Planetary Gearboxes Fault Diagnosis Based on Markov Transition Fields and SE-ResNet

Abstract

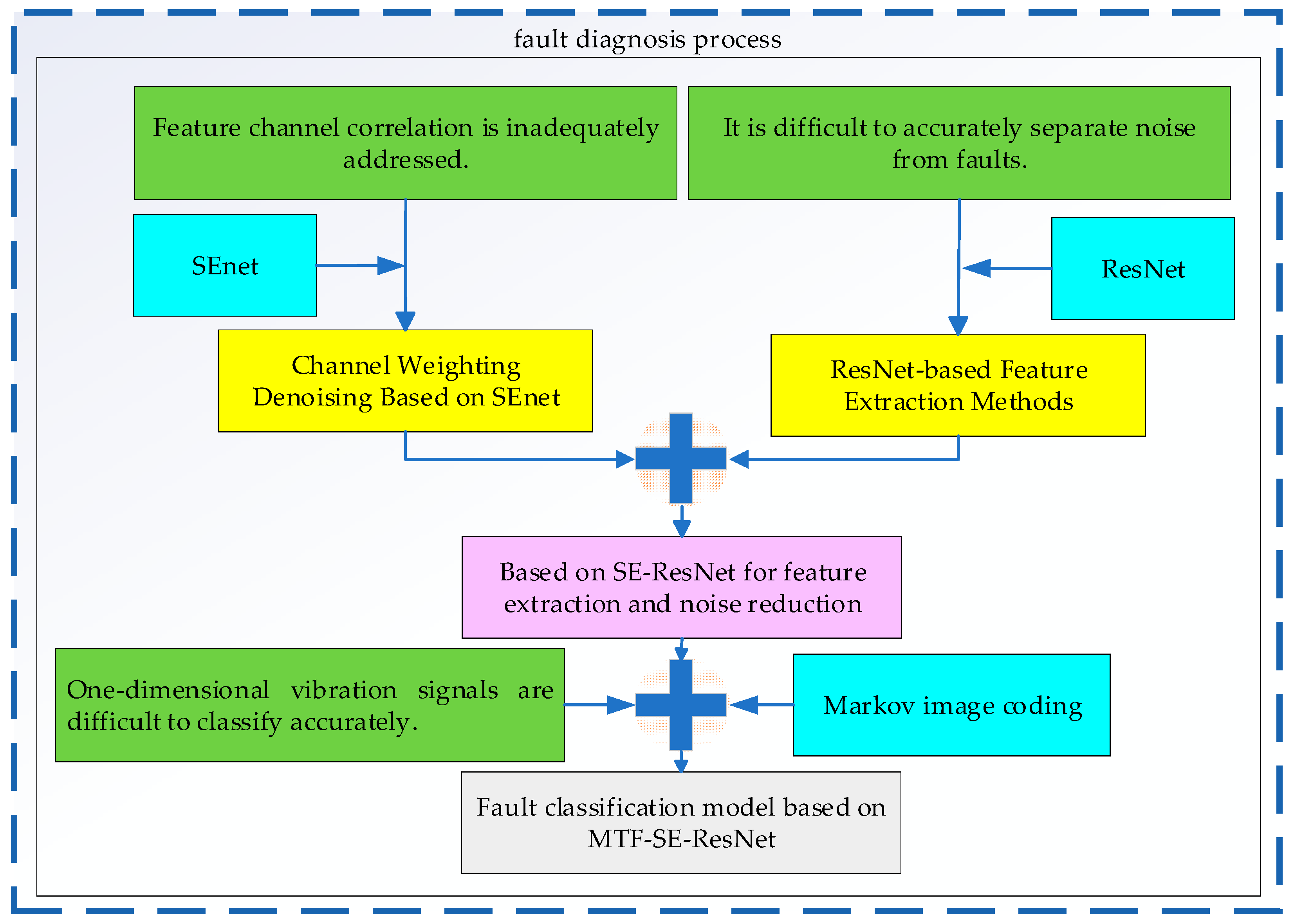

1. Introduction

2. Engineering Background and Vibration Data Processing

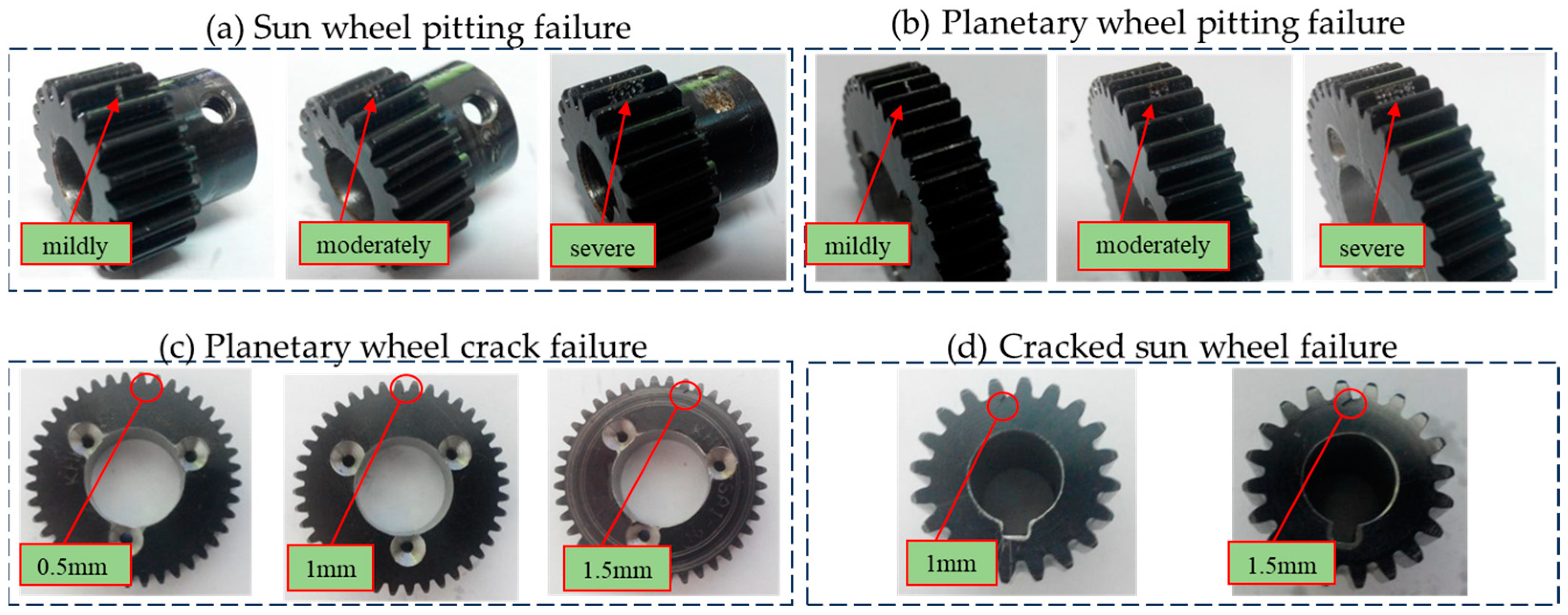

2.1. Engineering Background and Problems

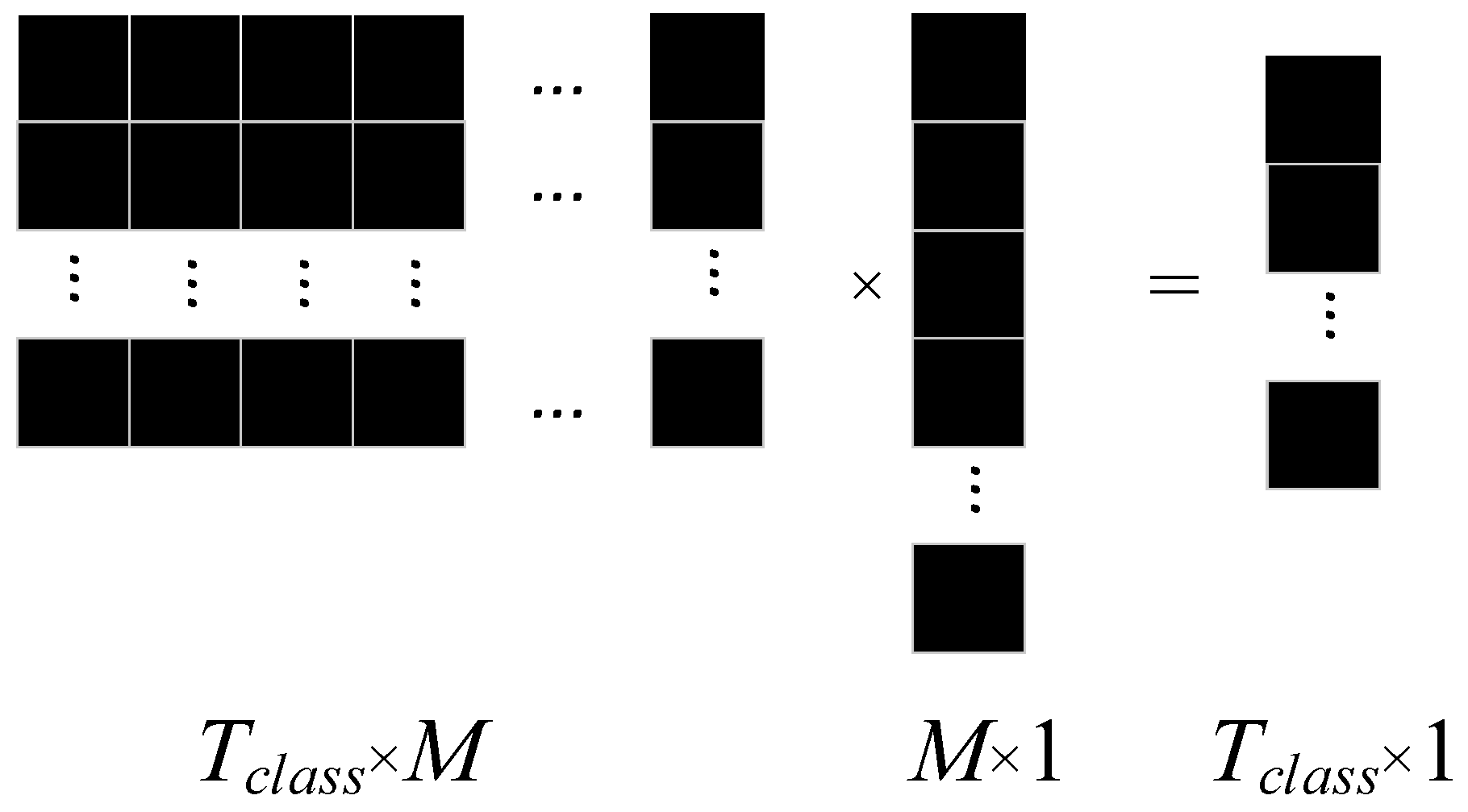

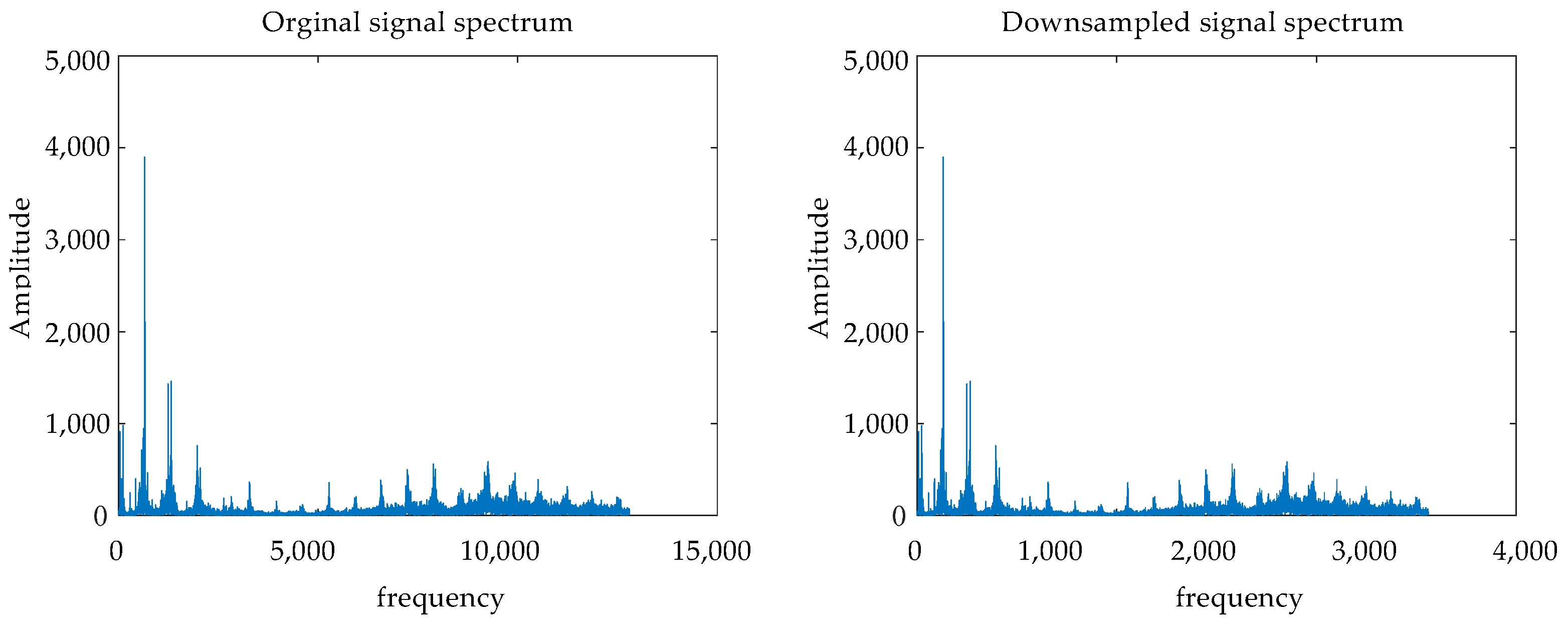

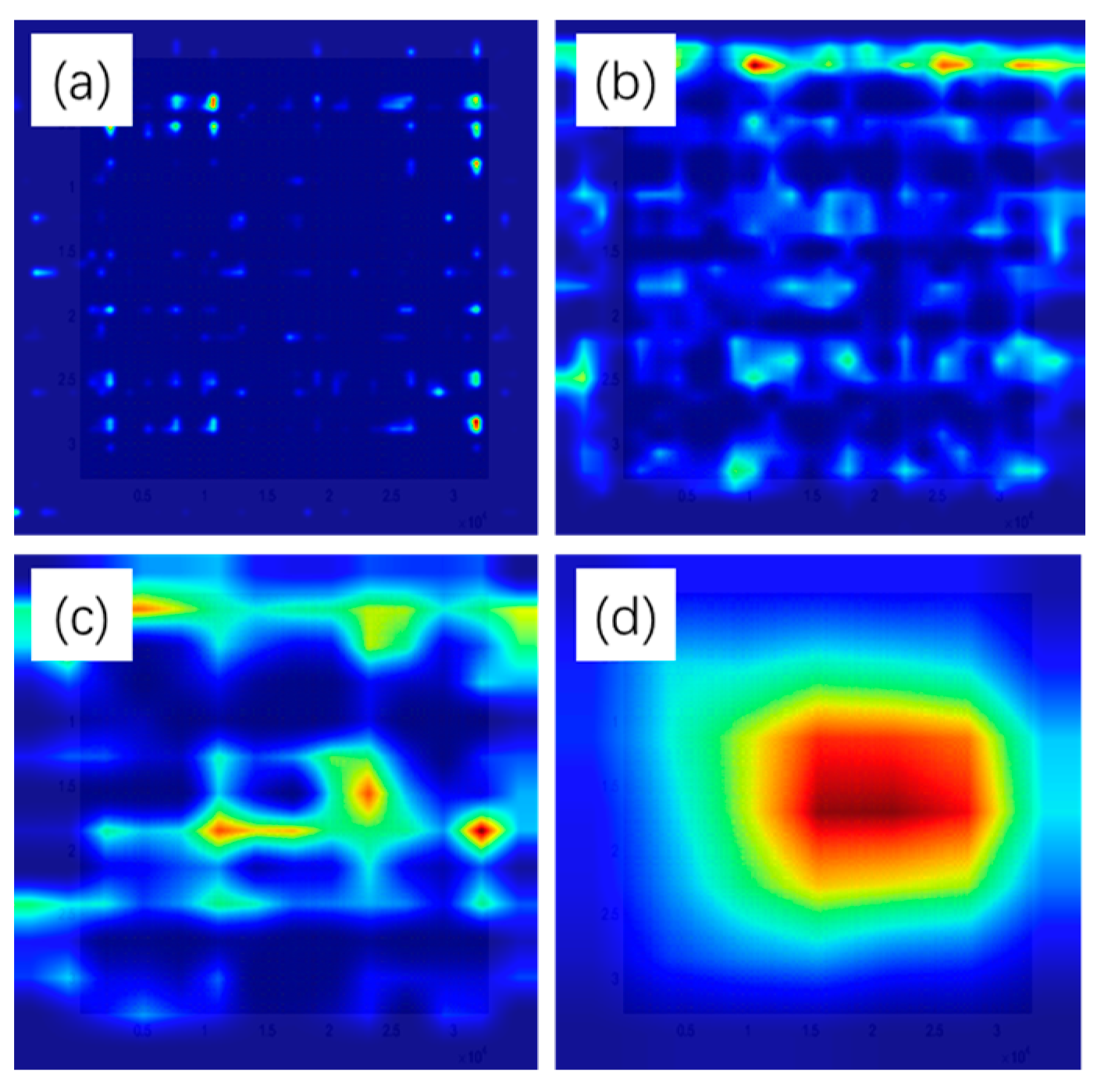

2.2. Vibration Data Processing Based on Markov Image Coding

- The time series X(t) is divided into Q equal parts according to time t, where the time series of the i equal part is denoted as Xi(t) (i = 1, 2, …, Q), and the Ni sampling points contained within the sequence of Xi(t) are denoted as xi,j in chronological order (j = 1, 2, …, Ni);

- The range of the sampling point is denoted as [XL, XU], and is equally divided into Q intervals, and the kth interval is denoted as qk = [XkL, XkU], XL = X1L,XU = XQU, where k (k = 1, 2, …, Q);

- The quantity of sampling points, xi,j, in Xi(t) falling into the interval qk = [XkL, XkU] is denoted as Zik;

- Calculate wik = Zik/(N1 + N2 + … NQ), traverse all i and k, and construct the transition matrix.

3. Intelligent Diagnostic Model for Planetary Gearboxes

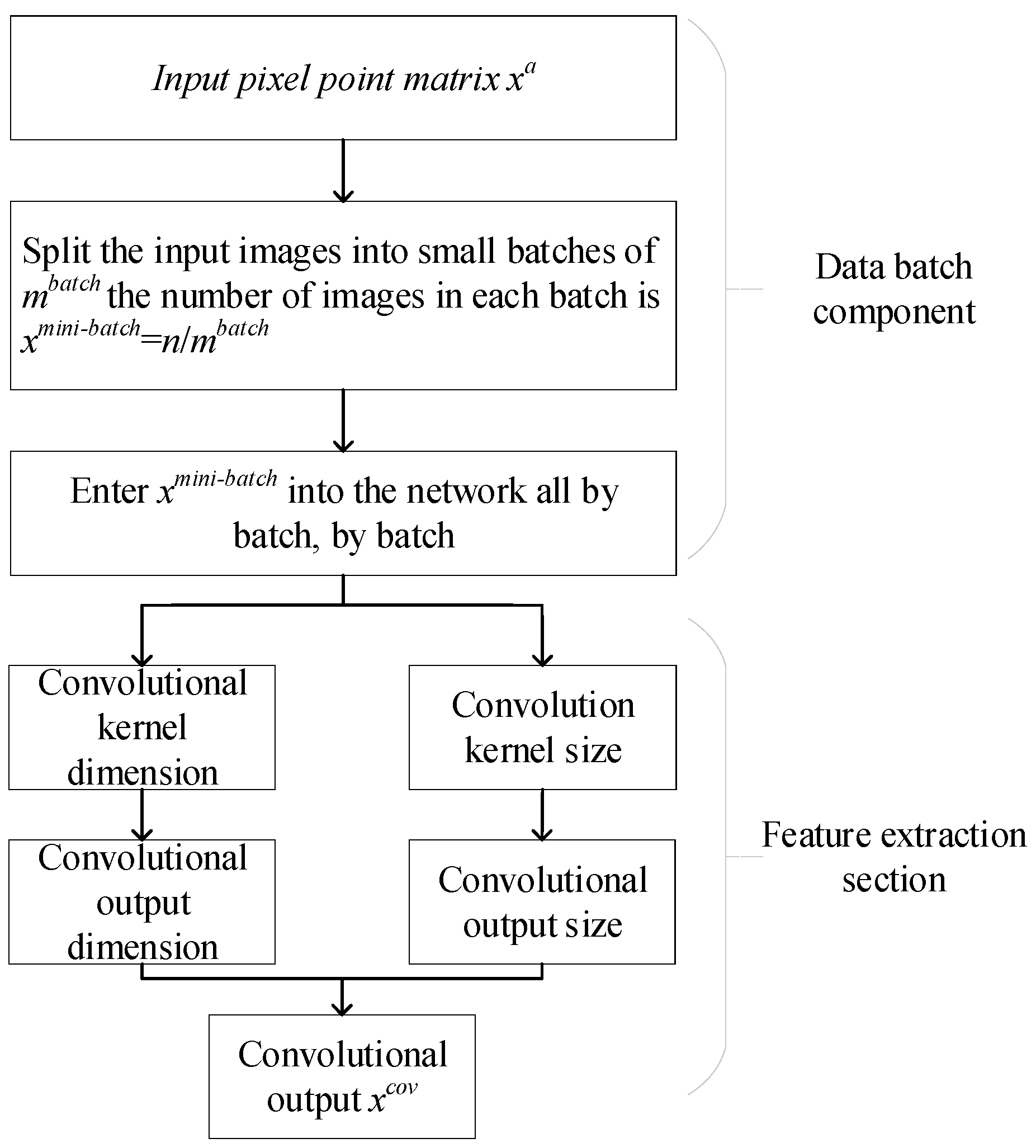

3.1. ResNet-Based Feature Extraction Methods

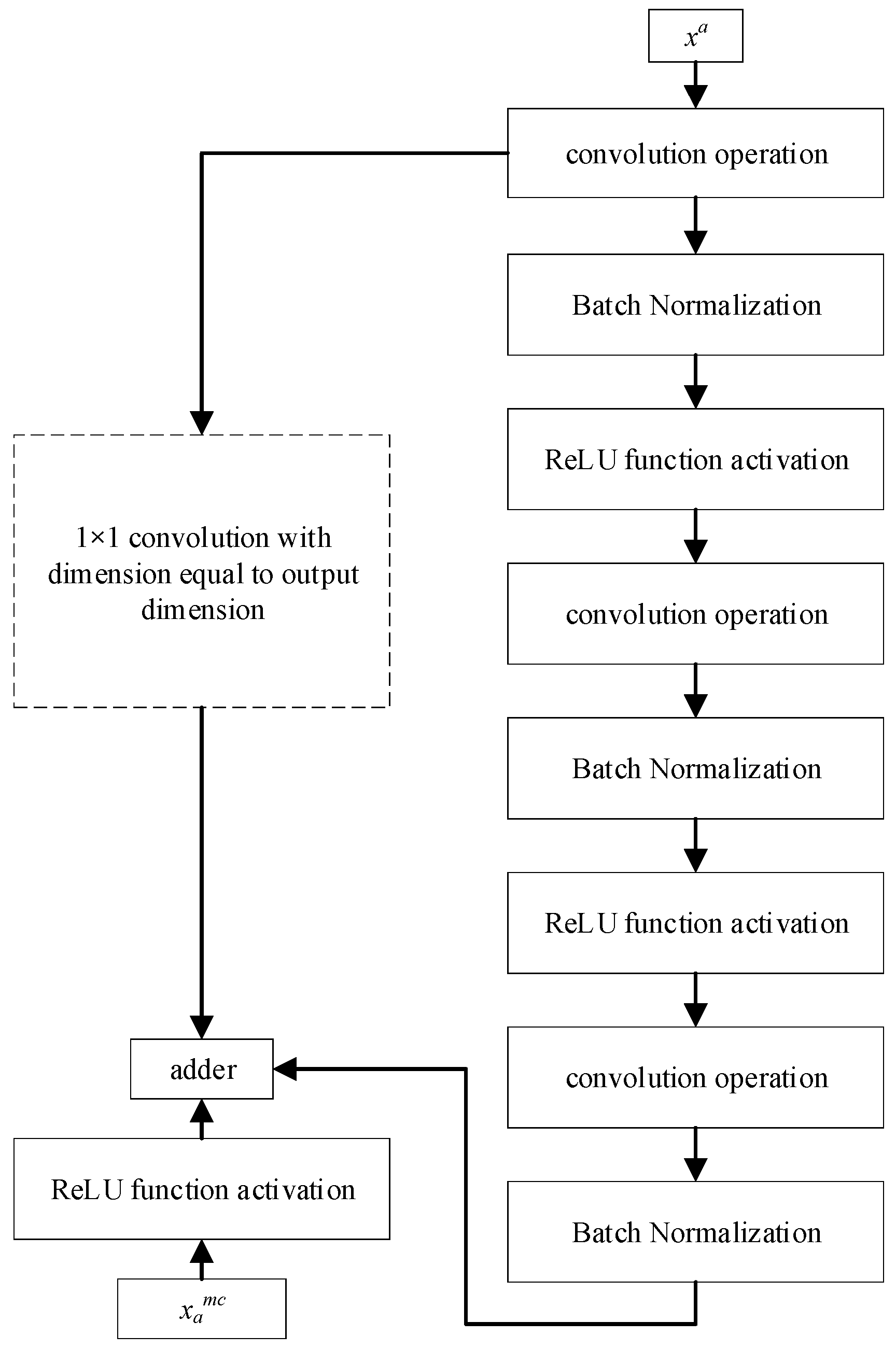

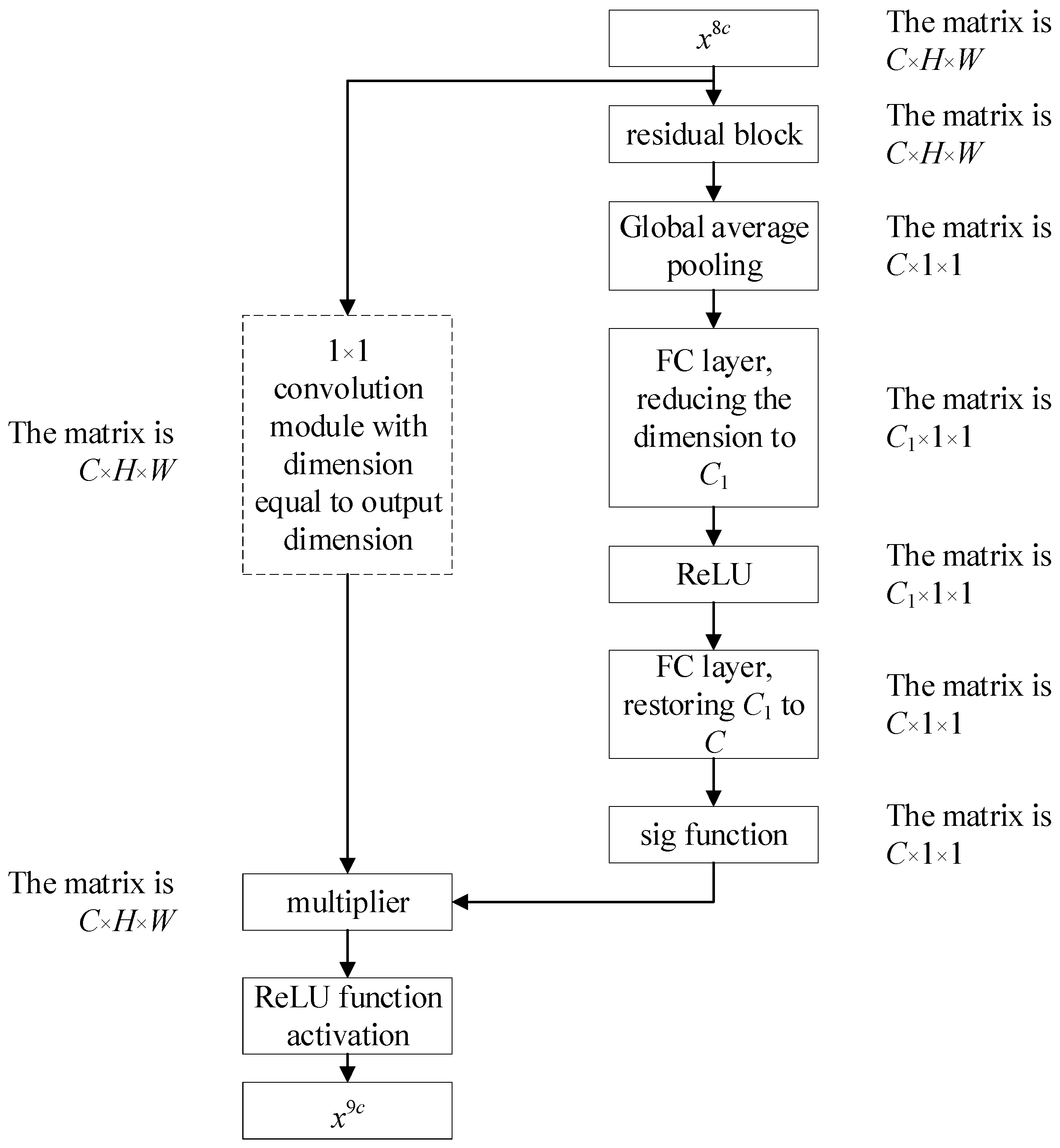

3.2. Channel Weighting Denoising Based on SEnet

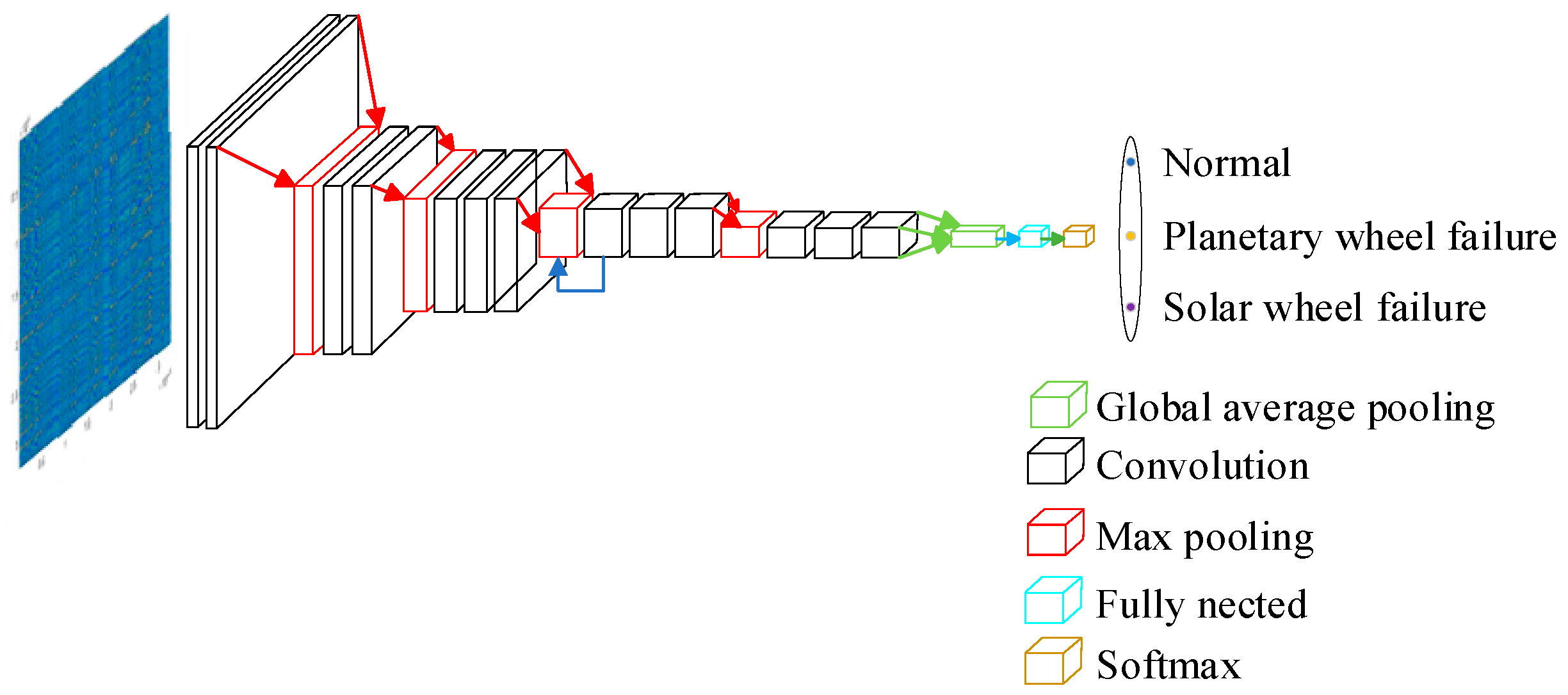

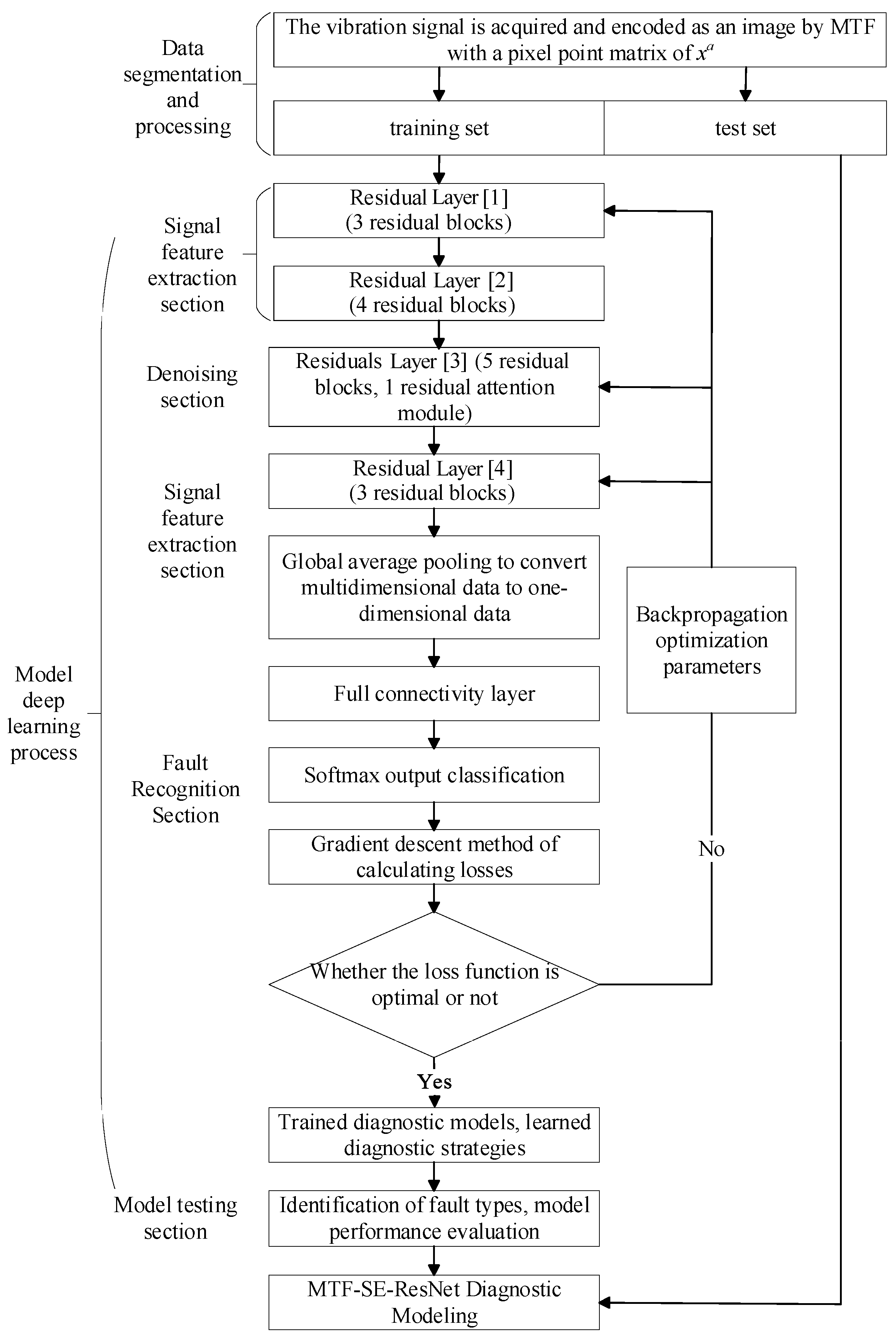

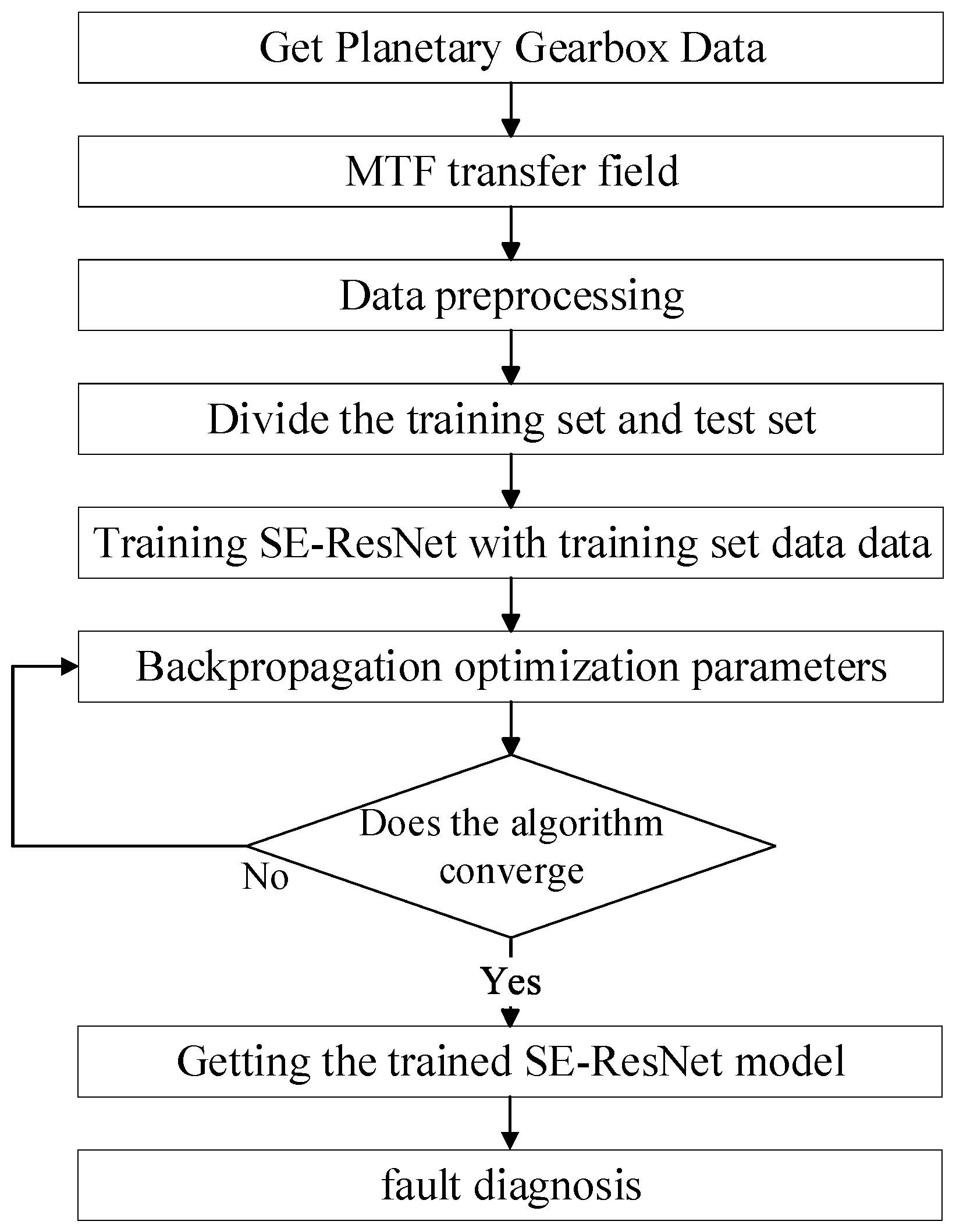

3.3. Fault Classification Model Based on MTF-SE-ResNet

- (1)

- Segmentation of planetary gearbox vibration signals: vibration signals are segmented according to a certain data length.

- (2)

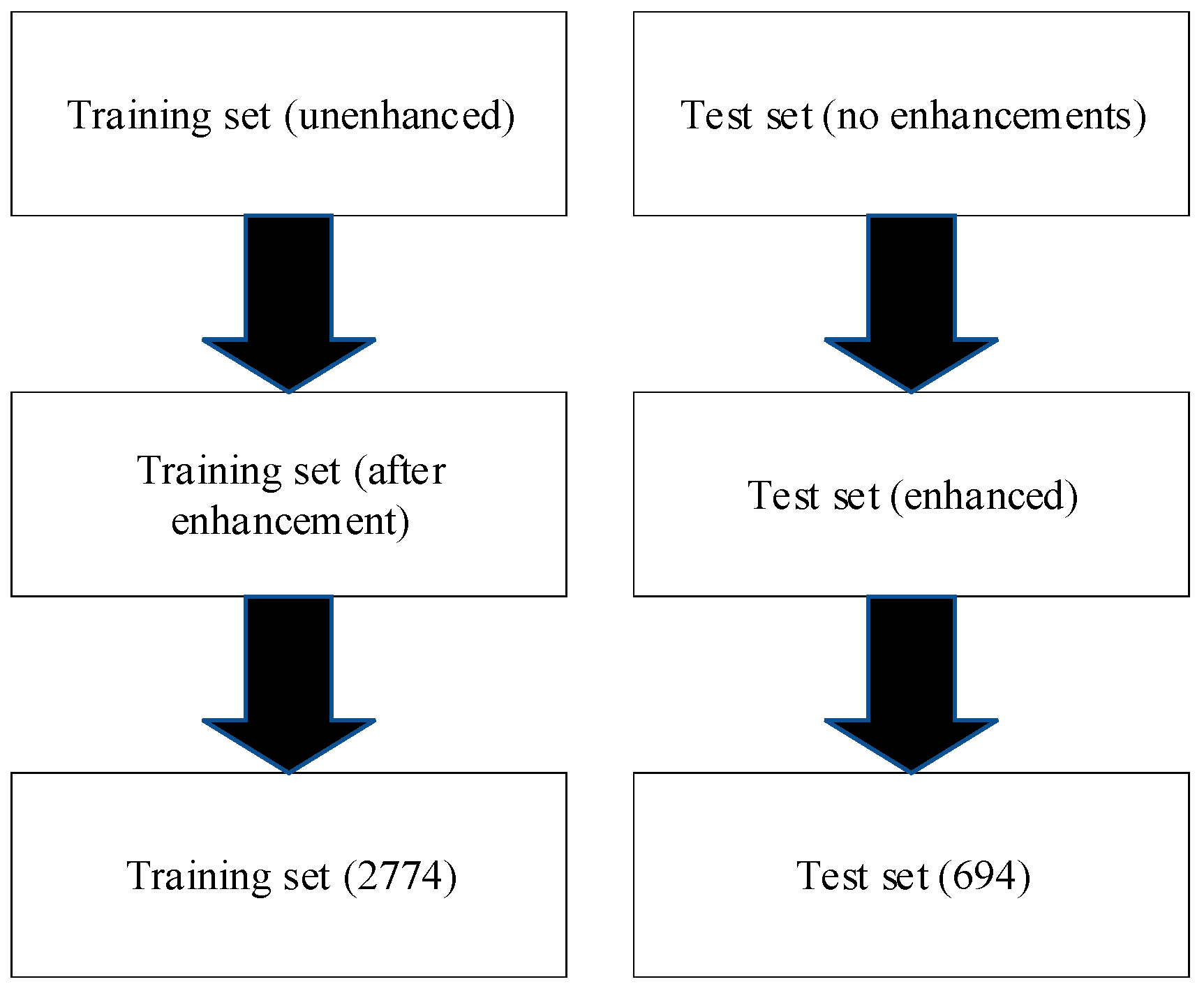

- Conversion and data enhancement: the segmented vibration signals are converted into 2D images using MTF, followed by data enhancement.

- (3)

- Model construction: under the premise that the original Resnet34 network remains unchanged, the fault diagnosis model MTF-SE-ResNet is obtained by inserting the residual attention module after the 1st residual block in the layer [3].

- (4)

- Input and feature extraction: the 2D images are divided into training and test sets and input into the MTF-SE-ResNet network to extract fault information.

- (5)

- Fault diagnosis: fault diagnosis is achieved by global average pooling and mapping the results to fault types using the Softmax function.

4. Experimental Validation and Analysis

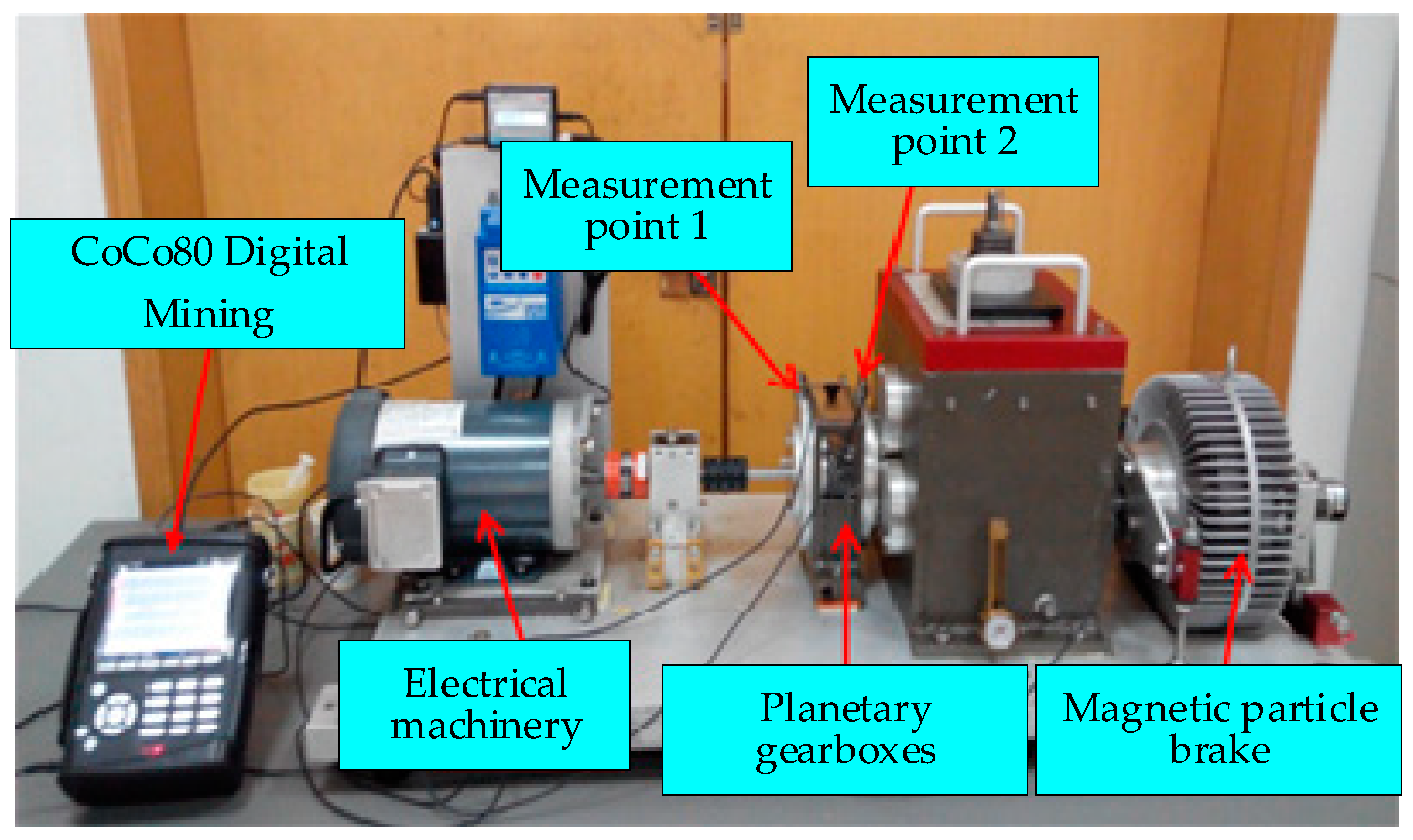

4.1. Test Platforms

4.2. Data Description

4.3. Data Preprocessing

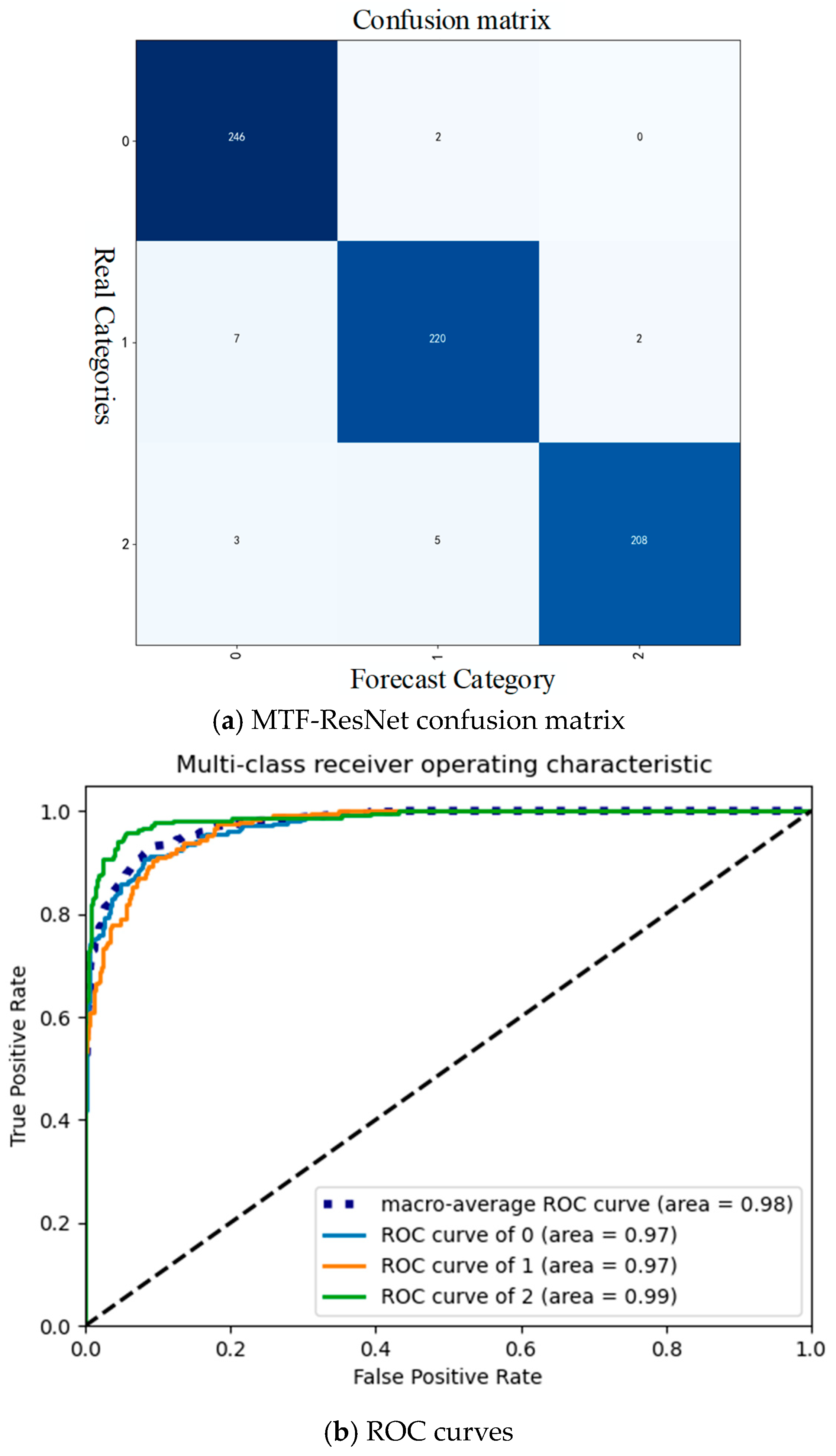

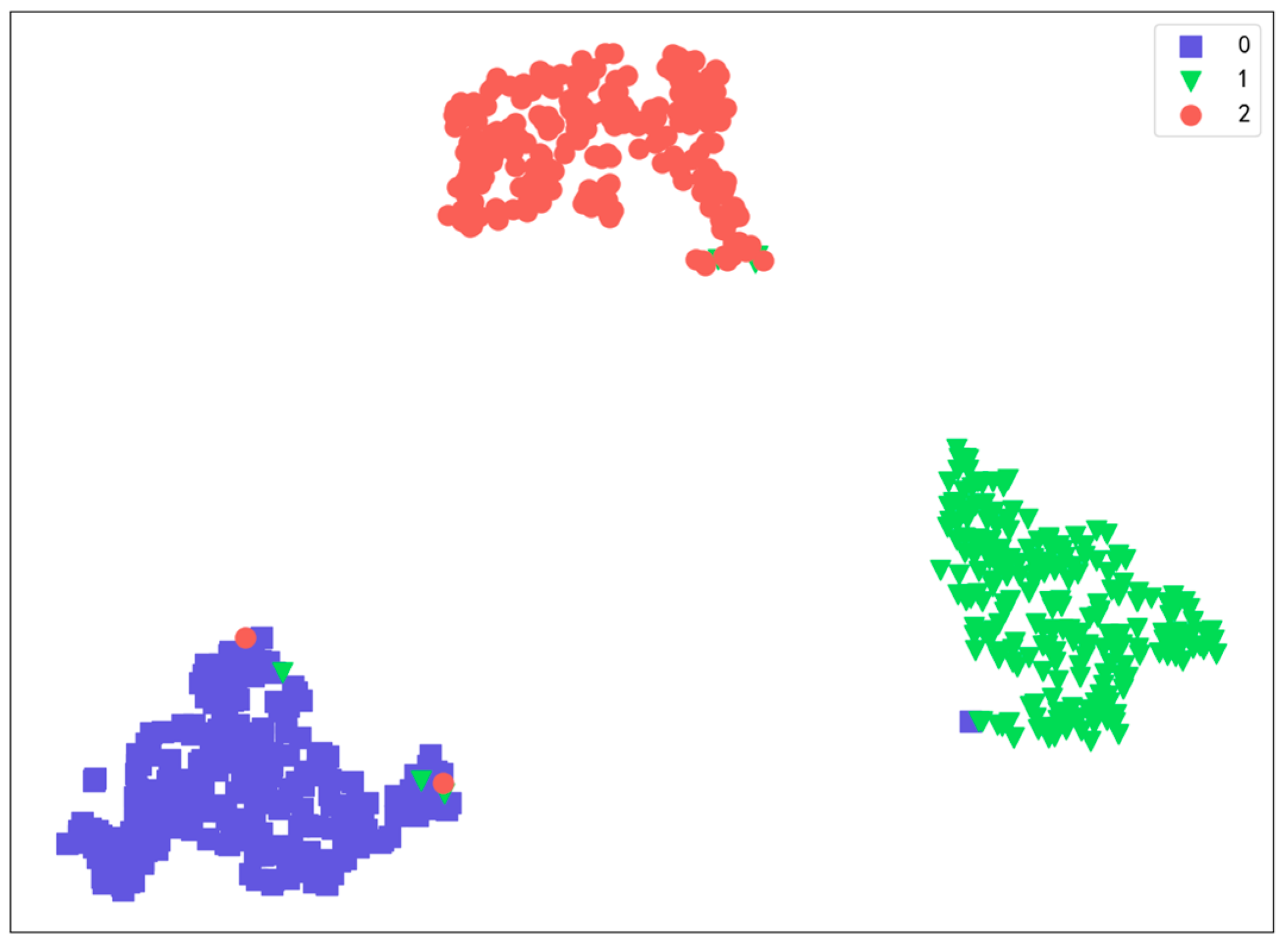

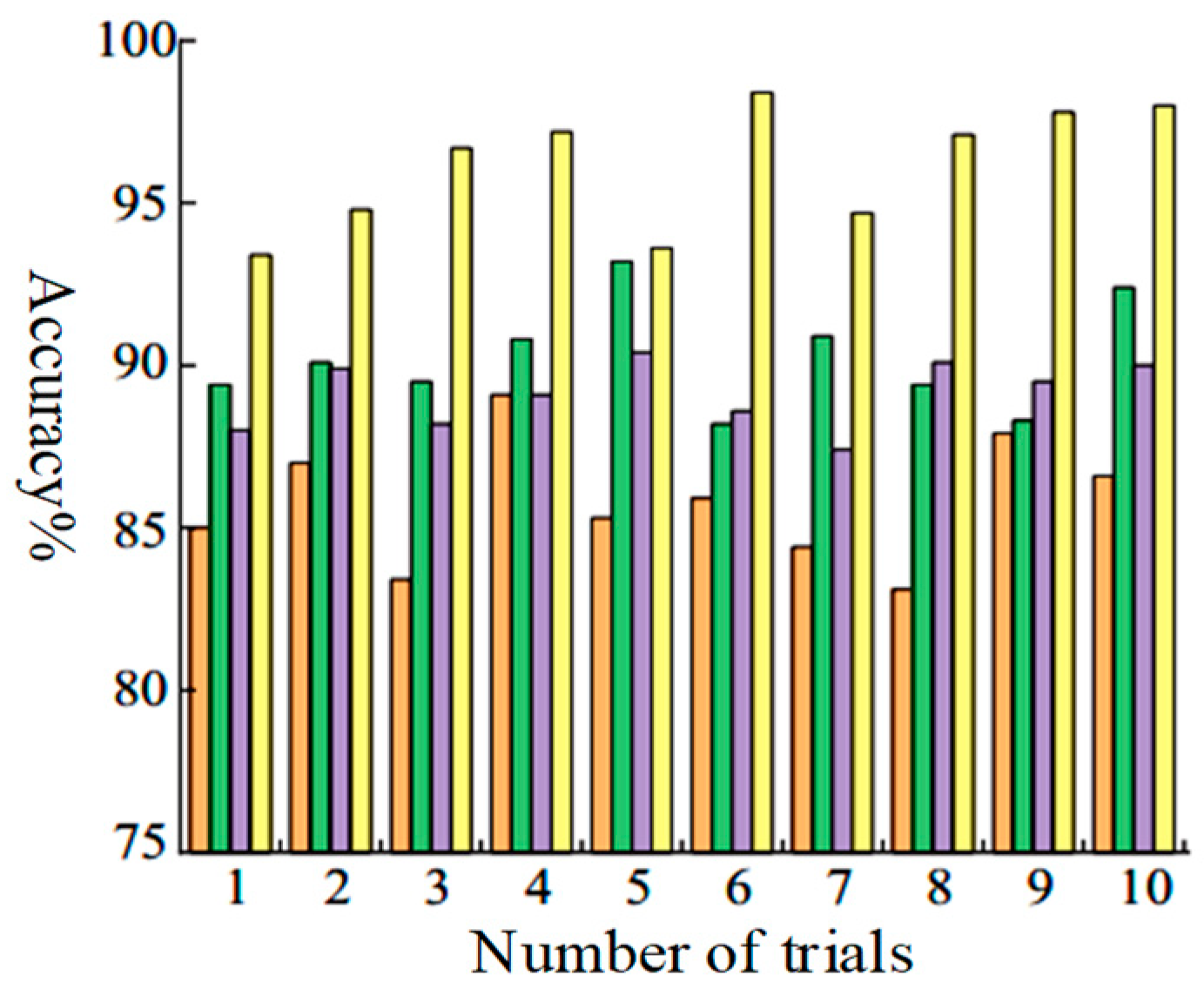

4.4. Comparison and Analysis of Results

5. Conclusions

- (1)

- Fault diagnosis of the planetary gearbox can be transformed into an image recognition task by utilizing the MTF to convert one-dimensional vibration signals into two-dimensional vibration images. As a result, the accuracy and stability of fault diagnosis can be significantly improved using ResNet.

- (2)

- The issue that deep network layers inadvertently learn noise as features is effectively resolved by inserting the SE attention mechanism into the traditional residual network.

- (3)

- Comparative experiments have demonstrated that the proposed method achieves a maximum classification accuracy of 98.1% and an average classification accuracy of 96.5%. This proves that the proposed method meet the engineering application requirements of planetary gearboxes under strong noise backgrounds.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Nejad, A.; Bachynski, E.E.; Moan, T. A comparative study on the dynamic behaviour of 10 MW conventional and compact gearboxes for offshore wind turbines. Wind Energy 2021, 24, 770–789. [Google Scholar] [CrossRef]

- Kim, J.-G.; Park, Y.-J.; Lee, G.-H.; Lee, S.-D.; Oh, J.-Y. Experimental study on the carrier pinhole position error affecting dynamic load sharing of planetary gearboxes. Int. J. Precis. Eng. Manuf. 2018, 19, 881–887. [Google Scholar] [CrossRef]

- Gao, M.; Shang, Z.; Li, W.; Liu, F.; Pang, H.; Liu, J. Analysis of Wear Mechanism and Fault Characteristics of Planet Gears with Multiple Wear Types in Planetary Gearbox. J. Vib. Eng. Technol. 2023, 11, 945–975. [Google Scholar] [CrossRef]

- Ding, C.; Zhao, M.; Lin, J. Sparse feature extraction based on periodical convolutional sparse representation for fault detection of rotating machinery. Meas. Sci. Technol. 2020, 32, 015008. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Gao, S. Current Collection Quality of High-speed Rail Pantograph-catenary Considering Geometry Deviation at 400 km/h and Above. IEEE Trans. Veh. Technol. 2024, 73, 14415–14424. [Google Scholar] [CrossRef]

- D’Elia, G.; Mucchi, E.; Cocconcelli, M. On the identification of the angular position of gears for the diagnostics of planetary gearboxes. Mech. Syst. Signal Process. 2017, 83, 305–320. [Google Scholar] [CrossRef]

- Wang, X.; Si, S.; Li, Y. Multiscale diversity entropy: A novel dynamical measure for fault diagnosis of rotating machinery. IEEE Trans. Ind. Inform. 2020, 17, 5419–5429. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Yang, Y.; Deng, Z. Multiscale symbolic fuzzy entropy: An entropy denoising method for weak feature extraction of rotating machinery. Mech. Syst. Signal Process. 2022, 162, 108052. [Google Scholar] [CrossRef]

- Milovančević, M.; Nikolić, V.; Petkovic, D.; Vracar, L.; Veg, E.; Tomic, N.; Jović, S. Vibration analyzing in horizontal pumping aggregate by soft computing. Measurement 2018, 125, 454–462. [Google Scholar] [CrossRef]

- Pang, X.; Xue, X.; Jiang, W.; Lu, K. An investigation into fault diagnosis of planetary gearboxes using a bispectrum convolutional neural network. IEEE/ASME Trans. Mechatron. 2020, 26, 2027–2037. [Google Scholar] [CrossRef]

- Li, Y.; Du, X.; Wan, F.; Wang, X.; Yu, H. Rotating machinery fault diagnosis based on convolutional neural network and infrared thermal imaging. Chin. J. Aeronaut. 2020, 33, 427–438. [Google Scholar] [CrossRef]

- Wang, D.-F.; Guo, Y.; Wu, X.; Na, J.; Litak, G. Planetary-gearbox fault classification by convolutional neural network and recurrence plot. Appl. Sci. 2020, 10, 932. [Google Scholar] [CrossRef]

- Scholtyssek, J.; Bislich, L.J.; Cordes, F.; Krieger, K.-L. Vibration-Based Detection of Bearing Damages in a Planetary Gearbox Using Convolutional Neural Networks. Appl. Sci. 2023, 13, 8239. [Google Scholar] [CrossRef]

- Chen, R.; Huang, X.; Yang, L.; Xu, X.; Zhang, X.; Zhang, Y. Intelligent fault diagnosis method of planetary gearboxes based on convolution neural network and discrete wavelet transform. Comput. Ind. 2019, 106, 48–59. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, X.; Sun, B.; Zhai, J.; Liu, Z. Multireceptive field denoising residual convolutional networks for fault diagnosis. IEEE Trans. Ind. Electron. 2021, 69, 11686–11696. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Zhao, Z.; Wang, R. A novel method for multi-fault feature extraction of a gearbox under strong background noise. Entropy 2017, 20, 10. [Google Scholar] [CrossRef]

- Zhao, M.; Kang, M.; Tang, B.; Pecht, M. Deep residual networks with dynamically weighted wavelet coefficients for fault diagnosis of planetary gearboxes. IEEE Trans. Ind. Electron. 2017, 65, 4290–4300. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, B.; Deng, L.; Tan, Q.; Yu, H. A fault diagnosis method for wind turbines gearbox based on adaptive loss weighted meta-ResNet under noisy labels. Mech. Syst. Signal Process. 2021, 161, 107963. [Google Scholar] [CrossRef]

- Xin, P.; Yang, K.X.; Wen, X.Q. Research on wind turbine fault diagnosis method based on improved SE-CNN. J. Jilin Inst. Chem. Technol. 2023, 40, 34–40. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, F.; Liu, Y.; Zha, X.; Yuan, S. A comparison of 1-D and 2-D deep convolutional neural networks in ECG classification. In Proceedings of the IEEE Engineering in Medicine and Biology Society, Honolulu, HI, USA, 17–21 July 2018. [Google Scholar] [CrossRef]

- Xu, M.Q.; Wang, Y.Q. An imbalanced fault diagnosis method for rolling bearing based on semi- supervised conditional generative adversarial network with spectral normalization. IEEE Access 2021, 9, 27736–27747. [Google Scholar] [CrossRef]

- Hu, J.; Shen, L.; Sun, G. Squeeze-and-excitation networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Gao, T.; Wu, W.; Sun, Y. Planetary Gearboxes Fault Diagnosis Based on Markov Transition Fields and SE-ResNet. Sensors 2024, 24, 7540. https://doi.org/10.3390/s24237540

Liu Y, Gao T, Wu W, Sun Y. Planetary Gearboxes Fault Diagnosis Based on Markov Transition Fields and SE-ResNet. Sensors. 2024; 24(23):7540. https://doi.org/10.3390/s24237540

Chicago/Turabian StyleLiu, Yanyan, Tongxin Gao, Wenxu Wu, and Yongquan Sun. 2024. "Planetary Gearboxes Fault Diagnosis Based on Markov Transition Fields and SE-ResNet" Sensors 24, no. 23: 7540. https://doi.org/10.3390/s24237540

APA StyleLiu, Y., Gao, T., Wu, W., & Sun, Y. (2024). Planetary Gearboxes Fault Diagnosis Based on Markov Transition Fields and SE-ResNet. Sensors, 24(23), 7540. https://doi.org/10.3390/s24237540