Implementation Method of Five-Axis CNC RTOS Kernel Based on gLink-II Bus

Abstract

1. Introduction

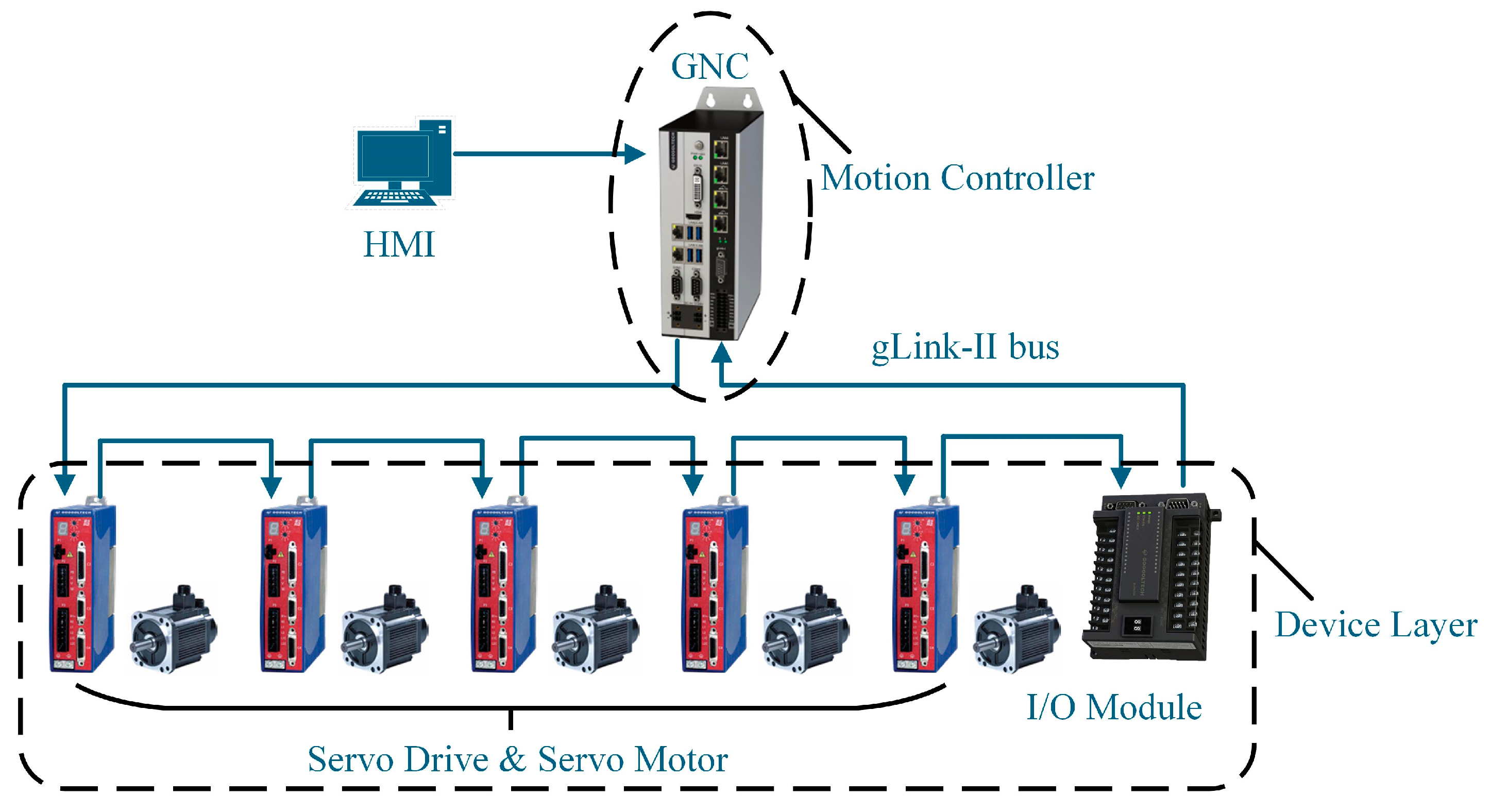

2. Materials

2.1. The Topology Structure of the gLink-II Bus Numerical Control System

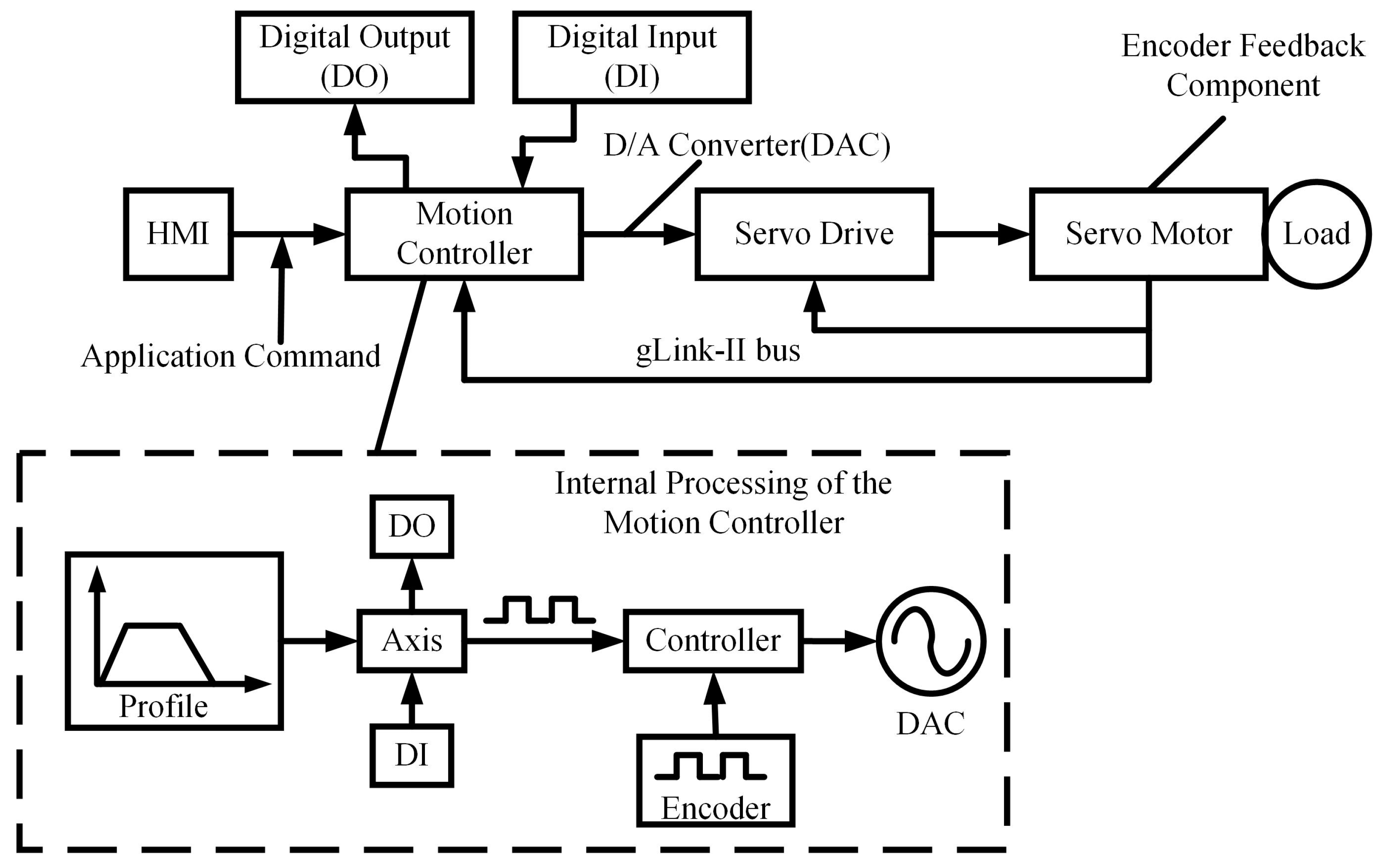

2.2. Configuration of System Closed-Loop Control Mode

3. Methods

3.1. Implementation of Functions in RTOS Kernel

3.1.1. Cutter Location File Parsing in RTOS

3.1.2. Calculation of Interpolated Command Position Data

3.1.3. Acceleration and Deceleration Control Based on Rotational Axis Kinematic Constraints

- (1)

- Based on the Rotational Axis Maximum Angular Velocity Constraint

- (2)

- Based on Rotational Axis Maximum Angular Acceleration Constraint

3.1.4. Real-Time Post-Processing of Interpolated Machining Cutter Locations

3.2. Communication Tasks and Mechanisms in RTOS

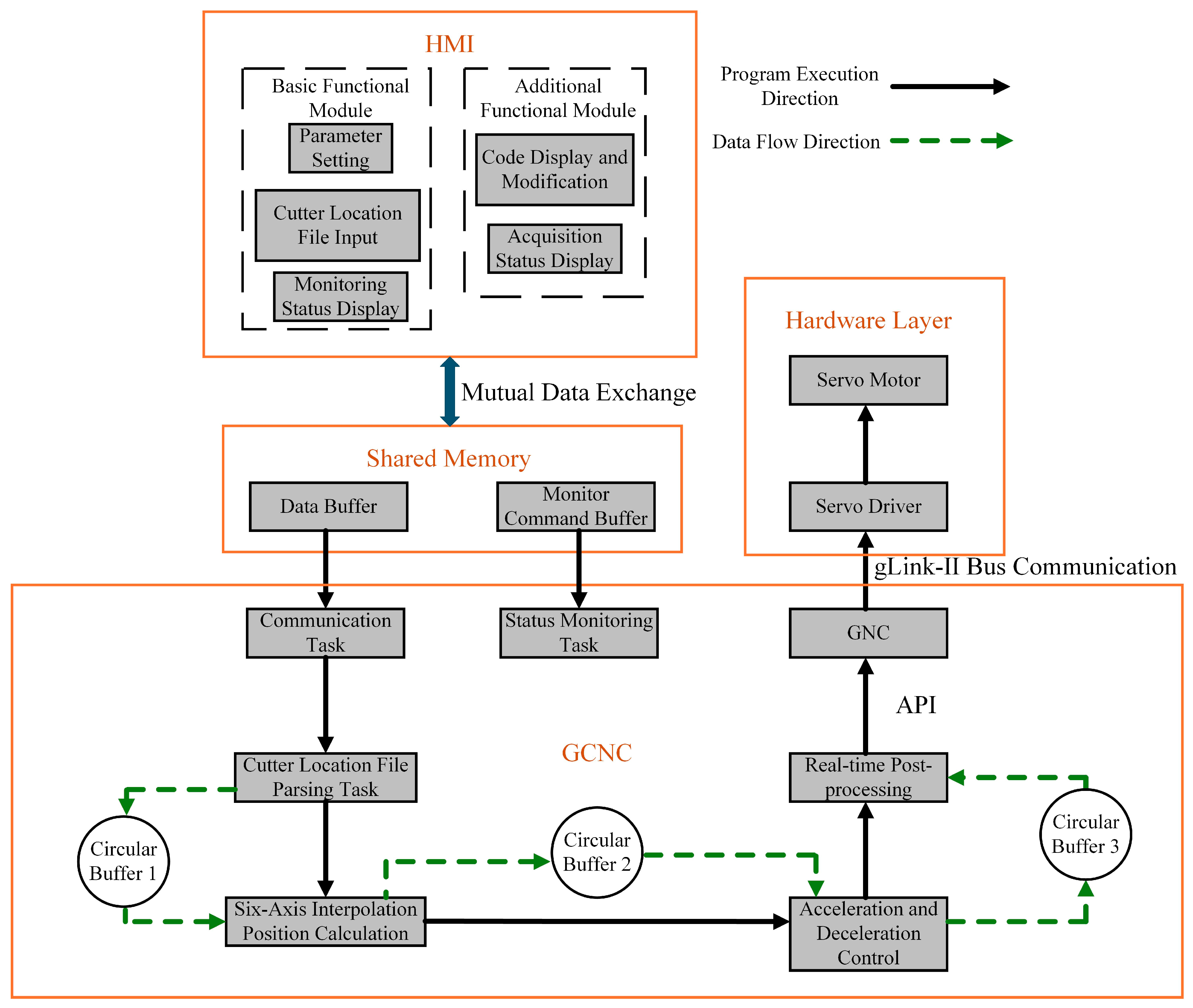

3.3. CNC System Program Execution and Data Flow Direction

4. Results

4.1. Experimental Platform

4.2. Motor Speed Simulation Example

4.3. Real-Time Performance Verification

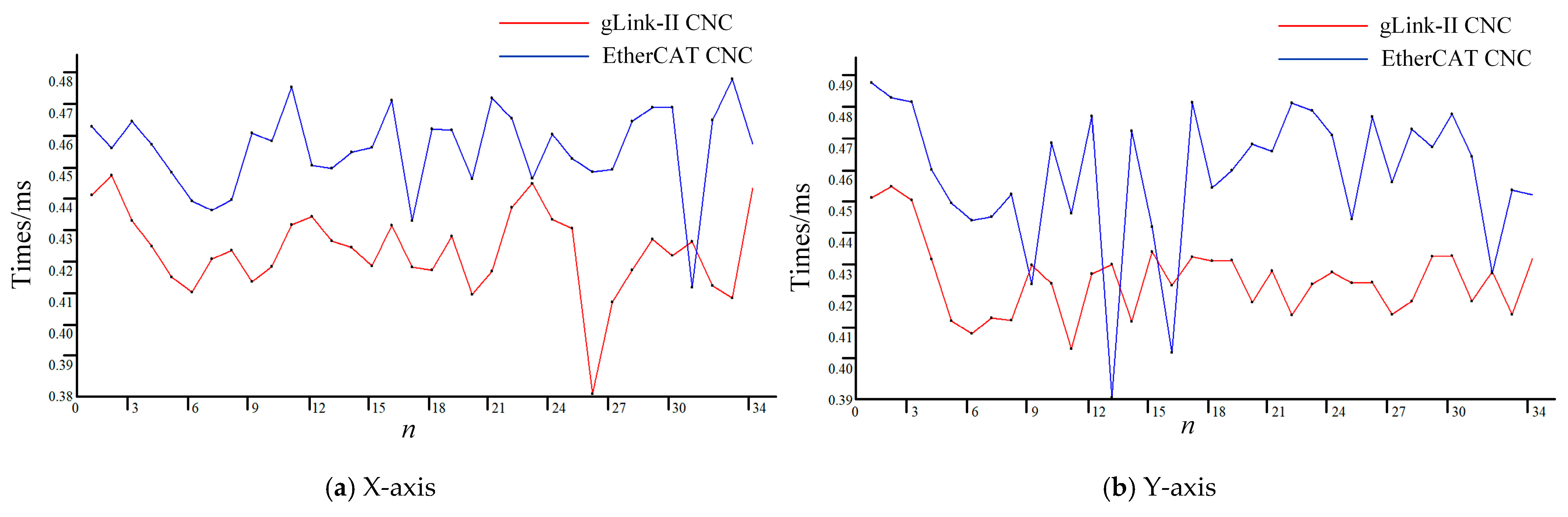

4.3.1. Response Error

4.3.2. Real-Time Performance Within the Interpolation Cycle

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kong, X.Y.; Wang, L.P.; Yu, G.A.; Li, W.T.; Li, M.Y. Research on Servo Matching of a Five-Axis Hybrid Machine Tool. Int. J. Adv. Manuf. Technol. 2023, 129, 983–997. [Google Scholar] [CrossRef]

- Wan, J.F.; Yang, J.; Wang, S.Y.; Li, D.; Li, P.; Xia, M. Cross-Network Fusion and Scheduling for Heterogeneous Networks in Smart Factory. IEEE Trans. Ind. Inform. 2020, 16, 6059–6068. [Google Scholar] [CrossRef]

- Kim, D.H.; Choi, J.Y. Development of a Common API for Multiple Ethernet Fieldbus Protocols in Embedded Slave Devices. Electronics 2025, 14, 613. [Google Scholar] [CrossRef]

- An, Y.M.; Kim, C.H.; Chol-Jun, O. A Novel External Modular Hardware Architecture for PC-Based Soft-CNC System. Int. J. Adv. Manuf. Technol. 2023, 127, 3061–3075. [Google Scholar] [CrossRef]

- Koyasako, Y.; Suzuki, T.; Hatano, T.; Shimada, T.; Yoshida, T. Demonstration of Industrial Ethernet Protocol Softwarization and Advanced Motion Control for Full Software-Defined Factory Network. IEEE Access 2024, 12, 104020–104030. [Google Scholar] [CrossRef]

- Aboshosha, A. Automation Network Computer Aided Design of Hybrid Electrical Energy Backup System for Nuclear Microgrids. Int. J. Hydrogen Energy 2024, 90, 992–1002. [Google Scholar] [CrossRef]

- Martínez-Ruedas, C.; Adame-Rodríguez, F.J.; Díaz-Cabrera, J.M. Integrating and Interconnecting of Older SINUMERIK CNC Machines with Industry 4.0 Using a Plug-And-Play System. J. Ind. Inf. Integr. 2024, 38, 100583. [Google Scholar] [CrossRef]

- Zhou, X.Y. An Optimized Data Interaction Structure for SERCOS-Based Open CNC System. Int. J. Adv. Manuf. Technol. 2023, 129, 4643–4661. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, H.T.; Xiao, J.L.; Tian, W.J.; Ma, Y.; Li, B. Open-Architecture of CNC System and Mirror Milling Technology for a 5-Axis Hybrid Robot. Robot. Comput.-Integr. Manuf. 2023, 81, 102504. [Google Scholar] [CrossRef]

- Ahmad, M.I.; Yusof, Y.; Mustapa, M.S.; Daud, M.E.; Latif, K.; Kadir, A.; Saif, Y.; Adam, A.; Hatem, N. A Novel Integration between Service-Oriented IoT-Based Monitoring with Open Architecture of CNC System Monitoring. Int. J. Adv. Manuf. Technol. 2022, 131, 5625–5636. [Google Scholar] [CrossRef]

- Hatem, N.; Yusof, Y.; Kadir, A.; Latif, K.; Mohammed, M.N. A Novel Integrating between Tool Path Optimization Using an ACO Algorithm and Interpreter for Open Architecture CNC System. Expert Syst. Appl. 2021, 178, 114988. [Google Scholar] [CrossRef]

- Liu, L.S.; Yao, Y.X.; Li, J.G. Development of a Novel Component-Based Open CNC Software System. Int. J. Adv. Manuf. Technol. 2020, 108, 3547–3562. [Google Scholar] [CrossRef]

- Wojtulewicz, A.; Chaber, P. Industrial Robot Control System with a Predictive Maintenance Module Using IIoT Technology. Sensors 2025, 25, 1154. [Google Scholar] [CrossRef]

- Zivanovic, S.; Dimic, Z.; Furtula, M.; Slavkovic, N.; Djurkovic, M.; Vidakovic, J. A Flexible Programming and Verification Methodology for Reconfigurable CNC Woodworking Machine. BioResources 2024, 19, 9708–9726. [Google Scholar] [CrossRef]

- Dimic, Z.; Zivanovic, S.; Pavlovic, D.; Furtula, M.; Djurkovic, M.; Rakic, A.; Kokotovic, B. Reconfigurable Open Architecture Control System with Integrated Digital Twin for 3-Axis Woodworking Milling Machine. Wood Mater. Sci. Eng. 2024, 19, 1295–1304. [Google Scholar] [CrossRef]

- Cheng, Y.M. Machining with a Precision Five-Axis Machine Tools Created by Combining a Horizontal Parallel Three-Axis Motion Platform and a Three-Axis Machine Tools. Materials 2022, 15, 2268. [Google Scholar] [CrossRef]

- Zhang, J.J.; Xia, M.J.; Li, H.; Li, S.S.; Shi, J. The Design and Real-Time Optimization of an EtherCAT Master for Multi-Axis Motion Control. Electronics 2024, 13, 3101. [Google Scholar] [CrossRef]

- Jinchuan, P.; Hu, Y.X.; Le, T.; Ziyong, L. DR-IS: Dynamic Response Incremental Scheduling in Time-Sensitive Network. China Commun. 2024, 21, 1–15. [Google Scholar] [CrossRef]

- Yoo, T.; Choi, B.W. Real-Time Performance Benchmarking of RISC-V Architecture: Implementation and Verification on an EtherCAT-Based Robotic Control System. Electronics 2024, 13, 733. [Google Scholar] [CrossRef]

- Adelt, J.; Gebker, J.; Herber, P. Reusable Formal Models for Concurrency and Communication in Custom Real-Time Operating Systems. Int. J. Softw. Tools Technol. Transf. 2024, 26, 229–245. [Google Scholar] [CrossRef]

- Jeon, B.; Yoon, J.-S.; Um, J.; Suh, S.-H. The Architecture Development of Industry 4.0 Compliant Smart Machine Tool System (SMTS). J. Intell. Manuf. 2020, 31, 1837–1859. [Google Scholar] [CrossRef]

- Zhou, Z.; Yu, D.; Chen, M.; Qiao, Y.S.; Hu, Y.; He, W.W. An Edge Intelligence-Based Model Deployment Method for CNC Systems. J. Manuf. Syst. 2024, 74, 716–751. [Google Scholar] [CrossRef]

- Dong, Y.; An, W.Z.; Wang, Z.H.; Zhang, D.Z. An Artificial Intelligence-Assisted Flexible and Wearable Mechanoluminescent Strain Sensor System. Nano-Micro Lett. 2024, 17, 62. [Google Scholar] [CrossRef]

- Huang, D.; Song, J.B.; Zhang, X.Y. Semi-Supervised Social Bot Detection with Relational Graph Attention Transformers and Characteristics of the Social Environment. Inf. Fusion 2025, 118, 102956. [Google Scholar] [CrossRef]

- Li, H.; Wu, W.; Rastegar, J.; Guo, A. A Real-Time and Look-Ahead Interpolation Algorithm with Axial Jerk-Smooth Transition Scheme for Computer Numerical Control Machining of Micro-Line Segments. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 233, 2007–2019. [Google Scholar] [CrossRef]

- Wan, M.; Qin, X.-B.; Xiao, Q.-B.; Liu, Y.; Zhang, W.-H. Asymmetrical Pythagorean-Hodograph (PH) Spline-Based C3 Continuous Corner Smoothing Algorithm for Five-Axis Tool Paths with Short Segments. J. Manuf. Process. 2021, 64, 1387–1411. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, G. Research and Development of Sampled-Data Interpolation Algorithm Software in CNC System Based on the Visual C++. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 042019. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Liu, Y.Y. Development of Sampled-Data Interpolation Algorithm Software in CNC System Based on the Visual C++. Appl. Mech. Mater. 2013, 321–324, 2948–2951. [Google Scholar] [CrossRef]

- Yang, J.; Ai, W.; Liu, Y.; Chen, B. Kinematics Model and Trajectory Interpolation Algorithm for CNC Turning of Non-Circular Profiles. Precis. Eng. 2018, 54, 212–221. [Google Scholar] [CrossRef]

- Varga, J.; Ižol, P.; Vrabeľ, M.; Kaščák, Ľ.; Drbúl, M.; Brindza, J. Surface Quality Evaluation in the Milling Process Using a Ball Nose End Mill. Appl. Sci. 2023, 13, 10328. [Google Scholar] [CrossRef]

- Li, Y.H.; Zhang, P.W.; Hu, H.C.; Yu, W.; Yang, S.K. Path Planning of Manipulator Based on Acceleration and Deceleration Control of Two-Phase Adaptive Path. IOP Conf. Ser. Earth Environ. Sci. 2020, 461, 012020. [Google Scholar] [CrossRef]

- Li, D.; Wu, J.W.; Wan, J.F.; Wang, S.Y.; Li, S.; Liu, C.L. The Implementation and Experimental Research on an S-Curve Acceleration and Deceleration Control Algorithm with the Characteristics of End-Point and Target Speed Modification on the Fly. Int. J. Adv. Manuf. Technol. 2016, 91, 1145–1169. [Google Scholar] [CrossRef]

- Han, J.; Jiang, Y.; Tian, X.; Chen, F.; Lu, C.; Xia, L. A Local Smoothing Interpolation Method for Short Line Segments to Realize Continuous Motion of Tool Axis Acceleration. Int. J. Adv. Manuf. Technol. 2017, 95, 1729–1742. [Google Scholar] [CrossRef]

- Tsai, M.-S.; Huang, Y.-C. A Novel Integrated Dynamic Acceleration/Deceleration Interpolation Algorithm for a CNC Controller. Int. J. Adv. Manuf. Technol. 2016, 87, 279–292. [Google Scholar] [CrossRef]

- Xiao, W.; Qiu, T.; Guo, J.; Zhao, G. MetaFactory: A Cloud-Based Framework to Configure and Generate Dynamic Data Structures from the STEP-NC Knowledge Graph. J. Manuf. Syst. 2025, 80, 89–107. [Google Scholar] [CrossRef]

- Chen, G.; Zhou, B.; Li, T.; Mao, J.; Li, B.; Fu, Z. Research on Thermal Error Compensation Modeling for the Machine Tool Integrated Drive System Based on Energy Consumption Big Data and an Optimized Bidirectional Network. Precis. Eng. 2025, 94, 91–112. [Google Scholar] [CrossRef]

- Jeon, J.; Sim, Y.; Lee, H.; Han, C.; Yun, D.; Kim, E.; Nagendra, S.L.; Jun, M.B.G.; Kim, Y.; Lee, S.W.; et al. ChatCNC: Conversational Machine Monitoring via Large Language Model and Real-Time Data Retrieval Augmented Generation. J. Manuf. Syst. 2025, 79, 504–514. [Google Scholar] [CrossRef]

- Wang, P.; Liu, J.; Qi, J.; Zhou, K.; Zhai, H. Multi-Task Dual-Level Adversarial Transfer Learning Boosted RUL Estimation of CNC Milling Tools. Knowl.-Based Syst. 2025, 312, 113152. [Google Scholar] [CrossRef]

- Gu, M.; Kang, S.; Xu, Z.; Lin, L.; Zhang, Z. AE-XGBoost: A Novel Approach for Machine Tool Machining Size Prediction Combining XGBoost, AE and SHAP. Mathematics 2025, 13, 835. [Google Scholar] [CrossRef]

- Wang, L.J.; Zhao, J.W.; Yu, Z.X.; Pan, Z.B.; Zheng, Z.L. Robust and High-Precision Position Control of PMLSM-Driven Feed Servo System Based on Adaptive Fast Nonsingular Terminal Sliding Mode. IEEE Trans. Transp. Electrif. 2024, 11, 4882–4894. [Google Scholar] [CrossRef]

- Zekalmi, Y.; Oliveros, M.J.; Albajez, J.A.; Aguado, S. Custom Post-Processor Based on the PSO Algorithm for 5 Axis Machine Tool Compensation. J. Manuf. Process. 2024, 132, 963–976. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Cao, Y.; Guo, J.D.; Sun, B.; Geng, N. Multi-Axis CNC Finishing and Surface Roughness Prediction of TC11 Titanium Alloy Open Integral Micro Impeller. Adv. Mech. Eng. 2024, 16, 16878132241244924. [Google Scholar] [CrossRef]

- Wei, W.; Tang, Q.; Zhang, C.; Wang, T.; Pan, Y.; Wang, Y. Post-Processing of a Nine-Axis and Five-Linkage Turn-Milling Compound Machine Tool. Int. J. Adv. Manuf. Technol. 2023, 127, 3935–3950. [Google Scholar] [CrossRef]

- Qiao, H.; Wei, Z.; Deng, R.; Xu, T.; Xiang, Y. Research and Development of Multi-Axis CNC Abrasive Belt-Grinding Machine Postprocessor. Int. J. Adv. Manuf. Technol. 2023, 126, 3109–3131. [Google Scholar] [CrossRef]

- Dabwan, A.; Anwar, S.; Al-Samhan, A.M.; Alqahtani, K.N.; Nasr, M.M.; Kaid, H.; Ameen, W. CNC Turning of an Additively Manufactured Complex Profile Ti6Al4V Component Considering the Effect of Layer Orientations. Processes 2023, 11, 1031. [Google Scholar] [CrossRef]

- Chen, W.C.; Lin, T.K.; Teng, H.M.; Tsao, C.-C. The Use of the Rapid Unequal Interval Interpolation Method (RUIIM) for a Non-RTCP NC Program and Five-Axis Machining. Int. J. Adv. Manuf. Technol. 2022, 124, 2701–2717. [Google Scholar] [CrossRef]

- Manoharan, M.; Kumaraguru, S. Novel Process Planning Approach for Support-Free Additive Manufacturing Using Multi-Axis Deposition Systems. Int. J. Comput. Integr. Manuf. 2022, 36, 807–829. [Google Scholar] [CrossRef]

- Garrido, J.; Silva, D.; Sáez, J. STEP-NC-Compliant Implementation to Support Mixed-Control Technologies Applied to Stone-Processing Machines Based on Industrial Automation Standards. Machines 2021, 9, 327. [Google Scholar] [CrossRef]

- Chen, L.; Xu, H.; Huang, Q.; Wang, P. An Integrated Method for Compensating and Correcting Nonlinear Error in Five-Axis Machining Utilizing Cutter Contacting Point Data. Sci. Rep. 2024, 14, 8763. [Google Scholar] [CrossRef]

- Chen, L.; Xu, H.; Li, H.; Gao, H.; Wang, H. Real-Time Measurement-Based Optimization of Tool Position and Tool Axis Vector for Five-Axis Machining Using Interpolated Cutter Contact Point. Meas. Sci. Technol. 2025, 36, 045002. [Google Scholar] [CrossRef]

- Ni, H.; Ji, S.; Liu, Y.; Ye, Y.; Zhang, C.; Chen, J. Velocity Planning Method for Position–Velocity–Time Control Based on a Modified S-Shaped Acceleration/Deceleration Algorithm. Int. J. Adv. Robot. Syst. 2022, 19, 172988142110724. [Google Scholar] [CrossRef]

- Benko Loknar, M.; Blažič, S.; Klančar, G. Minimum-Time Velocity Profile Planning for Planar Motion Considering Velocity, Acceleration and Jerk Constraints. Int. J. Control 2021, 96, 251–265. [Google Scholar] [CrossRef]

- Hu, G.; Ma, J.; Zuo, Y.M.; Wang, Y.F.; Yan, H.T.; Lv, Q. A Flexible Velocity Planning Algorithm for High-Speed Mounter with Both Efficiency and Precision. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 524. [Google Scholar] [CrossRef]

- Xu, L.M.; Wang, K.Z.; Xie, C.L.; Shi, L. Improved Spatial Acceleration and Jerk Distributions for Grinding Force Smoothness and Energy-Saving in Reciprocating Machining. J. Manuf. Process. 2023, 98, 186–195. [Google Scholar] [CrossRef]

| Segment Number | x/mm | y/mm | z/mm | i | j | k |

|---|---|---|---|---|---|---|

| 24 | 35.164 | −440.607 | −91.961 | −0.201263 | −0.975827 | 0.085182 |

| 25 | 34.946 | −440.586 | −91.755 | −0.201849 | −0.975709 | 0.085144 |

| Parameters | T/mm | Vmax/(mm/s) | Vs/(mm/s) | Ve/(mm/s) | amax/(mm/s²) | VA, Cmax/(rad/s) | aA, Cmax/(rad/s²) |

|---|---|---|---|---|---|---|---|

| Value | 0.5 | 25 | 19 | 21 | 5500 | 0.078 | 22 |

| Axis | Maximum Error (ms) | Minimum Error (ms) | Average Error (ms) |

|---|---|---|---|

| X | 0.15586 | 0.03631 | 0.08407 |

| Y | 0.16448 | 0.03445 | 0.08139 |

| Z | 0.16173 | 0.03009 | 0.07925 |

| A | 0.12959 | 0.02124 | 0.07231 |

| C | 0.12960 | 0.02073 | 0.07032 |

| Axis | Maximum Error (ms) | Minimum Error (ms) | Average Error (ms) |

|---|---|---|---|

| X | 0.22511 | 0.04044 | 0.12587 |

| Y | 0.22704 | 0.03842 | 0.11080 |

| Z | 0.19660 | 0.04360 | 0.11423 |

| A | 0.21414 | 0.02081 | 0.10926 |

| C | 0.20653 | 0.04287 | 0.09751 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Gao, H.; Li, H.; Xu, H. Implementation Method of Five-Axis CNC RTOS Kernel Based on gLink-II Bus. Sensors 2025, 25, 2960. https://doi.org/10.3390/s25102960

Chen L, Gao H, Li H, Xu H. Implementation Method of Five-Axis CNC RTOS Kernel Based on gLink-II Bus. Sensors. 2025; 25(10):2960. https://doi.org/10.3390/s25102960

Chicago/Turabian StyleChen, Liangji, Hansong Gao, Huiying Li, and Haohao Xu. 2025. "Implementation Method of Five-Axis CNC RTOS Kernel Based on gLink-II Bus" Sensors 25, no. 10: 2960. https://doi.org/10.3390/s25102960

APA StyleChen, L., Gao, H., Li, H., & Xu, H. (2025). Implementation Method of Five-Axis CNC RTOS Kernel Based on gLink-II Bus. Sensors, 25(10), 2960. https://doi.org/10.3390/s25102960