Modeling and Evaluation of an Energy-Saving Backpack with Adjustable Stiffness

Abstract

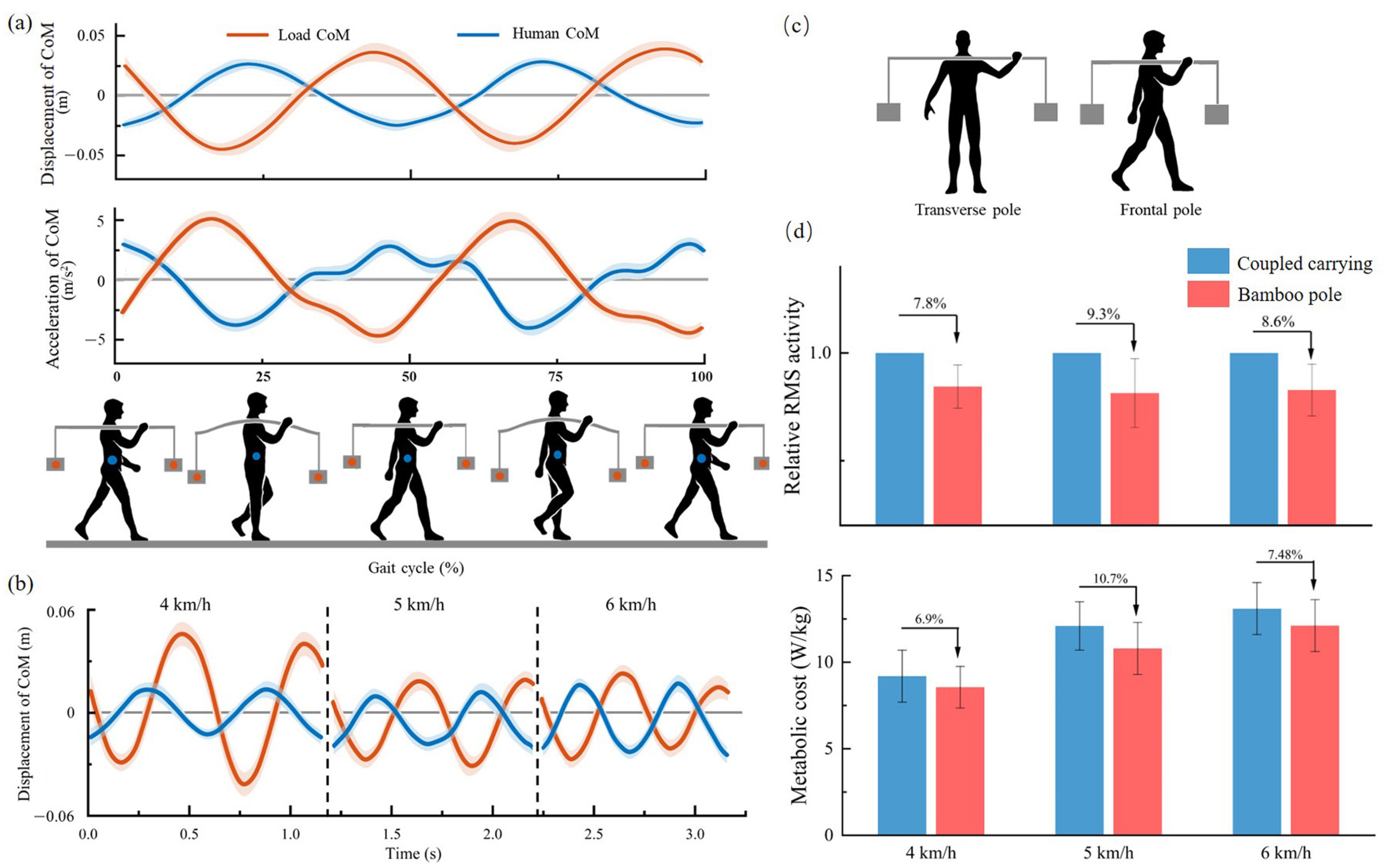

1. Introduction

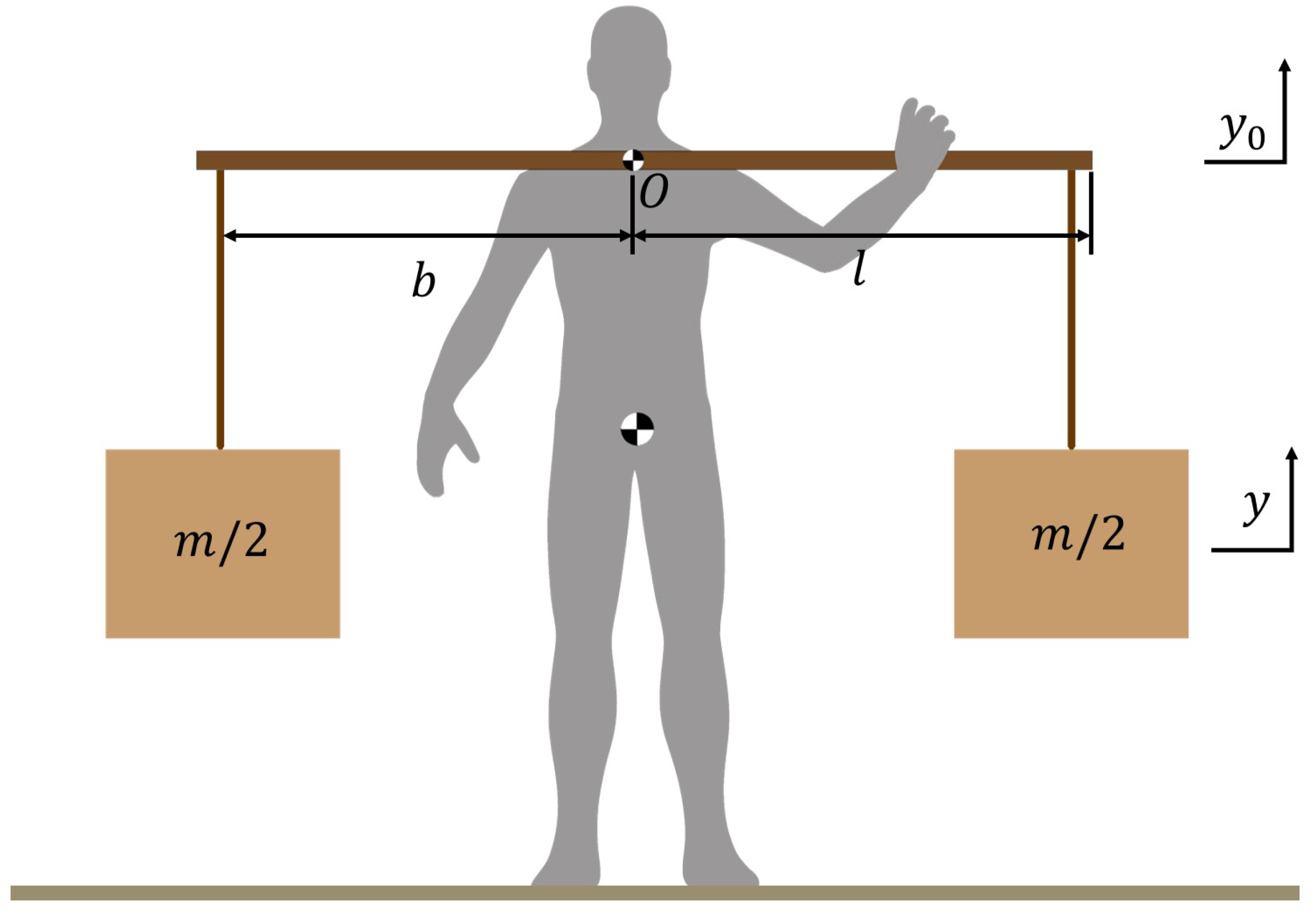

2. Development of Energy-Saving Theory

2.1. Theoretical Modeling

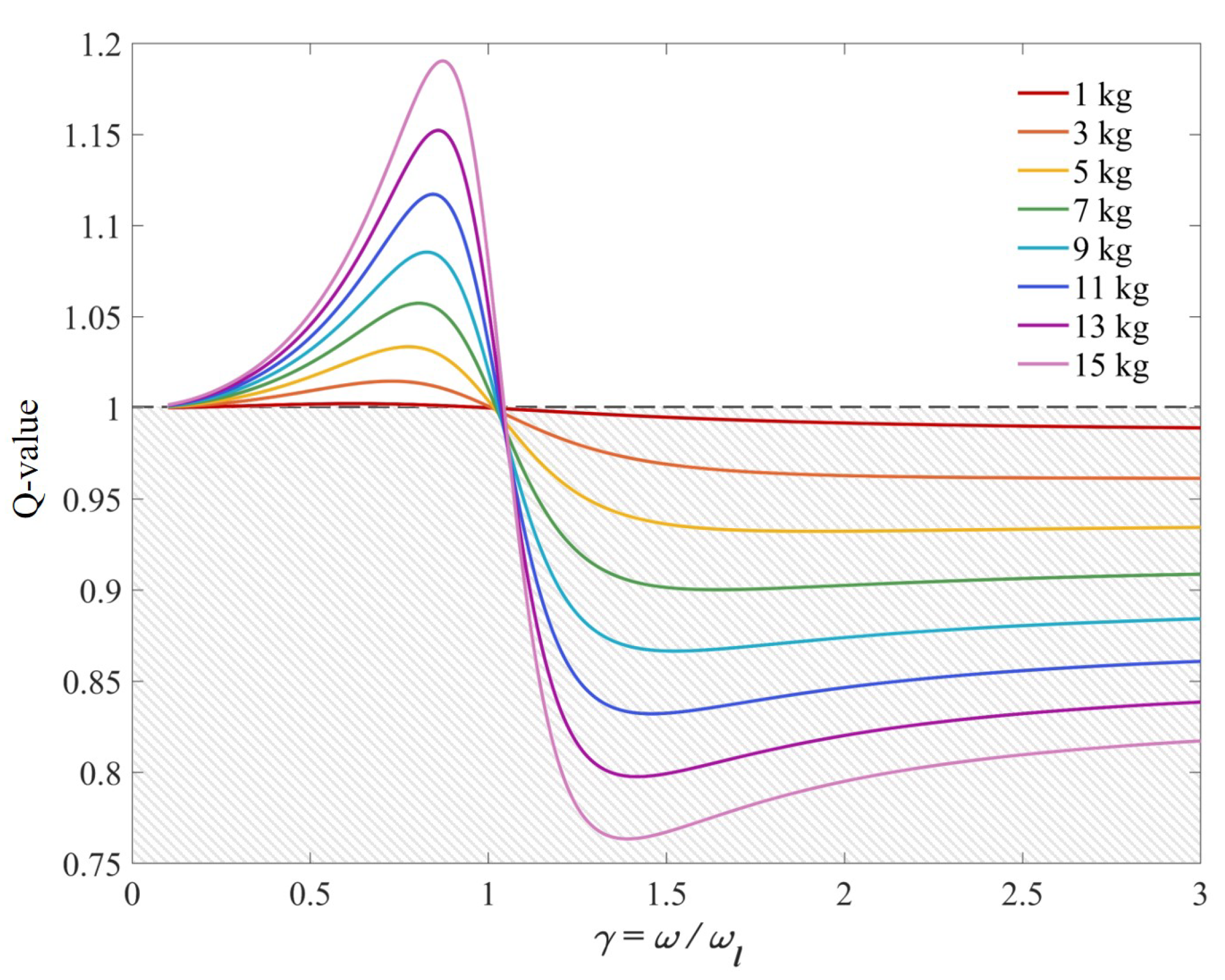

2.2. Energy-Saving Theory

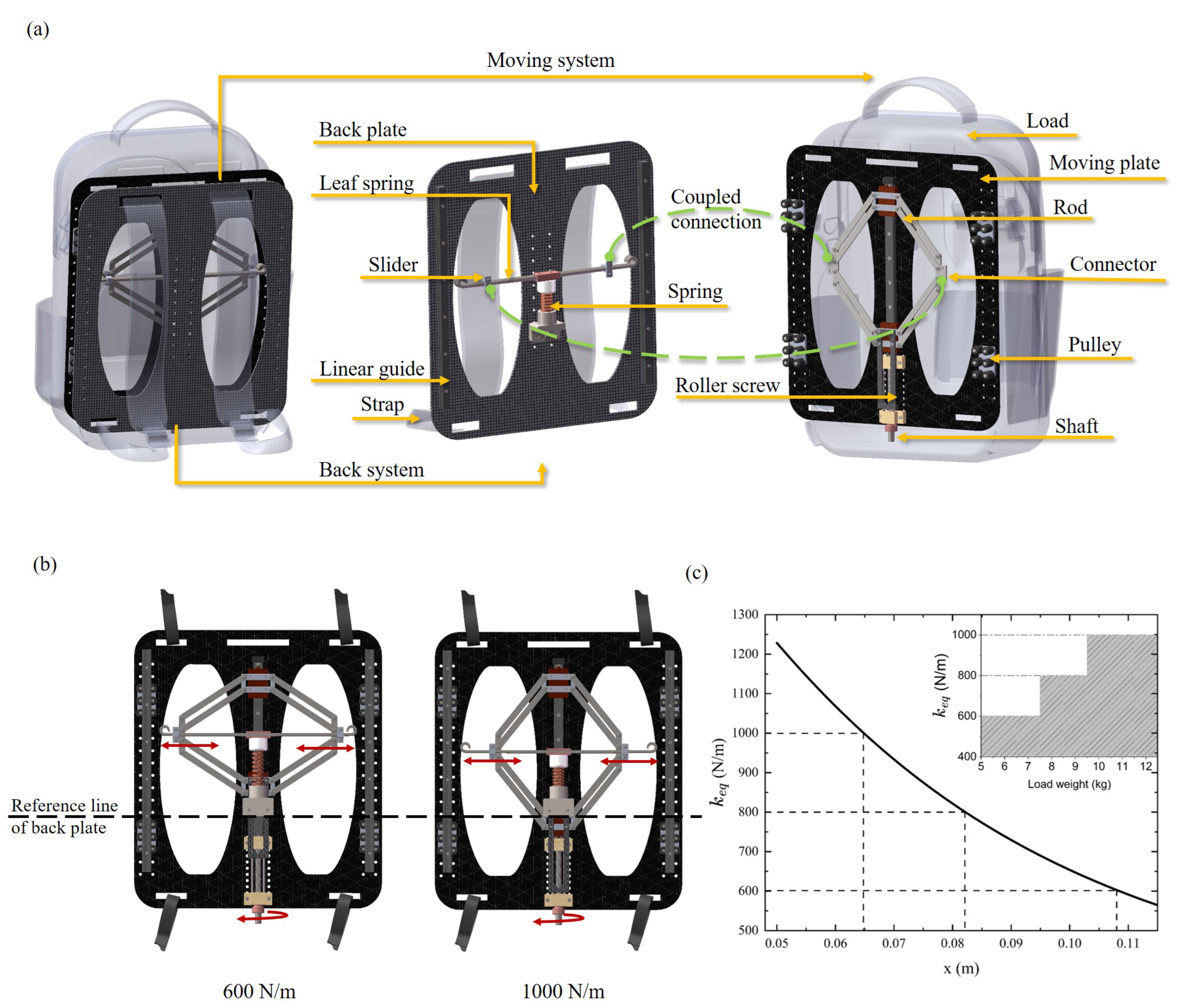

3. Design of Energy-Saving Backpack

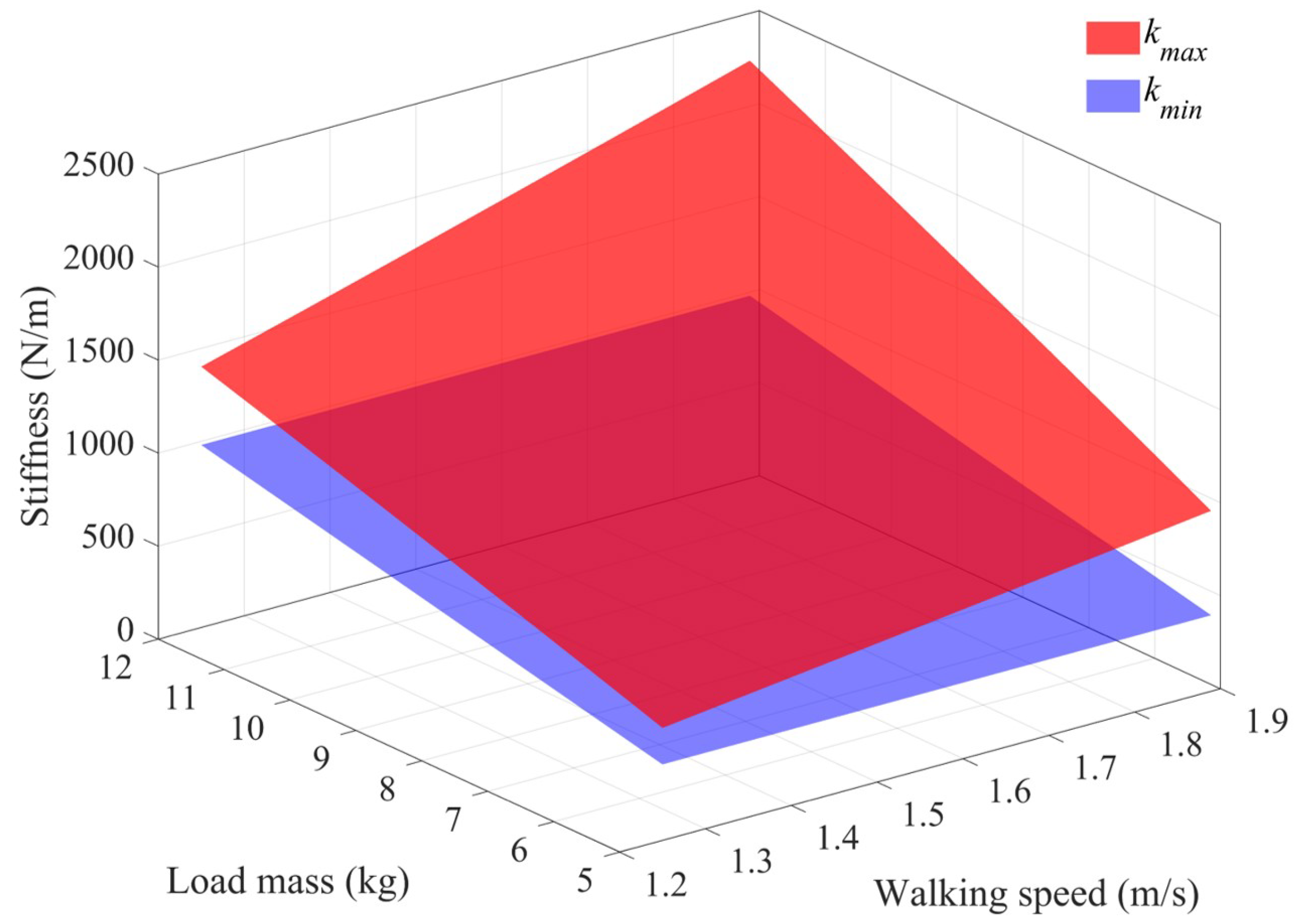

3.1. Parameter Selection

3.2. Backpack Design

4. Experiments and Results

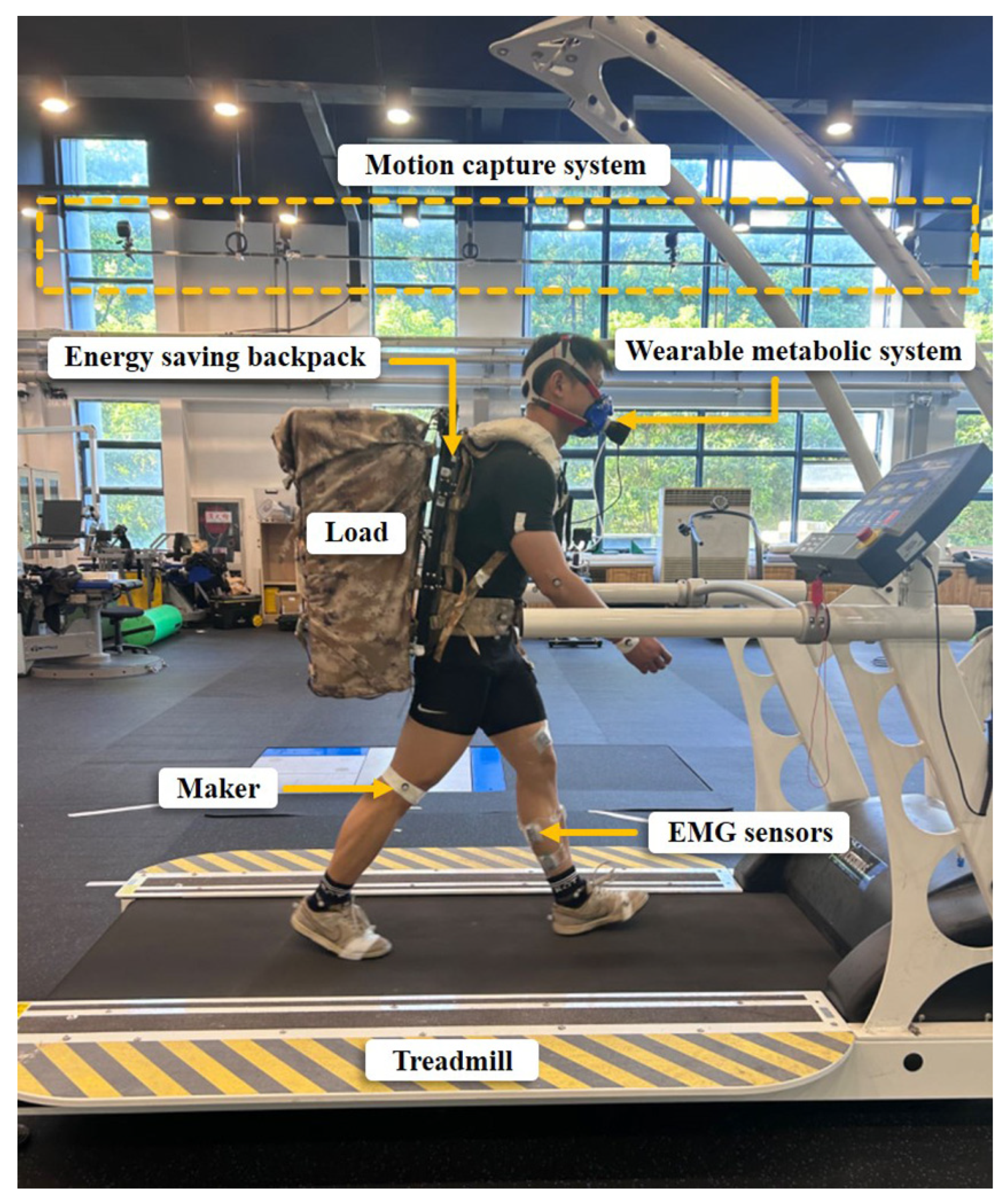

4.1. Experimental Setup

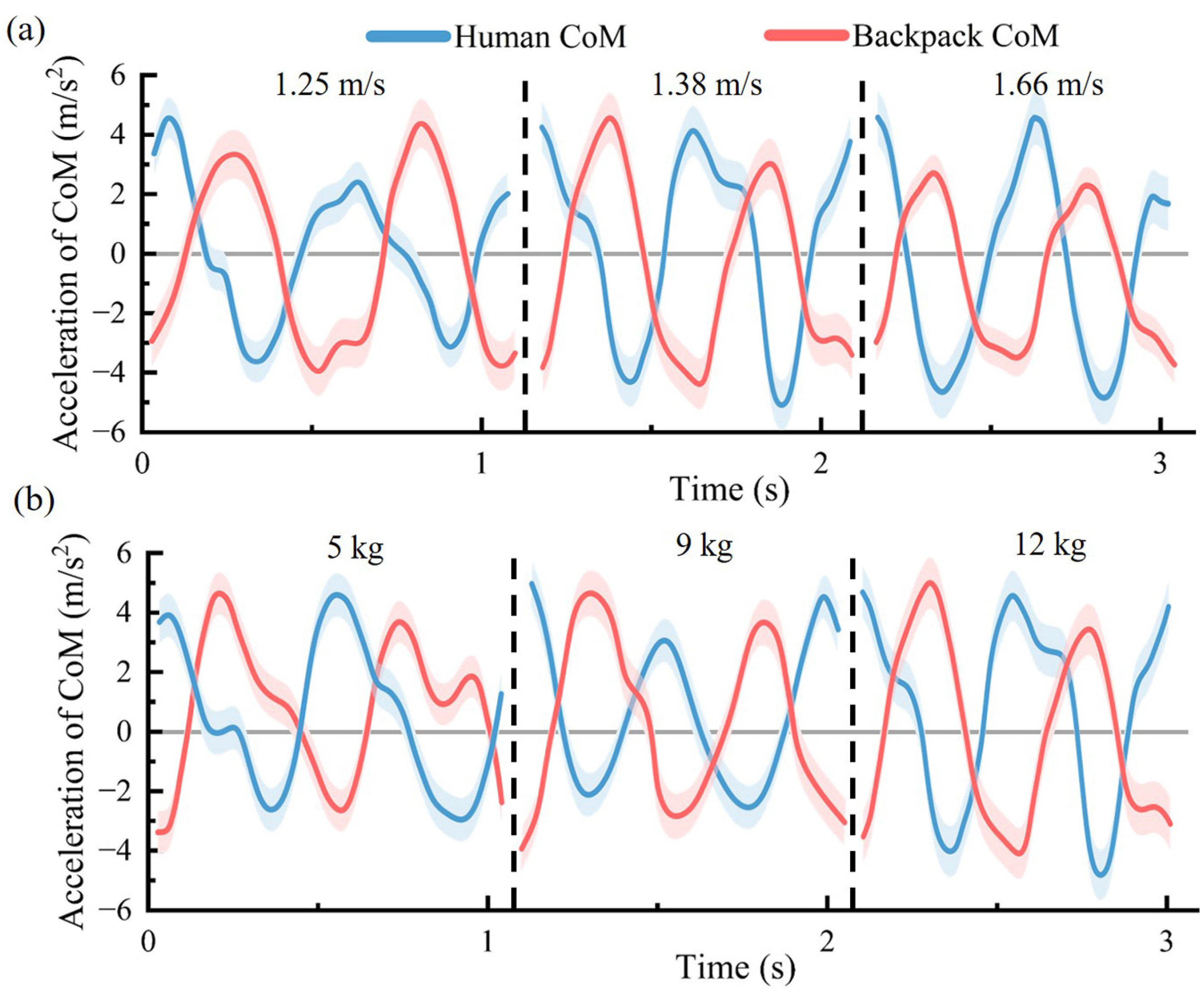

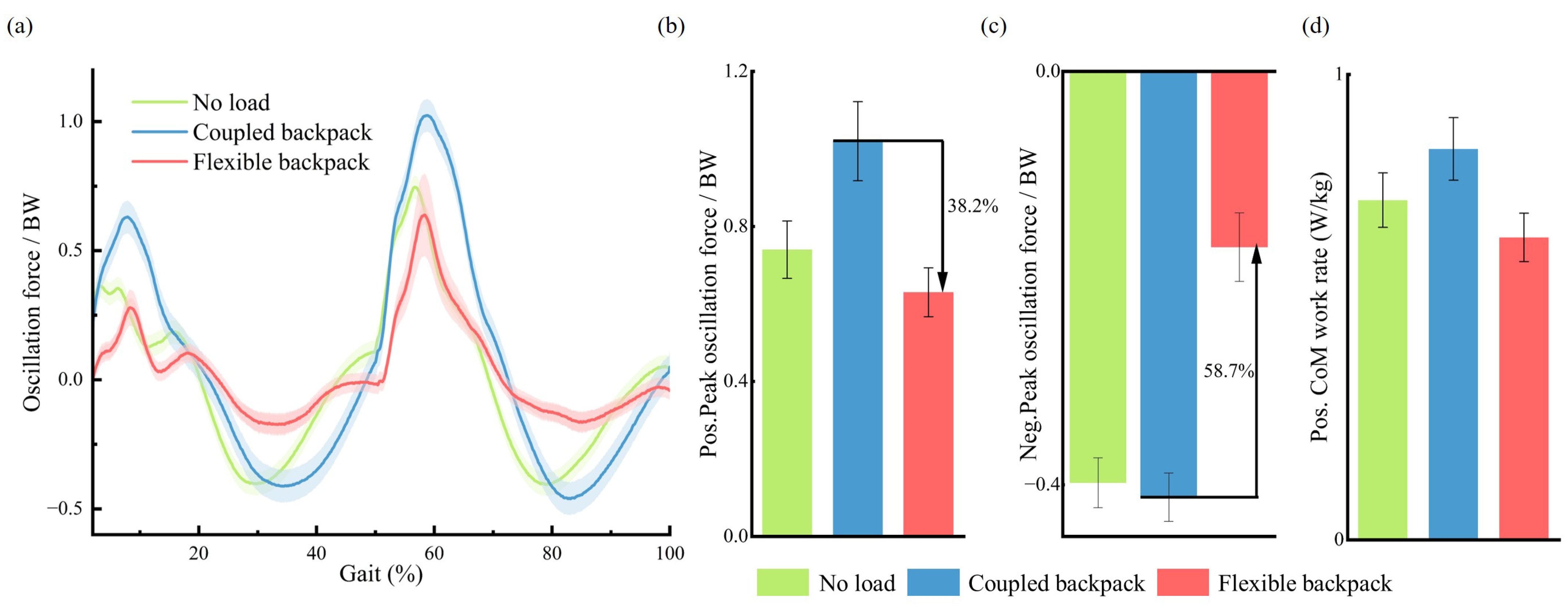

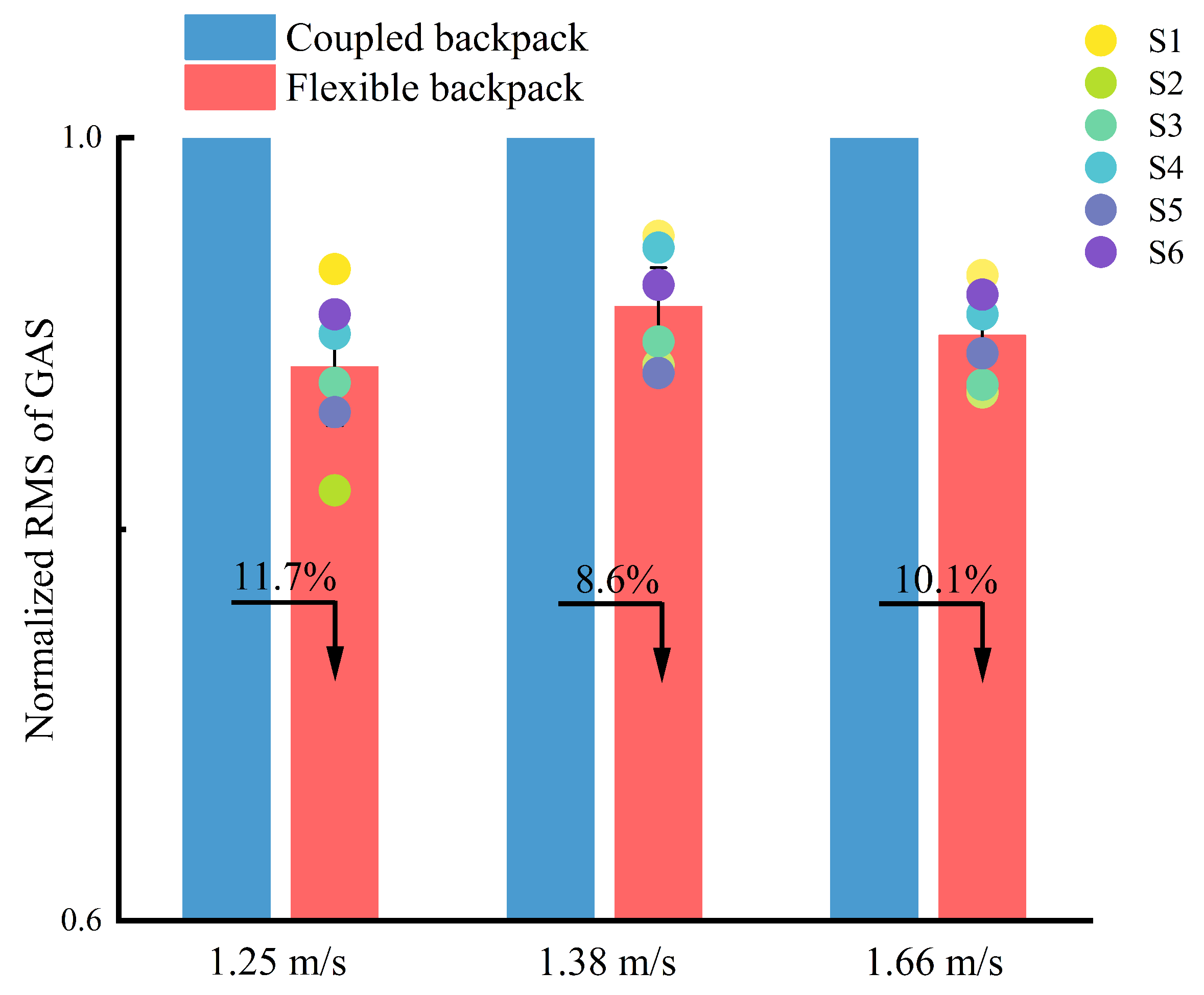

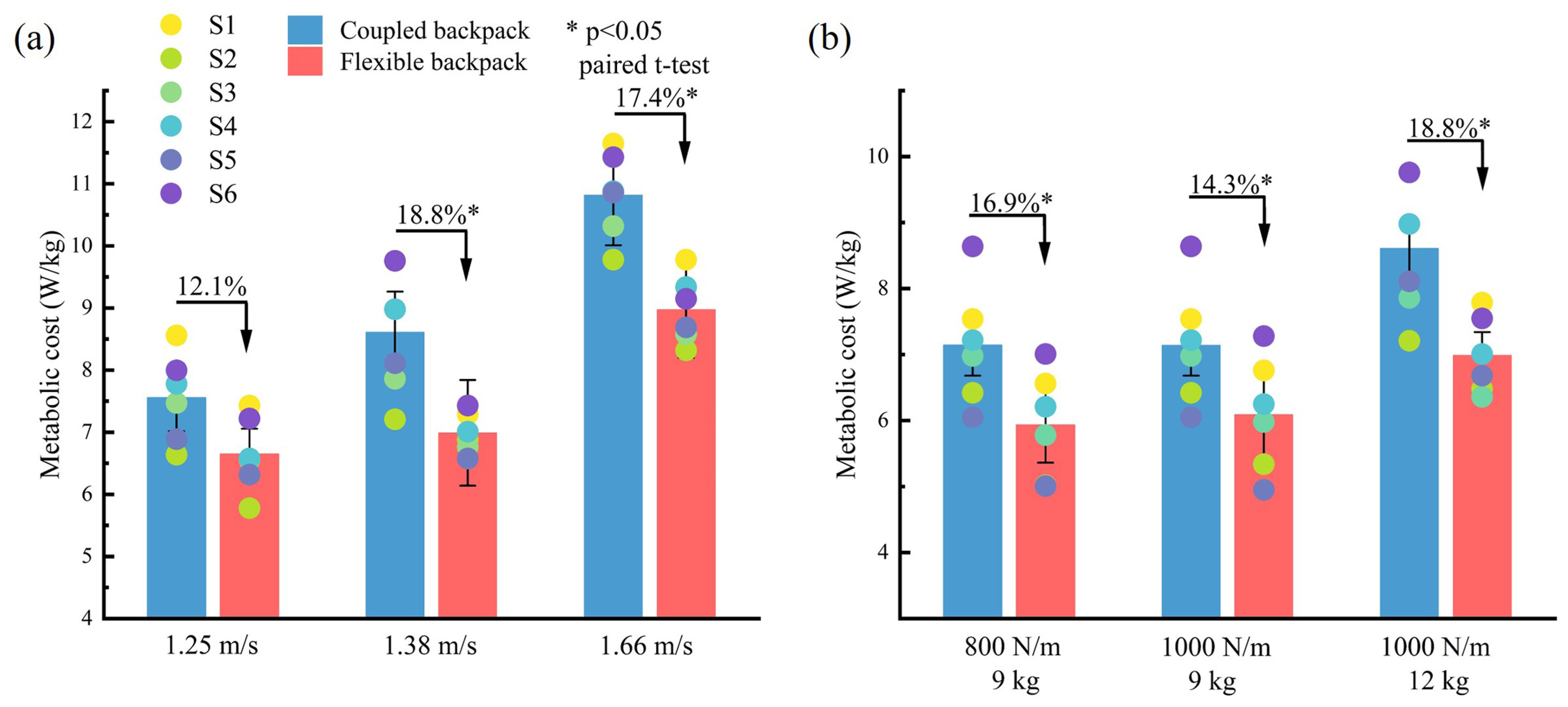

4.2. Results

5. Discussions

5.1. Stiffness Adjustment

5.2. Dynamic Oscillation Force

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kinoshita, H. Effects of different loads and carrying systems on selected biomechanical parameters describing walking gait. Ergonomics 1985, 28, 1347–1362. [Google Scholar] [CrossRef] [PubMed]

- Rohmert, W.; Wangenheim, M.; Mainzer, J.; Zipp, P. The effect of carried loads on the walking patterns of men and women. Clin. Biomech. 1987, 2, 55–59. [Google Scholar]

- Birrell, S.A.; Haslam, R.A. The effect of military load carriage on 3-D lower limb kinematics and spatiotemporal parameters. Ergonomics 2009, 52, 1298–1304. [Google Scholar] [CrossRef]

- Hong, Y.; Cheung, C.K. Gait and posture responses to backpack load during level walking in children. Gait Posture 2003, 17, 28–33. [Google Scholar] [CrossRef] [PubMed]

- Goodgold, S.; Mohr, K.; Samant, A.; Burns, T.; Parke, T.; Gardner, L. Trunk Forward Lean During Backpack Usage Under Varying Load and Task Demands: Pilot Findings of Two Boys. Pediatr. Phys. Ther. 2001, 13, 196. [Google Scholar] [CrossRef]

- Soangra, R.; Bhatt, H.; Rashedi, E. Effects of load carriage and surface inclination on linear and non-linear postural variability. Saf. Sci. 2018, 110, 427–437. [Google Scholar] [CrossRef]

- Roberts, M.; Talbot, C.; Kay, A.; Price, M.; Hill, M. Changes in postural sway and gait characteristics as a consequence of anterior load carriage. Gait Posture 2018, 66, 139–145. [Google Scholar] [CrossRef]

- Lyu, S.; LaBat, K.L. Effects of natural posture imbalance on posture deviation caused by load carriage. Int. J. Ind. Ergon. 2016, 56, 115–123. [Google Scholar] [CrossRef]

- Orloff, H.A.; Rapp, C.M. The effects of load carriage on spinal curvature and posture. Spine 2004, 29, 1325–1329. [Google Scholar] [CrossRef]

- Sheikhhoseini, R.; Sayyadi, P.; Piri, H. The Relationship between Schoolbag Carriage with Musculoskeletal Pain and Posture in Iranian Students: A Systematic Review Study. J. Orthop. Spine Trauma 2021, 7, 123–126. [Google Scholar] [CrossRef]

- Attwells, R.L.; Birrell, S.A.; Hooper, R.H.; Mansfield, N.J. Influence of carrying heavy loads on soldiers’ posture, movements and gait. Ergonomics 2006, 49, 1527–1537. [Google Scholar] [CrossRef]

- Birrell, S.A.; Hooper, R.H.; Haslam, R.A. The effect of military load carriage on ground reaction forces. Gait Posture 2007, 26, 611–614. [Google Scholar] [CrossRef] [PubMed]

- Orr, R.M.; Johnston, V.; Coyle, J.; Pope, R. Reported load carriage injuries of the Australian army soldier. J. Occup. Rehabil. 2015, 25, 316–322. [Google Scholar] [CrossRef]

- Fox, B.D.; Judge, L.W.; Dickin, D.C.; Wang, H. Biomechanics of military load carriage and resulting musculoskeletal injury: A review. J. Orthop. Orthop. Surg. 2020, 1, 6–11. [Google Scholar] [CrossRef]

- Walsh, G.S.; Low, D.C. Military load carriage effects on the gait of military personnel: A systematic review. Appl. Ergon. 2021, 93, 103376. [Google Scholar] [CrossRef]

- Kadota, J.L.; McCoy, S.I.; Bates, M.N.; Mnyippembe, A.; Njau, P.F.; Prata, N.; Harris-Adamson, C. The impact of heavy load carrying on musculoskeletal pain and disability among women in Shinyanga Region, Tanzania. Ann. Glob. Health 2020, 86, 17. [Google Scholar] [CrossRef] [PubMed]

- Golriz, S.; Walker, B. Can load carriage system weight, design and placement affect pain and discomfort? A systematic review. J. Back Musculoskelet. Rehabil. 2011, 24, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Liu, T.; Fan, W.; Zhang, J. Sliding mode control of the semi-active hover backpack based on the bioinspired skyhook damper model. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 9389–9395. [Google Scholar]

- Lin, X.; Yin, S.; Du, H.; Leng, Y.; Fu, C. Design and Investigation of a Suspended Backpack With Wide-Range Variable Stiffness Suspension for Reducing Energetic Cost. IEEE Trans.-Hum.-Mach. Syst. 2024, 54, 162–171. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, L.; Hu, J.; Wang, X.; Yang, Y.; Su, Y. Suspended-Load Backpacks to Reduce the Cost of Carrying Loads with Energy Scavenging Potential—Part 2: Bio-Inspired Pre-Rotation Design. Nanoenergy Adv. 2023, 3, 271–281. [Google Scholar] [CrossRef]

- He, L.; Xiong, C.; Zhang, Q.; Chen, W.; Fu, C.; Lee, K.M. A backpack minimizing the vertical acceleration of the load improves the economy of human walking. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1994–2004. [Google Scholar] [CrossRef]

- Park, J.H.; Stegall, P.; Zhang, H.; Agrawal, S. Walking with aBackpack using load distribution and dynamic load compensation reduces metabolic cost and adaptations to loads. IEEE Trans. Neural Syst. Rehabil. Eng. 2016, 25, 1419–1430. [Google Scholar] [CrossRef] [PubMed]

- Rome, L.C.; Flynn, L.; Yoo, T.D. Rubber bands reduce the cost of carrying loads. Nature 2006, 444, 1023–1024. [Google Scholar] [CrossRef]

- Huang, L.; Yang, Z.; Wang, R.; Xie, L. Physiological and biomechanical effects on the human musculoskeletal system while carrying a suspended-load backpack. J. Biomech. 2020, 108, 109894. [Google Scholar] [CrossRef]

- Leng, Y.; Lin, X.; Deng, R.; Chang, J.; Yang, L.; Zhang, K.; Fu, C. Design and Implement an Elastically Suspended Back Frame for Reducing the Burden of Carrier. In Proceedings of the 2021 6th IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Chongqing, China, 3–5 July 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 236–240. [Google Scholar]

- Leng, Y.; Lin, X.; Yang, L.; Zhang, K.; Chen, X.; Fu, C. A model for estimating the leg mechanical work required to walk with an elastically suspended backpack. IEEE Trans. Hum.-Mach. Syst. 2022, 52, 1303–1312. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, L.; Zeng, Z.; Wang, R.; Hu, R.; Xie, L. Evaluation of the load reduction performance via a suspended backpack with adjustable stiffness. J. Biomech. Eng. 2022, 144, 051001. [Google Scholar] [CrossRef]

- Foissac, M.; Millet, G.Y.; Geyssant, A.; Freychat, P.; Belli, A. Characterization of the mechanical properties of backpacks and their influence on the energetics of walking. J. Biomech. 2009, 42, 125–130. [Google Scholar] [CrossRef]

- Balogun, J.A. Ergonomic comparison of three modes of load carriage. Int. Arch. Occup. Environ. Health 1986, 58, 35–46. [Google Scholar] [CrossRef]

- Kram, R. Carrying loads with springy poles. J. Appl. Physiol. 1991, 71, 1119–1122. [Google Scholar] [CrossRef] [PubMed]

- Potwar, K.; Ackerman, J.; Seipel, J. Design of compliant bamboo poles for carrying loads. J. Mech. Des. 2015, 137, 011404. [Google Scholar] [CrossRef]

- Castillo, E.R.; Lieberman, G.M.; McCarty, L.S.; Lieberman, D.E. Effects of pole compliance and step frequency on the biomechanics and economy of pole carrying during human walking. J. Appl. Physiol. 2014, 117, 507–517. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhang, Y.; Yan, M.; Wang, X. Design and Analysis of an Energy-Saving Exoskeleton for Carrying Torso-Borne Loads. IEEE Robot. Autom. Lett. 2023, 8, 3518–3525. [Google Scholar] [CrossRef]

- Gottschall, J.S.; Kram, R. Energy cost and muscular activity required for propulsion during walking. J. Appl. Physiol. 2003, 94, 1766–1772. [Google Scholar] [CrossRef] [PubMed]

- Brockway, J. Derivation of formulae used to calculate energy expenditure in man. Hum. Nutrition. Clin. Nutr. 1987, 41, 463–471. [Google Scholar]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.-G. Statistical power analyses using g* power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, J.; Xu, Y.; Chen, K.; Fu, C. Energy performance analysis of a suspended backpack with an optimally controlled variable damper for human load carriage. Mech. Mach. Theory 2020, 146, 103738. [Google Scholar] [CrossRef]

- Kuo, A.D. The six determinants of gait and the inverted pendulum analogy: A dynamic walking perspective. Hum. Mov. Sci. 2007, 26, 617–656. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Chen, Z.; Zhang, Y.; Wang, X. Modeling and Evaluation of an Energy-Saving Backpack with Adjustable Stiffness. Sensors 2025, 25, 3099. https://doi.org/10.3390/s25103099

Wu J, Chen Z, Zhang Y, Wang X. Modeling and Evaluation of an Energy-Saving Backpack with Adjustable Stiffness. Sensors. 2025; 25(10):3099. https://doi.org/10.3390/s25103099

Chicago/Turabian StyleWu, Jiyuan, Zhiquan Chen, Yinglong Zhang, and Xingsong Wang. 2025. "Modeling and Evaluation of an Energy-Saving Backpack with Adjustable Stiffness" Sensors 25, no. 10: 3099. https://doi.org/10.3390/s25103099

APA StyleWu, J., Chen, Z., Zhang, Y., & Wang, X. (2025). Modeling and Evaluation of an Energy-Saving Backpack with Adjustable Stiffness. Sensors, 25(10), 3099. https://doi.org/10.3390/s25103099