In-Depth Analysis of Low-Cost Micro Electromechanical System (MEMS) Accelerometers in the Context of Low Frequencies and Vibration Amplitudes

Abstract

1. Introduction

1.1. Background for the Genesis of the Research Topic

1.2. MEMS Accelerometer Applications in the Context of Safety Monitoring

2. Materials and Methods

- Initial selection of sensors based on an assessment of the stability of their readings;

- Analysis of selected sensors in terms of the minimum acceleration amplitude threshold that can be correctly identified and interpreted by algorithms running in embedded systems.

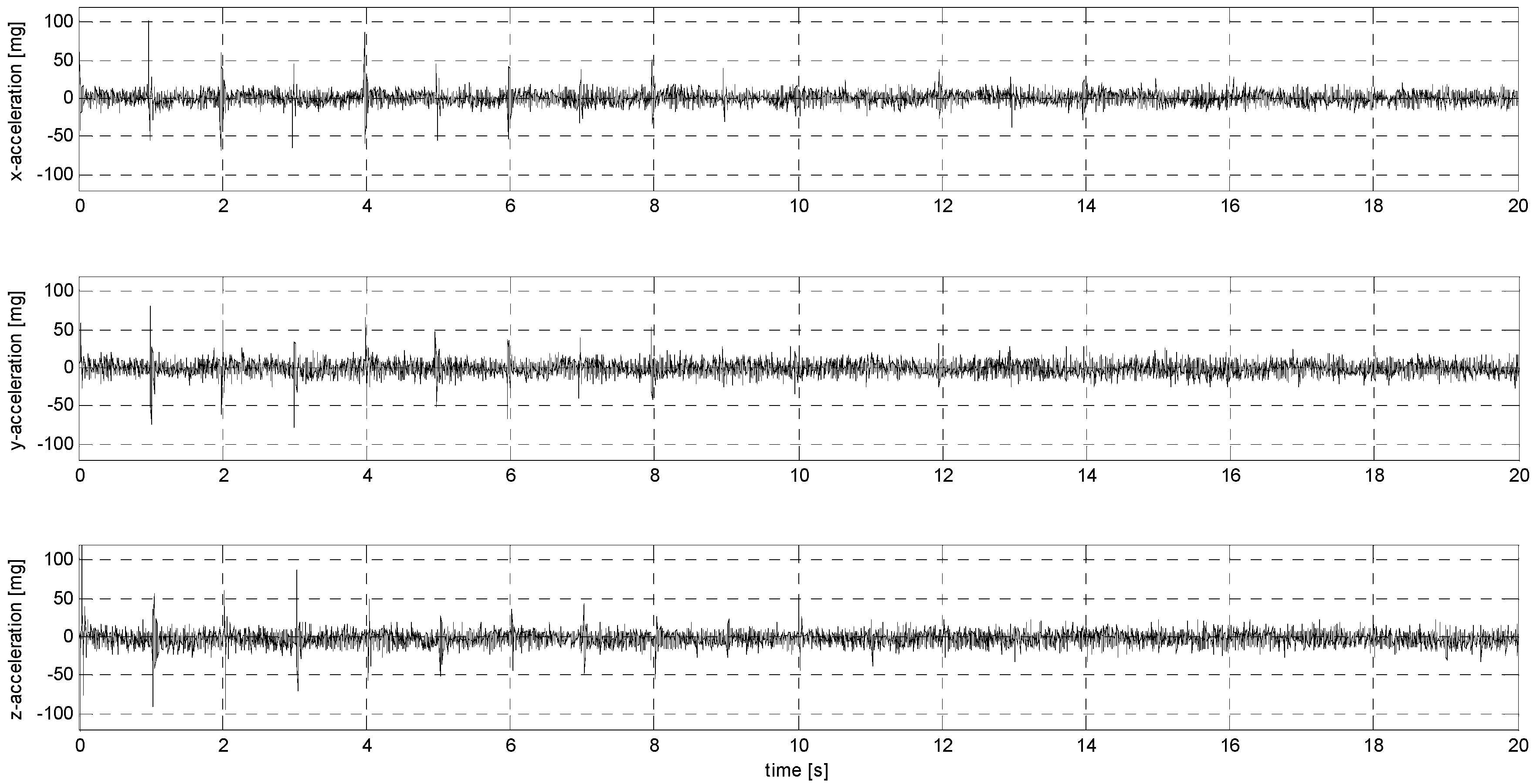

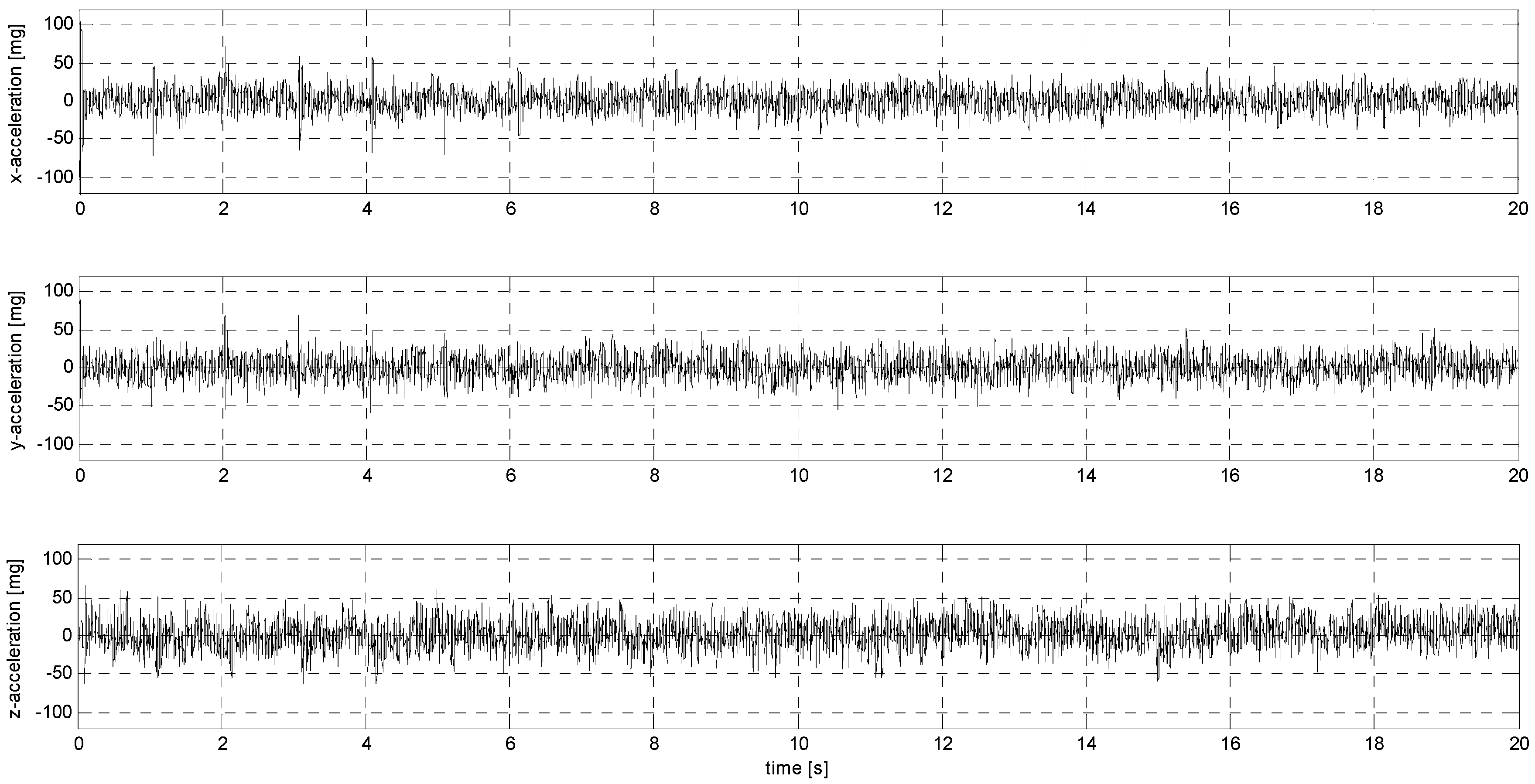

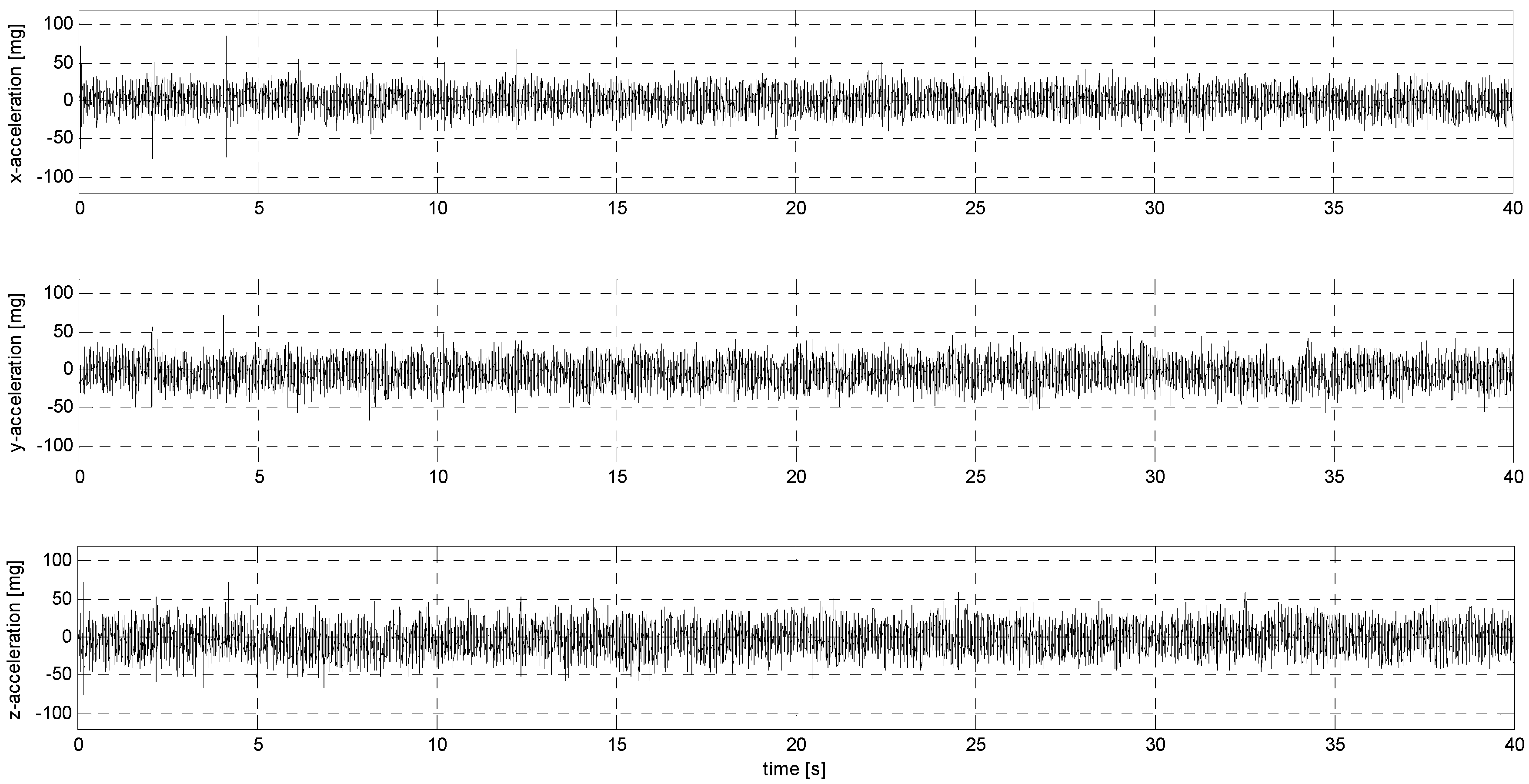

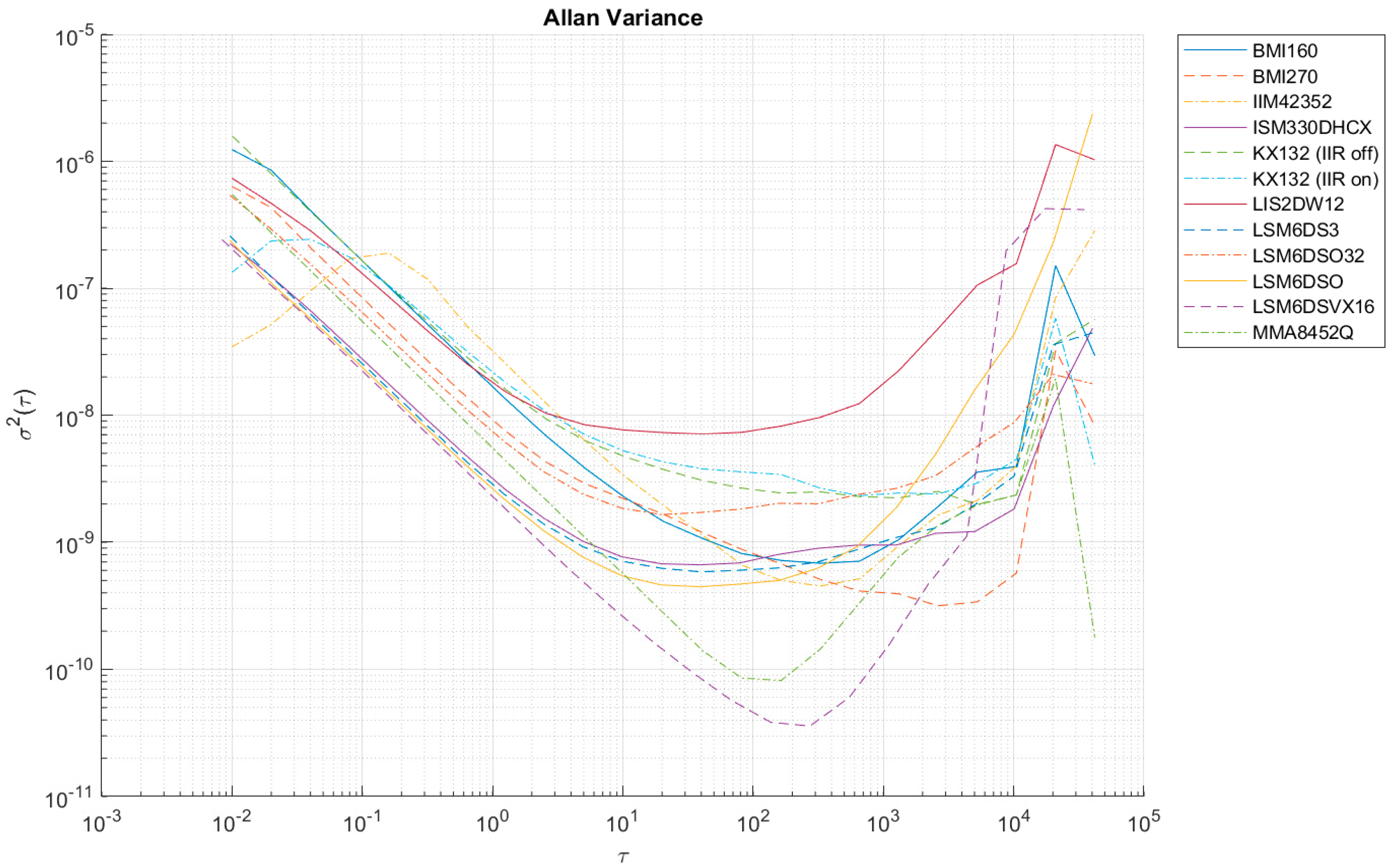

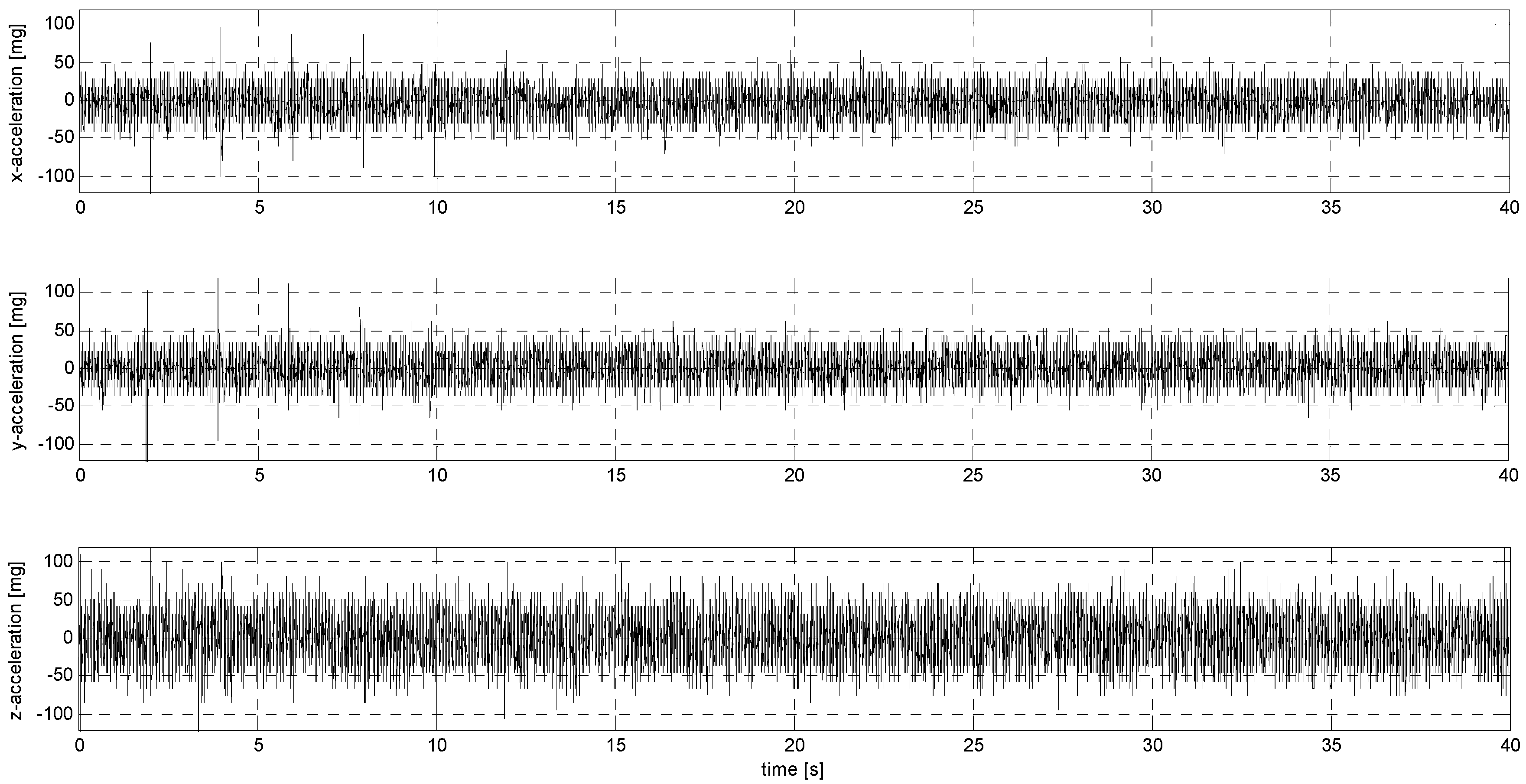

2.1. Stage I: Stability Testing

2.1.1. Selection of MEMS Accelerometers for Stability Testing

2.1.2. Method and Experimental Setup for Stability Testing

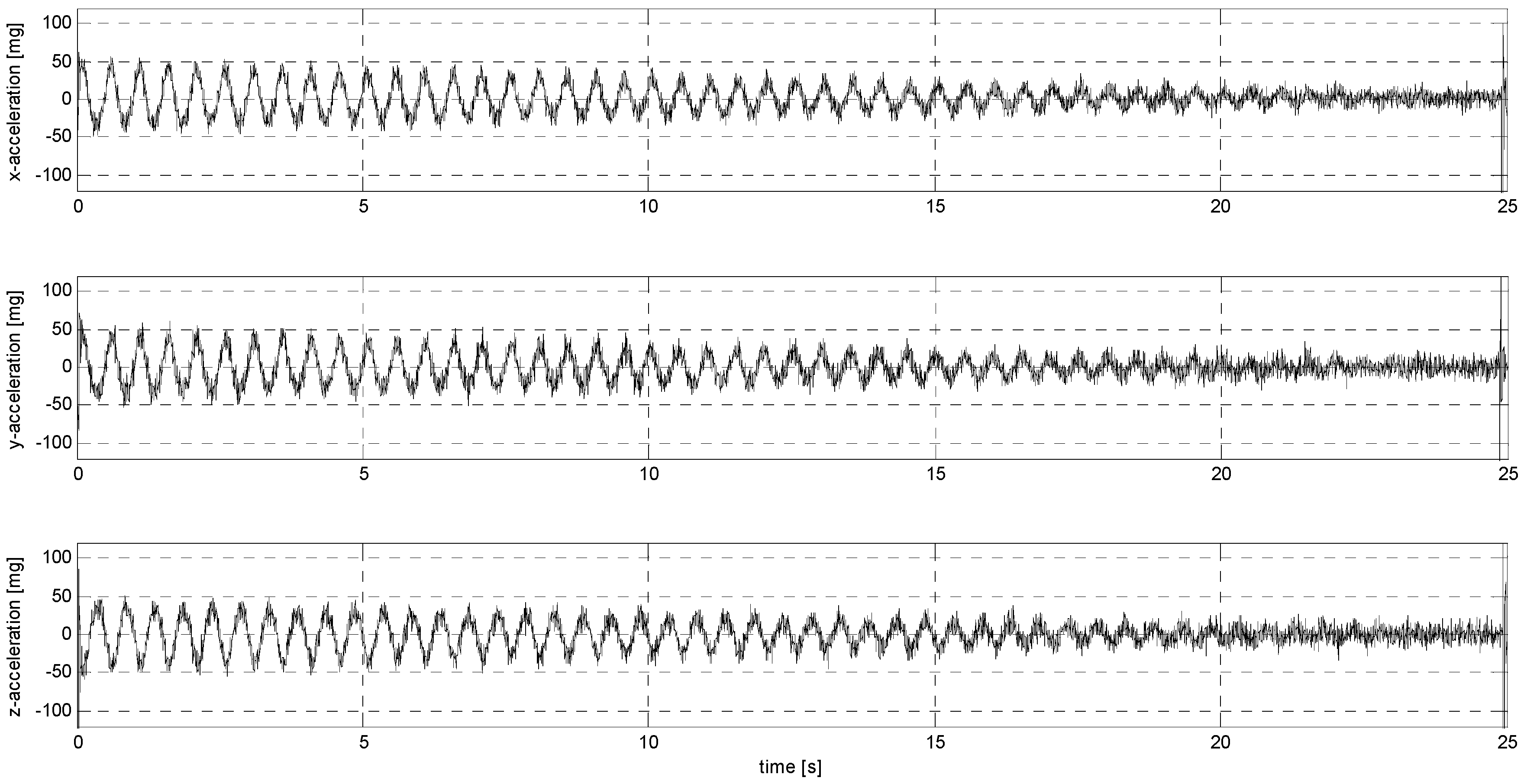

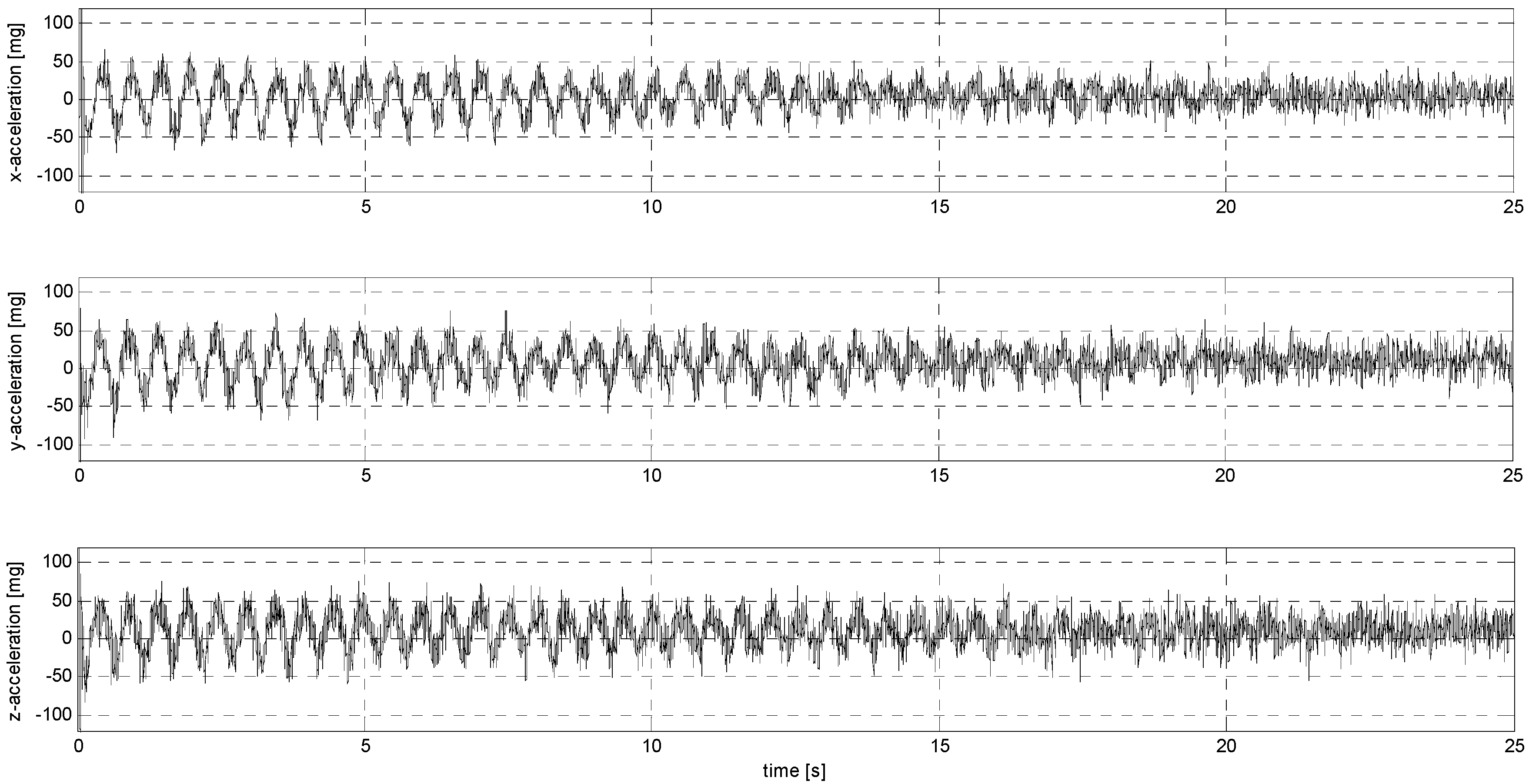

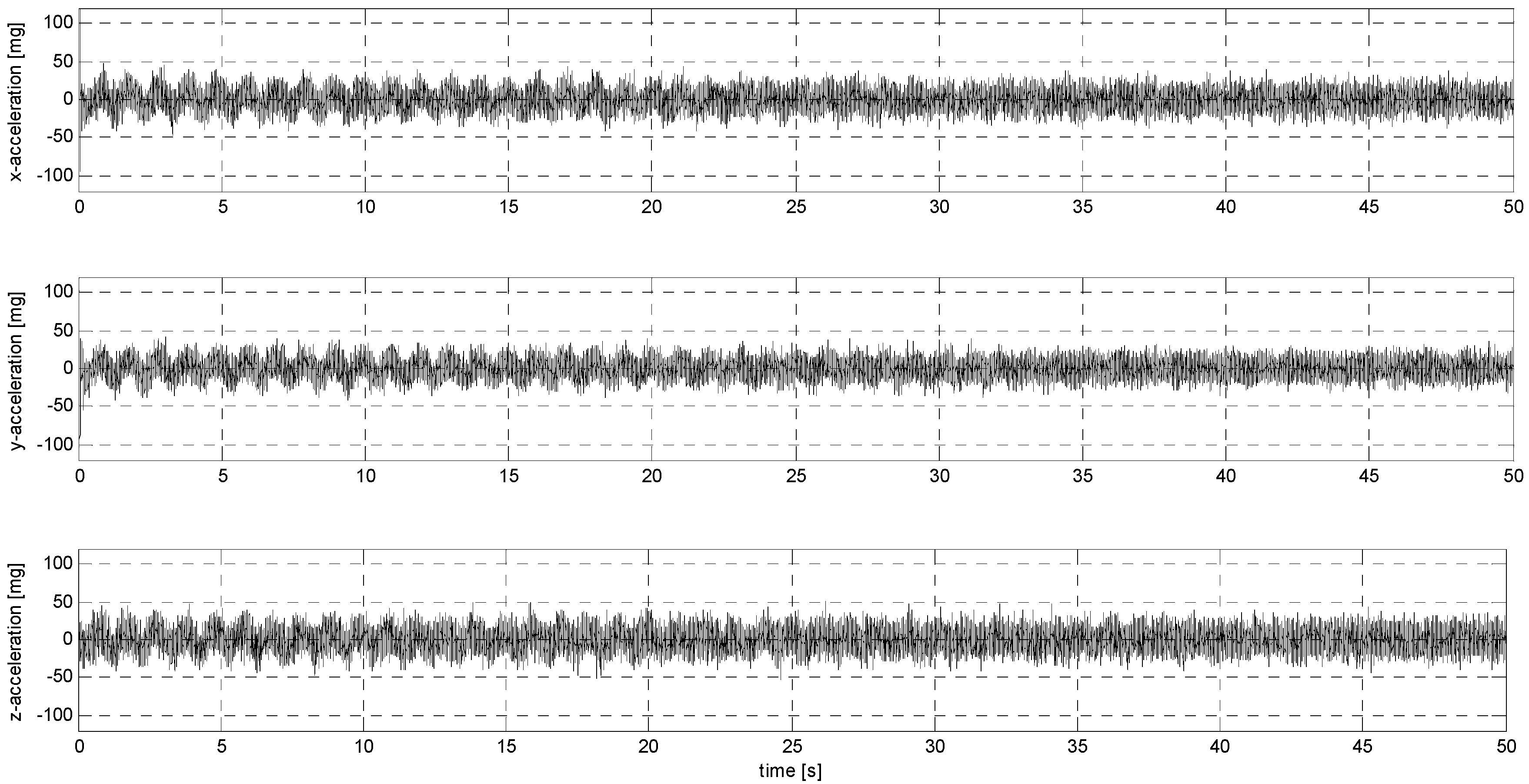

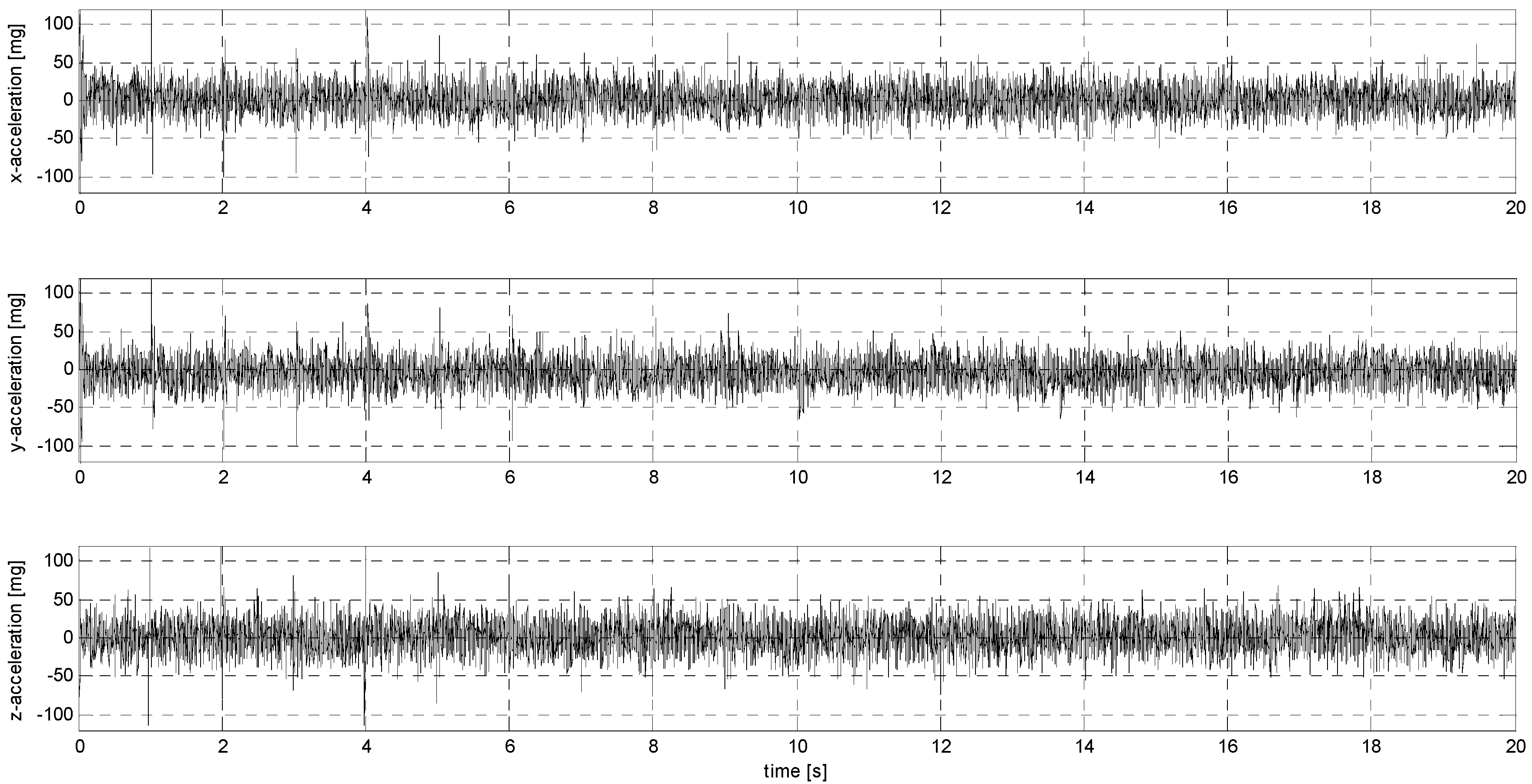

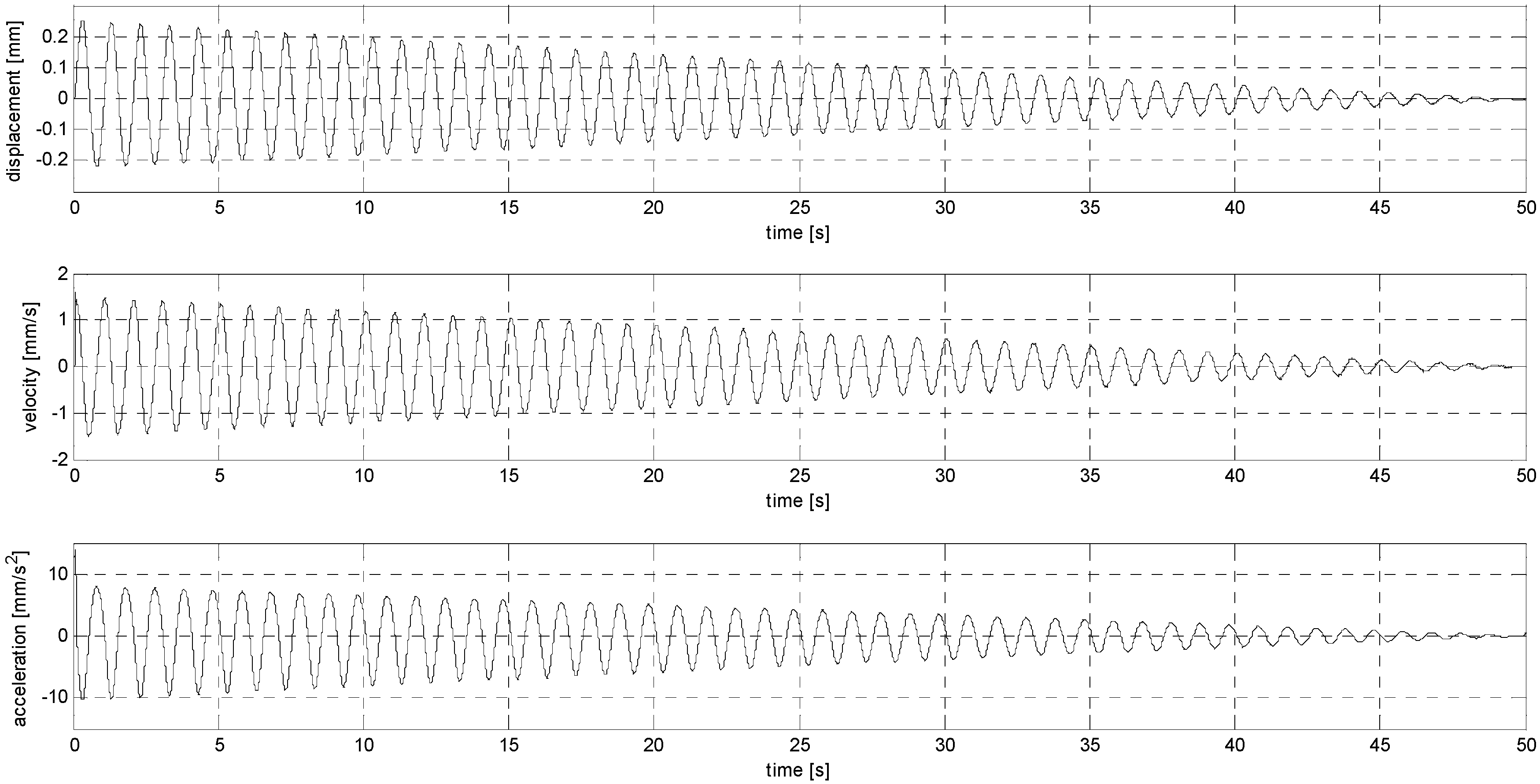

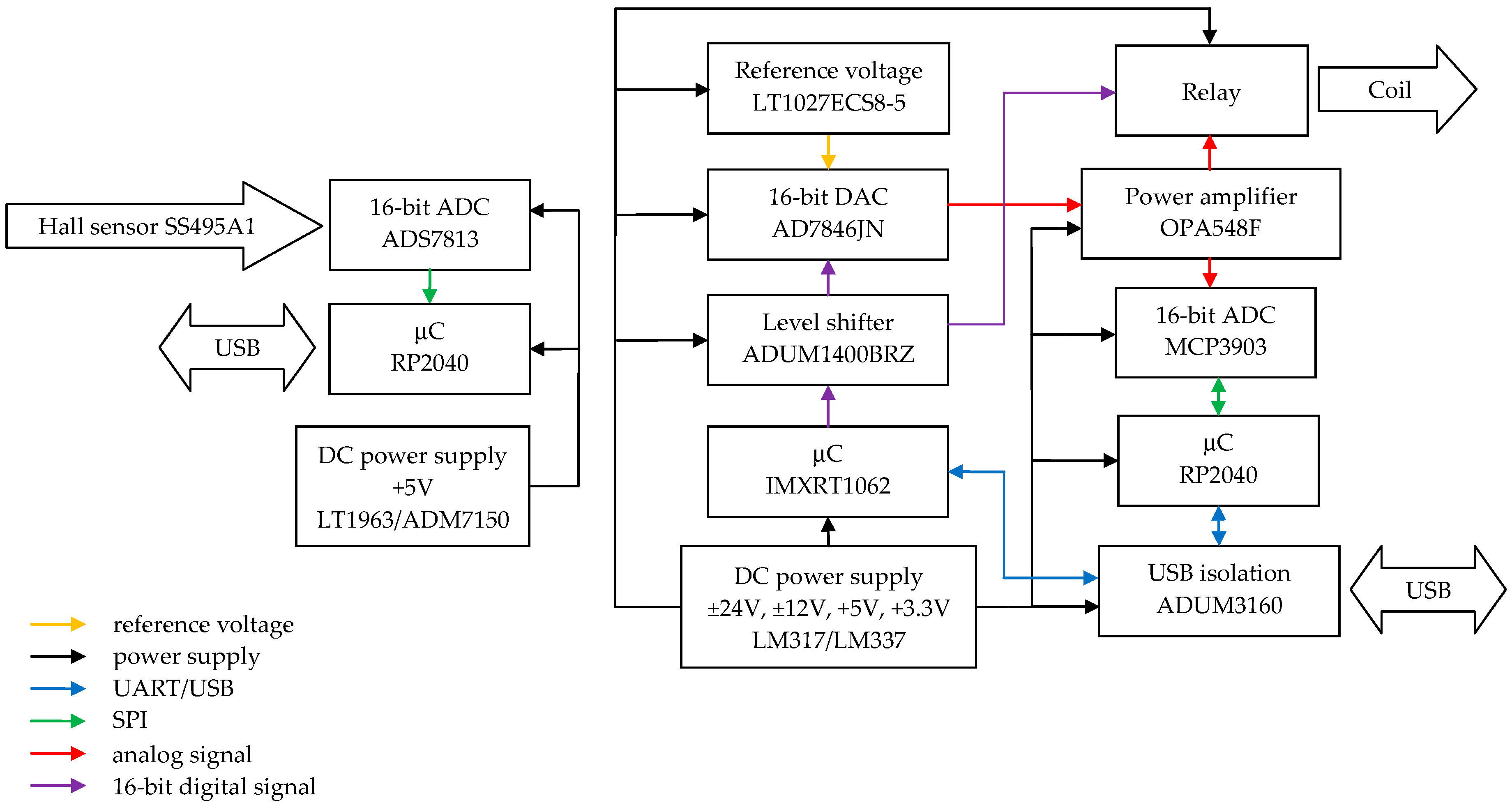

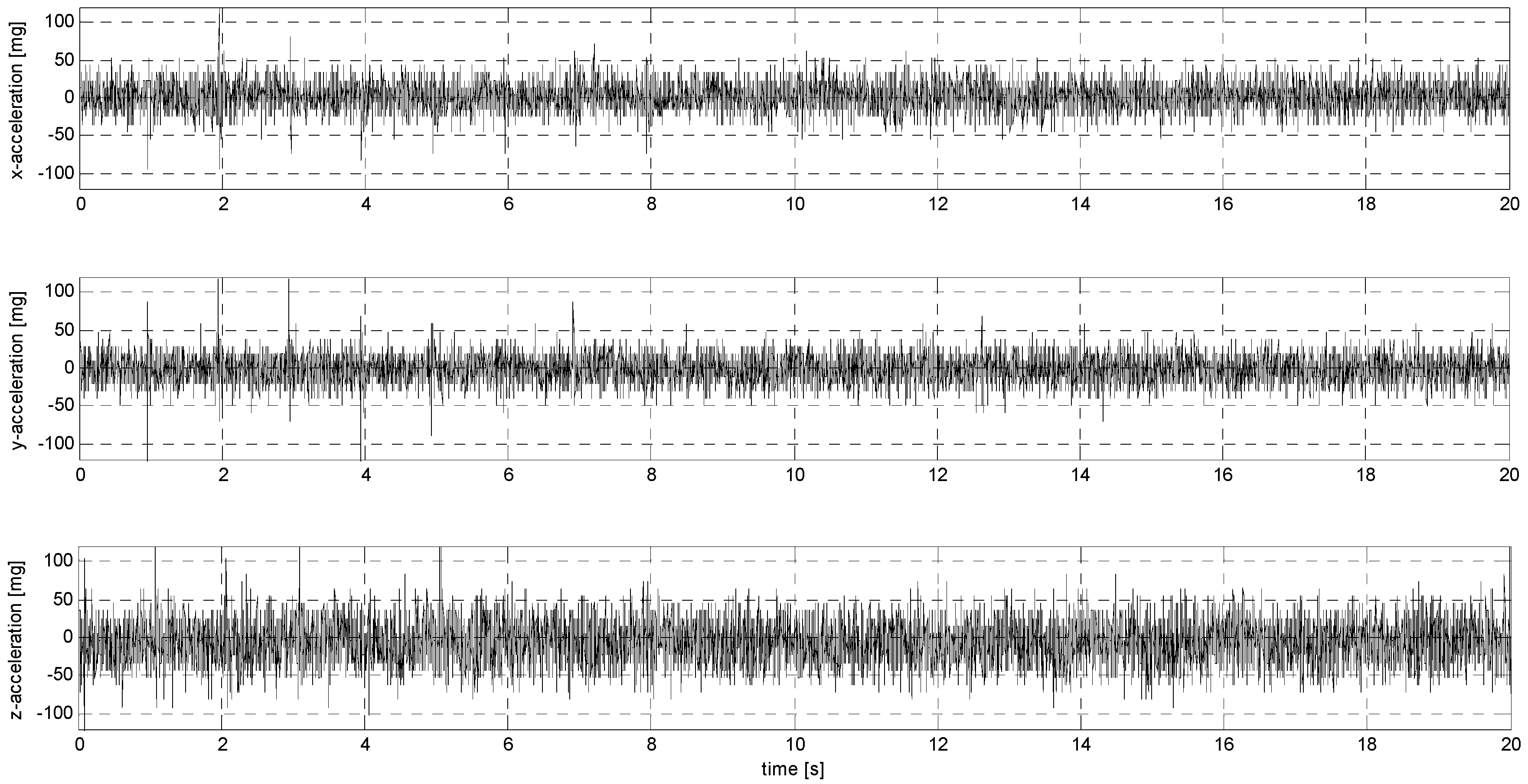

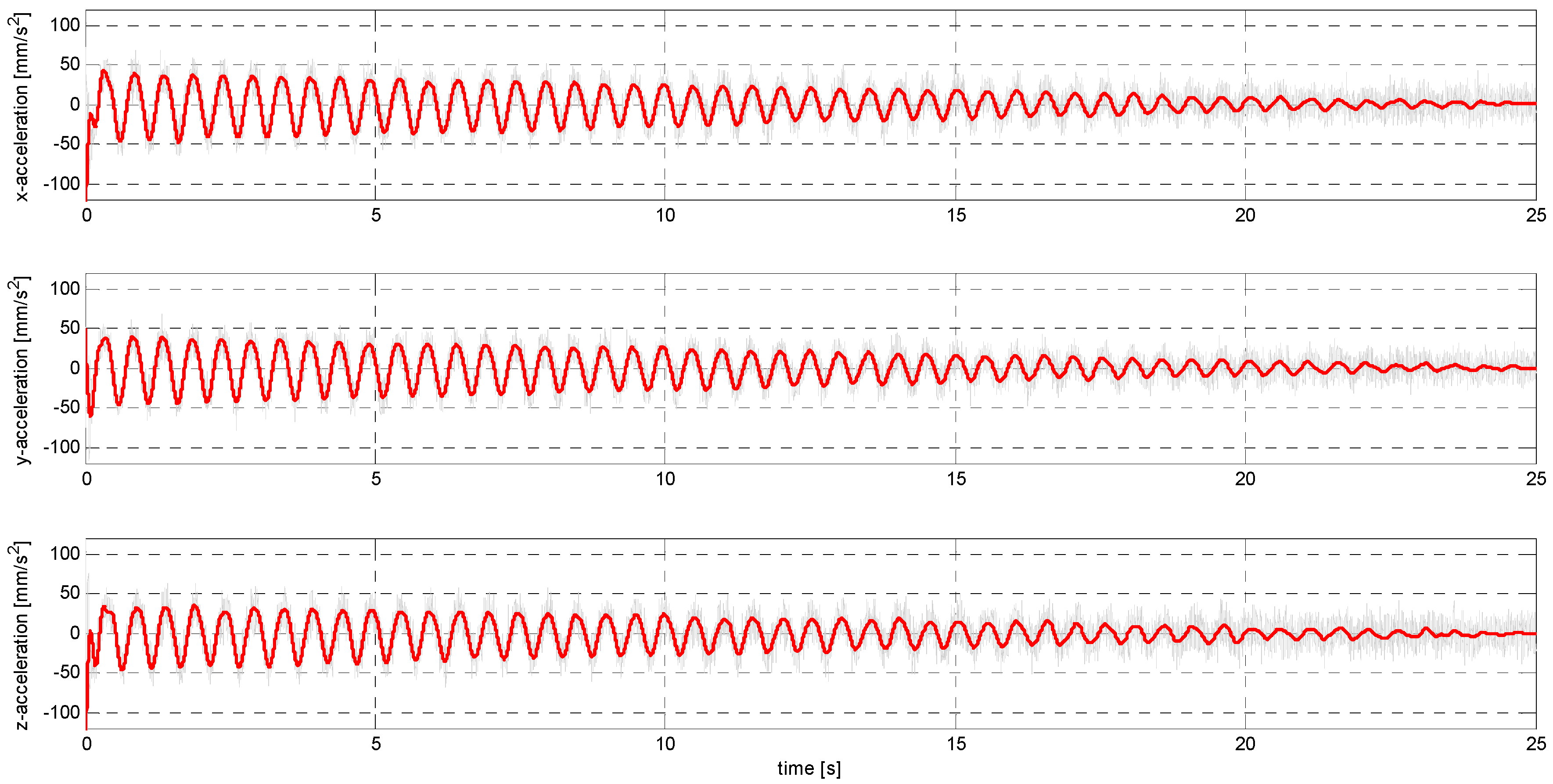

2.2. Stage II: Determination of Identifiable Minimum Amplitude of Low-Frequency Vibrations

2.2.1. Selection of MEMS Accelerometers for Stage II Testing

2.2.2. Method and Experimental Setup for Stage II Testing

- Extracting the signal from the raw data using a low-pass filter with an assumed cutoff frequency (cleaned signal);

- Determination of the noise based on the difference of the signals: raw and cleaned;

- Determination of the raw signal-to-noise ratio (SNR);

- Determination of the ratio of the cleaned signal to the noise (modified SNR, MSNR);

- Determination of the effective number of bits based on the SNR (ENOB);

- Determination of the threshold amplitudes based on the ENOB and MSNR.

3. Results

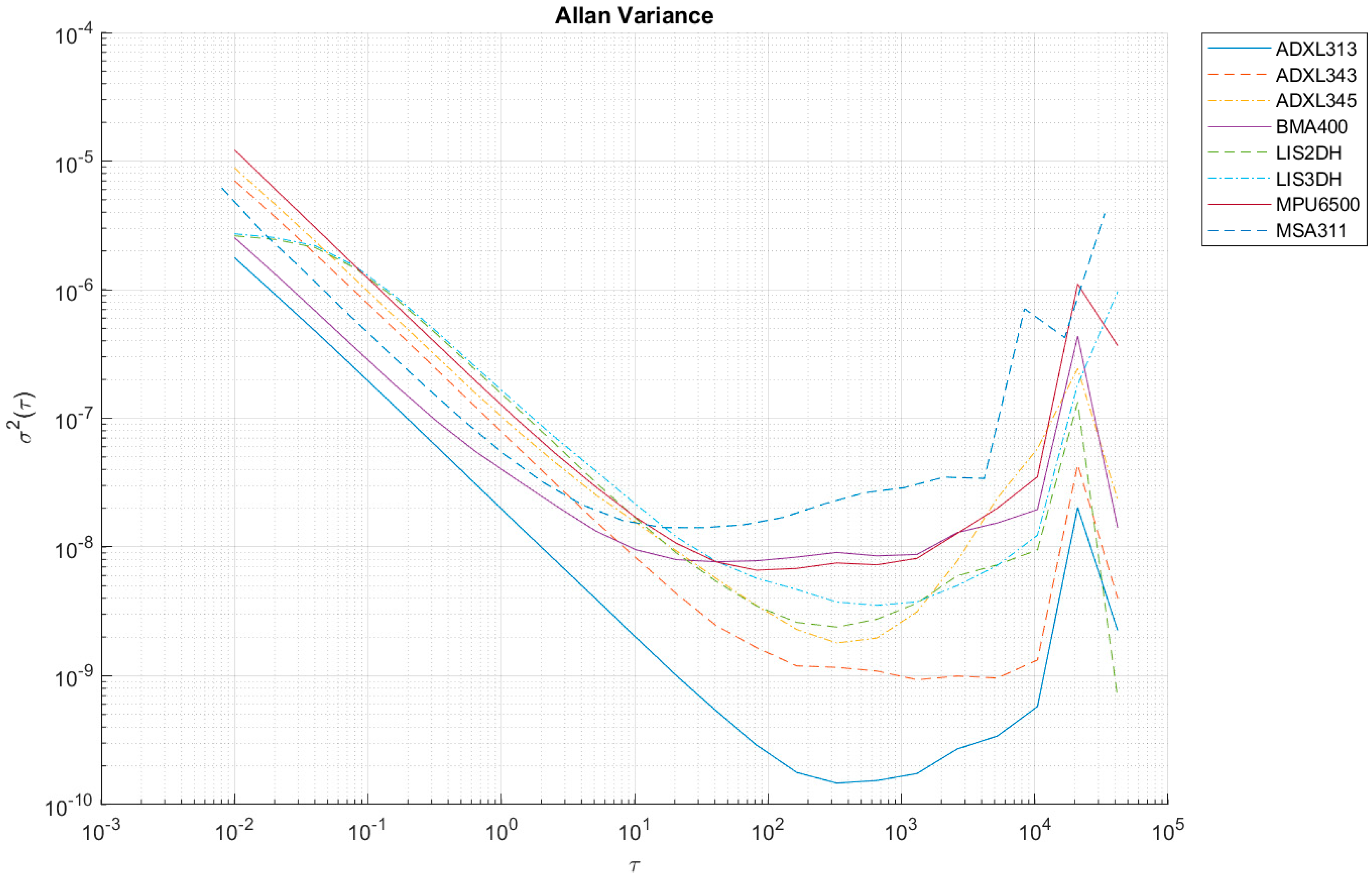

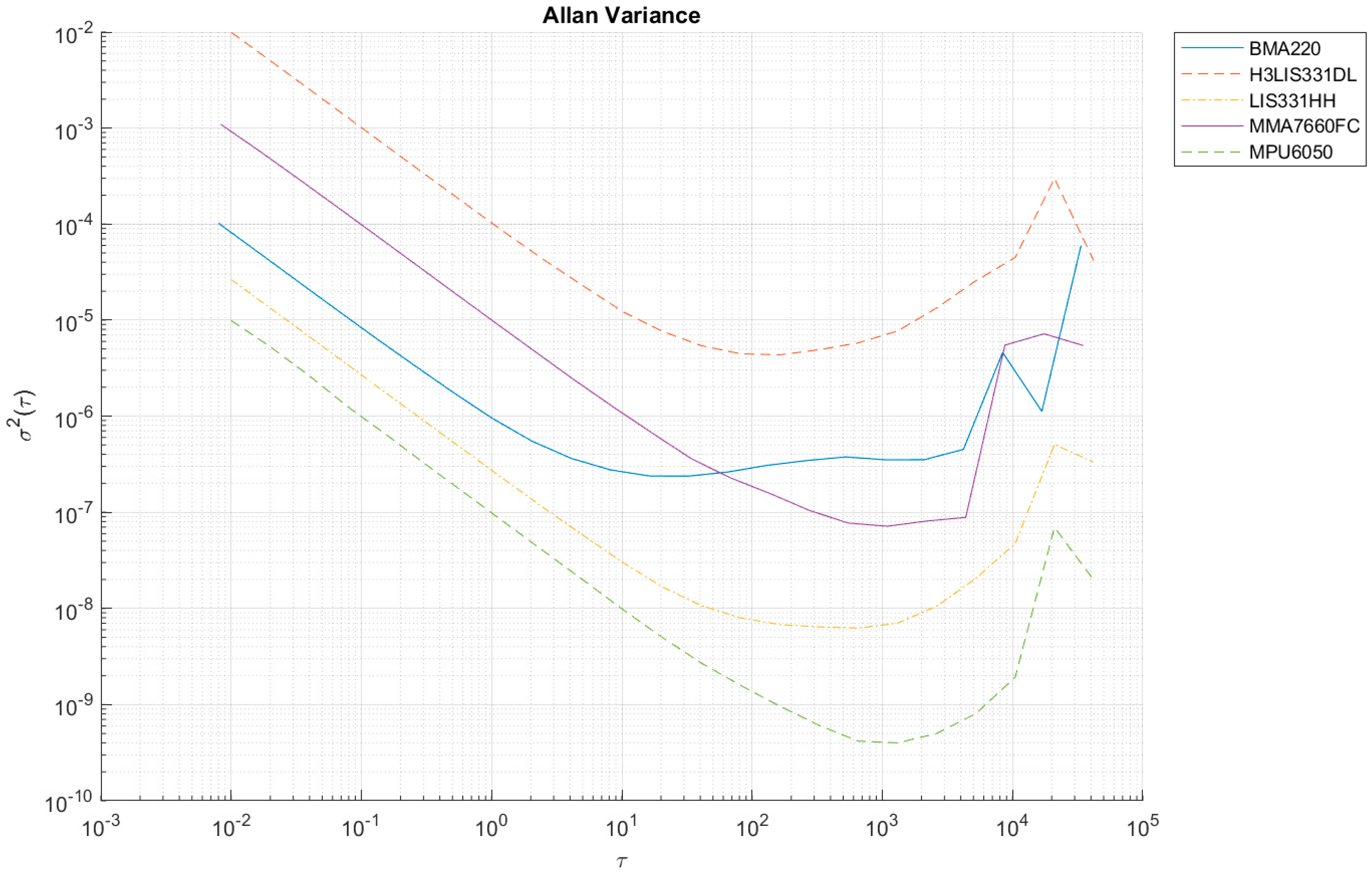

3.1. Stage I: Results

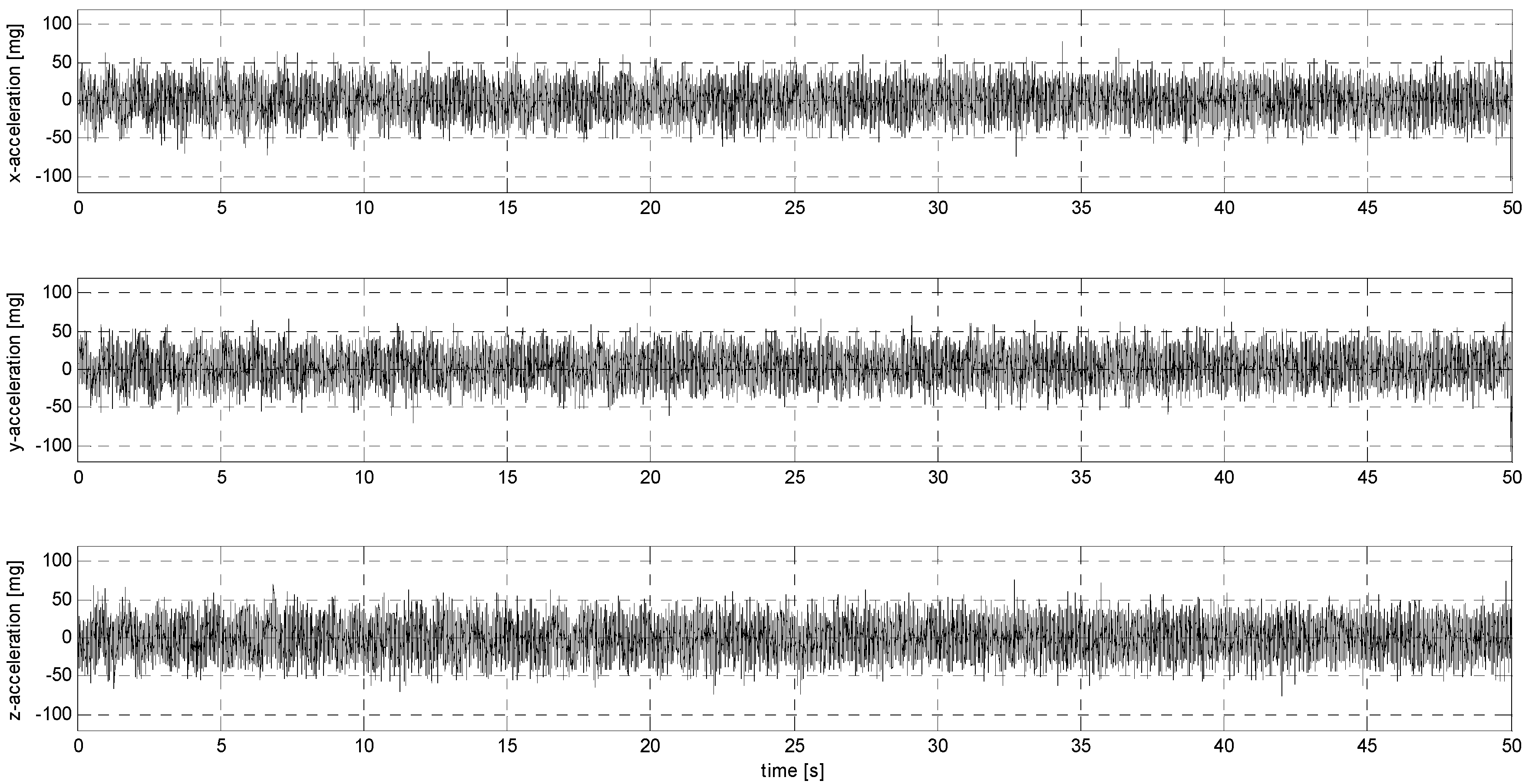

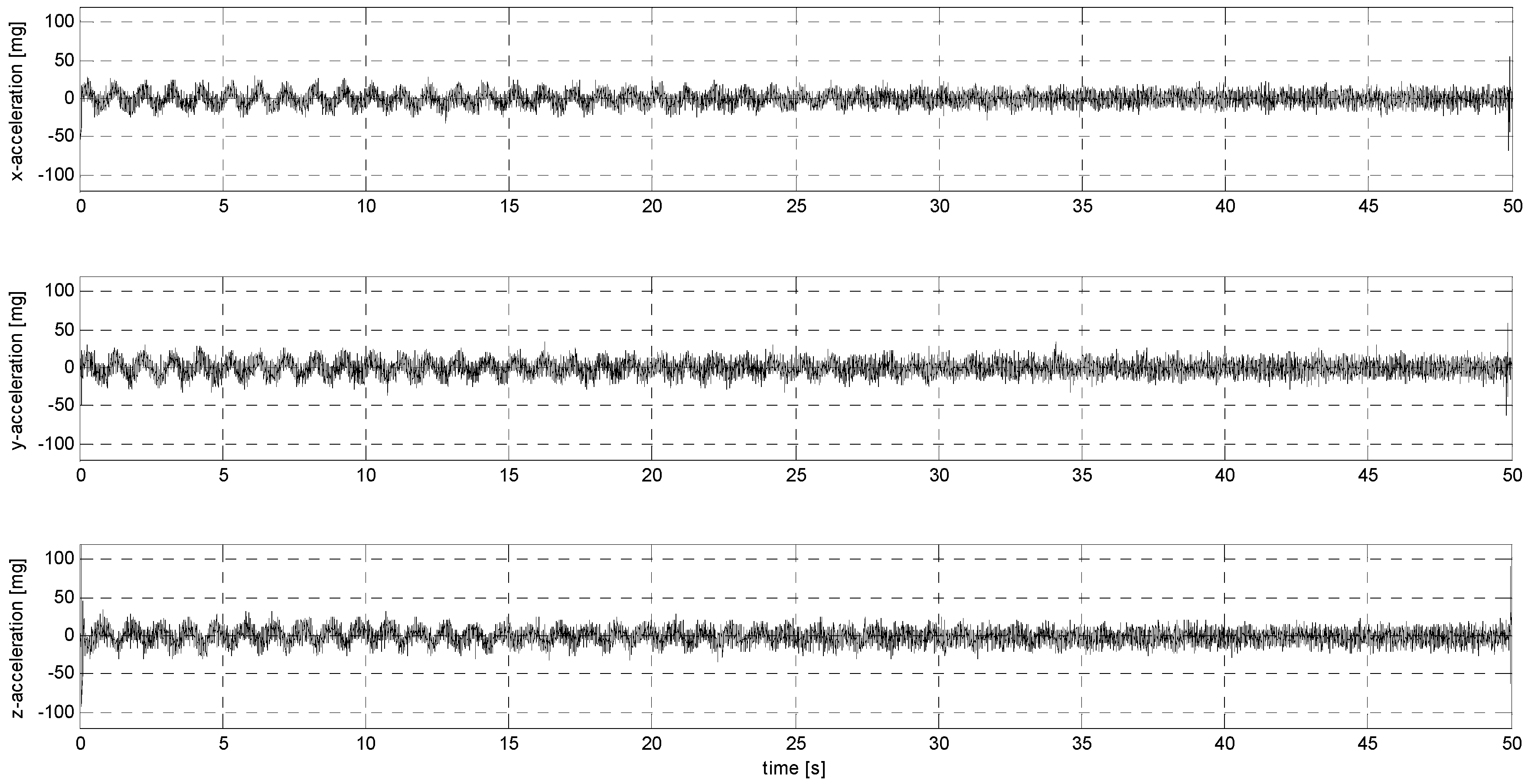

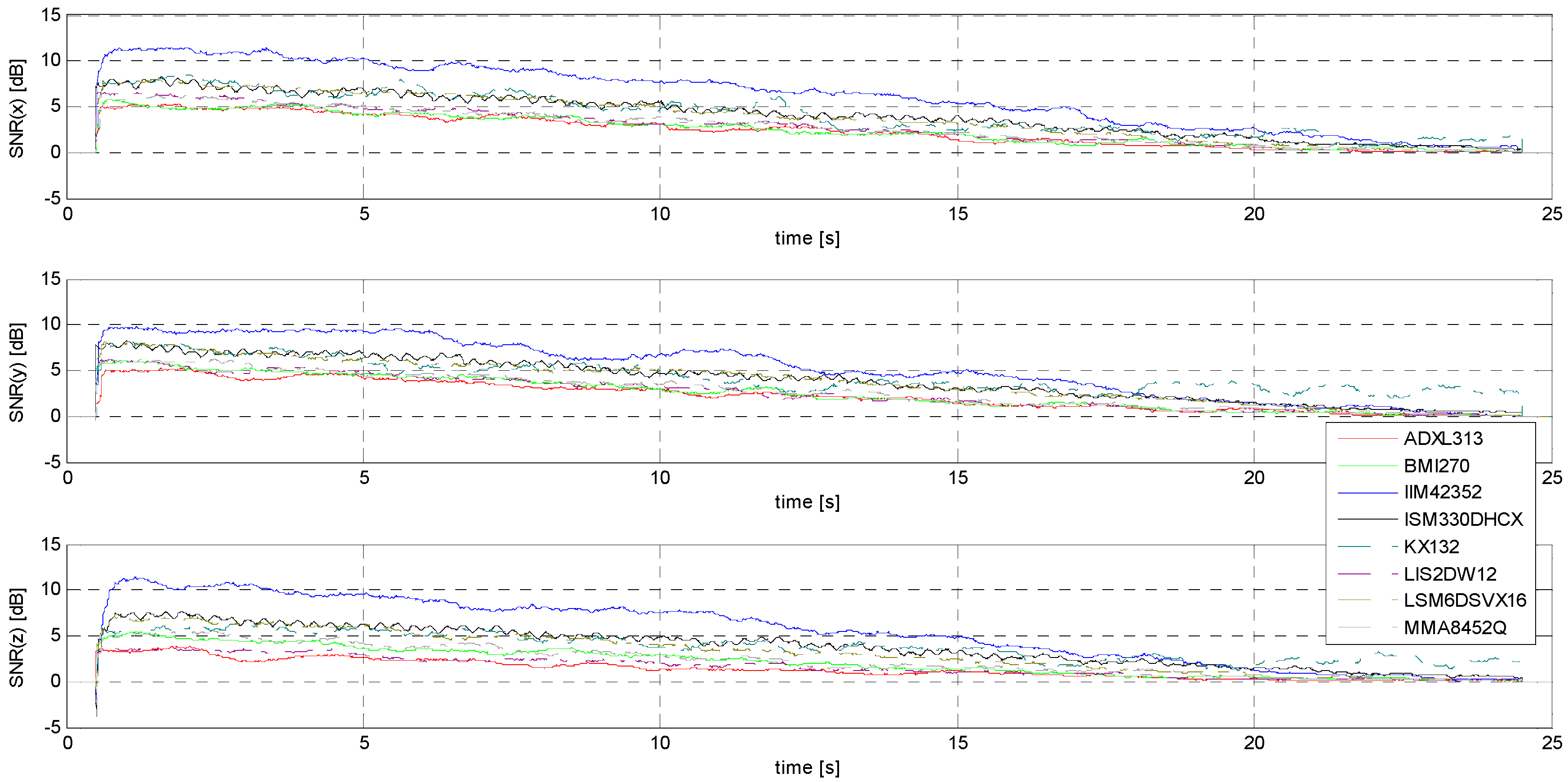

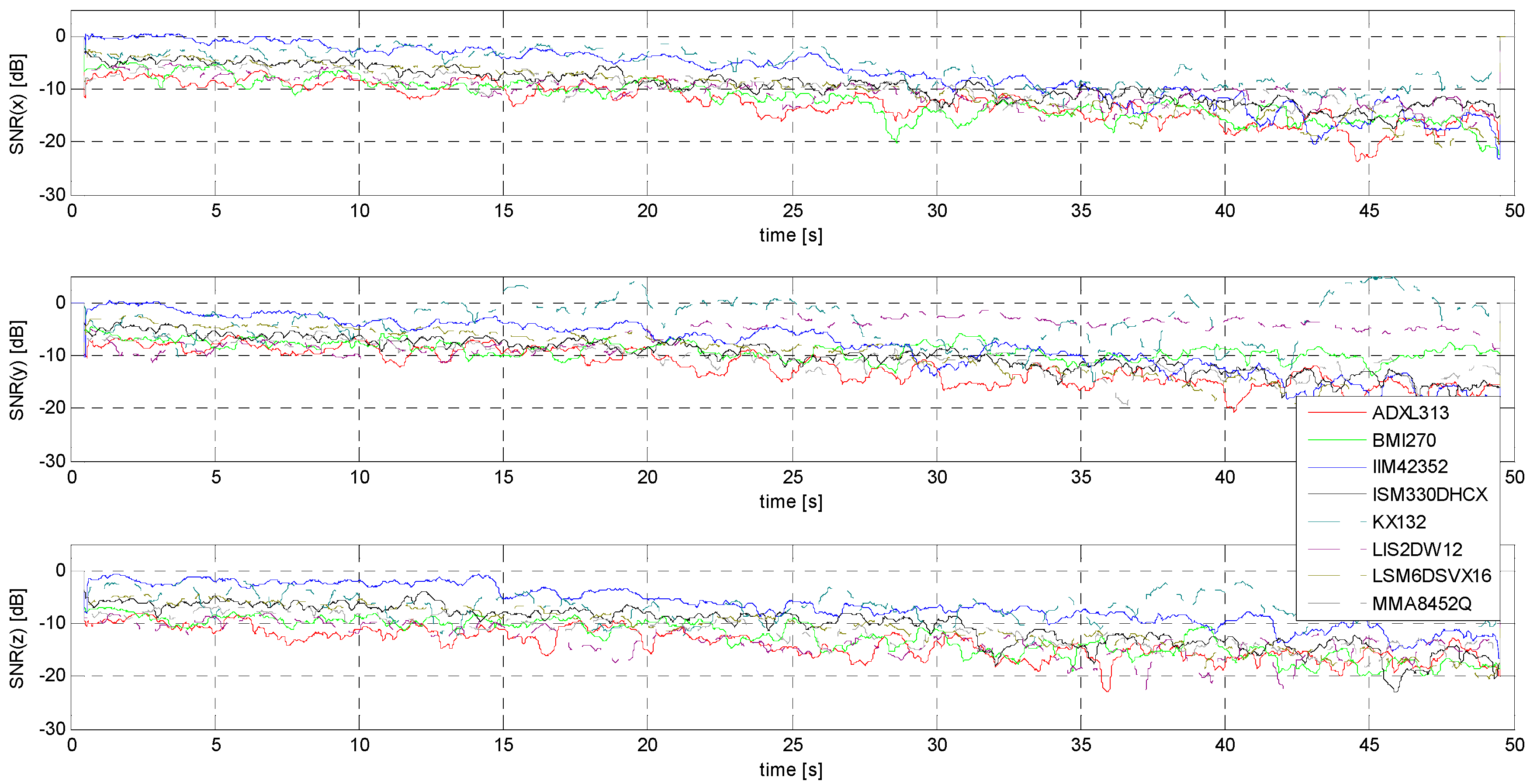

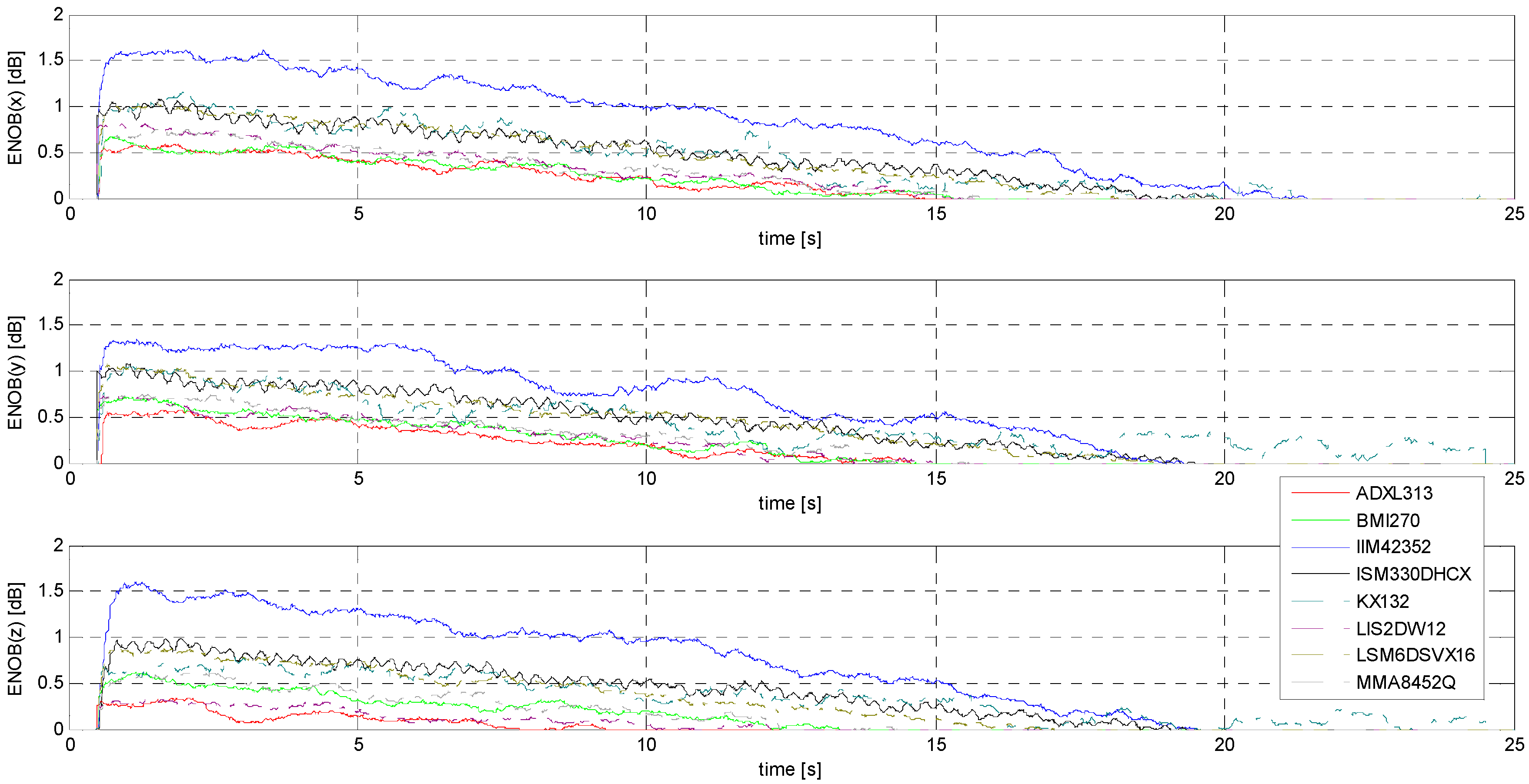

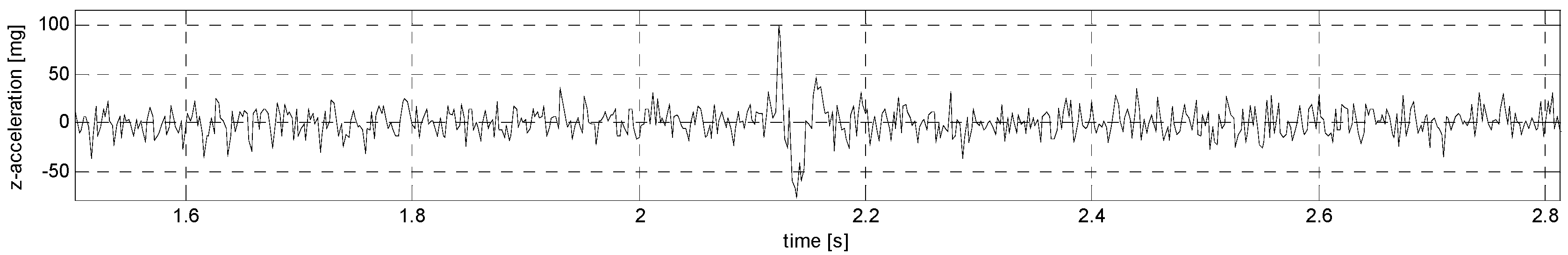

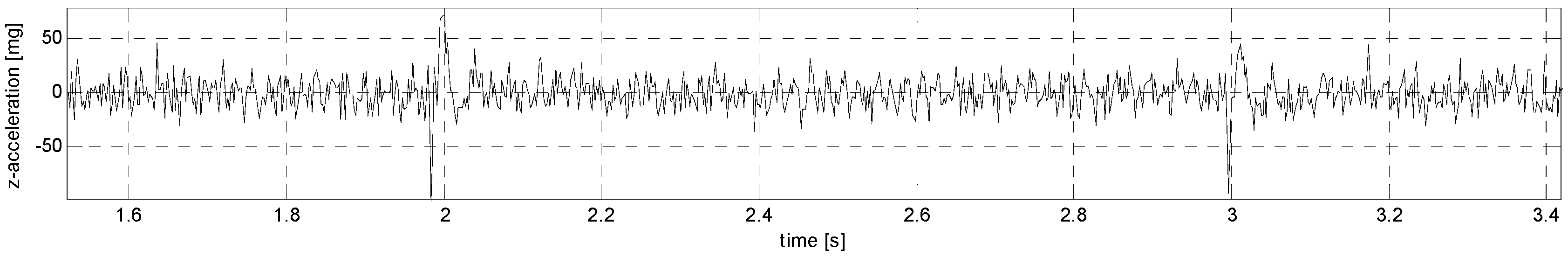

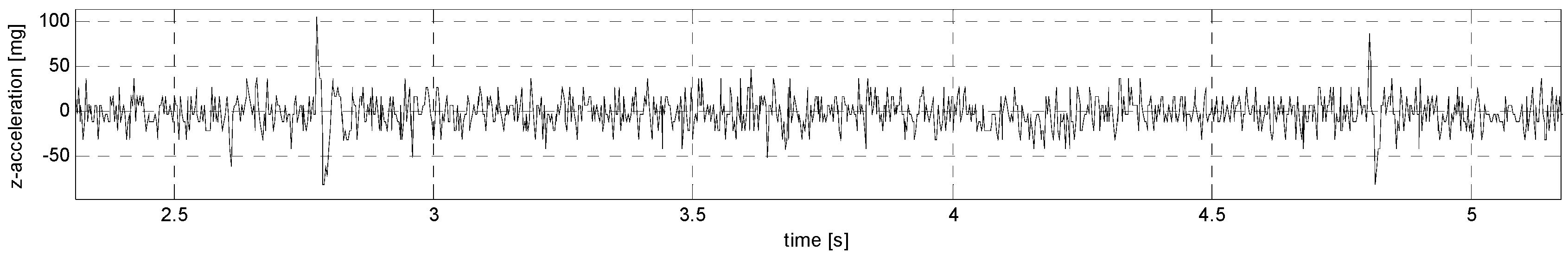

3.2. Stage II: Results

4. Interpretation of Results and Discussion

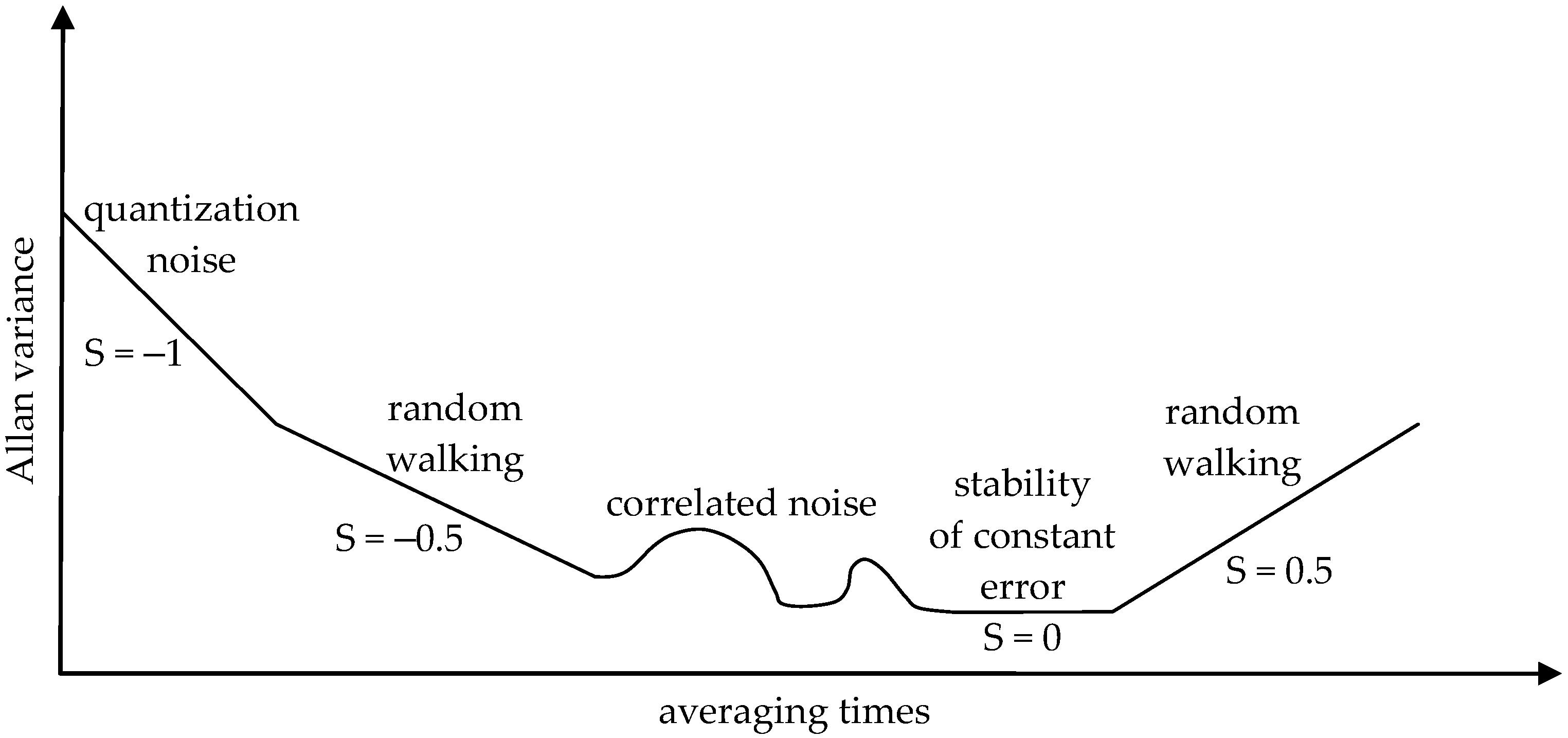

4.1. Interpretation of the Results of Stage I

4.2. Interpretation of the Results of Stage II, Sub-Stage S

- Extracting the clean signal from the raw data.

- Determination of the noise and signal-to-noise ratio (SNR)

- Determination of the modified SNR, MSNR.

- Determination of the ENOB.

- Determination of threshold amplitudes based on ENOB and MSNR.

4.3. Interpretation of the Results of Stage II, Sub-Stage P

5. Conclusions

- The selection of sensors can be successfully carried out by means of tests involving the loading of the tested sensors with:

- -

- Harmonic vibrations of linearly varying amplitude;

- -

- Vibrations of an impulsive nature;

- The proposed test procedures require the use of precise measurement equipment dedicated to this type of testing (exciters/shakers and data acquisition systems);

- The application of the proposed test procedure makes the process of interpretation of the obtained results relatively simple, although it requires the adoption of criteria depending on the purpose of the MEMS sensors under analysis;

- The results of the analysis showed that in the wide range of commonly available low-cost MEMS accelerometers, it is possible to select at least a few models characterized by satisfactory operating stability, high sensitivity, and energy efficiency (e.g., IIM42352, ISM330DHCX, LSM6DSVX16, or KX132);

- An analysis based solely on the catalog parameters of the sensors does not give a complete picture of the properties and suitability of the sensors for specific purposes; an example is sensors with lower resolutions, which can be successfully used in vibration monitoring systems in construction facilities (e.g., MMA8452Q).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Pytel, W.; Fuławka, K.; Mertuszka, P.; Pałac-Walko, B. Validation of Rayleigh Wave Theoretical Formulation with Single-Station Rotational Records of Mine Tremors in Lower Silesian Copper Basin. Sensors 2021, 21, 3566. [Google Scholar] [CrossRef] [PubMed]

- McGarr, A.; Simpson, D.; Seeber, L. Case histories of induced and triggered seismicity. Int. Geophys. 2002, 81, 647–661. [Google Scholar] [CrossRef]

- Lee, W.H.; Jennings, P.C.; Kisslinger, C.; Kanamori, H. International Handbook of Earthquake & Engineering Seismology, 1st ed.; Academic Press: Cambridge, MA, USA, 2002; Volume 81, pp. 1–951. [Google Scholar]

- Bourne, S.J.; Oates, S.J.; Elk, J.; Doornhof, D. A seismological model for earthquakes induced by fluid extraction from a subsurface reservoir. J. Geophys. Res. Solid Earth 2014, 119, 8991–9015. [Google Scholar] [CrossRef]

- Tracy, A.; Javernick-Will, A. Credible Sources of Information Regarding Induced Seismicity. Sustainability 2020, 12, 2308. [Google Scholar] [CrossRef]

- Bakema, M.M.; Parra, C.; McCann, P. Analyzing the Social Lead-Up to a Human-Induced Disaster: The Gas Extraction-Earthquake Nexus in Groningen, The Netherlands. Sustainability 2018, 10, 3621. [Google Scholar] [CrossRef]

- McGarr, A.; Bekins, B.; Burkardt, N.; Dewey, J.; Earle, P.; Ellsworth, W.; Ge, S.; Hickman, S.; Holland, A.; Majer, E.; et al. Coping with earthquakes induced by fluid injection. Science 2015, 347, 830–831. [Google Scholar] [CrossRef]

- Ruiz-Barajas, S.; Santoyo, M.A.; Oterino, M.B.; Alvarado, G.E.; Climent, A. Stress transfer patterns and local seismicity related to reservoir water-level variations. A case study in central Costa Rica. Sci. Rep. 2019, 9, 5600. [Google Scholar] [CrossRef]

- Ramírez-Zelaya, J.; Rosado, B.; Jiménez, V.; Gárate, J.; Peci, L.M.; de Gil, A.; Pérez-Peña, A.; Berrocoso, M. Design and Implementation of a Prototype Seismogeodetic System for Tectonic Monitoring. Sensors 2023, 23, 8986. [Google Scholar] [CrossRef]

- Li, L.; Zeng, X.; Pan, X.; Peng, L.; Tan, Y.; Liu, J. Microseismic Velocity Inversion Based on Deep Learning and Data Augmentation. Appl. Sci. 2024, 14, 2194. [Google Scholar] [CrossRef]

- Han, Z.; Zeng, G.; Ye, F. Research on Environmental Vibration Induced by High-Speed Maglev Transportation. Appl. Sci. 2024, 14, 413. [Google Scholar] [CrossRef]

- Beben, D.; Maleska, T.; Bobra, P.; Duda, J.; Anigacz, W. Influence of Traffic-Induced Vibrations on Humans and Residential Building—A Case Study. Int. J. Environ. Res. Public Health 2022, 19, 5441. [Google Scholar] [CrossRef] [PubMed]

- Guha, S.K. Underground Nuclear Explosion Related Seismicity. In Induced Earthquakes; Springer: Dordrecht, The Netherlands, 2000; pp. 217–264. [Google Scholar]

- Baranowski, P.; Damaziak, K.; Mazurkiewicz, Ł.; Mertuszka, P.; Pytel, W.; Małachowski, J.; Pałac-Walko, B.; Jones, T. Destress Blasting of Rock Mass: Multiscale Modelling and Simulation. Shock Vib. 2019, 2019, 2878969. [Google Scholar] [CrossRef]

- Tavasoli, O.; Ghazavi, M. Wave propagation and ground vibrations due to non-uniform cross-sections piles driving. Comput. Geotech. 2018, 104, 13–21. [Google Scholar] [CrossRef]

- EN 1998-1; Eurocode 8: Design of Structures Subjected to Seismic Impacts. Part 1: General Rules, Seismic Actions and Rules for Buildings. European Union: Brussels, Belgium, 2004.

- EN 1998-2; Eurocode 8: Design of Structures for Earthquake Rsistance—Part 2: Bridges. The European Union Regulation 305/2011, Directive 98/34/EC, Directive 2004/18/EC. European Union: Brussels, Belgium, 2005.

- DIN 4150-2; Structural Vibration, Part 2: Human Exposure to Vibration in Buildings. German Institute for Standardisation: Berlin, Germany, 1999.

- ISO 10137; Bases for Design of Structures—Serviceability of Buildings and Walkways Against Vibration. ISO: Geneva, Switzerland, 2007.

- EN 1990 (2002); Eurocode—Basis of Structural Design. The European Union Per Regulation 305/2011, Directive 98/34/EC, Directive 2004/18/EC. European Union: Brussels, Belgium, 2002.

- Alothman, A.; Mangalathu, S.; Al-Mosawe, A.; Alam, M.M.; Allawi, A. The influence of earthquake characteristics on the seismic performance of reinforced concrete buildings in Australia with varying heights. J. Build. Eng. 2023, 67, 105957. [Google Scholar] [CrossRef]

- Chung, A.I.; Cochran, E.S.; Kaiser, A.E.; Christensen, C.M.; Yildirim, B.; Lawrence, J.F. Improved rapid magnitude estimation for a community-based, low-cost MEMS accelerometer network. Bull. Seismol. Soc. Am. 2015, 105, 1314–1323. [Google Scholar] [CrossRef][Green Version]

- Bogue, R. MEMS sensors: Past, present and future. Sens. Rev. 2007, 27, 7–13. [Google Scholar] [CrossRef]

- Shah, M.A.; Iqbal, F. Simulation of a Dual Axis MEMS Seismometer for Building Monitoring System. In Proceedings of the 2015 COMSOL Conference, Boston, MA, USA, 7–9 October 2015. [Google Scholar]

- D’Alessandro, A.; Scudero, S.; Vitale, G. A Review of the Capacitive MEMS for Seismology. Sensors 2019, 19, 3093. [Google Scholar] [CrossRef]

- Hou, Y.; Jiao, R.; Yu, H. MEMS based geophones and seismometers. Sens. Actuators A Phys. 2021, 318, 112498. [Google Scholar] [CrossRef]

- Scudero, S.; D’Alessandro, A.; Greco, L.; Vitale, G. MEMS technology in seismology: A short review. In Proceedings of the 2018 IEEE International Conference on Environmental Engineering (EE), Milan, Italy, 12–14 March 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Technical Note: Triaxial Accelerometers for Improved Seismic and Geodetic Measurements. Paroscientific, Inc. Precision Pressure Instrumentation Doc. No. G8096 Rev. GK. Available online: https://paroscientific.com/pdf/G8096_Triaxial_Accelerometer.pdf (accessed on 21 October 2024).

- Binali, R.; Demirpolat, H.; Kuntoğlu, M.; Makhesana, M.; Yaghoubi, S.; Sayın Kul, B. A Comprehensive Review on Low-Cost MEMS Accelerometers for Vibration Measurement: Types, Novel Designs, Performance Evaluation, and Applications. J. Mol. Eng. Mater. 2024, 12, 2430002. [Google Scholar] [CrossRef]

- Lin, J.-F.; Li, X.-Y.; Wang, J.; Wang, L.-X.; Hu, X.-X.; Liu, J.-X. Study of Building Safety Monitoring by Using Cost-Effective MEMS Accelerometers for Rapid After-Earthquake Assessment with Missing Data. Sensors 2021, 21, 7327. [Google Scholar] [CrossRef]

- Liu, H.-F.; Luo, Z.-C.; Hu, Z.-K.; Yang, S.-Q.; Tu, L.-C.; Zhou, Z.-B.; Kraft, M. A review of high-performance MEMS sensors for resource exploration and geophysical applications. Pet. Sci. 2022, 19, 2631–2648. [Google Scholar] [CrossRef]

- Bravo-Haro, M.A.; Ding, X.; Elghazouli, A.Y. MEMS-based low-cost and open-source accelerograph for earthquake strong-motion. Eng. Struct. 2021, 230, 111675. [Google Scholar] [CrossRef]

- Wang, S.; Wei, X.; Zhao, Y.; Jiang, Z.; Shen, Y. A MEMS resonant accelerometer for low-frequency vibration detection. Sens. Actuators A Phys. 2018, 283, 151–158. [Google Scholar] [CrossRef]

- Havskov, J.; Alguacil, G. Instrumentation in Earthquake Seismology, 2nd ed.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Allan, D.W. Statistics of atomic frequency standards. Proc. IEEE 1966, 54, 221–230. [Google Scholar] [CrossRef]

- Woodman, O.J. An Introduction to Inertial Navigation; Technical Report UCAMCL-TR-696; Computer Laboratory, University of Cambridge: Cambridge, MA, USA, 2007. [Google Scholar]

- Tomaszewski, D.; Rapiński, J.; Śmieja, M. Analysis of the noise parameters and attitude alignment accuracy of INS conducted with the use of MEMS-based integrated navigation system. Acta Geodyn. Geromater. 2015, 12, 197–209. [Google Scholar] [CrossRef]

- Tomaszewski, D. Improving Positioning Methods with Using Integrated Measurements INS/GPS. Ph.D. Thesis, University of Warmia and Mazury in Olsztyn, Olsztyn, Poland, 2017. (In Polish). [Google Scholar]

- IEEE 952-1997; IEEE Standard Specification Format Guide and Test Procedure for Single—Axis Interferometric Fiber Optic Gyros. IEEE: New York, NY, USA, 1998.

- Zabielski, J.; Srokosz, P. Monitoring of Structural Safety of Buildings Using Wireless Network of MEMS Sensors. Buildings 2020, 10, 193. [Google Scholar] [CrossRef]

- Srokosz, P.; Dyka, I.; Bujko, M.; Bocheńska, M. A Modified Resonant Column Device for In-Depth Analysis of Vibration in Cohesive and Cohesionless Soils. Energies 2021, 14, 6647. [Google Scholar] [CrossRef]

- Prato, A.; Mazzoleni, F.; Schiavi, A. Traceability of digital 3-axis MEMS accelerometer: Simultaneous determination of main and transverse sensitivities in the frequency domain. Metrologia 2020, 57, 035013. [Google Scholar] [CrossRef]

- Prato, A.; Mazzoleni, F.; Schiavi, A. Evaluation and correction of systematic effects in a simultaneous 3-axis vibration calibration system. Acta IMEKO 2020, 9, 388–393. [Google Scholar] [CrossRef]

- Schiavi, A.; Mazzoleni, F.; Germak, A. Simultaneous 3-axis MEMS accelerometer primary calibration: Description of the test-rig and measurements. In Proceedings of the XXI IMEKO World Congress on Measurement in Research and Industry, Prague, Czech Republic, 30 August–4 September 2015; Volume 1, pp. 2161–2164. [Google Scholar] [CrossRef]

- ISO 16063-21; Methods for the Calibration of Vibration and Shock Transducers—Part 21: Vibration Calibration by Comparison to a Reference Transducer. International Organization for Standardization: Geneva, Switzerland, 2003.

- Shimoda, T.; Kokuyama, W.; Nozato, H. Primary calibration system for digital accelerometers. Metrology 2021, 58, 045002. [Google Scholar] [CrossRef]

- Seeger, B.; Bruns, T. Primary calibration of mechanical sensors with digital output for dynamic applications. Acta IMEKO 2021, 10, 177–184. [Google Scholar] [CrossRef]

| Name | Acc. Range [±g] | Resolution [bits] | Sensitivity [LSB/g] | Max. Output Data Rate [Hz] | Max. Bandwidth [Hz] | Nonlinearity [±%FS] | Current Consumption [mA] | Oper. Temp. Range [°C] | Approx. Cost * [$] |

|---|---|---|---|---|---|---|---|---|---|

| ADXL313 | 0.5:4.0 | 10:13 | 128:1024 | 3200 | 0.5 DR *** | 0.5 | 0.300 | −40:105 | 21.38 |

| ADXL343 | 2.0:16.0 | 10:13 | 32:256 | 3200 | 0.5 DR | 0.5 | 0.140 | −40:85 | 8.16 |

| ADXL345 | 2.0:16.0 | 10:13 | 32:256 | 3200 | 0.5 DR | 0.5 | 0.140 | −40:85 | 3.80 |

| BMA220 | 2.0:16.0 | 5:8 | 2:16 | 1000 | 32:1000 | 2.0 | 0.250 | −40:85 | 6.04 |

| BMA400 | 2.0:16.0 | 11 | 128:1024 | 800 | 0.48 DR | 0.5 | 0.015 | −40:85 | 9.55 |

| BMI160 | 2.0:16.0 | 16 | 2048:16,384 | 3200 | 0.22:0.43 DR | 0.5 | 0.600 | −40:85 | 4.16 |

| BMI270 | 2.0:16.0 | 16 | 2048:16,384 | 1600 | 0.43:0.46 DR | 0.5 | 0.970 | −40:85 | 17.82 |

| H3LIS331DL | 100:400 | 12 | 49:195 | 1000 | 0.5 DR | 2.0 | 0.370 | −40:85 | 17.20 |

| IIM42352 | 2.0:16.0 | 16 | 2048:16,384 | 32,000 | 4000 (1650 **) | 0.1 | 0.280 | −40:105 | 32.39 |

| ISM330DHCX | 2.0:16.0 | 16 | 2048:16,384 | 6667 | 0.5 ODR | n.d. | 0.430 | −40:105 | 30.05 |

| KX132 | 2.0:16.0 | 16 | 2048:16,384 | 25,600 | 4200 (2900 **) | 0.5 | 0.148 | −40:105 | 15.97 |

| LIS2DH | 2.0:16.0 | 8:12 | 1:192 | 5376 | n.d. | n.d. | 0.185 | −40:85 | 6.54 |

| LIS2DW12 | 2.0:16.0 | 16 | 128:4096 | 1600 | 0.5 DR | n.d. | 0.090 | −40:85 | 5.46 |

| LIS3DH | 2.0:16.0 | 16 | 1000:12,000 | 1250 | 0.5 DR | n.d. | 0.011 | −40:85 | 7.55 |

| LIS331HH | 6.0:24.0 | 16 | 3000:12,000 | 1000 | 0.5 DR | n.d. | 0.250 | −40:85 | 14.95 |

| LSM6DS3 | 2.0:16.0 | 16 | 2048:16,384 | 6664 | 0.5 DR | n.d. | 1.250 | −40:85 | 6.94 |

| LSM6DSO | 2.0:16.0 | 16 | 2048:16,384 | 6664 | 0.5 DR | n.d. | 0.550 | −40:85 | 15.88 |

| LSM6DSO32 | 4.0:32.0 | 16 | 1024:8196 | 6664 | 0.5 DR | n.d. | 0.550 | −40:85 | 17.32 |

| LSM6DSVX16 | 2.0:16.0 | 16 | 2048:16,384 | 7680 | 0.5 DR | n.d. | 0.650 | −40:85 | 23.96 |

| MMA7660FC | 1.5 | 6 | 21.33 | 120 | n.d. | n.d. | 0.294 | −40:85 | 10.86 |

| MMA8452Q | 2.0:8.0 | 8, 12 | 256:1024 | 800 | 0.5 DR | n.d. | 0.165 | −40:85 | 18.44 |

| MPU6050 | 2.0:16.0 | 16 | 2048:16,384 | 1000 | n.d. | 0.5 | 0.500 | −40:85 | 17.65 |

| MPU6500 | 2.0:16.0 | 16 | 2048:16,384 | 4000 | n.d. | 0.5 | 0.450 | −40:85 | 2.48 |

| MSA311 | 2.0:16.0 | 12 | 128:1024 | 1000 | 500 | 2.0 | 0.130 | −40:85 | 6.54 |

| Name | Data Rate [Hz] | Name | Data Rate [Hz] | Name | Data Rate [Hz] |

|---|---|---|---|---|---|

| ADXL313 | 100 | LIS2DW12 | 100 | IIM42352 | 100 |

| ADXL343 | 100 | LIS3DH | 100 | ISM330DHCX | 104 |

| ADXL345 | 100 | LIS331HH | 100 | KX132 | 100 |

| BMA220 | 125 | LSM6DS3 | 104 | LIS2DH | 100 |

| BMA400 | 100 | LSM6DSO | 104 | MMA8452Q | 100 |

| BMI160 | 100 | LSM6DSO32 | 104 | MPU6050 | 100 |

| BMI270 | 100 | LSM6DSVX16 | 120 | MPU6500 | 100 |

| H3LIS331DL | 100 | MMA7660FC | 120 | MSA311 | 125 |

| Sub-Stage | Signal | Frequency/ Duration | Maximum Amplitude | Number of Cycles/Steps |

|---|---|---|---|---|

| S1 | sinus | 1.0 Hz | 10 mm/s2 | 50 |

| S2 | sinus | 2.0 Hz | 40 mm/s2 | 50 |

| P1 | step | 1 s | 0.005 mm | 20 |

| P2 | step | 2 s | 0.005 mm | 20 |

| Drive System | Impedance [Ohm] | Max Power [W] | Max Amplitude [mm] | Frequency Range [Hz] |

|---|---|---|---|---|

| electromagnetic | 8 | 200 | ±10 | 0.001:2000 |

| Name | Acc. Range [±g] | Resolution [bits] | Sensitivity [LSB/g] | Output Data Rate [Hz] | Special Features |

|---|---|---|---|---|---|

| ADXL313 | 2.0 | 12 | 1024 | 400 | - |

| BMI270 | 2.0 | 16 | 16,384 | 400 | - |

| IIM42352 | 2.0 | 16 | 16,384 | 200 * | LNM ** |

| ISM330DHCX | 2.0 | 16 | 16,384 | 416 | - |

| KX132 | 2.0 | 16 | 16,384 | 400 | IIR |

| LIS2DW12 | 2.0 | 14 | 4096 | 400 | - |

| LSM6DSVX16 | 2.0 | 16 | 16,384 | 480 | - |

| MMA8452Q | 2.0 | 12 | 1024 | 400 | - |

| Name | X-Axis | Y-Axis | Z-Axis | Mean (AV0) | Grade |

|---|---|---|---|---|---|

| H3LIS331DL | 9.96 × 10−3 | 8.24 × 10−3 | 9.29 × 10−3 | 9.16 × 10−3 | C |

| MMA7660FC | 1.09 × 10−3 | 1.10 × 10−3 | 8.84 × 10−4 | 1.02 × 10−3 | |

| BMA220 | 1.02 × 10−4 | 3.81 × 10−6 | 7.96 × 10−5 | 6.18 × 10−5 | |

| LIS331HH | 2.65 × 10−5 | 2.30 × 10−5 | 2.98 × 10−5 | 2.64 × 10−5 | |

| MPU6050 | 9.90 × 10−6 | 9.51 × 10−6 | 1.96 × 10−5 | 1.30 × 10−5 | |

| MPU6500 | 4.49 × 10−6 | 4.48 × 10−6 | 1.22 × 10−5 | 7.06 × 10−6 | B |

| ADXL345 | 5.74 × 10−6 | 3.02 × 10−6 | 8.83 × 10−6 | 5.87 × 10−6 | |

| ADXL343 | 7.68 × 10−6 | 2.76 × 10−6 | 7.03 × 10−6 | 5.82 × 10−6 | |

| MSA311 | 2.75 × 10−6 | 3.03 × 10−6 | 6.21 × 10−6 | 4.00 × 10−6 | |

| LIS3DH | 2.45 × 10−6 | 2.10 × 10−6 | 2.72 × 10−6 | 2.42 × 10−6 | |

| LIS2DH | 2.27 × 10−6 | 2.04 × 10−6 | 2.62 × 10−6 | 2.31 × 10−6 | |

| BMA400 | 1.02 × 10−6 | 1.01 × 10−6 | 2.53 × 10−6 | 1.52 × 10−6 | |

| ADXL313 | 6.34 × 10−7 | 7.26 × 10−7 | 1.77 × 10−6 | 1.04 × 10−6 | |

| BMI160 | 8.07 × 10−7 | 7.72 × 10−7 | 1.24 × 10−6 | 9.39 × 10−7 | A |

| LSM6DSO32 | 8.17 × 10−7 | 6.73 × 10−7 | 5.40 × 10−7 | 6.77 × 10−7 | |

| BMI270 | 4.99 × 10−7 | 5.52 × 10−7 | 6.34 × 10−7 | 5.62 × 10−7 | |

| LIS2DW12 | 4.03 × 10−7 | 4.38 × 10−7 | 7.35 × 10−7 | 5.26 × 10−7 | |

| MMA8452Q | 4.99 × 10−7 | 5.19 × 10−7 | 5.49 × 10−7 | 5.22 × 10−7 | |

| LSM6DSO | 3.33 × 10−7 | 2.79 × 10−7 | 2.38 × 10−7 | 2.83 × 10−7 | |

| LSM6DS3 | 1.96 × 10−7 | 1.60 × 10−7 | 2.59 × 10−7 | 2.05 × 10−7 | |

| ISM330DHCX | 1.95 × 10−7 | 1.72 × 10−7 | 2.25 × 10−7 | 1.97 × 10−7 | |

| KX132 (IIR on) | 1.02 × 10−7 | 1.43 × 10−7 | 2.42 × 10−7 | 1.63 × 10−7 | |

| LSM6DSVX16 | 1.31 × 10−7 | 1.14 × 10−7 | 2.43 × 10−7 | 1.63 × 10−7 | |

| IIM42352 | 1.17 × 10−7 | 1.28 × 10−7 | 1.78 × 10−7 | 1.41 × 10−7 |

| Name | X-Axis [mm/s2] | Y-Axis [mm/s2] | Z-Axis [mm/s2] | Resolution [bits] | Threshold [mm/s2/LSB] |

|---|---|---|---|---|---|

| ADXL313 | 33.98 | 34.59 | 46.65 | 12 | 9.77 |

| BMI270 | 32.73 | 31.68 | 37.25 | 16 | 0.61 |

| IIM42352 | 17.52 | 17.85 | 19.01 | 16 | 0.61 |

| ISM330DHCX | 19.05 | 23.42 | 23.34 | 16 | 0.61 |

| KX132 | 25.71 | 27.54 | 19.39 | 16 | 0.61 |

| LIS2DW12 | 26.88 | 30.21 | 41.74 | 14 | 2.44 |

| LSM6DSVX16 | 18.98 | 19.68 | 23.69 | 16 | 0.61 |

| MMA8452Q | 26.43 | 29.11 | 35.45 | 12 | 9.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srokosz, P.E.; Daniszewska, E.; Banach, J.; Śmieja, M. In-Depth Analysis of Low-Cost Micro Electromechanical System (MEMS) Accelerometers in the Context of Low Frequencies and Vibration Amplitudes. Sensors 2024, 24, 6877. https://doi.org/10.3390/s24216877

Srokosz PE, Daniszewska E, Banach J, Śmieja M. In-Depth Analysis of Low-Cost Micro Electromechanical System (MEMS) Accelerometers in the Context of Low Frequencies and Vibration Amplitudes. Sensors. 2024; 24(21):6877. https://doi.org/10.3390/s24216877

Chicago/Turabian StyleSrokosz, Piotr Emanuel, Ewa Daniszewska, Jakub Banach, and Michał Śmieja. 2024. "In-Depth Analysis of Low-Cost Micro Electromechanical System (MEMS) Accelerometers in the Context of Low Frequencies and Vibration Amplitudes" Sensors 24, no. 21: 6877. https://doi.org/10.3390/s24216877

APA StyleSrokosz, P. E., Daniszewska, E., Banach, J., & Śmieja, M. (2024). In-Depth Analysis of Low-Cost Micro Electromechanical System (MEMS) Accelerometers in the Context of Low Frequencies and Vibration Amplitudes. Sensors, 24(21), 6877. https://doi.org/10.3390/s24216877