Incremental Clustering for Predictive Maintenance in Cryogenics for Radio Astronomy

Abstract

1. Introduction

State of the Art

2. Materials and Methods

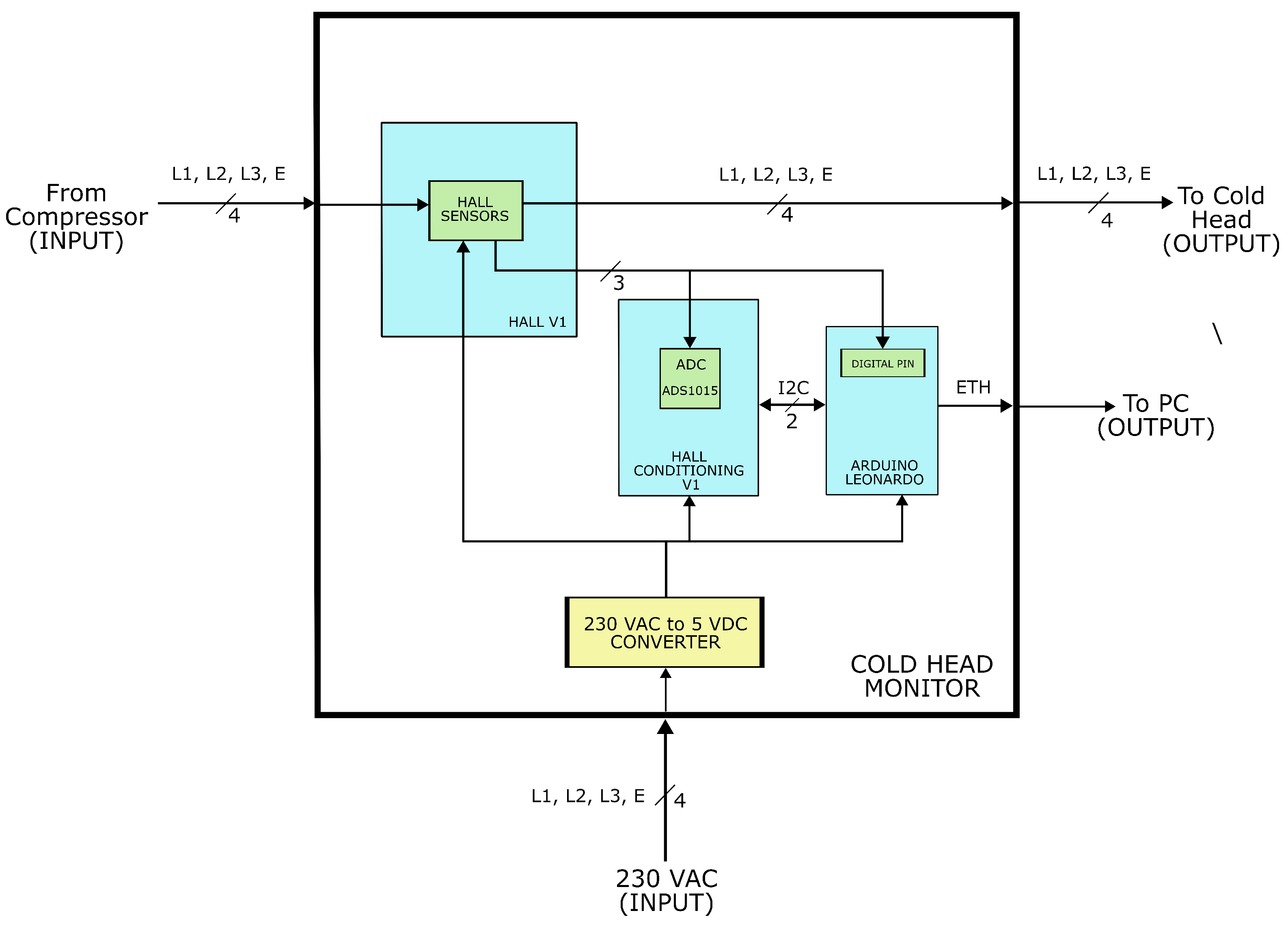

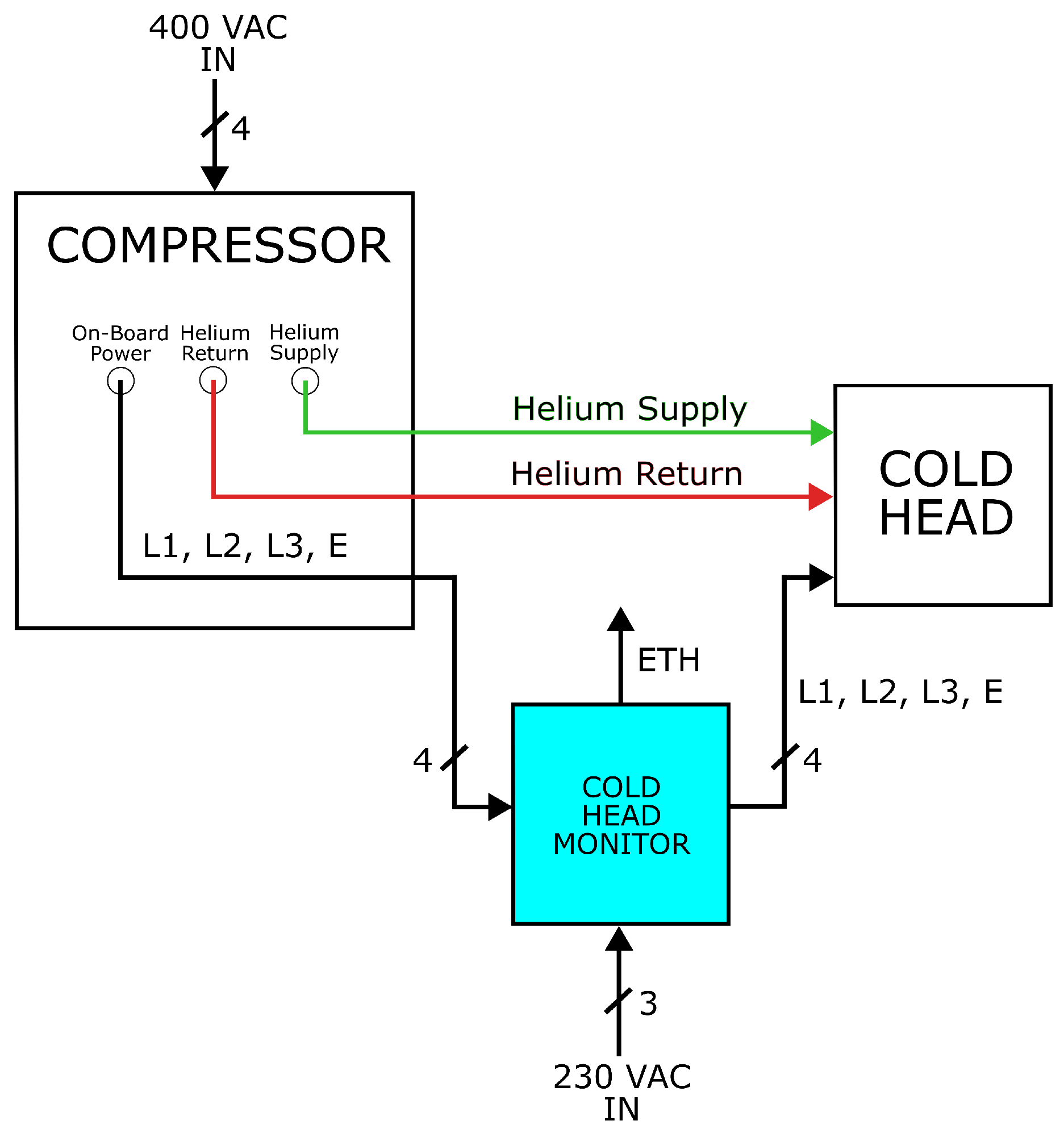

2.1. Hardware Description

- The first board, named HALL V1, contains Hall effect sensors ACS758xCB, produced by Allegro Microsystems, Manchester, NH, USA [13].

- The second board, named HALL CONDITIONING V1, includes the amplification stage and the voltage acquisition with the Analog-to-Digital Converter (ADC) ADS1015, produced by Texas Instruments, Dallas, TX, USA [14].

- An Arduino LEONARDO produced by Interaction Design Institute, Ivrea, Italy [15] for logic and additional acquisition through digital pins.

- A 230 VAC to 5 VDC power supply for powering the sensors, ADC, and the Arduino itself.

2.2. Firmware 1.0v and Acquisition Software 1.0v

2.3. Clustering Setup

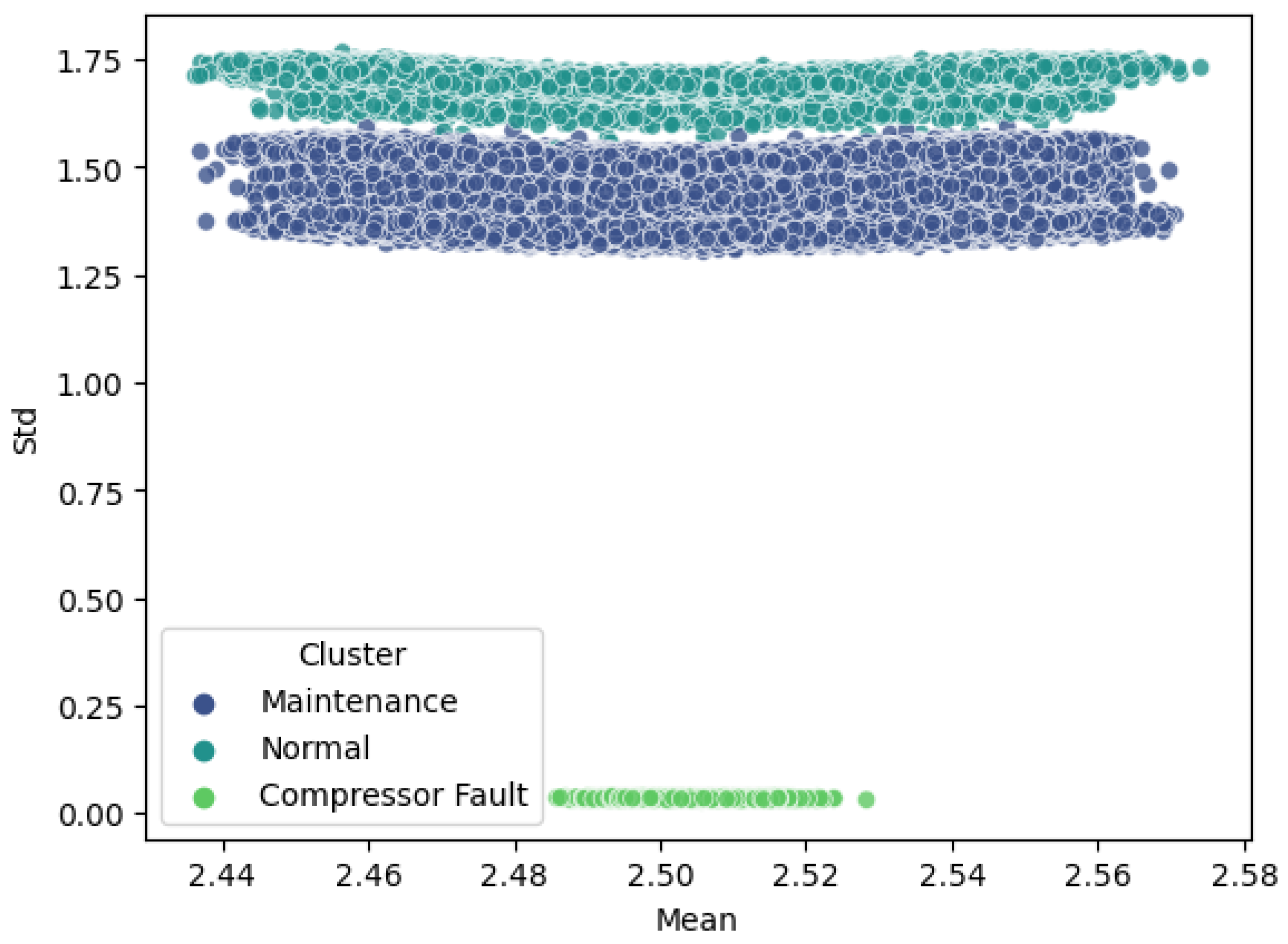

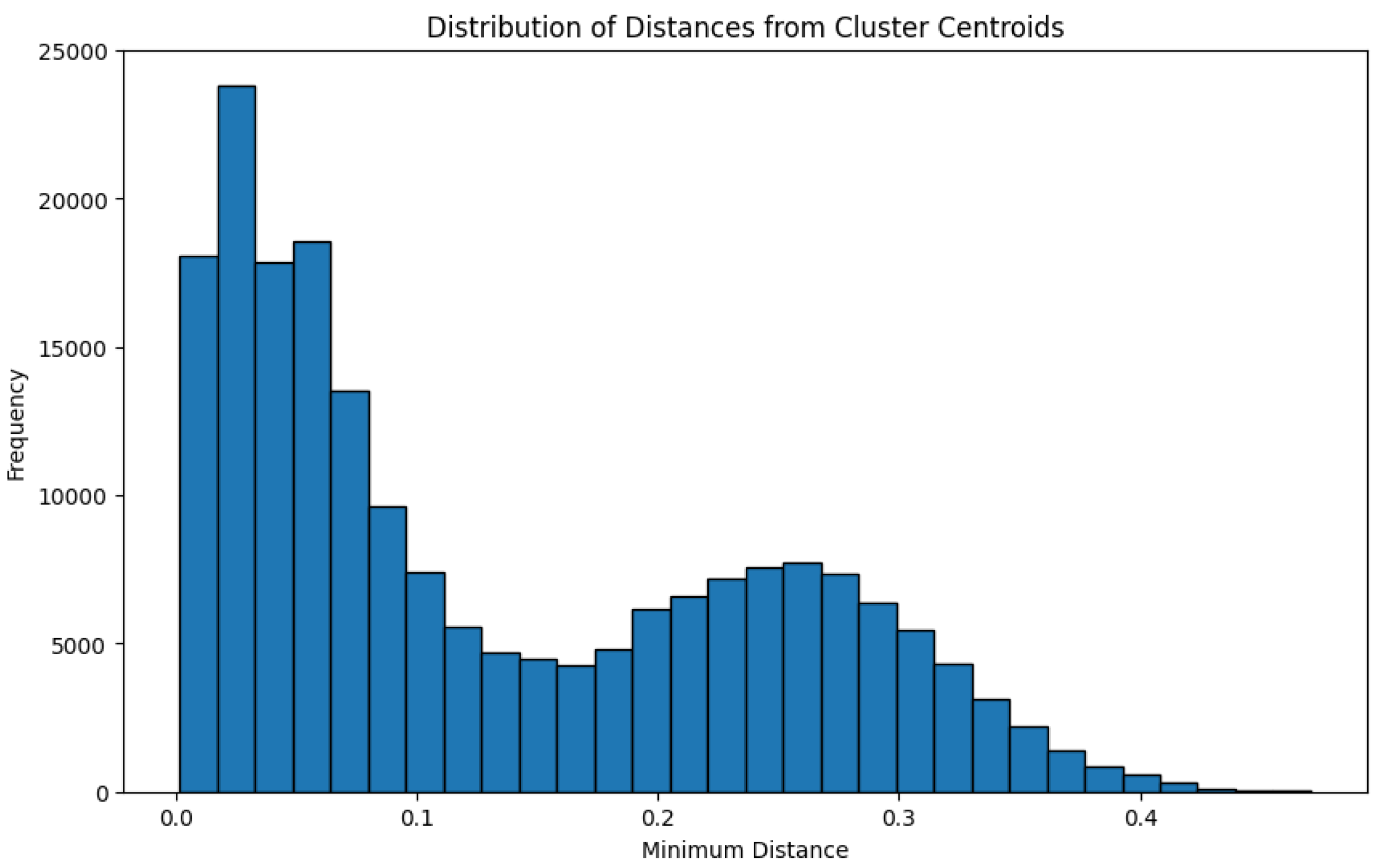

3. Results and Discussion

- The Silhouette score [21] provides a measure of internal cohesion and separation between clusters. The score ranges from −1 to 1, where a higher score indicates better clusters.

- The Calinski–Harabasz index [22] measures the cluster’s compactness. A higher value indicates better clusters.

- The Davies–Bouldin index [23] measures the “compactness” and “separation” of clusters, with lower values indicating better clusters.

| Metric | Value | Range |

|---|---|---|

| Silhouette score | 0.7848 | [−1, 1] |

| Calinski–Harabasz index | [0, +∞] | |

| Davies–Bouldin index | 0.2163 | [0, +∞] |

| Adjusted Rand index | 98% | [0, 100] |

4. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RF | Radio Frequency |

| SNR | Signal-to-Noise Ratio |

| CHM | Cold Head Monitor |

| MTBF | Mean Time Between Failure |

| ADC | Analog-to-Digital Converter |

| AC–DC | Alternate Current to Direct Current |

| API | Application Programming Interface |

| AI | Artificial intelligence |

| ML | Machine learning |

References

- Daniyan, L. The concept of radio telescope receiver design. Int. J. Electron. Commun. Eng. 2011, 4, 461–471. [Google Scholar]

- Tiuri, M. Radio astronomy receivers. IEEE Trans. Antennas Propag. 1964, 12, 930–938. [Google Scholar] [CrossRef]

- Ulaby, F.T.; Moore, R.K.; Fung, A.K. Microwave Remote Sensing: Active and Passive; Addison-Wesley Pub. Co., Advanced Book Program/World Science Division: Reading, MA, USA, 1981. [Google Scholar]

- Friis, H. Noise Figures of Radio Receivers. Proc. IRE 1944, 32, 419–422. [Google Scholar] [CrossRef]

- Fouquet, F. Friis Formula. In Noise in Radio-Frequency Electronics and Its Measurement; Wiley: Hoboken, NJ, USA, 2020; pp. 23–35. [Google Scholar] [CrossRef]

- Serna Puente, J.M. Cryogenic systems in Radio Astronomy. In Proceedings of the 2nd MCCT-SKADS Training School. Radio Astronomy: Fundamentals and the New Instruments, Sigüenza, Spain, 26 August–4 September 2009; p. 12. [Google Scholar] [CrossRef]

- Pospieszalski, M.W. Cryogenic amplifiers for Jansky Very Large Array receivers. In Proceedings of the 2012 19th International Conference on Microwaves, Radar and Wireless Communications, Warsaw, Poland, 21–23 May 2012; Volume 2, pp. 748–751. [Google Scholar] [CrossRef]

- Bryerton, E.W.; Morgan, M.; Pospieszalski, M.W. Ultra low noise cryogenic amplifiers for radio astronomy. In Proceedings of the 2013 IEEE Radio and Wireless Symposium, Austin, TX, USA, 20–23 January 2013; pp. 358–360. [Google Scholar] [CrossRef]

- Nagpal, A.; Jatain, A.; Gaur, D. Review based on data clustering algorithms. In Proceedings of the 2013 IEEE Conference on Information & Communication Technologies, Thuckalay, India, 11–12 April 2013; pp. 298–303. [Google Scholar] [CrossRef]

- Amruthnath, N.; Gupta, T. A research study on unsupervised machine learning algorithms for early fault detection in predictive maintenance. In Proceedings of the 2018 5th International Conference on Industrial Engineering and Applications (ICIEA), Singapore, 26–28 April 2018; pp. 355–361. [Google Scholar] [CrossRef]

- Madaan, D.; Yoon, J.; Li, Y.; Liu, Y.; Hwang, S.J. Representational Continuity for Unsupervised Continual Learning. In Proceedings of the International Conference on Learning Representations, Vienna, Austria, 4 May 2021. [Google Scholar]

- Shahriar, N.; Akib Al Faisal, S.M.; Pinjor, M.M.; Sharif Zobayer Rafi, M.A.; Rahman Sarkar, A. Comparative Performance Analysis of K-Means and DBSCAN Clustering algorithms on various platforms. In Proceedings of the 2019 22nd International Conference on Computer and Information Technology (ICCIT), Dhaka, Bangladesh, 18–20 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Allegro Microsystems. Thermally Enhanced, Fully Integrated, Hall-Effect-Based Linear Current Sensor IC with 100 μΩ Current Conductor. 2022. Available online: https://www.allegromicro.com/~/media/files/datasheets/acs758-datasheet.ashx (accessed on 27 October 2023).

- ADS1015 Data Sheet, Product Information and Support | TI.com. Available online: https://www.ti.com/product/ADS1015 (accessed on 27 October 2023).

- Arduino Leonardo|Arduino Documentation. Available online: https://docs.arduino.cc/hardware/leonardo (accessed on 27 October 2023).

- CTI-Cryogenics. CTI-Cryogenics 9600 Compressor. 2021. Available online: https://www.edwardsvacuum.com/content/dam/brands/edwards-vacuum/edwards-website-assets/our-markets/chamber-solutions/cti-datasheets/Edwards%20CTI%209600%20Compressor%20-%20Data%20sheet.pdf (accessed on 27 October 2023).

- CTI-CRYOGENICS. CTI-Cryogenics Cryodyne Refrigeration System. 2002. Available online: https://www.lakeshore.com/docs/default-source/default-document-library/cti-cryogenicscryodynerefrigerationsystemdatasheet.pdf?sfvrsn=6a6bee38_4 (accessed on 27 October 2023).

- Chakraborty, S.; Islam, S.; Samanta, D. Data Classification and Incremental Clustering in Data Mining and Machine Learning; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Jin, X.; Han, J. K-Means Clustering. In Encyclopedia of Machine Learning; Springer: Boston, MA, USA, 2010; pp. 563–564. [Google Scholar] [CrossRef]

- Dey, L.; Chakraborty, S.; Nagwani, N. Performance Comparison of Incremental K-means and Incremental DBSCAN Algorithms. Int. J. Comput. Appl. 2011, 27, 14–18. [Google Scholar] [CrossRef]

- Rousseeuw, P.J. Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 1987, 20, 53–65. [Google Scholar] [CrossRef]

- Caliński, T.; Harabasz, J. A dendrite method for cluster analysis. Commun. Stat. 1974, 3, 1–27. [Google Scholar] [CrossRef]

- Davies, D.L.; Bouldin, D.W. A Cluster Separation Measure. IEEE Trans. Pattern Anal. Mach. Intell. 1979, PAMI-1, 224–227. [Google Scholar] [CrossRef]

- Steinley, D. Properties of the Hubert-Arabie Adjusted Rand Index. Psychol. Methods 2004, 9, 386–396. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.; Nagwani, N.K. Analysis and Study of Incremental DBSCAN Clustering Algorithm. Int. J. Enterp. Comput. Bus. Syst. 2011, 1. [Google Scholar]

- Chakraborty, S.; Nagwani, N.K.; Dey, L. Performance Comparison of Incremental K-means and Incremental DBSCAN Algorithms. arXiv 2014, arXiv:1406.4751. [Google Scholar]

- Nvidia Jetson TX2|Nvidia Documentation. 2019. Available online: https://developer.nvidia.com/downloads/jetson-tx2-developer-kit-user-guide (accessed on 27 October 2023).

| Model | Operating Hours | Samples per Channel | Class | |

|---|---|---|---|---|

| 1 | CTI-1020 | >30 k | 161,172 | Maintenance |

| 2 | CTI-350 | <30 k | 139,098 | Normal Status |

| 3 | CTI-350 | >30 k | 151,192 | Maintenance |

| 4 | CTI-350 | >30 k | 130,716 | Maintenance |

| 5 | CTI-350 | <30 k | 150,415 | Normal Status |

| 6 | - | - | 150,919 | Compressor Fault |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabras, A.; Ortu, P.; Pisanu, T.; Maxia, P.; Caocci, R. Incremental Clustering for Predictive Maintenance in Cryogenics for Radio Astronomy. Sensors 2024, 24, 2278. https://doi.org/10.3390/s24072278

Cabras A, Ortu P, Pisanu T, Maxia P, Caocci R. Incremental Clustering for Predictive Maintenance in Cryogenics for Radio Astronomy. Sensors. 2024; 24(7):2278. https://doi.org/10.3390/s24072278

Chicago/Turabian StyleCabras, Alessandro, Pierluigi Ortu, Tonino Pisanu, Paolo Maxia, and Roberto Caocci. 2024. "Incremental Clustering for Predictive Maintenance in Cryogenics for Radio Astronomy" Sensors 24, no. 7: 2278. https://doi.org/10.3390/s24072278

APA StyleCabras, A., Ortu, P., Pisanu, T., Maxia, P., & Caocci, R. (2024). Incremental Clustering for Predictive Maintenance in Cryogenics for Radio Astronomy. Sensors, 24(7), 2278. https://doi.org/10.3390/s24072278