Innovating Household Food Waste Management: A User-Centric Approach with AHP–TRIZ Integration

Abstract

1. Introduction

- Explore factors and identify user preferences regarding the household food waste recycling issue.

- Present a theoretical approach for designing the household food waste management system, which can be applied to other household smart management issues and has the potential to evolve conventional products into smart management systems.

- Develop a practical solution incorporating smart technology to manage household food waste recycling based on the proposed approach.

2. Related Work

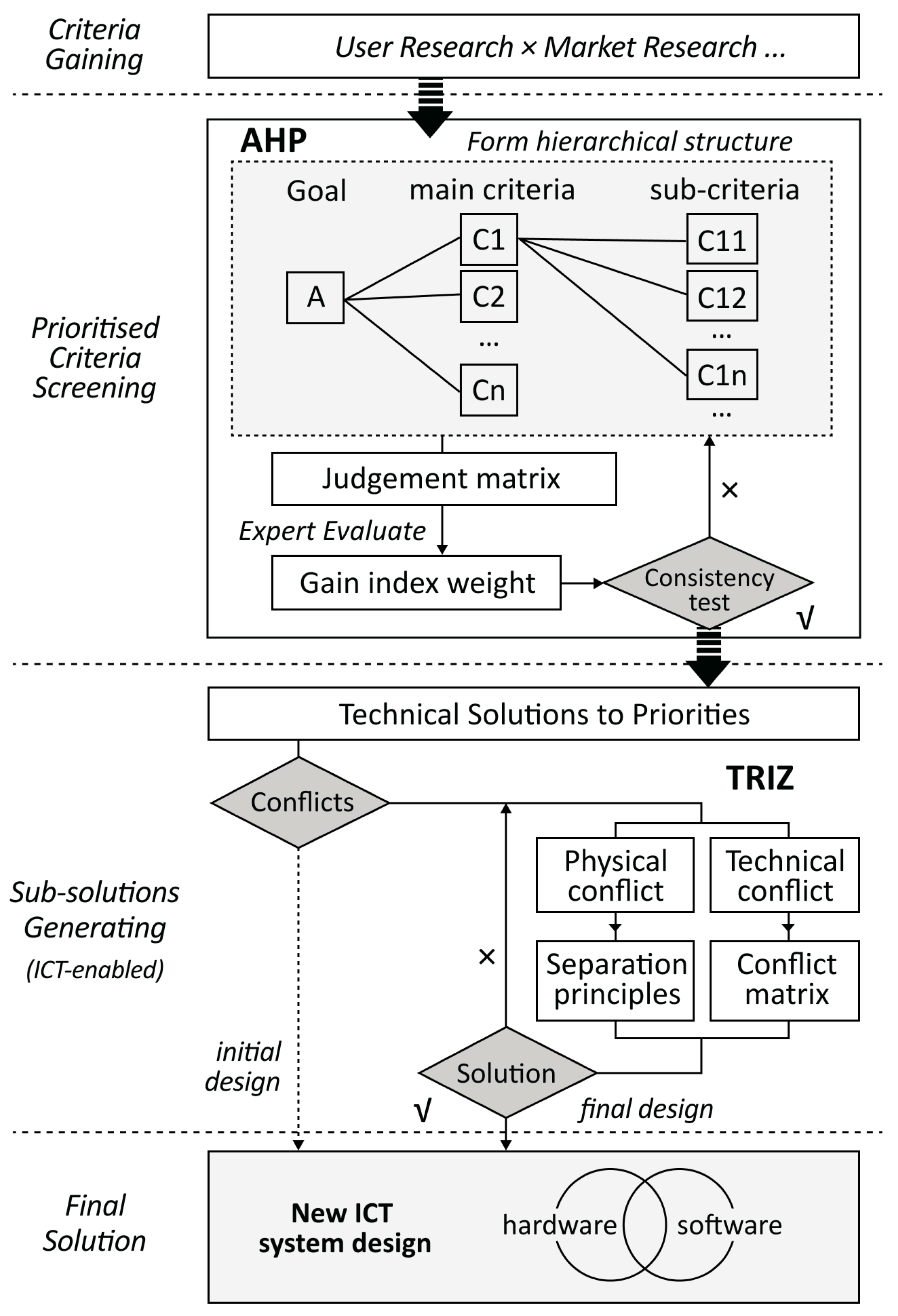

3. Research Methods

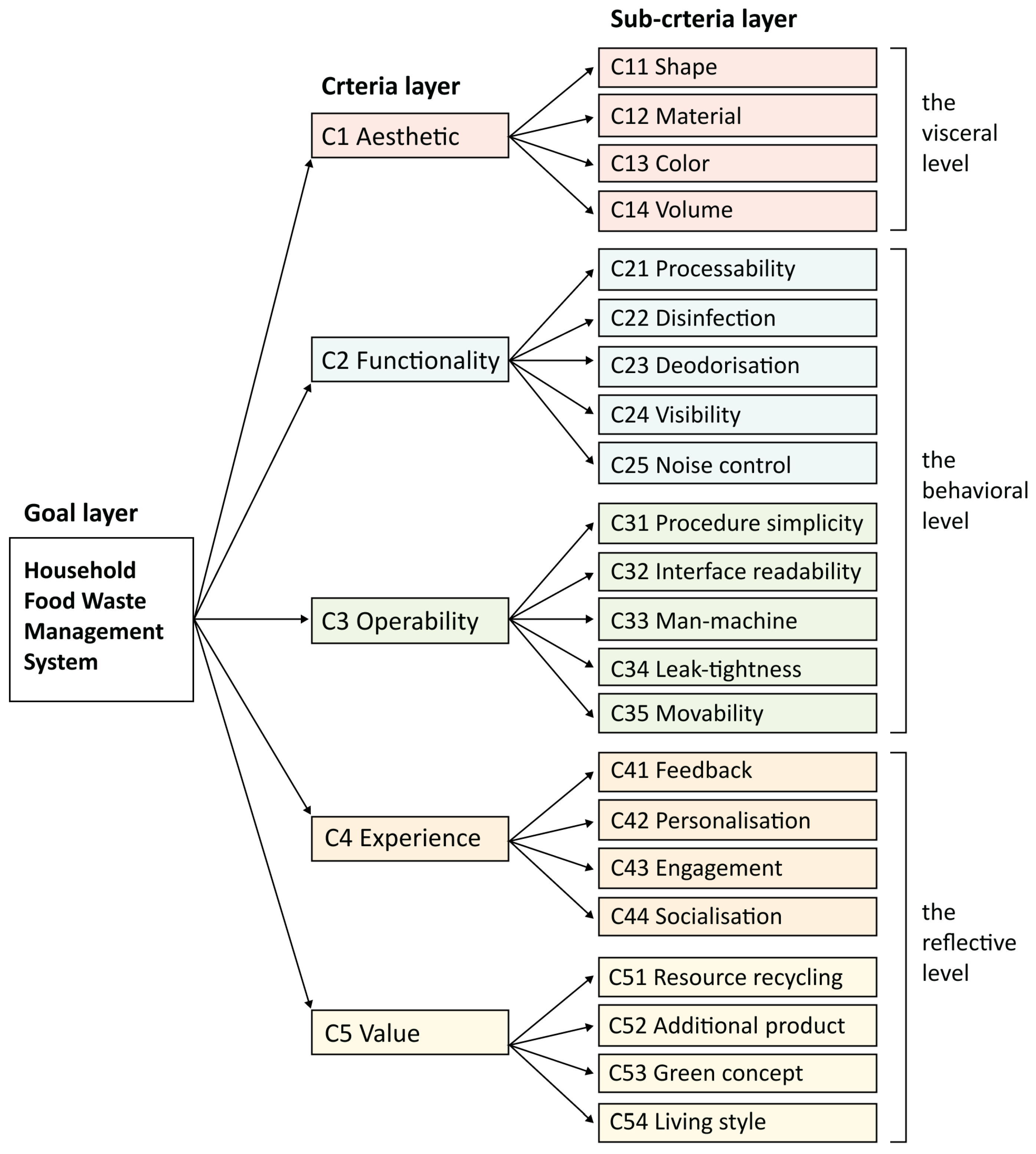

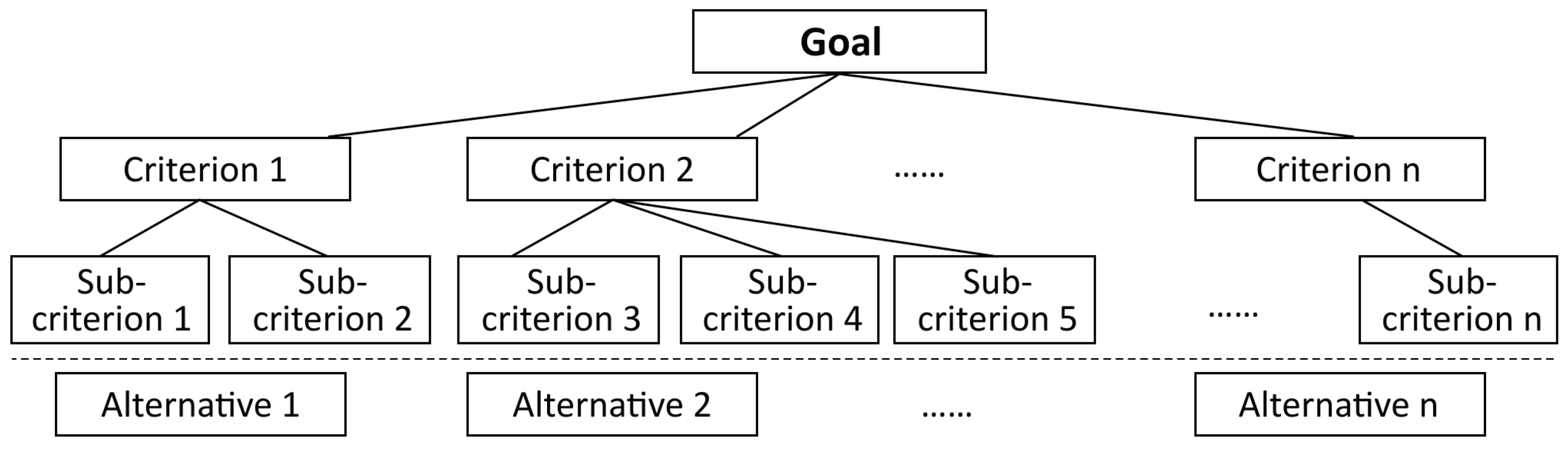

3.1. Use AHP to Evaluate the Weight of Each Criterion

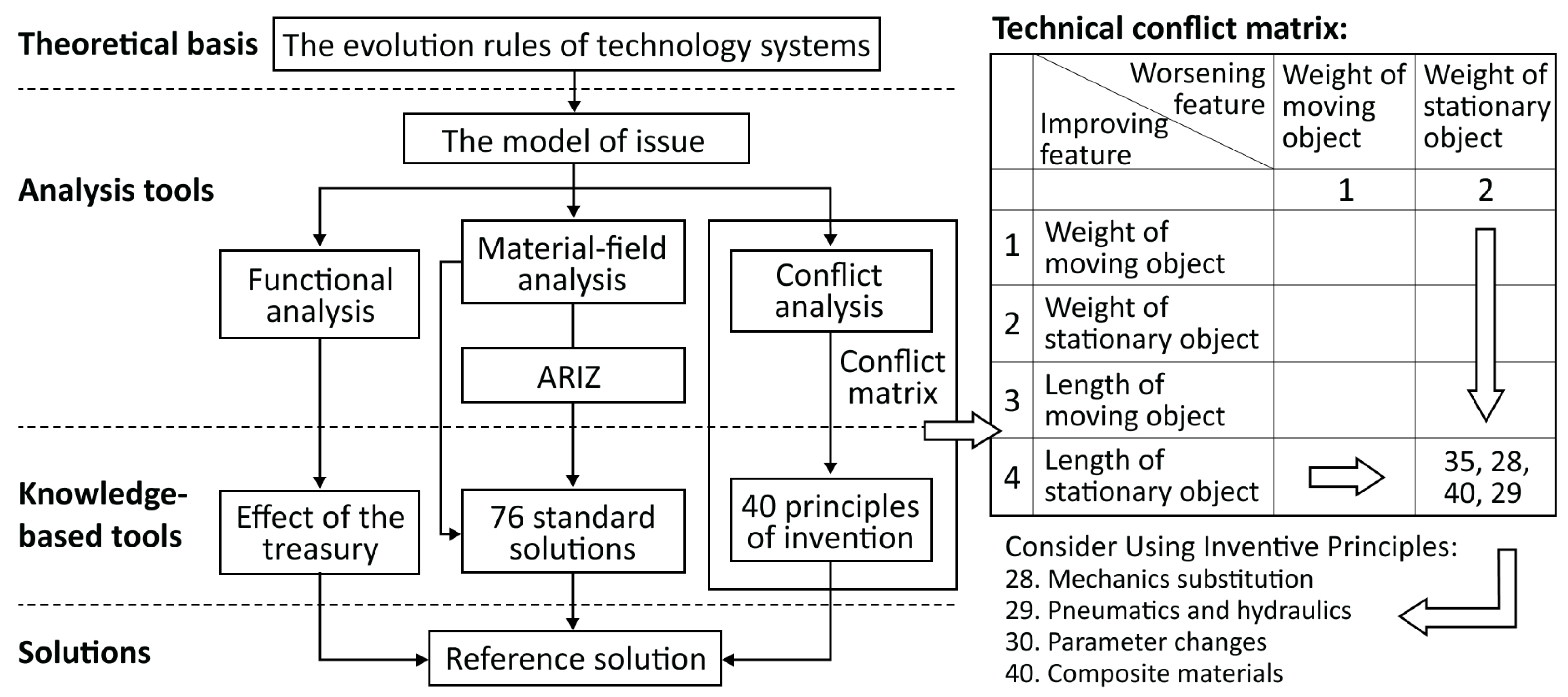

3.2. Use TRIZ to Solve Conflicts

3.2.1. Physical Conflict 1

3.2.2. Physical Conflict 2

3.2.3. Technical Conflict 1

3.2.4. Technical Conflict 2

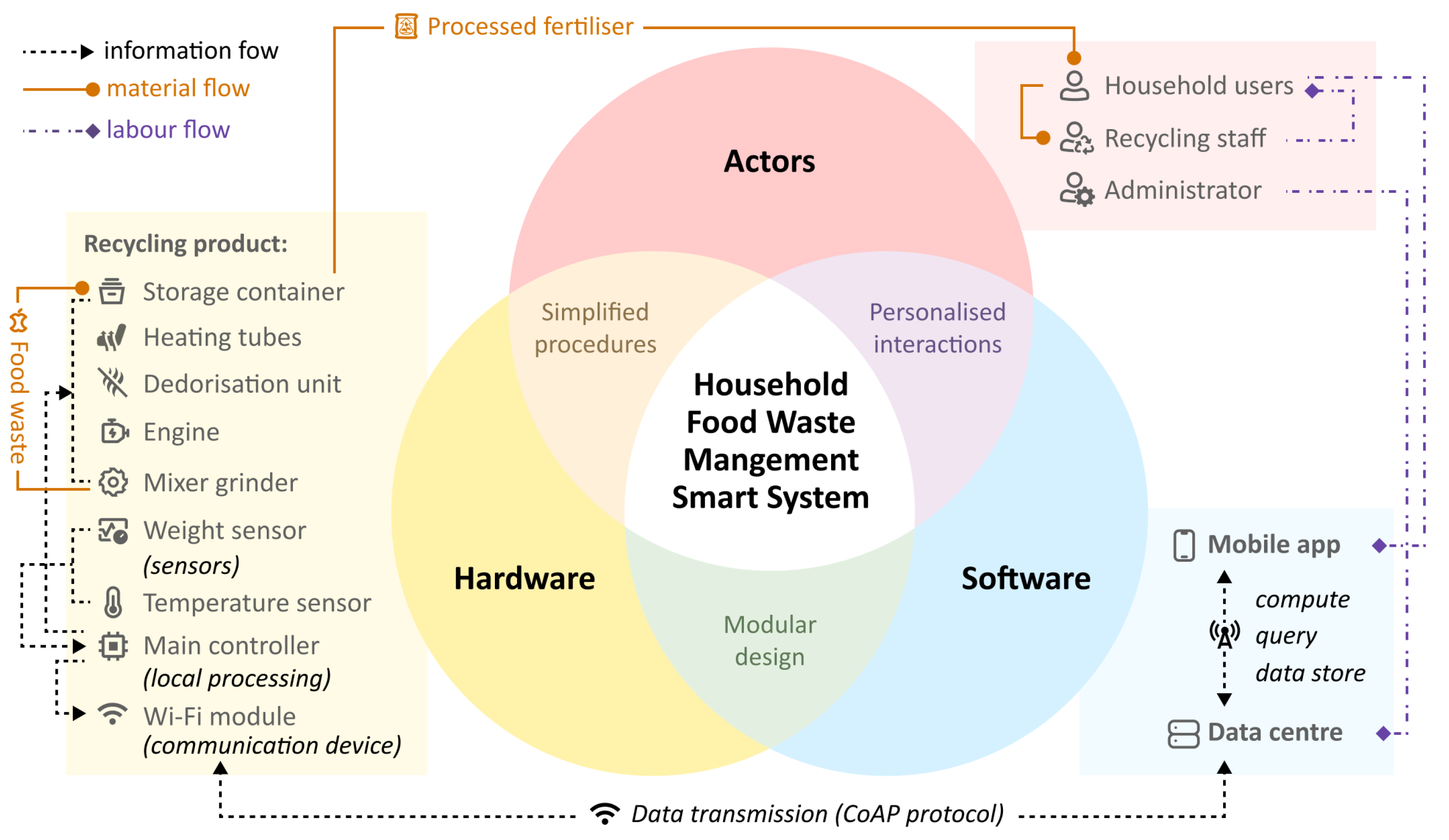

4. Design of the Household Food Waste Management Smart System

- (1)

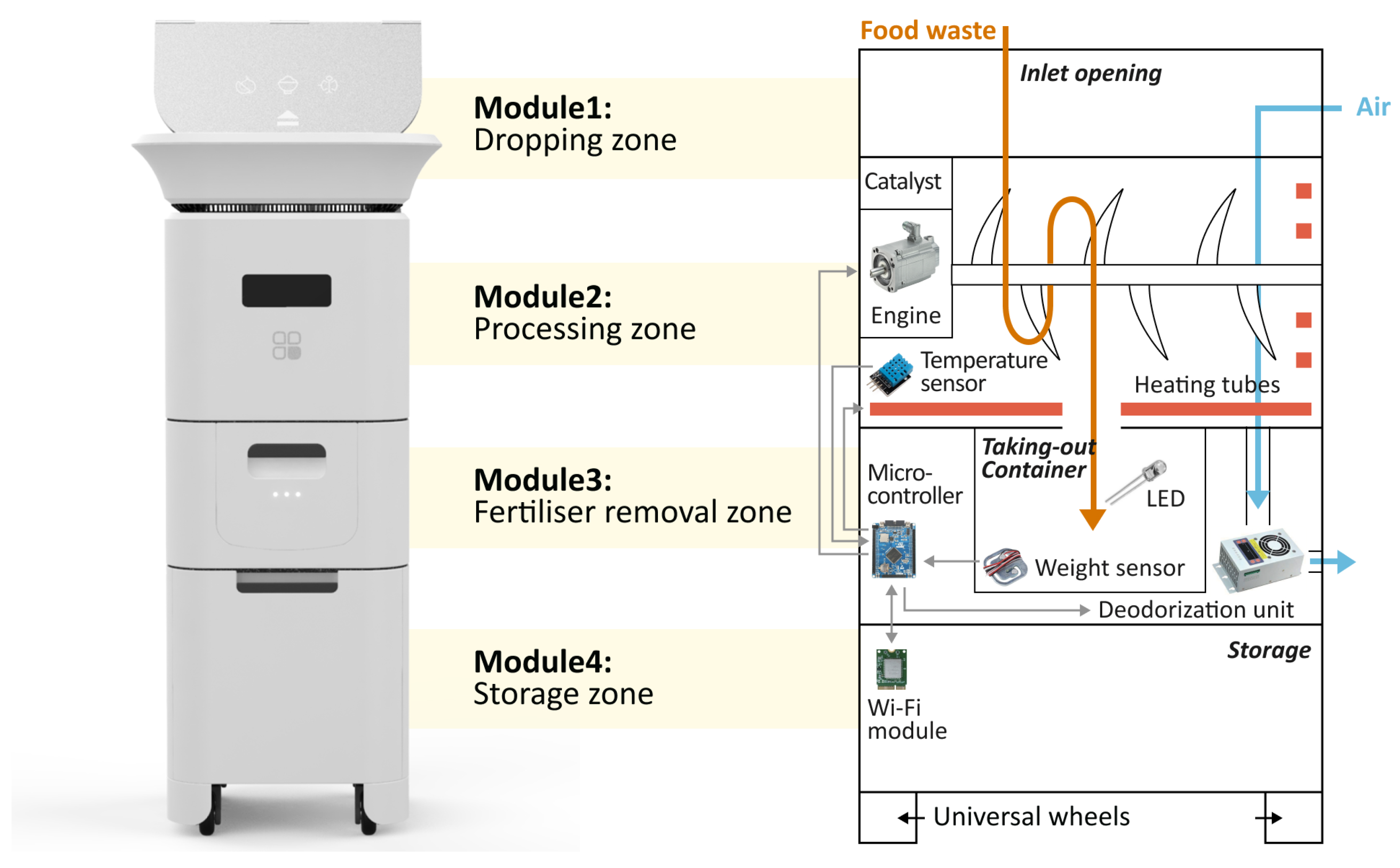

- Modular Design: As illustrated in Figure 8, the recycling product contains four modules arranged from top to bottom: the dropping zone, the processing zone, the fertiliser removal zone and the storage zone, enabling multiple key subfunctions. The dropping zone is designed for user input convenience with an expandable large opening and stainless steel material to prevent stains from liquid leakage. The processing zone contains stirring and grinding blades, a small container for microbial catalysts and an embedded temperature and humidity sensor. The main controller regulates heating pipes for the sterilisation of harmful bacteria and for maintaining the activity of decomposition microorganisms. The fertiliser removal zone stores processed products and has a weight sensor that sends capacity reminders via a Wi-Fi module. The bottom storage zone stores packaged value-added products, as well as tools such as gloves, compost packages and small shovels. It is also equipped with universal wheels for movability. The modular design of the recycling product helps to reduce the space it occupies. In Figure 9, when the storage zone is removed, the product can be placed on the countertop. By attaching universal wheels at the bottom, the product can be easily moved around the kitchen, balcony or other areas. This flexibility caters to the specific environment of Chinese households.

- (2)

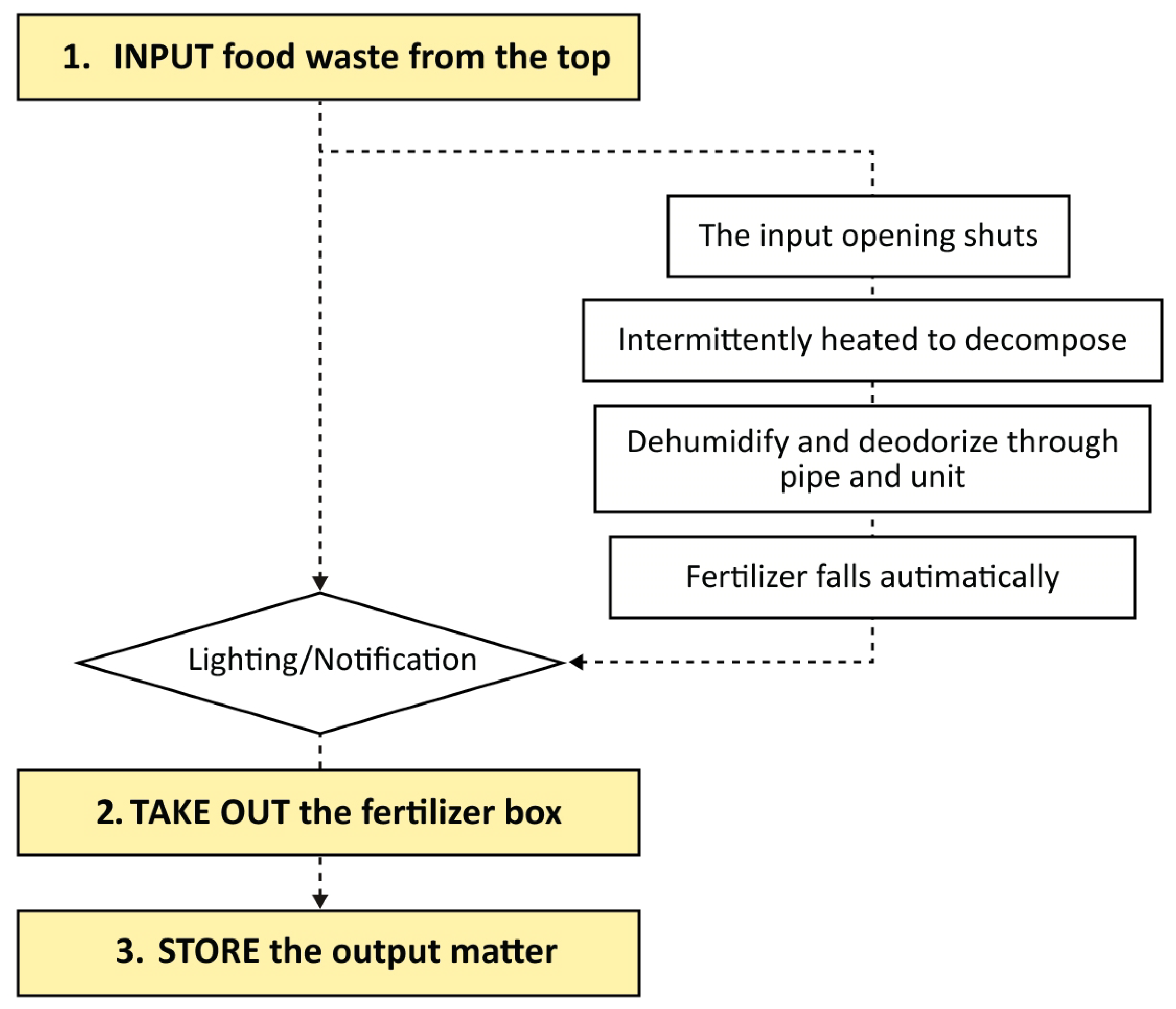

- Simplified User Workflow: Designed from a user-centric perspective, this system aims to facilitate long-term user engagement by minimising usage complexity and costs. Unlike traditional home composting processes in which users are required to regularly monitor, turn and control catalysts, this system incorporates sensors and automated mechanisms to simplify the intermediate steps. As depicted in Figure 10, the process can be summarised as input–take out–store. Users begin by inputting their food waste into the recycling product. The main controller operates the stirring and grinding device, while the temperature sensor and heat pipes regulate microbial activity and decomposition efficiency. Additionally, an air circulation system connected to an odour and moisture removal device automatically maintains hygiene and cleanliness across different modules of the machine. When the value-added product fills up the container, the heavy sensor provides feedback to the main controller, triggering a lighting indicator on the machine and sending a notification to the user’s mobile app. At this stage, users only need to take out the processed fertiliser and package it for storage without any check halfway through the process, awaiting scheduled collection by the recycling staff.

- (3)

- Personalised User Interaction: On the other hand, simplifying the operational steps does not mean standardising user interactions during the food waste recycling process. User engagement in the recycling process can be personalised and enriched through the functions provided by the mobile application as well as adaptive product processing.As illustrated in Figure 11, the data recognised and collected by the sensors in the hardware component can be broadly categorised into two types: basic data that can be presented to users and data analysed by the system to better understand user habits. Considering that household waste often contains sensitive personal information, data transmission is conducted using the CoAP security protocol specifically designed for IoT applications [22,40]. On the one hand, basic data, including processing count, reduction weight and recyclables weight, are made accessible to users through their mobile apps, and visually displayed. This allows users to conveniently track their disposal progress and history, imperceptibly fostering a sense of accomplishment and environmental consciousness. Additionally, users have the flexibility to choose between Quick Mode and Standard Mode, along with a do-not-disturb function, via the presetting feature, catering to their individual needs. On the other hand, data related to processing duration, time, frequency, corresponding processing modes and user input in the mobile app are recognised and processed using deep learning techniques [41,42]. This empowers the system to analyse and learn different users’ waste disposal habits, enabling it to adaptively adjust different households’ waste processing modes. As a result, users can benefit from automated and customised kitchen waste disposal modes tailored to their respective food consumption habits.

5. Discussion

5.1. A User-Centric Perspective to Promote Sustained Engagement

5.2. ICT-Enabled Solutions to Balance Conflicts within the System

5.3. Hardware–Software Integration to Shape the New Management System

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Criterion | Explanation |

|---|---|---|

| C1 | Aesthetic | The visual appeal of the products within the system. |

| C11 | Shape | Physical form (round or square; curvaceous or rectilinear). |

| C12 | Material | Choice of construction materials. |

| C13 | Colour | Use of colours in the system’s design. |

| C14 | Volume | Capacity or size of the product. |

| C2 | Functionality | The system’s ability to perform its intended tasks. |

| C21 | Processability | Efficient handling and processing of food waste. |

| C22 | Disinfection | Ensuring hygienic treatment of waste. |

| C23 | Deodorisation | Elimination of unpleasant odours. |

| C24 | Visibility | Clear visibility of the waste management process. |

| C25 | Noise control | Minimisation of noise generated during operation. |

| C3 | Operability | The ease of use and operation of the system. |

| C31 | Procedure simplicity | The simplicity of system operation procedures. |

| C32 | Interface readability | Clear and user-friendly interface design. |

| C33 | Man–machine | The scale of the product lines with human operations. |

| C34 | Leak-tightness | Prevention of any leakage or spillage. |

| C35 | Movability | Easy movement or portability of the product. |

| C4 | Experience | User’s overall experience when operating the system. |

| C41 | Feedback | Providing feedback to users (reminder, notification, etc.) |

| C42 | Personalisation | Customisation options for individual preferences. |

| C43 | Engagement | Encouraging user involvement and participation. |

| C44 | Socialisation | Promoting social interactions and community engagement. |

| C5 | Value | The system’s social impact and conceptual value. |

| C51 | Resource recycling | Substantial reduction in food waste. |

| C52 | Additional product | Creation of additional valuable products from food waste. |

| C53 | Green concept | Raising users’ environmentally friendly awareness. |

| C54 | Living Style | Changing the way users live. |

Appendix B

| matrix | C11 | C12 | C13 | C14 | |

|---|---|---|---|---|---|

| C11 | 1.00 | 1.11 | 1.94 | 0.71 | |

| C12 | 0.90 | 1.00 | 2.42 | 0.67 | |

| C13 | 0.52 | 0.41 | 1.00 | 0.38 | |

| C14 | 1.42 | 1.49 | 2.62 | 1.00 | |

| matrix | C21 | C22 | C23 | C24 | C25 |

| C21 | 1.00 | 1.05 | 0.84 | 2.21 | 1.63 |

| C22 | 0.95 | 1.00 | 1.38 | 3.31 | 1.41 |

| C23 | 1.19 | 0.73 | 1.00 | 3.34 | 1.35 |

| C24 | 0.45 | 0.30 | 0.30 | 1.00 | 0.41 |

| C25 | 0.61 | 0.71 | 0.74 | 2.44 | 1.00 |

| matrix | C31 | C32 | C33 | C34 | C35 |

| C31 | 1.00 | 1.50 | 1.99 | 1.29 | 3.81 |

| C32 | 0.67 | 1.00 | 1.62 | 0.75 | 2.46 |

| C33 | 0.50 | 0.62 | 1.00 | 0.67 | 2.17 |

| C34 | 0.78 | 1.33 | 1.48 | 1.00 | 3.02 |

| C35 | 0.26 | 0.41 | 0.46 | 0.33 | 1.00 |

| matrix | C41 | C42 | C43 | C44 | |

| C41 | 1.00 | 2.18 | 1.81 | 3.10 | |

| C42 | 0.46 | 1.00 | 1.94 | 3.40 | |

| C43 | 0.55 | 0.52 | 1.00 | 2.20 | |

| C44 | 0.32 | 0.29 | 0.45 | 1.00 | |

| C51 | 1.00 | 2.61 | 2.74 | 0.92 | |

| C52 | 0.38 | 1.00 | 0.75 | 0.60 | |

| C53 | 0.40 | 1.34 | 1.00 | 0.88 | |

| C54 | 1.08 | 1.66 | 1.14 | 1.00 |

References

- Ogunmoroti, A.; Liu, M.; Li, M.; Liu, W. Unraveling the environmental impact of current and future food waste and its management in Chinese provinces. Resour. Environ. Sustain. 2022, 9, 100064. [Google Scholar] [CrossRef]

- Lo, I.M.; Woon, K.S. Food waste collection and recycling for value-added products: Potential applications and challenges in Hong Kong. Environ. Sci. Pollut. Res. 2016, 23, 7081–7091. [Google Scholar] [CrossRef]

- Meng, M.; Wen, Z.; Luo, W.; Wang, S. Approaches and policies to promote Zero-waste City construction: China’s practices and lessons. Sustainability 2021, 13, 13537. [Google Scholar] [CrossRef]

- Xiao, L.; Zhang, G.; Zhu, Y.; Lin, T. Promoting public participation in household waste management: A survey based method and case study in Xiamen city, China. J. Clean. Prod. 2017, 144, 313–322. [Google Scholar] [CrossRef]

- Guo, Y.; Wei, R.; Zhang, X.; Chai, F.; Zhao, Y.; Zhou, T. Positive Impacts of the Overall-Process Management Measures on Promoting Municipal Solid Waste Classification: A Case Study of Chongqing, China. Sustainability 2022, 14, 14250. [Google Scholar] [CrossRef]

- Jiang, J.; Geng, S.; Luo, W.; Jiang, Y.; Gao, Y.; Chen, Z.; Yang, G.; Lan, T.; Meng, Y.; Ju, T.; et al. Review of hotspots of kitchen waste treatment in context of garbage classification in China in 2020. Sci. Technol. Rev. 2021, 39, 261–276. [Google Scholar]

- Chen, F.; Chen, H.; Wu, M.; Li, S.; Long, R. Research on the driving mechanism of waste separation behavior: Based on qualitative analysis of Chinese urban residents. Int. J. Environ. Res. Public Health 2019, 16, 1859. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y. Design and Application of Intelligent Waste Sorting and Recycling System. Packag. Eng. 2018, 39, 154–159. [Google Scholar]

- Dos Santos, P.H.; Neves, S.M.; Sant’Anna, D.O.; De Oliveira, C.H.; Carvalho, H.D. The analytic hierarchy process supporting decision making for sustainable development: An overview of applications. J. Clean. Prod. 2019, 212, 119–138. [Google Scholar] [CrossRef]

- Chou, J.R. A TRIZ-based product-service design approach for developing innovative products. Comput. Ind. Eng. 2021, 161, 107608. [Google Scholar] [CrossRef]

- Ijemaru, G.K.; Ang, L.M.; Seng, K.P. Swarm Intelligence Internet of Vehicles Approaches for Opportunistic Data Collection and Traffic Engineering in Smart City Waste Management. Sensors 2023, 23, 2860. [Google Scholar] [CrossRef]

- Jin, C.; Sun, S.; Yang, D.; Sheng, W.; Ma, Y.; He, W.; Li, G. Anaerobic digestion: An alternative resource treatment option for food waste in China. Sci. Total Environ. 2021, 779, 146397. [Google Scholar] [CrossRef]

- Li, Y.; Jin, Y.; Li, J.; Chen, Y.; Gong, Y.; Li, Y.; Zhang, J. Current situation and development of kitchen waste treatment in China. Procedia Environ. Sci. 2016, 31, 40–49. [Google Scholar] [CrossRef]

- Liu, D.; Ma, X.; Huang, J.; Shu, Z.; Chu, X.; Li, Y.; Jin, Y. Investigation of the aerobic biochemical treatment of food waste: A case study in Zhejiang and Jiangsu provinces in China. Sci. Total Environ. 2022, 806, 150414. [Google Scholar] [CrossRef]

- Hu, Y.B.; Wang, S.F.; Xiao, W.C. Design of mechanical compressive treatment device for wet waste. Chin. J. Eng. Des. 2021, 28, 374–380. [Google Scholar]

- Zhang, H.; Duan, H.; Andric, J.M.; Song, M.; Yang, B. Characterization of household food waste and strategies for its reduction: A Shenzhen City case study. Waste Manag. 2018, 78, 426–433. [Google Scholar] [CrossRef]

- Bernstad, A.; Davidsson, Å.; Tsai, J.; Persson, E.; Bissmont, M.; la Cour Jansen, J. Tank-connected food waste disposer systems–Current status and potential improvements. Waste Manag. 2013, 33, 193–203. [Google Scholar] [CrossRef]

- Maalouf, A.; El-Fadel, M. Effect of a food waste disposer policy on solid waste and wastewater management with economic implications of environmental externalities. Waste Manag. 2017, 69, 455–462. [Google Scholar] [CrossRef]

- Cecchi, F.; Cavinato, C. Smart approaches to food waste final disposal. Int. J. Environ. Res. Public Health 2019, 16, 2860. [Google Scholar] [CrossRef]

- Du, Y.; Wang, H.; Jin, Q.; Liu, W. Application status and analysis of kitchen waste treatment technology. Energy Environ. 2019, 1, 87. [Google Scholar]

- Zhou, X.; Yang, J.; Xu, S.; Wang, J.; Zhou, Q.; Li, Y.; Tong, X. Rapid in-situ composting of household food waste. Process Saf. Environ. Prot. 2020, 141, 259–266. [Google Scholar] [CrossRef]

- Marques, P.; Manfroi, D.; Deitos, E.; Cegoni, J.; Castilhos, R.; Rochol, J.; Pignaton, E.; Kunst, R. An IoT-based smart cities infrastructure architecture applied to a waste management scenario. Ad. Hoc. Netw. 2019, 87, 200–208. [Google Scholar] [CrossRef]

- Liegeard, J.; Manning, L. Use of intelligent applications to reduce household food waste. Crit. Rev. Food Sci. Nutr. 2020, 60, 1048–1061. [Google Scholar] [CrossRef]

- Cappelletti, F.; Papetti, A.; Rossi, M.; Germani, M. Smart strategies for household food waste management. Procedia Comput. Sci. 2022, 200, 887–895. [Google Scholar] [CrossRef]

- Spyridakis, I.; Holbrook, M.; Gruenke, B.; Latha, S.S. Smart resource management: Civic engagement and food recovery. In Proceedings of the 2019 IEEE International Smart Cities Conference (ISC2), Casablanca, Morocco, 14–17 October 2019; pp. 378–383. [Google Scholar]

- Balwada, J.; Samaiya, S.; Mishra, R.P. Packaging plastic waste management for a circular economy and identifying a better waste collection system using analytical hierarchy process (AHP). Procedia CIRP 2021, 98, 270–275. [Google Scholar] [CrossRef]

- Ho, W.; Ma, X. The state-of-the-art integrations and applications of the analytic hierarchy process. Eur. J. Oper. Res. 2018, 267, 399–414. [Google Scholar] [CrossRef]

- Ilevbare, I.M.; Probert, D.; Phaal, R. A review of TRIZ, and its benefits and challenges in practice. Technovation 2013, 33, 30–37. [Google Scholar] [CrossRef]

- Tang, R.; Huang, C.; Zhao, X.; Tang, Y. Research on Smart Tourism Oriented Sensor Network Construction and Information Service Mode. Sensors 2022, 22, 10008. [Google Scholar] [CrossRef]

- Basak, S.; Dey, B.; Bhattacharyya, B. Demand side management for solving environment constrained economic dispatch of a microgrid system using hybrid MGWOSCACSA algorithm. CAAI Trans. Intell. Technol. 2022, 7, 256–267. [Google Scholar] [CrossRef]

- Huang, D.; Li, M.; Fu, J.; Ding, X.; Luo, W.; Zhu, X. P2P Cloud Manufacturing Based on a Customized Business Model: An Exploratory Study. Sensors 2023, 23, 3129. [Google Scholar] [CrossRef]

- Plain, C. Build an affinity for KJ method. Qual. Prog. 2007, 40, 88. [Google Scholar]

- Norman, D. The Design of Everyday Things: Revised and Expanded Edition; Basic Books: New York, NY, USA, 2013. [Google Scholar]

- Jordan, P.W. Human factors for pleasure in product use. Appl. Ergon. 1998, 29, 25–33. [Google Scholar] [CrossRef]

- Bhandari, U.; Chang, K.; Neben, T. Understanding the impact of perceived visual aesthetics on user evaluations: An emotional perspective. Inf. Manag. 2019, 56, 85–93. [Google Scholar] [CrossRef]

- Yan, M.; Lou, X.; Chan, C.A.; Wang, Y.; Jiang, W. A semantic and emotion-based dual latent variable generation model for a dialogue system. CAAI Trans. Intell. Technol. 2023, 8, 319–330. [Google Scholar] [CrossRef]

- Zhao, Y.; Cai, J.; Zhang, P.; Qin, W.; Lou, Y.; Liu, Z.; Hu, B. Core fungal species strengthen microbial cooperation in a food-waste composting process. Environ. Sci. Ecotechnol. 2022, 12, 100190. [Google Scholar] [CrossRef]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manag. 2017, 190, 140–157. [Google Scholar] [CrossRef]

- Yan, M.; Xiong, R.; Wang, Y.; Li, C. Edge Computing Task Offloading Optimization for a UAV-assisted Internet of Vehicles via Deep Reinforcement Learning. IEEE Trans. Veh. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- Naik, N. Choice of effective messaging protocols for IoT systems: MQTT, CoAP, AMQP and HTTP. In Proceedings of the 2017 IEEE International Systems Engineering Symposium (ISSE), Vienna, Austria, 11–13 October 2017; pp. 1–7. [Google Scholar]

- Wang, C.; Qin, J.; Qu, C.; Ran, X.; Liu, C.; Chen, B. A smart municipal waste management system based on deep-learning and Internet of Things. Waste Manag. 2021, 135, 20–29. [Google Scholar] [CrossRef]

- Abdullayeva, F.J. Internet of Things-based healthcare system on patient demographic data in Health 4.0. CAAI Trans. Intell. Technol. 2022, 7, 644–657. [Google Scholar] [CrossRef]

- Wang, S.; Xu, J. Design of Intelligent Household Food Waste Product Based on AHP-TRIZ Method. In Proceedings of the 2022 International Conference on Culture-Oriented Science and Technology (CoST), Lanzhou, China, 18–21 August 2022; pp. 95–98. [Google Scholar]

| Work | Scenarios | Treatment | ICT | Goal |

|---|---|---|---|---|

| Bernstad et al. [17] | Household: under the sink | Mechanical: grind and discharge into sewers | - | • reduce waste • create methane |

| Cecchi and Cavinato [19] | Public: under the sink to waste stations | Mechanical and biological: grind and then dispose in treatment plant | - | • avoid transportation • energy recovery |

| Zhou et al. [21] | Household: kitchen composting bins | Biological: high- temperature composting | - | • food waste reduction • make value-added products |

| Marques et al. [22] | Public: outdoor and indoor bins | ICT-related: sensing and recognition | RFID sensors, cloud platform, etc. | • correct separation • a simultaneous bin network |

| Liegeard and Manning [23] | Household: kitchen smart fridges | ICT-related: packaging for food track | Biosensors, RFID, a control unit, etc. | • manage stock control • reduce food waste |

| Cappelletti et al. [24] | Household: kitchen smart fridges | ICT-related: food stock track | A smart fridge an application | • food waste reduction • healthy diet |

| Spyridakis et al. [25] | Public: campus dining halls | ICT-related: pick-up and delivery | An open-source website | • sharing concept • reduce food waste |

| C1 | C2 | C3 | C4 | C5 | |

|---|---|---|---|---|---|

| C1 | 1.00 | 0.44 | 0.42 | 0.68 | 1.06 |

| C2 | 2.29 | 1.00 | 1.89 | 3.28 | 2.74 |

| C3 | 2.38 | 0.53 | 1.00 | 2.69 | 1.34 |

| C4 | 1.48 | 0.30 | 0.37 | 1.00 | 1.71 |

| C5 | 0.95 | 0.36 | 0.75 | 0.58 | 1.00 |

| A | C1 | C2 | C3 | C4 | C5 | |

|---|---|---|---|---|---|---|

| CI | 0.040 | 0.004 | 0.012 | 0.036 | 0.034 | 0.023 |

| RI | 1.12 | 0.89 | 1.12 | 1.12 | 0.89 | 0.89 |

| CR | 0.036 | 0.005 | 0.011 | 0.032 | 0.038 | 0.026 |

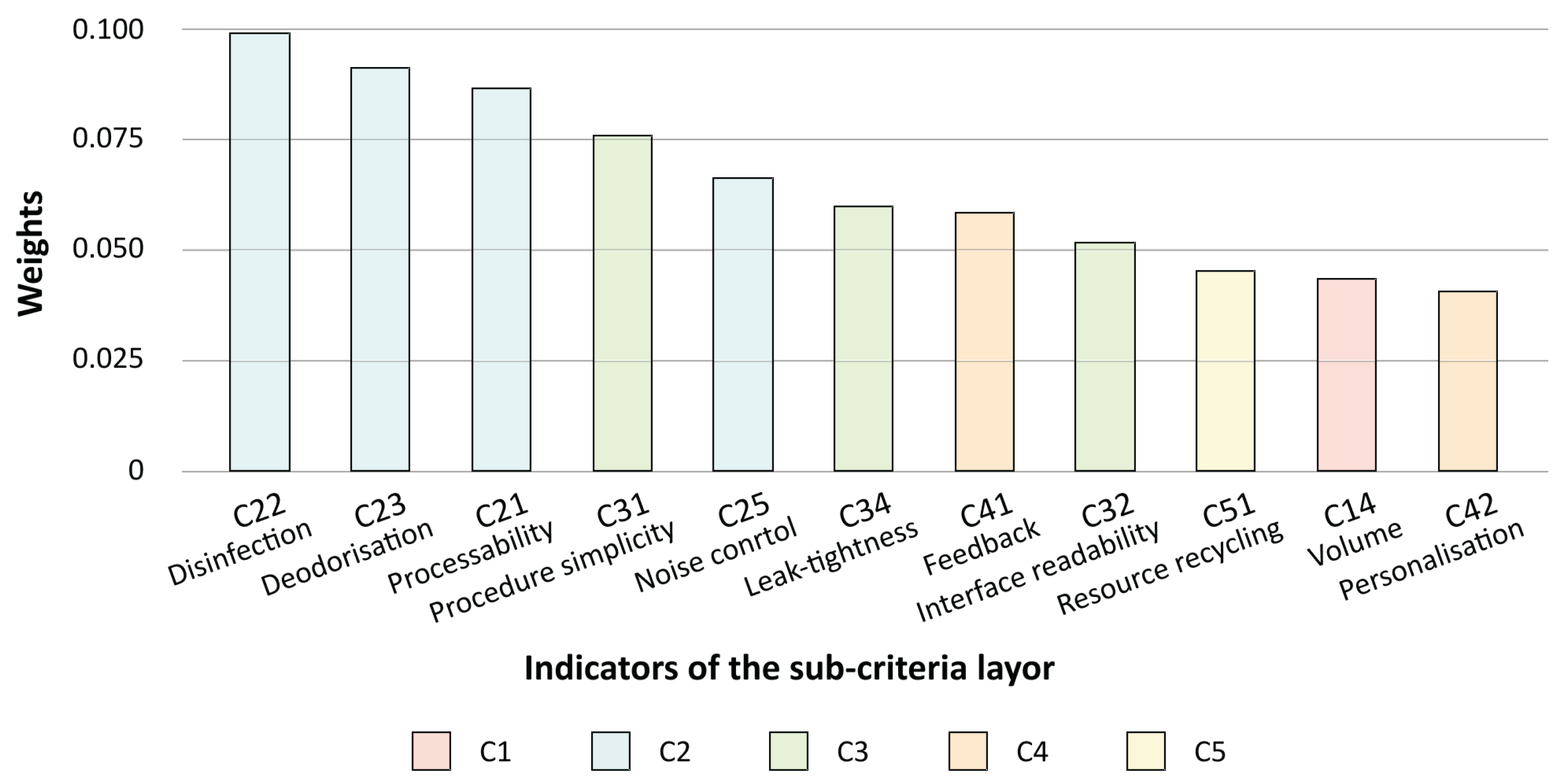

| Criteria | Sub-Criteria | Weight | Ranking |

|---|---|---|---|

| C1: Aesthetic 0.120 | C11: Shape | 0.031 | 14 |

| C12: Material | 0.031 | 15 | |

| C13: Colour | 0.015 | 21 | |

| C14: Volume | 0.043 | 10 | |

| C2: Functionality 0.374 | C21: Processability | 0.087 | 3 |

| C22: Disinfection | 0.099 | 1 | |

| C23: Deodorisation | 0.091 | 2 | |

| C24: Visibility | 0.031 | 16 | |

| C25: Noise control | 0.066 | 5 | |

| C3: Operability 0.243 | C31: Procedure simplicity | 0.076 | 4 |

| C32: Interface readability | 0.051 | 8 | |

| C33: Man–machine | 0.038 | 12 | |

| C34: Leak-tightness | 0.060 | 6 | |

| C35: Movability | 0.019 | 19 | |

| C4: Experience 0.140 | C41: Feedback | 0.058 | 7 |

| C42: Personalisation | 0.041 | 11 | |

| C43: Engagement | 0.028 | 17 | |

| C44: Socialisation | 0.014 | 22 | |

| C5: Value 0.123 | C51: Resource recycling | 0.045 | 9 |

| C52: Additional product | 0.019 | 20 | |

| C53: Green concept | 0.024 | 18 | |

| C54: Living style | 0.035 | 13 |

| No. | Type | Paradoxical Attributes | General Engineering Parameters | TRIZ Principles |

|---|---|---|---|---|

| 1 | Physical conflict | Disinfection–no germ | 31 Harmful side effects | Separation upon condition |

| Processability–contain germ | ||||

| 2 | Physical conflict | Deodorisation–let in air | 32 Manufacturability | Separation in space |

| Leak-tightness–air-proof | ||||

| 3 | Technical conflict | Requirement of multi-function | 36 Complexity of device | no. 1 Segmentation |

| Volume | 8 Volume of non-moving object | |||

| 4 | Technical conflict | Procedure simplicity | 33 Convenience of use | no. 10 Preliminary |

| Personalisation | 24 Loss of information |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Park, H.; Xu, J. Innovating Household Food Waste Management: A User-Centric Approach with AHP–TRIZ Integration. Sensors 2024, 24, 820. https://doi.org/10.3390/s24030820

Wang S, Park H, Xu J. Innovating Household Food Waste Management: A User-Centric Approach with AHP–TRIZ Integration. Sensors. 2024; 24(3):820. https://doi.org/10.3390/s24030820

Chicago/Turabian StyleWang, Shuyun, Hyunyim Park, and Jifeng Xu. 2024. "Innovating Household Food Waste Management: A User-Centric Approach with AHP–TRIZ Integration" Sensors 24, no. 3: 820. https://doi.org/10.3390/s24030820

APA StyleWang, S., Park, H., & Xu, J. (2024). Innovating Household Food Waste Management: A User-Centric Approach with AHP–TRIZ Integration. Sensors, 24(3), 820. https://doi.org/10.3390/s24030820