Automated Anomaly Detection in Blast Furnace Shaft Static Pressure Using Adversarial Autoencoders and Mode Decomposition

Abstract

1. Introduction

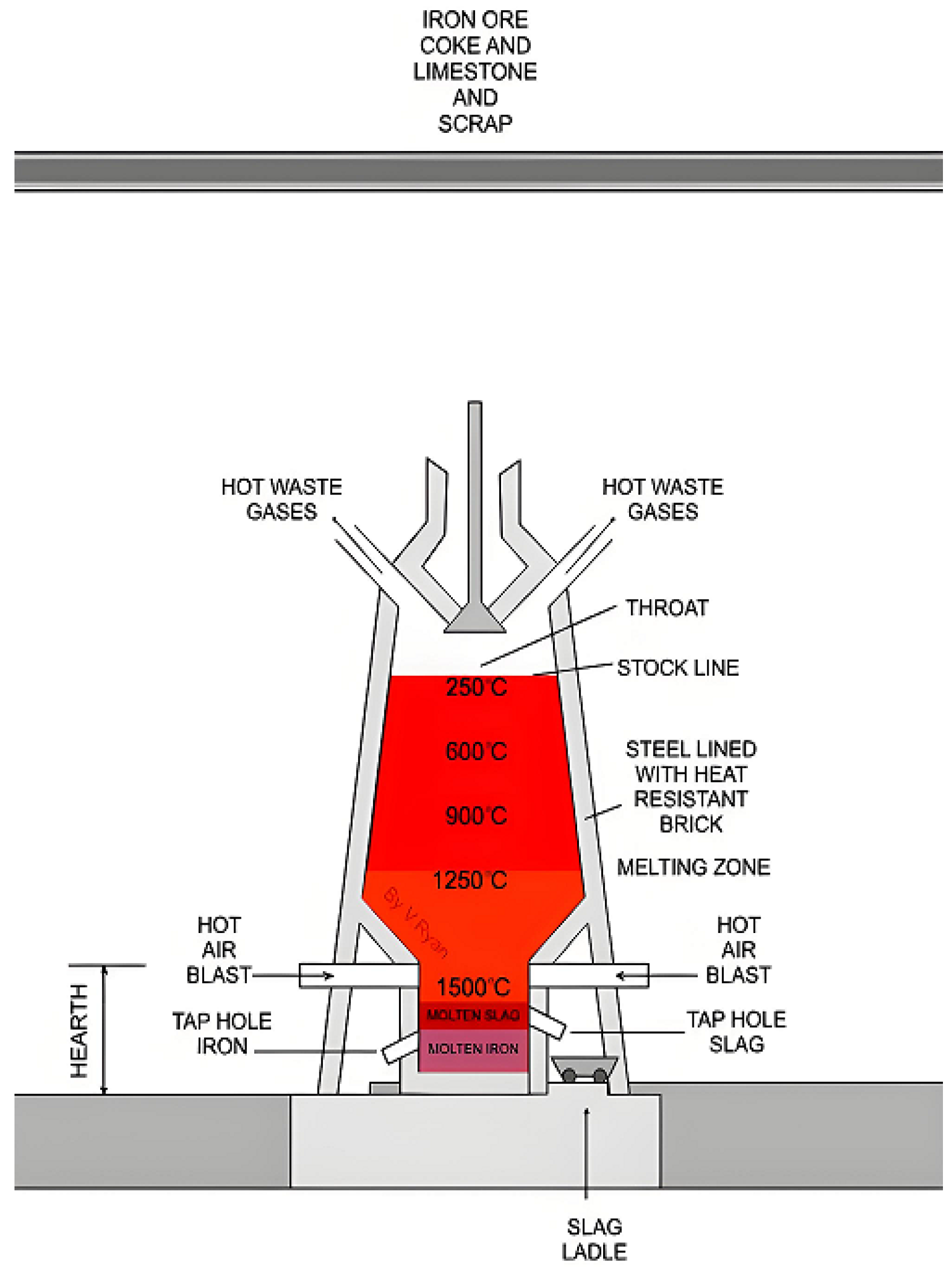

2. Process Introduction and Problem Description

2.1. Blast Furnace Ironmaking Process

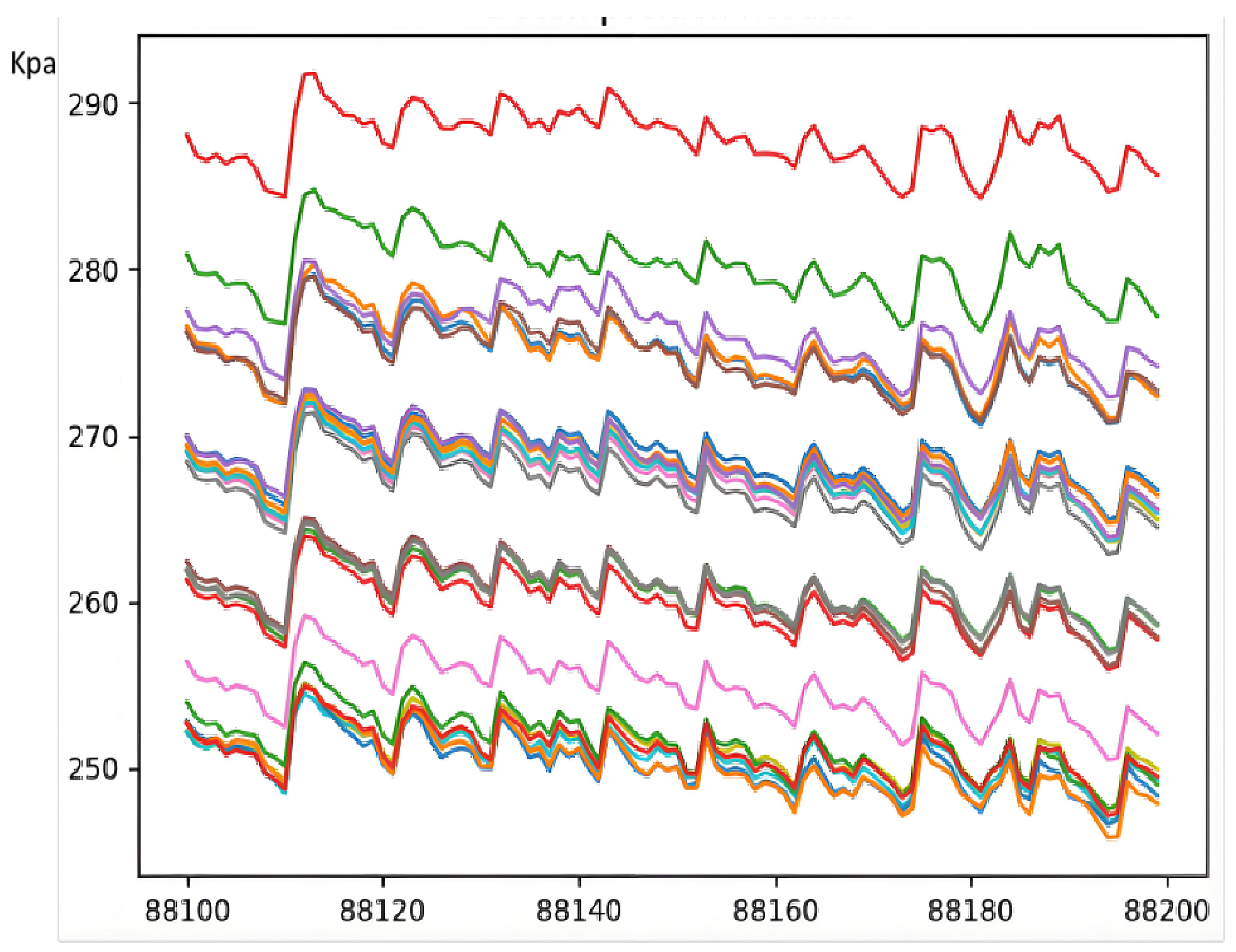

2.2. Problem Description

2.3. Problem Formulation

3. Method

3.1. Anomaly Detection Method

3.2. Time Series Data Processing

- Given a time series: .

- Sequence segmentation: Divide the time series into vectors using a window length m. Each vector sequence is represented as: .

- Distance calculation: Compute the distance between each m-dimensional vector sequence and all other k m-dimensional vector sequences. The distance is defined as the maximum absolute difference between corresponding elements of two vectors:

- Threshold definition: , where r is a coefficient (typically 0.1–0.25) and is the standard deviation of the sequence.

- Ratio statistics: Count the ratio of m-dimensional vector sequences with distances exceeding F to the total number (excluding self-comparisons), denoted as . Calculate the average of all , denoted as .

- Sample entropy calculation: Repeat steps 2–5 with window length to obtain . Compute sample entropy using:

- Sample entropy clustering: Cluster the VMD-decomposed sequences using k-means into three categories representing trend, cycle, and residual fluctuations. Combine components within each cluster to form three final components: (trend), (cycle), and (residual).

3.3. Implementation Framework

- Step 1: Perform VMD decomposition on the raw data to obtain multiple components. Since subsequent steps involve post-processing the VMD decomposition results, this paper does not focus on adaptive parameter adjustment for VMD. The raw data are preliminarily split into 10 components, retaining dynamic baseline drift, with the convergence criterion set to “”.

- Step 2: Due to the variable-length periodic characteristics of the data and the need for model interpretability, post-processing of the IMF components decomposed in Step 1 is required. Key steps include calculating the sample entropy of different components, standardizing the data to eliminate dimensional effects, and setting the tolerance to 0.1 to balance robustness and noise impact. Further, k-means clustering is applied to the entropy values, categorizing the components into three classes—trend, periodic, and residual (remaining details)—based on data morphology. Thus, the number of clusters is set to 3. The clustered components are recombined to decompose the original time series data into trend, periodic, and residual components. This separation mitigates the influence of periodic fluctuations and impact-type anomalies on model performance.

- Step 3: Since the shaft static pressure data is multi-dimensional time series, after decomposing each time series via VMD and regrouping them into three components, identical component types across multiple dimensions are grouped to form three 2D arrays. These arrays are individually input into the improved H-AAE network for training and anomaly detection. Given the presence of multiple anomaly types in this scenario, each with distinct physical meanings and operational implications, the detected anomaly results from each component in the H-AAE model are combined via a union operation. All anomalies are presented to process experts, who evaluate the necessity and approach for handling them by integrating other production parameters.

4. Experiments

4.1. Dataset Description

4.2. Evaluation Methodology

4.3. Experimental Results

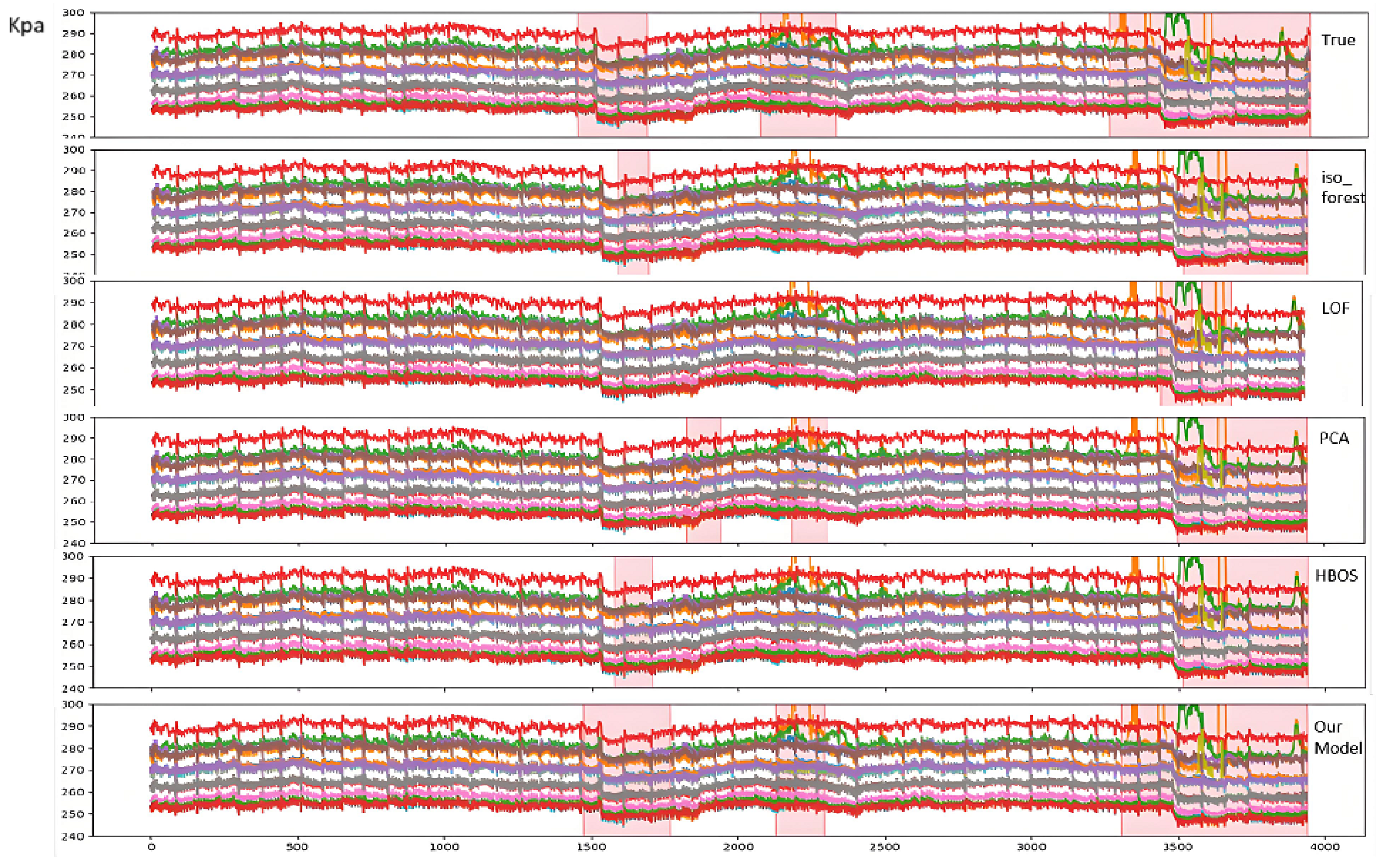

4.3.1. Comparison Experimental Results

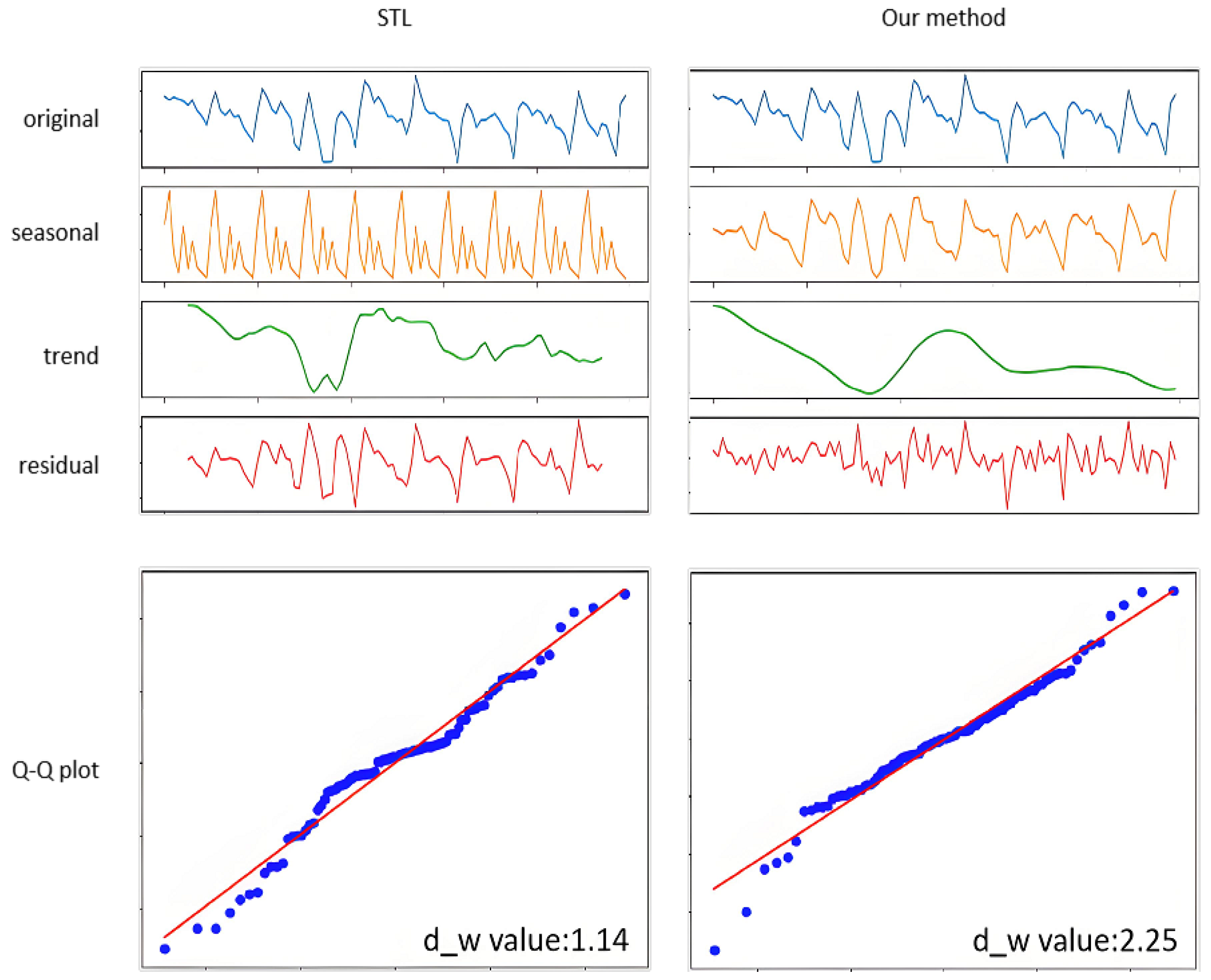

- The upper part of Figure 4 illustrates the contrasting extraction effects of STL and the proposed method on trend, periodic, and residual components. By observing the morphology of each component in the time-series plots, it is evident that the original data exhibits oscillatory periodic fluctuations with variations in cycle length and morphological details, alongside a gradual declining trend. The proposed method achieves accurate extraction of the actual periodic patterns while successfully isolating significant trend components, ensuring the extracted features maintain physically interpretable characteristics. In contrast, STL decomposition requires predefined cycle lengths, leading to extracted periodic components that deviate markedly from observed patterns. This suboptimal periodic extraction further causes incomplete separation of trend and residual components from cyclic influences. Notably, residual components fail to reliably identify impact-type anomalies due to uncorrected periodic interference.

- The lower part of Figure 4 further analyzes the decomposed residual components using Q–Q plots. Results indicate that residuals from our method show no significant autocorrelation (Durbin–Watson statistic between 1.5 and 2.5), with most scatter points clustered near and parallel to the red reference line. In contrast, STL residuals demonstrate moderate positive autocorrelation (DW = 1.14), exhibiting oscillatory scatter patterns around the red line. The Q–Q plot also reveals that extreme residual values correspond to localized anomalies.

4.3.2. Ablation Experimental Results

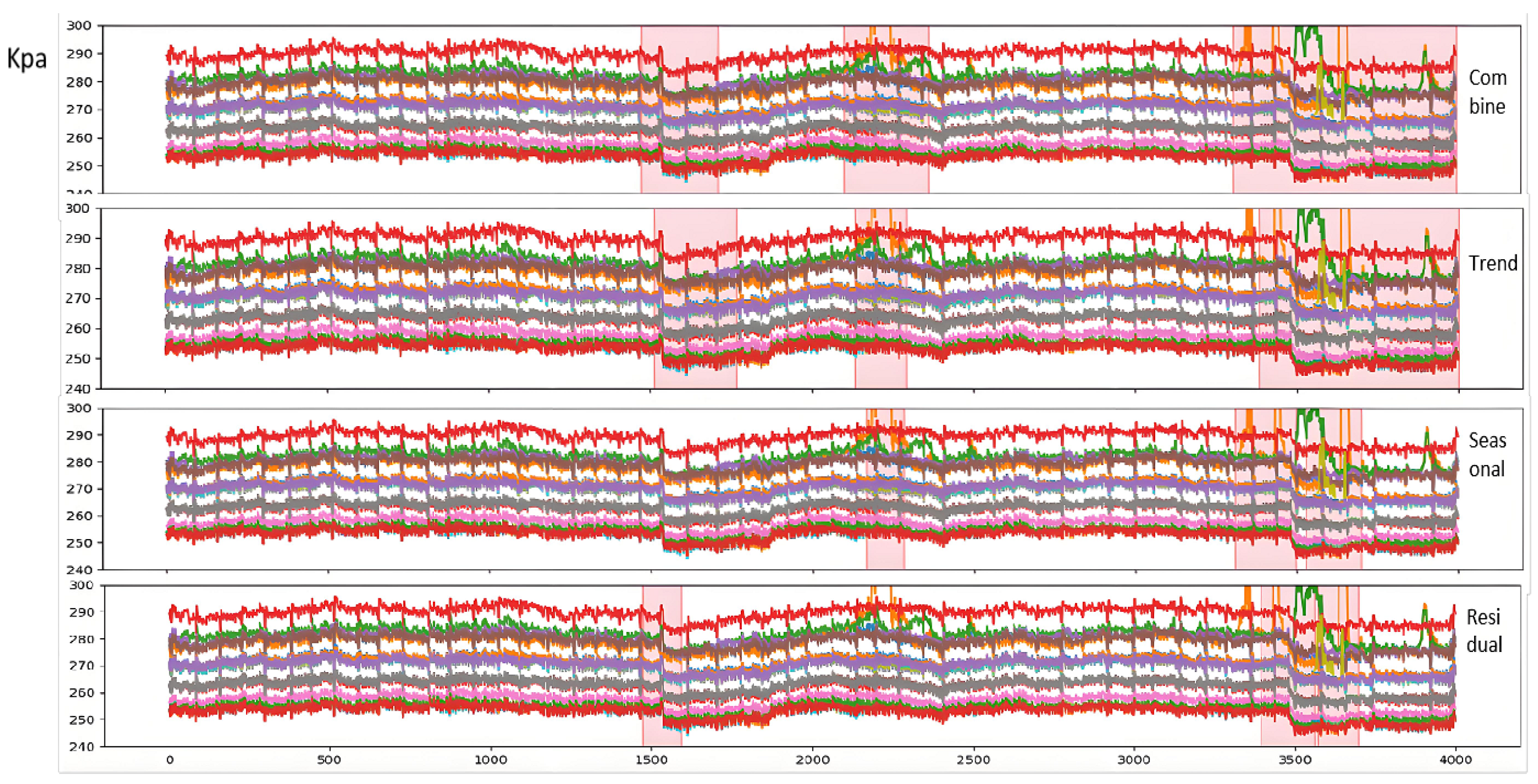

- Anomaly Segment Annotation: The pink semi-transparent boxes in the figure indicate anomaly segments manually labeled or algorithmically identified. Due to the sliding window approach (window width = 60) used in this study for extracting time-series data fragments, the annotated anomaly start points precede actual anomaly timestamps. This design does not compromise the real-time online alarm performance in practical production.

- Model Comparison: Observations from Figure 6 reveal that while both AE and H-AAE models can identify anomaly segments overlapping with manual annotations, the AE model only detects anomalies characterized by “significant sustained elevation or reduction” in specific segments. For example:The second anomaly segment identified by AE corresponds to a sharp global decline followed by gradual recovery; The third AE-detected anomaly segment reflects a distinct “bulge” morphology in the data; The fourth AE-detected segment combines both “bulge” and sharp decline anomalies; Additionally, AE erroneously flags the first anomaly segment due to poor robustness.To address AE’s robustness limitations, this study integrates GAN mechanisms and modifies the loss function, enabling H-AAE to recognize broader anomaly types. The modified H-AAE avoids AE’s false identifications (e.g., Segment 1) but remains reliant on detecting “significant sustained variations”, showing only marginal metric improvements.After introducing VMD postprocessing to decompose trend, periodic, and residual components, the model demonstrates enhanced performance: our model identifies anomalies during early trend declines (e.g., Anomaly segment 1 corresponding to AE’s Segment 1 and H-AAE’s Segment 2), demonstrating short-term trend detection capability; e.g., Anomaly segment 3 (mapped to AE’s Segment 4 and H-AAE’s Segment 3) successfully captures short-term fluctuations; quantitative metrics show substantial improvements in accuracy and recall, confirming the critical role of signal decomposition.

- Component-Wise Anomaly Analysis: Trend Component: Detects significant long-term increases/decreases. Undecomposed data risks masking other anomaly types under dominant trends; Periodic Component: Improved via Huber-modified loss functions, effectively identifying transient or sustained “fluctuation” patterns; Residual Component: Captures spike anomalies and short-term deviations, enabling early micro-anomaly warnings. Final anomaly results combine outputs from all three components. Component-specific anomaly types aid fault diagnosis and severity assessment, enhancing interpretability; Fusion logic adapts dynamically to operational requirements, enabling refined detection and alert strategies.While most models detect extreme-value anomalies, our method excels in identifying subtle anomalies (e.g., morphological shifts, abrupt changes) akin to expert judgment. The trend, periodic, and residual components, respectively, specialize in global trends, cyclical fluctuations, and transient peaks, with flexible fusion strategies supporting customized industrial needs.

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amano, S.; Takarabe, T.; Nakamori, T.; Oda, H.; Taira, M.; Seki, T. Expert System for Blast Furnace Operation at Kimitsu Works. ISIJ Int. 1990, 30, 105–110. [Google Scholar] [CrossRef]

- Yang, T.; Yang, S.; Zuo, G.; Wei, H.; Xu, J.; Zhou, Y. An expert system for abnormal status diagnosis and operation guide of a blast furnace. IFAC Proc. Vol. 1992, 25, 59–63. [Google Scholar] [CrossRef]

- Gao, C.; Ge, Q.; Jian, L. Rule extraction from fuzzy-based blast furnace SVM multiclassifier for decision-making. IEEE Trans. Fuzzy Syst. 2013, 22, 586–596. [Google Scholar] [CrossRef]

- Wang, H.; Sheng, C.; Lu, X. Knowledge-Based Control and Optimization of Blast Furnace Gas System in Steel Industry. IEEE Access 2017, 5, 25034–25045. [Google Scholar] [CrossRef]

- Cui, L.; Zhang, Q.; Shi, Y.; Yang, L.; Wang, Y.; Wang, J.; Bai, C. A method for satellite time series anomaly detection based on fast-DTW and improved-KNN. Chin. J. Aeronaut. 2023, 36, 149–159. [Google Scholar] [CrossRef]

- Kozitsin, V.; Katser, I.; Lakontsev, D. Online forecasting and anomaly detection based on the ARIMA model. Appl. Sci. 2021, 11, 3194. [Google Scholar]

- Çelik, M.; Dadaşer-Çelik, F.; Dokuz, A.Ş. Anomaly detection in temperature data using DBSCAN algorithm. In Proceedings of the 2011 International Symposium on Innovations in Intelligent Systems and Applications, Istanbul, Turkey, 15–18 June 2011; pp. 91–95. [Google Scholar]

- Zamanzadeh Darban, Z.; Webb, G.I.; Pan, S.; Aggarwal, C.C.; Salehi, M. Deep learning for time series anomaly detection: A survey. ACM Comput. Surv. 2024, 57, 1–42. [Google Scholar] [CrossRef]

- Kim, J.; Kang, H.; Kang, P. Time-series anomaly detection with stacked Transformer representations and 1D convolutional network. Eng. Appl. Artif. Intell. 2023, 10, 105964. [Google Scholar]

- Belay, M.A.; Blakseth, S.S.; Rasheed, A.; Rossi, P.S. Unsupervised anomaly detection for IoT-based multivariate time series: Existing solutions, performance analysis and future directions. Sensors 2023, 23, 2844. [Google Scholar]

- Ding, C.; Sun, S.; Zhao, J. MST-GAT: A multimodal spatial-temporal graph attention network for time series anomaly detection. Inf. Fusion 2023, 89, 527–536. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Ma, M.; Liu, Y.; Ding, R.; Li, B.; He, S.; Rajmohan, S.; Lin, Q.; Zhang, D. Imdiffusion: Imputed diffusion models for multivariate time series anomaly detection. arXiv 2023, arXiv:2307.00754. [Google Scholar] [CrossRef]

- Zeng, F.; Chen, M.; Qian, C.; Wang, Y.; Zhou, Y.; Tang, W. Multivariate time series anomaly detection with adversarial transformer architecture in the Internet of Things. Future Gener. Comput. Syst. 2023, 144, 244–255. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Y.; Jian, S.; Liao, Q.; Wang, Y.; Pang, G. Calibrated one-class classification for unsupervised time series anomaly detection. IEEE Trans. Knowl. Data Eng. 2024, 36, 5723–5736. [Google Scholar] [CrossRef]

- Li, H.; Zheng, W.; Tang, F.; Zhu, Y.; Huang, J. Few-shot time-series anomaly detection with unsupervised domain adaptation. Inf. Sci. 2023, 649, 119610. [Google Scholar] [CrossRef]

- Zheng, M.; Man, J.; Wang, D.; Chen, Y.; Li, Q.; Liu, Y. Semi-supervised multivariate time series anomaly detection for wind turbines using generator SCADA data. Reliab. Eng. Syst. Saf. 2023, 235, 109235. [Google Scholar] [CrossRef]

- Wang, R.; Liu, C.; Mou, X.; Gao, K.; Guo, X.; Liu, P.; Wo, T.; Liu, X. Deep contrastive one-class time series anomaly detection. In Proceedings of the 2023 SIAM International Conference on Data Mining (SDM), Minneapolis, MN, USA, 27–29 April 2023; pp. 694–702. [Google Scholar]

- He, X.; Li, Y.; Tan, J.; Wu, B.; Li, F. OneShotSTL: One-shot seasonal-trend decomposition for online time series anomaly detection and forecasting. arXiv 2023, arXiv:2304.01506. [Google Scholar] [CrossRef]

- Ergen, T.; Kozat, S.S. Unsupervised anomaly detection with LSTM neural networks. IEEE Trans. Neural Netw. Learn. Syst. 2019, 31, 3127–3141. [Google Scholar] [CrossRef]

- Malhotra, P.; Ramakrishnan, A.; An, G.; Vig, L.; Agarwal, P.; Shroff, G. LSTM-based encoder-decoder for multi-sensor anomaly detection. arXiv 2016, arXiv:1607.00148. [Google Scholar]

- Gong, D.; Liu, L.; Le, V.; Saha, B.; Mansour, M.R.; Venkatesh, S.; Hengel, A.V.D. Memorizing normality to detect anomaly: Memory-augmented deep autoencoder for unsupervised anomaly detection. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Seoul, Korea, 27 October–2 November 2019; pp. 1705–1714. [Google Scholar]

- Chen, H.; Liu, H.; Chu, X.; Liu, Q.; Xue, D. Anomaly detection and critical SCADA parameters identification for wind turbines based on LSTM-AE neural network. Renew. Energy 2021, 172, 829–840. [Google Scholar] [CrossRef]

- Wang, Z.; Pei, C.; Ma, M.; Wang, X.; Li, Z.; Pei, D.; Rajmohan, S.; Zhang, D.; Lin, Q.; Zhang, H.; et al. Revisiting VAE for Unsupervised Time Series Anomaly Detection: A Frequency Perspective. In Proceedings of the ACM on Web Conference 2024, Singapore, 13–17 May 2024; pp. 3096–3105. [Google Scholar]

- Huang, T.; Chen, P.; Li, R. A semi-supervised VAE based active anomaly detection framework in multivariate time series for online systems. In Proceedings of the ACM Web Conference 2022, Lyon, France, 25–29 April 2022; pp. 1797–1806. [Google Scholar]

- Niu, Z.; Yu, K.; Wu, X. LSTM-based VAE-GAN for time-series anomaly detection. Sensors 2020, 20, 3738. [Google Scholar] [CrossRef]

- Audibert, J.; Michiardi, P.; Guyard, F.; Marti, S.; Zuluaga, M.A. USAD: Unsupervised anomaly detection on multivariate time series. In Proceedings of the 26th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Virtual, 6–10 July 2020; pp. 3395–3404. [Google Scholar]

- Zhang, H.; Song, Z.; Yang, J.; Gao, Y. Adversarial Autoencoder Empowered Joint Anomaly Detection and Signal Reconstruction From Sub-Nyquist Samples. IEEE Trans. Cogn. Commun. Netw. 2023, 9, 618–628. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, B.; Guo, J.; Zhang, K.; Liu, P. A lightweight unsupervised adversarial detector based on autoencoder and isolation forest. Pattern Recognit. 2024, 147, 110127. [Google Scholar] [CrossRef]

- Zhou, Y.; Liang, X.; Zhang, W.; Zhang, L.; Song, X. VAE-based Deep SVDD for anomaly detection. Neurocomputing 2021, 453, 131–140. [Google Scholar]

- Liu, S.; Lang, X.; Wu, J.; Zhang, Y.; Lei, C.; Su, H. Corrective variational mode decomposition to detect multiple oscillations in process control systems. Control Eng. Pract. 2025, 154, 106123. [Google Scholar]

- Wang, H.; Liu, X.; Ma, L.; Zhang, Y. Anomaly detection for hydropower turbine unit based on variational modal decomposition and deep autoencoder. Energy Rep. 2021, 7, 938–946. [Google Scholar] [CrossRef]

- Guan, K.; Gong, X. A new hybrid deep learning model for monthly oil prices forecasting. Energy Econ. 2023, 128, 107136. [Google Scholar] [CrossRef]

- Ergun, S. Pressure drop in blast furnace and in cupola. Ind. Eng. Chem. 1953, 45, 477–485. [Google Scholar] [CrossRef]

- Clevel, R.B.; Clevel, W.S.; McRae, J.E. STL: A seasonal-trend decomposition. J. Off. Stat. 1990, 6, 3–73. [Google Scholar]

- Yang, S.; Deng, Z.; Li, X.; Zheng, C.; Xi, L.; Zhuang, J.; Zhang, Z.; Zhang, Z. A novel hybrid model based on STL decomposition and one-dimensional convolutional neural networks with positional encoding for significant wave height forecast. Renew. Energy 2021, 173, 531–543. [Google Scholar] [CrossRef]

| Model | Precision | Recall | F1-Score |

|---|---|---|---|

| IsoForest | 1.00 | 0.46 | 0.63 |

| LOF | 1.00 | 0.19 | 0.31 |

| PCA | 0.82 | 0.50 | 0.62 |

| HBOS | 1.00 | 0.49 | 0.66 |

| Proposed | 0.95 | 0.91 | 0.93 |

| Model | Precision | Recall | F1-Score |

|---|---|---|---|

| AE | 0.88 | 0.82 | 0.85 |

| H-AAE | 0.92 | 0.82 | 0.86 |

| Proposed | 0.95 | 0.91 | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Zhu, J.; Tang, B.; Jiang, Z. Automated Anomaly Detection in Blast Furnace Shaft Static Pressure Using Adversarial Autoencoders and Mode Decomposition. Sensors 2025, 25, 3473. https://doi.org/10.3390/s25113473

Sun X, Zhu J, Tang B, Jiang Z. Automated Anomaly Detection in Blast Furnace Shaft Static Pressure Using Adversarial Autoencoders and Mode Decomposition. Sensors. 2025; 25(11):3473. https://doi.org/10.3390/s25113473

Chicago/Turabian StyleSun, Xiaodong, Jie Zhu, Bing Tang, and Zhaohui Jiang. 2025. "Automated Anomaly Detection in Blast Furnace Shaft Static Pressure Using Adversarial Autoencoders and Mode Decomposition" Sensors 25, no. 11: 3473. https://doi.org/10.3390/s25113473

APA StyleSun, X., Zhu, J., Tang, B., & Jiang, Z. (2025). Automated Anomaly Detection in Blast Furnace Shaft Static Pressure Using Adversarial Autoencoders and Mode Decomposition. Sensors, 25(11), 3473. https://doi.org/10.3390/s25113473