Research on Combustion State System Diagnosis Based on Voiceprint Technology

Abstract

1. Introduction

2. Feature Extraction Algorithm

2.1. Data Preprocessing

2.2. MFCC Extraction Process

- (1)

- The pre-emphasized signal in the previous step is divided into frames and windowed using Hamming window.

- (2)

- The signal, now framed and windowed, is subjected to a Fast Fourier Transform, resulting in the frequency spectrum of the signal.

- (3)

- The energy spectrum is passed through a set of triangular filters designed according to the Mel scale. The frequency response of the triangular filters [] and the response formula for Mel frequency to actual frequency f are given by Equation (7). After band-pass filtering, the results are corrected using a logarithmic function to adjust for the non-linearity of sound intensity, thus obtaining the logarithmic energy output for each filter group. In this study, three types are designed, with M = 19, 39, 57, with corresponding to linear frequency, indicating the logarithmic energy output of each filter group.

- (4)

- The cepstrum is computed through an Inverse Discrete Fourier Transformation, and the static MFCCs are derived from the logarithmic energy calculated in the previous step by applying a Discrete Cosine Transform (DCT). The formula for calculating static MFCC coefficients is as follows:

- (5)

- The calculation of the first-order derivative of MFCC is accomplished through differencing operations on the MFCCs. The formula for the first-order derivative of MFCC is as follows

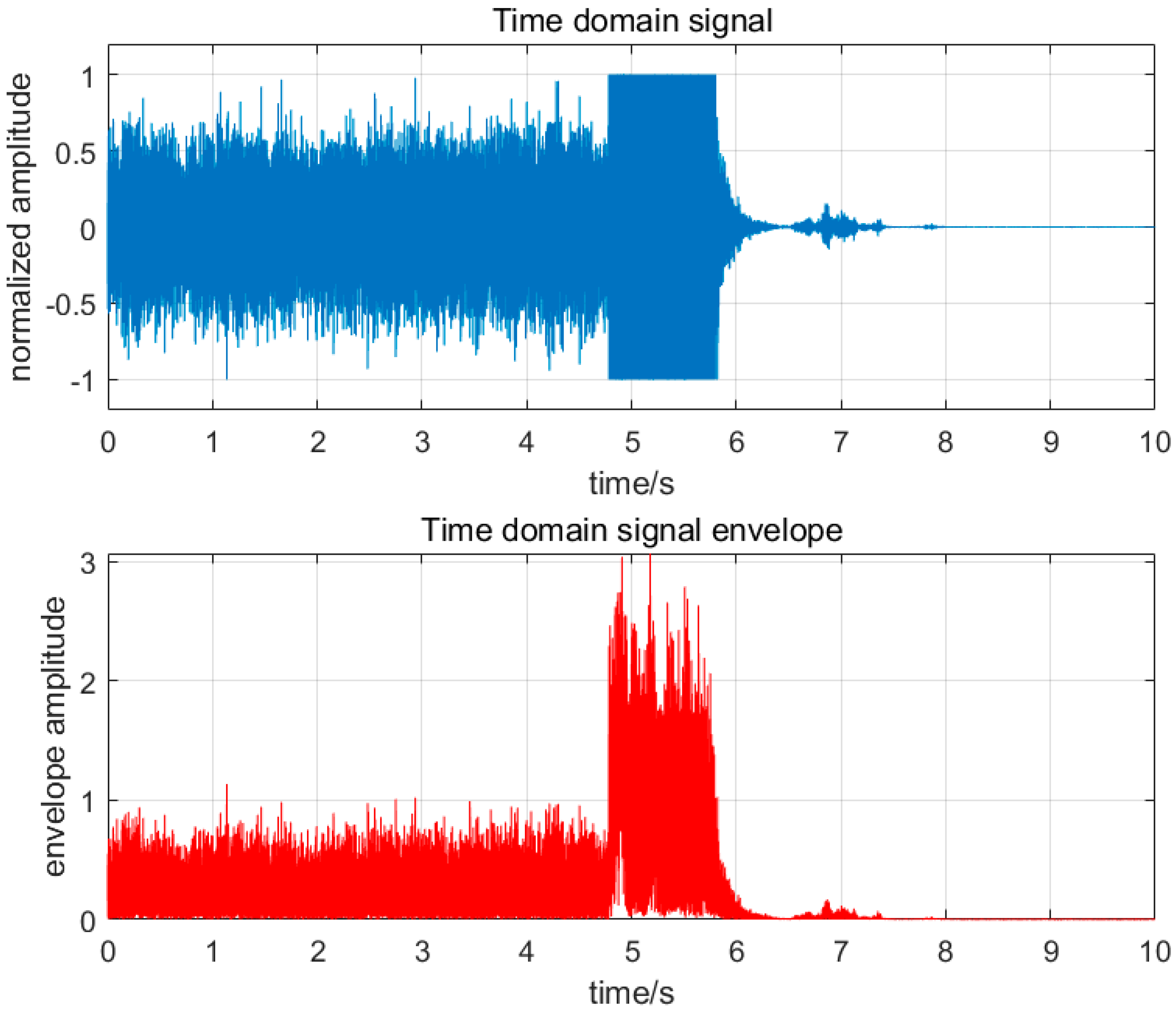

2.3. The Step Index P

- (1)

- Obtain the original signal and perform the Hilbert transform on the original signal.

- (2)

- An imaginary part of the signal is obtained by the Hilbert transform, which is combined with the original signal to form an analyzed signal

- (3)

- The step index P is the amplitude of the resolved signal

3. Experimental

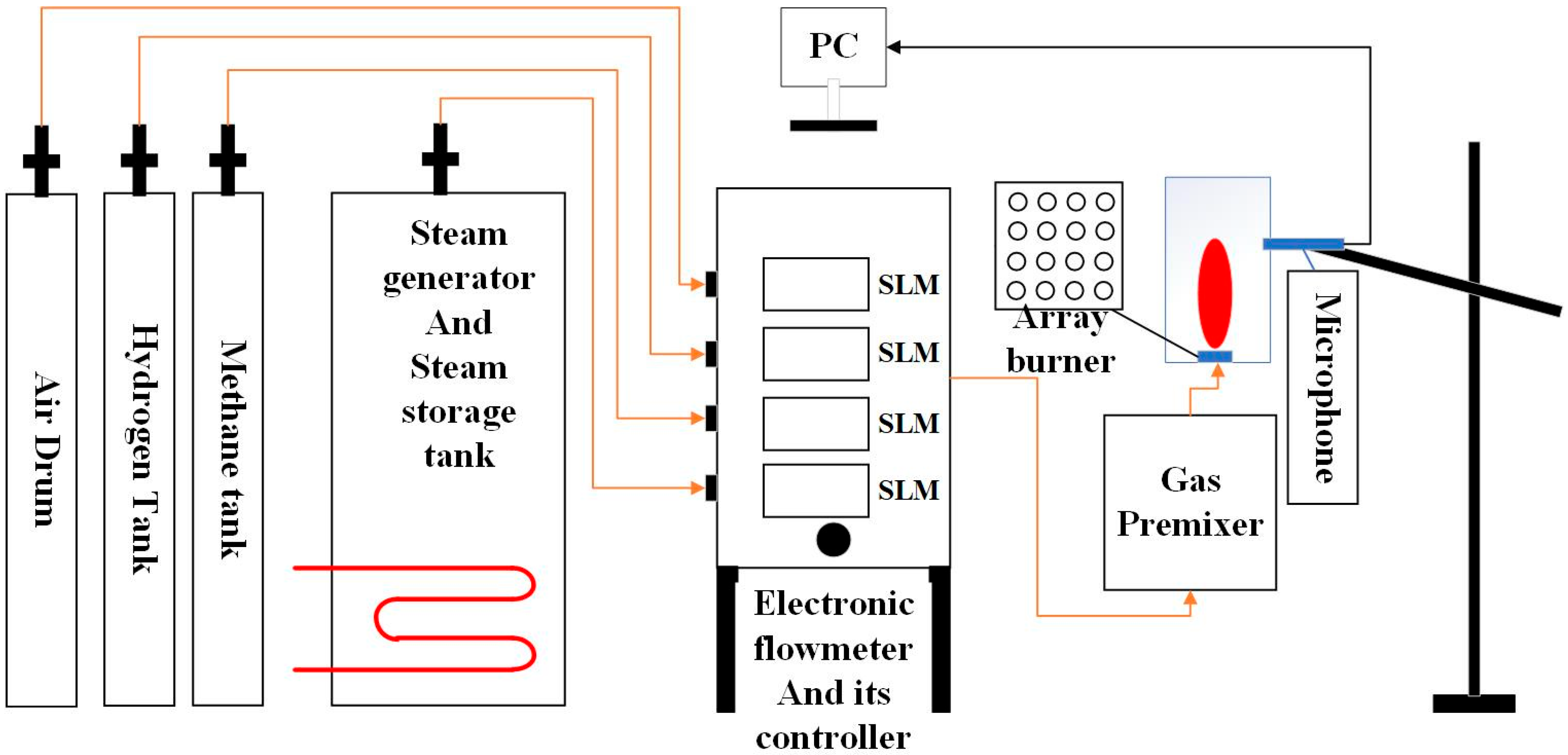

3.1. Experimental Apparatus

3.2. Experimental Design

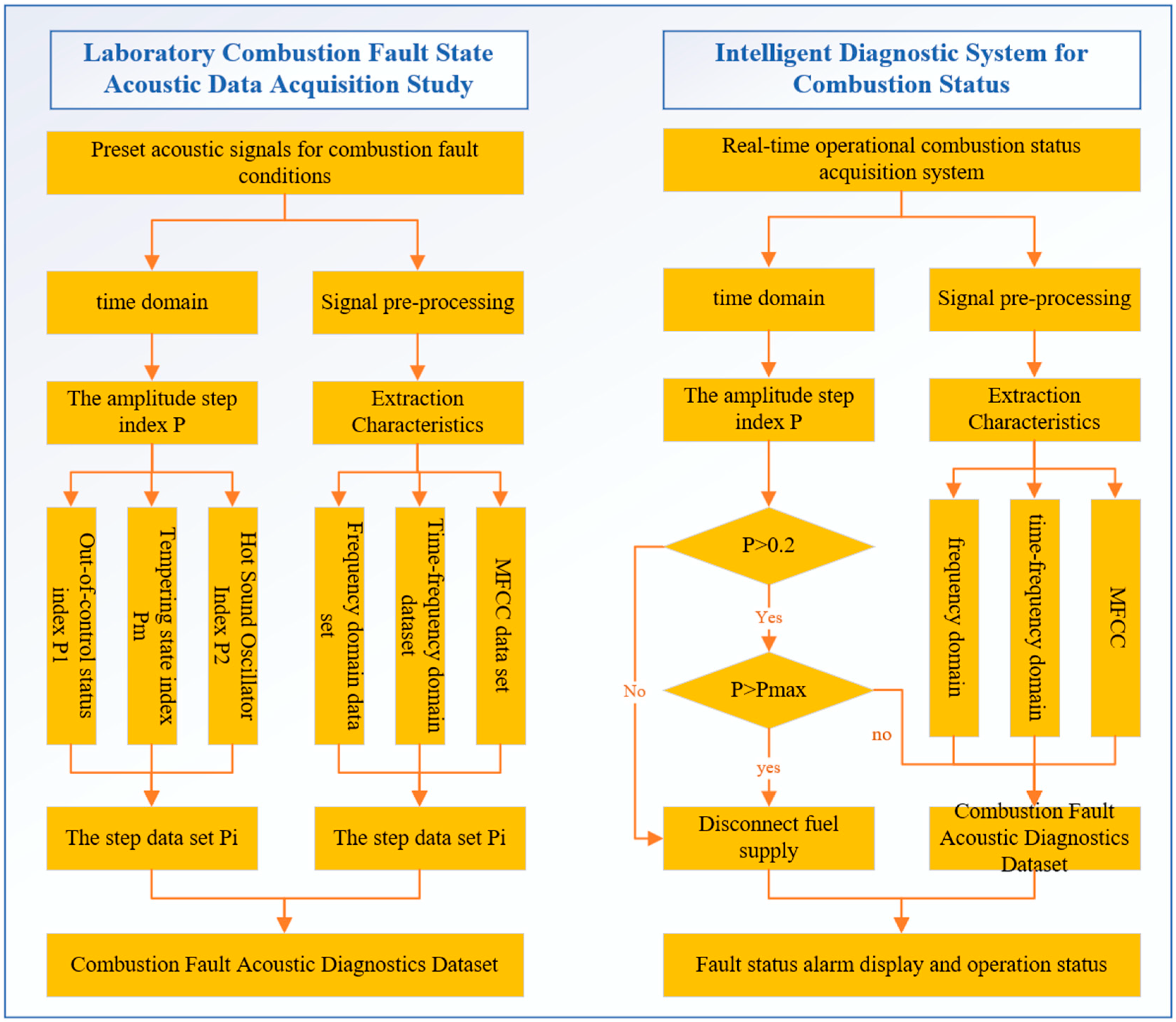

3.3. Flow Chart of Combustion Voiceprint Intelligent Diagnosis System

3.4. Input Parameters of Combustion Voiceprint

3.4.1. Amplitude Step Index P

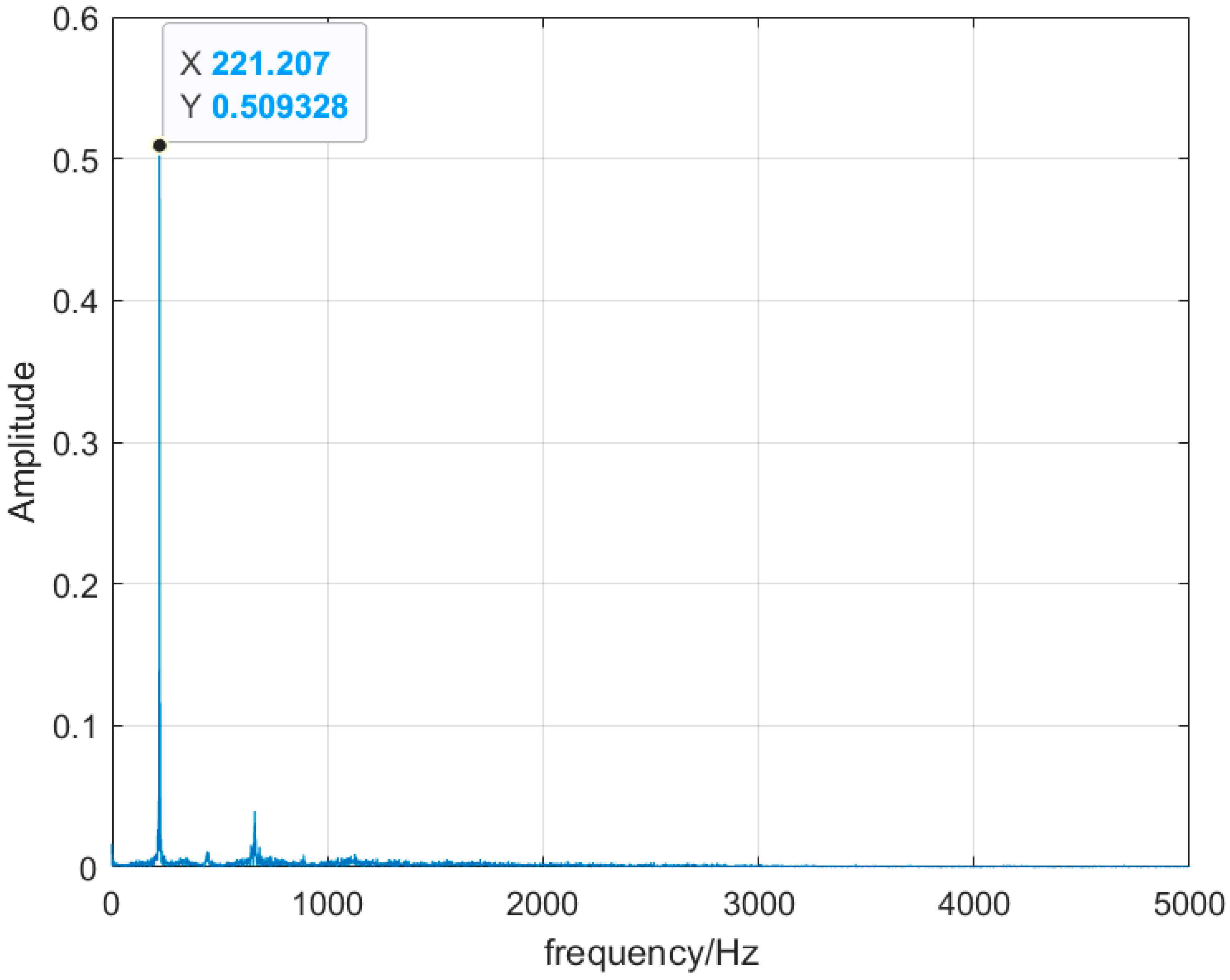

3.4.2. Frequency-Domain Signal

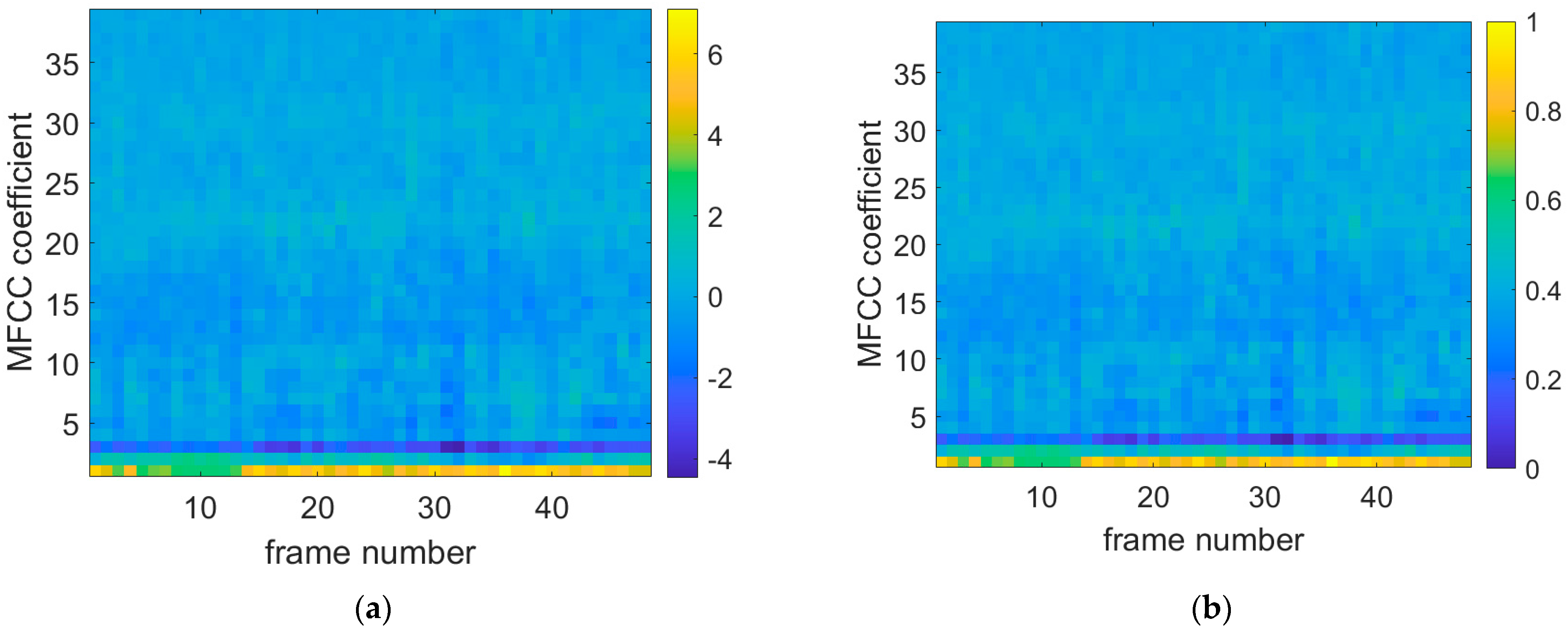

3.4.3. MFCC Feature

4. Results and Discussion

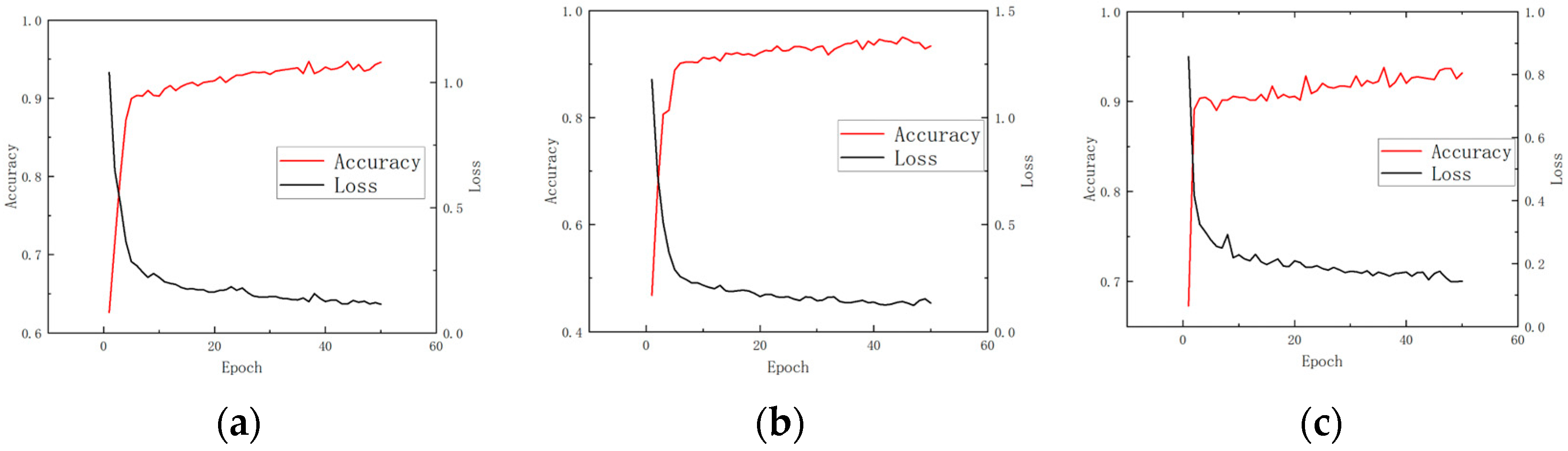

4.1. The Training Performance of Different Models Under Different Working Conditions

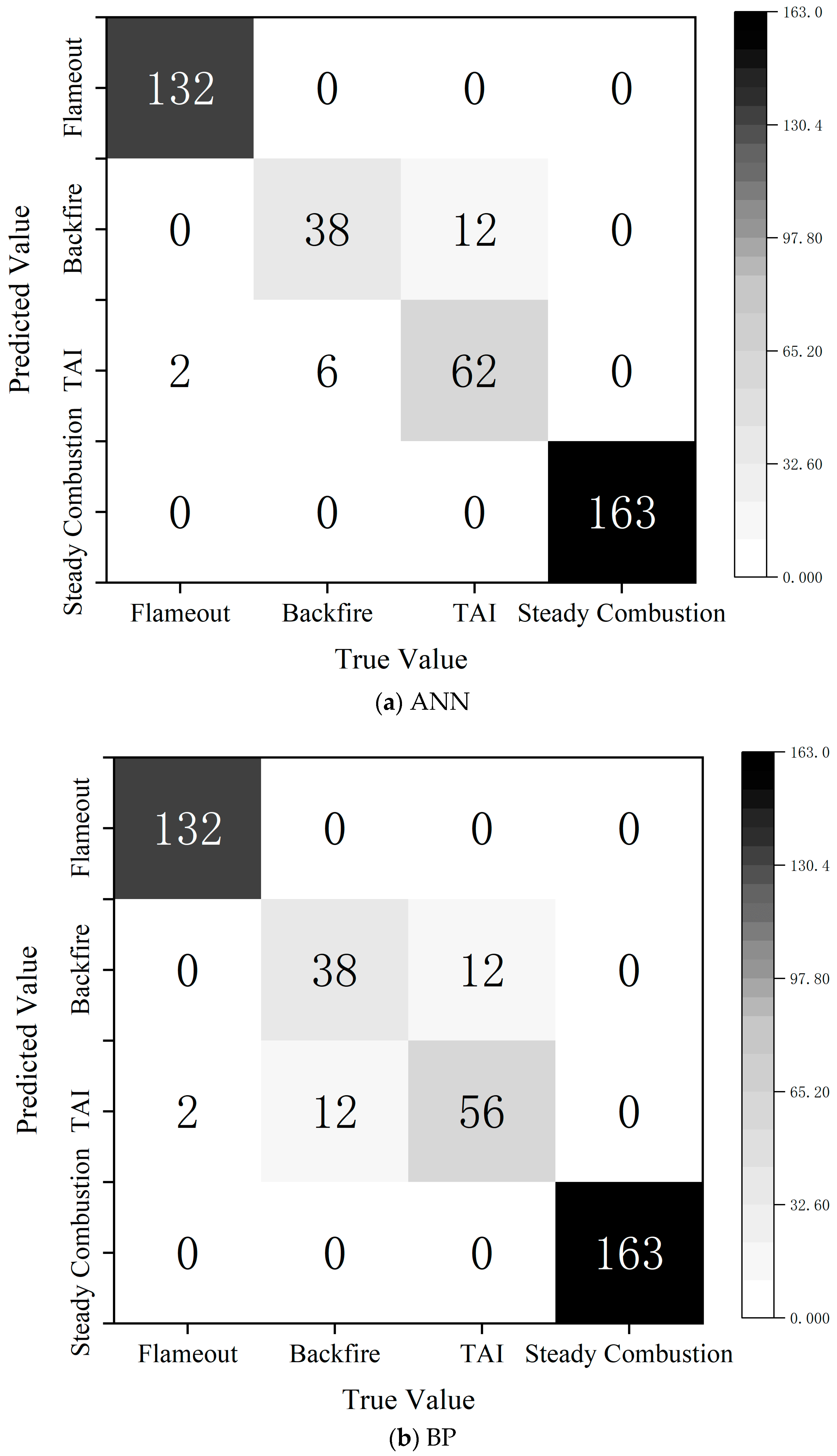

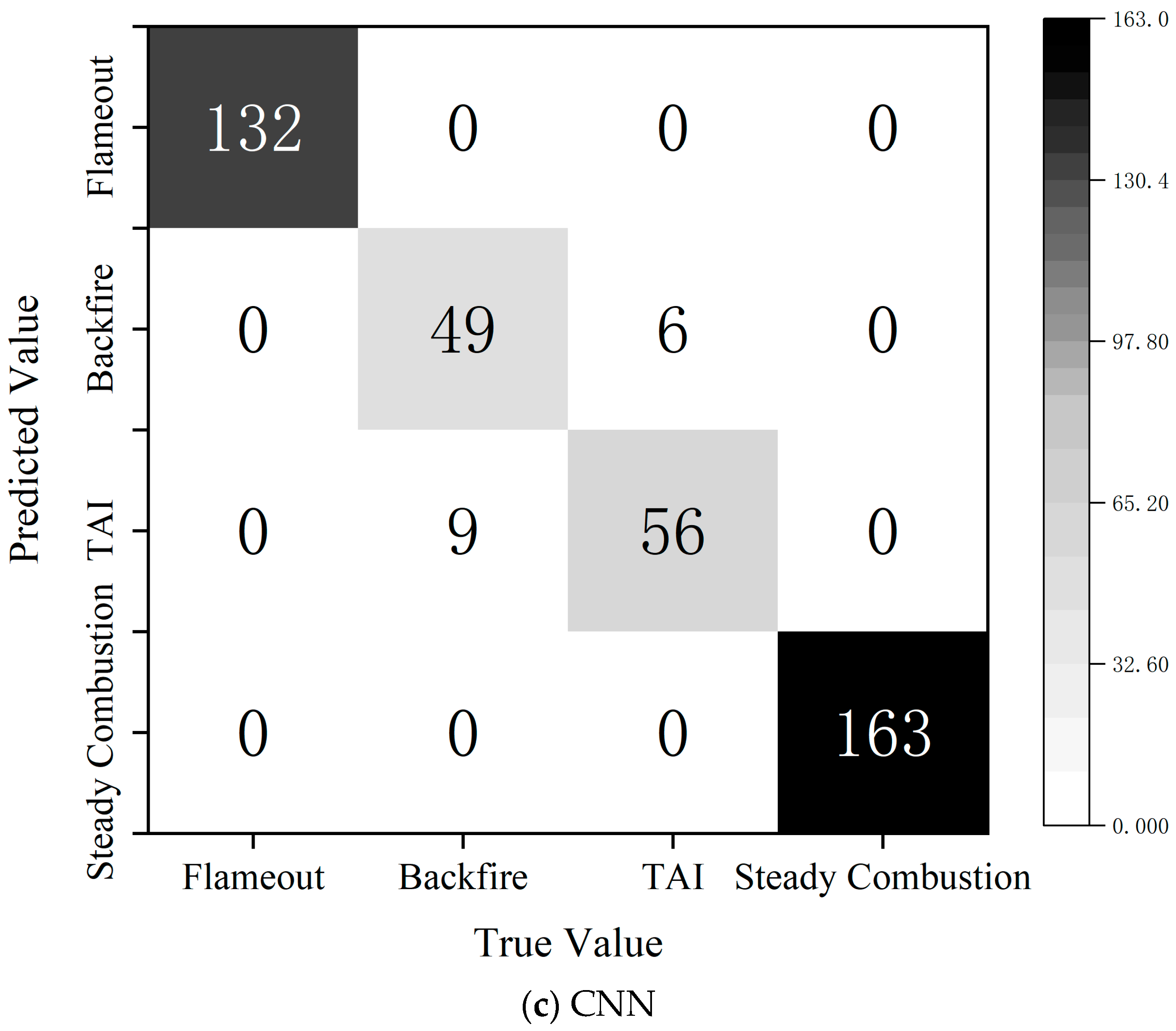

4.2. Diagnosis Results of Different Models

5. Summary, Conclusions, and Future Work

- (1)

- The step index P exhibits high specificity in the flameback state, allowing it to effectively distinguish abnormal changes in the combustion state. It serves as a decision-making tool to determine whether to disconnect the fuel supply, thereby enhancing combustion safety.

- (2)

- By monitoring the frequency-domain characteristics of the signal, the change in the burner state can be accurately identified. Compared to time-domain analysis, frequency-domain information provides a more intuitive reflection of the dynamic changes in combustion state, offering valuable insight for combustion stability analysis.

- (3)

- In the combustion state diagnosis system, CNN demonstrates the best classification ability, effectively distinguishing between the four states: flameout, flameback, thermoacoustic oscillation, and stable combustion. Its confusion matrix reveals the lowest misjudgment rate and the strongest generalization ability. While ANN performs slightly worse than CNN in classification accuracy, it exhibits some local fluctuations during the training process, potentially influenced by local optimization. The BP neural network, on the other hand, has a slow training convergence speed, a high misjudgment rate for flameback and thermoacoustic oscillation states, and relatively weak overall diagnostic performance. In summary, this study shows that the combustion state diagnosis system based on the CNN model combined with voiceprint features has the best performance, and the combination of step index P for flameback diagnosis and frequency-domain monitoring can further enhance the accurate identification and safety control of combustion state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Zhou, W. Support carbon neutrality target—Which flexible power source is the best option for China? Energy 2023, 285, 128682. [Google Scholar] [CrossRef]

- Su, X.; Fang, Q.; Ma, L.; Yao, B.; Li, Y.; Zhao, X.; Mao, R.; Yin, C. Improving combustion and lowering NO emissions of an industrial coal swirl burner by optimizing its nozzle structure. Appl. Therm. Eng. 2023, 218, 119340. [Google Scholar] [CrossRef]

- Shao, X.; Shi, W.; Jia, H.; Yang, X.; Pei, B.; Pu, L.; Gao, J. Flameback identification and air intrusion prevention in small flow hydrogen flare stack emissions. Int. J. Hydrogen Energy 2024, 53, 717–727. [Google Scholar] [CrossRef]

- Ma, B.; Li, J.; Zhang, Z.; Xi, Y.; Zhao, D.; Wang, N. Experimental and theoretical studies on thermoacoustic limit cycle oscillation in a simplified solid rocket motor using flat flame burner. Acta Astronaut. 2021, 189, 26–42. [Google Scholar] [CrossRef]

- Chen, X.; Hemchandra, S.; Fathy, H.; O’connor, J. Linear control of thermoacoustic oscillations with flame dynamics modeled by a level-set method. Combust. Flame 2022, 237, 111686. [Google Scholar] [CrossRef]

- Kasthuri, P.; Pawar, S.A.; Gejji, R.; Anderson, W.; Sujith, R.I. Coupled interaction between acoustics and unsteady flame dynamics during the transition to thermoacoustic instability in a multi-element rocket combustor. Combust. Flame 2022, 240, 112047. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, Y.; DING, F.; Wang, H.; Cen, K. Investigation on control effects of loudspeaker on the thermoacoustic instability in a Rijke combustor. J. Vib. Shock 2016, 35, 22. [Google Scholar]

- Ji, L.; Wang, J.; Zhang, W.; Li, D.; Hu, G.; Huang, Z. Nonlinear dynamic characteristics of self-excited thermoacoustic instabilities in premixed swirling flames. Exp. Therm. Fluid Sci. 2024, 150, 111033. [Google Scholar] [CrossRef]

- Yang, J.; Yan, S.; Gong, Y.; Guo, Q.; Ding, L.; Yu, G. Application study of Dynamic Mode Decomposition coupled with a high-speed imaging system in jet zone oscillation behavior diagnosis of impinging flames. Control Eng. Pract. 2023, 135, 105494. [Google Scholar] [CrossRef]

- Ming, Z.; Liu, H.; Cui, Y.; Wen, M.; Zhang, X.; Yao, M. Optical diagnosis study of fuel volatility on combustion characteristics of spray flame and wall-impinging flame. Fuel Process. Technol. 2023, 250, 107880. [Google Scholar] [CrossRef]

- He, L.; Guo, Q.; Gong, Y.; Wang, F.; Yu, G. Investigation of OH* chemiluminescence and heat release in laminar methane–oxygen co-flow diffusion flames. Combust. Flame 2019, 201, 12–22. [Google Scholar] [CrossRef]

- Butterworth, T.D.; Cha, M.S. Electric field measurement in electric-field modified flames. Proc. Combust. Inst. 2020, 38, 6651–6660. [Google Scholar] [CrossRef]

- Bhattacharya, C.; De, S.; Mukhopadhyay, A.; Sen, S.; Ray, A. Detection and Classification of Lean Blow-Out and Thermoacoustic Instability in Turbulent Combustors. Appl. Therm. Eng. 2020, 180, 115808. [Google Scholar] [CrossRef]

- Tang, L.; Tian, H.; Huang, H.; Shi, S.; Ji, Q. A survey of mechanical fault diagnosis based on audio signal analysis. Measurement 2023, 220, 113294. [Google Scholar] [CrossRef]

- Detriche, P.; Lanore, J.C. An acoustic study of pulsation features of fires. Fire Technol 1980, 16, 204–211. [Google Scholar] [CrossRef]

- Yu, M.; Gupta, A.; Bryden, K.M. Sensor Response and Sensor Network Development for Practical Combustors. In Proceedings of the 16th International Conference on Computer Communications and Networks, Honolulu, Hawaii, 13–16 August 2007. [Google Scholar]

- Singh, A.V.; Yu, M.; Gupta, A.K.; Bryden, K.M. Thermo-acoustic behavior of a swirl stabilized diffusion flame with heterogeneous sensors. Appl. Energy 2013, 106, 1–16. [Google Scholar] [CrossRef]

- Khalil, A.E.; Gupta, A.K. Acoustic and heat release signatures for swirl assisted distributed combustion. Appl. Energy 2017, 193, 125–138. [Google Scholar] [CrossRef]

- Mondal, S.; Bhattacharya, C.; Chattopadhyay, P.; Mukhopadhyay, A.; Ray, A. Prediction of Thermoacoustic Instabilities in a Premixed Combustor based on FFT-based Dynamic Characterization. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 20 October 2023. [Google Scholar]

- Hanifa, R.M.; Isa, K.; Mohamad, S. A review on speaker recognition: Technology and challenges. Comput. Electr. Eng. 2021, 90, 107005. [Google Scholar] [CrossRef]

- Shan, S.; Liu, J.; Wu, S.; Shao, Y.; Li, H. A motor bearing fault voiceprint recognition method based on Mel-CNN model. Measurement 2023, 207, 112408. [Google Scholar] [CrossRef]

- Li, X.; Xiao, J.; Gao, S.; Wang, F.; Wang, W.; Xia, J. Study on the acoustic features of a heavy-duty gas turbine combustor. J. Eng. Res. 2023, 11, 100068. [Google Scholar] [CrossRef]

- Yao, P.; Wang, J.; Zhang, F.; Li, W.; Lv, S.; Jiang, M.; Jia, L. Intelligent Rolling Bearing Imbalanced Fault Diagnosis Based on Mel-Frequency Cepstrum Coefficient and Convolutional Neural Networks. Measurement 2022, 205, 112143. [Google Scholar] [CrossRef]

- Luan, X.; Liu, G.; Sha, Y.; He, H.; Guo, X. Experiment study on traveling wave resonance of fatigue fracture of high-speed bevel gear in aero-engne based on acoustic measurement method. J. Sound Vib. 2021, 511, 116345. [Google Scholar] [CrossRef]

- Broatch, A.; Novella, R.; García-Tíscar, J.; Gomez-Soriano, J. On the shift of acoustic characteristics of compression-ignited engines when operating with gasoline partially premixed combustion. Appl. Therm. Eng. 2018, 146, 223–231. [Google Scholar] [CrossRef]

- Picone, J. Signal modeling techniques in speech recognition. Proc. IEEE 1993, 81, 1215–1247. [Google Scholar] [CrossRef]

- Chowdhury, A.; Ross, A. Fusing MFCC and LPC features using 1D triplet CNN for speaker recognition in severely degraded audio signals. IEEE Trans. Inf. Forensics Secur. 2019, 15, 1616–1629. [Google Scholar] [CrossRef]

- Rao, K.S.; Manjunath, K.E. Speech Recognition Using Articulatory and Excitation Source Features; Springer Nature: Dordrecht, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Zheng, F.; Zhang, G.; Song, Z. Comparison of different implementations of MFCC. J. Comput. Sci. Technol. 2000, 16, 582–589. [Google Scholar] [CrossRef]

- Ganchev, T.; Fakotakis, N.; Kokkinakis, G. Comparative evaluation of various MFCC implementations on the speaker verification task. In Proceedings of the International Conference on Speech and Computer (SPECOM), Patras, Greece, 7–19 October 2005; pp. 191–194. [Google Scholar]

- Wang, Y.; Wu, J.; Yu, Z.; Hu, J.; Zhou, Q. A structurally re-parameterized convolution neural network-based method for gearbox fault diagnosis in edge computing scenarios. Eng. Appl. Artif. Intell. 2023, 126, 107091. [Google Scholar] [CrossRef]

| Condition | (SLM) | (SLM) | (SLM) | (SLM) | Air (SLM) |

|---|---|---|---|---|---|

| 0.95–1 | 112 | 59 | 30.4 | 30.4 | 171 |

| 0.95–2 | 112 | 59 | 22.4 | 30.4 | 171 |

| 0.90–1 | 112 | 62 | 30.4 | 30.4 | 173 |

| 0.90–2 | 112 | 62 | 21.4 | 30.4 | 173 |

| 0.85–1 | 112 | 65 | 30.4 | 30.4 | 176 |

| 0.85–2 | 112 | 65 | 20.4 | 30.4 | 176 |

| 0.80–1 | 112 | 69 | 30.4 | 30.4 | 180 |

| 0.80–2 | 112 | 69 | 19.4 | 30.4 | 180 |

| 0.75–1 | 112 | 74 | 30.4 | 30.4 | 185 |

| 0.75–2 | 112 | 74 | 18.4 | 30.4 | 185 |

| Model | Final Accuracy Rate | Loss of Convergence Speed | Stability | Generalization Ability |

|---|---|---|---|---|

| ANN | About 90% | The slowest convergence. | Has a rather great fluctuation. | Poor, lack of generalization ability. |

| BP | 91–93% | The convergence is slow, and the first 10 rounds fluctuate greatly. | Medium, but the loss fluctuates greatly. | Good, but easy to fall into local optimum. |

| CNN | 93.49% | The convergence is the fastest, and it is mostly stable after 10 rounds. | The most stable, no obvious shock. | Optimal, training error and test error minimum. |

| Misclassification Mode | The Misclassification Number of ANN Model | The Misclassification Number of BP Model | The Misclassification Number of CNN Model | Analysis |

|---|---|---|---|---|

| Misclassification of misfire extinguishment | 0 | 0 | 0 | All models can accurately classify the flameout state. |

| Flameback is mistaken for thermoacoustic oscillation | 12 | 12 | 6 | CNN is the least, BP and ANN are more, indicating that BP/ANN has a weak ability to classify flameback. |

| Thermoacoustic oscillation is misjudged as flameback | 6 | 12 | 9 | CNN has fewer misjudgments, and ANN performs slightly better than BP in this category. |

| Thermoacoustic oscillation is mistaken for flameout | 2 | 2 | 0 | CNN did not have this problem, and BP and ANN made misjudgments. |

| Misclassification of stable combustion | 0 | 0 | 0 | All models can accurately classify stable combustion states. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Wang, Y.; An, L.; Shen, G. Research on Combustion State System Diagnosis Based on Voiceprint Technology. Sensors 2025, 25, 3152. https://doi.org/10.3390/s25103152

Yan J, Wang Y, An L, Shen G. Research on Combustion State System Diagnosis Based on Voiceprint Technology. Sensors. 2025; 25(10):3152. https://doi.org/10.3390/s25103152

Chicago/Turabian StyleYan, Jidong, Yuan Wang, Liansuo An, and Guoqing Shen. 2025. "Research on Combustion State System Diagnosis Based on Voiceprint Technology" Sensors 25, no. 10: 3152. https://doi.org/10.3390/s25103152

APA StyleYan, J., Wang, Y., An, L., & Shen, G. (2025). Research on Combustion State System Diagnosis Based on Voiceprint Technology. Sensors, 25(10), 3152. https://doi.org/10.3390/s25103152