1. Introduction

The urban gas pipeline network in China is complex. During actual inspections, not only do pipeline defects and damages affect the operation of MFL detectors but the pipeline’s roughness and diameter variations also influence the detector’s movement and detection efficacy. The driving force and speed of the MFL detector within the pipeline critically affect the accuracy of detection results. If the detector moves too quickly, signal recording and data processing cannot keep pace, resulting in data loss and failure to meet the inspection’s objectives. Conversely, if the detector moves too slowly, inspection time is prolonged, severely impacting efficiency and potentially causing the detector to become lodged in the pipeline, leading to substantial transportation disruptions. The detector’s speed is related to the forces acting upon it, primarily driven by the differential gas pressure at its front and rear ends. During operation, the detector also experiences frictional resistance from contact with the pipeline wall.

Therefore, analyzing the forces acting on the detector, combined with experimental tests to derive its motion patterns and controlling its speed within an optimal range, is essential for ensuring successful inspection operations. Additionally, the movement of the detector within the pipeline can affect the distribution of natural gas. The urban gas network, characterized by numerous facilities, extensive pipelines, and uneven gas consumption among users, further complicates this issue. Studying the impact of the detector’s operation on natural gas supplies is crucial for ensuring normal gas usage by consumers during inspections and for the smooth execution of the inspection process.

Previous research primarily relied on simplified dynamic models of the MFL detector within gas pipelines without considering how variations in the driving components affect frictional resistance in the motion equations. Current numerical methods have mapped the differential gas pressure distribution along the pipeline during stable operation of the detector but have not thoroughly explored the impact of structural design on driving pressure differences. Moreover, these theories lack experimental validation, leading to uncertainties. Additionally, the relationship between the detector’s structural design and the pressure required for movement, as well as the impact of the movement speed on the required pressure differential, has not been addressed.

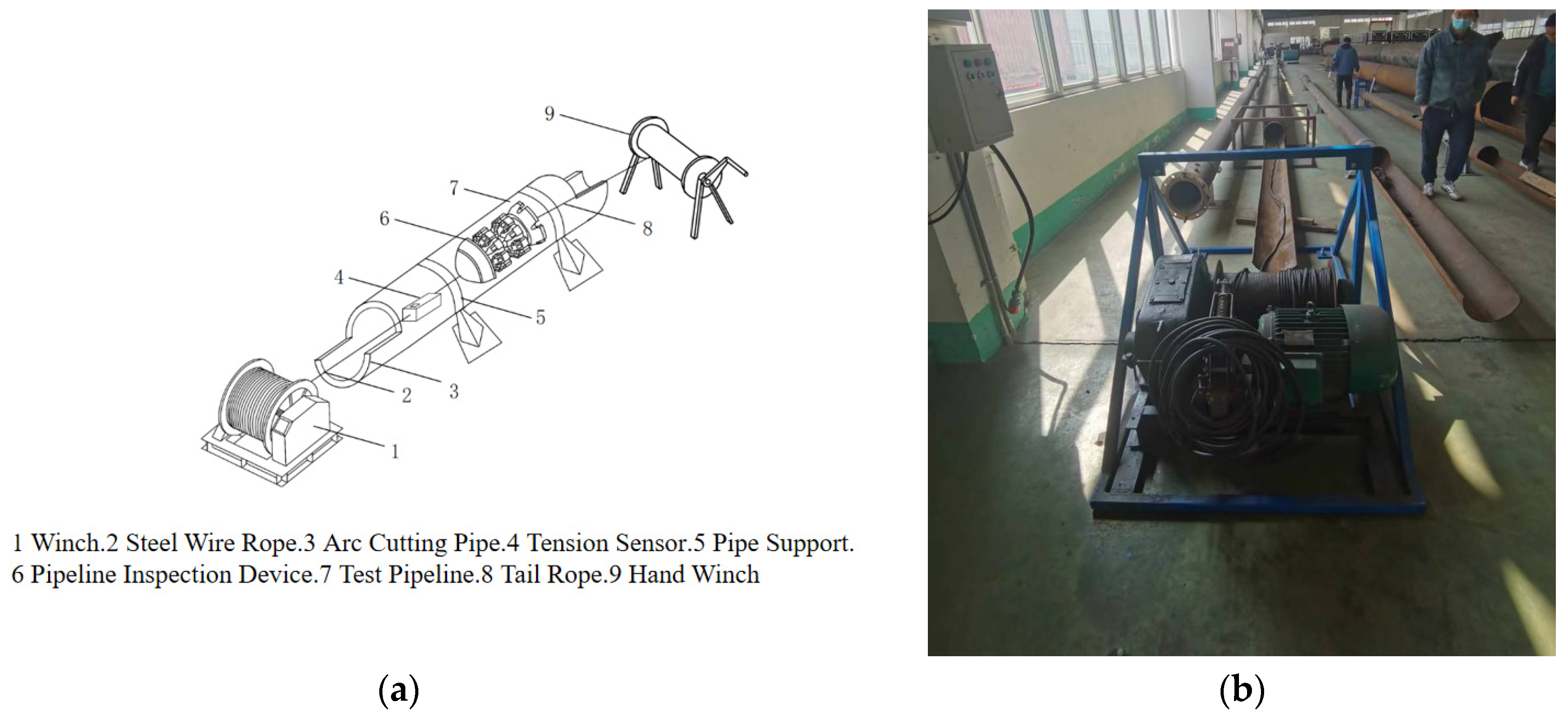

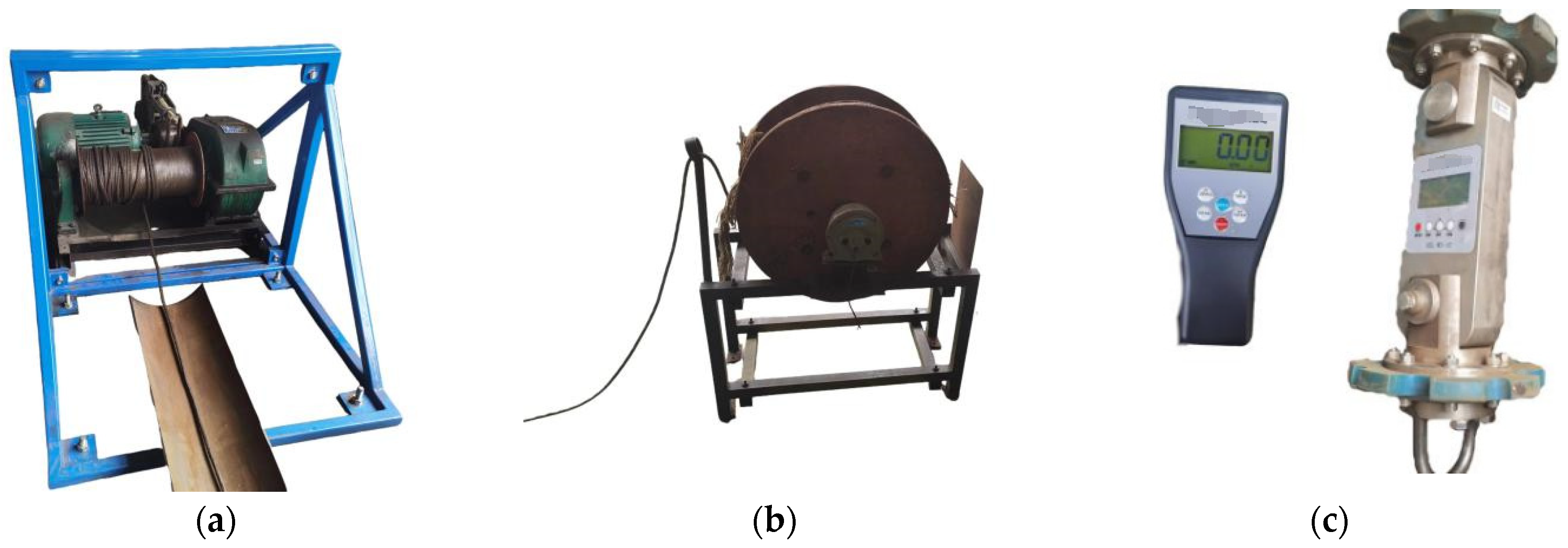

This study aims to comprehensively explore the sources and influencing factors of resistance encountered by magnetic flux leakage (MFL) detectors in natural gas pipelines through theoretical analysis, experimental research, and numerical simulation. The study includes analyzing the frictional resistance between the detector and the pipeline wall, examining the resistance variation at the cup and plate ends under different interference and thickness conditions, and experimentally validating the accuracy of mathematical models and simulation results.

3. Numerical Simulation

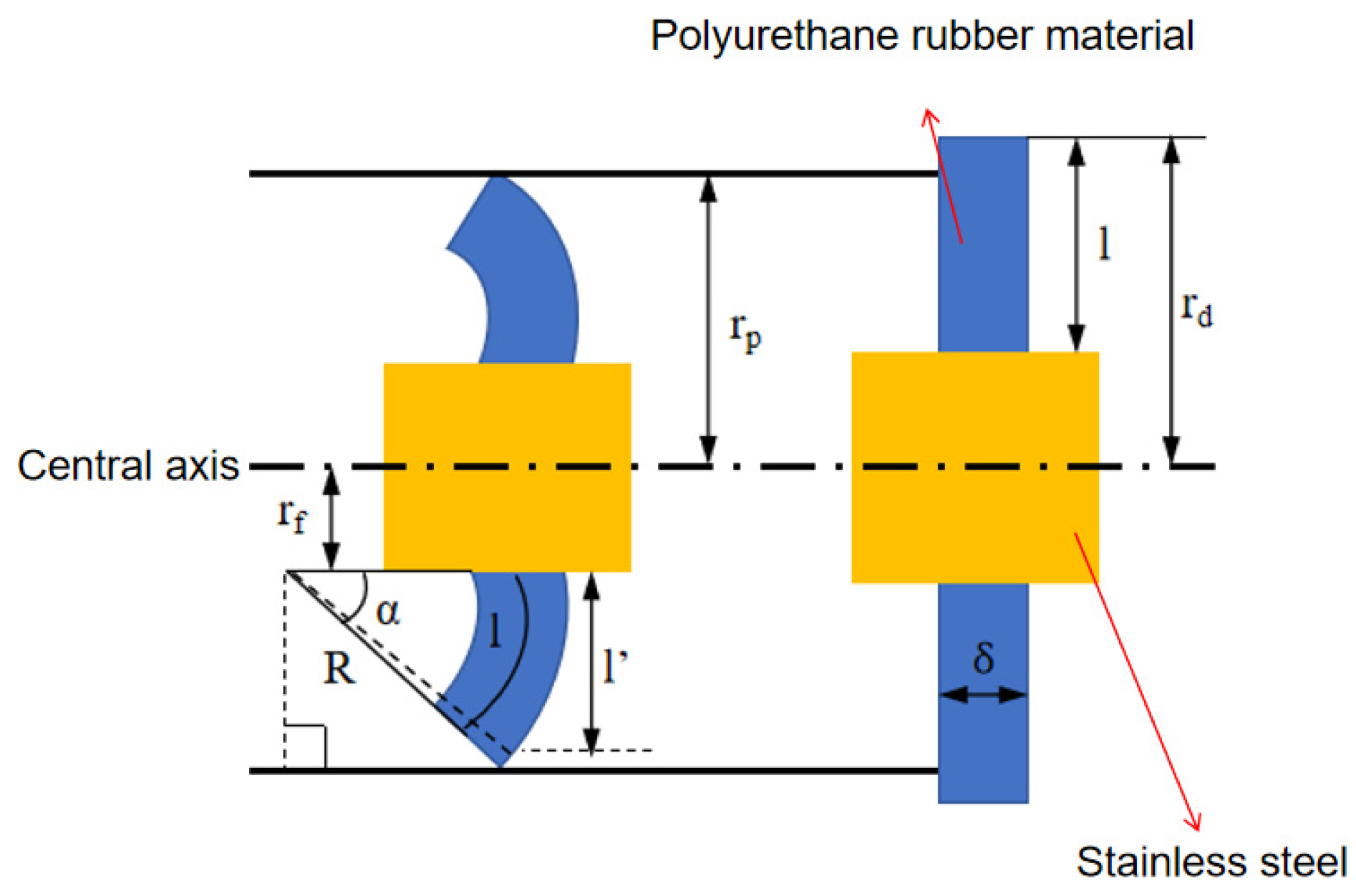

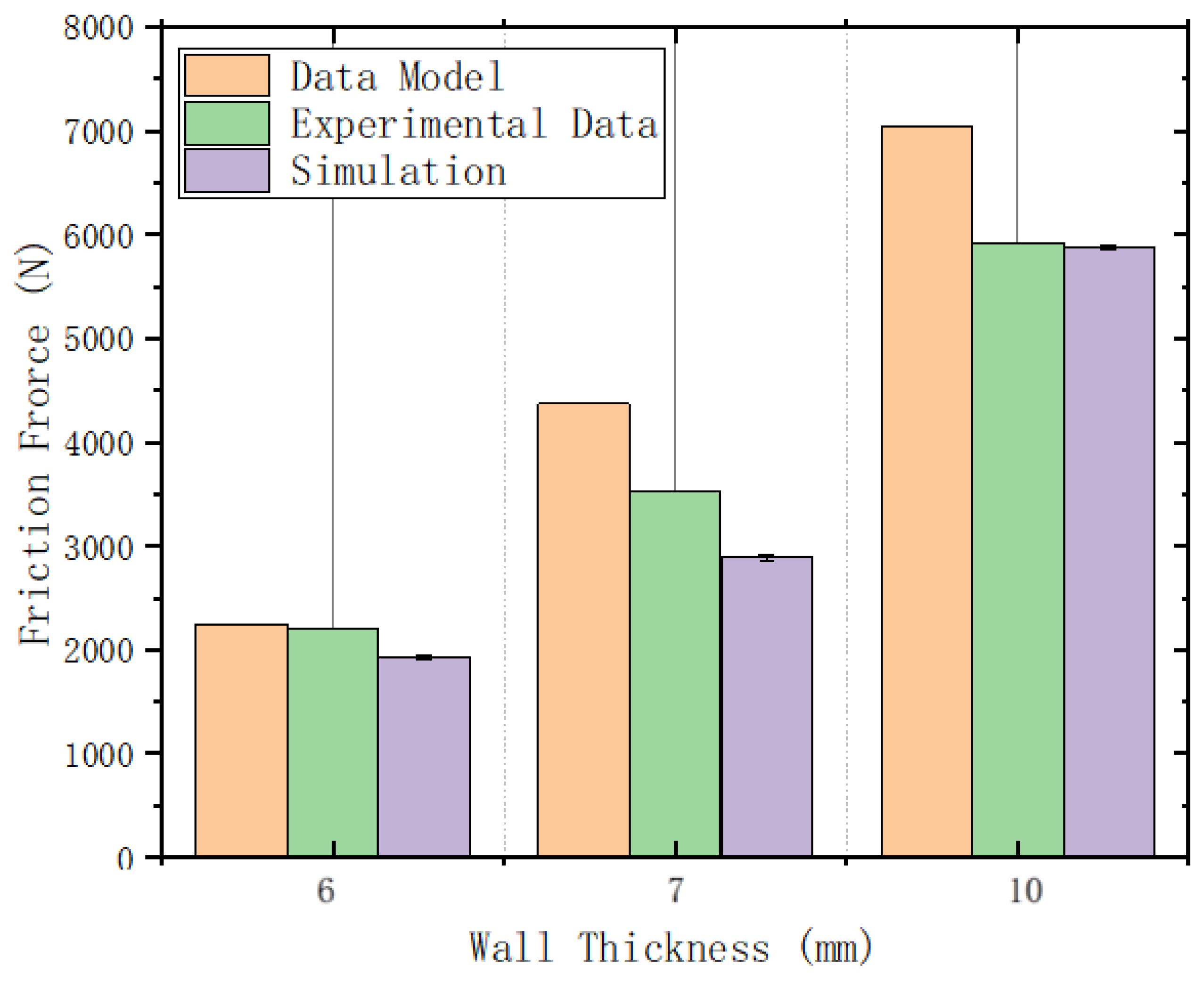

Based on the structure and force analysis of the MFL detector, a corresponding finite element model is established using ABAQUS software. Ignoring the effects of gravity, the frictional deformation at the cup end and straight plate end during operation in a gas pipeline is simulated, yielding the frictional resistance between the detector’s driving section and the steel pipeline wall. The parameters of the driving section are shown in

Table 4.

The parameters of the MFL detector’s driving section under actual operating conditions are shown in the table. Using the previously established mathematical model, the frictional resistance of the driving section is calculated as

Table 5:

Based on the structure and stress analysis of the in-line inspection tool, an equivalent finite element model was created using the ABAQUS software. Ignoring gravitational effects, the model simulates and analyzes the frictional deformation between the cup end and the flat end of the inspection tool as it operates within a gas pipeline, outputting the frictional resistance between the dynamic seal of the tool and the steel pipe wall.

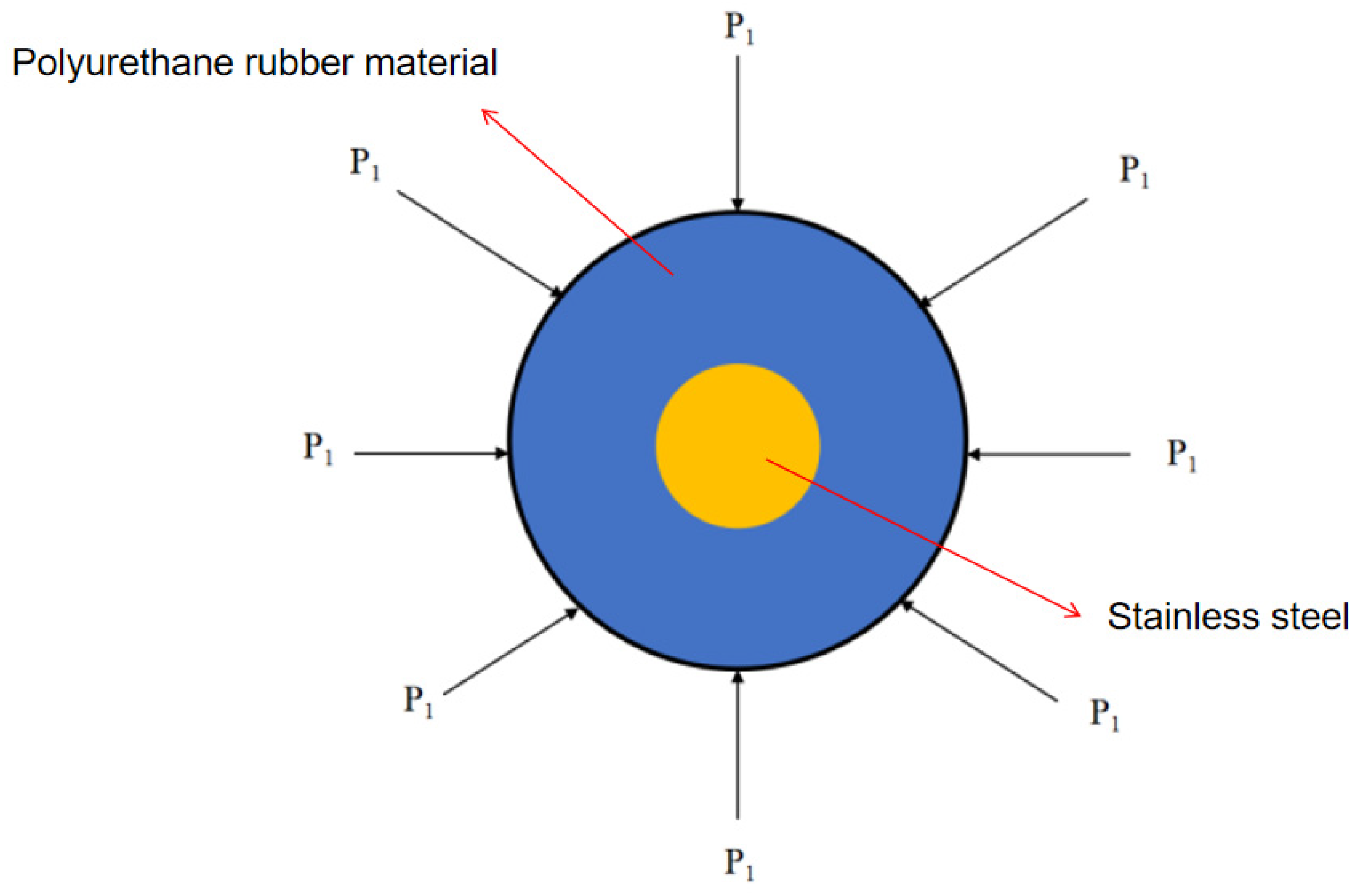

Currently, the dynamic cups and flat ends of the inspection tool primarily use polyurethane rubber due to its high elasticity, hardness, tear resistance, and abrasion resistance. Given its hyperelastic and incompressible properties, the simulation results are highly influenced by the choice of constitutive model and material parameters. To further investigate the impact of linear and nonlinear constitutive models on the mechanical state, a nonlinear material model is employed in this study. The Shore hardness of the polyurethane rubber is obtained via a durometer, and constitutive parameters are calculated through empirical formulas to achieve more accurate material settings.

As a typical hyperelastic material, polyurethane rubber can be represented by various constitutive models [

8]. Two common models include the molecular chain network model based on thermodynamic statistical methods and the phenomenological model based on continuum mechanics [

9]. The former, which encompasses Gaussian and non-Gaussian statistical models, posits that the molecular structure of hyperelastic materials is disordered when not subjected to external forces, with entropy decreasing as the tensile force increases. This model reflects the polymer physics of the material, allowing material parameters to have physical significance. However, it requires detailed material property data, limiting its practical application. The second type, based on the phenomenological theory of continuum mechanics, includes the Mooney–Rivlin, Neo-Hookean, and Ogden models. This approach uses basic material tests such as uniaxial and biaxial stretching to define the stress–strain relationship of hyperelastic materials, and the strain energy function is derived through data fitting.

In this study, the phenomenological theory of continuum mechanics is employed based on the following assumptions: (1) isotropy—polyurethane rubber possesses identical properties in regard to strength, stiffness, and elongation in all directions; (2) incompressibility—the material’s density remains unchanged during deformation. The main forms include polynomial models, the Mooney–Rivlin model, the Neo-Hookean model, and the Yeoh model.

As a commonly used form of strain energy potential function, the polynomial model can be expressed as:

Expanding this equation in a Taylor series yields:

where N represents the model order, W the strain energy per unit reference volume, C

ij the material shear performance parameter,

the compression performance parameter,

and

the first and second strain invariants, and J the elastic volume ratio. If the material is considered fully incompressible, all D

i values default to zero and the second part of Equation (31) is omitted [

10].

The Mooney–Rivlin model is a simplified version of the polynomial model. It is derived through shear tests on rubber materials under less than 100% deformation following these assumptions: (1) rubber is isotropic and incompressible; (2) under shear deformation, it obeys Hooke’s law, where strain and stress are linearly related. Mooney first proposed a model based on

, with the strain energy function expressed as:

Rivlin extended this by replacing the terms with higher-order expressions with the strain energy function as:

where

,

are material shear performance parameters and

= 0.

In the Neo-Hookean model,

= 0, and its expression is:

The Neo-Hookean model is the simplest form of strain energy function and an extension of Hooke’s law that is suitable for small to medium deformations in rubber but not for large deformations. This model, derived through shear tests, is widely applicable in shear mechanics. Due to its single material parameter, results are relatively stable, especially when fitting the stress–strain curve under a single loading condition.

The Yeoh model is expressed as:

The Yeoh model overcomes the drawback that the Mooney—Rivlin model has in regard to poor performance in describing the hardening ability of rubber under large-deformation conditions. is much larger than . As the strain variable increases, gradually decreases and tends towards zero. It can describe the strain conditions of rubber materials under various working conditions; however, its accuracy is poor in terms of fitting biaxial tensile tests.

Due to each rubber material constitutive model’s unique advantages, disadvantages, and applicable range, this study employs the Mooney–Rivlin model for analyzing polyurethane cups, given the model’s suitability for small-to-medium deformations, which aligns with the limited interference fit of the polyurethane cup.

In this study, the flat and cup ends of the dynamic segment use polyurethane rubber material, and their response to force during operation relates to their hardness. Using empirical formulas, the rubber hardness was converted into the Mooney–Rivlin elastic parameters

and

, significantly reducing testing costs [

11,

12,

13].

For small deformations, the relationship between polyurethane rubber’s elastic modulus and shear modulus satisfies the following equation:

where is Poisson’s ratio of the material.

Assuming an incompressible property for rubber,

= 0.5, thus

= 3G, and the relationship between shear modulus, elastic modulus, and

is shown below:

Based on IRHD hardness H and elastic modulus

experimental data for rubber materials, the fitting provides:

The above equation shows that IRHD hardness depends on Rivlin parameters and .

Shore Hardness, a widely recognized indicator of material deformation under compression or puncture resistance, measures how far a steel indenter penetrates the material’s surface when fully engaged. The Shore hardness, represented by L, inversely correlates with hardness: a higher L indicates lower hardness and vice versa. Shore hardness type HA represents softer rubber, while HD represents harder rubber or plastics. The polyurethane rubber used in this study applies to HA-type Shore hardness.

Tester experimental procedures and standards for the Shore hardness tester (as shown in

Figure 9) followed GB531, and the results are listed in

Table 6.

Calculating the average hardness value for the sealing element provides the Rivlin coefficients for polyurethane rubber at the flat and cup ends, with C10 being set to 1.423 and C01 being set to 0.356.

The main body of the dynamic segment and pipeline materials, composed of steel, undergo minimal deformation during operation. Thus, a linear elastic constitutive model was selected with an elastic modulus of E = 200 MPa and a Poisson’s ratio of = 0.3.

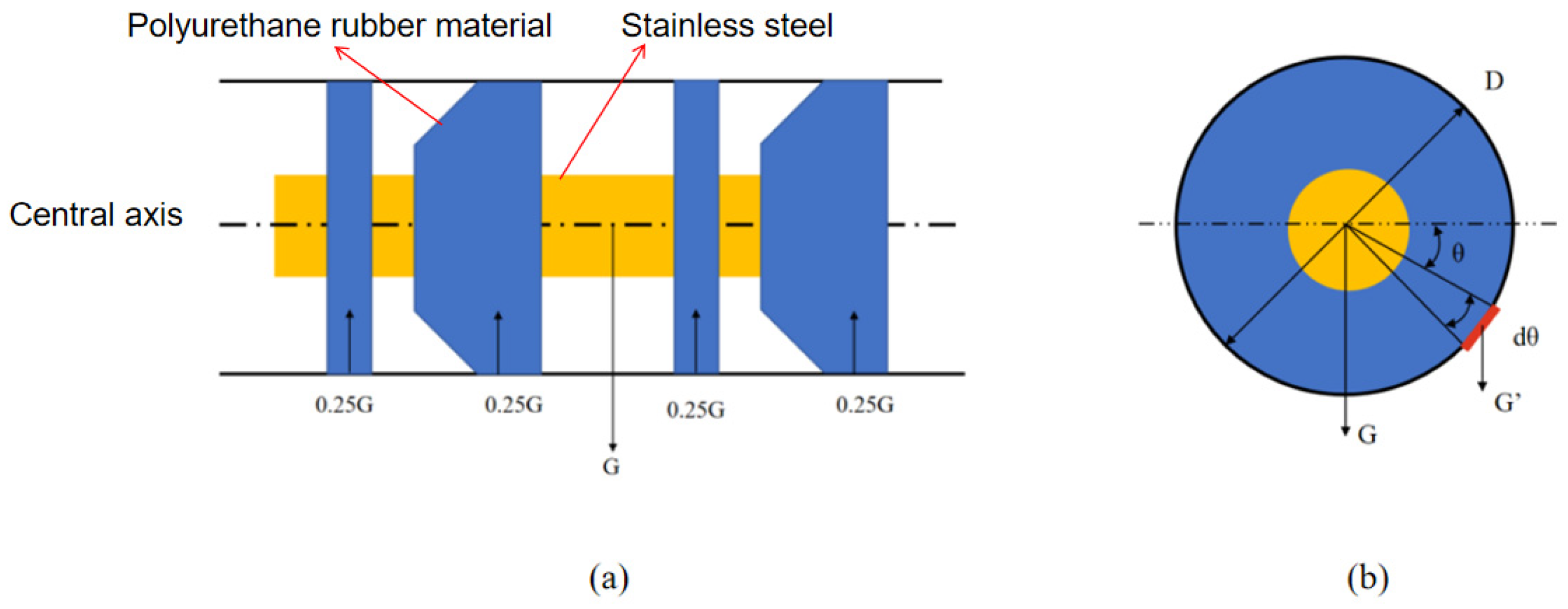

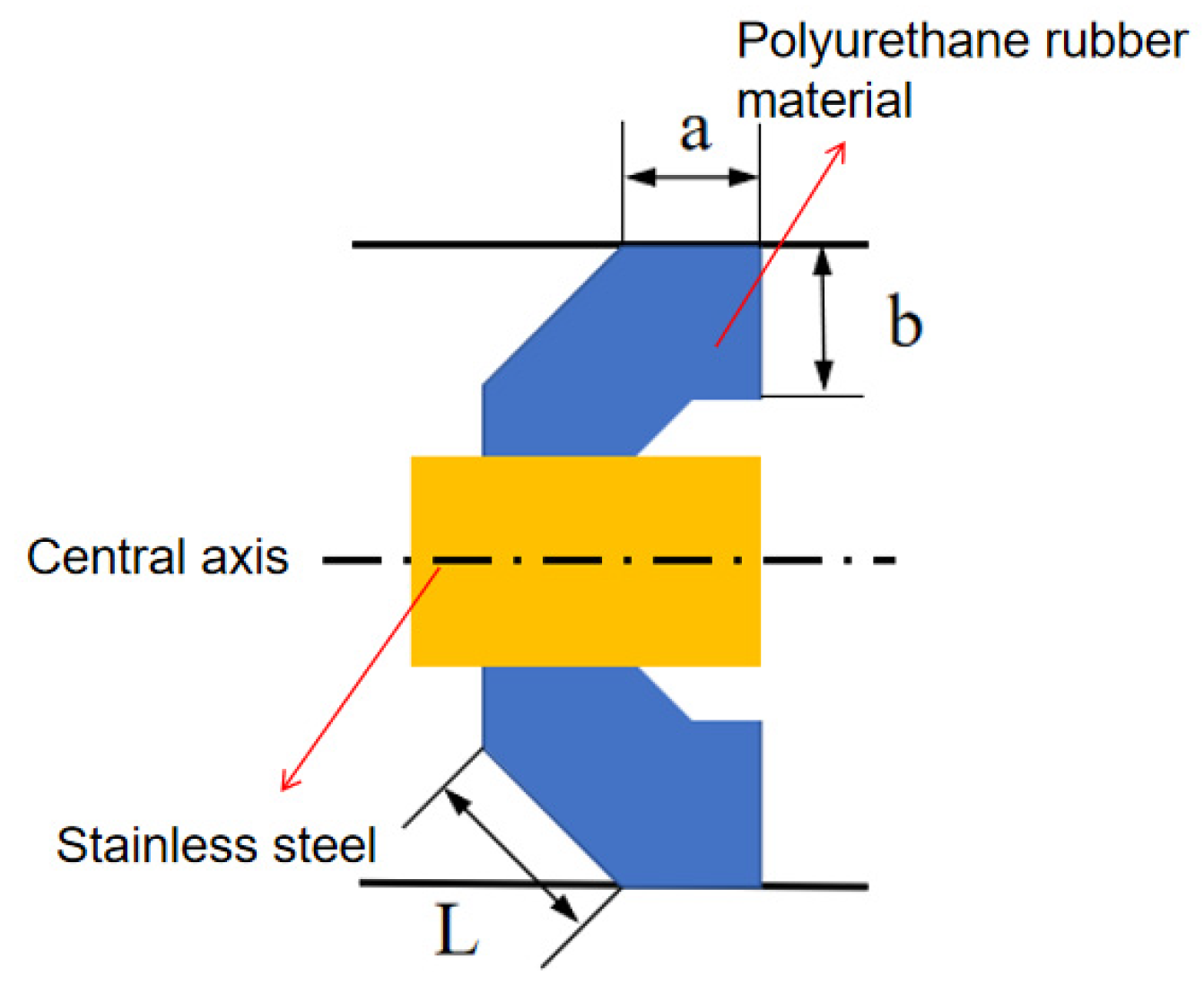

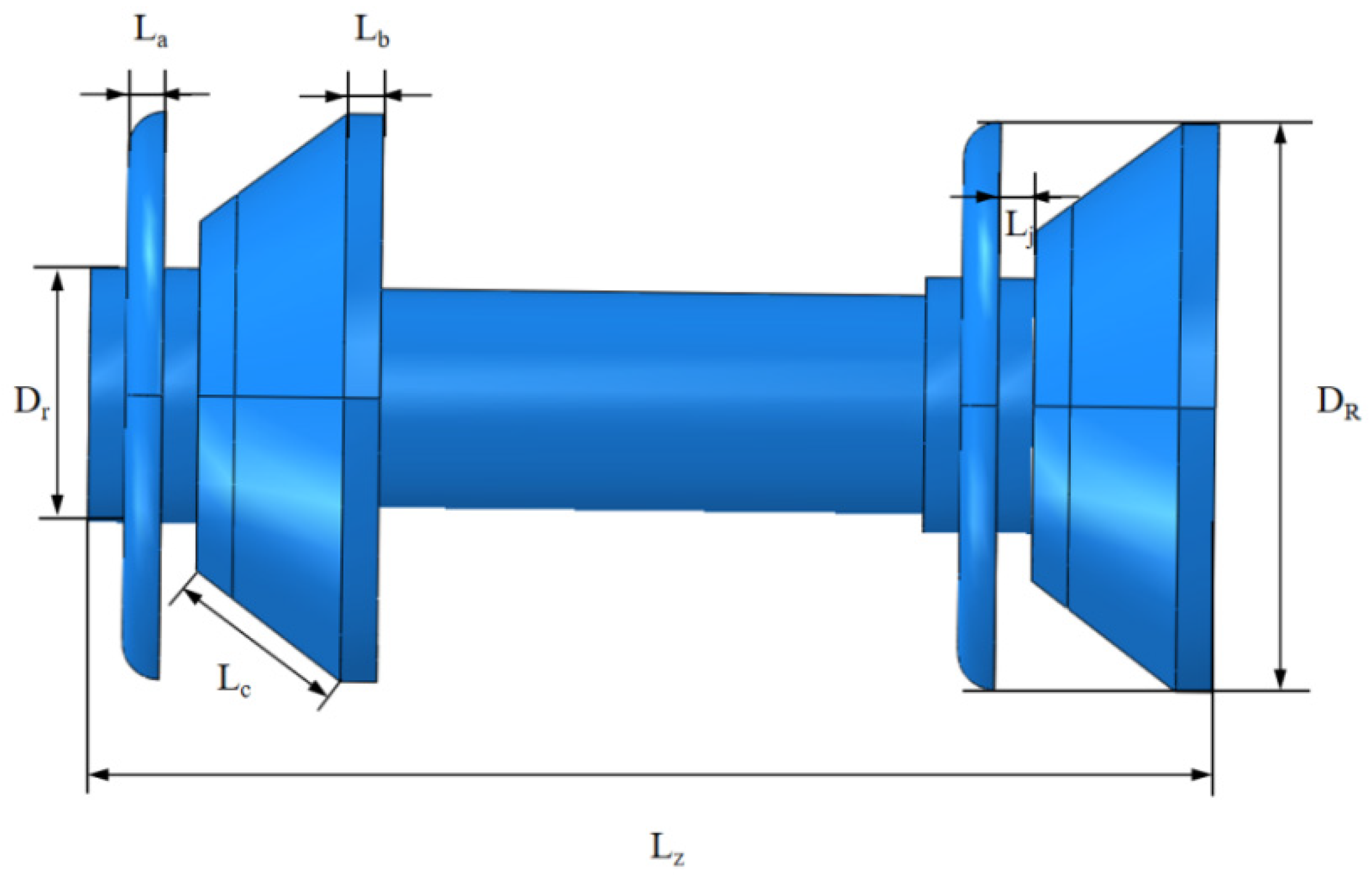

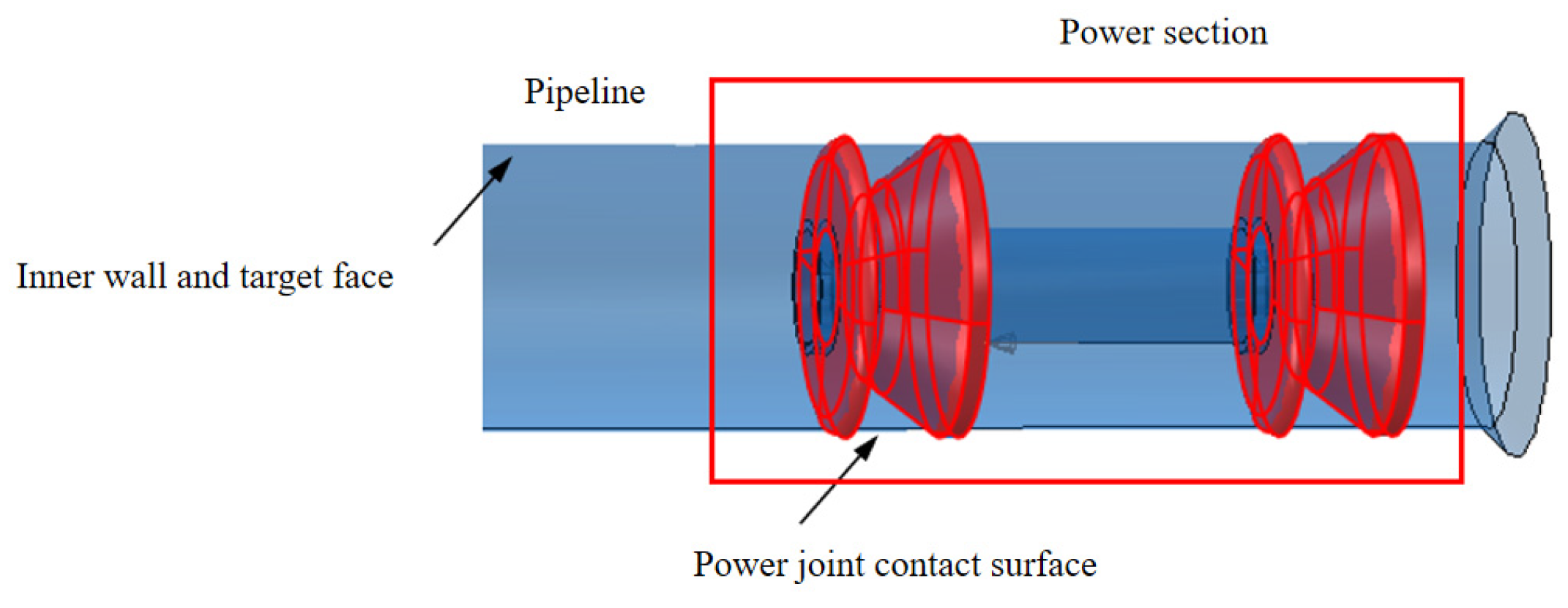

The driving section structure selected for this study is a common mandrel type, as shown in

Figure 10. The main components include cups, straight plates, mandrels, and clamping plates. During assembly, the straight plates and cups are sequentially fitted onto the mandrel, with clamping plates being installed on both sides for fixation.

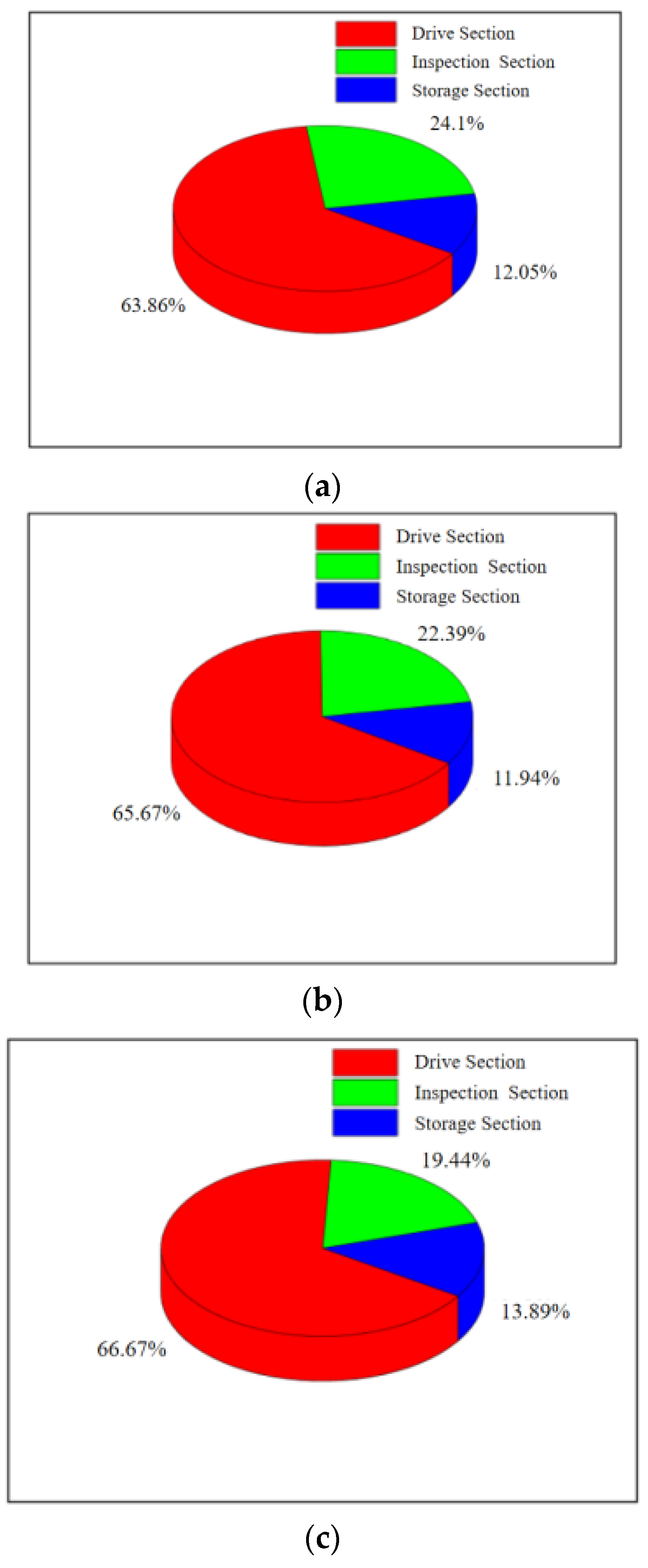

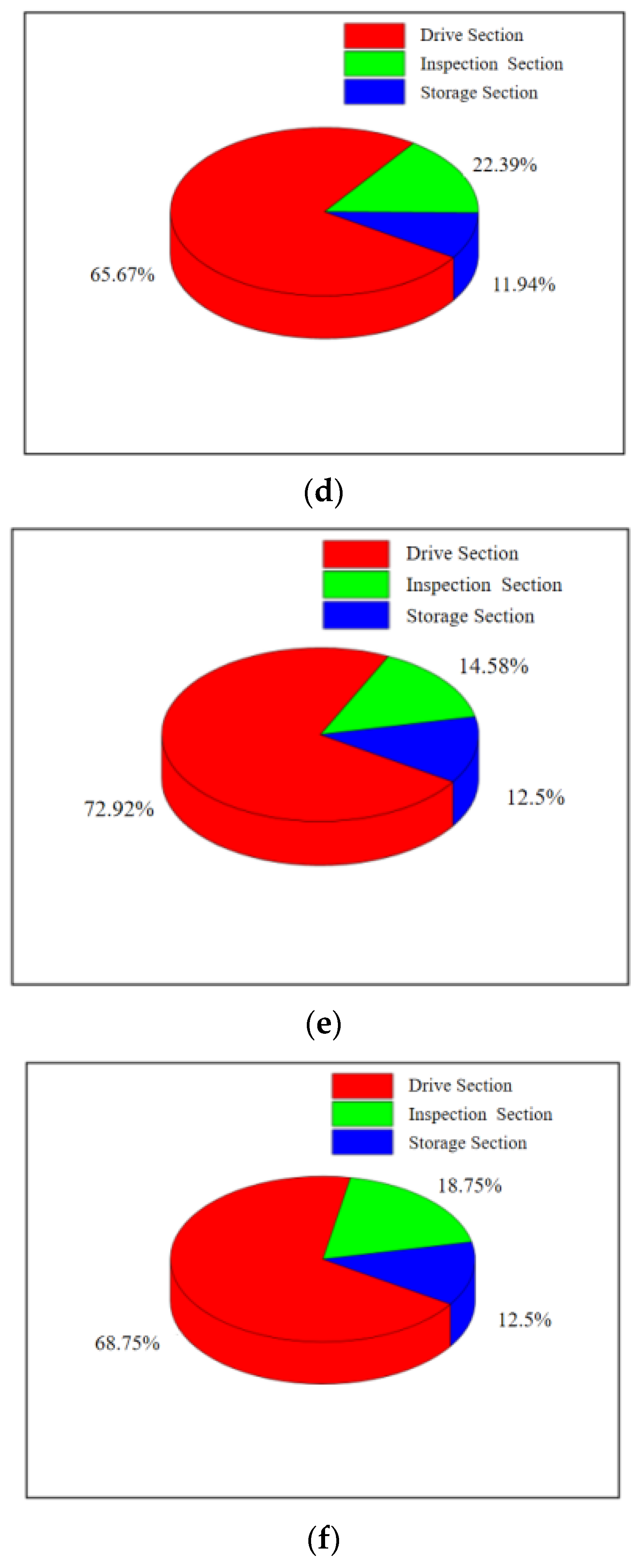

This study analyzes the driving section under different pipeline wall thickness conditions, as shown in

Table 7.

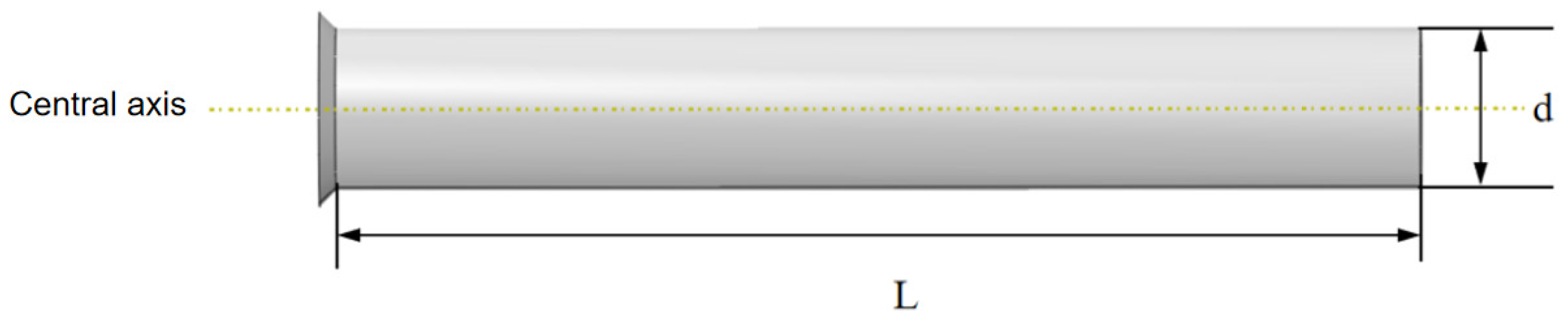

In this study, the parameters of the driving section remain constant under different conditions, with the variation in interference fit being primarily influenced by changes in the inner diameter of the steel pipeline. The geometric model of the pipeline is shown in

Figure 11.

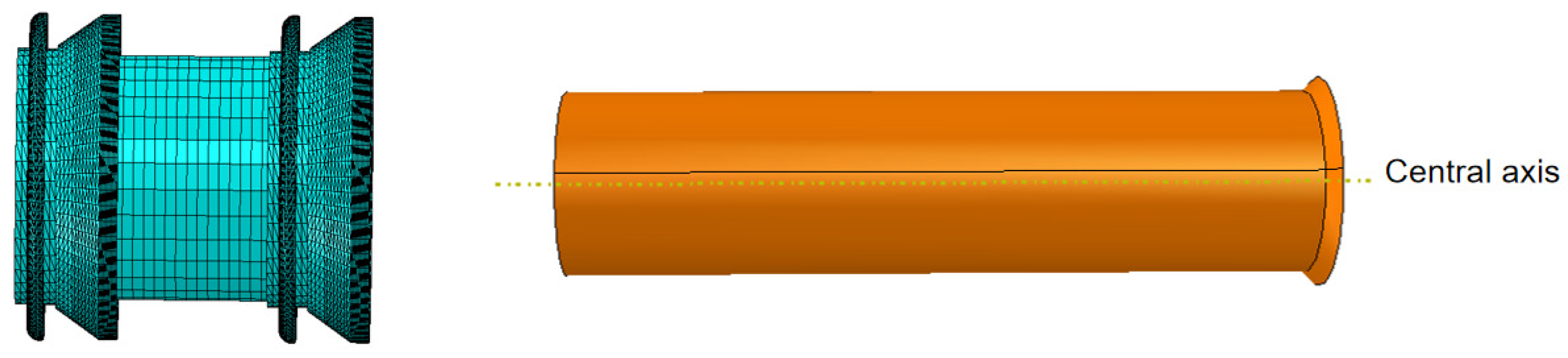

The study uses ABAQUS software to establish a fluid–structure interaction model of the MFL detector’s driving section in a straight gas pipeline, as shown in

Figure 12. The main body of the model is meshed using regular C3D8 elements, presenting a well-organized cubic structure. For the edge regions of the model (cup area), regular C3D4 elements are used to accommodate the complex boundary geometry. As shown in

Figure 13, the straight plate and cup ends of the driving section are fixed with clamping plates and no displacement occurs between components, hence binding contact is used. Face-to-face contact is selected between the straight plates, cups, and the pipeline using the penalty function algorithm. The Coulomb friction coefficient between the straight plates, cups, and the pipeline inner wall is set to 0.5 [

14].

In the model, the gas pipeline and the main shaft of the MFL detector are made of steel, which, compared to the polyurethane rubber material of the straight plate and cup ends, undergoes negligible deformations. To further simplify calculations, the steel pipeline and the main body are coupled as rigid bodies. In this study, the steel pipeline is set with full constraint conditions, remaining stationary. The driving section of the detector is subjected to speed loading, set at 30 mm/s, and solved using the Explicit solver with a quasi-static approach.

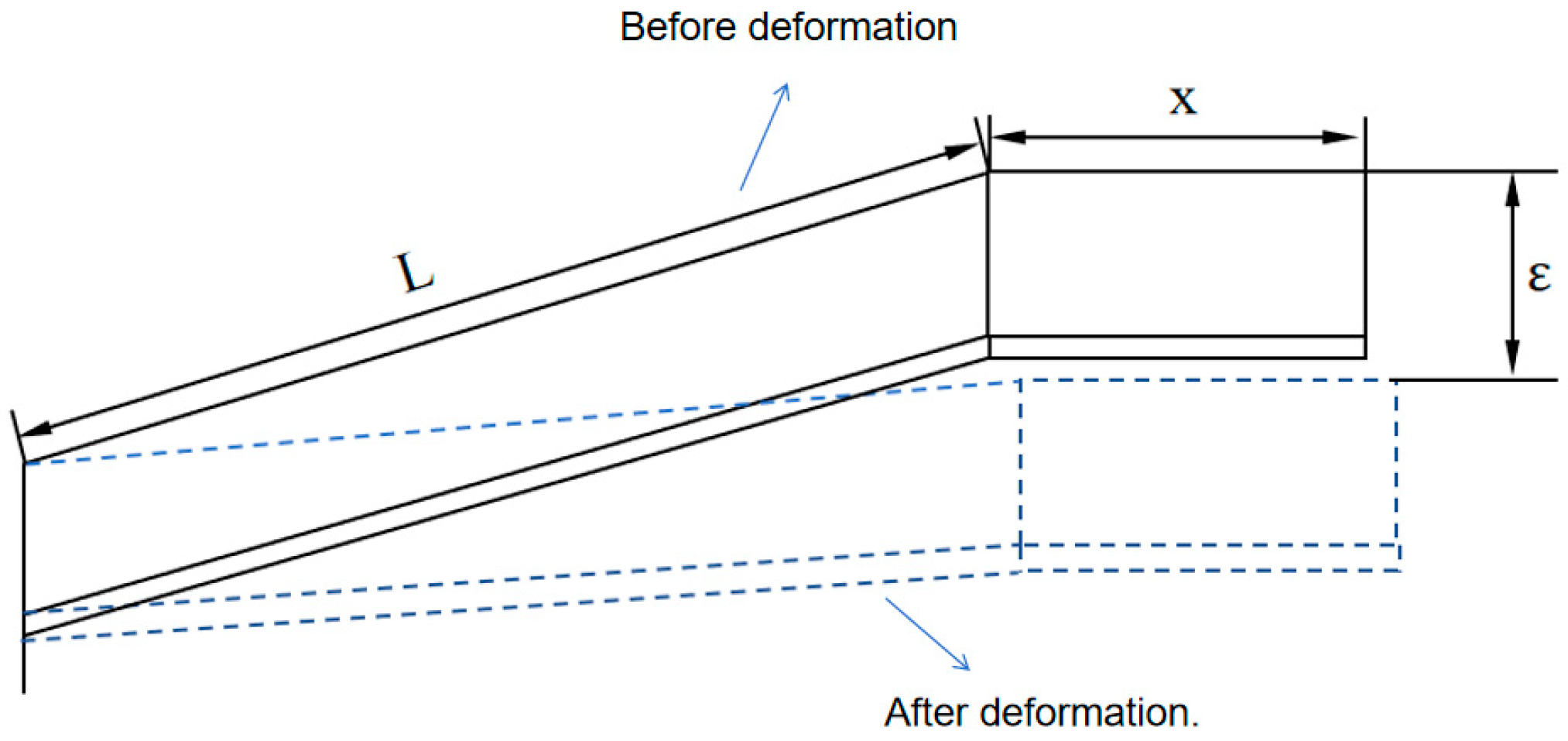

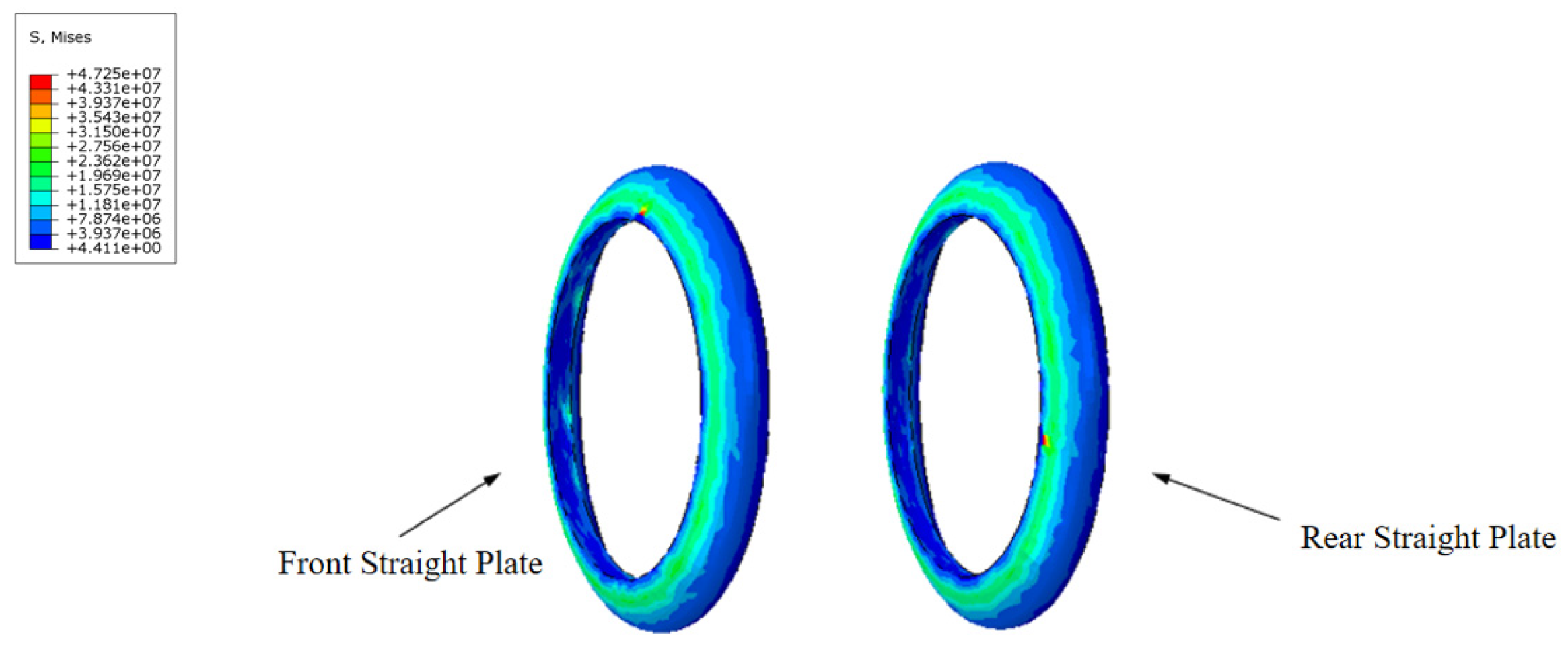

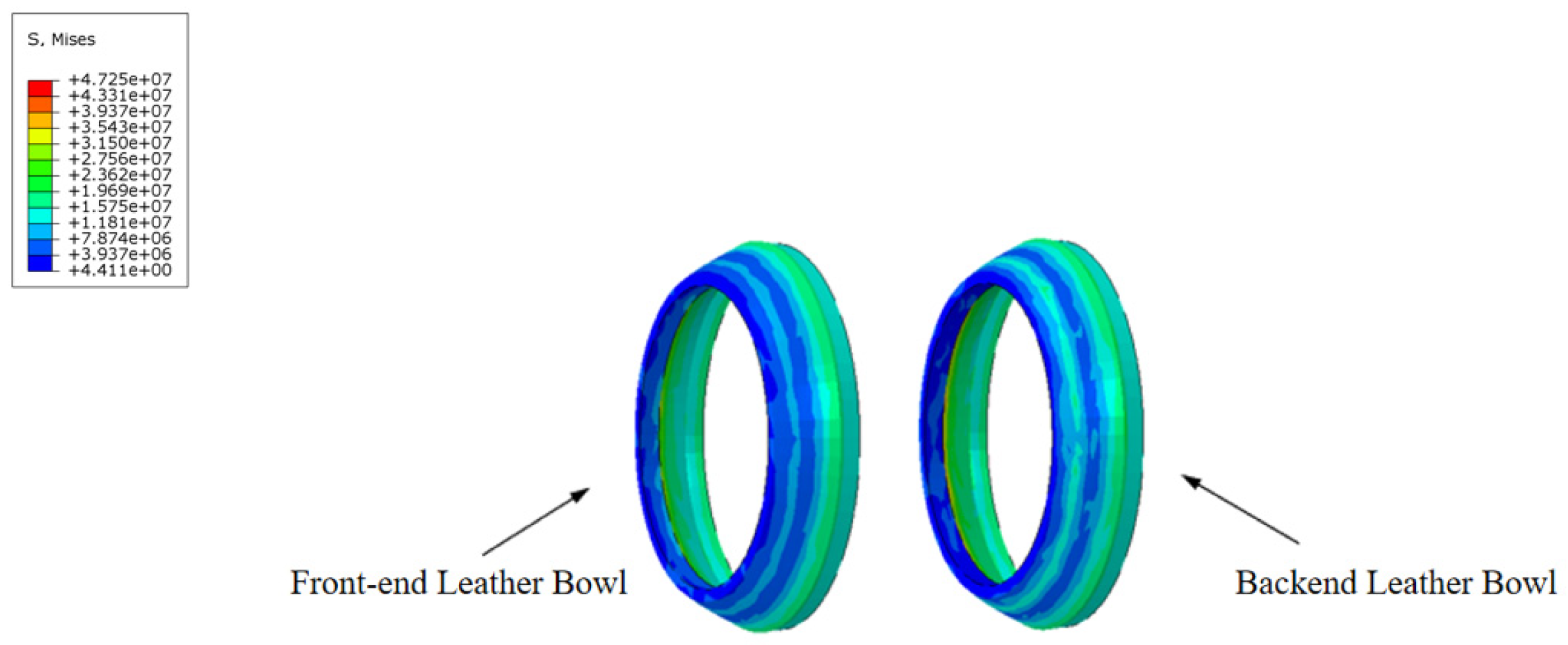

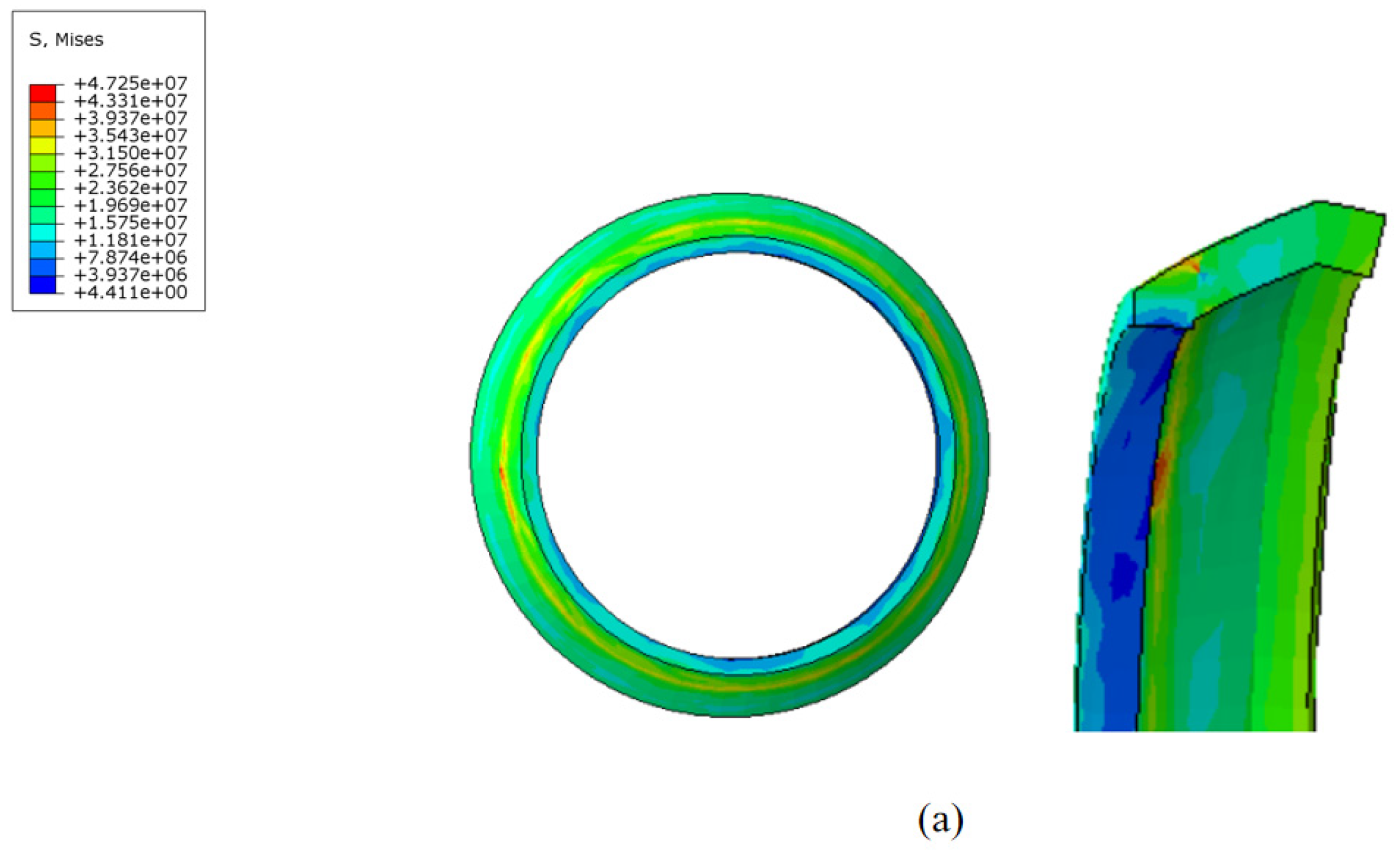

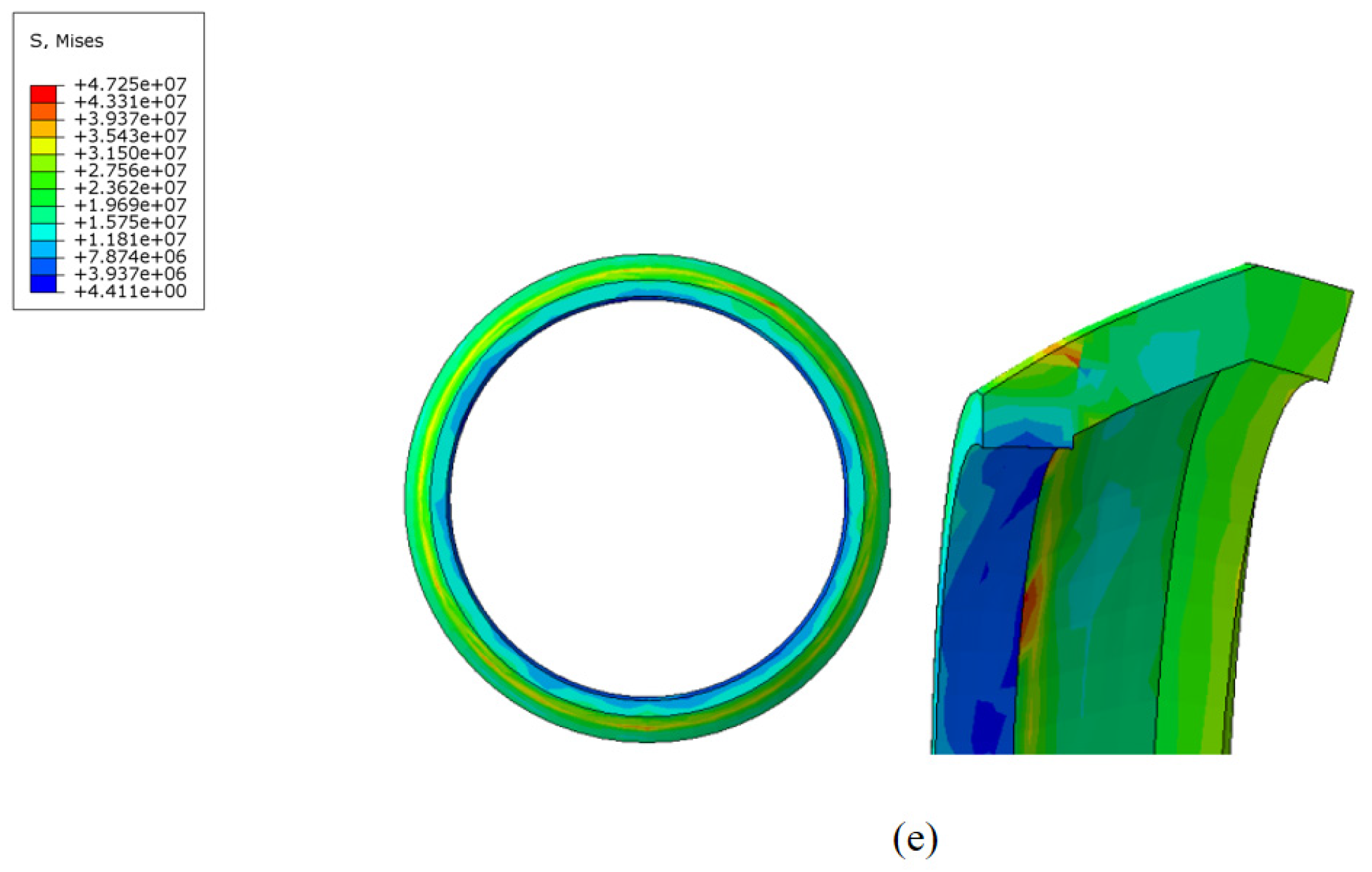

During the movement of the MFL detector’s driving section in the steel pipeline, the cup and straight plate ends closely adhere to the steel pipeline. The contact stress between them directly reflects the degree of adherence and the magnitude of the operating friction. Taking a driving section component with an interference fit of 4.6% as an example, when the driving section fully enters the steel pipeline and stabilizes, the contact stress distribution of each component is shown in

Figure 14 and

Figure 15. The contact stress size and distribution of the front and rear components are approximately the same. To further analyze the contact stress distribution under different interference fits, the front half of the driving section’s straight plate end and cup segment is selected for discussion.

The contact stress and distribution at the straight plate end under different interference fits are shown in

Figure 16. When the MFL detector operates within the pipeline, the contact force distribution at the straight plate end under various interference conditions is similar. Due to the interference fit, the straight plate end is compressed by the pipeline wall, with maximum contact stress occurring at the outer edge of the straight plate end, decreasing from the outside in. Comparing different conditions reveals that, as the interference fit increases, the degree of bending deformation at the straight plate end increases, further raising the contact stress.

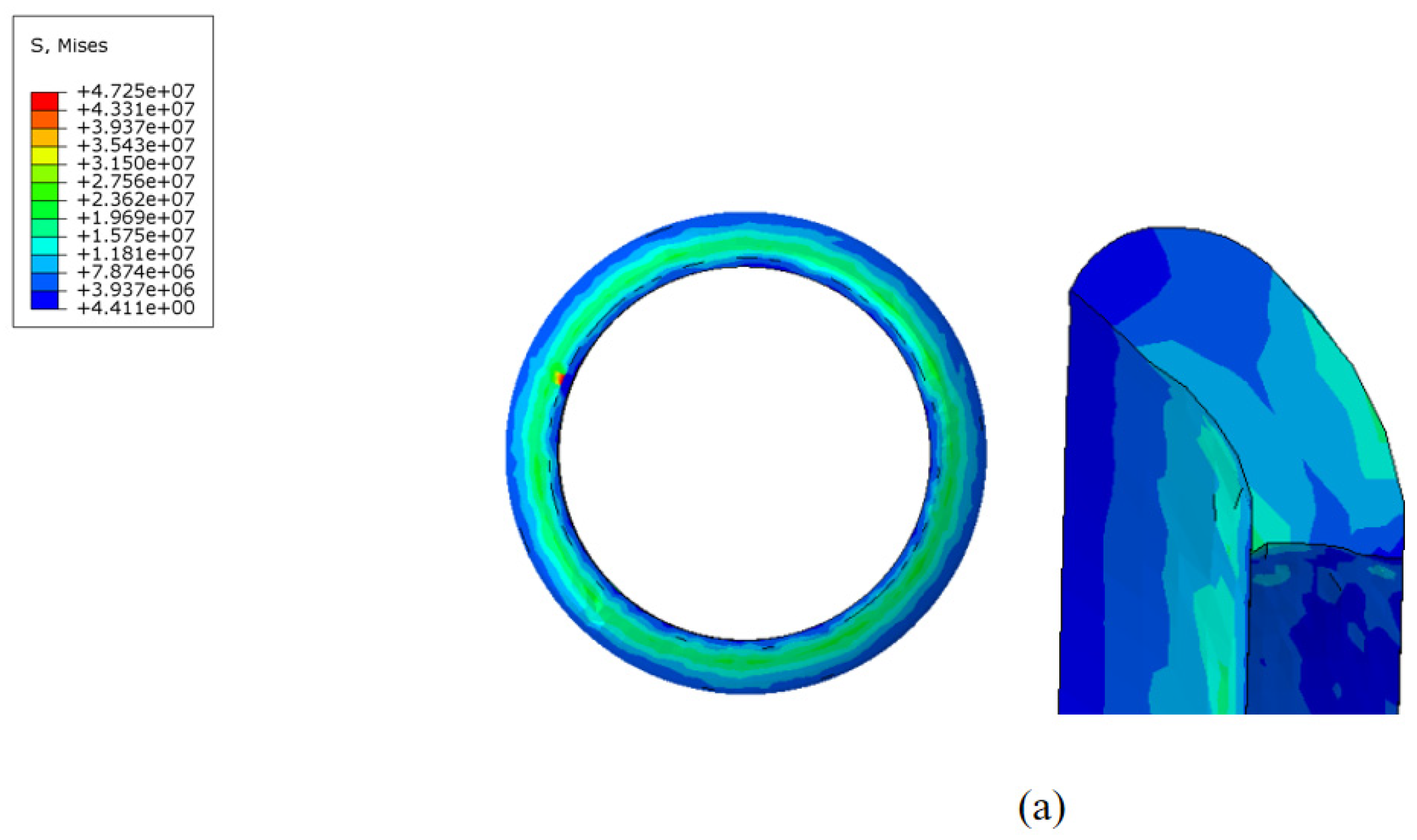

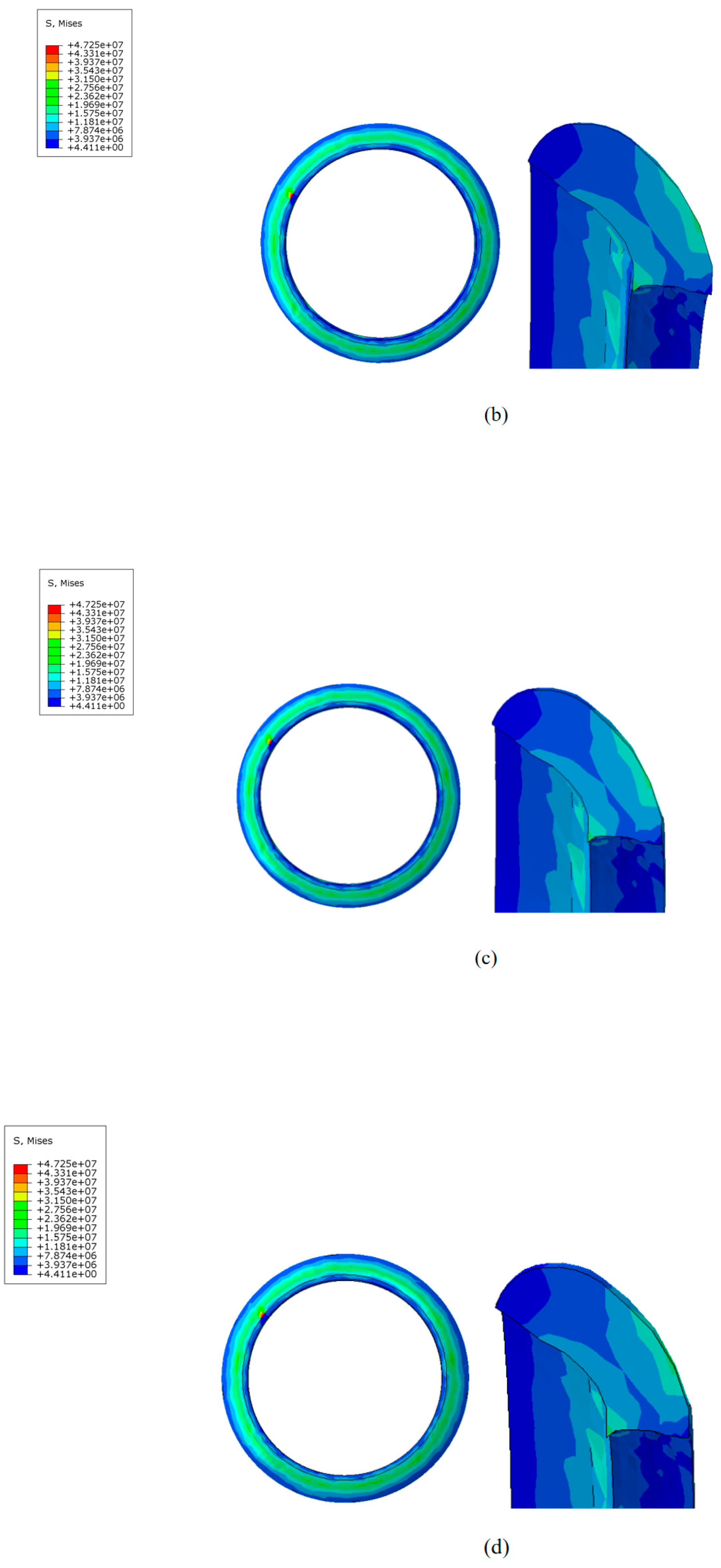

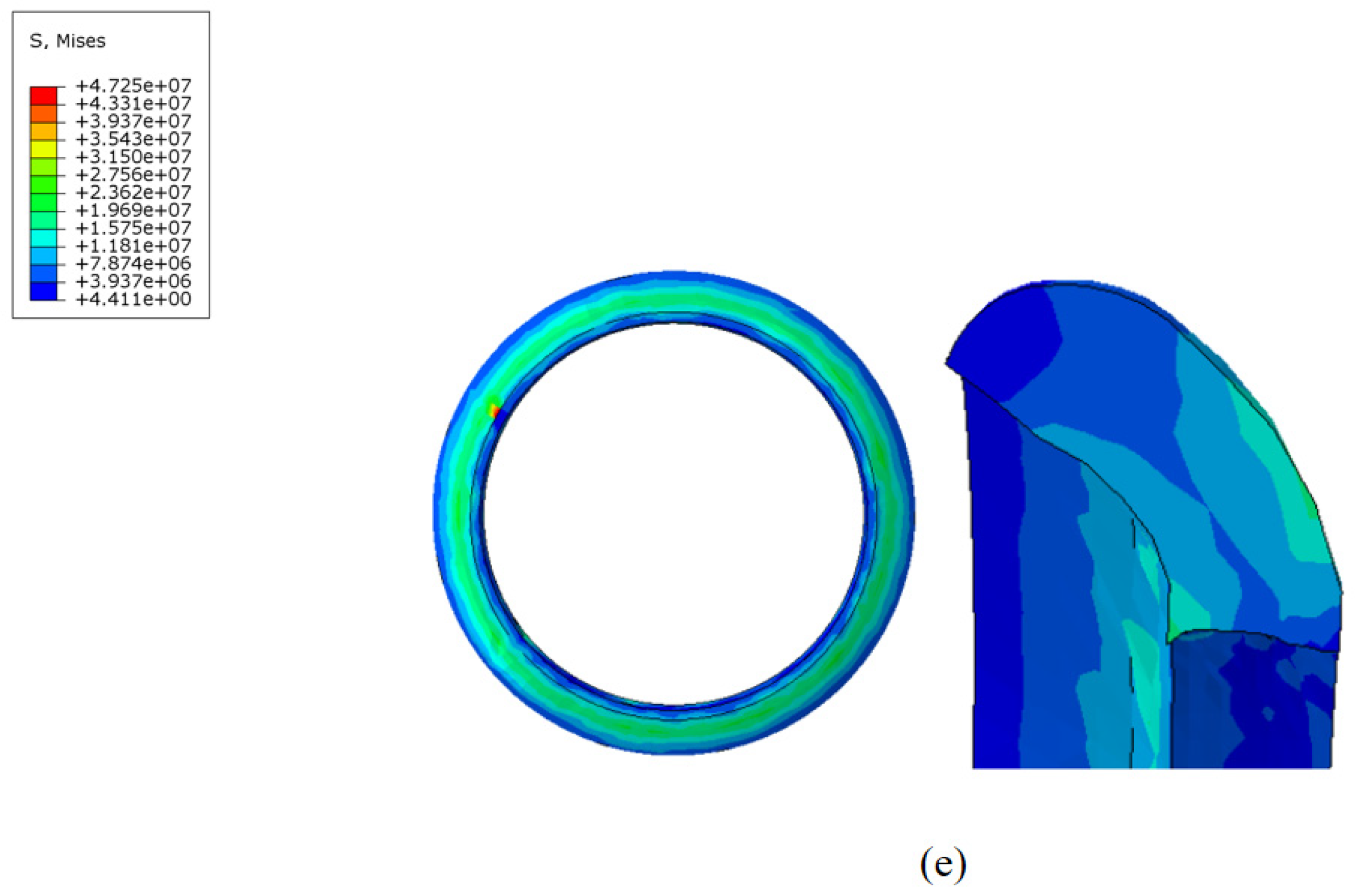

The contact stress at the cup end under different interference fits is shown in

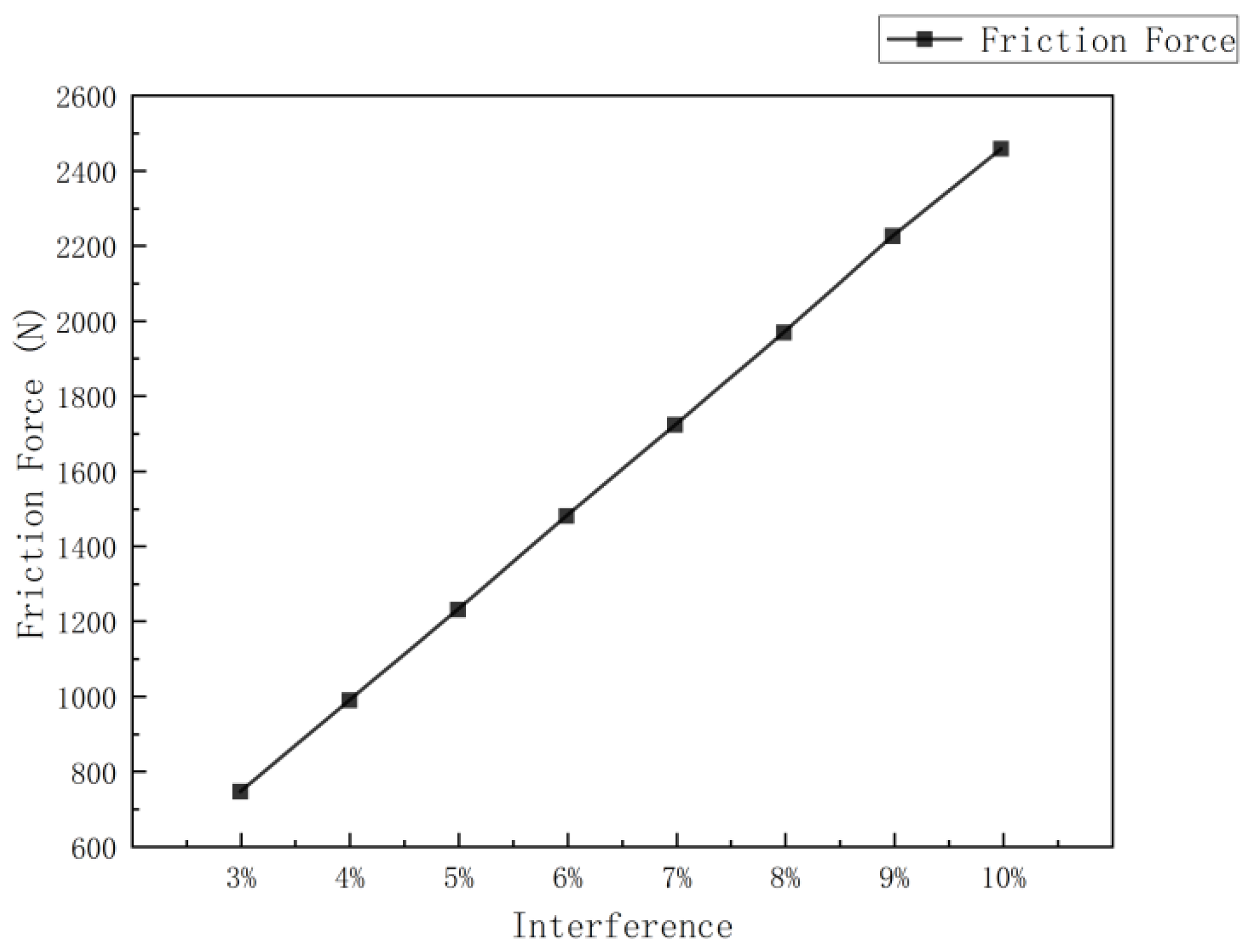

Figure 17. Under various interference conditions, the contact stress distribution at the cup end of the MFL detector’s driving section is relatively similar. Due to the interference fit, the cup end does not remain tightly attached to the steel pipeline wall but is compressed, with the front end of the cup being pressed down and tightly contacting the steel pipeline wall at the fold of the cup end. This differs somewhat from the theoretical conditions considered earlier. When the interference fit is small, the maximum contact stress at the cup end is at the end of the contact position with the steel pipeline. As the interference fit increases, the maximum contact stress and position move towards the end of the cup, and, as the interference fit increases, the contact position and maximum contact stress at the cup end move further down. The variation in frictional resistance in the driving section with the wall thickness of a 273 mm pipeline is shown in

Figure 18.