A Novel Spatter Detection Algorithm for Real-Time Quality Control in Laser-Directed Energy Deposition-Based Additive Manufacturing

Abstract

1. Introduction

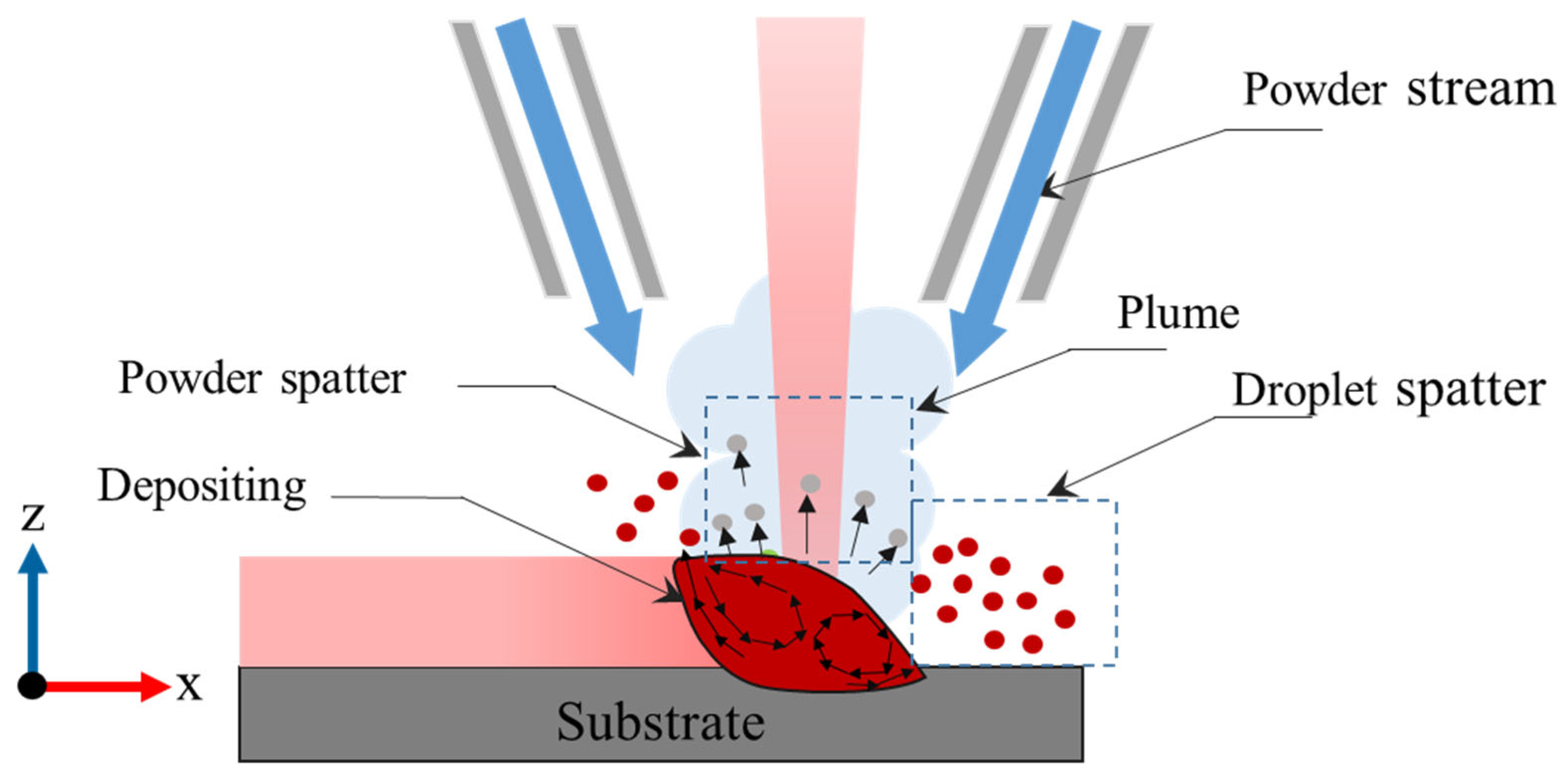

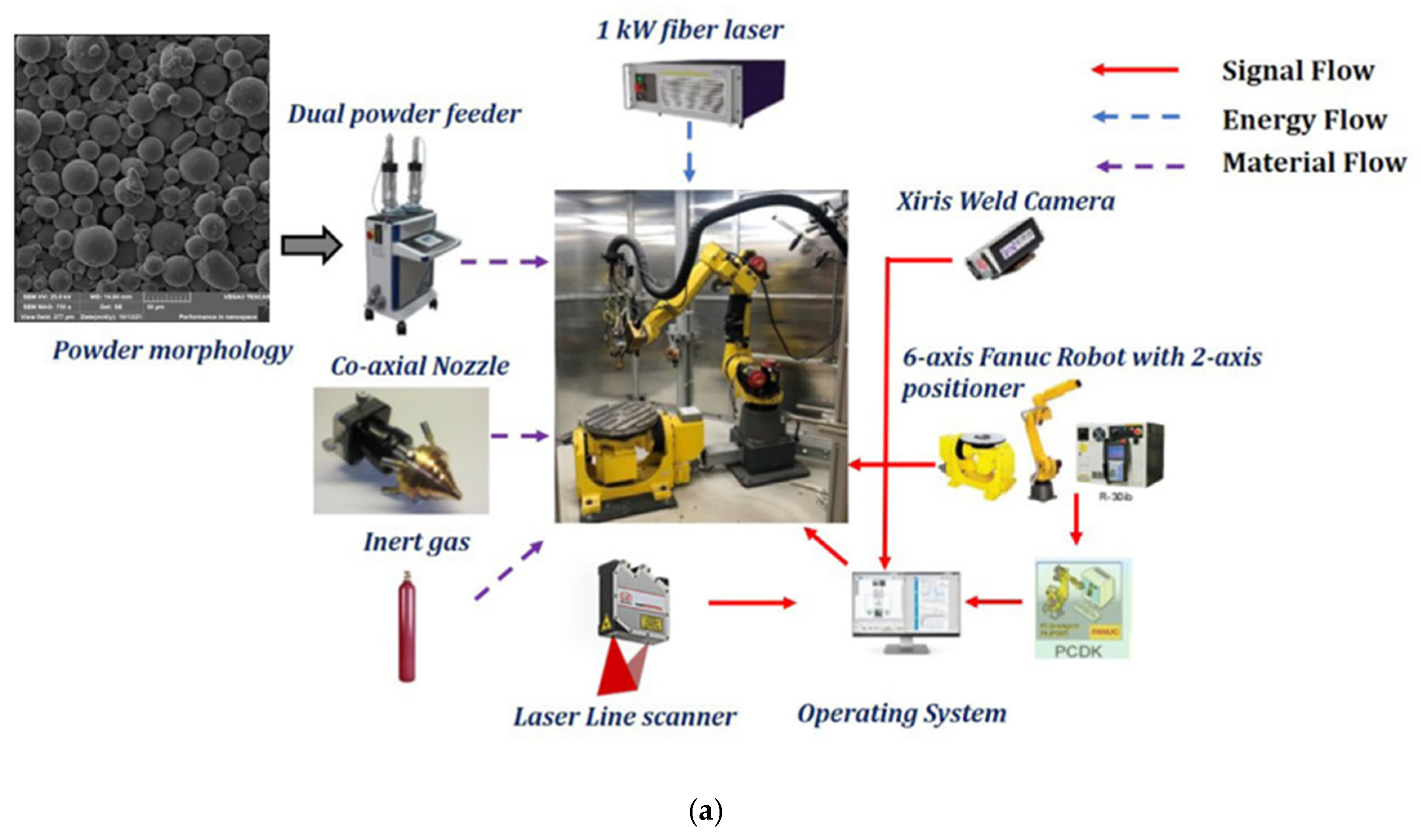

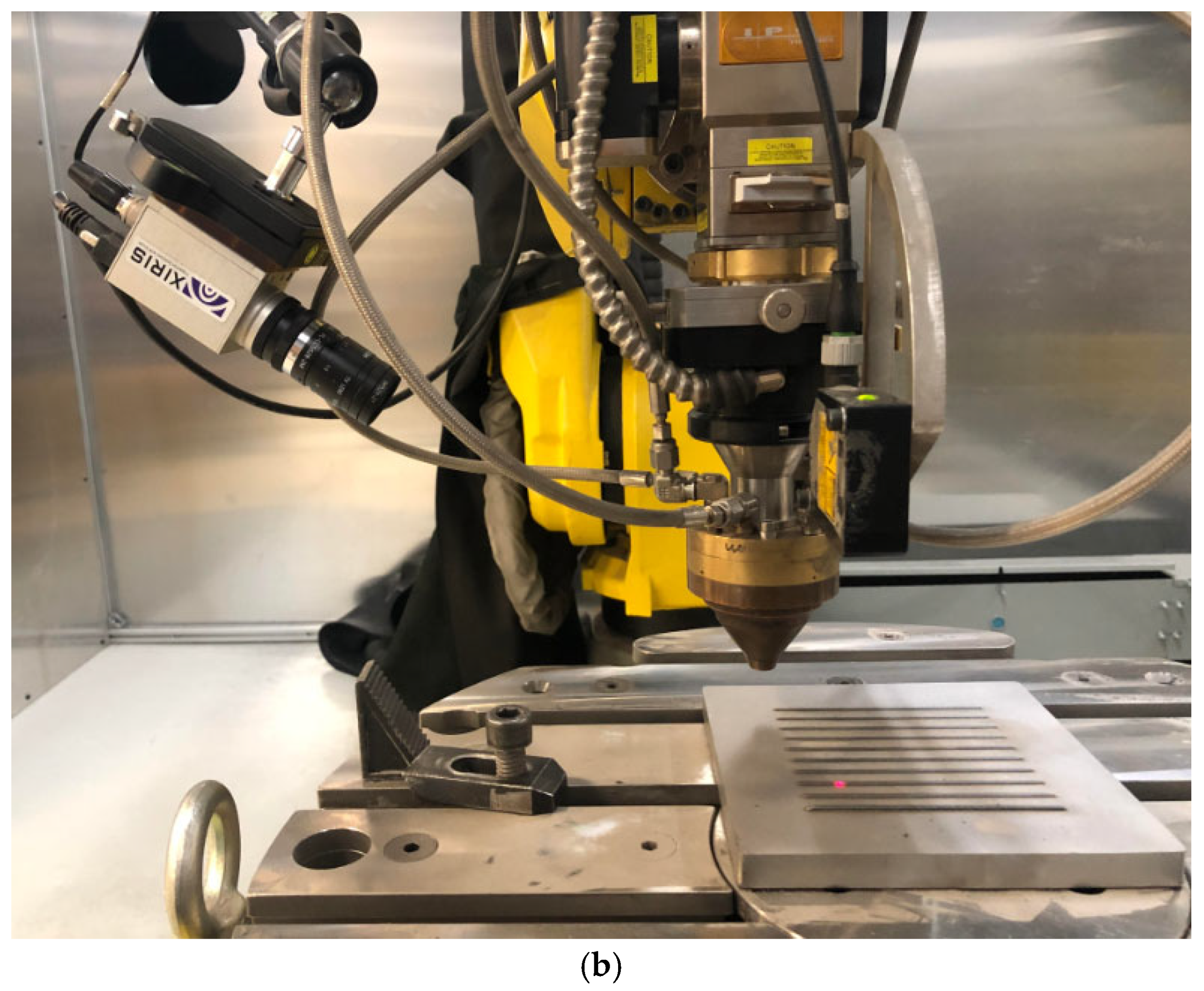

2. Materials and Methods

3. Results and Discussion

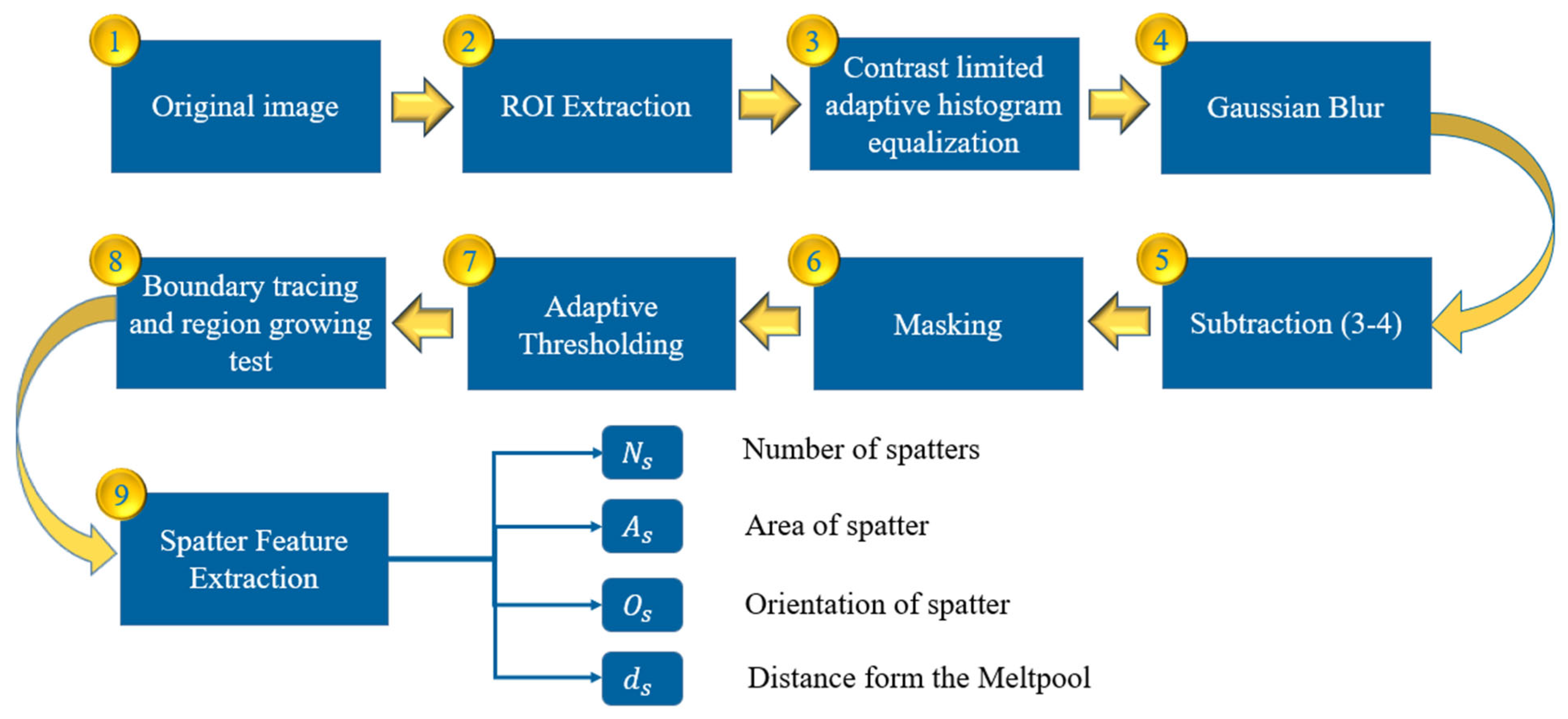

3.1. Algorithm Development

- Gaussian kernel standard deviation: ;

- Gaussian kernel size: .

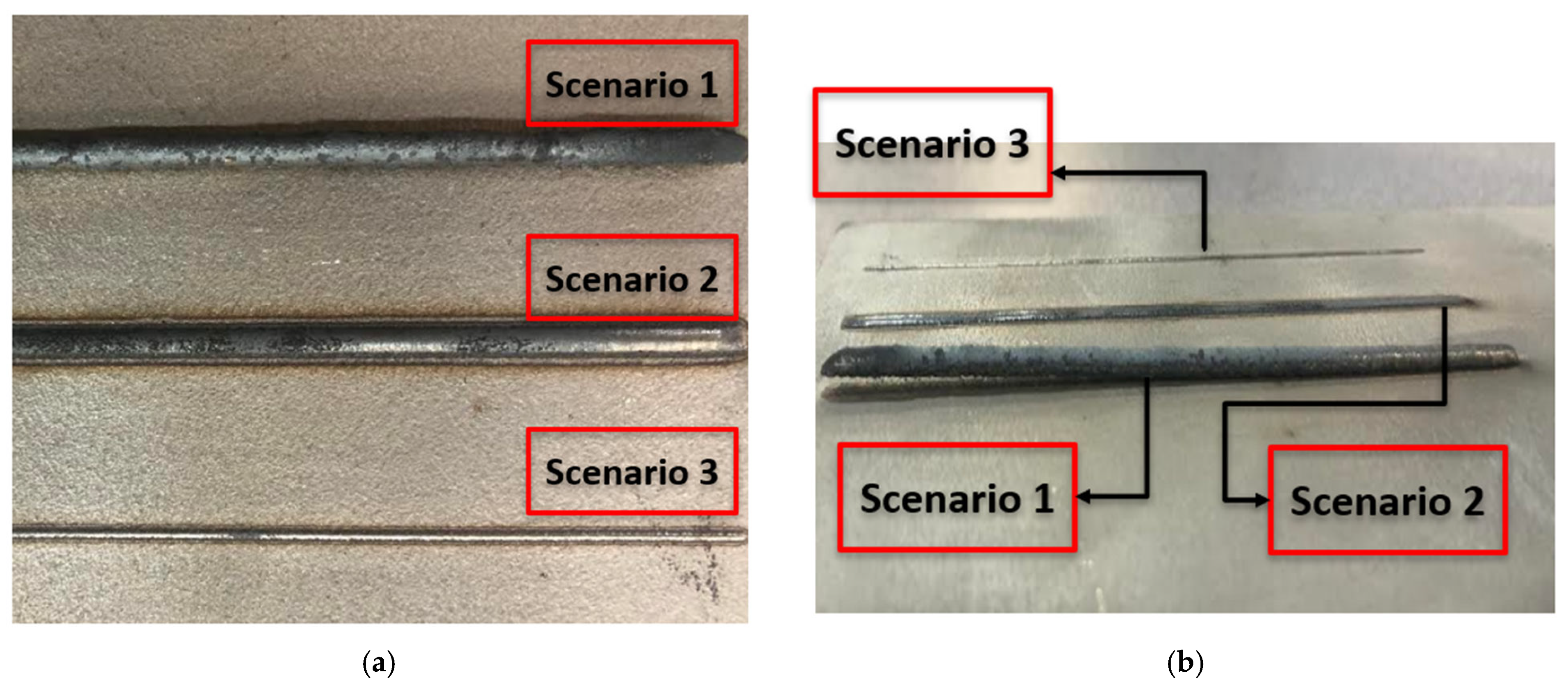

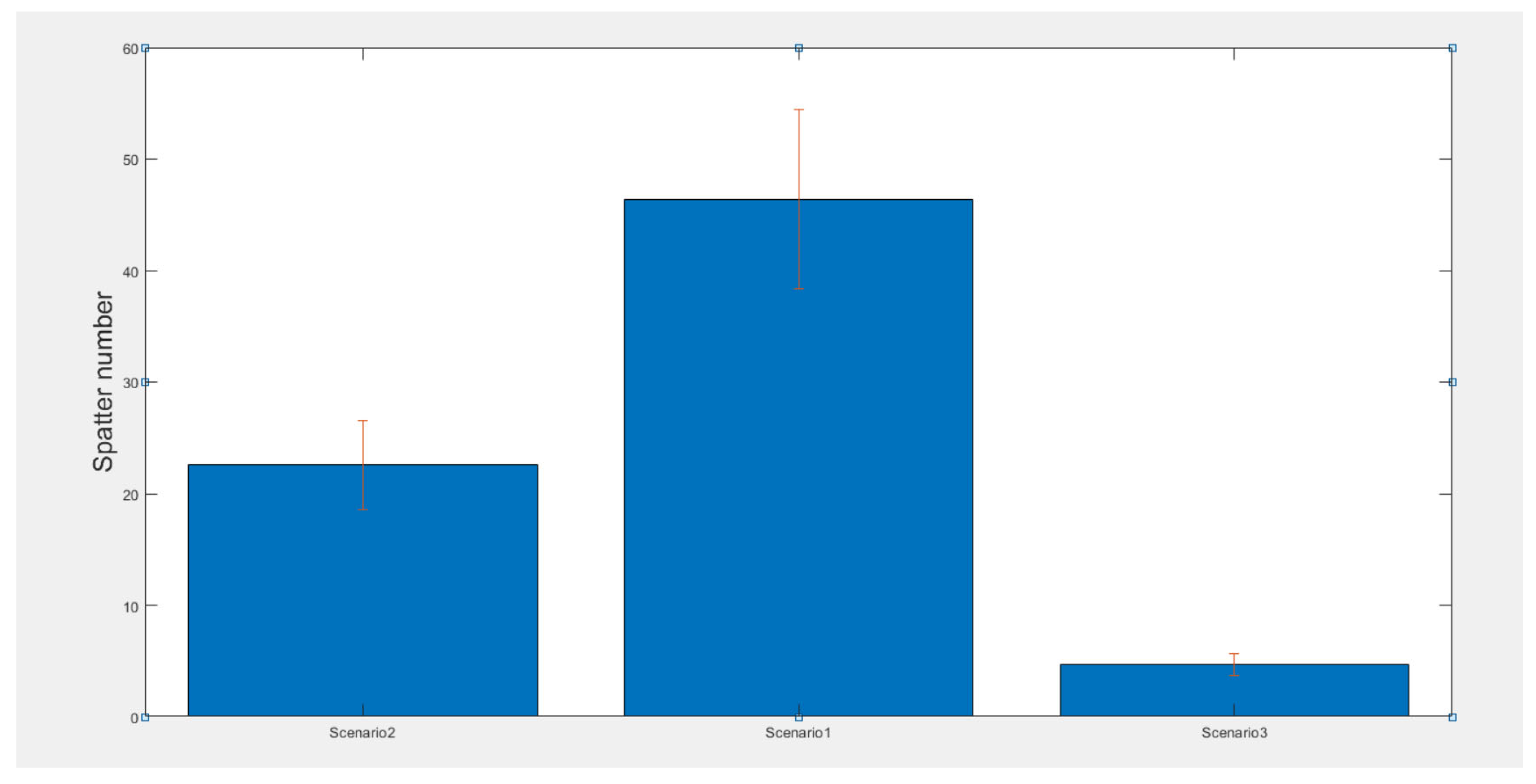

3.2. Spatter Detection and Analysis

3.3. Validation and Accuracy

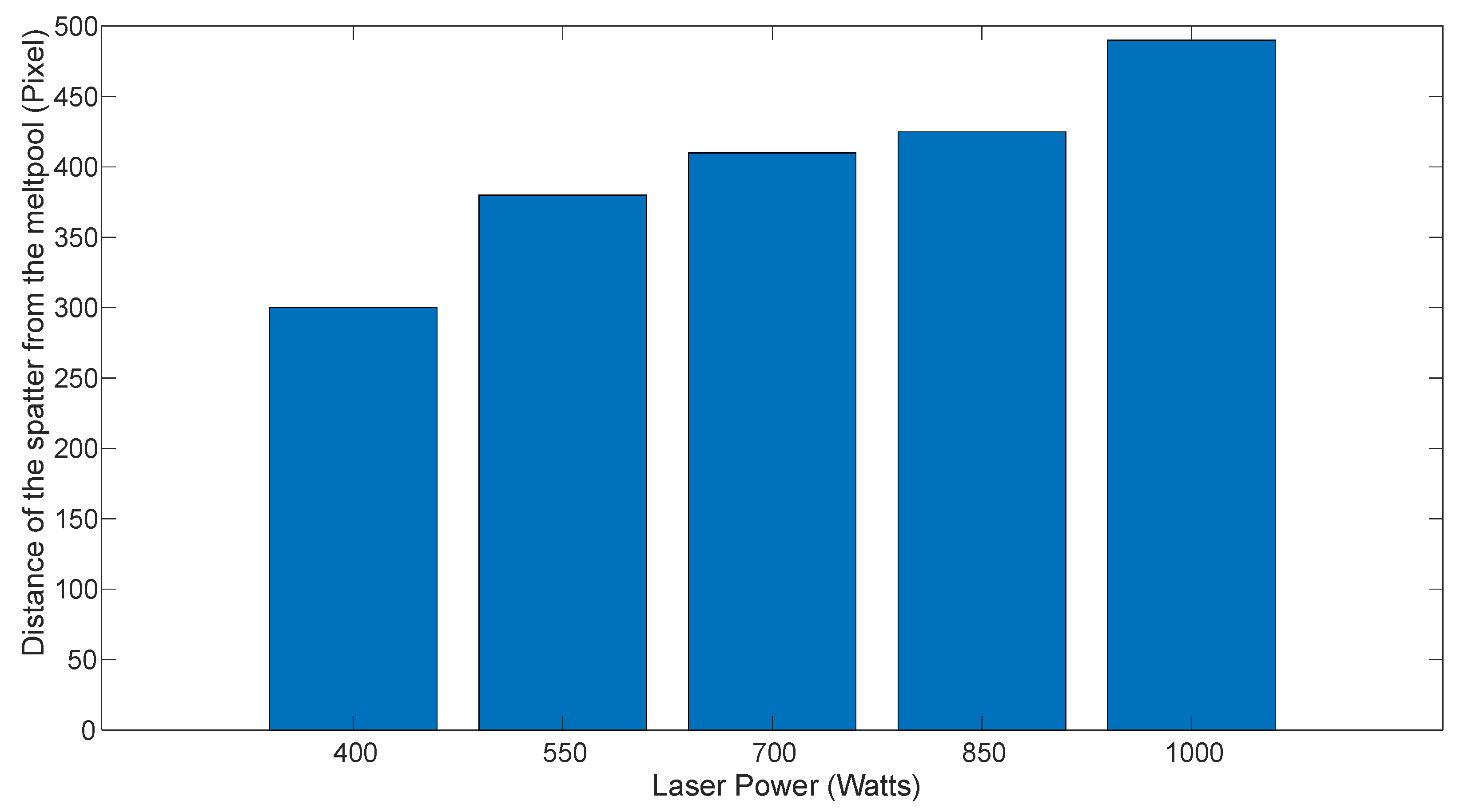

3.4. Sensitivity Analysis

3.5. Spatter Formation Mechanisms

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaji, F.; Nguyen-Huu, H.; Narayanan, J.A.; Zimny, M.; Toyserkani, E. Intermittent adaptive trajectory planning for geometric defect correction in large-scale robotic laser directed energy deposition based additive manufacturing. J. Intell. Manuf. 2024, 35, 3149–3168. [Google Scholar] [CrossRef]

- Kaji, F.; Jinoop, A.N.; Zardoshtian, A.; Hallen, P.; Frikel, G.; Tang, T.; Zimny, M.; Toyserkani, E. Robotic laser directed energy deposition-based additive manufacturing of tubular components with variable overhang angles: Adaptive trajectory planning and characterization. Addit. Manuf. 2023, 61, 103366. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Fu, F.; Mai, S.; Yang, Y.; Liu, Y.; Song, C. Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater. Des. 2017, 117, 121–130. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Ly, S.; Rubenchik, A.M.; Khairallah, S.A.; Guss, G.; Matthews, M.J. Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing. Sci. Rep. 2017, 7, 4085. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of metal powder layers in laser powder bed fusion processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Iravani-Tabrizipour, M.; Toyserkani, E. An image-based feature tracking algorithm for real-time measurement of clad height. Mach. Vis. Appl. 2007, 18, 343–354. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Powell, J. Laser welding: The spatter map. In Proceedings of the 29th International Congress on Applications of Lasers and Electro-Optics, ICALEO 2010—Congress Proceedings, Anaheim, CA, USA, 26–30 September 2010. [Google Scholar] [CrossRef]

- Bidanda, B.; Rubinovitz, J.; Raman, S. Development of a spatter index for automated welding inspection using computer vision. Comput. Ind. Eng. 1989, 16, 215–224. [Google Scholar] [CrossRef]

- Hugger, F.; Hofmann, K.; Kohl, S.; Dobler, M.; Schmidt, M. Spatter formation in laser beam welding using laser beam oscillation. Weld. World 2014, 59, 165–172. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Mai, S.; Wang, D.; Song, C. Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater. Des. 2015, 87, 797–806. [Google Scholar] [CrossRef]

- Yin, J.; Wang, D.; Yang, L.; Wei, H.; Dong, P.; Ke, L.; Wang, G.; Zhu, H.; Zeng, X. Correlation between forming quality and spatter dynamics in laser powder bed fusion. Addit. Manuf. 2020, 31, 100958. [Google Scholar] [CrossRef]

- Grünewald, J.; Gehringer, F.; Schmöller, M.; Wudy, K. Influence of Ring-Shaped Beam Profiles on Process Stability and Productivity in Laser-Based Powder Bed Fusion of AISI 316L. Metals 2021, 11, 1989. [Google Scholar] [CrossRef]

- Cui, J.; Liang, H.; Chen, S.; Shao, Y.; Chen, H.; Yang, M.; Yang, Y. Recent progress and perspectives in laser additive manufacturing of biodegradable zinc alloy. J. Mater. Res. Technol. 2024, 33, 6958–6979. [Google Scholar] [CrossRef]

- Zhang, Y.; Fuh, J.Y.H.; Ye, D.; Hong, G.S. In-situ monitoring of laser-based PBF via off-axis vision and image processing approaches. Addit. Manuf. 2019, 25, 263–274. [Google Scholar] [CrossRef]

- Schweier, M.; Haubold, M.W.; Zaeh, M.F. Analysis of spatters in laser welding with beam oscillation: A machine vision approach. CIRP J. Manuf. Sci. Technol. 2016, 14, 35–42. [Google Scholar] [CrossRef]

- Nicolosi, L.; Abt, F.; Blug, A.; Heider, A.; Tetzlaff, R.; Höfler, H. A novel spatter detection algorithm based on typical cellular neural network operations for laser beam welding processes. Meas. Sci. Technol. 2012, 23, 015401. [Google Scholar] [CrossRef]

- Haubold, M.W.; Wulf, L.; Zaeh, M.F. Validation of a spatter detection algorithm for remote laser welding applications. J. Laser Appl. 2017, 29, 022011. [Google Scholar] [CrossRef]

- Zuiderveld, K. Contrast Limited Adaptive Histogram Equalization. In Graphics Gems; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar] [CrossRef]

- Fan, W.; Peng, Y.; Qi, Y.; Tan, H.; Feng, Z.; Wang, Y.; Zhang, F.; Lin, X. Partially melted powder in laser based directed energy deposition: Formation mechanism and its influence on microstructure. Int. J. Mach. Tools Manuf. 2023, 192, 104072. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.; Marussi, S.; Fan, X.; Fitzpatrick, M.; Bhagavath, S.; Majkut, M.; Lukic, B.; Jakata, K.; Rack, A.; et al. Pore evolution mechanisms during directed energy deposition additive manufacturing. Nat. Commun. 2024, 15, 1715. [Google Scholar] [CrossRef]

- Qiu, Y.; Purwar, S.; Gong, H.; Beese, A.M. A review of spatter in laser powder bed fusion additive manufacturing: In situ detection, generation, effects, and countermeasures. Addit. Manuf. 2024, 65, 102744. [Google Scholar]

- Prasad, H.S.; Brueckner, F.; Kaplan, A.F.H. Powder incorporation and spatter formation in high deposition rate blown powder directed energy deposition. Addit. Manuf. 2020, 35, 101413. [Google Scholar] [CrossRef]

- Ertay, D.S.; Naiel, M.A.; Vlasea, M.; Fieguth, P. Process performance evaluation and classification via in-situ melt pool monitoring in directed energy deposition. CIRP J. Manuf. Sci. Technol. 2021, 35, 298–314. [Google Scholar] [CrossRef]

- Guo, J.; Ma, J.; García-Fernández, Á.F.; Zhang, Y.; Liang, H. A survey on image enhancement for Low-light images. Heliyon 2023, 9, e14558. [Google Scholar] [CrossRef] [PubMed]

| Process Parameter | Value/Range |

|---|---|

| Laser power | 400–1000 Watts |

| Scanning speed | 6 mm/s |

| Powder feed rate | 5 g/min |

| Shielding gas feed rate | 5 L/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaji, F.; Narayanan, J.A.; Zimny, M.; Toyserkani, E. A Novel Spatter Detection Algorithm for Real-Time Quality Control in Laser-Directed Energy Deposition-Based Additive Manufacturing. Sensors 2025, 25, 3610. https://doi.org/10.3390/s25123610

Kaji F, Narayanan JA, Zimny M, Toyserkani E. A Novel Spatter Detection Algorithm for Real-Time Quality Control in Laser-Directed Energy Deposition-Based Additive Manufacturing. Sensors. 2025; 25(12):3610. https://doi.org/10.3390/s25123610

Chicago/Turabian StyleKaji, Farzaneh, Jinoop Arackal Narayanan, Mark Zimny, and Ehsan Toyserkani. 2025. "A Novel Spatter Detection Algorithm for Real-Time Quality Control in Laser-Directed Energy Deposition-Based Additive Manufacturing" Sensors 25, no. 12: 3610. https://doi.org/10.3390/s25123610

APA StyleKaji, F., Narayanan, J. A., Zimny, M., & Toyserkani, E. (2025). A Novel Spatter Detection Algorithm for Real-Time Quality Control in Laser-Directed Energy Deposition-Based Additive Manufacturing. Sensors, 25(12), 3610. https://doi.org/10.3390/s25123610