Spaces Using Response Surface Methodology: A Case Study of Yunlong Mountain Civil Defense in Xuzhou. Sci. Rep. 2024, 14, 22989. [Google Scholar] [CrossRef]

- Li, J.; Li, A.; Zhang, C.; Guo, J.; Yin, Y.; Wang, T.; Fan, Y.; Hou, Y. Comparative Studies and Optimizations of Air Distribution of Underground Building Ventilation Systems Based on Response Surface Methodology: A Case Study. J. Build. Eng. 2023, 75, 106952. [Google Scholar] [CrossRef]

- Wang, F.; Deng, Y.; Wang, M. Numerical Simulation to Optimize the Position of Subway’s Shaft. Chin. J. Comput. Mech. 2010, 3, 569–573. [Google Scholar]

- Zarnaghsh, A.; Abouali, O.; Emdad, H.; Ahmadi, G. A Numerical Study of the Train-Induced Unsteady Airflow in a Tunnel and Its Effects on the Performance of Jet Fans. J. Wind. Eng. Ind. Aerodyn. 2019, 187, 1–14. [Google Scholar] [CrossRef]

- Egilsrud, P.E.; Harvey, N.A. Memorial Tunnel Fire Ventilation Test Program: The Extraction Tests. ASHRAE Trans. 1997, 103, 687–700. [Google Scholar]

- Lowndes, I.S.; Fogarty, T.; Yang, Z.Y. The Application of Genetic Algorithms to Optimise the Performance of a Mine Ventilation Network: The Influence of Coding Method and Population Size. Soft Comput. 2005, 9, 493–506. [Google Scholar] [CrossRef]

- Hu, D.; Li, Z.; Wang, H.; Xu, H.; Miao, C. Smoke Dispersion Test and Emergency Control Plan of Fire in Mine Roadway during Downward Ventilation. Sci. Rep. 2023, 13, 3683. [Google Scholar] [CrossRef]

- TB/T 2783-2017; Exhaust Emission Tests for Diesel Engines of Motive Power Units. National Railway Administration: Beijing, China, 2017.

- JTG D70-2004; Ministry of Transport of the People’s Republic of China Specifications for Design of Highway Tunnels. China Communications Press: Beijing, China, 2005.

- TB 10068-2024; Code for Design on Operation Ventilation of Railway Tunnel. National Railway Administration: Beijing, China, 2024.

- Li, W.; Gu, Y.; Liu, T.; Deng, Y.; Zhao, W.; Fan, X. Mitigating Aerodynamic Effects through Segment Length Allocation of Variable Cross-Section Tunnels. Tunn. Undergr. Sp. Technol. 2025, 157, 106341. [Google Scholar] [CrossRef]

| Harmful Gas (g/kW·h) | Smoke and Dust (m−1) | |||

|---|---|---|---|---|

| CO | NOx | PM | HC | |

| 1.5 | 2.0 | 0.02 | 0.46 | 0.5 |

| Month | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | Jan. | Feb. | Mar. | Apr. |

|---|---|---|---|---|---|---|---|---|---|---|

| Average wind velocity (m/s) | 0.66 | 0.68 | 0.69 | 0.72 | 0.76 | 0.79 | 0.78 | 0.77 | 0.81 | 0.84 |

| Average temperature (°C) | 28.10 | 28.20 | 28.39 | 28.62 | 28.91 | 29.08 | 29.25 | 30.40 | 31.34 | 31.46 |

| Average humidity (%RH) | 66.94 | 65.18 | 62.84 | 58.57 | 52.49 | 49.16 | 49.00 | 48.65 | 50.15 | 31.46 |

| Traffic Scenario | Speed (km/h) | Number of Test Times |

|---|---|---|

| Upward operating condition | 55 | 5 |

| Downward operating condition | 55 | 5 |

| Bidirectional operating condition | 55 | 5 |

| Vertical Shaft Designation | Projection Mileage | Vertical Shaft Depth (m) |

|---|---|---|

| Vertical shaft #1 | DK149 + 672 | 205.80 |

| Vertical shaft #2 | DK152 + 762 | 396.18 |

| Vertical shaft #3 | DK156 + 062 | 428.28 |

| Vertical shaft #4 | DK158 + 572 | 431.25 |

| Fan Types | Rated Power (kW) | Number |

|---|---|---|

| Jet fan | 45 | 48 |

| Axial flow fan | 132 | 12 |

| Axial flow fan | 185 | 8 |

| Axial flow fan | 220 | 4 |

| Axial flow fan | 280 | 4 |

| In total | 7224 kW | 76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Sun, S.; Wu, J.; Ling, T.; Li, L.; Shi, X.; Yang, H. Ventilation Design of an Extra-Long Single-Bore Double-Track Railway Tunnel with High Traffic Density. Sensors 2025, 25, 4009. https://doi.org/10.3390/s25134009

Chen X, Sun S, Wu J, Ling T, Li L, Shi X, Yang H. Ventilation Design of an Extra-Long Single-Bore Double-Track Railway Tunnel with High Traffic Density. Sensors. 2025; 25(13):4009. https://doi.org/10.3390/s25134009

Chicago/Turabian StyleChen, Xiaohan, Sanxiang Sun, Jianyun Wu, Tianyang Ling, Lei Li, Xianwei Shi, and Haifu Yang. 2025. "Ventilation Design of an Extra-Long Single-Bore Double-Track Railway Tunnel with High Traffic Density" Sensors 25, no. 13: 4009. https://doi.org/10.3390/s25134009

APA StyleChen, X., Sun, S., Wu, J., Ling, T., Li, L., Shi, X., & Yang, H. (2025). Ventilation Design of an Extra-Long Single-Bore Double-Track Railway Tunnel with High Traffic Density. Sensors, 25(13), 4009. https://doi.org/10.3390/s25134009