Fuzzy-Based Sensor Fusion for Cognitive Load Assessment in Inclusive Manufacturing Strategies

Abstract

1. Introduction

2. Literature Review

2.1. Single Technologies

2.2. Sensor Fusion

2.3. Human–Robot Collaboration and Cognitive Workload Assessment

2.4. Integration with Machine Learning for Enhanced Assessment

2.5. Implications for Neurodiverse Populations in Industrial Settings

3. Research Framework and Methodology

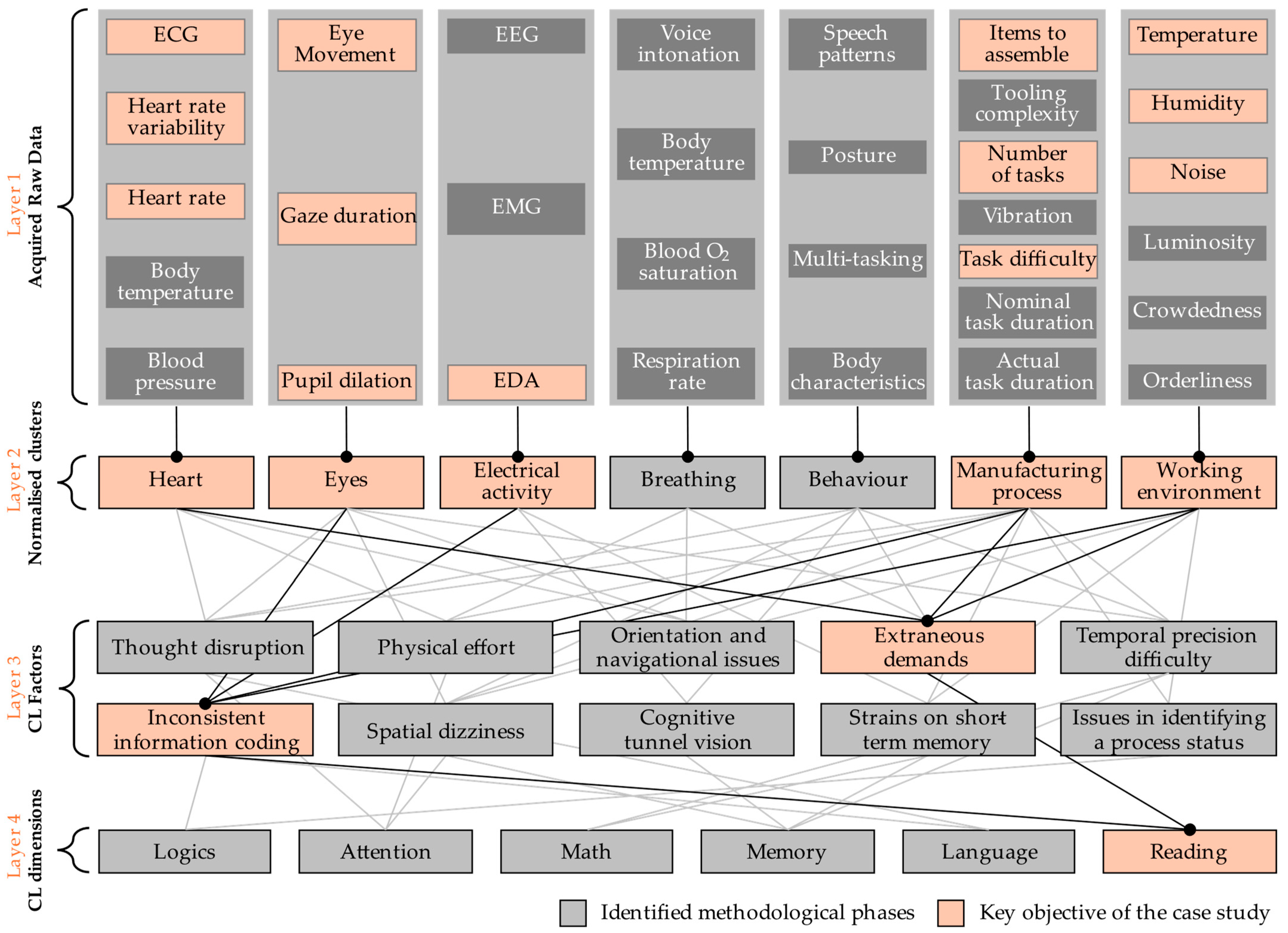

3.1. Layer-Wise Structure

3.1.1. Layer 1: Acquired Raw Data

3.1.2. Layer 2: Normalised Variable Clusters

3.1.3. Layer 3: Cognitive Load Factors

- Thought disruption: Refers to interruptions that break the continuity of mental processing, leading to fragmented cognitive flow and reduced task performance;

- Physical effort: Captures the mental burden associated with physically demanding tasks, such as manual operations or sustained postural exertion;

- Orientation and navigation problems: Encompass the cognitive load required to interpret spatial layouts or navigate through physical or procedural environments;

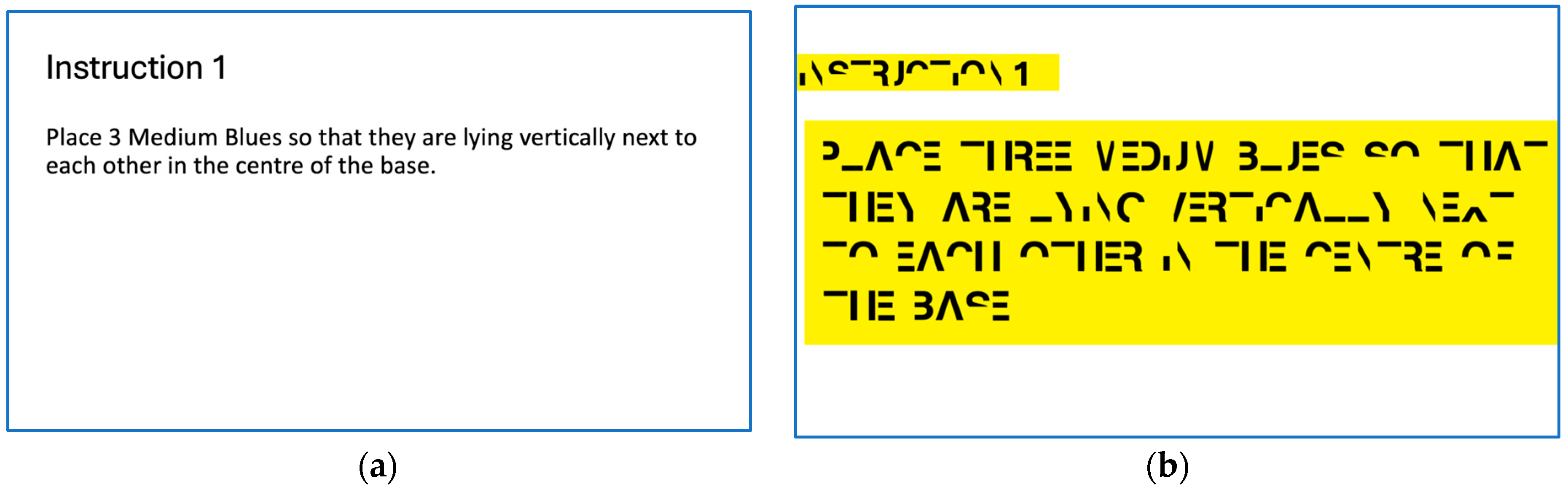

- Extraneous demands: Mental effort imposed by inefficient tasks or system design, such as unclear instructions, redundant steps, or poorly organized interfaces. These demands consume attention and processing resources without contributing to task goals, often hindering performance and increasing the likelihood of error;

- Temporal precision difficulty: Refers to increased cognitive effort when tasks demand strict timing coordination or synchronization with external events;

- Inconsistent information coding: Reflects the mental effort required to reconcile or interpret data presented in varying formats or terminologies;

- Spatial dizziness: Involves disorientation due to complex or rapidly changing spatial environments, affecting situational awareness;

- Cognitive tunnel vision: A narrowing of attention where the individual fixates on certain elements of a task while neglecting others, often induced by high workload or stress;

- Strains on short-term memory: Reflects overload in working memory capacity due to complex tasks or environmental distractions, impairing temporary information storage and manipulation;

- Issues in identifying process status: Represents challenges in monitoring and understanding the current state of a process, often due to poor system feedback or unclear indicators.

3.1.4. Layer 4: Cognitive Load Dimensions

- 11.

- Logic: The ability to engage in logical reasoning and process information for decision making;

- 12.

- Attention: The ability to maintain focus and awareness in the face of distractions or task demands;

- 13.

- Mathematics: Challenges associated with performing calculations or engaging in tasks that require numerical skills;

- 14.

- Memory: The recall and application of information in the short term;

- 15.

- Language: Understanding and using language to carry out tasks;

- 16.

- Reading: The ability to read and interpret written material, distinguishing relevant information from irrelevant information.

3.2. Data Processing

3.3. Fuzzy Logic Modelling

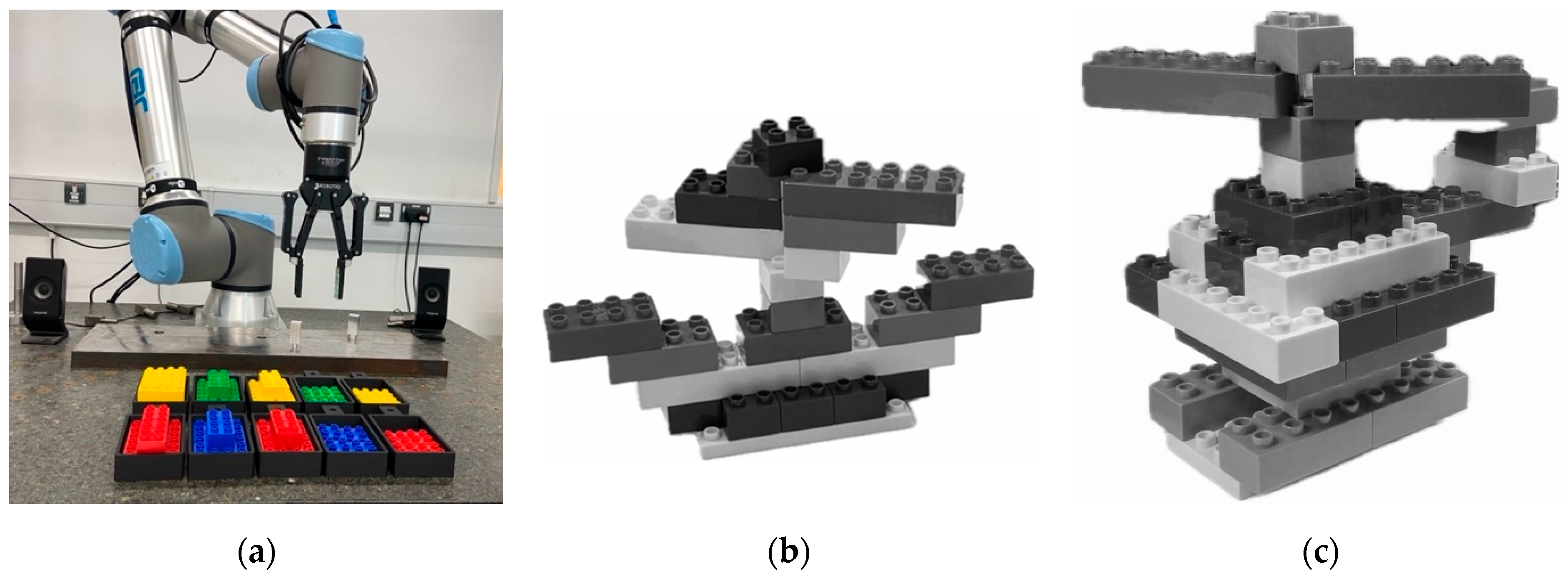

4. Case Study

4.1. Participants

4.2. Data Acquisition

4.3. Cognitive Load Assessment

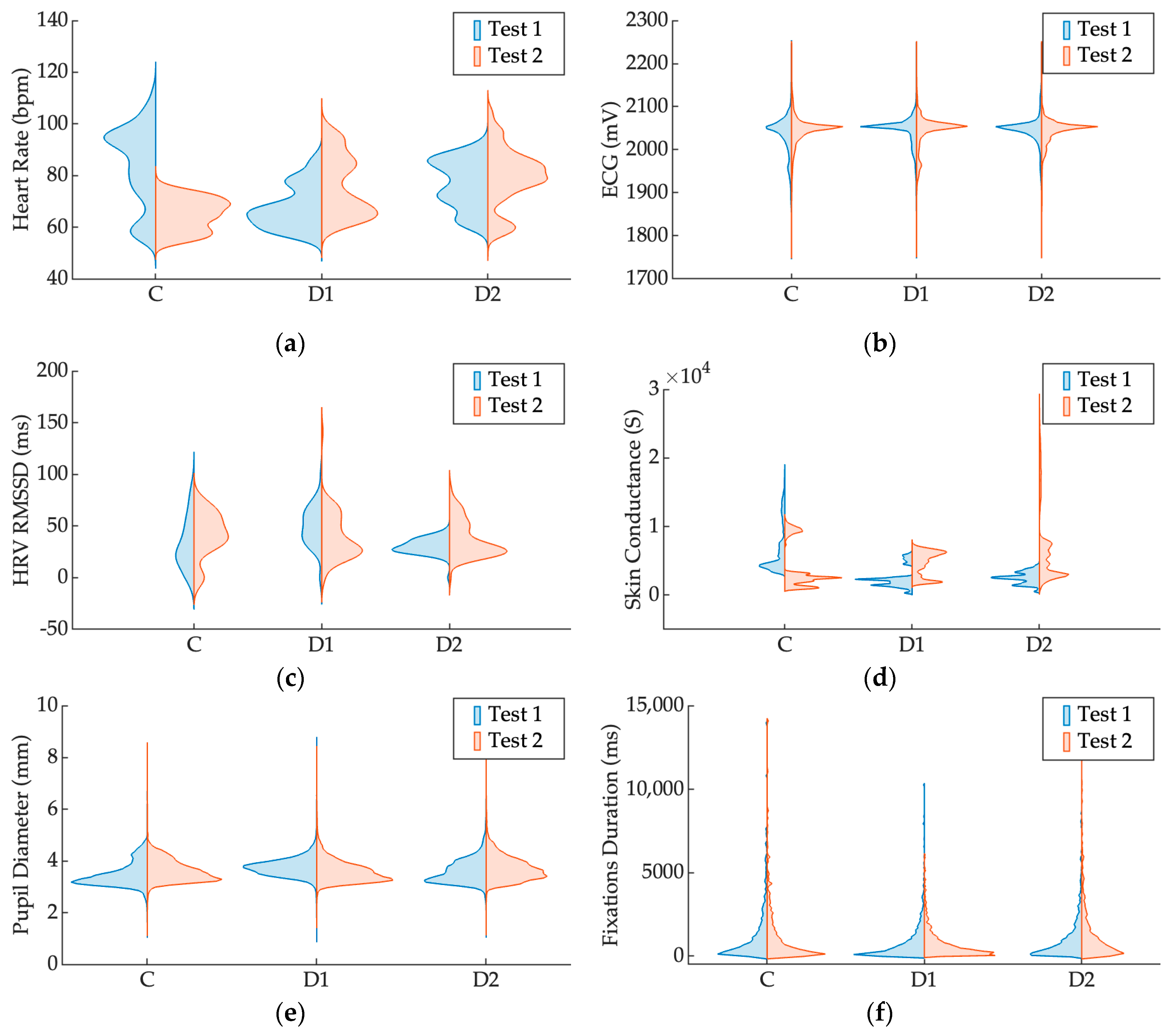

5. Results and Discussion

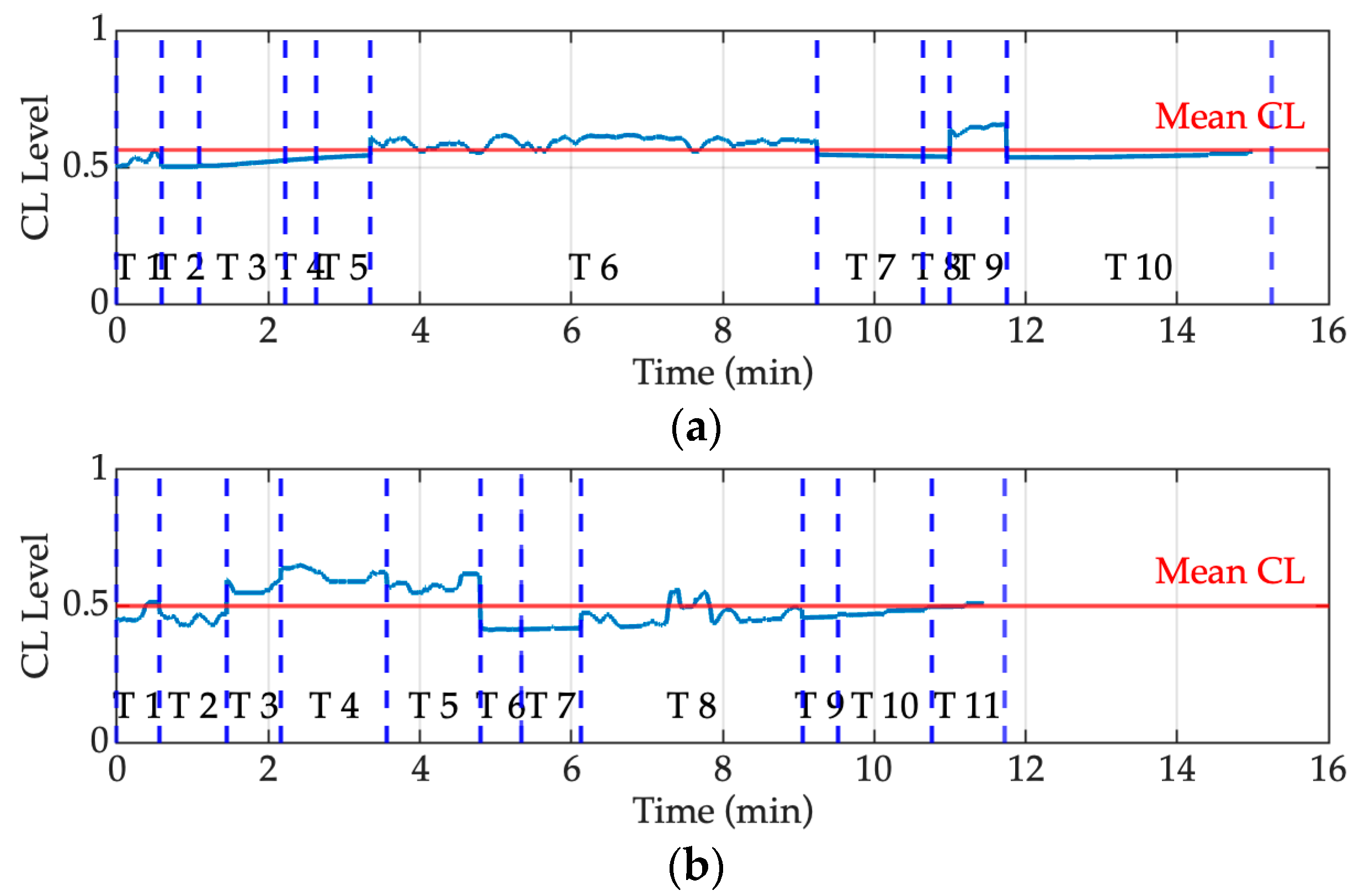

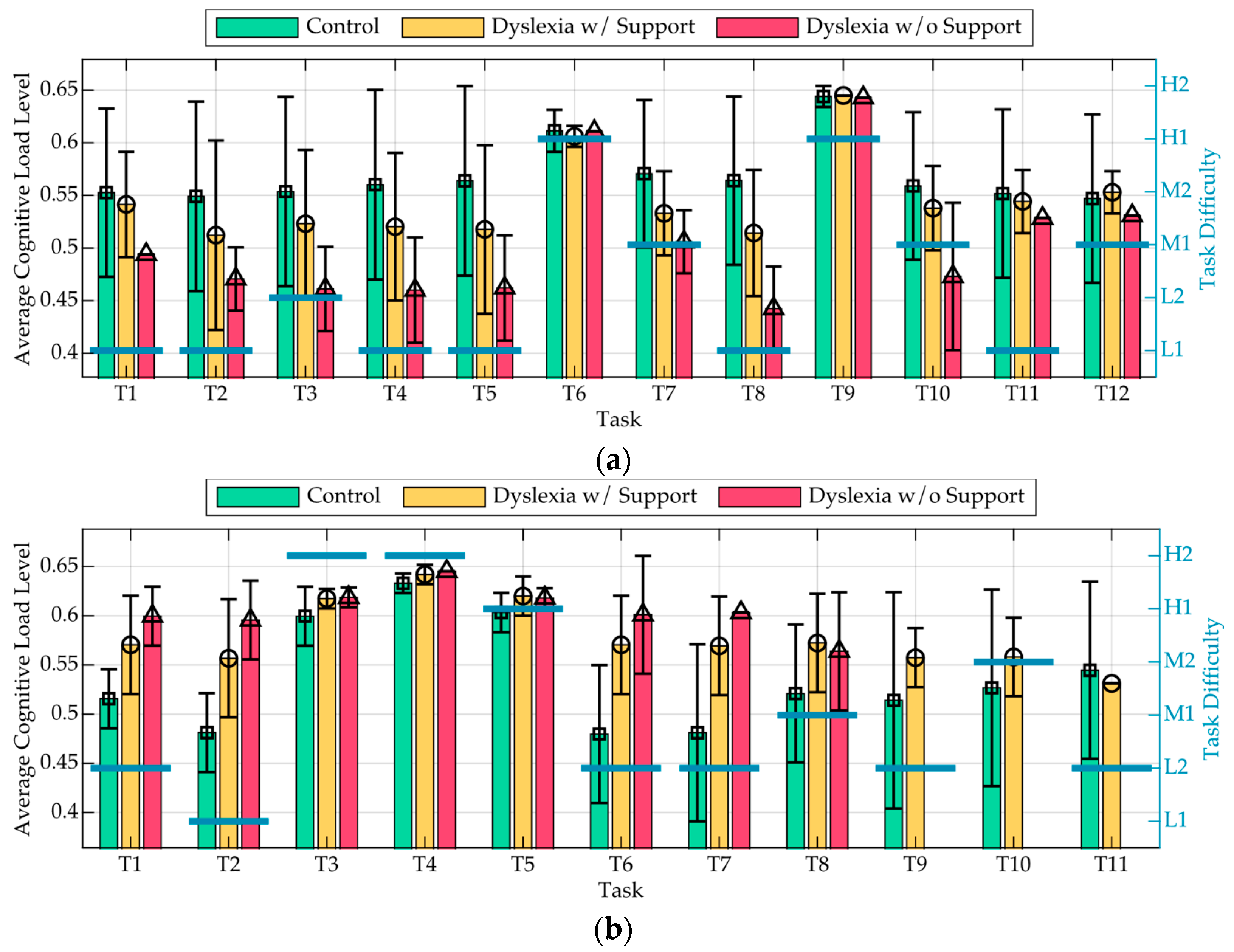

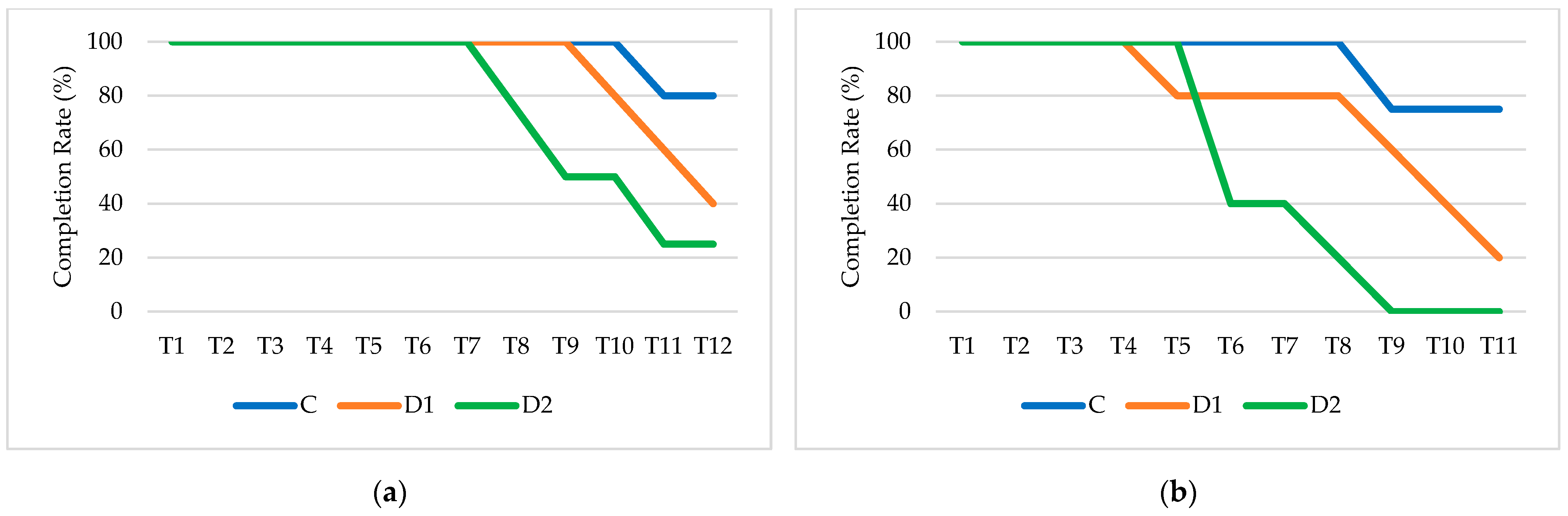

5.1. Cognitive Load Results

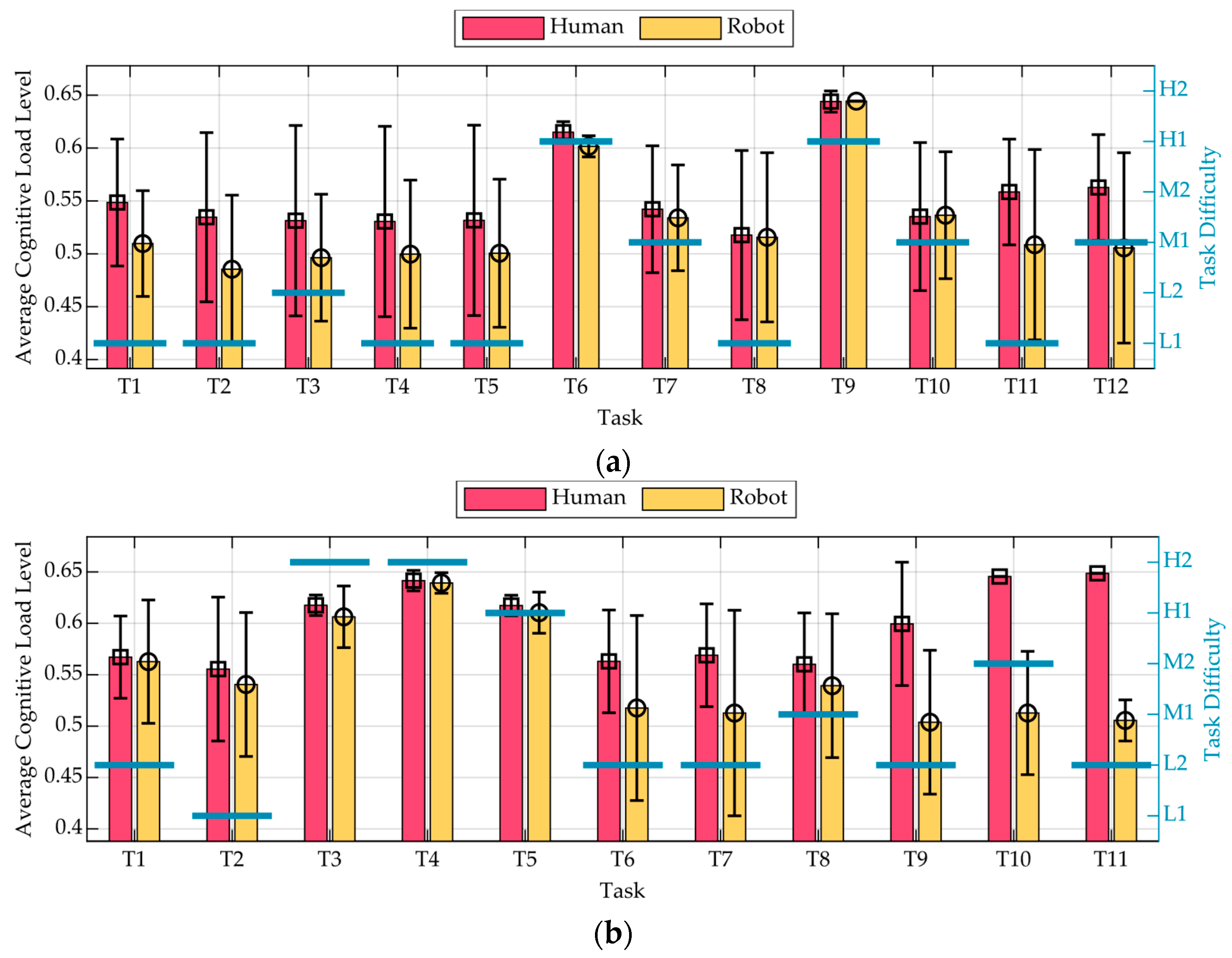

5.2. Human–Robot Assistance Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moore, C.B.; McIntyre, N.H.; Lanivich, S.E. ADHD-Related Neurodiversity and the Entrepreneurial Mindset. Entrep. Theory Pract. 2021, 45, 64–91. [Google Scholar] [CrossRef]

- Lauder, K. Towards Neuro-Inclusive Workplaces: Insights From Neurodivergent Individuals in a Conservation-Based Organization. J. Organ. Psychol. 2025, 24, 128–145. [Google Scholar] [CrossRef]

- Blackburn, B. Managing Neurodiversity in Workplaces. Occup. Med. (Chic. Ill.) 2023, 73, 57–58. [Google Scholar] [CrossRef] [PubMed]

- Doyle, N. Neurodiversity at Work: A Biopsychosocial Model and the Impact on Working Adults. Br. Med. Bull. 2020, 135, 108–125. [Google Scholar] [CrossRef]

- Macdonald, S.J.; Cosgrove, F. Dyslexia and Policing. Equal. Divers. Incl. Int. J. 2019, 38, 634–651. [Google Scholar] [CrossRef]

- Perrachione, T.K.; Del Tufo, S.N.; Winter, R.; Murtagh, J.; Cyr, A.; Chang, P.; Halverson, K.; Ghosh, S.S.; Christodoulou, J.A.; Gabrieli, J.D.E. Dysfunction of Rapid Neural Adaptation in Dyslexia. Neuron 2016, 92, 1383–1397. [Google Scholar] [CrossRef] [PubMed]

- Pricope, M.; Mazilu, S.; Popa, F. Online tools for introducing neurodiversity in job interviews with engineering students. eLearning Softw. Educ. 2020, 3, 471–479. [Google Scholar]

- Kersten, A.; Scholz, F.; van Woerkom, M.; Krabbenborg, M.; Smeets, L. A Strengths-Based Human Resource Management Approach to Neurodiversity: A Multi-Actor Qualitative Study. Hum. Resour. Manage 2025, 64, 229–245. [Google Scholar] [CrossRef]

- Bertelli, M.O.; De Groef, J.; Rondini, E. Phenomenological Psychopathology of Neurodiversity. In The Oxford Handbook of Phenomenological Psychopathology; Stanghellini, G., Broome, M., Raballo, A., Fernandez, A.V., Fusar-Poli, P., Rosfort, R., Eds.; Oxford University Press: Oxford, UK, 2019; pp. 1077–1108. [Google Scholar]

- Abidi, S.; Hadi, N. The Future of Neurodiversity in the Workplace: Opportunities and Challenges. Psychol. Res. Individ. Except. Needs 2024, 2, 8. [Google Scholar] [CrossRef]

- Shah, P.; Holmes, J. Neurodiversity: Towards an Interdisciplinary Approach. Neurodiversity 2023, 1. [Google Scholar] [CrossRef]

- Rollnik-Sadowska, E.; Grabińska, V. Managing Neurodiversity in Workplaces: A Review and Future Research Agenda for Sustainable Human Resource Management. Sustainability 2024, 16, 6594. [Google Scholar] [CrossRef]

- Silver, E.R.; Nittrouer, C.L.; Hebl, M.R. Beyond the Business Case: Universally Designing the Workplace for Neurodiversity and Inclusion. Ind. Organ. Psychol. 2023, 16, 45–49. [Google Scholar] [CrossRef]

- Zakeri, Z.; Arif, A.; Omurtag, A.; Breedon, P.; Khalid, A. Multimodal Assessment of Cognitive Workload Using Neural, Subjective and Behavioural Measures in Smart Factory Settings. Sensors 2023, 23, 8926. [Google Scholar] [CrossRef]

- Paliga, M. The Relationships of Human-Cobot Interaction Fluency with Job Performance and Job Satisfaction among Cobot Operators—The Moderating Role of Workload. Int. J. Environ. Res. Public Health 2023, 20, 5111. [Google Scholar] [CrossRef]

- Al Fawwaz, A.; Rahma, O.N.; Ain, K.; Ittaqillah, S.I.; Chai, R. Measurement of Mental Workload Using Heart Rate Variability and Electrodermal Activity. IEEE Access 2024, 12, 197589–197601. [Google Scholar] [CrossRef]

- Delliaux, S.; Delaforge, A.; Deharo, J.-C.; Chaumet, G. Mental Workload Alters Heart Rate Variability, Lowering Non-Linear Dynamics. Front. Physiol. 2019, 10, 565. [Google Scholar] [CrossRef]

- Schaich, C.L.; Malaver, D.; Chen, H.; Shaltout, H.A.; Zeki Al Hazzouri, A.; Herrington, D.M.; Hughes, T.M. Association of Heart Rate Variability With Cognitive Performance: The Multi-Ethnic Study of Atherosclerosis. J. Am. Heart Assoc. 2020, 9, e013827. [Google Scholar] [CrossRef] [PubMed]

- Nicolini, P.; Malfatto, G.; Lucchi, T. Heart Rate Variability and Cognition: A Narrative Systematic Review of Longitudinal Studies. J. Clin. Med. 2024, 13, 280. [Google Scholar] [CrossRef] [PubMed]

- Posada-Quintero, H.F.; Chon, K.H. Innovations in Electrodermal Activity Data Collection and Signal Processing: A Systematic Review. Sensors 2020, 20, 479. [Google Scholar] [CrossRef]

- Shukla, J.; Barreda-Angeles, M.; Oliver, J.; Nandi, G.C.; Puig, D. Feature Extraction and Selection for Emotion Recognition from Electrodermal Activity. IEEE Trans. Affect. Comput. 2021, 12, 857–869. [Google Scholar] [CrossRef]

- Kyriakou, K.; Resch, B.; Sagl, G.; Petutschnig, A.; Werner, C.; Niederseer, D.; Liedlgruber, M.; Wilhelm, F.; Osborne, T.; Pykett, J. Detecting Moments of Stress from Measurements of Wearable Physiological Sensors. Sensors 2019, 19, 3805. [Google Scholar] [CrossRef]

- Krebl, M.; Podlesek, A.; Geršak, G. A Study of Baseline in Psychophysiological Experiments. In Proceedings of the 8th European Medical and Biological Engineering Conference, Portorož, Slovenia, 29 November–3 December 2020; pp. 45–50. [Google Scholar]

- Skaramagkas, V.; Giannakakis, G.; Ktistakis, E.; Manousos, D.; Karatzanis, I.; Tachos, N.; Tripoliti, E.; Marias, K.; Fotiadis, D.I.; Tsiknakis, M. Review of Eye Tracking Metrics Involved in Emotional and Cognitive Processes. IEEE Rev. Biomed. Eng. 2023, 16, 260–277. [Google Scholar] [CrossRef] [PubMed]

- Qu, H.; Gao, X.; Pang, L. Classification of Mental Workload Based on Multiple Features of ECG Signals. Inform. Med. Unlocked 2021, 24, 100575. [Google Scholar] [CrossRef]

- Debie, E.; Fernandez Rojas, R.; Fidock, J.; Barlow, M.; Kasmarik, K.; Anavatti, S.; Garratt, M.; Abbass, H.A. Multimodal Fusion for Objective Assessment of Cognitive Workload: A Review. IEEE Trans. Cybern. 2021, 51, 1542–1555. [Google Scholar] [CrossRef] [PubMed]

- Affanni, A. Wireless Sensors System for Stress Detection by Means of ECG and EDA Acquisition. Sensors 2020, 20, 2026. [Google Scholar] [CrossRef]

- Bussolan, A.; Baraldo, S.; Gambardella, L.M.; Valente, A. Multimodal Fusion Stress Detector for Enhanced Human-Robot Collaboration in Industrial Assembly Tasks. In Proceedings of the 2024 33rd IEEE International Conference on Robot and Human Interactive Communication (ROMAN), Pasadena, CA, USA, 26–30 August 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 978–984. [Google Scholar]

- Ayres, P.; Lee, J.Y.; Paas, F.; van Merriënboer, J.J.G. The Validity of Physiological Measures to Identify Differences in Intrinsic Cognitive Load. Front. Psychol. 2021, 12, 702538. [Google Scholar] [CrossRef]

- Vanneste, P.; Raes, A.; Morton, J.; Bombeke, K.; Van Acker, B.B.; Larmuseau, C.; Depaepe, F.; Van den Noortgate, W. Towards Measuring Cognitive Load through Multimodal Physiological Data. Cogn. Technol. Work. 2021, 23, 567–585. [Google Scholar] [CrossRef]

- Ma, X.; Monfared, R.; Grant, R.; Goh, Y.M. Determining Cognitive Workload Using Physiological Measurements: Pupillometry and Heart-Rate Variability. Sensors 2024, 24, 2010. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Y.; Tao, H.; Ye, Z.; Wang, S.; Li, H.; Hu, D.; Zhou, Z.; Zeng, L.-L. Cognitive Load Prediction from Multimodal Physiological Signals Using Multiview Learning. IEEE J. Biomed. Health Inform. 2023, 29, 3282–3292. [Google Scholar] [CrossRef]

- Kuttala, R.; Subramanian, R.; Oruganti, V.R.M. Multimodal Hierarchical CNN Feature Fusion for Stress Detection. IEEE Access 2023, 11, 6867–6878. [Google Scholar] [CrossRef]

- Gualtieri, L.; Fraboni, F.; De Marchi, M.; Rauch, E. Development and Evaluation of Design Guidelines for Cognitive Ergonomics in Human-Robot Collaborative Assembly Systems. Appl. Ergon. 2022, 104, 103807. [Google Scholar] [CrossRef]

- Rajavenkatanarayanan, A.; Nambiappan, H.R.; Kyrarini, M.; Makedon, F. Towards a Real-Time Cognitive Load Assessment System for Industrial Human-Robot Cooperation. In Proceedings of the 2020 29th IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), Naples, Italy, 31 August–4 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 698–705. [Google Scholar]

- Wang, C.; Li, X.; Huang, J.; Zhao, P.; Wang, M.; Zhuang, G.; Sun, X. A Framework for Cognitive Load Recognition Based on Machine Learning and Multimodal Physiological Signals by Wearable Sensors. In Proceedings of the 2023 IEEE 4th International Conference on Pattern Recognition and Machine Learning (PRML), Urumqi, China, 4–6 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 299–306. [Google Scholar]

- Guo, H.; Wu, B.; Li, Q.; Ding, Z.; Jiang, F.; Yi, C. Investigating the Impact of Cognitive Load on Human Trust in Hybrid Human-Robot Collaboration. Preprint 2024. [Google Scholar]

- Hopko, S.K.; Mehta, R.K.; Pagilla, P.R. Physiological and Perceptual Consequences of Trust in Collaborative Robots: An Empirical Investigation of Human and Robot Factors. Appl. Ergon. 2023, 106, 103863. [Google Scholar] [CrossRef]

- Safari, M.; Shalbaf, R.; Bagherzadeh, S.; Shalbaf, A. Classification of Mental Workload Using Brain Connectivity and Machine Learning on Electroencephalogram Data. Sci. Rep. 2024, 14, 9153. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Smythe, D.; Cao, J.; Hu, Z.; Proctor, K.J.; Owens, A.P.; Zhao, Y. Characterisation of Cognitive Load Using Machine Learning Classifiers of Electroencephalogram Data. Sensors 2023, 23, 8528. [Google Scholar] [CrossRef] [PubMed]

- Afzal, M.A.; Gu, Z.; Bukhari, S.U.; Afzal, B. Brainwaves in the Cloud: Cognitive Workload Monitoring Using Deep Gated Neural Network and Industrial Internet of Things. Appl. Sci. 2024, 14, 5830. [Google Scholar] [CrossRef]

- Fan, Y.; Antonelli, D.; Simeone, A.; Bao, N. Intelligent Robot Assistants for the Integration of Neurodiverse Operators in Manufacturing Industry. Procedia CIRP 2024, 126, 236–241. [Google Scholar] [CrossRef]

- Dai, X.; Vitrano, G. Evaluating Mental Workload Measures in Human-Robot Collaborative Assembly. In Proceedings of the 2024 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 15–18 December 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1059–1063. [Google Scholar]

- Biondi, F.N.; Cacanindin, A.; Douglas, C.; Cort, J. Overloaded and at Work: Investigating the Effect of Cognitive Workload on Assembly Task Performance. Hum. Factors J. Hum. Factors Ergon. Soc. 2021, 63, 813–820. [Google Scholar] [CrossRef]

- Simeone, A.; Fan, Y.; Antonelli, D.; Catalano, A.R.; Priarone, P.C.; Settineri, L. Inclusive Manufacturing: A Contribution to Assembly Processes with Human-Machine Reciprocal Learning. CIRP Ann. 2024, 73, 5–8. [Google Scholar] [CrossRef]

- Liu, J.-C.; Li, K.-A.; Yeh, S.-L.; Chien, S.-Y. Assessing Perceptual Load and Cognitive Load by Fixation-Related Information of Eye Movements. Sensors 2022, 22, 1187. [Google Scholar] [CrossRef]

- Hossain, M.-B.; Kong, Y.; Posada-Quintero, H.F.; Chon, K.H. Comparison of Electrodermal Activity from Multiple Body Locations Based on Standard EDA Indices’ Quality and Robustness against Motion Artifact. Sensors 2022, 22, 3177. [Google Scholar] [CrossRef] [PubMed]

- Ansori, N.; Pratama, F.R.A.; Agustina, F.; Utami, I.D.; Widiaswanti, E.; Annisa, R. Compromise Parameters of Temperature, Light, and Noise in Confined Spaces on Work Duration and Number of Errors. In Proceedings of the The 8th Mechanical Engineering, Science and Technology International Conference, Perlis, Malaysia, 11–12 December 2024; MDPI: Basel, Switzerland, 2025; p. 4. [Google Scholar]

- Alessa, F.M.; Alhaag, M.H.; Al-harkan, I.M.; Nasr, M.M.; Kaid, H.; Hammami, N. Evaluating Physical Stress across Task Difficulty Levels in Augmented Reality-Assisted Industrial Maintenance. Appl. Sci. 2023, 14, 363. [Google Scholar] [CrossRef]

- Oppelt, M.P.; Foltyn, A.; Deuschel, J.; Lang, N.R.; Holzer, N.; Eskofier, B.M.; Yang, S.H. ADABase: A Multimodal Dataset for Cognitive Load Estimation. Sensors 2022, 23, 340. [Google Scholar] [CrossRef]

- Mahajan, R.; Bansal, D. Identification of Heart Beat Abnormality Using Heart Rate and Power Spectral Analysis of ECG. In Proceedings of the 2015 International Conference on Soft Computing Techniques and Implementations (ICSCTI), Faridabad, India, 8–10 October 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 131–135. [Google Scholar]

- Pretty, E.J.; Guarese, R.; Dziego, C.A.; Fayek, H.M.; Zambetta, F. Multimodal Measurement of Cognitive Load in a Video Game Context: A Comparative Study Between Subjective and Objective Metrics. IEEE Trans. Games 2024, 16, 854–867. [Google Scholar] [CrossRef]

- Gabr, W.; Dorrah, H.T. New Fuzzy Logic-Based Arithmetic and Visual Representations for Systems’ Modelling and Optimization. In Proceedings of the 2008 IEEE International Conference on Robotics and Biomimetics, Bangkok, Thailand, 21–26 February 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 715–722. [Google Scholar]

- Arutyunova, K.R.; Bakhchina, A.V.; Konovalov, D.I.; Margaryan, M.; Filimonov, A.V.; Shishalov, I.S. Heart Rate Dynamics for Cognitive Load Estimation in a Driving Simulation Task. Sci. Rep. 2024, 14, 31656. [Google Scholar] [CrossRef]

- Krejtz, K.; Duchowski, A.T.; Niedzielska, A.; Biele, C.; Krejtz, I. Eye Tracking Cognitive Load Using Pupil Diameter and Microsaccades with Fixed Gaze. PLoS ONE 2018, 13, e0203629. [Google Scholar] [CrossRef]

- Rahma, O.N.; Putra, A.P.; Rahmatillah, A.; Putri, Y.S.K.A.; Fajriaty, N.D.; Ain, K.; Chai, R. Electrodermal Activity for Measuring Cognitive and Emotional Stress Level. J. Med. Signals Sens. 2022, 12, 155–162. [Google Scholar] [CrossRef]

- Thorvald, P.; Lindblom, J.; Andreasson, R. On the Development of a Method for Cognitive Load Assessment in Manufacturing. Robot. Comput. Integr. Manuf. 2019, 59, 252–266. [Google Scholar] [CrossRef]

- Taylor, L.; Watkins, S.L.; Marshall, H.; Dascombe, B.J.; Foster, J. The Impact of Different Environmental Conditions on Cognitive Function: A Focused Review. Front. Physiol. 2016, 6, 372. [Google Scholar] [CrossRef]

- Simeone, A.; Grant, R.; Ye, W.; Caggiano, A. A Human-Cyber-Physical System for Operator 5.0 Smart Risk Assessment. Int. J. Adv. Manuf. Technol. 2023, 129, 2763–2782. [Google Scholar] [CrossRef]

- Galy, E.; Cariou, M.; Mélan, C. What Is the Relationship between Mental Workload Factors and Cognitive Load Types? Int. J. Psychophysiol. 2012, 83, 269–275. [Google Scholar] [CrossRef] [PubMed]

- Karmakar, S.; Koley, C.; Sinha, A.; Saha, S.K.; Pal, T. Fuzzy Rule-Based Approach Towards Cognitive Load Measurement During Mental Task Using FNIRS. In Proceedings of the Pattern Recognition and Machine Intelligence, Kolkata, India, 12–15 December 2023; pp. 577–586. [Google Scholar]

- Chen, S.; Anwar, U.; Kirton-Wingate, J.; Doctor, F.; Hussain, A.; Zhou, T.; Anwary, A.; Dashtipour, K.K.; Gogate, M.; Hou, J.-C.; et al. Mobile Phone-Based Speech Enhancement Using Cognitive Load and Fuzzy Reasoning for Normal and Hearing-Impaired Users. In Proceedings of the 3rd COG-MHEAR Workshop on Audio-Visual Speech Enhancement (AVSEC), Kos, Greece, 1 September 2024; ISCA: Sydney, Australia, 2024; pp. 56–60. [Google Scholar]

- Aarif, M.; Anjum, A.; Sharma, T.; Arikrishnan, A.; Rao, V.S.; Balakumar, A. Implementing Fuzzy Logic in Cognitive Sensor Networks for Environmental Monitoring. In Proceedings of the 2024 Third International Conference on Electrical, Electronics, Information and Communication Technologies (ICEEICT), Trichirappalli, India, 24–26 July 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Snowling, M.J.; Hulme, C.; Nation, K. Defining and Understanding Dyslexia: Past, Present and Future. Oxf. Rev. Educ. 2020, 46, 501–513. [Google Scholar] [CrossRef] [PubMed]

- Kizilaslan, A.; Tunagür, M. Dyslexia and Working Memory: Understanding Reading Comprehension and High Level Language Skills in Students with Dyslexia. Kastamonu Eğitim Derg. 2021, 29, 941–952. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, J.; Jiang, W.; Sui, Y.; Wu, Y.; Ma, S.; Kang, C.; Li, H. Influences of Augmented Reality Assistance on Performance and Cognitive Loads in Different Stages of Assembly Task. Front. Psychol. 2019, 10, 1703. [Google Scholar] [CrossRef]

- Fournier, É.; Kilgus, D.; Landry, A.; Hmedan, B.; Pellier, D.; Fiorino, H.; Jeoffrion, C. The Impacts of Human-Cobot Collaboration on Perceived Cognitive Load and Usability during an Industrial Task: An Exploratory Experiment. IISE Trans. Occup. Ergon. Hum. Factors 2023, 10, 83–90. [Google Scholar] [CrossRef]

- Stark, Z.; Franzen, L.; Johnson, A.P. Insights from a Dyslexia Simulation Font: Can We Simulate Reading Struggles of Individuals with Dyslexia. Dyslexia 2020, 28, 228–243. [Google Scholar] [CrossRef]

- Daniel Britton Dyslexia—Typographic Design. Available online: https://danielbritton.info/dyslexia/ (accessed on 5 March 2025).

- Derawi, H.; Reinisch, E.; Gabay, Y. Increased Reliance on Top-down Information to Compensate for Reduced Bottom-up Use of Acoustic Cues in Dyslexia. Psychon. Bull. Rev. 2022, 29, 281–292. [Google Scholar] [CrossRef]

- Law, M.K.H.; Stankov, L.; Kleitman, S. I Choose to Opt-Out of Answering: Individual Differences in Giving Up Behaviour on Cognitive Tests. J. Intell. 2022, 10, 86. [Google Scholar] [CrossRef]

| Participant | Pre-Test | Test 1 | Test 2 | Assistance |

|---|---|---|---|---|

| Participant 1 | Baseline | Dyslexia with support | Control | Human |

| Participant 2 | Baseline | Control | Dyslexia with support | Human |

| Participant 3 | Baseline | Dyslexia without support | Control | Human |

| Participant 4 | Baseline | Control | Dyslexia without support | Human |

| Participant 5 | Baseline | Dyslexia with support | Dyslexia without support | Human |

| Participant 6 | Baseline | Dyslexia without support | Dyslexia with support | Human |

| Participant 7 | Baseline | Dyslexia with support | Dyslexia with support | Human |

| Participant 8 | Baseline | Dyslexia without support | Dyslexia without support | Human |

| Participant 9 | Baseline | Control | Control | Human |

| Participant 10 | Baseline | Dyslexia with support | Control | Robot |

| Participant 11 | Baseline | Control | Dyslexia with support | Robot |

| Participant 12 | Baseline | Dyslexia without support | Control | Robot |

| Participant 13 | Baseline | Control | Dyslexia without support | Robot |

| Participant 14 | Baseline | Dyslexia with support | Dyslexia without support | Robot |

| Participant 15 | Baseline | Dyslexia without support | Dyslexia with support | Robot |

| Participant 16 | Baseline | Dyslexia with support | Dyslexia with support | Robot |

| Participant 17 | Baseline | Dyslexia without support | Dyslexia without support | Robot |

| Participant 18 | Baseline | Control | Control | Robot |

| Task Number | Number of Items to Be Assembled | Number of Operations | Task Difficulty |

|---|---|---|---|

| Task 1 | 3 | 6 | Low |

| Task 2 | 1 | 2 | Low |

| Task 3 | 1 | 2 | Low |

| Task 4 | 1 | 2 | Low |

| Task 5 | 1 | 2 | Low |

| Task 6 | 4 | 8 | High |

| Task 7 | 3 | 5 | Medium |

| Task 8 | 0 | 1 | Low |

| Task 9 | 6 | 10 | High |

| Task 10 | 0 | 2 | Medium |

| Task 11 | 1 | 2 | Low |

| Task 12 | 1 | 2 | Medium |

| Task Number | Number of Items to Be Assembled | Number of Operations | Task Difficulty |

|---|---|---|---|

| Task 1 | 4 | 8 | Low |

| Task 2 | 2 | 4 | Low |

| Task 3 | 4 | 8 | High |

| Task 4 | 6 | 12 | High |

| Task 5 | 4 | 8 | High |

| Task 6 | 1 | 2 | Low |

| Task 7 | 1 | 2 | Low |

| Task 8 | 3 | 5 | Medium |

| Task 9 | 0 | 1 | Low |

| Task 10 | 2 | 2 | Medium |

| Task 11 | 3 | 6 | Low |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Testa, A.; Simeone, A.; Zecca, M.; Paoli, A.; Settineri, L. Fuzzy-Based Sensor Fusion for Cognitive Load Assessment in Inclusive Manufacturing Strategies. Sensors 2025, 25, 3356. https://doi.org/10.3390/s25113356

Testa A, Simeone A, Zecca M, Paoli A, Settineri L. Fuzzy-Based Sensor Fusion for Cognitive Load Assessment in Inclusive Manufacturing Strategies. Sensors. 2025; 25(11):3356. https://doi.org/10.3390/s25113356

Chicago/Turabian StyleTesta, Agnese, Alessandro Simeone, Massimiliano Zecca, Andrea Paoli, and Luca Settineri. 2025. "Fuzzy-Based Sensor Fusion for Cognitive Load Assessment in Inclusive Manufacturing Strategies" Sensors 25, no. 11: 3356. https://doi.org/10.3390/s25113356

APA StyleTesta, A., Simeone, A., Zecca, M., Paoli, A., & Settineri, L. (2025). Fuzzy-Based Sensor Fusion for Cognitive Load Assessment in Inclusive Manufacturing Strategies. Sensors, 25(11), 3356. https://doi.org/10.3390/s25113356