3.1. Signal Acquisition and Processing

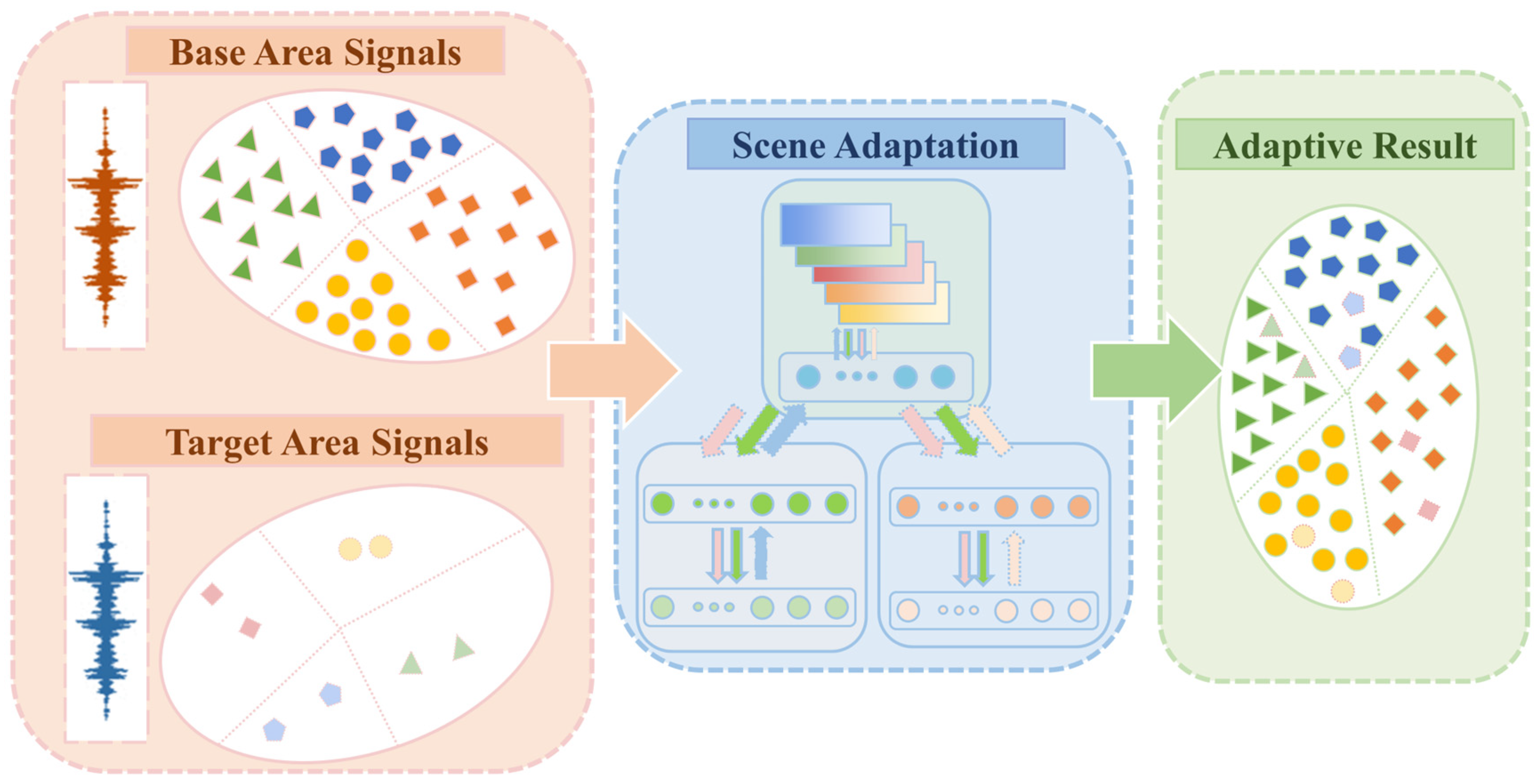

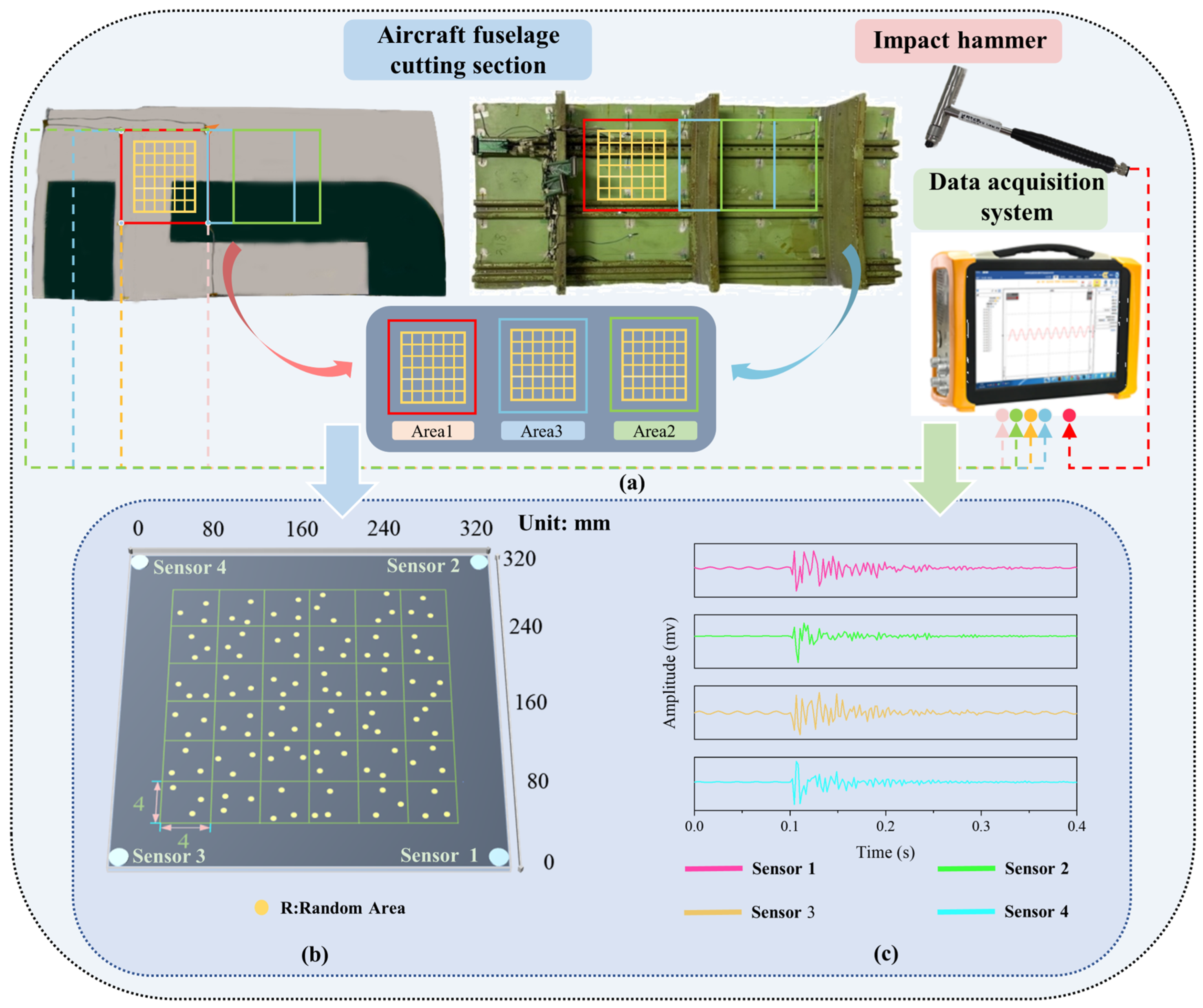

In order to investigate whether the proposed model can achieve high accuracy of load identification under different impact conditions and different structural conditions, in this experiment, the structure cut section of the aircraft was selected as the research object, whose back contains longitudinal and transverse reinforcement structures with complex structural characteristics of real aircraft. An impact test platform was designed based on this fuselage structure cut section, as shown in

Figure 5, to simulate the impact scenarios under different impact conditions and different structural conditions.

In order to validate that the model can complete the load identification transfer in different areas of the fuselage cutting section, three areas are selected for impact according to the structural characteristics: Area1, Area2 and Area3, where Area1 is the reference area, which has two reinforced structures crossing transversely and no reinforced structures crossing longitudinally and is 5 cm away from the nearest longitudinal reinforced structure. First, to validate whether the proposed model can accomplish better transfer in similar structural areas, Area2 is selected with similar structural conditions as Area1, which also has two reinforcement structures crossing in the transverse direction and is 5 cm away from the nearest longitudinal reinforcement structure. To further discuss the generalization ability and small sample transfer ability of the model, Area3 with completely different area structure conditions from Area1 and Area2 was selected, containing two horizontal structures and two vertical structures. The sizes of Area1, Area2 and Area3 are all 240 mm × 240 mm, and each local area is divided into 36 sub-areas, and each sub-area is a regular grid of 40 mm × 40 mm. Four PZT piezoelectric sensors were arranged around the three different areas to receive the impact response signals, and the arrangement and number of piezoelectric sensors are shown in

Figure 5b. The sensors are PZT-5 type piezo-ceramic plates with Φ5 mm × 0.5 mm, the dielectric constant of this type of PZT is 2000 and the piezo-strain constant d

33 is in the range of 420–620.

The impact is generated by the impact force hammer KSI-728A001 (Keshan Technology Co., Ltd., Beijing, China). The impact energy level of the impact force hammer is divided into low-energy impact and high-energy impact. The impact energy level of low-energy impact is below 200 N, while that of high-energy impact is above 200 N. In the practical impact process, instead of performing a fixed strength impact, random strength size impacts are performed within the delimited energy level range, so as to better verify the algorithm’s ability to identify arbitrary impact energy levels.

The impact response signals were acquired by the data acquisition device DH5925N (Donghua Testing Technology Co., Ltd., Taizhou City, China). For each impact, the sensor signals at each location were recorded at 50 KHz sampling frequency, and the number of acquisition points was 750,000. Continuous impacts containing two impact energy levels were performed in Area1 using the impactor, with each location containing 10 impacts. To further validate the algorithm’s ability to transfer areas and to transfer at different impact energy levels, a series of experiments were performed in Area2. The experiments were performed in Area2 using the impact head for two different impact energy levels, with five consecutive impacts for each case. To further validate the model’s ability to migrate in the area, impact experiments were conducted in Area3 for two different impact energy levels, with five consecutive impacts for each case. The 10/5 impacts do not occur at exactly the same location within each small square area. Our design allows for a certain amount of randomness in the impact points within the small square area in order to simulate the variety of impacts that may be encountered in actual use. The collected datasets are shown in

Table 1. Since the method in this paper is based on 2D image input, the discrete signals from the sensors need to be processed into the appropriate format to facilitate subsequent processing. This format allows complete characterization of the signal, such as signal arrival time and signal amplitude, thus ensuring that this important information is fully retained.

3.2. Location Identification of Impact Load

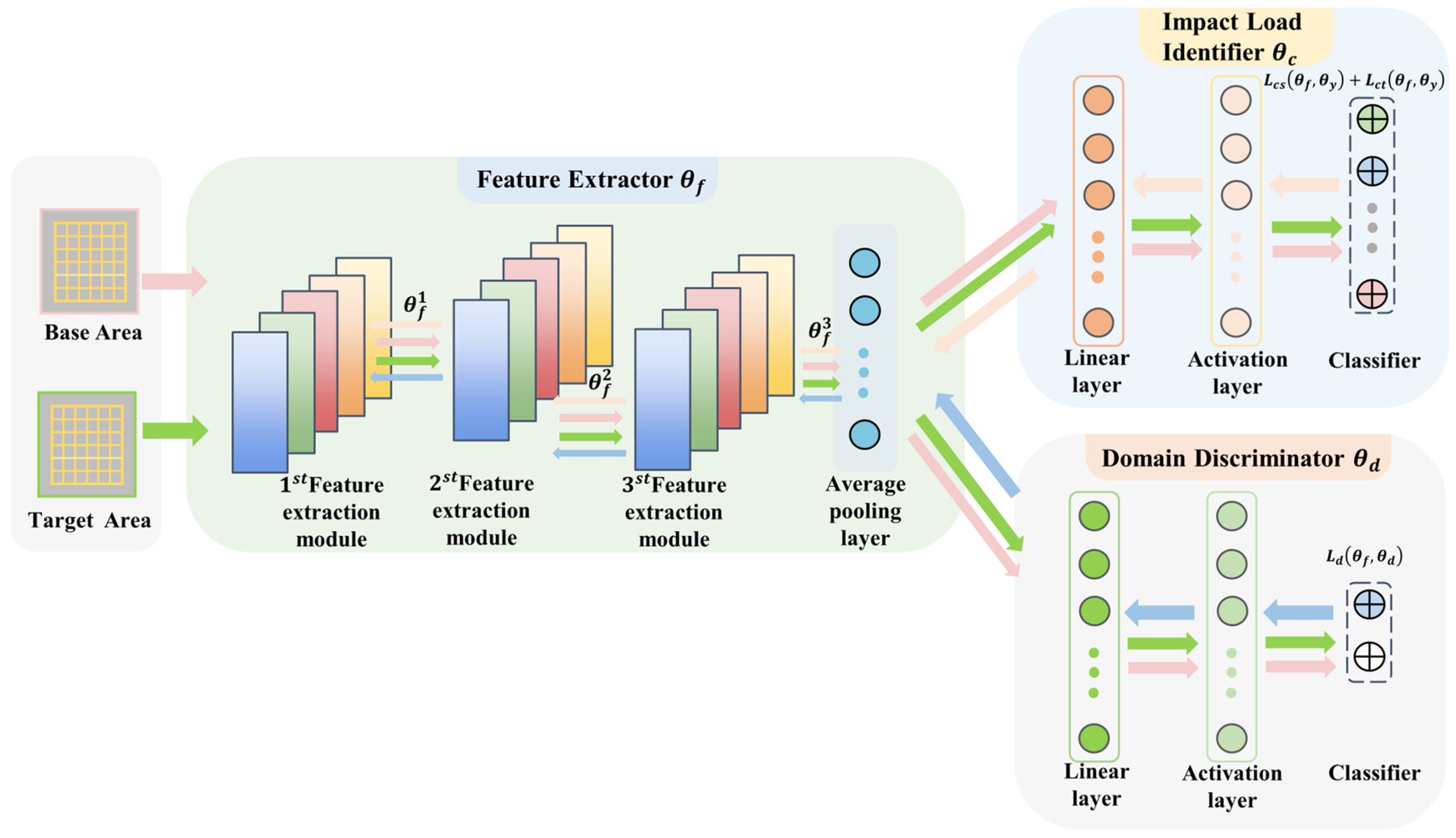

In this section, the supervised scene adaptation model is used to predict the impact locations and to validate the transfer ability of the model under different structures and different impact energy levels. Here, the supervised scene adaptation model is compared with the original FCN model without transfer learning and the FCN network model with transfer learning to check whether the proposed model has improved generalization ability compared with the traditional deep learning model and the transfer learning model. Firstly, validate whether the model can transfer better under similar area structure and different area structure conditions, secondly, verify the generalization performance of the model under different impact energy level conditions, and finally, discuss the transfer effect of the model under mixed scenarios with different structures and different impact energy levels.

(1) Transfer ability of model in similar area/structure scenarios

First, the transfer ability of the model was verified in similar area/structure scenarios. For this research objective, two datasets were selected for training, which were from Area1 and Area2. High-energy impact A1B from Area1 was selected to form the baseline set. The same treatment was performed for the dataset from Area2, and the high-energy impact dataset A2B was selected to divide the dataset into a calibration set and test set accordingly.

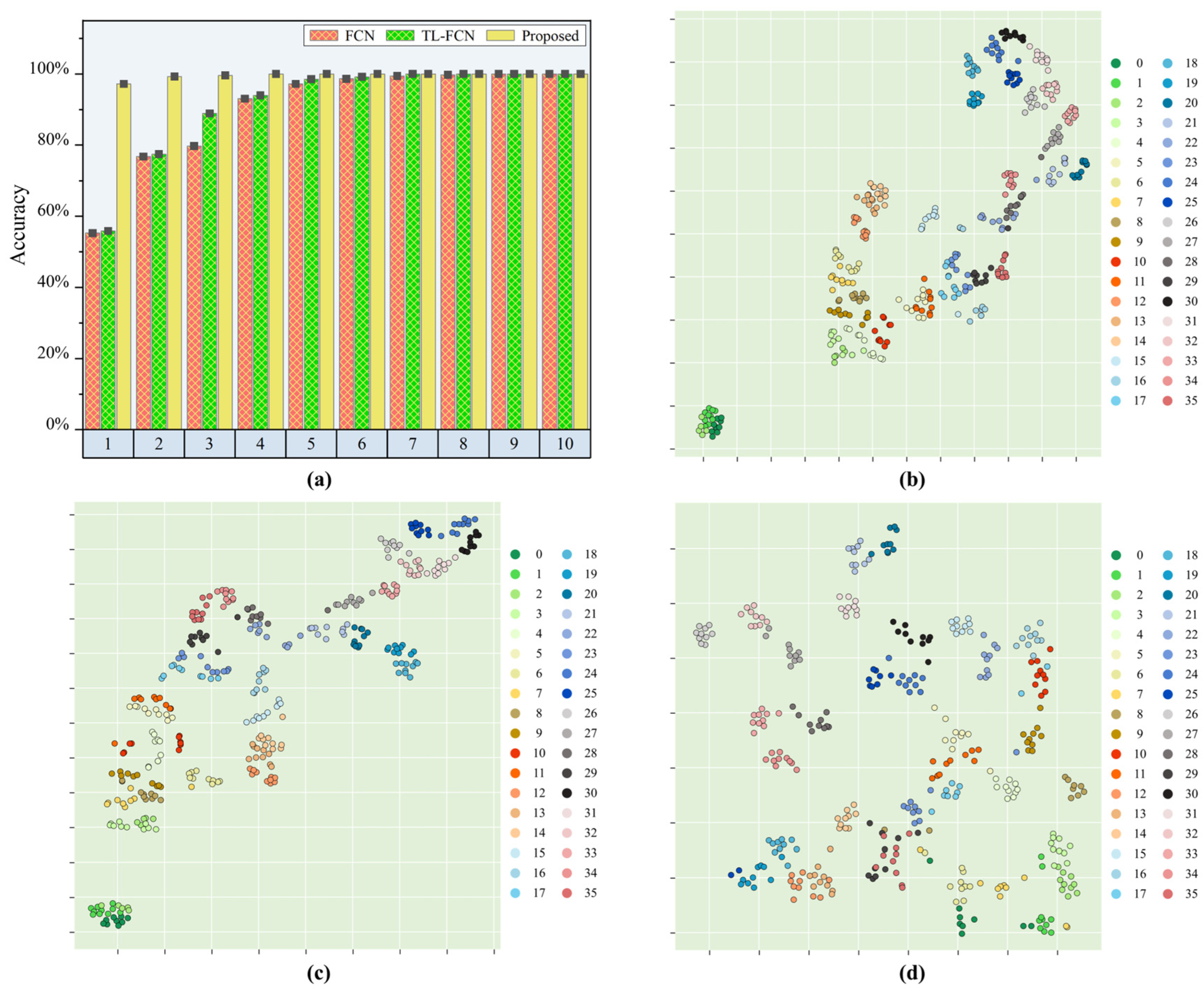

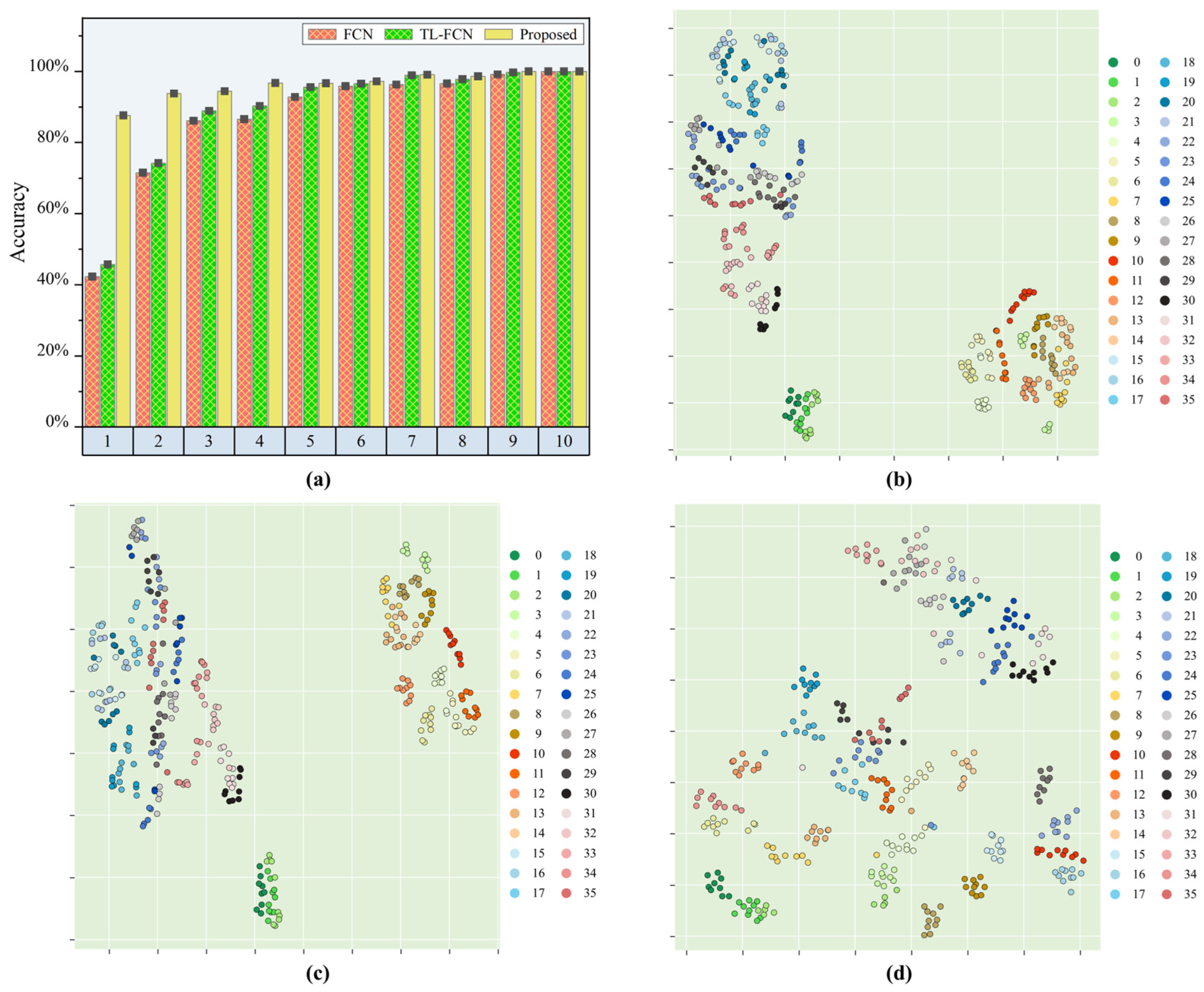

After experimental validation, the experimental results are presented in

Table 2 and

Figure 6. When there was one sample from each sub-region of Area2 involved in the calibration, the proposed model could achieve high accuracy recognition of Area2 with a prediction accuracy of 97.22%. The proposed model achieved significant improvement in load identification compared to the baseline FCN model, with an improvement of 41.97%, while the traditional transfer learning-based FCN model only improved by 0.58%. The proposed model achieved 99.3% accuracy in identifying samples from the target region Area2 when two samples from each sub-region of Area2 were involved in the calibration. The improvement was significant compared to the baseline FCN model, with 22.56% accuracy improvement. In contrast, the FCN model that performs transfer learning had only a small improvement in prediction effectiveness compared to the benchmark FCN model, with an improvement of only 0.69%. The prediction accuracy of the proposed model reached 100% when the calibration samples for each subregion were boosted to 4. From experiment validation, it was found that when the number of calibration samples in each sub-area reaches more than two, the identification ability of the proposed model for the target region remained basically unchanged even if the number of sub-area samples increased again. This was because the perfect projection of the impact response signals from the reference region and the target region to the common feature space could be completed with only two samples in the target region, so the improvement of the identification effect by increasing the calibration samples was not significant. When the calibration samples were less than 4, the identification effect of the proposed method was much better than that of the traditional transfer learning and benchmark model, especially when the calibration samples totaled 1, when the calibration effect was especially obvious. Therefore, it could be inferred that the proposed model had good engineering application value.

In order to understand more visually the transfer capability of the proposed model under similar structural conditions, the fully connected layer outputs of the baseline FCN model, the pre-trained TL-FCN model and the supervised scene adaptive model were further projected into the two-dimensional space using t-SNE.

Figure 6b–d represent the feature distributions of the FCN model, TL-FCN model and supervised scene adaptation model for the test set predicted with the calibration set of one sample per sub-area. Ten samples were selected for tracking in each impact region, and the identification accuracy of each model was analyzed by identifying the distances within and between classes in the feature distribution plots. From

Figure 6b, it can be seen that the baseline FCN model has a huge error in predicting the test data, and the distances of the impact response signal feature distributions in different sub-regions are small and almost mixed together. The small difference between

Figure 6b,c indicates that the traditional transfer learning approach has very limited performance improvement in this case of very few samples. The feature distribution of the supervised scene adaptive model for prediction of test data is shown in

Figure 6d, and it can be clearly seen that the impact response signal features in different sub-regions are distributed at a large interval, and the impact response signal features in the same sub-region also achieve effective clustering.

The above identification results and t-SNE feature analysis indicated that the proposed model could accomplish the transfer of similar structures well, and after a certain amount of baseline data, similar structures could be identified with high accuracy by the model with only a very small amount of calibration data collected from the baseline region and the target region. And compared with the traditional FCN model and TL-FCN model, there was a great improvement in the identification accuracy of few samples.

(2) Transfer ability of model in completely different scenarios of area/structure

This subsection continues to discuss the transfer capability of the model under completely different area/structure conditions, and further verifies whether the model could accomplish the transfer in any area/structure. To validate this goal, datasets A1B and A3B from Area1 and Area3, respectively, were selected. A1B was used as the baseline dataset for the initial training of the model, and A3B was divided into calibration and test sets to complete the calibration and testing of the model.

The results shown in

Table 3 and

Figure 7 were obtained after experimental validation. The identification accuracy of the proposed method was twice as high as that of the baseline FCN model when the calibration sample for each subregion was one, with an improvement of 45.37%. In contrast, the optimization effect of the traditional transfer learning-based FCN model with one calibration sample was small, and the prediction accuracy was only improved by 3.4% compared to the benchmark FCN model. When the calibration sample was increased to 2 for each subregion, the proposed method achieved 93.75% load identification accuracy, which was 22.22% higher than the benchmark FCN model. In comparison, the improvement of the traditional transfer learning-based FCN model was still limited to 2.64%. The load identification capability of the proposed model increased with the increase in calibration samples, and the load identification accuracy reached over 95% for four calibration samples in a single sub-area and over 99% for seven calibration samples in a single sub-area. In comparison, the identification effect of the baseline FCN model and the traditional transfer learning-based FCN model with very few calibration samples was very limited, and the identification accuracy of a single sub-area with less than three calibration samples was less than 80%. It was also found that the load identification improvement effect of the FCN model with the introduction of traditional transfer learning mechanism was also very limited, and the improvement effect was less than 5%. Through further experiments, the proposed model still had high identification accuracy for the different target area structures from the baseline area structure, and only one calibration sample for a single sub-area was needed to calibrate the model to obtain a good result. Compared with the baseline FCN model and the traditional FCN model based on transfer learning, the proposed model showed excellent performance in different area structure scenarios and had good engineering applicability.

The t-SNE could observe the effect of transfer learning strategy and scene adaptation strategy more intuitively. Therefore, the fully connected layer high-dimensional output vectors of the baseline FCN model, the pre-trained TL-FCN model and the supervised scene adaptation model were transformed into two-dimensional features by t-SNE here, and the respective feature distributions are plotted in

Figure 7b–d. Here, the feature distributions of each model after feature extraction for a test set with a single sub-area of ten samples were analyzed when the calibration dataset was a single subregion of one sample.

Figure 7b,c show little difference in the feature distributions, which indicates that the traditional transfer learning strategy has a limited effect on the improvement of the baseline FCN model.

By analyzing the load identification results with the t-SNE feature maps, the supervised scene adaptation model could accomplish the transfer better even under the completely different conditions of regional structure. Under the condition of very few samples, the supervised scene adaptation model identification was much better than the baseline FCN model and TL-FCN model.

(3) Transfer ability of model under different impact energy scenarios

This subsection further investigated the impact of impacts in different energy level conditions on the model for load identification. In order to make the load identification capability of the model cover various energy impacts, traditional deep learning methods could only simulate or collect impact response signals of small and large energy level impacts in large quantities to improve the generalization of the model to different energy impacts. And since multiple large-energy impacts might cause damage to the aircraft structure, it would mean that large-energy impact experiments relying on actual platforms cannot be repeated in large numbers.

First, the transfer capability of the model under different energy level impacts was validated. Combined with the problems faced in engineering applications, the sample set under small-energy impact events was selected in this section as the baseline set to train the model, and then a small amount of impact response signals generated by large-energy impact events were collected to calibrate the model. The small-energy impact dataset A1S from Area1 and the large-energy impact dataset A1B were selected here. A1S was used as the baseline set to complete the basic training of the model, while A1B was divided into a calibration set and test set according to a certain ratio, and the calibration set was used to calibrate the model for new scenarios, while the test set was used to test the prediction of the model under the large-energy impact.

After a series of experimental validation, the results are shown in

Figure 8 and

Table 4. The load identification accuracy of the supervised scene adaptation model reached 91.98% when the number of calibration samples in a single sub-area was 1, which was 40.75% higher than the load identification accuracy of the baseline FCN model. In contrast, the identification accuracy of the traditional transfer learning-based FCN model only improved by 3.4%, which was far from the accuracy standard required for practical engineering applications. The proposed method achieved 94.44% load recognition accuracy when the calibration sample was 2, while the identification accuracies of the baseline FCN model and the traditional deep learning-based FCN model were only 62.15% and 74.65%, respectively. The baseline FCN model and the traditional transfer learning-based FCN model showed better load identification ability only when the calibration sample size reached 4 or more. Meanwhile, the supervised scene adaptation model had about 2% prediction performance improvement compared to the baseline FCN model.

In order to obtain visualization of the transfer learning strategy and the domain adaptation strategy, the output of the fully connected layer was transformed to a two-dimensional space using t-SNE and then a scatter plot was drawn. Here, a calibration dataset with one sample for a single sub-area and a test set with ten samples for a single sub-area are selected.

Figure 8b–d present the feature distribution plots of the FCN model, TL-FCN model and supervised scene adaptive model for the prediction of the test set. They had similar feature distributions, but the supervised scene adaptation model had a larger and more dispersed interval distance between each category compared to the baseline FCN model and TL-FCN model, which explained from the side why the supervised scene adaptation model still had better load identification with very few samples.

The above identification results with t-SNE feature analysis demonstrated that the supervised scene adaptation model could effectively improve the generalization to different energy impacts. Compared with the baseline FCN model and TL-FCN model, the accuracy of load identification in the case of few samples with very few samples was greatly improved.

(4) Transfer ability of model with completely different scenarios of impact energy level and area/structure

Past studies divided and discussed the situations encountered in practical scenarios, and did not sufficiently analyze the situation where multiple complex conditions might be encountered in practical application scenarios. Therefore, this subsection further validates the effectiveness of the proposed model for load identification in mixed scenarios with different impact energy levels and different area structures, and further demonstrates whether the model could achieve high performance transfer for any energy impact with any structure area.

Combined with some problems faced by the practical application of engineering, sufficient small-energy impact experiments were conducted in the benchmark area, and then small amounts of large-energy impact samples were collected in the target area to complete the validation of the model’s generalization ability under complex conditions. Here, the small-energy impact dataset A1S from Area1 was selected as the benchmark set, and the large-energy impact dataset A3B from Area3 was divided into a calibration set and test set in a certain proportion to complete the calibration and performance testing of the model for new scenarios.

The load identification results of the experimentally validated model are shown in

Figure 9 and

Table 5. The load identification accuracy of the supervised scene adaptation model was nearly twice as high as that of the baseline FCN model and the traditional transfer learning-based FCN model, reaching 87.04% for one single sub-area calibration sample. In contrast, the identification accuracy of both the baseline FCN model and the traditional transfer learning-based FCN model was below 50%. When the calibration samples totaled 2, the load identification accuracy of the proposed model reached 92.71%, which was improved by 26.39% compared to the benchmark FCN model. In contrast, the FCN model based on traditional transfer learning improved by only 1.18% compared to the original model. The supervised scene adaptation model achieved identification accuracy of 93.60% when the calibration samples totaled 3, which was improved by 21.77% compared to the original model. The identification accuracies of the baseline FCN model, the traditional transfer learning-based FCN model, and the supervised scene adaptation model all reached more than 90% when the calibration samples for each subregion were larger than 4. And as the sample size continued to increase, the performance improvement that the supervised scene adaptation model could bring gradually reached the limit.

To explain the results presented in the experiments, t-SNE was further used to convert the fully connected layer high-dimensional output vectors of the baseline FCN model, the pre-trained TL-FCN model, and the supervised scene adaptation model into two-dimensional vectors. The feature distributions of the FCN model, the TL-FCN and the supervised scene adaptation model are shown in

Figure 9b–d. The distributions of the extracted features of the three models were similar. Compared with the baseline FCN model, the distribution interval density of the TL-FCN extracted features did not change much, so the TL-FCN model was poorly boosted in the case of very few samples. The supervised scene adaptation model extracted more discrete feature distribution intervals for different sub-areas of the impact response signal. Therefore, the supervised scene adaptive model could accomplish high-accuracy identification of loads with very few samples for training.

This subsection further validated the load identification effect of the proposed model in mixed scenarios with different impact energy levels and different area structures, and analyzed the load identification results with t-SNE feature maps. The results demonstrated that the supervised scene adaptation model could be effectively applied to practical scenarios where multiple complex conditions coexist. Even in the scenarios with different impact energy levels and different regional structures, the supervised adaptation model still performed well with very few samples and could be well suited for practical engineering applications.

3.3. Energy Identification of Impact Load

In practical engineering application scenarios, predicting the energy of external impacts was critical for assessing the extent of damage that might be caused to the structure internally by the impact. This section further validated the ability of the supervised scene adaptation model to perform impact load energy identification and discussed the transfer ability of the model to perform impact energy identification in similar areas/structures versus different areas/structures. Here, the supervised scene adaptive model was compared with the baseline FCN model and the transfer learning-based TL-FCN model to validate whether the proposed model had any improvement in generalization ability compared with the traditional deep learning model with the introduction of the transfer learning strategy. This subsection first discusses the transfer effect of the model for load energy identification in the similar area structure scenario, and verifies whether the model could accomplish more effective energy level evaluation in similar structures. Considering that the practical application scenarios involved the transfer of the model under different structural conditions, this section further discusses the transfer effect of the model for load energy level identification under different area structure scenarios.

(1) Transfer ability of model in similar area/structure scenarios

The transfer performance of the model was verified under similar area structure scenarios. Here, four datasets from Area1 and Area2 were selected for mixing and partitioning. A1S and A1B from Area1 were mixed and labeled to form the A1 hybrid dataset, and dataset A1 was used as the baseline set. Further, A2S and A2B from Area2 were mixed to obtain the A2 mixed dataset. Then, the A2 mixed dataset was divided according to a certain ratio to obtain the calibration set and test set to complete the calibration and testing of the model.

After a series of experimental validation, the result can be obtained as illustrated in

Figure 10 with

Table 6.

Figure 10a displays the prediction results of the transfer model under similar area structure scenes. The supervised scene adaptation model reached more than 99% accurate identification rate when there were one to three samples for each impact energy level. In particular, the supervised scene adaptation model improved by 39.72% compared to the baseline FCN model when there was one sample per impact energy level, while the traditional transfer learning-based TL-FCN model improved by only 24.99%. With four samples per impact energy level, the supervised scene adaptation model accomplished 100% accurate identification rate. The baseline FCN model achieved only 90.42% accuracy. The accuracy of the baseline FCN model only reached over 95% when the calibration samples totaled six, and 99% when the calibration samples totaled ten. Meanwhile, the identification accuracy of the TL-FCN model based on traditional transfer learning was only about 3% higher than that of the baseline FCN model, which indicated that the optimization effect of traditional transfer learning was relatively limited.

In order to explain the results presented by the experiments, the high-dimensional vectors of the fully connected layers of each model were further downscaled into two-dimensional vectors using t-SNE. Here, the distribution of features presented by each model after feature extraction for test sets of 20 samples per energy level was analyzed when the calibration data set included one sample per energy level. From

Figure 10b–d, it could be observed that the feature distributions extracted by the baseline FCN model for the impact response signals of different energy levels overlapped severely. TL-FCN was able to separate the features of different impact energy levels to some extent, but there was still some crossover in the feature distributions extracted by TL-FCN. The separation effect of the supervised scene adaptation model was better compared to TL-FCN, which fully achieved the dispersion isolation of features with different energy levels. In this validation experiment, the enhancement effect of TL-FCN on the energy level identification of loads was better than the location identification of loads due to the fact that the energy level identification task involves more distinct features relative to the location identification of loads, and the distribution of samples collected from different regional structures has some similarity. The superior identification effect of the supervised scene adaptation model over TL-FCN was due to its alignment idea, where data from different scenes were projected into a common feature space and aligned.

This subsection further validates the proposed model for load energy identification under similar regional structure scenarios, and analyzes the load identification results with t-SNE feature maps. The results indicate that the transfer effect of the proposed model for load energy identification under similar area structure was better, and the performance was still superior in the case of very few samples, which could better fit the practical engineering applications.

(2) Transfer ability of model in completely different scenarios of area/structure

The transfer capability of the model for load energy identification under different conditions of the area structure was validated. Combined with the practical engineering application scenarios, the small-energy impact dataset A1S from Area1 was mixed with the large-energy impact dataset A1B to obtain dataset A1. Then, the small-energy impact dataset A3S from Area3 was mixed with the large-energy impact dataset A3B to obtain dataset A3, and then the calibration set and test set were divided according to certain ratio. The calibration set and test set were then divided according to a certain ratio.

Figure 11a and

Table 7 show the transfer performance of each model for load energy identification under different region structures. The supervised scene adaptation model attained 98.85% accuracy with one calibration sample and 100% accuracy with two calibration samples. In contrast, the baseline FCN model only achieves 90.14% with five calibration samples. The improvement effect of the TL-FCN model based on traditional transfer learning was relatively limited, with only 21.59% improvement with one calibration sample and 5.84% improvement with two calibration samples, and the improvement effect diminished when the number of calibration samples was increased gradually. Through the above results, the supervised adaptive model was better than the traditional transfer learning model in performing the load energy identification task, and had better transfer effects for different regional structures, which could meet the practical engineering application requirements.

Figure 11a and

Table 7 show the transfer performance of each model for load energy identification under different area structures. The supervised scene adaptation model attained 98.85% accuracy with one calibration sample and 100% accuracy with two calibration samples. In contrast, the baseline FCN model only achieved 90.14% with five calibration samples. The improvement effect of the TL-FCN model based on traditional transfer learning was relatively limited, with only 21.59% improvement with one calibration sample and 5.84% improvement with two calibration samples, and the improvement effect diminished when the number of calibration samples was increased gradually. Through the above results, the supervised adaptive model was better than the traditional transfer learning model in implementing the load energy identification task, and had better transfer effects for different regional structures, which could meet the practical engineering application requirements.

To obtain visualization of the transfer learning strategy and the adaptive strategy, the output features of the fully connected layer were dimensioned down to two-dimensional features using t-SNE and then converted into scatter plots. Here, the calibration dataset of one sample for each energy level and the test set of twenty samples for each energy level were selected.

Figure 11b–d represent the distribution of features predicted by the FCN model, TL-FCN model and supervised scene adaptation model for the test set. The features extracted by the FCN model, TL-FCN model and supervised scene adaptation model had similar distribution. However, the supervised scenario adaptation model resulted in greater distance between the impact response signals of different energy levels and tighter clustering of impact response signals of the same energy level compared with the baseline FCN model and TL-FCN model. The feature distribution diagram effectively illustrates why the supervised scene adaptive model was better in load identification even with very few samples.

The above identification results and the t-SNE feature analysis demonstrate that the supervised scene adaptation strategy could effectively improve the generalization of the model to perform the impact load energy identification task, even under the condition of completely different area structures, and still accomplish the accurate prediction of the load energy level with very few samples.