Use of Augmented Reality as a Tool to Support Cargo Handling Operations at the CARGO Air Terminal

Abstract

1. Introduction

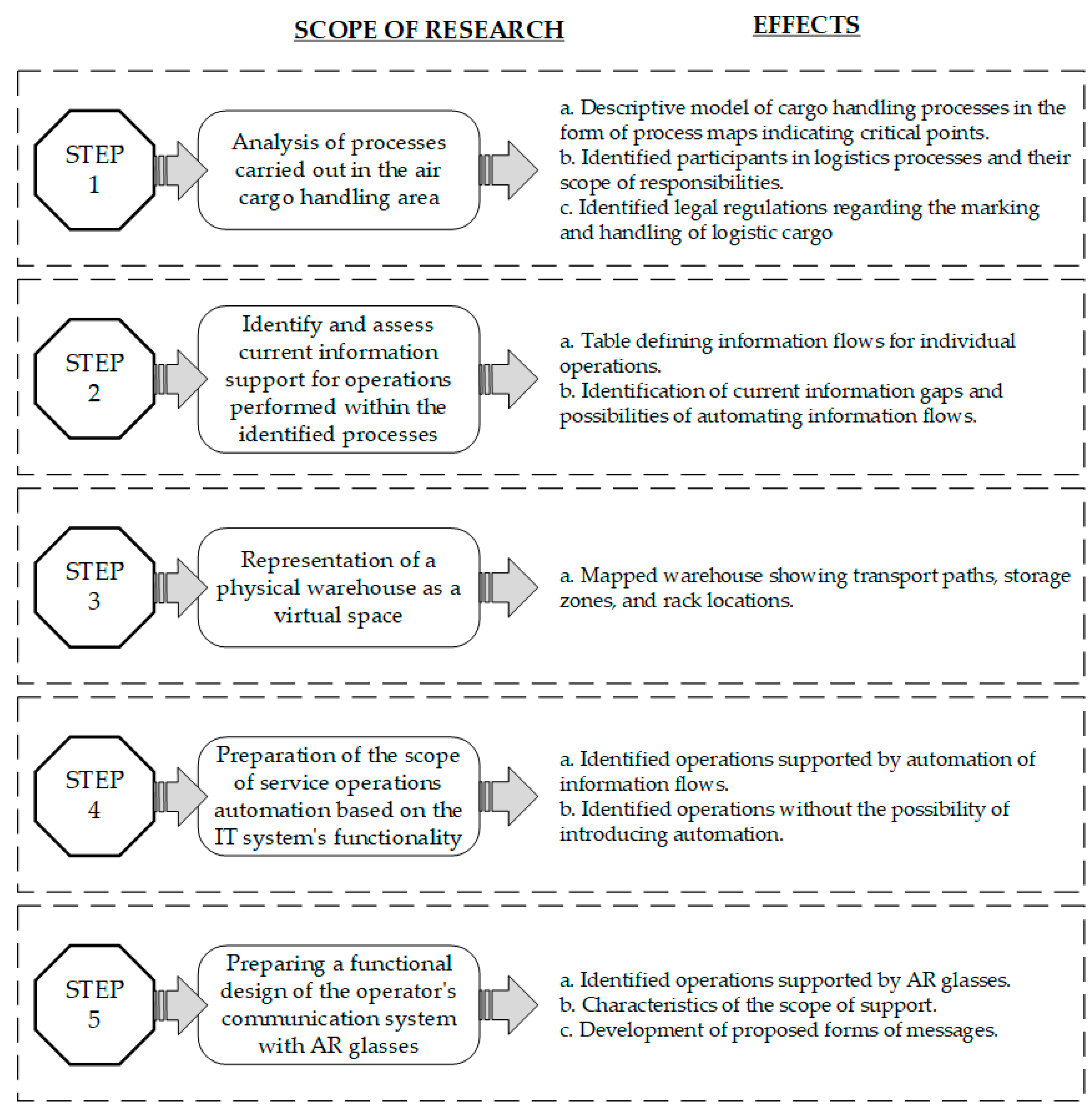

- Identification of information flows related to air cargo handling at the CARGO terminal, along with identification of potential for automation.

- Formulation of the research procedure stages for the design of AR tools supporting air cargo handling.

- Presentation of the functionality design of an AR tool to support warehouse operators.

- Identification of challenges associated with the application of AR technology in air cargo handling.

2. Theoretical Background

- A video camera that transmits an actual image of the environment in which the user is located.

- Tracking Module, which monitors the relative position and orientation of the camera in real time. This module can be based on every type of sensor technology: (1) 9D IMU (3-axis accelerometer, 3-axis gyroscope, and 3-axis magnetometer), (2) ultrasonic sensors, (3) video cameras, (4) GPS modules, and (5) RFID devices.

- Graphic Processing Module processes images captured by the video camera and adds virtual objects to them.

- Display provides users with an integrated image of the physical world combined with virtual objects.

- Reducing the incidence of human error (e.g., incorrect picking, assembly, or maintenance) [23].

- Increased visual control and monitoring of products and stock-keeping units;

- Efficiency and potential cost savings through minimization of errors during product identification, losses, and damages;

- Increased efficiency and productivity through minimization of search time, mis-picks, fatigue, and errors;

- Efficient inventory management and order-picking processes through better visualization and guidance.

- Visualization: (a) the information displayed in the operators’ field of view decreases task completion times by eliminating unnecessary head and body movement; (b) documenting all operator actions, continuous monitoring, naturally following the user’s attention, providing more information;

- Interaction: (a) building safer and more productive work environments by promoting beneficial uses of technology for people; (b) being able to identify and mitigate risks with ARSGs; (c) improving human–environment interaction and human perception to complete tasks;

- User convenience: (a) efficient, versatile, and comfortable to wear; (b) does not distract workers; (c) enables hands-free access to information;

- Navigation: (a) ability to move quickly along optimized paths; (b) precise location and the ability to track position at all times; (c) easily find physical targets.

3. Methods

- RQ1: How is the air cargo handling process carried out at the CARGO terminal, what factors regulate its execution, and what information flows accompany the logistics operations performed?

- RQ2: Which information flows can be automated using an appropriate information system?

- RQ3: Which handling operations can be supported by augmented reality solutions, and how will this affect process execution?

- Information feeding the implementation of operations;

- The current form of obtaining in-feed information;

- The person carrying out operations at the terminal;

- The type of authorization required to carry out the operation;

- Information generated as a result of the execution of the operation;

- The current form of the generated output information.

4. Results

4.1. Stage 1—Analysis of Logistics Processes

- Shipper—a shipping company or direct shipper (e.g., a manufacturing company or an individual) responsible for handling the shipment in terms of booking a seat on the aircraft;

- Cargo agent—a person with the authority to handle shipments: WHA and/or LAR and/or DGR in category six and handling the respective internal transport and with authority to handle goods after security screening;

- Operator—a person with the authorization to handle the given internal transport and the mandatory Basic Cargo authorization and possible additional WHA and/or DGR category seven and/or eight authorizations to handle consignments after security control;

- Security Control employee—a person with DGR authorization in category 12 and to operate the Heimann X-ray viewer;

- Customs and Revenue employee—a person with authorization for customs and revenue handling of imported and exported shipments.

4.2. Stage 2—Characterization of Current Information Flows

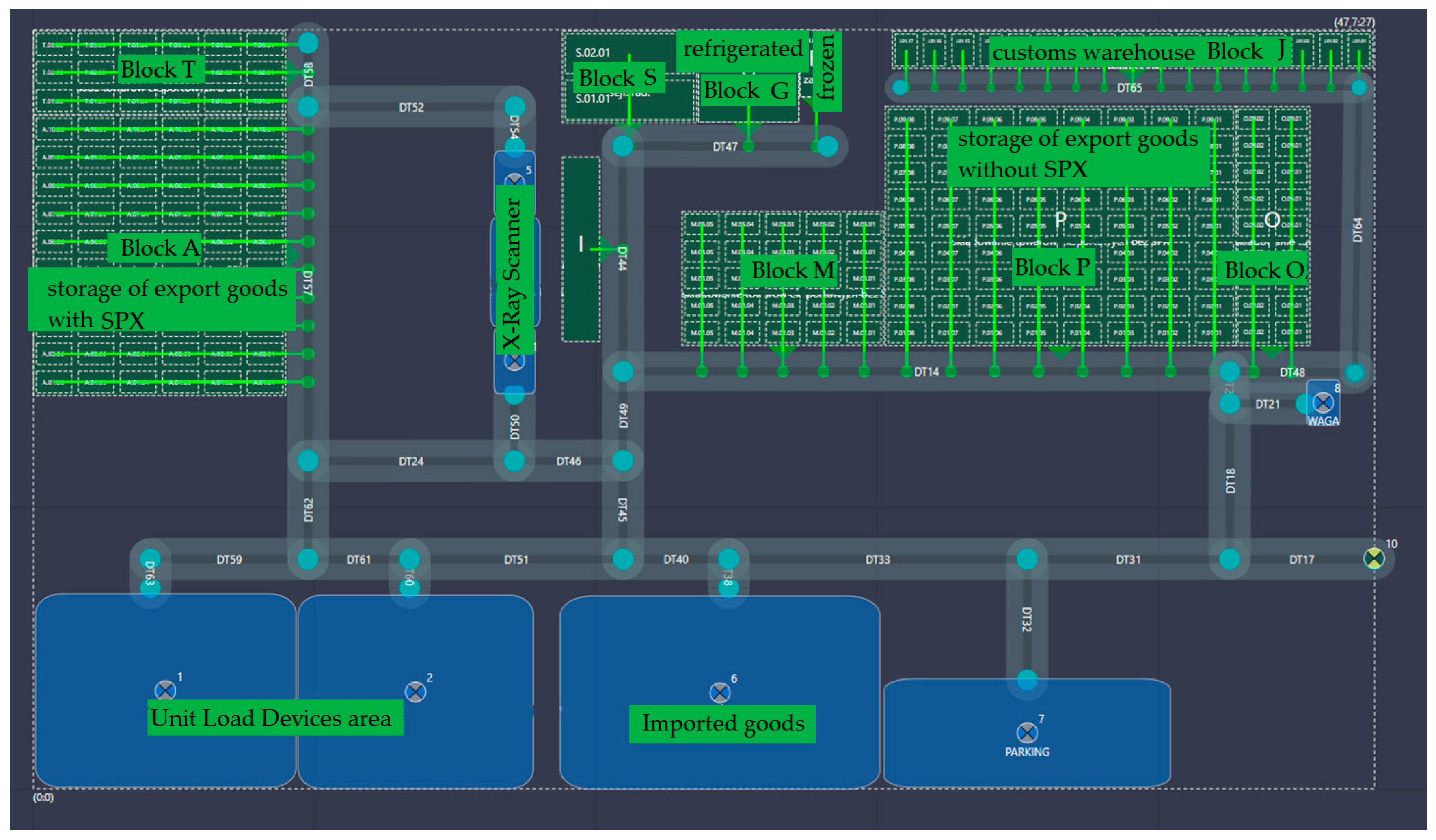

4.3. Stage 3—Visualization of the Physical Warehouse

- storage of export goods without SPX (Block M, Block O, and Block P);

- storage of export goods with SPX (Block A and Block T);

- refrigerated goods warehouse (Block G);

- frozen goods warehouse (Block H);

- customs warehouse (Block J);

- storage of radioactive goods and valuable shipments (Block S).

4.4. Stage 4—Preparation of the Scope of Automation of Handling Operations Based on the Functionality of the Information System

4.5. Stage 5—Preparation of the Functionality Design of the AR System

5. Discussion

- the lack of fixed storage locations, causing difficulties in the distribution and picking of cargo in a short period;

- the large number of variables determining the location of cargo in the warehouse—(a) the timing of cargo release for transport; (b) the location of cargo from other sources that will be placed in common transport packages; (c) the weight, size, and type of cargo;

- the wide range of markings used for goods transported by air.

- detection of markings applied to a given shipment or baggage;

- indication of missing markings;

- identification of irregularities in applied markings (e.g., incorrect orientation, mislabeling, soiling, and damage).

- varying handling requirements resulting from, among other things, the physical characteristics of shipments (e.g., maximum pressures), but also specific customer requirements;

- heavily heterogeneous cargoes that make it difficult to group and distribute cargoes in a shared space—including irregularity of shape and the need to ensure isolation of cargoes from other cargo groups;

- organizational impediments—taking into account the priority of the shipment due to the timing of transport and the need to load several shipments on one ULD (e.g., described by one AWB or sent to one intermediate or final destination).

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2019, 12, 86. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A Systematic Review towards a New Logistics System. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Tubis, A.A.; Grzybowska, K. In Search of Industry 4.0 and Logistics 4.0 in Small-Medium Enterprises—A State of the Art Review. Energies 2022, 15, 8595. [Google Scholar] [CrossRef]

- Tubis, A.A.; Grzybowska, K.; Król, B. Supply Chain in the Digital Age: A Scientometric–Thematic Literature Review. Sustainability 2023, 15, 11391. [Google Scholar] [CrossRef]

- Bigliardi, B.; Casella, G.; Bottani, E. Industry 4.0 in the Logistics Field: A Bibliometric Analysis. IET Collab. Intell. Manuf. 2021, 3, 4–12. [Google Scholar] [CrossRef]

- Hamdy, W.; Al-Awamry, A.; Mostafa, N. Warehousing 4.0: A Proposed System of Using Node-Red for Applying Internet of Things in Warehousing. Sustain. Futures 2022, 4, 100069. [Google Scholar] [CrossRef]

- Tubis, A.A.; Rohman, J. Intelligent Warehouse in Industry 4.0—Systematic Literature Review. Sensors 2023, 23, 4105. [Google Scholar] [CrossRef] [PubMed]

- Zoubek, M.; Simon, M. Evaluation of the Level and Readiness of Internal Logistics for Industry 4.0 in Industrial Companies. Appl. Sci. 2021, 11, 6130. [Google Scholar] [CrossRef]

- Zigart, T.; Schlund, S. Evaluation of Augmented Reality Technologies in Manufacturing—A Literature Review. In Advances in Human Factors and Systems Interaction. AHFE 2020. Advances in Intelligent Systems and Computing; Nunes, I., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1207, pp. 75–82. [Google Scholar]

- Palmarini, R.; Erkoyuncu, J.A.; Roy, R.; Torabmostaedi, H. A Systematic Review of Augmented Reality Applications in Maintenance. Robot Comput. Integr. Manuf. 2018, 49, 215–228. [Google Scholar] [CrossRef]

- Song, Y.; Koeck, R.; Luo, S. Review and Analysis of Augmented Reality (AR) Literature for Digital Fabrication in Architecture. Autom. Constr. 2021, 128, 103762. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.F.; Poelman, R. A Survey of Augmented Reality Technologies, Applications and Limitations. Int. J. Virtual Real. 2010, 9, 1. [Google Scholar] [CrossRef]

- Daponte, P.; De Vito, L.; Picariello, F.; Riccio, M. State of the Art and Future Developments of the Augmented Reality for Measurement Applications. Measurement 2014, 57, 53–70. [Google Scholar] [CrossRef]

- Azuma, R.; Baillot, Y.; Behringer, R.; Feiner, S.; Julier, S.; MacIntyre, B. Recent Advances in Augmented Reality. IEEE Comput. Graph. Appl. 2001, 21, 34–47. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented Reality in Support of Industry 4.0—Implementation Challenges and Success Factors. Robot Comput. Integr. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- de Souza Cardoso, L.F.; Mariano, F.C.M.Q.; Zorzal, E.R. A Survey of Industrial Augmented Reality. Comput. Ind. Eng. 2020, 139, 106159. [Google Scholar] [CrossRef]

- Syberfeldt, A.; Holm, M.; Danielsson, O.; Wang, L.; Brewster, R.L. Support Systems on the Industrial Shop-Floors of the Future—Operators’ Perspective on Augmented Reality. Procedia CIRP 2016, 44, 108–113. [Google Scholar] [CrossRef]

- Danielsson, O.; Holm, M.; Syberfeldt, A. Augmented Reality Smart Glasses in Industrial Assembly: Current Status and Future Challenges. J. Ind. Inf. Integr. 2020, 20, 100175. [Google Scholar] [CrossRef]

- Hofmann, B.; Haustein, D.; Landeweerd, L. Smart-Glasses: Exposing and Elucidating the Ethical Issues. Sci. Eng. Ethics 2017, 23, 701–721. [Google Scholar] [CrossRef]

- Devagiri, J.S.; Paheding, S.; Niyaz, Q.; Yang, X.; Smith, S. Augmented Reality and Artificial Intelligence in Industry: Trends, Tools, and Future Challenges. Expert Syst. Appl. 2022, 207, 118002. [Google Scholar] [CrossRef]

- Guo, A.; Raghu, S.; Xie, X.; Ismail, S.; Luo, X.; Simoneau, J.; Gilliland, S.; Baumann, H.; Southern, C.; Starner, T. A Comparison of Order Picking Assisted by Head-up Display (HUD), Cart-Mounted Display (CMD), Light, and Paper Pick List. In Proceedings of the 2014 ACM International Symposium on Wearable Computers, ACM, New York, NY, USA, 13 September 2014; pp. 71–78. [Google Scholar]

- Hou, L.; Wang, X. A Study on the Benefits of Augmented Reality in Retaining Working Memory in Assembly Tasks: A Focus on Differences in Gender. Autom. Constr. 2013, 32, 38–45. [Google Scholar] [CrossRef]

- Wang, X.; Ong, S.K.; Nee, A.Y.C. Multi-Modal Augmented-Reality Assembly Guidance Based on Bare-Hand Interface. Adv. Eng. Inform. 2016, 30, 406–421. [Google Scholar] [CrossRef]

- Egger, J.; Masood, T. Augmented Reality in Support of Intelligent Manufacturing—A Systematic Literature Review. Comput. Ind. Eng. 2020, 140, 106195. [Google Scholar] [CrossRef]

- Hanson, R.; Falkenström, W.; Miettinen, M. Augmented Reality as a Means of Conveying Picking Information in Kit Preparation for Mixed-Model Assembly. Comput. Ind. Eng. 2017, 113, 570–575. [Google Scholar] [CrossRef]

- Zywicki, K.; Bun, P. Process of Materials Picking Using Augmented Reality. IEEE Access 2021, 9, 102966–102974. [Google Scholar] [CrossRef]

- Reif, R.; Günthner, W.A.; Schwerdtfeger, B.; Klinker, G. Evaluation of an Augmented Reality Supported Picking System Under Practical Conditions. Comput. Graph. Forum 2010, 29, 2–12. [Google Scholar] [CrossRef]

- Stoltz, M.-H.; Giannikas, V.; McFarlane, D.; Strachan, J.; Um, J.; Srinivasan, R. Augmented Reality in Warehouse Operations: Opportunities and Barriers. IFAC-PapersOnLine 2017, 50, 12979–12984. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Leong, G.K.; Treiblmaier, H. Potentials and Challenges of Augmented Reality Smart Glasses in Logistics and Supply Chain Management: A Systematic Literature Review. Int. J. Prod. Res. 2021, 59, 3747–3776. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Wamba, S.F.; Treiblmaier, H. The Potentials of Augmented Reality in Supply Chain Management: A State-of-the-Art Review. Manag. Rev. Q. 2021, 71, 819–856. [Google Scholar] [CrossRef]

| PROCESS: DELIVERY OF THE SHIPMENT TO THE WAREHOUSE | |||

|---|---|---|---|

| Operation: Verification of shipment data delivered to the warehouse | |||

| Person performing the operation (current form): Cargo agent | |||

| Information supporting the implementation of operations | The current form of obtaining supporting information | Information generated after the operation is completed | The current form of the output information generated |

| details of the person transporting the shipment/driver | sent e-mail from the sender—no standard form | confirmation of data compliance/determination of inconsistency | verbal message given to the operator along with the order to unload the shipment/telephone contact with the sender of the shipment |

| registration number of the long-distance transport vehicle | CMR (road transport document) or other consignment note | ||

| shipper | |||

| number of loading units in the shipment | |||

| Operation | Scope of Automation | Justification |

|---|---|---|

| Checking whether the vehicle’s seal has not been broken | Automatic ticket generation when a seal violation is detected | Ensuring registration of information on verification processes carried out in the system. Possibility to archive information about detected nonconformities and actions taken. |

| Checking for damage in each load unit | Identification of damaged load units in the process—e.g., an automatically printed sticker with a local shipment number confirming its damage | Ensuring registration of information on verification processes carried out in the system. Possibility to archive information about detected nonconformities and actions taken |

| Measurement of the maximum length, width, height, and weight of each accepted load unit and verification of shipment parameters. | Automatic ticket generation with detected damages (connection to the sender’s key) | Registration of order status. Possibility to archive information about detected inconsistencies. Tracking the history of changes. |

| Preparation of the admission protocol | Assigning data to the shipment_id in the system and automatic redirection to verification of parameters | The measurement results of the unit after entering the system are the basis for verifying the data contained in the notification. The data are used to indicate the location of the warehouse. |

| Checking whether the vehicle’s seal has not been broken | Automatic ticket generation in case of non-compliance | Registration of order status. Possibility to archive information about detected inconsistencies. Tracking the history of changes. |

| Checking for damage in each load unit | Automatic generation of the admission report | The cargo agent’s acceptance of the entered and verified data in the system results in the automatic generation of an acceptance protocol |

| Operation | Scope of Support | Description | Message Proposal |

|---|---|---|---|

| PROCESS: DELIVERY OF THE SHIPMENT TO THE WAREHOUSE | |||

| Verification of shipment data delivered to the warehouse | Displaying to the operator a message about an order to unload a shipment with the specified CMR or AWB, along with an indication of the place of unloading the goods | Message about an unloading order should appear in an additional panel (e.g., in the form of an upper bar with icons), along with the date and time of receipt, status, and place of unloading. After selecting the order, navigation to the unloading place should be started. | Graphic form to signal a new order (icon notifying about a new order). Navigation (e.g., showing the way with arrows) |

| PROCESS: RECEPTION OF LOADS INTO THE WAREHOUSE | |||

| Checking whether the vehicle’s seal has not been broken | Reporting the need to check the seal | Message about the next step in the service procedure | Text message: “Check the seal”. Graphic icon indicating task completion (e.g., thumbs up) |

| Checking for damage in each load unit | Registration of information about damaged cargo. Possibility to take a photo of the damage. | Message about the next step in the service procedure. Function of taking a photo of the damage using AR glasses and sending it to the system | Text message: “Damaged?” with the option to select “YES/NO”. A graphic form of the “take a photo of the damage” message after selecting the YES option |

| Measurement of the maximum length, width, height, and weight of each accepted load unit and verification of shipment parameters. | Reporting the need to perform a measurement | Message about the next step in the service procedure. Delivering cargo to measuring devices. | A graphic icon indicating the need for measurement. Navigate with arrows. A graphic icon indicating that the task has been completed |

| Preparation of the admission protocol | Preparation of the admission protocol | Message about the generated protocol with the option to confirm or report an error | Graphic icons: Green for acceptance and red for rejection (in case of rejection, you must indicate the protocol field that requires change) |

| PROCESS: STORAGE | |||

| Determining the location and transport of the load to the storage area | Indicating the storage area and leading to the indicated location | Message with the designation of the storage area. Delivery to the indicated location. | Text message: “Transport to” + storage box symbol. Navigate with arrows. |

| Special shipment verification | Verification of graphic markings on the shipment (e.g., checking whether the shipment contains all required markings) | Message about the required graphic markings on the shipment in accordance with its specifications. | Graphic icons: green—complete marking; red—incomplete |

| PROCESS: SAFETY CONTROL | |||

| Transport of the shipment to the X-ray machine | Identification of a free X-ray machine and delivery to its location | Message informing about the need to perform a security check. Delivery to the indicated location. | Graphic icon of an X-ray machine. Navigate with arrows. |

| Determining the location and transport of the load to the storage area | Indication of the storage area and delivery to the indicated location | Message with the designation of the storage area. Delivery to the indicated location. | Text message: “Transport to” + storage box symbol. Navigate with arrows. |

| PROCESS: PICKING | |||

| Printout of the picking list | Display of items from the picking list with status | The system should include a module of picking lists with their implementation status (e.g., to be implemented, in progress, or completed) and priority. For each list, there should be an “Execute” option, which will open the given list | The list is presented in text form. Graphical icon for “Execute” |

| Collection of empty ULDs and their transport | Indication of the need for ULD | Displaying the number of ULDs needed to be downloaded (continuously updated) | Text message: “Download X ULDs” |

| Transport of shipments to the picking zone | Indicating the storage area and leading to the indicated location | Message with the designation of the storage area. Delivery to the indicated location. | Text message: “Transport to” + storage box symbol. Navigate with arrows. |

| Placing the shipment on ULD | Indicating the location of the shipment on the ULD | The place of storage is indicated by the displayed solid outline. Updating the picking list after the shipment has been placed in the indicated place. | Graphic icon indicating task completion (e.g., thumbs up) |

| ULD protection | Indication of required security measures for ULD | Display a reminder to apply security measures. The system should include requirements regarding the security measures used for particular types of cargo. | List of requirements presented in text form. A graphic icon symbolizing a security check |

| Storage of completed ULDs | Indication of the storage area and delivery to the selected location | Message with the designation of the storage area. Delivery to the indicated location. | Text message: “Transport to” + storage box symbol. Navigate with arrows. |

| PROCESS: RELEASE FOR TRANSPORT | |||

| Transporting the ULD to the vehicle | Delivery to vehicle | Message of release for transport. Support for delivery to the vehicle parking location | Graphic icon indicating release for transport. Navigation by arrows. |

| Placement and securing of ULDs inside the vehicle | Support for correct ULD stowage and verification of correct cargo securing | Message about the ULD stowage location and verification of correct stowage, displaying a message about the need to secure the cargo | Indicating the location of stowage with the help of the outline of the lump. Text message: “Check ULD security”. Graphic icon indicating the completion of the task |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tubis, A.A.; Jodejko-Pietruczuk, A.; Nowakowski, T. Use of Augmented Reality as a Tool to Support Cargo Handling Operations at the CARGO Air Terminal. Sensors 2024, 24, 1099. https://doi.org/10.3390/s24041099

Tubis AA, Jodejko-Pietruczuk A, Nowakowski T. Use of Augmented Reality as a Tool to Support Cargo Handling Operations at the CARGO Air Terminal. Sensors. 2024; 24(4):1099. https://doi.org/10.3390/s24041099

Chicago/Turabian StyleTubis, Agnieszka A., Anna Jodejko-Pietruczuk, and Tomasz Nowakowski. 2024. "Use of Augmented Reality as a Tool to Support Cargo Handling Operations at the CARGO Air Terminal" Sensors 24, no. 4: 1099. https://doi.org/10.3390/s24041099

APA StyleTubis, A. A., Jodejko-Pietruczuk, A., & Nowakowski, T. (2024). Use of Augmented Reality as a Tool to Support Cargo Handling Operations at the CARGO Air Terminal. Sensors, 24(4), 1099. https://doi.org/10.3390/s24041099