Abstract

With the rapid development of smart manufacturing, data-driven deep learning (DL) methods are widely used for bearing fault diagnosis. Aiming at the problem of model training crashes when data are imbalanced and the difficulty of traditional signal analysis methods in effectively extracting fault features, this paper proposes an intelligent fault diagnosis method of rolling bearings based on Gramian Angular Difference Field (GADF) and Improved Dual Attention Residual Network (IDARN). The original vibration signals are encoded as 2D-GADF feature images for network input; the residual structures will incorporate dual attention mechanism to enhance the integration ability of the features, while the group normalization (GN) method is introduced to overcome the bias caused by data discrepancies; and then the model is trained to complete the classification of faults. In order to verify the superiority of the proposed method, the data obtained from Case Western Reserve University (CWRU) bearing data and bearing fault experimental equipment were compared with other popular DL methods, and the proposed model performed optimally. The method eventually achieved an average identification accuracy of 99.2% and 97.9% on two different types of datasets, respectively.

1. Introduction

Rolling bearings are widely used in modern machinery manufacturing, which accounts for most of the market share [1]. Rolling bearings have large working loads, large differences in operating speeds and harsh working environments, so they are often prone to many kinds of failures in production [2]. Obtaining information about internal faults that may occur in bearings during operation and determining the health status of bearings through accurate and intelligent methods is a hot topic of current research [3,4].

Currently there are two types of bearing fault diagnosis methods: one is the traditional fault signal analysis method. Ding et al. proposed a gene mutation particle swarm optimisation variational modal decomposition (GMPSO-VMD) algorithm; this method can effectively deal with the problem of the fault signals of early rolling bearings being weak and difficult to extract [5]; Ye et al. used an improved empirical modal decomposition (IEMD) method applied to bearing fault diagnosis, which has good identification of weak noise and sudden impulses of bearing fault signals [6,7], and Wu et al. in order to accurately separate and extract the composite fault signal features of bearings, proposed a method combining adaptive variational modal decomposition (AVMD) and improved multivariate universe optimisation (IMUO) algorithms parameterised with maximum correlation kurtosis inverse convolution (MCKD) [8]. However, these types of methods require the mastery of advanced signal processing techniques and manual selection of sensitive features.

Another is the data-driven deep learning based method. Table 1 summarises the literature review related to the use of data-driven methods for reliability prediction in different industry applications. Zhou et al. proposed a rolling bearing fault diagnosis method based on Whale grey wolf optimization algorithm-variable modal decomposition-support vector machine (WGWOA-VMD-SVM) [9]. Zhang et al. proposed an optimised long short-term memory (LSTM) neural network fault diagnosis method for reliability analysis of gearboxes [10]; Wan et al. proposed a rolling bearing fault diagnosis method based on Spark and Improved Random Forest Algorithm [11], and Hadi et al. proposed an AutoML method to improved bearing fault classification for predictive maintenance in industrial IoT [12]. Although these types of intelligent diagnostic methods can automatically extract features, there are some unavoidable drawbacks; for example, extracting features and fault classification need to be carried out independently, and the learning efficiency is insufficient.

Table 1.

Summary of literature of data-driven methods models.

The emergence of convolutional neural networks (CNNs) has overcome the above drawbacks and has been favoured by many researchers. Tian et al. designed a hybrid particle swarm optimisation (HPSO) based CNN-LSTM bearing fault diagnosis model for early fault diagnosis [13]; Ye et al. proposed a TCNN for fault diagnosis of rotating machinery to address the problem of model training crash with small samples [14]. Han et al. propose a GAF-EDL method for the problem of poor model classification under noisy samples [15]. Some researchers have also used GAF in combination with CNNs. Zhou et al. proposed the bearing fault diagnosis method based on GAF and DenseNet, which achieved good results [16]; Wei et al. and Cui et al. proposed fault diagnosis models combining GAF with lightweight channel attention networks to improve classification accuracy [17,18], and Cai et al. combined GAF with deep residual networks (ResNeXt50) in order to extract more fault features [19].

Although current neural networks can achieve a decent level of classification, there are still some problems with the above methods:

- Most methods preprocess the original signals before inputting them into the network for model training; this may filter out some important features and limit the extraction of features by the network.

- In the traditional neural network structure, more features are extracted by stacking the layers of the network, but the network degradation phenomenon occurs and the features are not sufficiently extracted.

- Many methods use equivalent data distributions (equal number of samples for each fault class) to train the model; whereas in real plants often the data distribution is uneven, and the model may breakdown under imbalanced data.

In order to solve the above problems, this paper proposes an intelligent diagnosis of rolling bearings based on Gramian Angular Difference Field and Improved Dual Attention Residual Network, and the main contributions are as follows:

- The vibration signals were converted into images using the GADF method, so that the fault features were fully represented in the images; both retaining the timing information and enhancing the features to improve the network’s recognition capability.

- The residual structure introduced into the GN was used as the network body, which solves the network degradation problem and reduces the bias caused by the difference in the distribution of training samples. Meanwhile, Dual-Attention mechanism was introduced to enhance feature integration and make full use of channels and deep information.

- The effects of different sets of GNs and different attentional mechanisms introduced on the model were verified on the CWRU bearing dataset.

- Small samples of imbalanced data were divided on the bearing fault experimental equipment and compared with current advanced fault diagnostic models, and the proposed method achieved the best diagnostic results in several datasets with different data distributions.

The structure of this paper is as follows. Section 2 describes the specific principles of the relevant contents. Section 3 details the proposed IDARN fault diagnosis model and the specific diagnosis process. Section 4 outlines the experimental analyses to verify the validity of the proposed model by using data collected from popular bearing datasets and faulty bearing experimental equipment. Section 5 presents the conclusions.

2. Related Work

This chapter provides an overview of the related methods of use. The specific implementation of GADF is presented in Section 2.1, the structure of the residual network and the specific computational process of the GN method are described in Section 2.2, and the implementation of the two attention mechanisms is explored in Section 2.3.

2.1. Gramian Angular Difference Field (GADF)

Gramian Angular Difference Field is a coding method that converts one-dimensional time series into two-dimensional images [20]; using it as preprocessing of vibration signals allows the network to efficiently identify vibration signals. Assuming the existence of a one-dimensional time series X = {x1, x2, …, xn}, the GADF coding process can be divided into the following steps, some notations used in this paper are illustrated in Table 2.

Table 2.

Commonly used notations.

Step 1: The X is normalised to fall in the interval [0, 1], determined by the following equation:

Step 2: Transform the scaled sequence data into polar coordinate system. Think of the numerical values as the angle cosines and the timestamps as the radius, representing in polar coordinates the rescaled time series X, determined by the following equation:

Step 3: For the polar coordinate system that stores the time information, it can be encoded into the geometric structure of the matrices by calculating the trigonometric difference of each polar coordinate in the system, defined as:

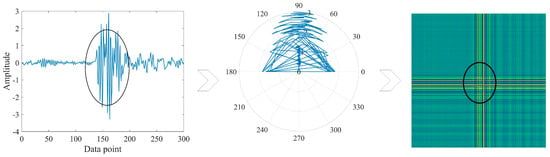

The differences in vibration signals are mainly on different time scales, which contain their own unique fault features. Figure 1 illustrates the coding process. When the one-dimensional signal has dramatic amplitude, the image corresponds to the appearance of obvious cross lines, and the larger the amplitude the more obvious the cross. GADF coding both retains the timing information and achieves the feature enhancement, which is helpful for the feature extraction of the network.

Figure 1.

GADF coding process.

2.2. Network and Methodology Introduction

2.2.1. Residual Neural Networks

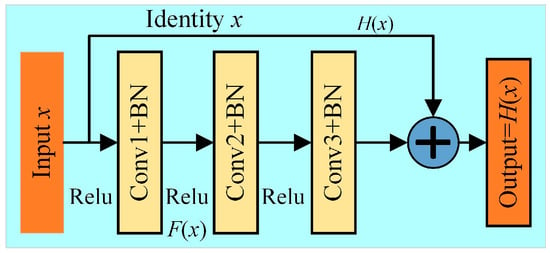

In traditional convolutional neural networks, with the number of network layers, stacked models will have the problem of gradient disappearance or explosion. Residual neural networks emerged to solve this problem and have been widely used in image processing [21]; the structure is as shown in Figure 2, and determined by Equation (5).

H(x) = F(x) + x

Figure 2.

Residual structure.

The residual structure can pass the features from the bottom layers of the network to the top layers directly through shortcuts, just ensuring that the input vector x and the residual mapping function F(x) have the same size. With the residual structure stacks, not only the depth of the convolutional layers is increased, but the network degradation problem is solved and the stability of the model is improved.

2.2.2. Group Normalization Method (GN)

Residual network involves multiple layers of superposition, and the data distribution of the network can be affected by changes in parameters. Therefore, normalisation methods can be used to adjust the data distribution and effectively reduce the impact of data changes. In recent years, batch normalisation (BN) has been proposed to perform global normalisation in order to improve the training speed of neural networks. It is now widely used in fault diagnosis to improve the performance of networks.

Although BN is widely used, it is very sensitive to batch size. The calculated mean and variance are insufficient to represent the entire data distribution and may lead to poor diagnostic performance when used with small batches. Therefore, this paper introduced a new normalisation method, the GN method, to replace the BN method and eliminate the small batch effect.

In GN, it is assumed that the given input is X = {x1, x2, …, xM}, X ∈ RM×H×W×C, GN first divides the channel into G groups and then solves for the mean and standard deviation of each group, which can be defined as:

Then, the function representing GN is:

The BN method relies on the mean and variance of the data to obtain the desired performance. When the dataset changes, the mean and variance change with it, resulting in inconsistency between the training and validation stages. However, GN relies on dividing the channels into different groups and normalise the data in each group to fit the different distribution forms of each group. Therefore, the feature matrices of the training and validation sets are accepted by each convolutional layer after GN, which guarantees a good classification ability from imbalanced similarly distributed data.

2.3. Attention Mechanisms

In residual networks, stacked convolutional layers can capture lots of feature data, but these data may contain excessively repetitive information, causing some performance loss. For this reason, this paper introduces two attention mechanisms to refine the feature information layer by layer from the channel dimension to the spatial dimension, which makes the network more attentive to the fault features of the image data [22,23].

2.3.1. Channel Attention Mechanism

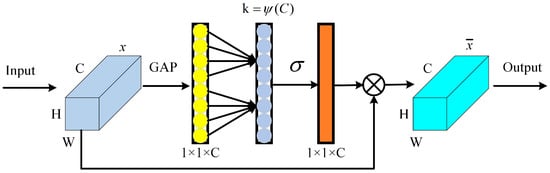

ECA is a streamlined channel attention mechanism that has been widely used in image processing. The complexity of the model is reduced by local cross-channel information interaction without dimensionality reduction; it can add weights to the features of different channels so that the network can better attention to the weights of different features, which helps in feature extraction. Figure 3 shows the ECA structure.

Figure 3.

Efficient Channel Attention (ECA).

The following steps can be taken to realise ECA:

Firstly, the input data are subjected to Global Average Pooling (GAP) which is determined by the following equation:

Secondly, feature interaction between channels is achieved by 1D convolution of Equation (11); where the size of the 1D convolution kernel k is determined by Equation (12):

Finally, features with different weights are obtained after performing dot product operation of input data with channel weights. Therefore, ECA allows the integration of features in the channel dimension, making the residual network more effective in extracting fault features.

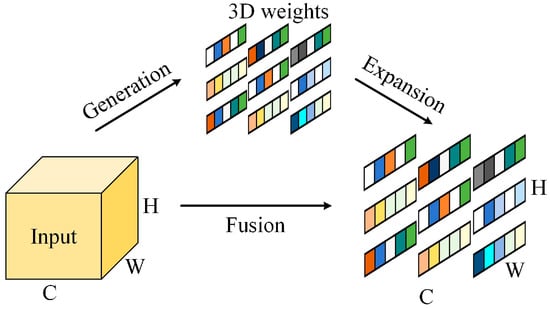

2.3.2. Spatial Attention Mechanism

SimAM is a parameter-free spatial attention mechanism. It accurately calculates the similarity metric between features by adaptively learning and utilising the similarity information between targets so that the weights of different features can be determined; this allows more attention to be paid to different features in images and classified. The structure is shown in Figure 4.

Figure 4.

SimAM structure.

It designs an energy function for calculating the attention weights, which can be defined as:

The importance of different features can be derived from the calculation of the energy function to achieve an enhancement effect on different classes of weak features; therefore, SimAM can focus further on the features after channel attention refinement.

3. Model Structure and Fault Diagnosis Process

This chapter gives an overview of the model structure of the Improved Dual Attention Residual Network and the specific process used for bearing fault diagnosis.

3.1. IDARN Model Structure

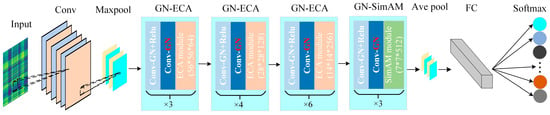

In this section, the IDARN method for rolling bearing fault diagnosis is proposed, which is generally divided into improved residual layer, FC fully connected layer and Softmax classification layer. The specific model structure is shown in Figure 5; the parameters are shown in Table 3.

Figure 5.

IDARN model structure.

Table 3.

IDARN model parameters.

The IDARN model adopts 34-layer residual structure as the backbone, and introduced the channel and spatial attention mechanisms to extract and refine the features layer by layer from the channel to the spatial dimension; meanwhile, the GN method is also introduced in the residual layers to adapt to the different distribution forms of each set of data. In this way, the network has excellent ability to identify and classify different weak fault features, and effectively reduces the computational errors brought by different data distributions.

3.2. Fault Diagnosis Process

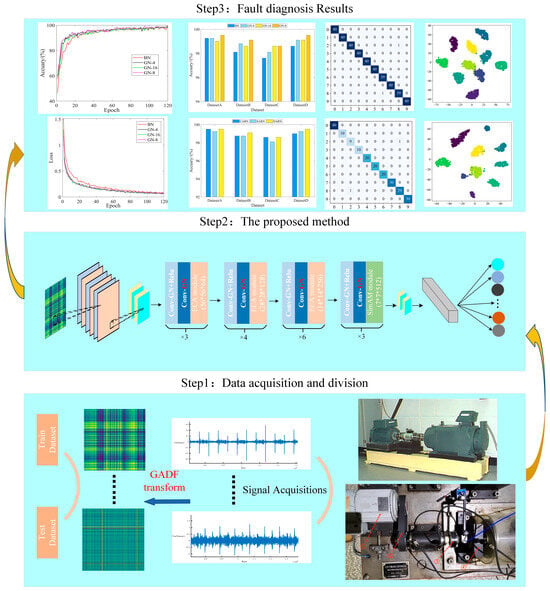

Figure 6 demonstrates the general process of rolling bearing diagnosis based on GADF and Improved Dual Attention Residual Network. It can be divided into the following steps:

Figure 6.

Fault diagnosis process.

Step 1: The original signals collected from the bearing failure experimental equipment were converted into two-dimensional images after GADF encoding, and the corresponding data sets were divided.

Step 2: Set the network parameters and input the divided datasets into improved dual attention residual network for training.

Step 3: The influence of the different number of GN groups on the model was verified in several datasets, then divided and compared with other attentional mechanisms.

Step 4: Comparison of existing popular CNN models on the small-sample unbalanced datasets was performed to validate the superiority of the proposed method.

4. Experimental Analysis

In this chapter, data obtained from CWRU bearing data and the bearing failure experimental equipment were used to evaluate the effectiveness of the diagnostic methods. All network models were trained in Pytorch framework using Python 3.8 programming with Intel Core i5-7300 CPU@2.5 GHz and GTX1050(4G) under Windows 10.

4.1. Case 1: CWRU Bearing Dataset Analysis

4.1.1. Data Processing

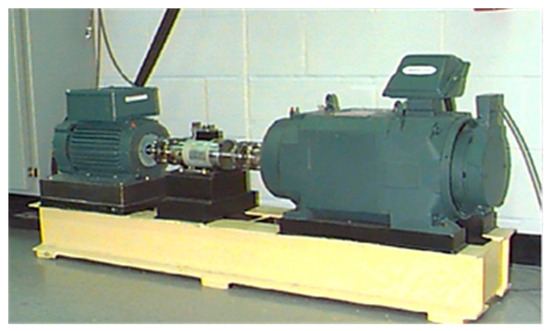

The experimental setup is shown in Figure 7. Taking the drive-end bearing SKF-6205 as example, the experimenter set different failure diameters of damage to the outer ring (@3, @6, @12), inner ring, and rolling body of the bearing respectively. Acceleration sensors were installed on the drive end bearing housing to collect fault signals with a sampling frequency of 12 kHz. In this paper, a load of 0.75 kw was selected, and the corresponding rotational speed of the motor was 1772 r/min.

Figure 7.

Experimental equipment of CWRU [24].

Three different damage diameters of the inner ring, outer ring (@6), and rolling body types were selected as the failure data samples, and one health state data sample was also selected, which was divided into ten categories, and the different failure types were recorded as “IF”, “OF (@6)”, “RE”, and “NO”. It is worth noting that DatasetB/C/D were imbalanced datasets, simulating the missing data in real working conditions; DatasetA can be regarded as a balanced dataset in the ideal state. To avoid the effects of chance, the 400 data points in each category were randomly assigned in a ratio of 9:1 for training and validation. For the imbalanced data, 100/200/300 GADF data were randomly selected from the measured signal segments; again, these were randomly assigned in a 9:1 ratio, and the validity of the proposed model classification was verified using the datasets in Table 4.

Table 4.

Division of the datasets.

4.1.2. Data Preprocessing and Network Training Settings

The data points were collected using a sliding window for translational sliding on the one-dimensional data while generating GADF-encoded images. To ensure that each image contains sampling points for one week of bearing rotation, the size of the sliding window was calculated using the following equation.

From the above equation, the bearing samples approximately 400 data points per revolution; therefore, the sliding window size was set to 400 to sample with the smallest sliding window.

In order to ensure data utilisation and signal integrity, data enhancement was used to expand the data. The data enhancement method used in this paper was to overlap the samples of the original one-dimensional sequences by taking a sliding window with a step size of 200 for overlap sampling. Since each input sequence was obtained in a single fault state, the enhanced samples have the same fault labels as the original sequence.

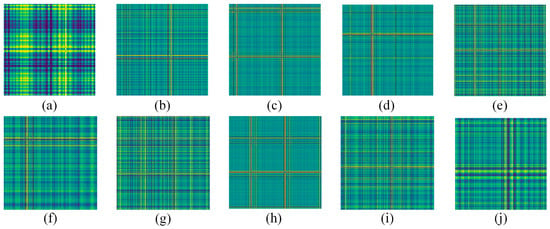

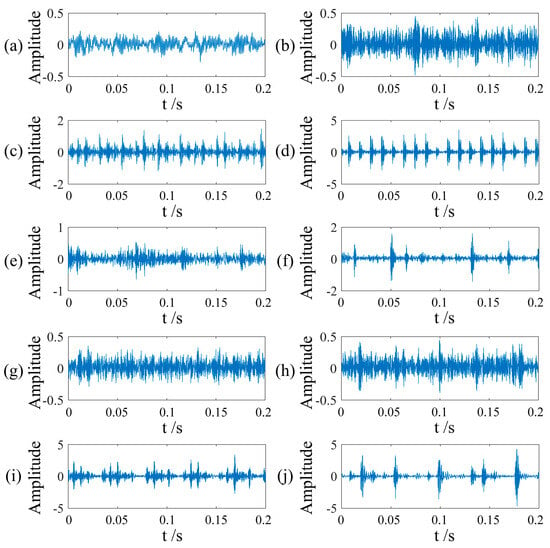

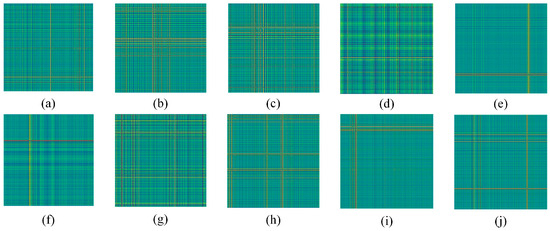

Finally, considering the effect of hardware devices, the sliding window was panned once to generate a 300 × 300 GADF coded image. Figure 8 shows the fault images of different categories, each of which has obvious features that can be used for fault classification. Figure 9 shows the vibration images of different bearings under different faults. The network training parameters were shown in Table 5.

Figure 8.

Fault coded images. (a) NO; (b) IF-0.007in; (c) IF-0.014in; (d) IF-0.021in; (e) RE-0.007in; (f) RE-0.014in; (g) RE-0.021in; (h) OF-0.007in; (i) OF-0.014in; (j) OF-0.021in.

Figure 9.

Vibration images of faults. (a) NO; (b) RE-0.007in; (c) IF-0.007in; (d) OR-0.007in; (e) RE-0.014in; (f) IR-0.014in; (g) OF-0.014in; (h) RE-0.021in; (i) IF-0.021in; (j) OF-0.021in.

Table 5.

Network training parameters.

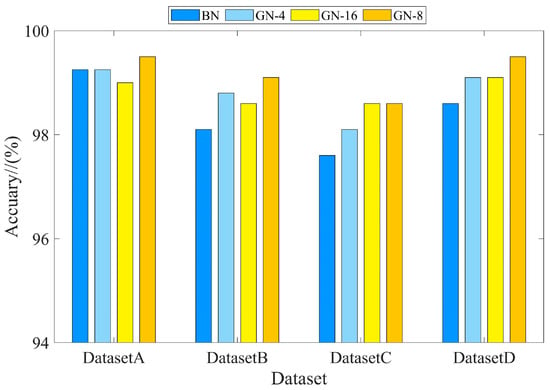

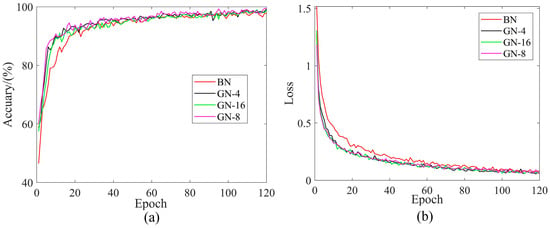

4.1.3. Analysis of Different Methods

The BN and GN methods were introduced for comparison under four datasets to highlight the superiority of the GN method. The number of groups in GN has an impact on the performance of the model, so different numbers of groups for the GN method were considered in this experiment. Each training iteration was 120 rounds and the training parameters are shown in Table 5. Figure 10 and Table 6 show the results of comparing the two methods with four datasets. For further analysis, DatasetA was taken as an example, and the corresponding training curves are shown in Figure 11.

Figure 10.

Comparison of different normalisation methods.

Table 6.

Accuracy of different normalisation methods.

Figure 11.

Training performance curves of BN and GN method comparison. (a) Accuracy (DatasetA); (b) Loss (DatasetA).

As can be seen from the Figure 10, the introduced GN method was better than the BN method and achieved the optimal classification accuracy under the four datasets. As shown in Figure 11b, the training loss of the GN method was lower than BN. More importantly, the GN method can overcome the bias caused by data discrepancy, while the BN method cannot, and thus the GN had to perform better under the four datasets.

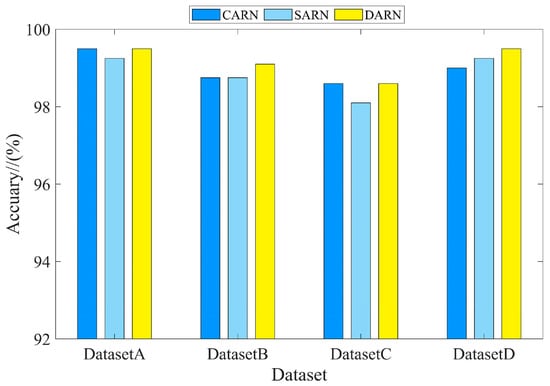

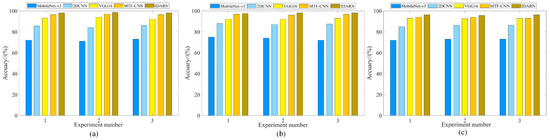

In order to verify the superiority of the dual attention mechanism for feature extraction, the channel (CARN) or spatial (SARN) attention methods were compared under the same GN method. Each dataset was trained for 120 rounds, and the comparison results are shown in Figure 12 and Table 7. From these results, it can be concluded that the dual attention mechanism was able to focus on more features and achieve the highest classification accuracy under the four datasets.

Figure 12.

Comparison of different methods of attention.

Table 7.

Accuracy of different attention methods.

4.1.4. Comparison with Related Models (CWRU Failure Data)

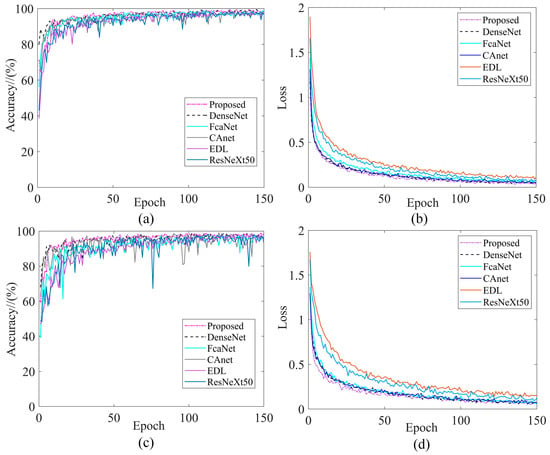

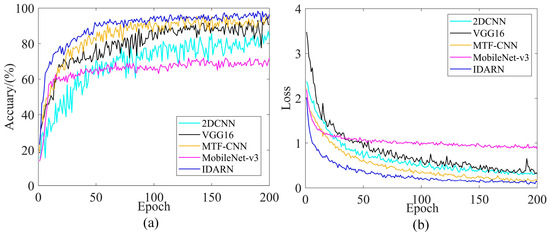

In recent years, many researchers have also used GAF in combination with other DL models for fault diagnosis. To demonstrate the superiority of combining GADF with IDARN, we compared the methods of references [15,16,17,18,19] with the proposed method, using the same GADF processing, input to different models for training. To ensure each model converged sufficiently, each model was iterated 150 times, taking DatasetA and DatasetB (one balanced and one imbalanced data) as examples, Figure 13 illustrates the training performance curves for the different methods.

Figure 13.

Training performance curves. (a) Accuracy/DatasetA; (b) Loss/DatasetA; (c) Accuracy/DatasetB; (d) Loss/DatasetB.

As can be seen from Figure 13a, all models on DatasetA were relatively stable when trained and gradually converge. In the first 20 rounds of training, the training accuracy of proposed model was not as good as that of DenseNet; whereas after 20 rounds of training, the two models were almost equal and the stability of fluctuation was better than that of the other four models. From Figure 13b, it can be seen that the training loss of the present model was lowest at 10–100 rounds of training, and at 100–150 rounds it was similar to CAnet and DenseNet, but in general the proposed model can achieve the lowest training loss.

As can be seen from Figure 13c,d, all models were trained with significantly higher fluctuations for imbalanced data than for balanced data, and the training loss was slightly higher relative to the balanced dataset. This can also reflect the impact of the amount of data on model training in deep learning, but for the proposed method, a good training result can still be achieved on imbalanced datasets, with a steady convergence.

Evaluation indicators are standards for judging the performance of diagnostic algorithms and are important in data analysis. In the field of deep learning fault diagnosis, Accuracy (Ac), Precision (Pr), Recall (Re), and F1 score are all standards for judging the performance of the model, and the expressions are as in Equations (15)–(18). In order to analyse the advantages and shortcomings of each model, Table 8 shows the classification accuracy on the four datasets, Table 9, Table 10, Table 11 and Table 12 shows the different indicators for the different models in DatasetA/B/C/D. For a more comprehensive analysis, we also refer to the training time.

where: TP and TN are the number of correct predictions in i categories; FP and FN are the number of incorrect predictions in i categories.

Table 8.

Comparative accuracy in validation set.

Table 9.

Comparative indicators in DatasetA.

Table 10.

Comparative indicators in DatasetB.

Table 11.

Comparative indicators in DatasetC.

Table 12.

Comparative indicators in DatasetD.

From Table 9, on the balanced dataset, it can be seen that the proposed method was slightly lower than DenseNet in the three indicators, which was due to the fact that DenseNet uses a deeper network (121 layers, while the proposed method is 34 layers) to extract features resulting in a better classification of a particular label than the proposed model, but its training time was not as good as that of the proposed model. The other comparative methods were lower than the proposed model in all the indicators.

From Table 10, Table 11 and Table 12, on the imbalanced datasets, it can be seen that the proposed method has slightly lower Re on DatasetB and Pr on DatasetC than DenseNet, and outperforms the other methods on DatasetD for all indicators. Combining all the indicators, the proposed method has clear advantages in terms of imbalanced data.

4.1.5. Analysis of Results Compared with Different Methods

In recent years, many researchers have focused on fault diagnosis of balanced datasets. In order to further prove the superiority of the IDARN method, this section was compared with some commonly used methods. The comparison results were shown in Table 13. The proposed method achieves the highest classification accuracy of 99.5% with balanced datasets. Compared with references [25,26,27,28,29], the IDARN method identifies more fault types and substantially improves the classification accuracy.

Table 13.

Comparative results.

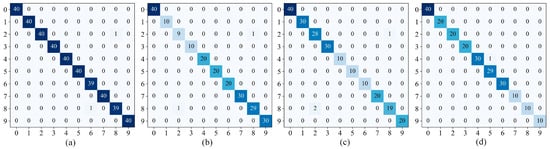

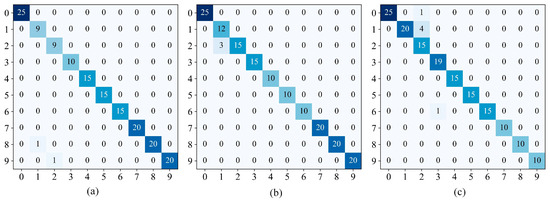

4.1.6. Visualisation and Analysis

Figure 14 showed the classification confusion matrix of the IDARN model under the four datasets. The y label in the confusion matrix represents the predicted label, the x label represents the true label, and the numbers on the diagonal represent the overlap between the true label and the predicted label. Using the validation set of different datasets as an example, a specific categorisation of each fault can be derived. It can be seen that in DatasetA label 6 and label 8 had the lowest accuracy; in DatasetB/C label 2 and label 8 had the lowest accuracy; and in DatasetD only label 5 had the lowest accuracy. Some labels had misclassification because there may be similar features between samples, but overall IDARN had good classification performance.

Figure 14.

Confusion matrices. (a) DatasetA; (b) DatasetB; (c) DatasetC; (d) DatasetD.

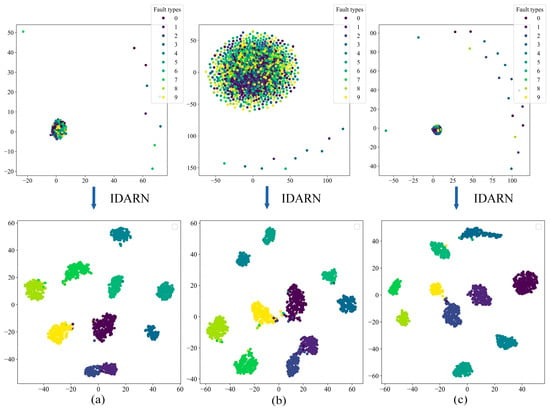

In order to demonstrate the classification effect of this model more intuitively, several datasets were visualised and analysed using the t-SNE method, as shown in Figure 15. In the left half of each subfigure is the original feature distribution of the training set for each dataset, and the right half is the classification result of the fully connected layer after the training set of each dataset has been trained by IDARN. As can be seen from the figures, the original cluttered features distribution of the dataset becomes uniformly clustered through this training method, and there was almost no substantial overlap between each category. As such, the method had good classification effect on the balanced/unbalanced data of rolling bearings.

Figure 15.

t-SNE. (a) DatasetA; (b) DatasetB; (c) DatasetC; (d) DatasetD.

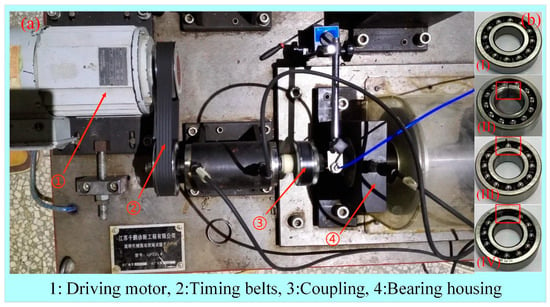

4.2. Case 2: Data Analysis of Variable Speed Bearing Fault Experimental Equipment

4.2.1. Data Collection and Segmentation

The experimental data were obtained from the bearing fault experimental equipment (QPZZ-II), as shown in Figure 16a. According to the practical application, an acceleration sensor was placed on the bearing housing to collect the vibration data of the bearing. In the experiment, the sampling time of the sensor was set to 15 s each time, and the sampling rate was 20480 S/s. Depending on the designed fault scenes, these data were labelled as “Normal (NO)”, “Inner Ring Fault (IF)”, “Outer Ring Fault (OF)”, and “Rolling Element Failure (RE)”, and the different bearing states were shown in Figure 16b.

Figure 16.

Bearing fault experimental equipment. (a) Experimental equipment (QPZZ-II); (b) Different states of the bearings: (I) Normal; (II) Failure of the inner ring; (III) Failure of the outer ring; (IV) Roller body failure.

Type of bearings in the experiment: HRB-1205ATN self-aligning ball bearings, the number of rolling elements: 12 (single row). Bearing size: outer diameter is 52 mm, inner diameter is 25 mm, inner ring diameter is 33.3 mm, width is 15 mm.

Generation and shape of bearing defects: (1) Failure of the inner ring: processing by wire-cut method until the inner ring breaks (width about 1 mm) (Figure 16(b-II)). (2) Failure of the outer ring: a groove with a width of 1 mm and a depth of about 1 mm is machined inside the outer ring of the bearing by wire-cutting method (Figure 16(b-III)). (3) Roller body failure: randomly removed two adjacent balls (Figure 16(b-IV)).

Bearing operating conditions: Temperature of 20 °C and speed range of 75–1500 rpm (500/1000/1500 rpm in the experiment, respectively). No load, lubricant soaked, then 1/2 grease applied.

According to Equation (14), the smallest sliding window was taken for sampling. Different faults with different rotational speeds were used to divide the corresponding datasets; considering the imbalanced fault samples and fewer samples in practice, the imbalanced datasets with small samples were divided. For the imbalanced data, to avoid the effects of chance, 100/150/200 GADF data were randomly selected from the measured signal segments; again, these were randomly assigned in a 9:1 ratio as shown in Table 14. The corresponding GADF coded images generated were shown in Figure 17.

Table 14.

Data division.

Figure 17.

Fault coded images. (a) NO; (b) IF-500; (c) IF-1000; (d) IF-1500; (e) OF-500; (f) OF-1000; (g) OF-1500; (h) RE-500; (i) RE-1000; (j) RE-1500.

4.2.2. Comparative Experimental Analysis

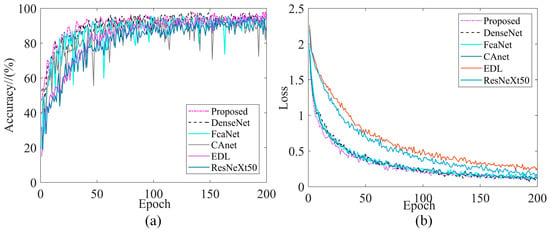

In this section, IDARN used a grouping form of G = 8. Several popular fault diagnosis methods were compared under three datasets to highlight the superiority of the present method. Liang et al. proposed a 2DCNN approach applied to fault diagnosis of rotating machinery [30]; Wu et al. proposed a VGG16 approach for fault diagnosis of high-voltage DC transmission lines [31]; Wang et al. proposed the MTF-CNN for fault diagnosis of rolling bearings [32], and Gu et al. used MobileNet-v3 network for automatic fault detection of variable speed bearings [33]. Each method was trained for 200 rounds each time, and all the experiments were trained 3 times to avoid the effect of randomness. The experimental results are shown in Figure 18 and Table 15. It can be seen that the recognition accuracies of MobileNet-v3 and 2DCNN under the three datasets were 72.2% and 85.5%, respectively, which was an obvious change that can reflect the superiority of the method.

Figure 18.

Comparison results. (a) Dataset1; (b) Dataset2; (c) Dataset3.

Table 15.

Accuracy of different methods.

Taking Dataset1 as an example, the corresponding training performance curves were shown in Figure 19. It can be seen that the two training performances of IDARN were better than other advanced CNN models. It is worth noting that the Mobilenet-v3 model cannot achieve good classification results after 200 iterations, and more iterations were needed; the rest of the models all converge stably.

Figure 19.

Training performance curves for popular model comparisons. (a) Accuracy (Dataset1); (b) Loss (Dataset1).

The different indicators on the three datasets are shown in Table 16, Table 17 and Table 18. As can be seen from the table, although several other models had shorter training times, other indicators were not as good as the proposed model. This is due to the fact that their inherent shallow structure does not allow for better extraction of image features. Therefore, IDARN can identify more fault features and achieve the best classification results with a limited number of iterations.

Table 16.

Comparative indicators of popular CNN models in Dataset1.

Table 17.

Comparative indicators of popular CNN models in Dataset2.

Table 18.

Comparative indicators of popular CNN models in Dataset3.

4.2.3. Comparison with Related Models (QPZZ-II Bearing Failure Data)

In order to further compare the advantages and disadvantages of different models, take Dataset2 as an example. Comparing the literature [15,16,17,18,19] under the same training conditions, the training performance curves are shown in Figure 20. Table 19, Table 20 and Table 21 shows several indicators corresponding to each model.

Figure 20.

Training performance curves for related model comparison. (a) Accuracy (Dataset2); (b) Loss (Dataset2).

Table 19.

Comparative Indicators of related models in Dataset1.

Table 20.

Comparative Indicators of related models in Dataset2.

Table 21.

Comparative Indicators of related models in Dataset3.

From Figure 20a, it can be seen that the accuracy of DenseNet was higher than the proposed model in the initial stage of training, and the proposed model was higher than the other models when the training reached 40–50 rounds, and after 60 rounds of training the two models, DenseNet and IDARN were almost equal. It is worth noting that the other models occasionally jumped around during the overall training process and were not as stable as the proposed model.

From Figure 20b, it can be seen that the EDL model had the highest loss, while the loss of IDARN in the first 50 rounds of training was significantly lower than the other models, and the training loss of IDARN was slightly lower than that of DenseNet at iterations 50–200 rounds. This was due to the deeper structure of DenseNet, but overall, the average loss was essentially equal to that of the proposed model.

As can be seen from Table 19, Table 20 and Table 21, DenseNet and IDARN achieved the highest accuracy on Dataset2, while IDARN had the shortest training time. Comparing all the indicators on the three datasets, the model proposed in this paper still outperforms the other models, therefore IDARN has good robustness under small sample imbalanced data.

4.2.4. Visualisation and Analysis of Results

Figure 21 shows the confusion matrices of the proposed method under the three datasets. It can be seen that label 1 and label 2 have the lowest accuracy under the three datasets and the rest of the labels achieve full classification. Figure 22 shows the results obtained by the proposed method after t-SNE clustering under the three datasets; it can be seen that there was no confounding between the different categories and the faults were classified well. Therefore, IDARN can be used for fault classification of small sample imbalanced data.

Figure 21.

Confusion matrices. (a) Dataset1; (b) Dataset2; (c) Dataset3.

Figure 22.

t-SNE. (a) Dataset1; (b) Dataset2; (c) Dataset3.

5. Conclusions

To address the problems of deep network models degradation and the collapse of model training when the data distribution is imbalanced; this paper proposes an intelligent diagnosis of rolling bearings based on Gramian Angular Difference Field and Improved Dual Attention Residual Network, and mainly draws the following conclusions:

- Using GADF to convert one-dimensional signals into two-dimensional images preserves the correlation of the time series and enhances the shock signature; which is more beneficial for the network’s identification of fault features.

- The residual structure introduced into the GN is used as the body of the network, which solves the network degradation problem and reduces the bias caused by the difference in the distribution of the training samples; meanwhile, the dual-attention mechanism introduced can enhance the integration ability of the features.

- The effects of different normalisation methods and different attention mechanisms on the model were validated on the CWRU bearing dataset. An average recognition accuracy of 99.2% was achieved with the four datasets divided.

- An average identification accuracy of 97.9% was obtained on small samples of imbalanced data divided on the bearing fault experimental equipment.

Although the GADF-IDARN method can obtain good fault diagnosis performance, this method is trained from scratch and therefore the present method requires a longer training cycle compared to other shallow neural network methods. In further work, transfer learning methods can be utilised for fault diagnosis tasks to reduce training time. In addition, the GADF-IDARN methodology should also be utilised to perform on a wider range of datasets.

Author Contributions

Conceptualization, L.X. and A.T.; methodology, A.T. and J.Z.; software, A.T.; writing-original draft preparation, A.T.; writing-review and editing, A.T., L.X. and J.Z.; visualization, A.T.; supervision, L.X. and J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Science and Technology Major Project of China (J2019-IV-0002-0069).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Case Western Reserve University Bearing Data. https://engineering.case.edu/bearingdatacenter (accessed on 25 September 2023).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, X.; Zhou, J. Multi-fault diagnosis for rolling element bearings based on ensemble empirical mode decomposition and optimized support vector machines. Mech. Syst. Signal Process 2013, 41, 127–140. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, J.; Hu, B. Intelligent fault diagnosis of rolling bearings using variational mode decomposition and self-organizing feature map. J. Vib. Control 2020, 26, 1886–1897. [Google Scholar] [CrossRef]

- Khan, S.; Yairi, T. A review on the application of deep learning in system health management. Mech. Syst. Signal Process 2018, 107, 241–265. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Huang, L.; Xiao, D.; Li, X. GMPSO-VMD Algorithm and Its Application to Rolling Bearing Fault Feature Extraction. Sensors 2020, 20, 1946. [Google Scholar] [CrossRef] [PubMed]

- Ye, X.; Hu, Y.; Shen, J.; Feng, R.; Zhai, G. An Improved Empirical Mode Decomposition Based on Adaptive Weighted Rational Quartic Spline for Rolling Bearing Fault Diagnosis. IEEE Access 2020, 8, 123813–123827. [Google Scholar] [CrossRef]

- Ye, X.; Hu, Y.; Shen, J.; Chen, C.; Zhai, G. An Adaptive Optimized TVF-EMD Based on a Sparsity-Impact Measure Index for Bearing Incipient Fault Diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 3507311. [Google Scholar] [CrossRef]

- Wu, S.; Zhou, J.; Liu, T. Compound Fault Feature Extraction of Rolling Bearing Acoustic Signals Based on AVMD-IMVO-MCKD. Sensors 2022, 22, 6769. [Google Scholar] [CrossRef]

- Zhou, J.; Xiao, M.; Niu, Y.; Ji, G. Rolling Bearing Fault Diagnosis Based on WGWOA-VMD-SVM. Sensors 2022, 22, 6281. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, S.; Yin, X.; He, W.; Gao, Z. Research on Gearbox Fault Diagnosis Method Based on VMD and Optimized LSTM. Appl. Sci. 2023, 13, 11637. [Google Scholar] [CrossRef]

- Wan, L.; Gong, K.; Zhang, G.; Yuan, X.; Li, C.; Deng, X. An Efficient Rolling Bearing Fault Diagnosis Method Based on Spark and Improved Random Forest Algorithm. IEEE Access 2021, 9, 37866–37882. [Google Scholar] [CrossRef]

- Hadi, R.H.; Hady, H.N.; Hasan, A.M.; Al-Jodah, A.; Humaidi, A.J. Improved Fault Classification for Predictive Maintenance in Industrial IoT Based on AutoML: A Case Study of Ball-Bearing Faults. Processes 2023, 11, 1507. [Google Scholar] [CrossRef]

- Tian, H.; Fan, H.; Feng, M.; Cao, R.; Li, D. Fault Diagnosis of Rolling Bearing Based on HPSO Algorithm Optimized CNN-LSTM Neural Network. Sensors 2023, 23, 6508. [Google Scholar] [CrossRef] [PubMed]

- Ye, L.; Ma, X.; Wen, C. Rotating Machinery Fault Diagnosis Method by Combining Time-Frequency Domain Features and CNN Knowledge Transfer. Sensors 2021, 21, 8168. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Li, B.; Huang, Y.; Li, L. Bearing fault diagnosis method based on Gramian angular field and ensemble deep learning. J. Vibroeng. 2022, 25, 42–52. [Google Scholar] [CrossRef]

- Zhou, Y.; Long, X.; Sun, M.; Chen, Z. Bearing fault diagnosis based on Gramian angular field and DenseNet. Math. Biosci. Eng. 2022, 19, 14086–14101. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Peng, X.; Cao, Y. Rolling bearing fault diagnosis based on Gramian angular difference field and improved channel attention model. PeerJ Comput. Sci. 2024, 10, 1807. [Google Scholar] [CrossRef]

- Cui, J.; Zhong, Q.; Zheng, S.; Peng, L.; Wen, J. A Lightweight Model for Bearing Fault Diagnosis Based on Gramian Angular Field and Coordinate Attention. Machines 2022, 10, 282. [Google Scholar] [CrossRef]

- Cai, C.; Li, R.; Ma, Q.; Gao, H. Bearing fault diagnosis method based on the Gramian angular field and an SE-ResNeXt50 transfer learning model. Insight 2023, 65, 695–704. [Google Scholar] [CrossRef]

- Wang, Z.; Oates, T. Imaging time-series to improve classification and imputation. In Proceedings of the 24th International Joint Conference on Artificial Intelligence (IJCAI), Buenos Aires, Argentina, 25–30 January 2015; pp. 3939–3945. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, B.; Zhu, P.; Li, P.; Zuo, W.; Hu, Q. Supplementary material for ECA-Net: Efficient channel attention for deep convolutional neural networks. In Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition, IEEE, Seattle, WA, USA, 7 April 2020; pp. 13–19. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, R.; Li, L.; Xie, X. Simam: A simple, Parameter Free attention module for convolutional neural networks. In Proceedings of the International Conference on Machine Learning, Virtual, 18–24 July 2021; pp. 11863–11874. [Google Scholar]

- Case Western Reserve University Bearing Data Center [EB/OL]. 2018. Available online: https://csegroups.case.edu/bearingdatacenter/pages/download-data-file (accessed on 20 February 2024).

- Li, H.; Huang, J.; Ji, S. Bearing Fault Diagnosis with a Feature Fusion Method Based on an Ensemble Convolutional Neural Network and Deep Neural Network. Sensors 2019, 19, 2034. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

- Yan, J.; Kan, J.; Luo, H. Rolling Bearing Fault Diagnosis Based on Markov Transition Field and Residual Network. Sensors 2022, 22, 3936. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, L. A combination of residual and long-short-term memory networks for bearing fault diagnosis based on time-series model analysis. Meas. Sci. Technol. 2021, 32, 5904. [Google Scholar] [CrossRef]

- Eren, L.; Ince, T.; Kiranyaz, S. A Generic Intelligent Bearing Fault Diagnosis System Using Compact Adaptive 1D CNN Classifier. J. Signal Process. Syst. 2019, 91, 179–189. [Google Scholar] [CrossRef]

- Liang, H.; Cao, J.; Zhao, X. Average Descent Rate Singular Value Decomposition and Two-Dimensional Residual Neural Network for Fault Diagnosis of Rotating Machinery. IEEE Trans. Instrum. Meas. 2022, 71, 3512616. [Google Scholar] [CrossRef]

- Wu, H.; Yang, Y.; Deng, S.; Wang, Q.; Song, H. GADF-VGG16 based fault diagnosis method for HVDC transmission lines. PLoS ONE 2022, 17, e0274613. [Google Scholar] [CrossRef]

- Wang, M.; Wang, W.; Zhang, X.; Lu, H. A New Fault Diagnosis of Rolling Bearing Based on Markov Transition Field and CNN. Entropy 2022, 24, 751. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Chen, R.; Wu, K.; Huang, P.; Qiu, G. A variable-speed-condition bearing fault diagnosis methodology with recurrence plot coding and MobileNet-v3 model. Rev. Sci. Instrum. 2023, 94, 034710. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).