Design and Performance Analysis of Foldable Solar Panel for Agrivoltaics System

Abstract

1. Introduction

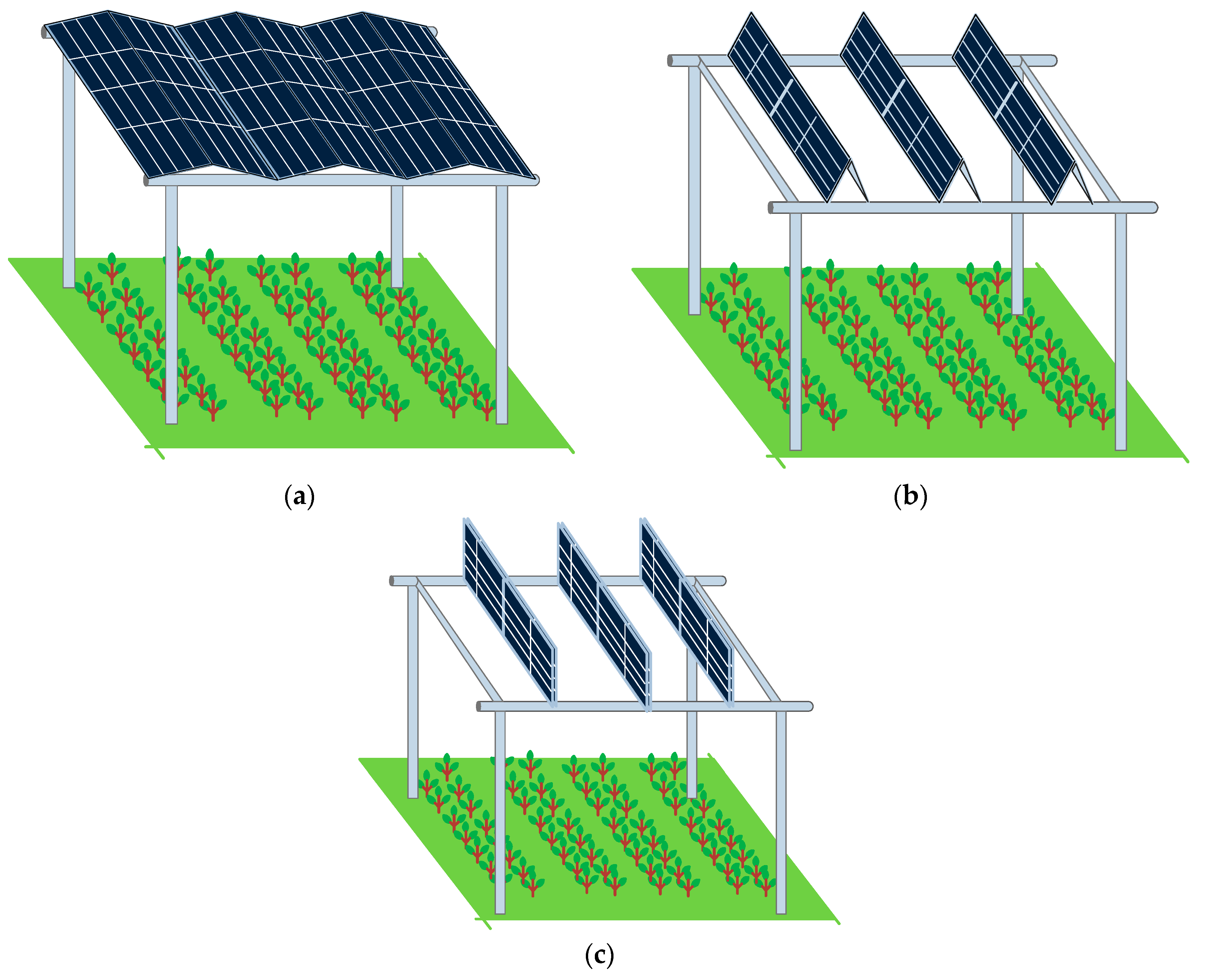

2. Related Works

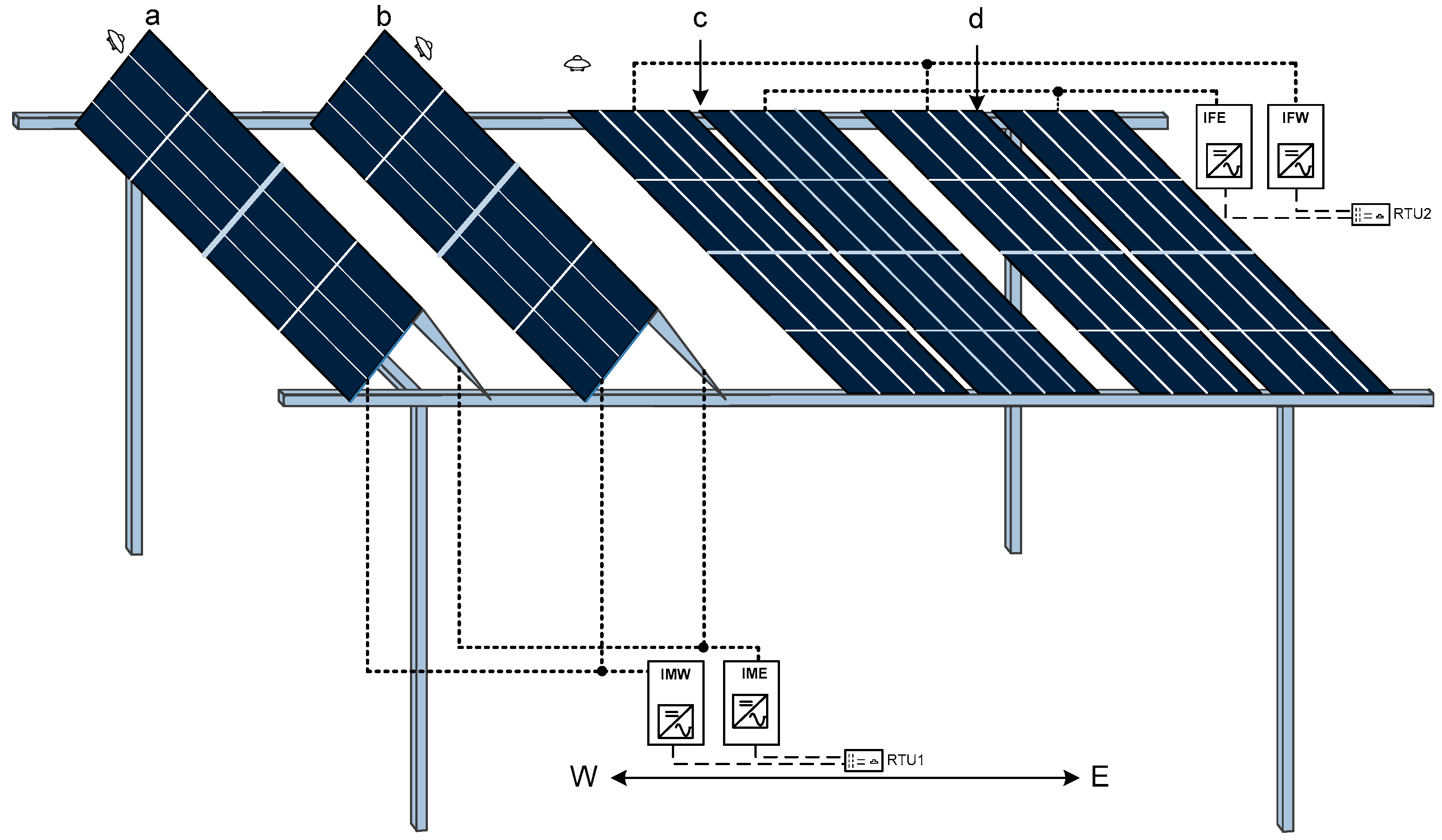

3. Proposed Agrivoltaics System

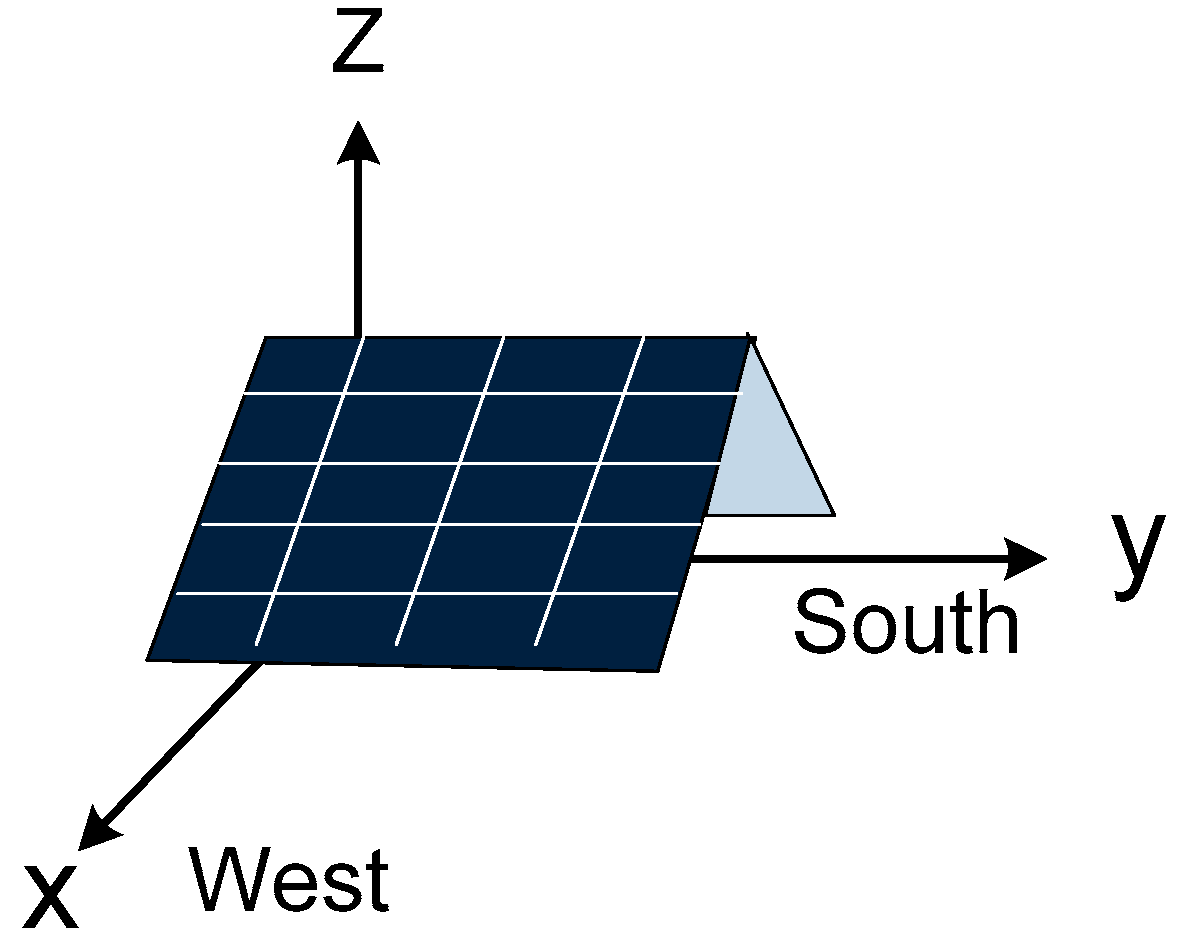

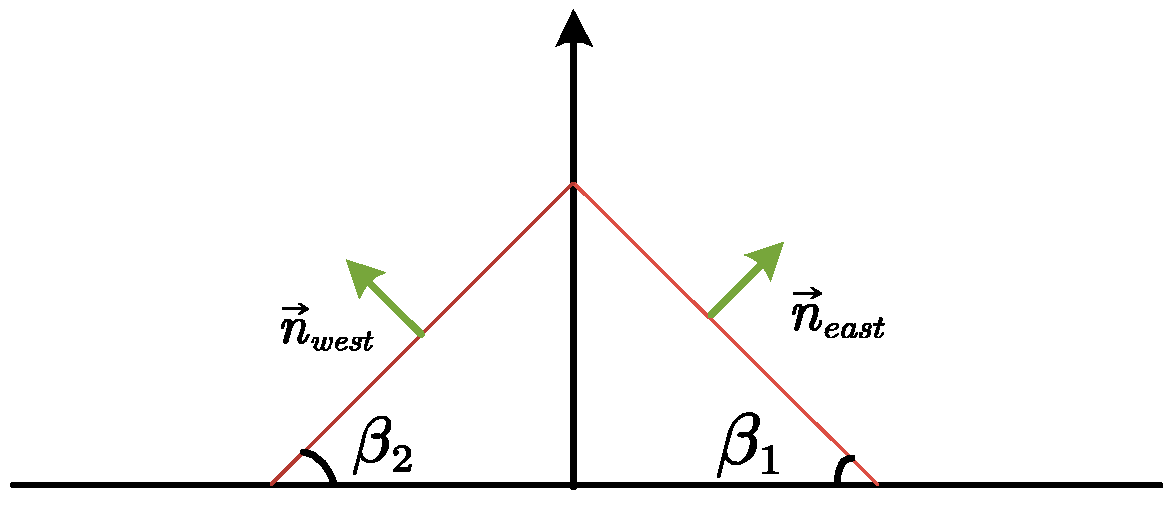

3.1. Foldable Module Design

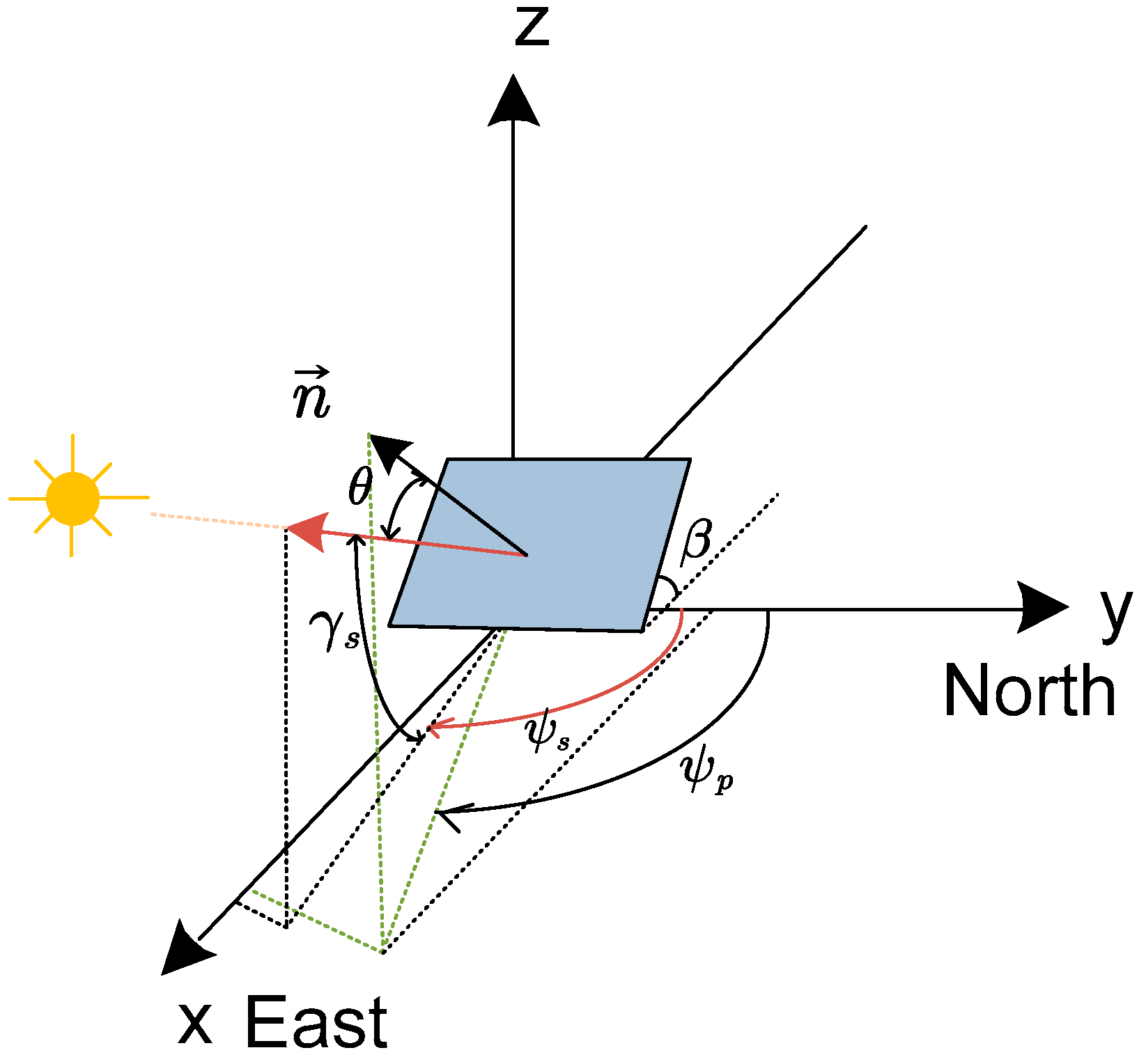

3.2. Time-Based Single-Axis Tracking Algorithm

| Algorithm 1: Time-based Solar Tracking |

| Definitions Angle control |

3.3. Shadow Effect

| Algorithm 2: Improved Time-based Solar Tracking |

| Definitions Control Algorithm: Angle control |

4. Experiments

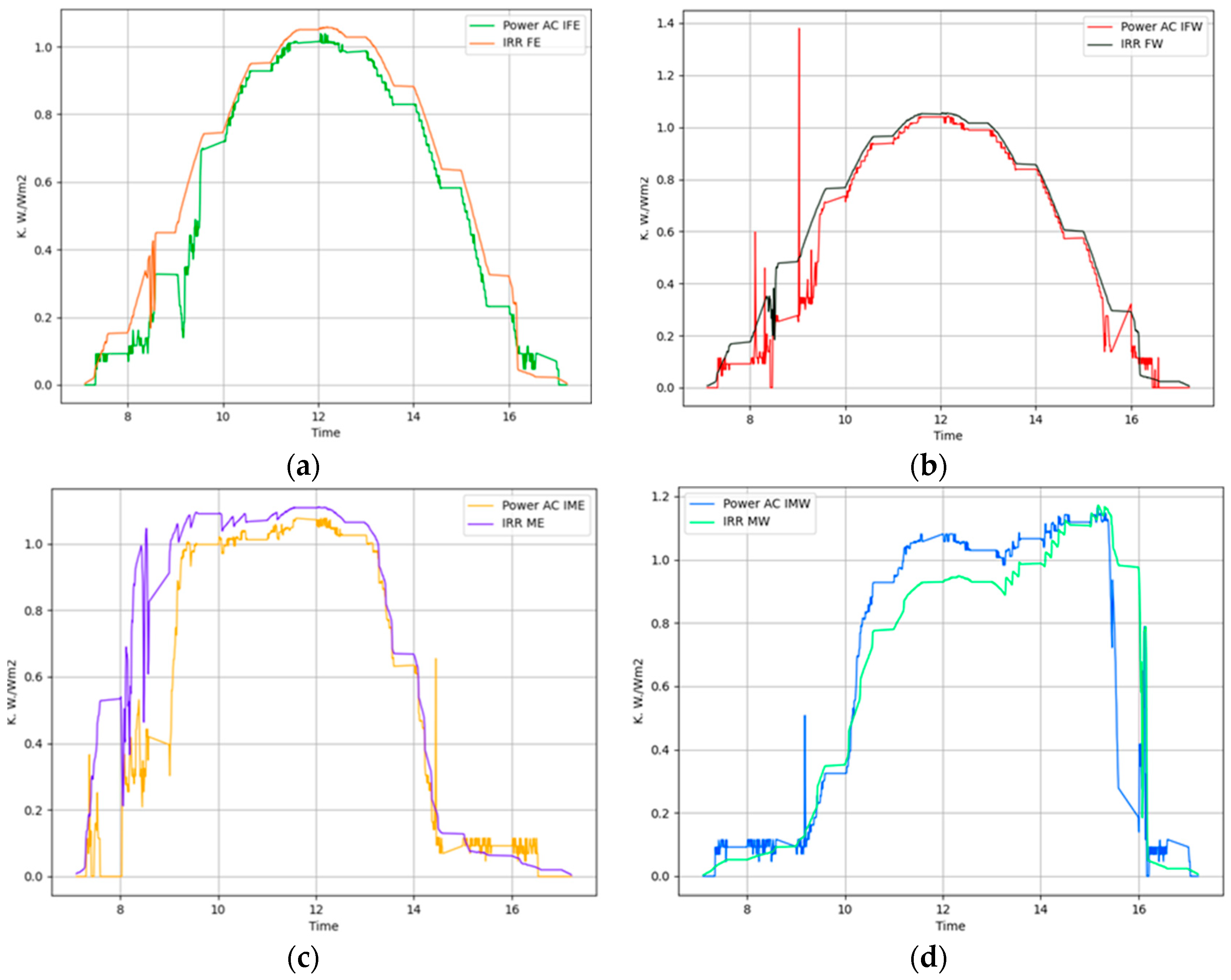

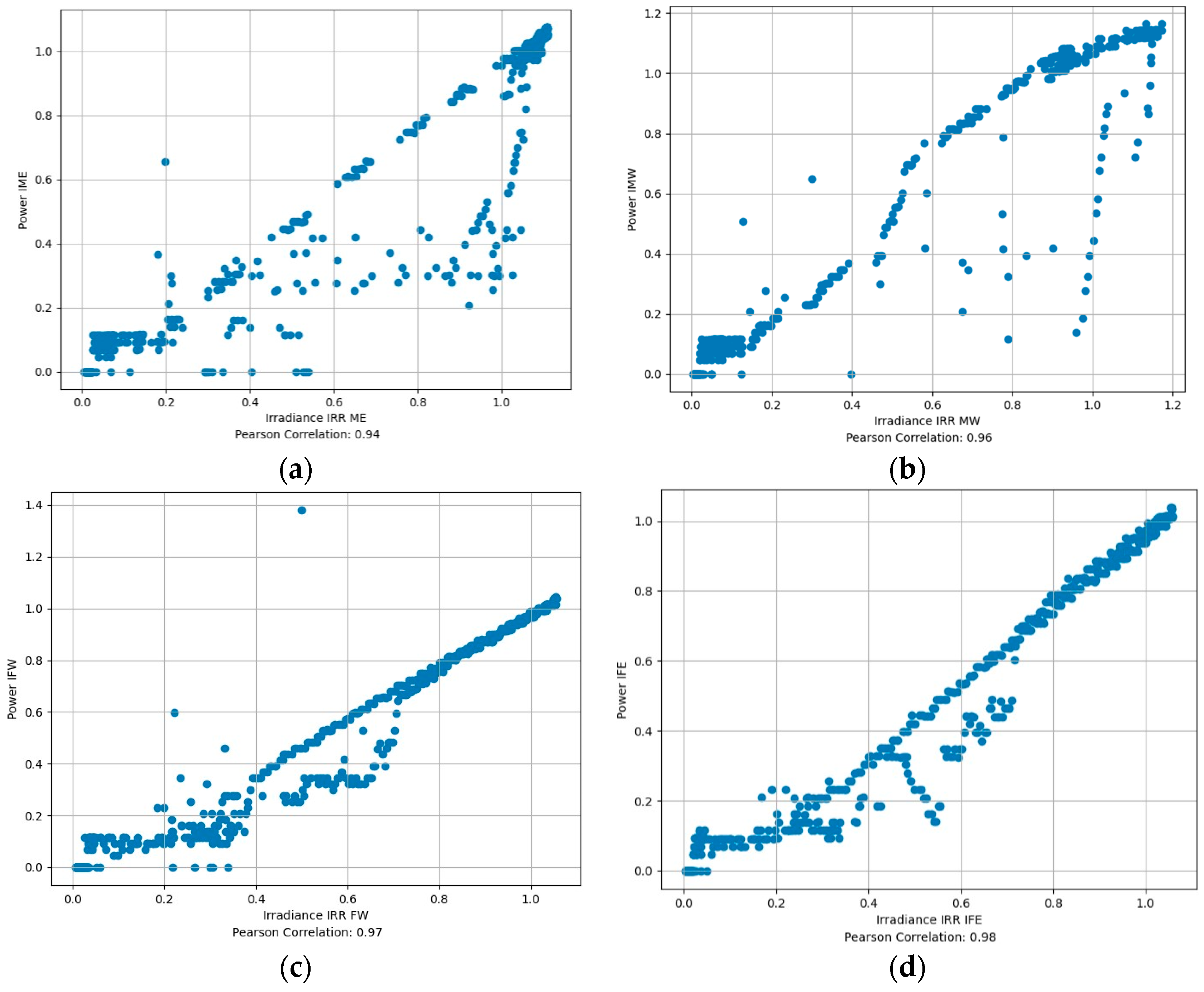

4.1. Data Collection

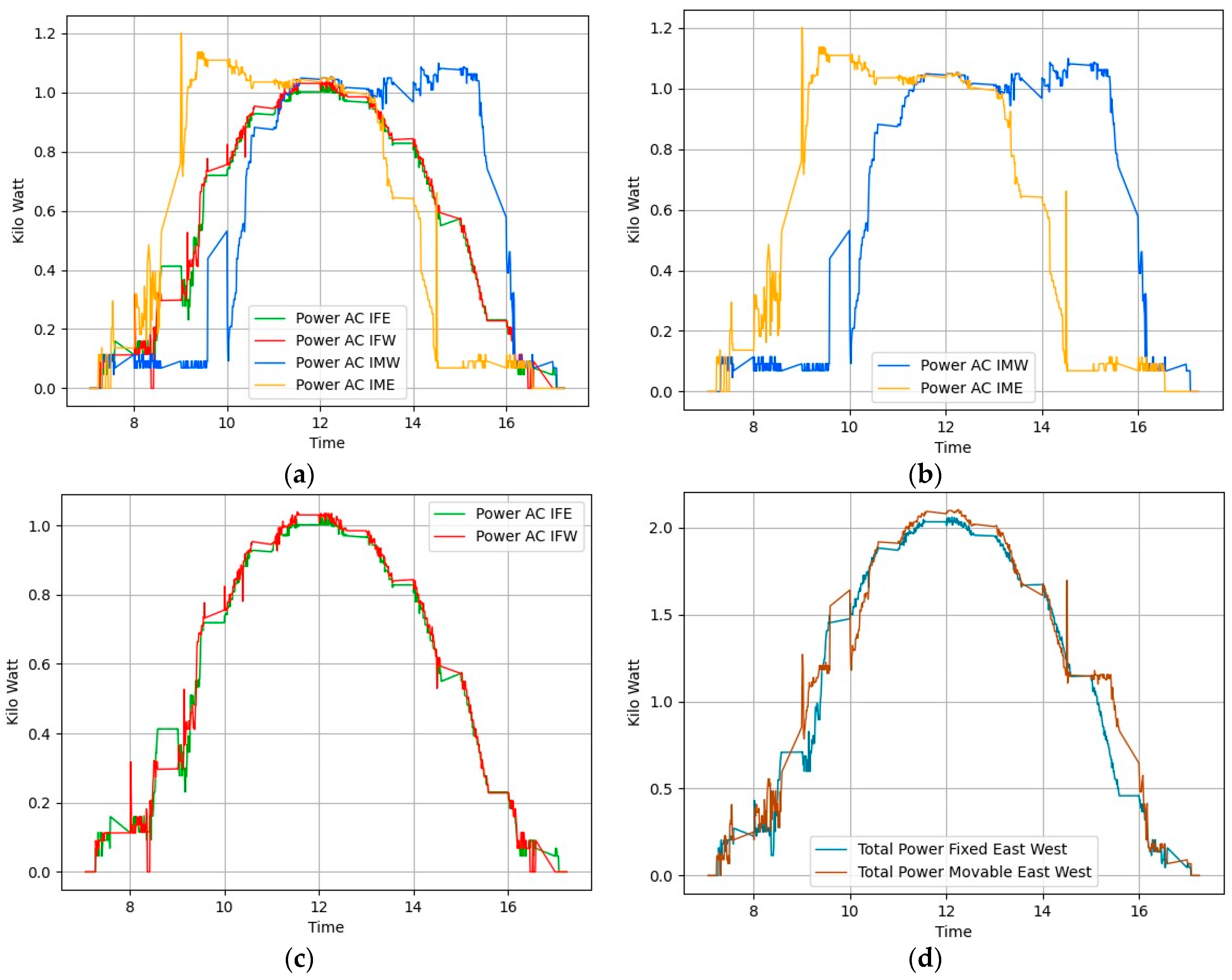

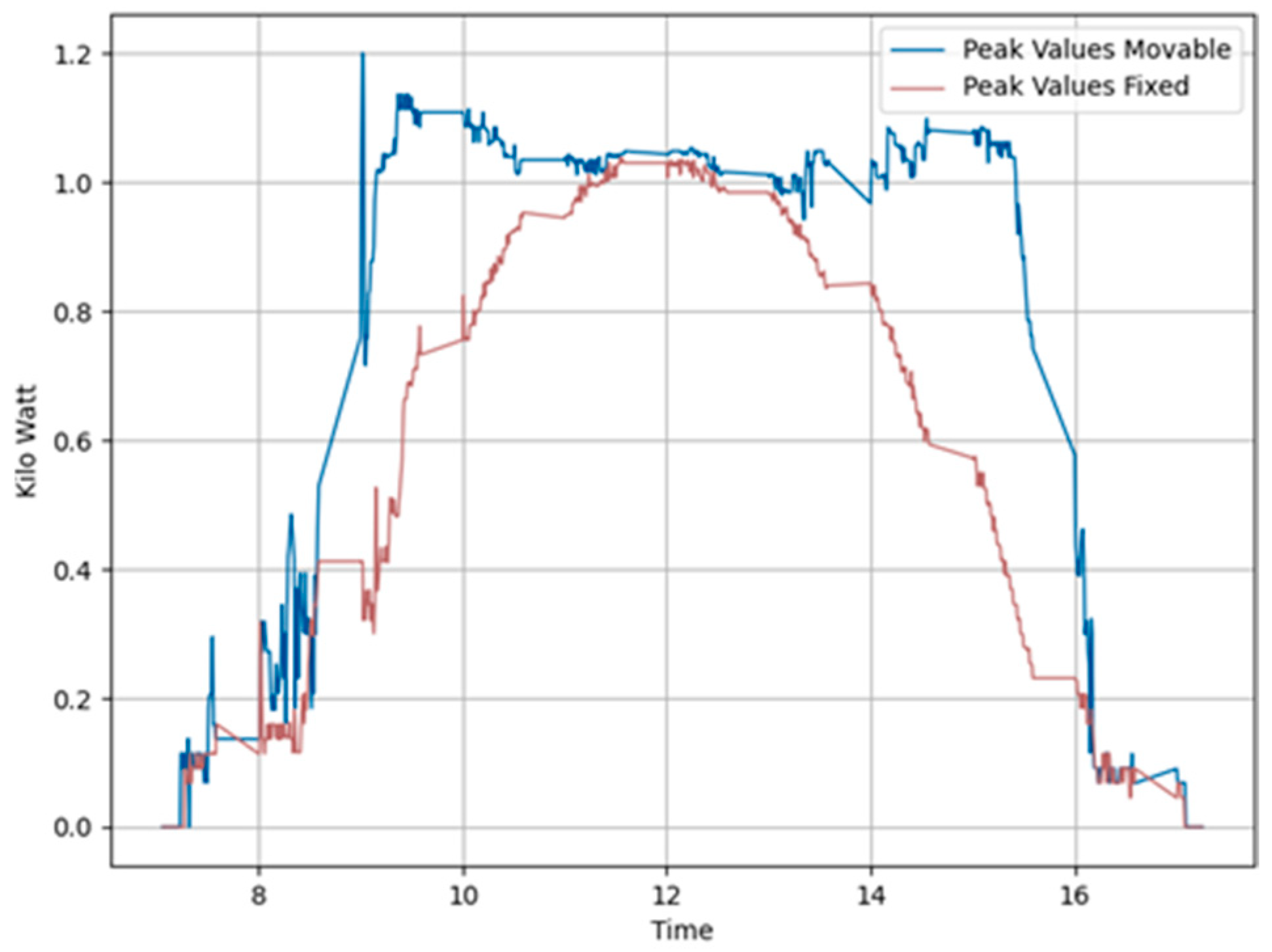

4.2. Performance Evaluation

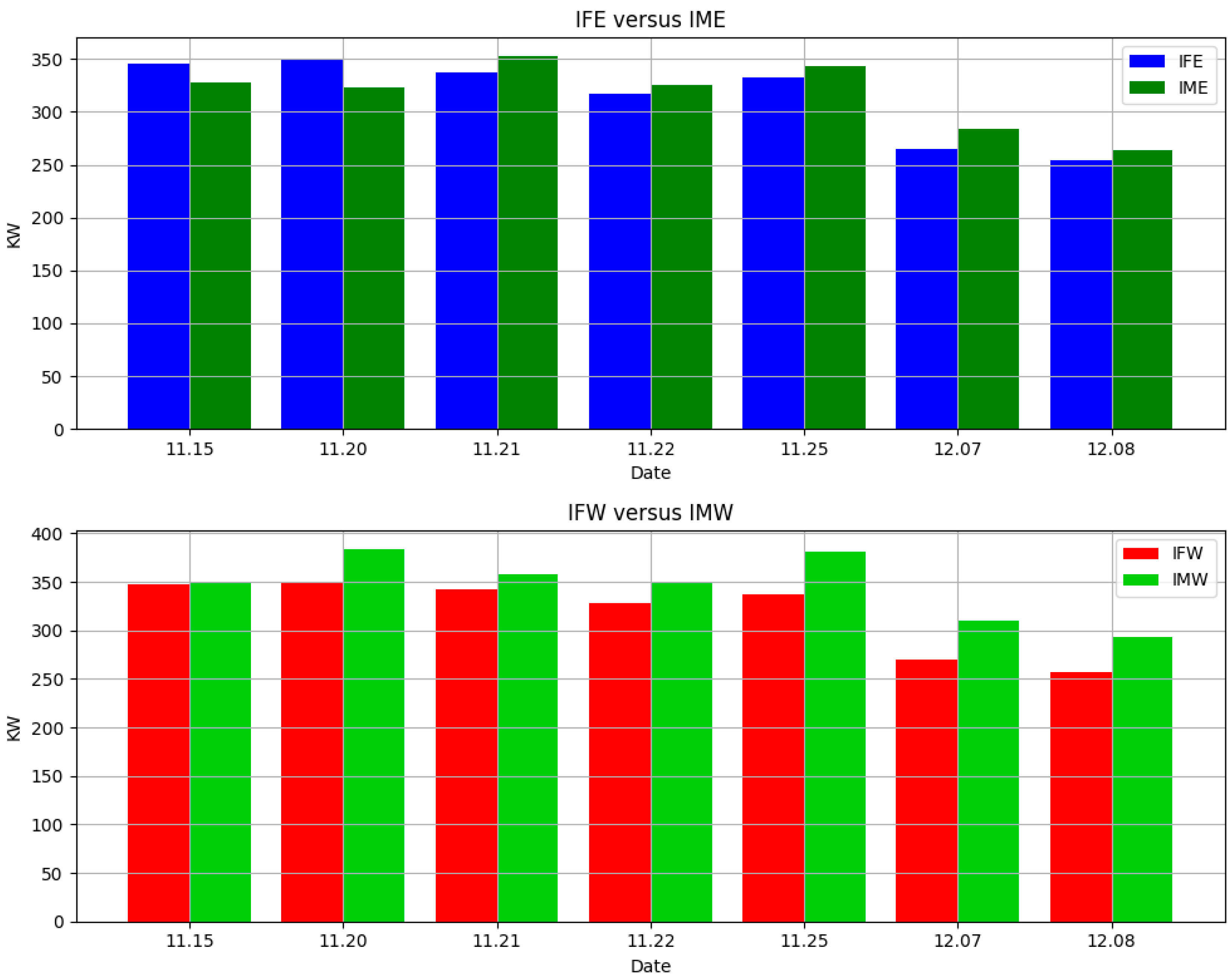

4.3. Results

- Algorithm 1 refers to Algorithm 1 derived in Section 3.2

- Algorithm 2 refers to Algorithm 2 derived in Section 3.3

- PIFE: Cumulative sum of the power of inverter connected to east-facing fixed panel in kilowatts.

- PIFW: Cumulative sum of the power of inverter connected to west-facing fixed panel in kilowatts.

- PIME: Cumulative sum of the power of inverter connected to east-facing foldable panel in kilowatts.

- PIMW: Cumulative sum of the power of inverter connected to west-facing foldable panel in kilowatts.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimizing land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 35. [Google Scholar] [CrossRef]

- Toledo, C.; Scognamiglio, A. Agrivoltaic systems design and assessment: A critical review, and a descriptive model towards a sustainable landscape vision (three-dimensional agrivoltaic patterns). Sustainability 2021, 13, 6871. [Google Scholar] [CrossRef]

- Goetzberger, A.; Zastrow, A. On the coexistence of solar-energy conversion and plant cultivation. Int. J. Sol. Energy 1982, 1, 55–69. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Gruber, S.; Keinath, T.; Hopf, M.; Hermann, C.; Schönberger, F.; Zikeli, S.; Ehmann, A.; Weselek, A.; Bodmer, U.; et al. Agrivoltaics: Opportunities for Agriculture and the Energy Transition. Fraunhofer Institute for Solar Energy Systems ISE, 2nd ed.; Fraunhofer Institute for Solar Energy Systems ISE Heidenhofstrasse 2: Freiburg, Germany, 2022. [Google Scholar]

- Locke, J.; Dsilva, J.; Zarmukhambetova, S. Decarbonization strategies in the UAE built environment: An evidence-based analysis using COP26 and COP27 recommendations. Sustainability 2023, 15, 11603. [Google Scholar] [CrossRef]

- Martins, A.C.; Pereira, M.D.C.; Pasqualino, R. Renewable Electricity Transition: A Case for Evaluating Infrastructure Investments through Real Options Analysis in Brazil. Sustainability 2023, 15, 10495. [Google Scholar] [CrossRef]

- Macknick, J.; Beatty, B.; Hill, G. Overview of Opportunities for Co-Location of Solar Energy Technologies and Vegetation (No. NREL/TP-6A20-60240); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2013. [Google Scholar]

- Buari, O.K.; Kumari, K. Optimizing Agrivoltaics Electricity Generation in Sweden: A techno-economic analysis of latitude-dependent design systems, Sweden. 2023. Available online: https://www.diva-portal.org/smash/get/diva2:1774070/FULLTEXT01.pdf (accessed on 12 January 2024).

- Available online: https://next2sun.com/en/ (accessed on 10 January 2024).

- Available online: https://www.akuoenergy.com/en/agrinergie (accessed on 10 January 2024).

- Available online: https://remtec.energy/en/agrovoltaico (accessed on 12 January 2024).

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimise land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Available online: https://www.baywa-re.com/en/solar-projects/agri-pv (accessed on 12 January 2024).

- Imran, H.; Riaz, M.H.; Butt, N.Z. Optimization of single-axis tracking of photovoltaic modules for agrivoltaic systems. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1353–1356. [Google Scholar]

- Kanwal, T.; Rehman, S.U.; Ali, T.; Mahmood, K.; Villar, S.G.; Lopez, L.A.D.; Ashraf, I. An intelligent dual-axis solar tracking system for remote weather monitoring in the agricultural field. Agriculture 2023, 13, 1600. [Google Scholar] [CrossRef]

- Malu, P.R.; Sharma, U.S.; Pearce, J.M. Agrivoltaic potential on grape farms in India. Sustain. Energy Technol. Assess. 2017, 23, 104–110. [Google Scholar] [CrossRef]

- Hassanpour Adeh, E.; Selker, J.S.; Higgins, C.W. Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLoS ONE 2018, 13, e0203256. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Gulakhmadov, A.; Kumar, A.; Safaraliev, M.; Chen, X. Comparative Analysis for a Solar Tracking Mechanism of Solar PV in Five Different Climatic Locations in South Indian States: A Techno-Economic Feasibility. Sustainability 2022, 14, 11880. [Google Scholar] [CrossRef]

- Campana, P.E.; Stridh, B.; Amaducci, S.; Colauzzi, M. Optimisation of vertically mounted agrivoltaic systems. J. Clean. Prod. 2021, 325, 129091. [Google Scholar] [CrossRef]

- Jing, R.; Liu, J.; Zhang, H.; Zhong, F.; Liu, Y.; Lin, J. Unlock the hidden potential of urban rooftop agrivoltaics energy-food-nexus. Energy 2022, 256, 124626. [Google Scholar] [CrossRef]

- Grubbs, E.K.; Gruss, S.M.; Schull, V.Z.; Gosney, M.J.; Mickelbart, M.V.; Brouder, S.; Gitau, M.W.; Bermel, P.; Tuinstra, M.R.; Agrawal, R. Optimized agrivoltaic tracking for nearly-full commodity crop and energy production. Renew. Sustain. Energy Rev. 2024, 191, 114018. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Y.; Sun, C.; Li, W.; Zomaya, A.; Sun, Y. Towards a data-driven symbiosis of agriculture and photovoltaics. In Proceedings of the 2019 International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Atlanta, GA, USA, 14–17 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 903–908. [Google Scholar]

- Zhang, F.; Li, M.; Zhang, W.; Liu, W.; Omer, A.A.A.; Zhang, Z.; Zheng, J.; Liu, W.; Zhang, X. Large-scale and cost-efficient agrivoltaics system by spectral separation. iScience 2023, 26, 108129. [Google Scholar] [CrossRef]

- Evans, M.E.; Langley, J.A.; Shapiro, F.R.; Jones, G.F. A validated model, scalability, and plant growth results for an agrivoltaic greenhouse. Sustainability 2022, 14, 6154. [Google Scholar] [CrossRef]

- Williams, H.J.; Hashad, K.; Wang, H.; Zhang, K.M. The potential for agrivoltaics to enhance solar farm cooling. Appl. Energy 2023, 332, 120478. [Google Scholar] [CrossRef]

- Marucci, A.; Monarca, D.; Colantoni, A.; Campiglia, E.; Cappuccini, A. Analysis of the internal shading in a photovoltaic greenhouse tunnel. J. Agric. Eng. 2017, 48, 154–160. [Google Scholar] [CrossRef]

- La Notte, L.; Giordano, L.; Calabrò, E.; Bedini, R.; Colla, G.; Puglisi, G.; Reale, A. Hybrid and organic photovoltaics for greenhouse applications. Appl. Energy 2020, 278, 115582. [Google Scholar] [CrossRef]

- Dipta, S.S.; Schoenlaub, J.; Rahaman, M.H.; Uddin, A. Estimating the potential for semitransparent organic solar cells in agrophotovoltaic greenhouses. Appl. Energy 2022, 328, 120208. [Google Scholar] [CrossRef]

- Touil, S.; Richa, A.; Fizir, M.; Bingwa, B. Shading effect of photovoltaic panels on horticulture crops production: A mini review. Rev. Environ. Sci. Bio/Technol. 2021, 20, 281–296. [Google Scholar] [CrossRef]

- Musa, A.; Alozie, E.; Suleiman, S.A.; Ojo, J.A.; Imoize, A.L. A Review of Time-Based Solar Photovoltaic Tracking Systems. Information 2023, 14, 211. [Google Scholar] [CrossRef]

- Reda, I.; Afshin, A. Solar Position Algorithm for Solar Radiation Applications; Technical Report NREL/TP-560-3402; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008; Available online: http://www.nrel.gov/docs/fy08osti/34302.pdf (accessed on 12 November 2023).

- Narvarte, L.; Lorenzo, E. Tracking and ground cover ratio. Prog. Photovolt. Res. Appl. 2008, 16, 703–714. [Google Scholar] [CrossRef]

- Quaschning, V.; Hanitsch, R. Shade calculations in photovoltaic systems. In Proceedings of the ISES Solar World Conference, Harare, Zimbabwe, 11–15 September 1995. [Google Scholar]

- Wagner, M.; Lask, J.; Kiesel, A.; Lewandowski, I.; Weselek, A.; Högy, P.; Trommsdorff, M.; Schnaiker, M.A.; Bauerle, A. Agrivoltaics: The Environmental Impacts of Combining Food Crop Cultivation and Solar Energy Generation. Agronomy 2023, 13, 299. [Google Scholar] [CrossRef]

- Agostini, A.; Colauzzi, M.; Amaducci, S. Innovative agrivoltaic systems to produce sustainable energy: An economic and environmental assessment. Appl. Energy 2021, 281, 116102. [Google Scholar] [CrossRef]

- Zheng, J.; Meng, S.; Zhang, X.; Zhao, H.; Ning, X.; Chen, F.; Abaker Omer, A.A.; Ingenhoff, J.; Liu, W. Increasing the comprehensive economic benefits of farmland with Even-lighting Agrivoltaic Systems. PLoS ONE 2021, 16, e0254482. [Google Scholar] [CrossRef]

| PIFE (Kilo-Watt) | PIFW (Kilo-Watt) | PIME (Kilo-Watt) | PIMW (Kilo-Watt) | Peak Variance Ratio (STDPP) | PG (%) | |

|---|---|---|---|---|---|---|

| Time-based Solar Tracking (Algorithm 1) [31] | 345.98 | 347.39 | 328.29 | 349.73 | 1.11 | −2.21% |

| Improved Time-based Solar Tracking (Algorithm 2) | 336.8 | 342.37 | 352.43 | 358.41 | 1.13 | 4.66% |

| Improved Time-based Solar Tracking (Algorithm 2) | 331.92 | 337.62 | 343.17 | 380.90 | 1.11 | 8.14% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lama, R.K.; Jeong, H. Design and Performance Analysis of Foldable Solar Panel for Agrivoltaics System. Sensors 2024, 24, 1167. https://doi.org/10.3390/s24041167

Lama RK, Jeong H. Design and Performance Analysis of Foldable Solar Panel for Agrivoltaics System. Sensors. 2024; 24(4):1167. https://doi.org/10.3390/s24041167

Chicago/Turabian StyleLama, Ramesh Kumar, and Heon Jeong. 2024. "Design and Performance Analysis of Foldable Solar Panel for Agrivoltaics System" Sensors 24, no. 4: 1167. https://doi.org/10.3390/s24041167

APA StyleLama, R. K., & Jeong, H. (2024). Design and Performance Analysis of Foldable Solar Panel for Agrivoltaics System. Sensors, 24(4), 1167. https://doi.org/10.3390/s24041167