Mental Fatigue Detection of Crane Operators Based on Electroencephalogram Signals Acquired by a Novel Rotary Switch-Type Semi-Dry Electrode Using Multifractal Detrend Fluctuation Analysis

Abstract

1. Introduction

2. Materials and Methods

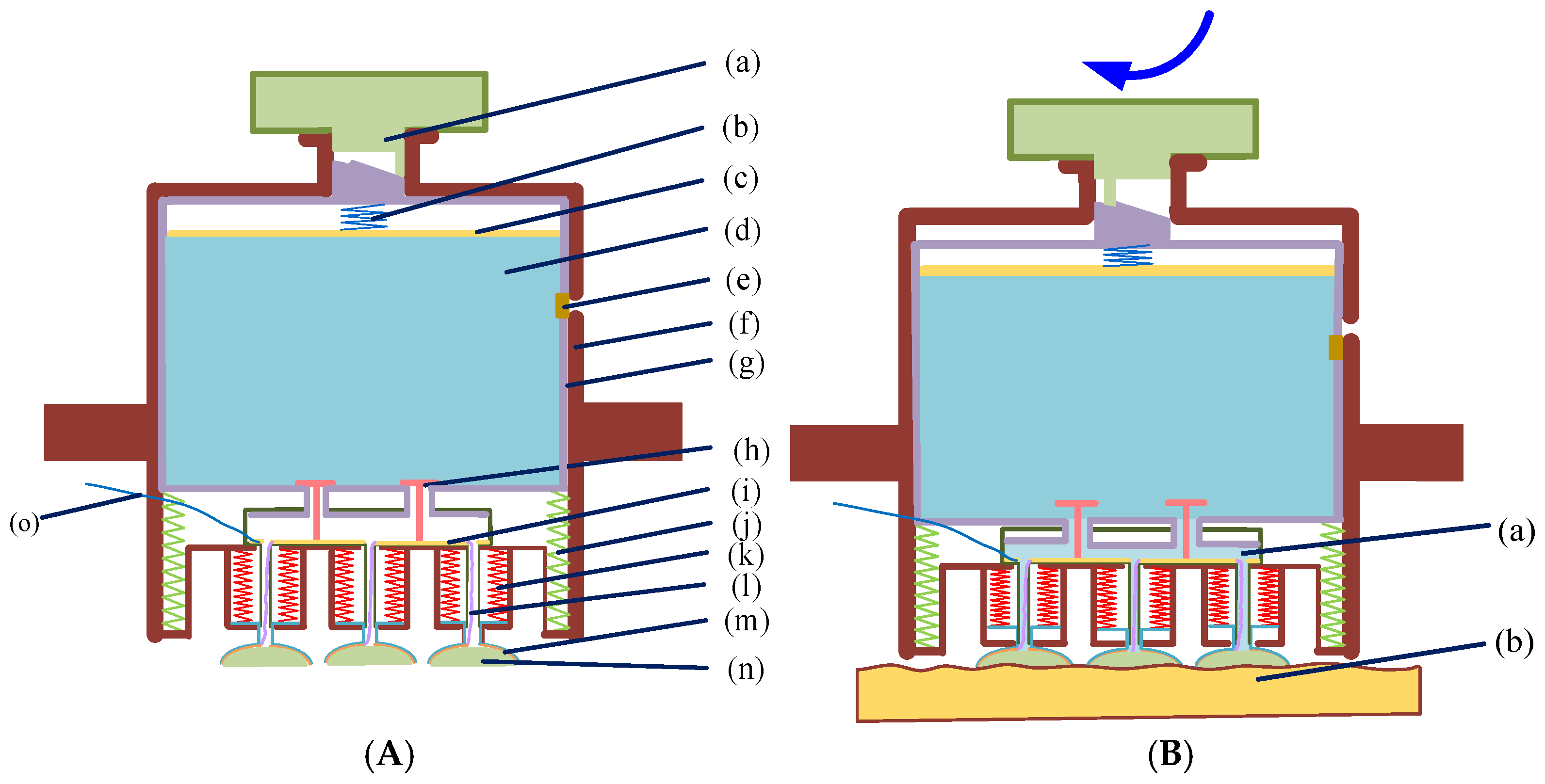

2.1. Rotating Switch-Type Semi-Dry Electrode

2.1.1. Structural Design

2.1.2. Manufacturing of Electrodes

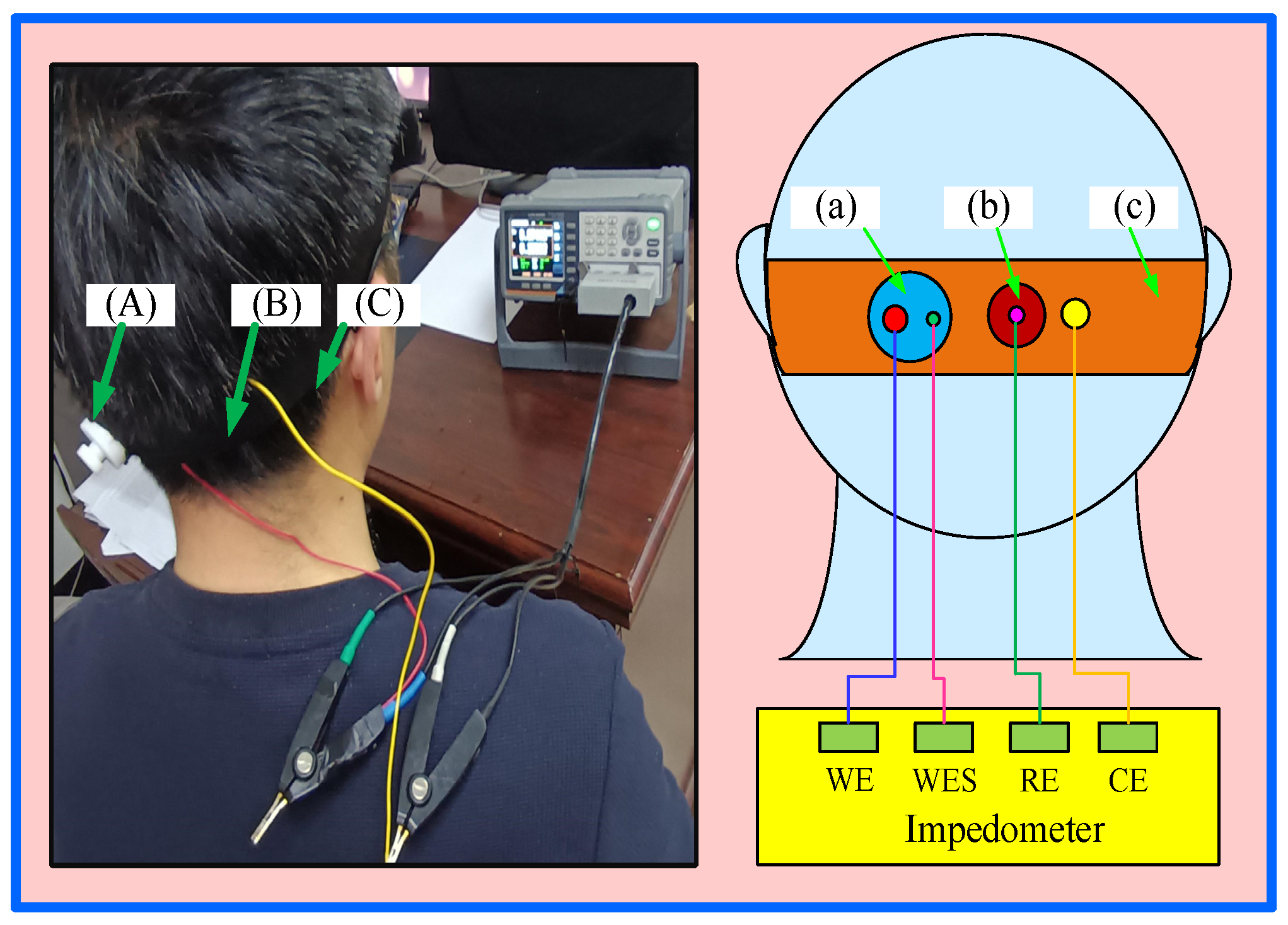

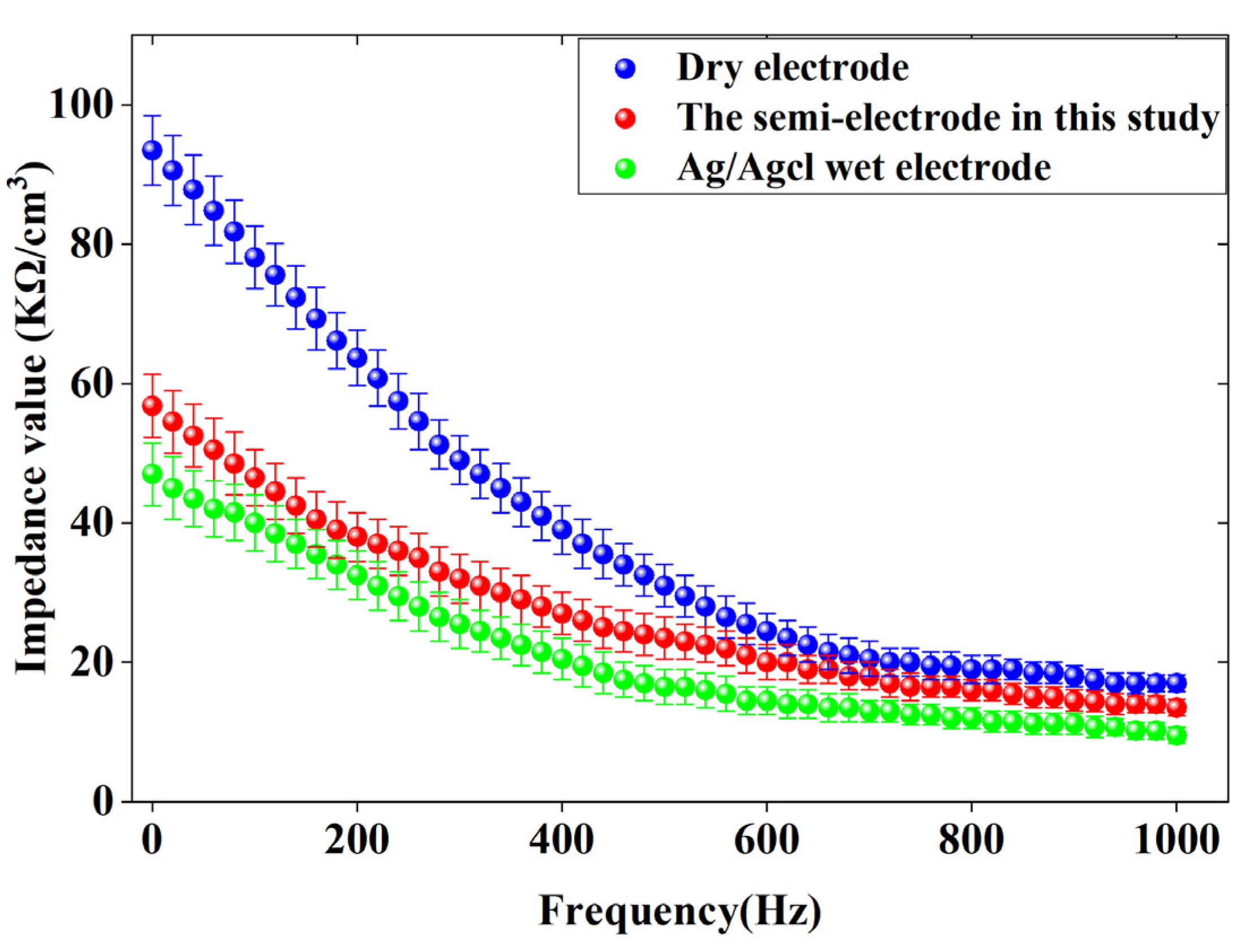

2.1.3. Impedance Test of Electrode

2.1.4. Electrode Life Test

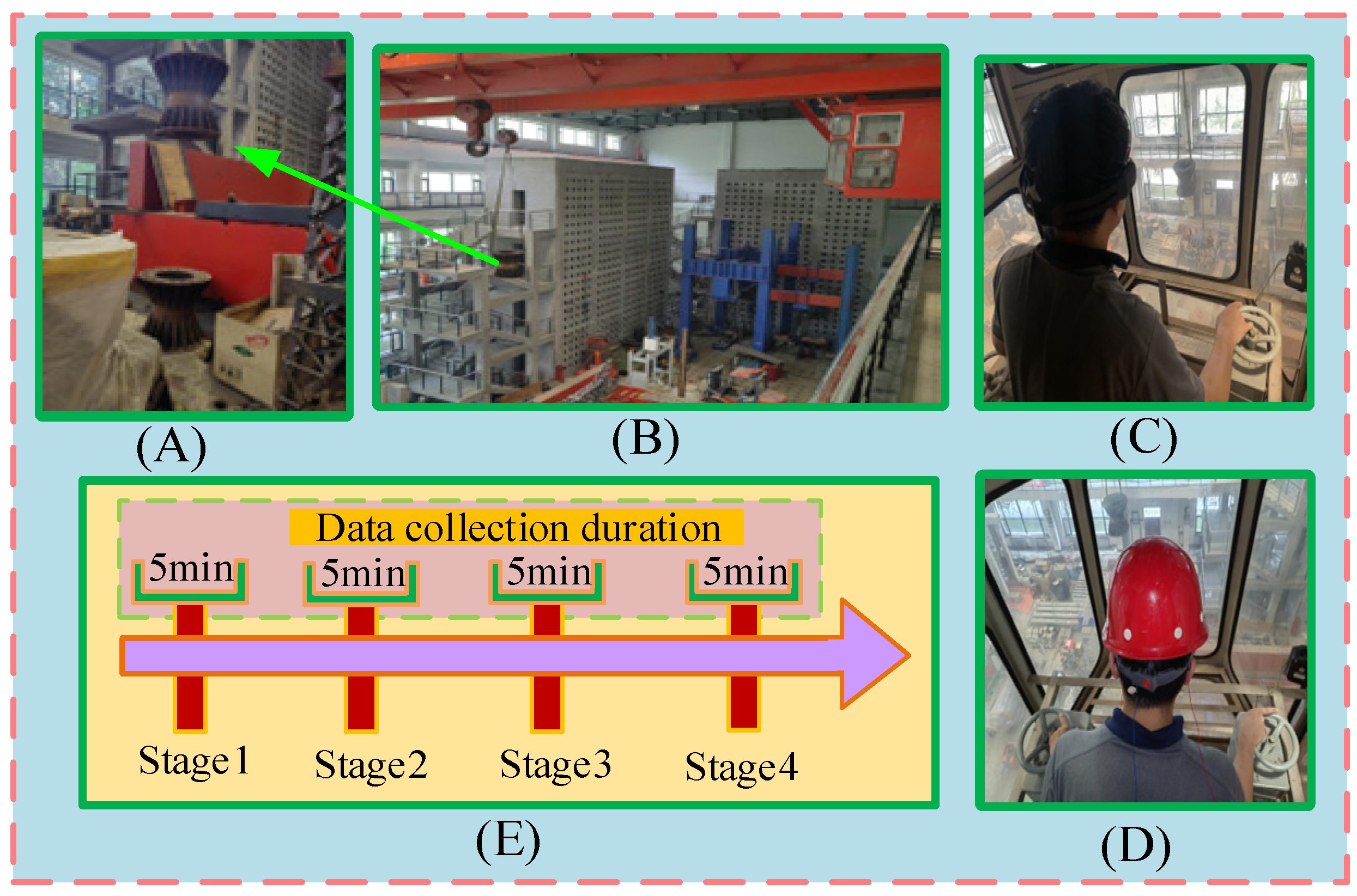

2.2. Experiment

2.2.1. Subjects

2.2.2. Experimental Paradigm

2.3. Methods

2.3.1. Data Preparation Algorithm

2.3.2. MF-DFA Algorithm

- (1)

- Construct the signal profile Y(i) as shown in Equation (1).

- (2)

- Divide contour into non-overlapping data segments of equal length s.

- (3)

- Separate contour into data segments of equal lengths that do not overlap.

- (4)

- Calculate the local trend function by fitting a regression based on an m-order polynomial to the data in subinterval .

- (5)

- Calculate the data variance for each segment as shown in Equations (2) and (3).

- (6)

- Calculate the mean value of the qth order fluctuation function as indicated in Equation (4).

- (7)

- The existence of a self-similarity characteristic in the time series zk is indicated by a power law relationship between the qth order fluctuation function mean and the time scale s, as shown in Equation (5).

3. Results

3.1. Electrode Properties

3.1.1. Contact Impedance of Electrodes

3.1.2. Service Life of Electrodes

3.1.3. Long-Term Stability Comparison

3.2. MF-DFA

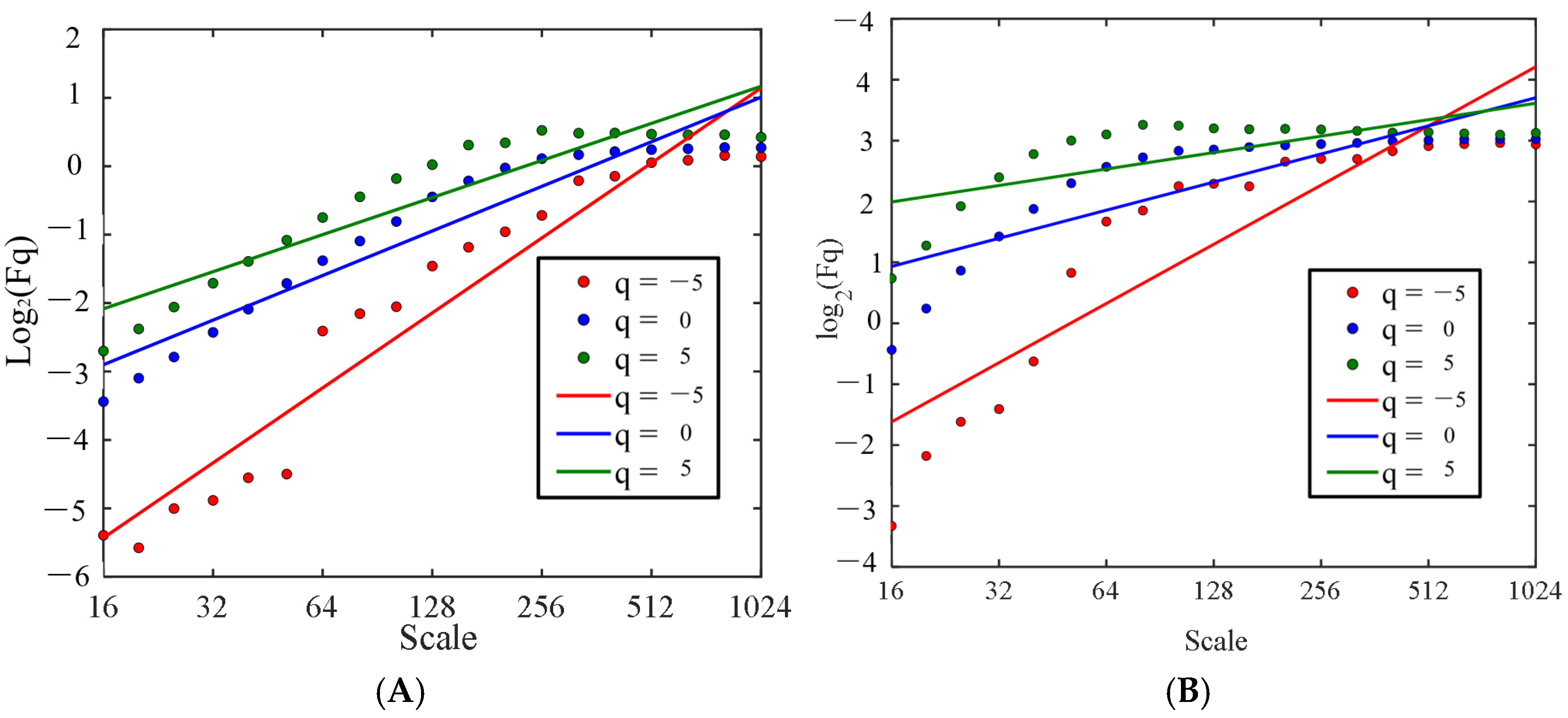

3.2.1. The Fluctuation Function

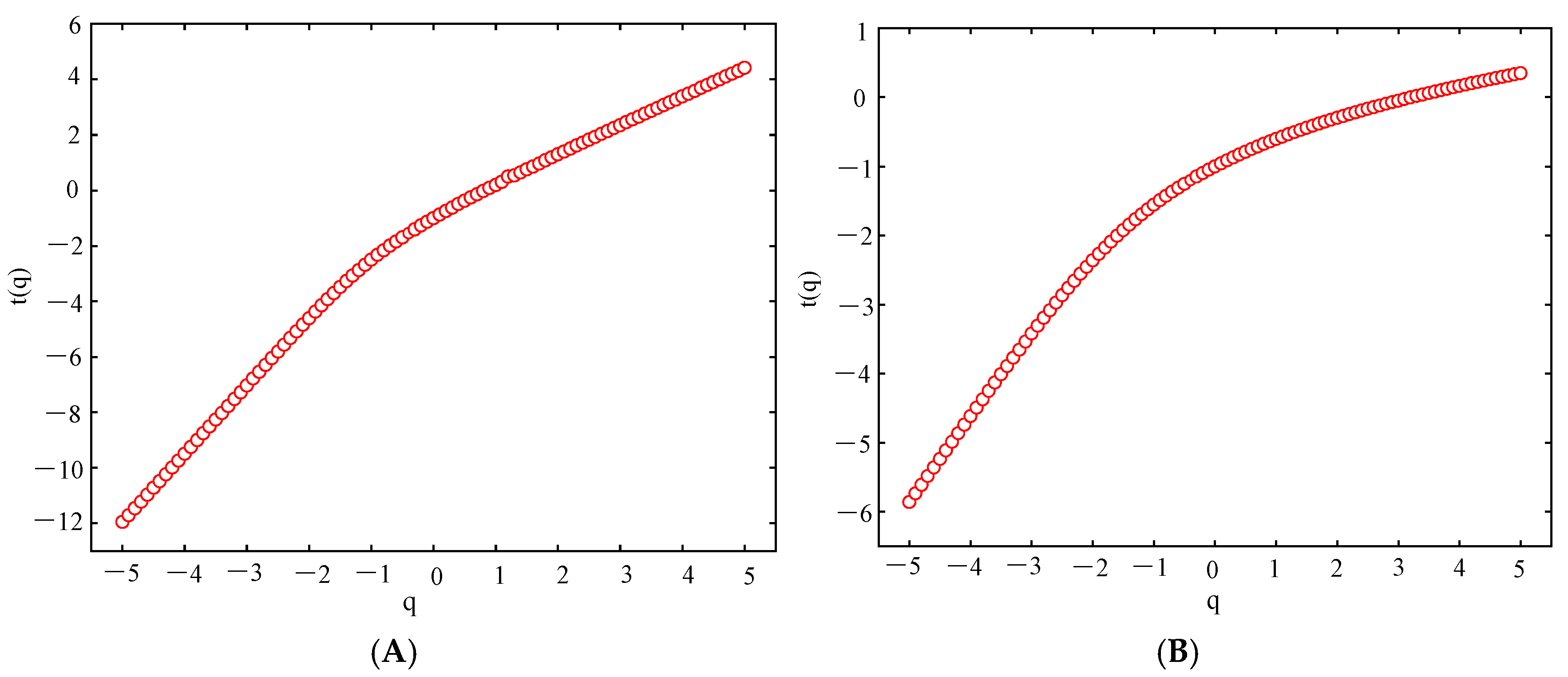

3.2.2. Mass Exponent

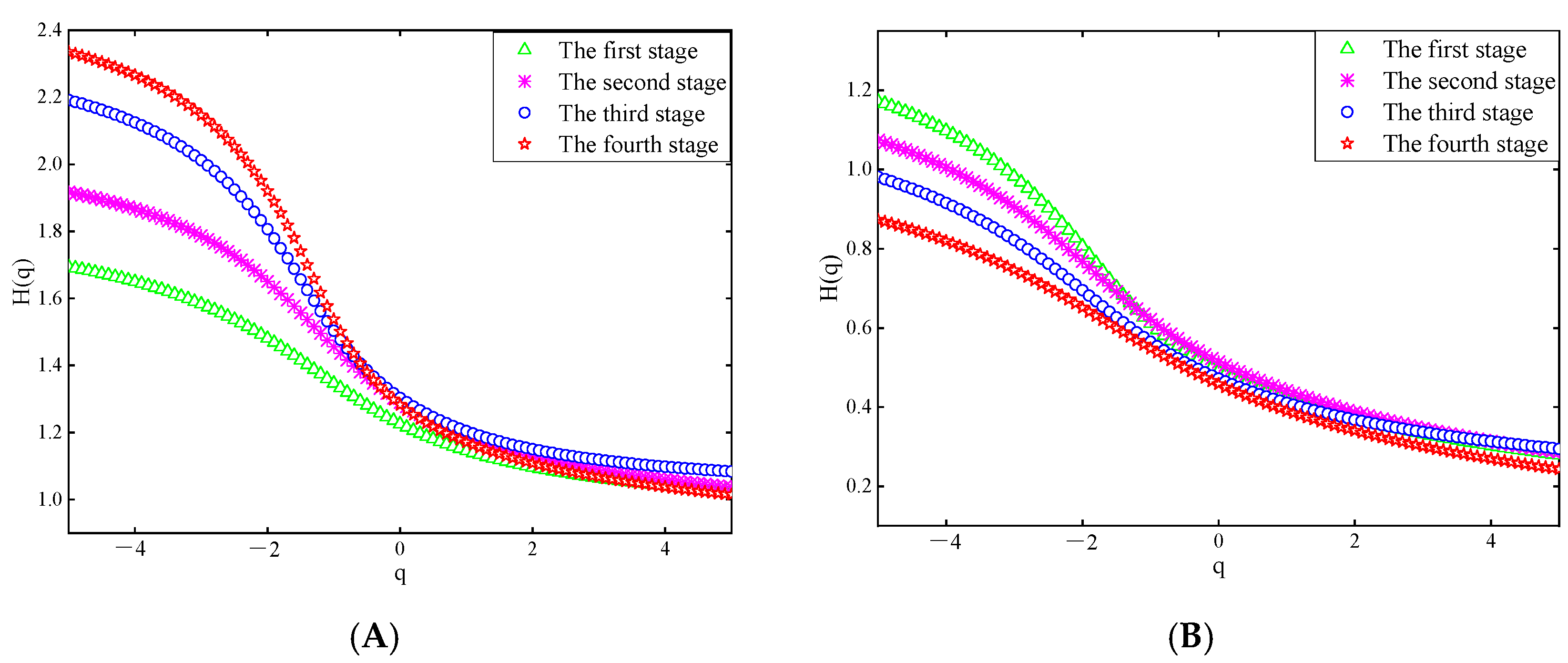

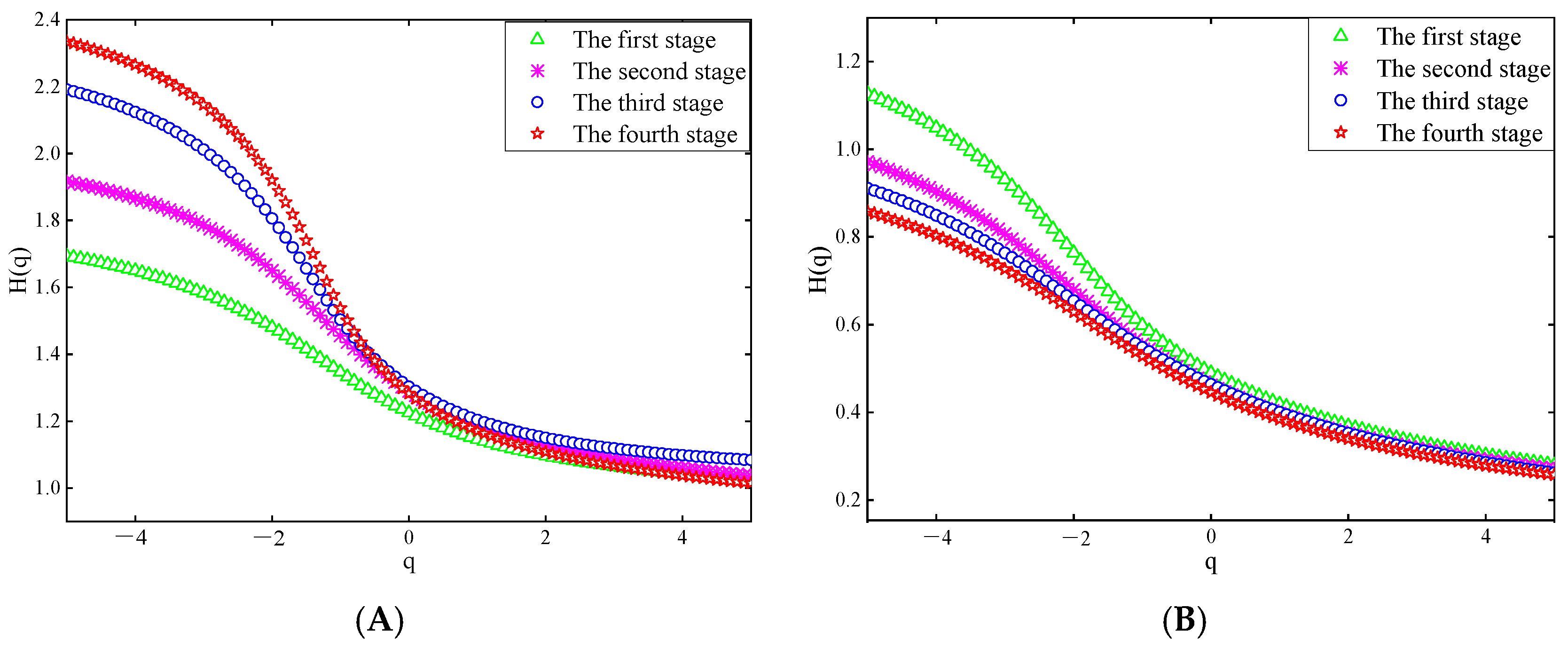

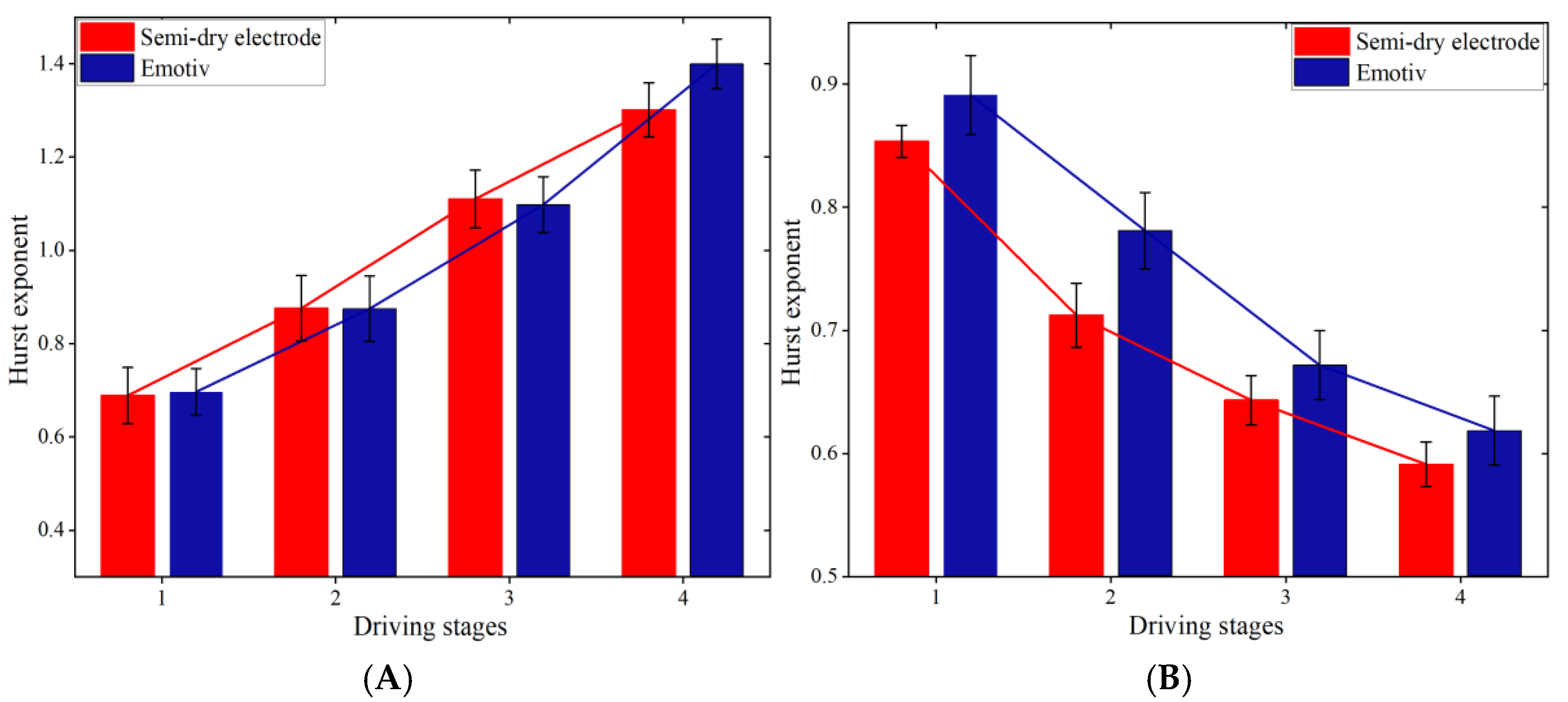

3.2.3. Hurst Exponent

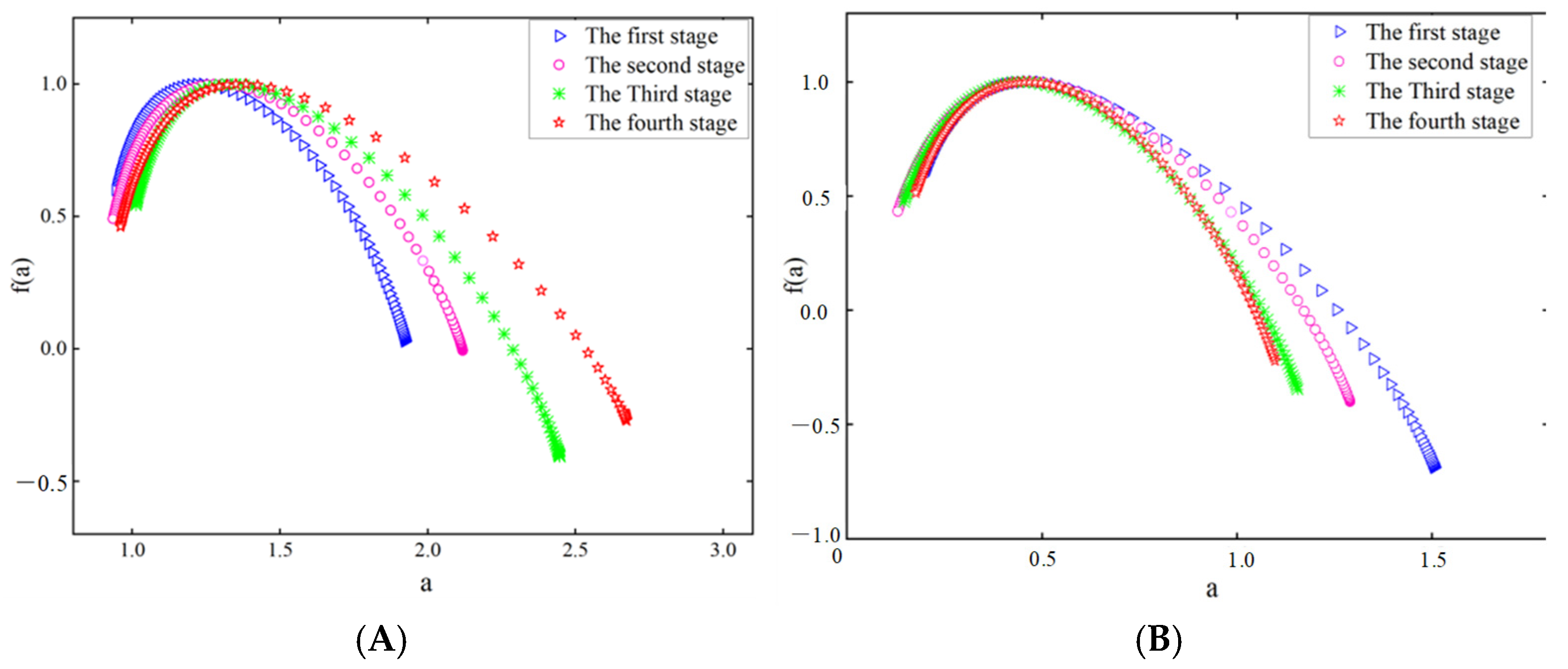

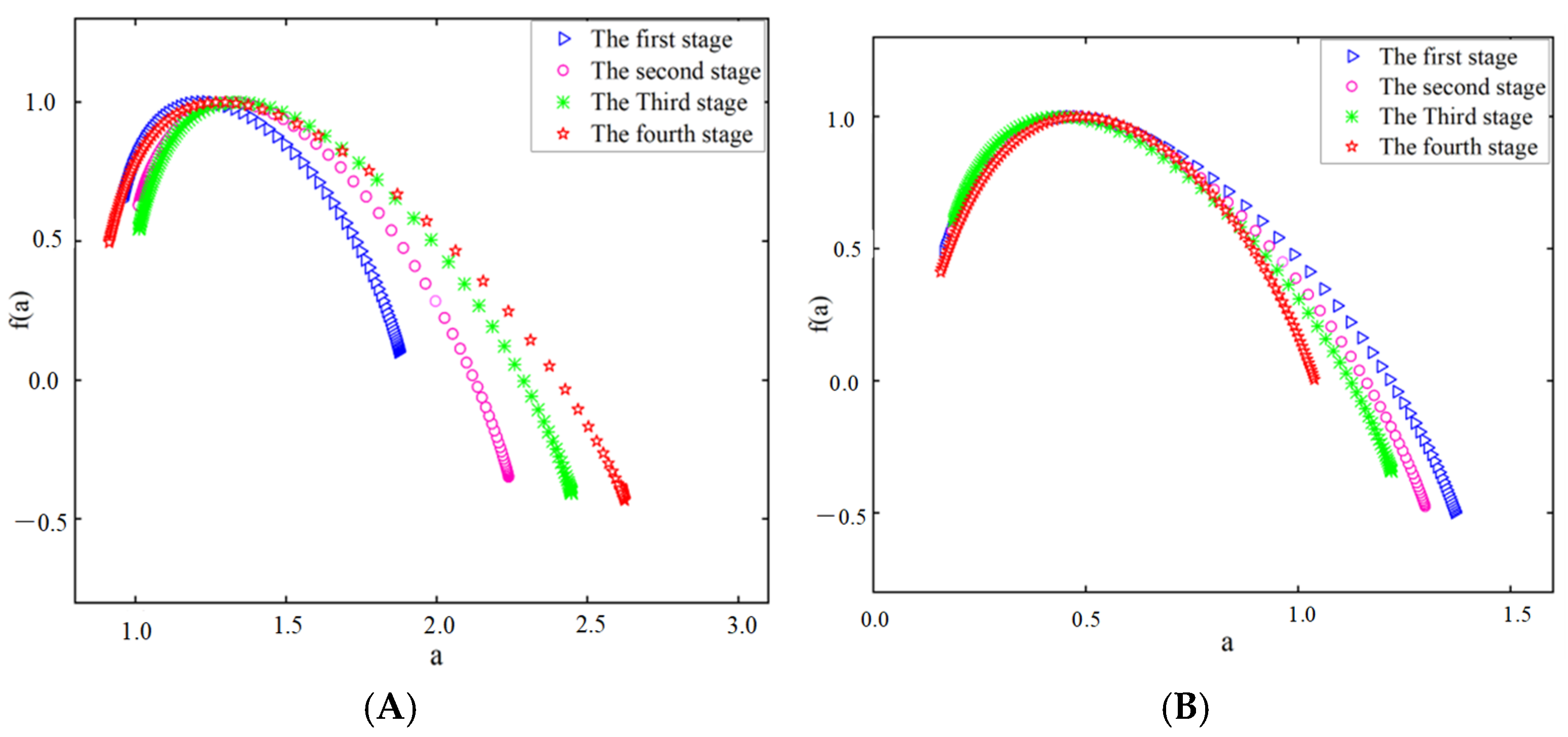

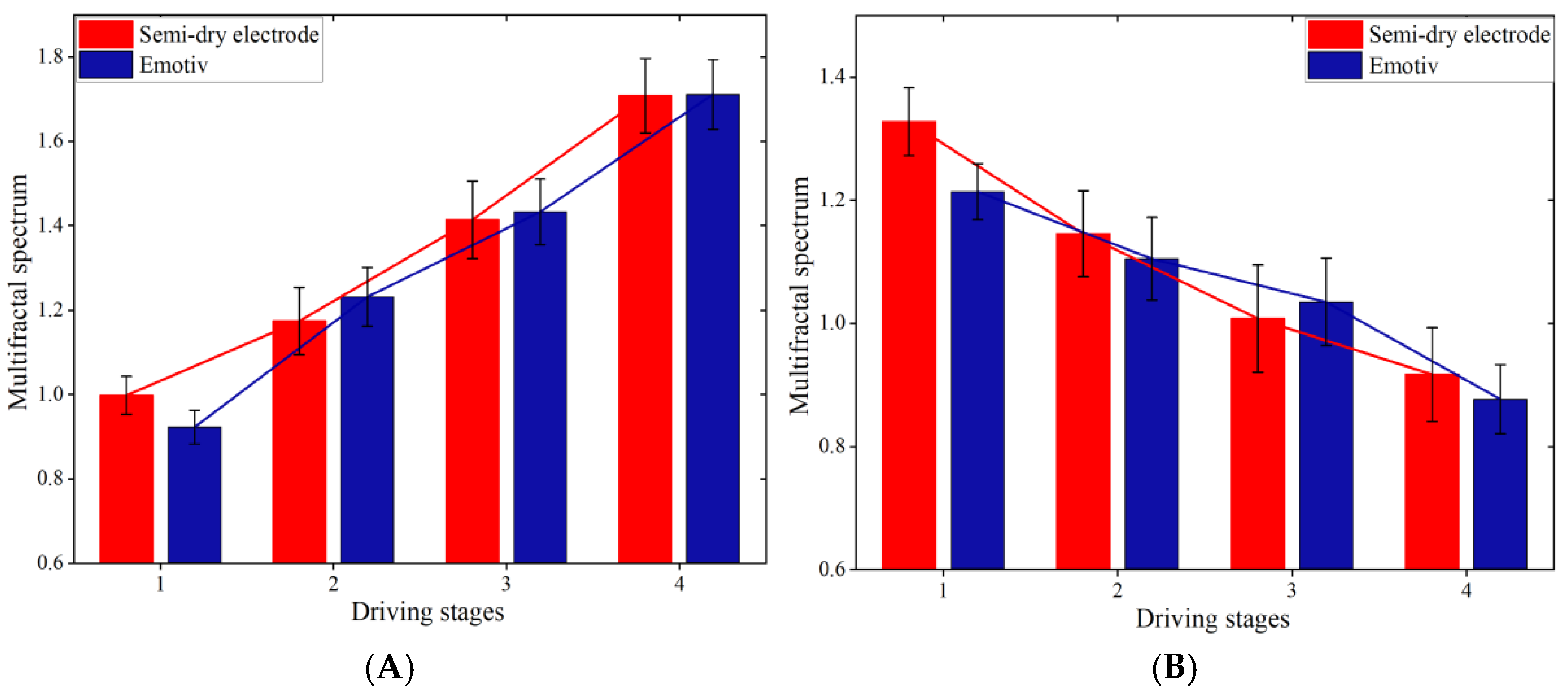

3.2.4. Multifractal Spectrum

3.2.5. Statistical Analysis

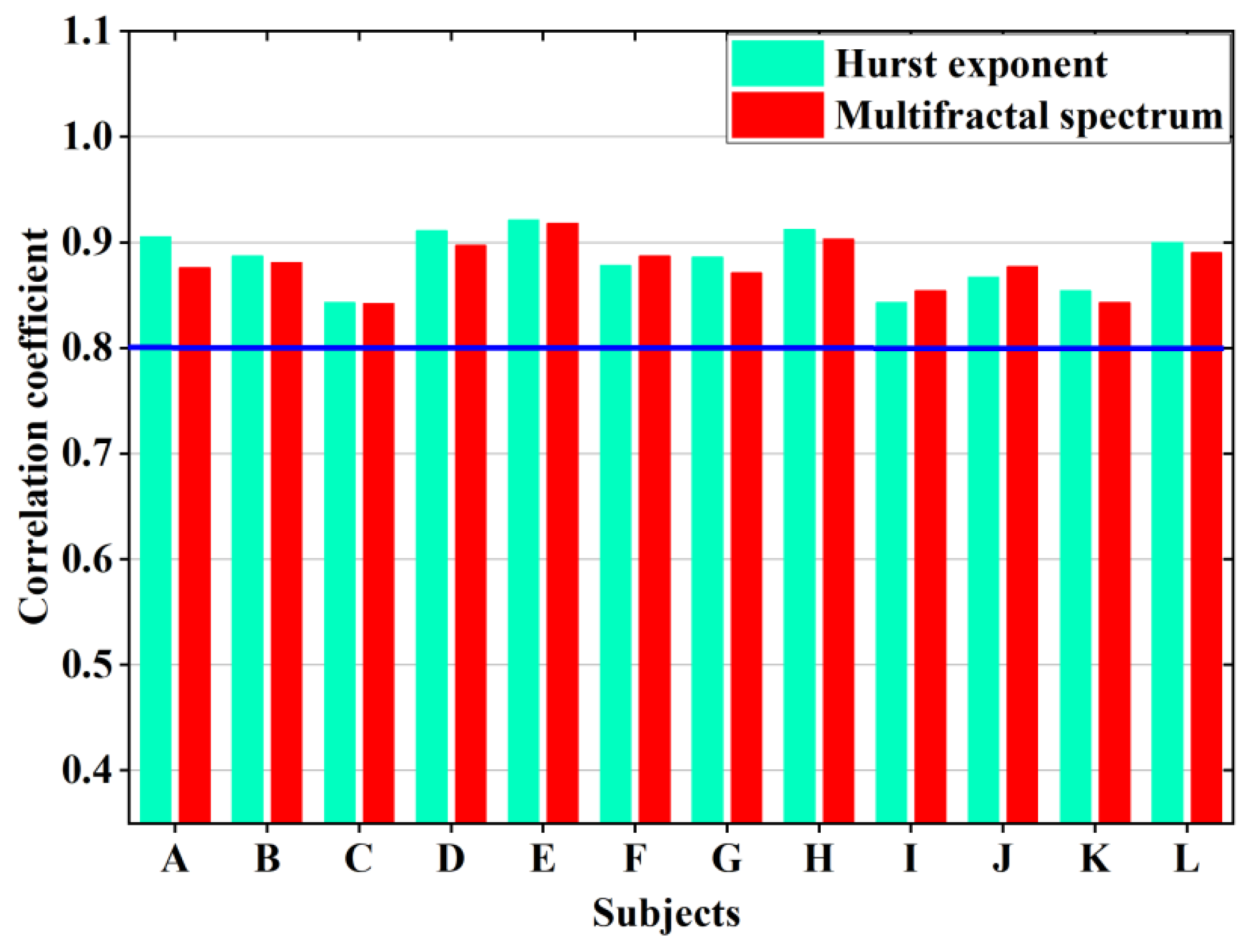

3.3. Correlation Analysis

4. Discussion

4.1. CS Method

4.2. Rotary Switch-Type Semi-Dry Electrode

4.3. Fatigue Detection Method

4.4. Limitations and Future Prospects

5. Conclusions

5.1. The Rotating Switch-Type Semi-Dry Electrode

5.2. The MF-DFA Methods

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tehrani, B.M.; Wang, J.; Truax, D. Assessment of mental fatigue using electroencephalography (EEG) and virtual reality (VR) for construction fall hazard prevention. Eng. Constr. Archit. Manag. 2022, 29, 3593–3616. [Google Scholar] [CrossRef]

- Junior, A.F.; Chierotti, P.; Gabardo, J.M. Residual effects of mental fatigue on subjective fatigue, reaction time and cardiac responses. Rev. Psicol. Deporte 2020, 29, 27–34. [Google Scholar]

- Zhao, G.; He, Y.; Yang, H. Research on fatigue detection based on visual features. IET Image Process. 2022, 16, 1044–1053. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, G.; Chen, S. Assessment of eye fatigue caused by head-mounted displays using eye-tracking. Biomed. Eng. Online 2019, 18, 111. [Google Scholar] [CrossRef]

- Charbonnier, S.; Roy, R.N.; Bonnet, S. EEG index for control operators’ mental fatigue monitoring using interactions between brain regions. Expert Syst. Appl. 2016, 52, 91–98. [Google Scholar] [CrossRef]

- Nathan, V.; Jafari, R. Design principles and dynamic front end reconfiguration for low noise EEG acquisition with finger based dry electrodes. IEEE Trans. Biomed. Circuits Syst. 2015, 9, 631–640. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Yang, L.; Sun, Y. A Nanoclay-Enhanced Hydrogel for Self-Adhesive Wearable Electrophysiology Electrodes with High Sensitivity and Stability. Gels 2023, 9, 323. [Google Scholar] [CrossRef]

- Wang, L.F.; Liu, J.Q.; Yan, X.X. A MEMS-based pyramid micro-needle electrode for long-term EEG measurement. Microsyst. Technol. 2013, 19, 269–276. [Google Scholar] [CrossRef]

- Chen, Y.C.; Lin, B.S.; Pan, J.S. Novel noncontact dry electrode with adaptive mechanical design for measuring EEG in a hairy site. IEEE Trans. Instrum. Meas. 2015, 64, 3361–3368. [Google Scholar] [CrossRef]

- Marini, F.; Lee, C.; Wagner, J. A comparative evaluation of signal quality between a research-grade and a wireless dry-electrode mobile EEG system. J. Neural Eng. 2019, 16, 054001. [Google Scholar] [CrossRef]

- Wang, F.; Chen, D.; Lu, B. A novel semi-dry electrode suitable for collecting EEG data for detecting driving fatigue in long-period driving case. IEEE Sens. J. 2023, 23, 17891–17900. [Google Scholar] [CrossRef]

- Pasion, R.; Paiva, T.O.; Pedrosa, P. Assessing a novel polymer-wick based electrode for EEG neurophysiological research. J. Neurosci. Methods 2016, 267, 126–131. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Huang, J.; Li, M. Evaluation of flexible multi-claw and multi-channel semi-dry electrodes for evoked electroencephalography recording. Sens. Actuators A Phys. 2022, 340, 113547. [Google Scholar] [CrossRef]

- Hua, H.; Tang, W.; Xu, X. Flexible multi-layer semi-dry electrode for scalp EEG measurements at hairy sites. Micromachines 2019, 10, 518. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, X. Estimating mental fatigue based on electroencephalogram and heart rate variability. Pol. J. Med. Phys. Eng. 2010, 16, 67–84. [Google Scholar] [CrossRef]

- Mu, Z.; Hu, J.; Min, J. Driver fatigue detection system using electroencephalography signals based on combined entropy features. Appl. Sci. 2017, 7, 150. [Google Scholar] [CrossRef]

- Diez, P.; Orosco, L.; Garcés Correa, A. Assessment of visual fatigue in SSVEP-based brain-computer interface: A comprehensive study. Med. Biol. Eng. Comput. 2024, 62, 1475–1490. [Google Scholar] [CrossRef]

- Han, D.; Qi, H.; Wang, S.; Hou, D.; Wang, C. Adaptive stepsize forward–backward pursuit and acoustic emission-based health state assessment of high-speed train bearings. Struct. Health Monit. 2024. [Google Scholar] [CrossRef]

- Hou, D.; Qi, H.; Luo, H.; Wang, C.; Yang, J. Comparative study on the use of acoustic emission and vibration analyses for the bearing fault diagnosis of high-speed trains. Struct. Health Monit. 2022, 21, 1518–1540. [Google Scholar] [CrossRef]

- Qi, H.; Han, D.; Hou, D.; Wang, C. A novel acoustic emission sensor design and modeling method for monitoring the status of high-speed train bearings. Struct. Health Monit. 2023, 22, 3761–3784. [Google Scholar] [CrossRef]

- Han, D.; Qi, H.; Hou, D.; Wang, S.; Kong, J.; Xu, X.; Wang, C. Dynamic detection mechanism model of acoustic emission for high-speed train axle box bearings with local defects. Mech. Syst. Signal Process. 2025, 235, 112943. [Google Scholar] [CrossRef]

- Zorick, T.; Landers, J.; Leuchter, A. EEG multifractal analysis correlates with cognitive testing scores and clinical staging in mild cognitive impairment. J. Clin. Neurosci. 2020, 76, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Kappel, S.L.; Rank, M.L.; Toft, H.O. Dry-contact electrode ear-EEG. IEEE Trans. Biomed. Eng. 2018, 66, 150–158. [Google Scholar] [CrossRef]

- Shin, S.; Lee, S.; Choi, S.J.; Joo, E.Y.; Suh, S. Validation of the Karolinska Sleepiness Scale in Korean. J. Clin. Neurol. 2024, 20, 501. [Google Scholar] [CrossRef]

- Lai, Q.; Hu, G. A nonuniform pixel split encryption scheme integrated with compressive sensing and its application in IoMT. IEEE Trans. Ind. Inform. 2024, 20, 11262–11272. [Google Scholar] [CrossRef]

- Ihlen, E.A.F. Introduction to multifractal detrended fluctuation analysis in Matlab. Front. Physiol. 2012, 3, 141. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Gordo, M.A.; Sanchez-Morillo, D.; Valle, F.P. Dry EEG electrodes. Sensors 2014, 14, 12847–12870. [Google Scholar] [CrossRef]

- Kam, J.W.Y.; Griffin, S.; Shen, A. Systematic comparison between a wireless EEG system with dry electrodes and a wired EEG system with wet electrodes. NeuroImage 2019, 184, 119–129. [Google Scholar] [CrossRef]

- Wang, F.; Li, G.; Chen, J. Novel semi-dry electrodes for brain–computer interface applications. J. Neural Eng. 2016, 13, 046021. [Google Scholar] [CrossRef]

- Tseghai, G.B.; Malengier, B.; Fante, K.A. Dry electroencephalography textrode for brain activity monitoring. IEEE Sens. J. 2021, 21, 22077–22085. [Google Scholar] [CrossRef]

- Fan, Q.; Liu, S.; Wang, K. Multiscale multifractal detrended fluctuation analysis of multivariate time series. Phys. A Stat. Mech. Its Appl. 2019, 532, 121864. [Google Scholar] [CrossRef]

- Grosu, G.F.; Hopp, A.V.; Moca, V.V. The fractal brain: Scale-invariance in structure and dynamics. Cereb. Cortex 2023, 33, 4574–4605. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Yao, Q. The effect of circadian rhythm on the correlation and multifractality of heart rate signals during exercise. Phys. A Stat. Mech. Its Appl. 2018, 509, 1207–1213. [Google Scholar] [CrossRef]

- Wątorek, M.; Tomczyk, W.; Gawłowska, M. Multifractal organization of EEG signals in multiple sclerosis. Biomed. Signal Process. Control 2024, 91, 105916. [Google Scholar] [CrossRef]

- Gaurav, G.; Anand, R.S.; Kumar, V. EEG based cognitive task classification using multifractal detrended fluctuation analysis. Cogn. Neurodynamics 2021, 15, 999–1013. [Google Scholar] [CrossRef]

- Wang, F.; Lin, J.; Wang, W. EEG-based mental fatigue assessment during driving by using sample entropy and rhythm energy. In Proceedings of the 2015 IEEE International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (CYBER), Shenyang, China, 8–12 June 2015; pp. 1906–1911. [Google Scholar]

- Tyagi, A.; Semwal, S.; Shah, G. A review of EEG sensors used for data acquisition. J. Comput. Appl. (IJCA) 2012, 13–17. [Google Scholar] [CrossRef]

- Rusanen, M.; Myllymaa, S.; Kalevo, L. An in-laboratory comparison of FocusBand EEG device and textile electrodes against a medical-grade system and wet gel electrodes. IEEE Access 2021, 9, 132580–132591. [Google Scholar] [CrossRef]

- Fu, Y.; Zhao, J.; Dong, Y. Dry electrodes for human bioelectrical signal monitoring. Sensors 2020, 20, 3651. [Google Scholar] [CrossRef]

- Gao, S.; Gong, J.; Chen, B. Use of advanced materials and artificial intelligence in electromyography signal detection and interpretation. Adv. Intell. Syst. 2022, 4, 2200063. [Google Scholar] [CrossRef]

- Radhakrishnan, J.K.; Nithila, S.; Kartik, S.N. A novel, needle-array dry-electrode with stainless steel micro-tips, for electroencephalography monitoring. J. Med. Devices 2018, 12, 041001. [Google Scholar] [CrossRef]

- Krishnan, A.; Kumar, R.; Venkatesh, P. Low-cost carbon fiber-based conductive silicone sponge EEG electrodes. In Proceedings of the 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 18–21 July 2018; pp. 1287–1290. [Google Scholar]

- Liu, J.; Liu, X.; He, E. A novel dry-contact electrode for measuring electroencephalography signals. Sens. Actuators A Phys. 2019, 294, 73–80. [Google Scholar] [CrossRef]

- Gargiulo, G.; Calvo, R.A.; Bifulco, P. A new EEG recording system for passive dry electrodes. Clin. Neurophysiol. 2010, 121, 686–693. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, S.; Li, M. Towards real-life EEG applications: Novel superporous hydrogel-based semi-dry EEG electrodes enabling automatically ‘charge–discharge’ electrolyte. J. Neural Eng. 2021, 18, 046016. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Ma, M.; Fu, R. EEG-based detection of driving fatigue using a novel electrode. Sens. Actuators A Phys. 2024, 365, 114895. [Google Scholar] [CrossRef]

- Han, L.; Li, C.; Liu, H. Feature extraction method of rolling bearing fault signal based on EEMD and cloud model characteristic entropy. Entropy 2015, 17, 6683–6697. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Zhou, X. A driving fatigue feature detection method based on multifractal theory. IEEE Sens. J. 2022, 22, 19046–19059. [Google Scholar] [CrossRef]

- Abásolo, D.; Simons, S.; Morgado da Silva, R. Lempel-Ziv complexity of cortical activity during sleep and waking in rats. J. Neurophysiol. 2015, 113, 2742–2752. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Zhou, X. Study on the effect of judgment excitation mode to relieve driving fatigue based on MF-DFA. Brain Sci. 2022, 12, 1199. [Google Scholar] [CrossRef]

| Method | Training Time (s) | Test Time (ms) |

|---|---|---|

| Not using CS methods | 32.67 | 17.33 |

| Using CS methods | 24.34 | 14.68 |

| Types of Electrodes | The Amount of Conductive Liquid | Impedance (10 Hz) | Hours of Use |

|---|---|---|---|

| Ag/AgCl wet electrode | Need more | 9.5 KΩ | 2 h |

| Emotiv electrode | Need more | 10.6 KΩ | 2 h |

| A novel dry-contact electrode [43] | No need | 16.7 KΩ | / |

| Passive dry electrodes [44] | No need | 17.4 KΩ | / |

| Flexible multilayer semi-dry electrode [14] | Need less | 14.6 KΩ | 5 h |

| Novel superporous hydrogel-based semi-dry EEG electrodes [45] | Need less | 13.8 KΩ | 8 h |

| Novel semi-dry electrode [11] | Need less | 13.8 KΩ | 8 h |

| Semi-dry electrode [46] | Need less | 14.1 KΩ | 8 h |

| Rotary switch-type semi-dry electrode (this study) | Need less | 12.3 KΩ | 10 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Chen, D.; Zhang, X. Mental Fatigue Detection of Crane Operators Based on Electroencephalogram Signals Acquired by a Novel Rotary Switch-Type Semi-Dry Electrode Using Multifractal Detrend Fluctuation Analysis. Sensors 2025, 25, 3994. https://doi.org/10.3390/s25133994

Wang F, Chen D, Zhang X. Mental Fatigue Detection of Crane Operators Based on Electroencephalogram Signals Acquired by a Novel Rotary Switch-Type Semi-Dry Electrode Using Multifractal Detrend Fluctuation Analysis. Sensors. 2025; 25(13):3994. https://doi.org/10.3390/s25133994

Chicago/Turabian StyleWang, Fuwang, Daping Chen, and Xiaolei Zhang. 2025. "Mental Fatigue Detection of Crane Operators Based on Electroencephalogram Signals Acquired by a Novel Rotary Switch-Type Semi-Dry Electrode Using Multifractal Detrend Fluctuation Analysis" Sensors 25, no. 13: 3994. https://doi.org/10.3390/s25133994

APA StyleWang, F., Chen, D., & Zhang, X. (2025). Mental Fatigue Detection of Crane Operators Based on Electroencephalogram Signals Acquired by a Novel Rotary Switch-Type Semi-Dry Electrode Using Multifractal Detrend Fluctuation Analysis. Sensors, 25(13), 3994. https://doi.org/10.3390/s25133994