A Novel Friction Compensation Method for Machine Tool Drive Systems in Insufficient Lubrication

Abstract

1. Introduction

2. Conventional Friction Model and Proposed Friction Model

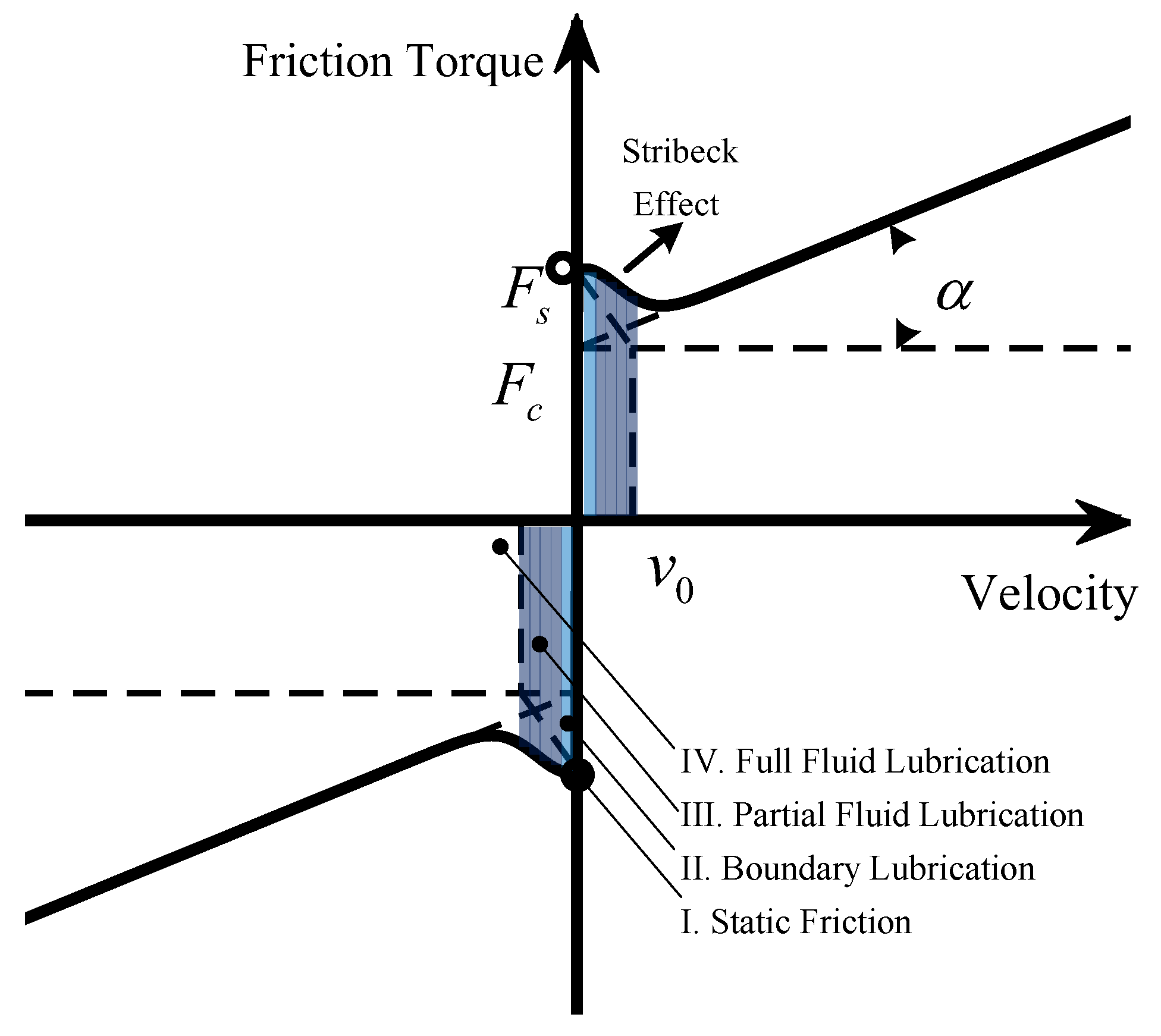

2.1. Conventional Friction Model

2.2. Proposed Friction Model

3. Identification of Friction Models

3.1. Experimental Setup

3.2. Feed Drive Dynamics

3.3. Identification of Conventional Model

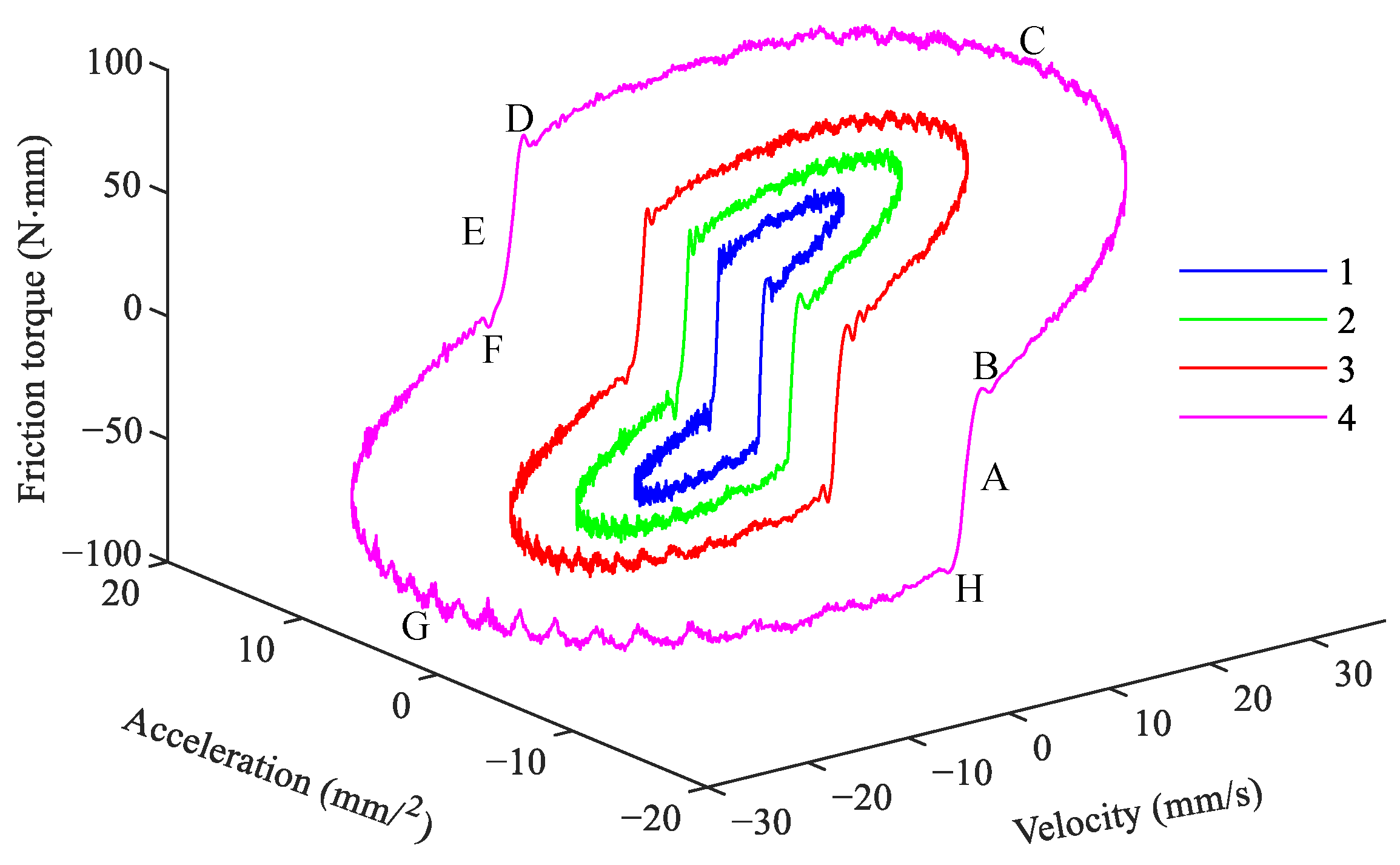

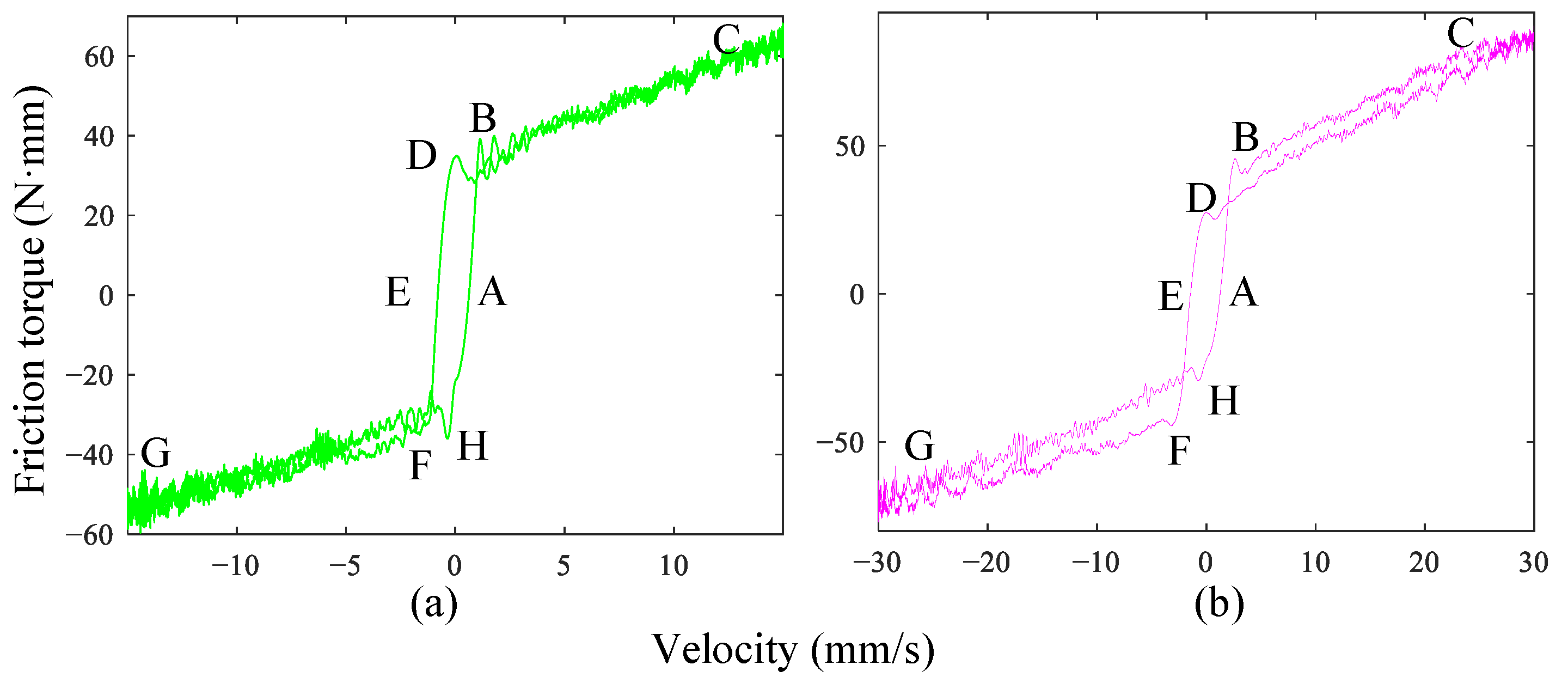

3.4. Identification of the Proposed Friction Model

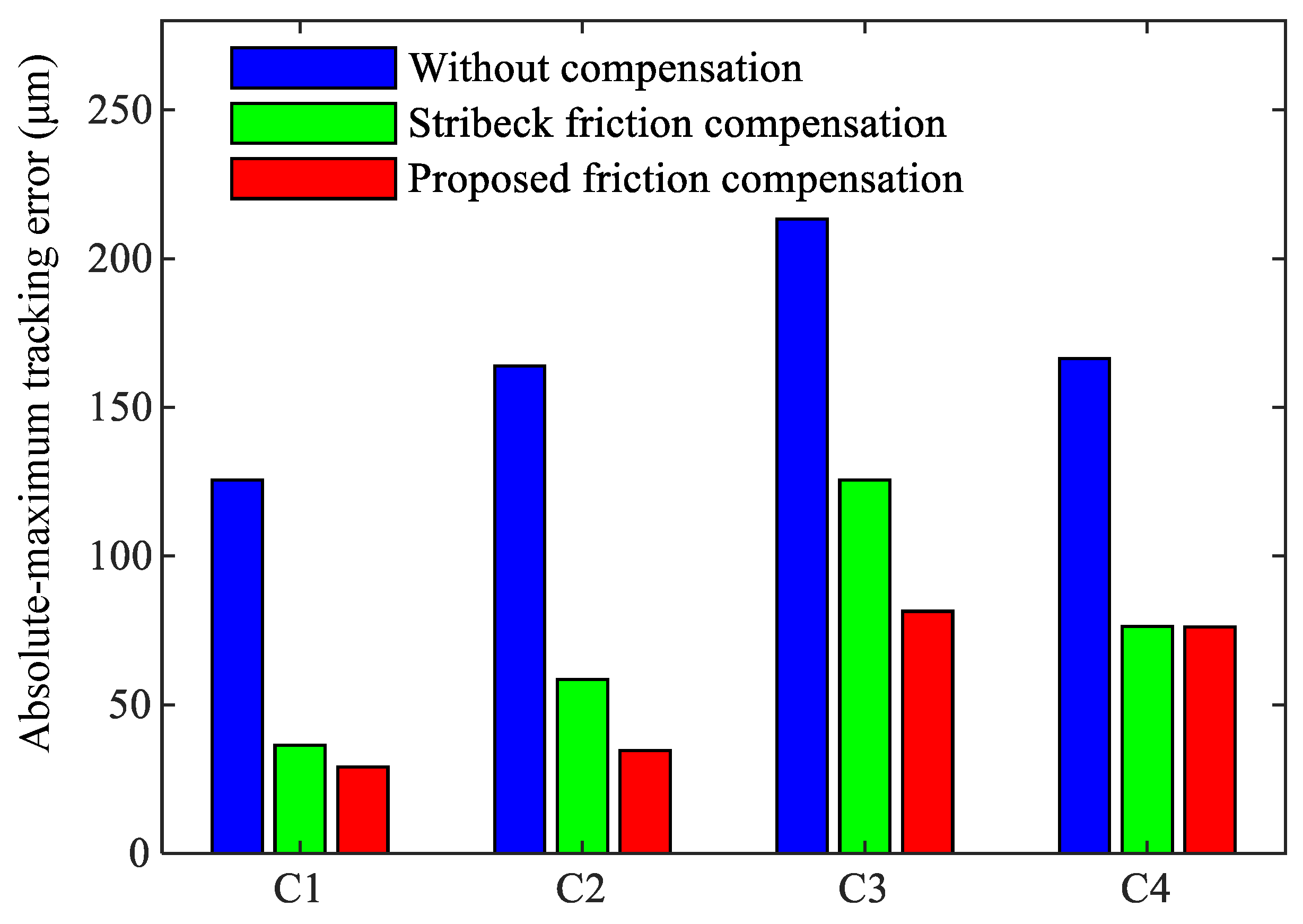

- C1: Sinusoidal motion with 25 mm amplitude and 0.4 rad/s angular frequency;

- C2: Sinusoidal motion with 50 mm amplitude and 0.4 rad/s angular frequency;

- C3: Sinusoidal motion with 50 mm amplitude and 0.8 rad/s angular frequency;

- C4: S-Curve motion with 10 mm amplitude, 10 mm/s speed, and 100 ms acceleration time.

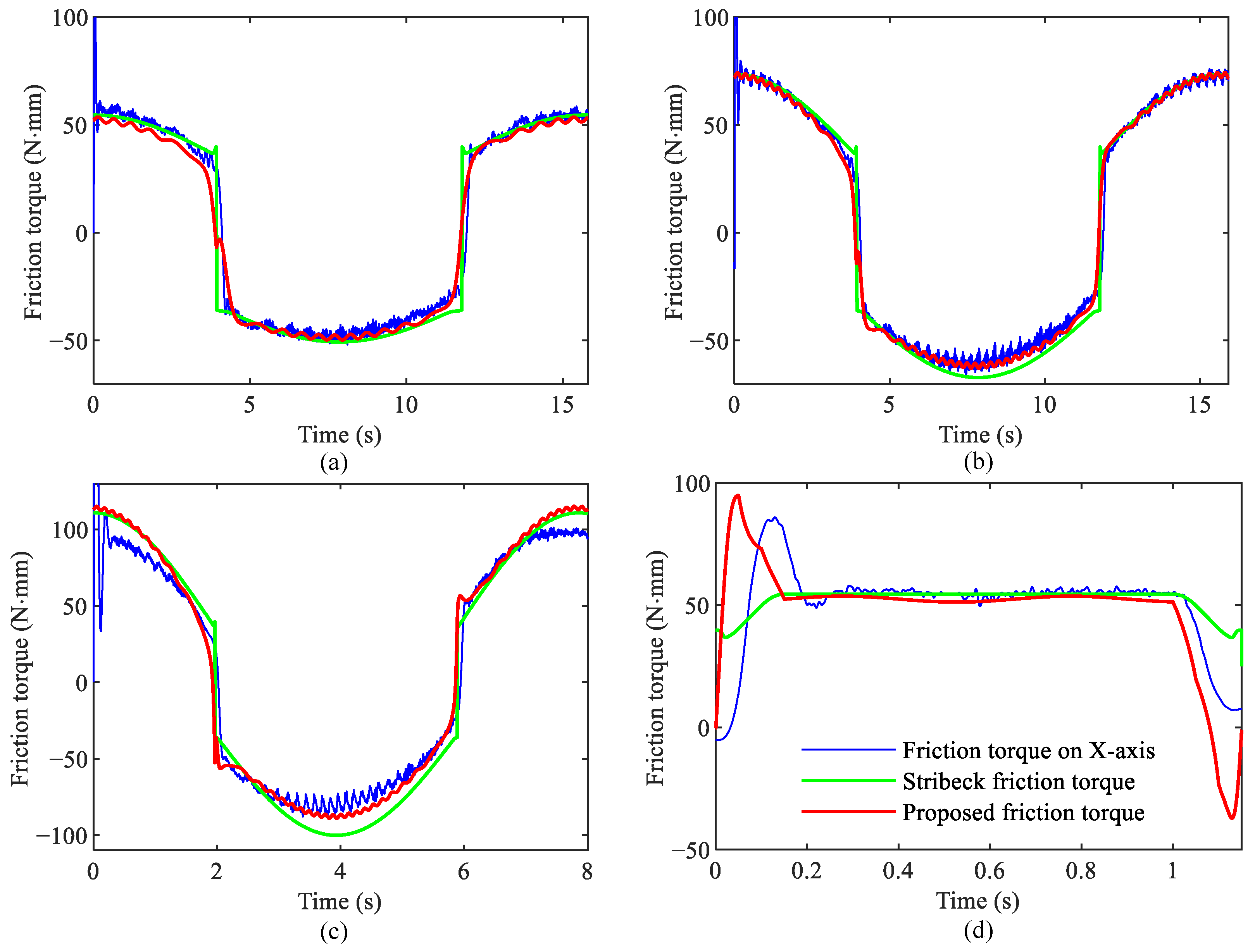

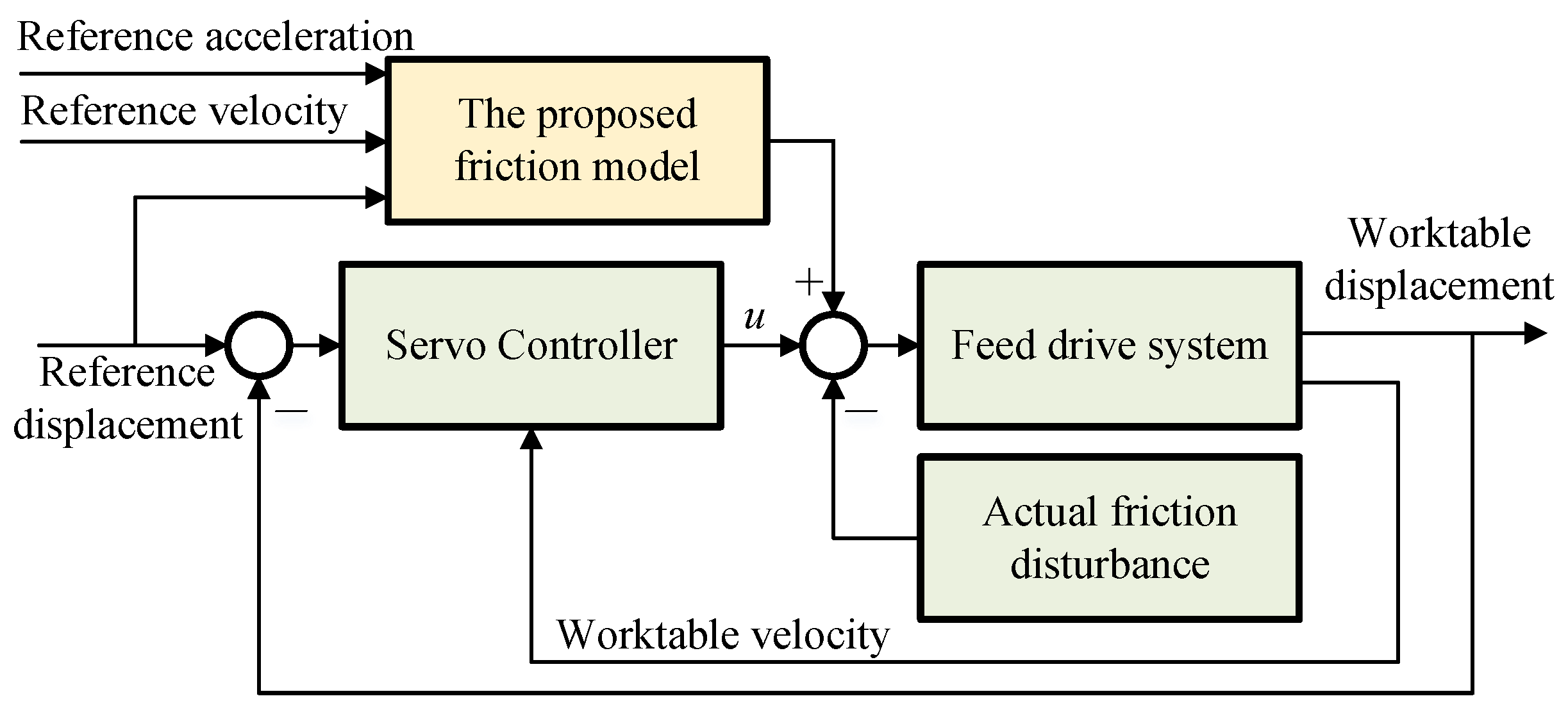

4. Friction Compensation and Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Chen, W.H.; Li, S.; Guo, L.; Yan, Y. Disturbance/Uncertainty Estimation and Attenuation Techniques in PMSM Drives—A Survey. IEEE Trans. Ind. Electron. 2017, 64, 3273–3285. [Google Scholar] [CrossRef]

- Peng, H.; Song, N.; Li, F.; Tang, S. A Mechanistic-Based Data-Driven Approach for General Friction Modeling in Complex Mechanical System. J. Appl. Mech. 2022, 89, 071005. [Google Scholar] [CrossRef]

- Lee, W.; Lee, C.Y.; Min, B.K. Simulation-Based Energy Usage Profiling of Machine Tool at the Component Level. Int. J. Precis. Eng. -Manuf.-Green Technol. 2014, 1, 183–189. [Google Scholar] [CrossRef]

- Huang, T.; Kang, Y.; Du, S.; Zhang, Q.; Luo, Z.; Tang, Q.; Yang, K. A Survey of Modeling and Control in Ball Screw Feed-Drive System. Int. J. Adv. Manuf. Technol. 2022, 121, 2923–2946. [Google Scholar] [CrossRef]

- Lin, C.J.; Lee, C.Y. Observer-Based Robust Controller Design and Realization of a Gantry Stage. Mechatronics 2011, 21, 185–203. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Yang, Z.; Su, J.; Chen, R.; Shang, D. Transmission Friction Measurement and Suppression of Dual-Inertia System Based on RBF Neural Network and Nonlinear Disturbance Observer. Measurement 2022, 202, 111793. [Google Scholar] [CrossRef]

- Yang, Z.J.; Tsubakihara, H.; Kanae, S.; Wada, K.; Su, C.Y. A Novel Robust Nonlinear Motion Controller with Disturbance Observer. IEEE Trans. Control. Syst. Technol. 2007, 16, 137–147. [Google Scholar] [CrossRef]

- Yue, F.; Li, X. Robust Adaptive Integral Backstepping Control for Opto-Electronic Tracking System Based on Modified LuGre Friction Model. ISA Trans. 2018, 80, 312–321. [Google Scholar] [CrossRef]

- Selmic, R.R.; Lewis, F.L. Neural-Network Approximation of Piecewise Continuous Functions: Application to Friction Compensation. IEEE Trans. Neural Netw. 2002, 13, 745–751. [Google Scholar] [CrossRef]

- Keck, A.; Zimmermann, J.; Sawodny, O. Friction Parameter Identification and Compensation Using the Elastoplastic Friction Model. Mechatronics 2017, 47, 168–182. [Google Scholar] [CrossRef]

- Elfizy, A.T.; Bone, G.M.; Elbestawi, M.A. Model-Based Controller Design for Machine Tool Direct Feed Drives. Int. J. Mach. Tools Manuf. 2004, 44, 465–477. [Google Scholar] [CrossRef]

- Peng, H.; Wei, S.; Huang, X.; Li, R.; Yang, Z. A Novel Ball-Screw-Driven Rigid–Flexible Coupling Stage with Active Disturbance Rejection Control to Compensate for Friction Dead Zone. Mech. Syst. Signal Process. 2024, 208, 110963. [Google Scholar] [CrossRef]

- Lee, T.H.; Tan, K.K.; Huang, S. Adaptive Friction Compensation with a Dynamical Friction Model. IEEE/Asme Trans. Mechatron. 2010, 16, 133–140. [Google Scholar] [CrossRef]

- Freidovich, L.; Robertsson, A.; Shiriaev, A.; Johansson, R. LuGre-model-based Friction Compensation. IEEE Trans. Control. Syst. Technol. 2009, 18, 194–200. [Google Scholar] [CrossRef]

- Du, F.; Zhang, M.; Wang, Z.; Yu, C.; Feng, X.; Li, P. Identification and Compensation of Friction for a Novel Two-Axis Differential Micro-Feed System. Mech. Syst. Signal Process. 2018, 106, 453–465. [Google Scholar] [CrossRef]

- Armstrong-Helouvry, B. Control of Machines with Friction; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1991; Volume 128. [Google Scholar]

- Márton, L.H.; Lantos, B. Control of Mechanical Systems with Stribeck Friction and Backlash. Syst. Control. Lett. 2009, 58, 141–147. [Google Scholar] [CrossRef]

- De Wit, C.C.; Olsson, H.; Astrom, K.J.; Lischinsky, P. A New Model for Control of Systems with Friction. IEEE Trans. Autom. Control 1995, 40, 419–425. [Google Scholar] [CrossRef]

- De Wit, C.C.; Lischinsky, P. Adaptive Friction Compensation with Partially Known Dynamic Friction Model. Int. J. Adapt. Control. Signal Process. 1997, 11, 65–80. [Google Scholar] [CrossRef]

- Al-Bender, F.; Lampaert, V.; Swevers, J. The Generalized Maxwell-slip Model: A Novel Model for Friction Simulation and Compensation. IEEE Trans. Autom. Control 2005, 50, 1883–1887. [Google Scholar] [CrossRef]

- Jamaludin, Z.; Van Brussel, H.; Swevers, J. Friction Compensation of an XY Feed Table Using Friction-Model-Based Feedforward and an Inverse-Model-Based Disturbance Observer. IEEE Trans. Ind. Electron. 2009, 56, 3848–3853. [Google Scholar] [CrossRef]

- Park, E.C.; Lim, H.; Choi, C.H. Position Control of XY Table at Velocity Reversal Using Presliding Friction Characteristics. IEEE Trans. Control. Syst. Technol. 2003, 11, 24–31. [Google Scholar] [CrossRef]

- Yang, M.; Yang, J.; Ding, H. A Two-Stage Friction Model and Its Application in Tracking Error Pre-Compensation of CNC Machine Tools. Precis. Eng. 2018, 51, 426–436. [Google Scholar] [CrossRef]

- Bui, B.D.; Uchiyama, N.; Simba, K.R. Contouring Control for Three-Axis Machine Tools Based on Nonlinear Friction Compensation for Lead Screws. Int. J. Mach. Tools Manuf. 2016, 108, 95–105. [Google Scholar] [CrossRef]

- Bui, B.D.; Uchiyama, N.; Sano, S. Nonlinear Friction Modeling and Compensation for Precision Control of a Mechanical Feed-Drive System. Sens. Mater. 2015, 27, 971–984. [Google Scholar]

| No. | A (mm) | (rad/s) |

|---|---|---|

| 1 | 50 | 0.2 |

| 2 | 50 | 0.3 |

| 3 | 50 | 0.4 |

| 4 | 50 | 0.6 |

| Parameters | Value |

|---|---|

| 11,500 | |

| 12,500 | |

| 12,500 | |

| (A/V) | 0.2335 |

| (N·m/A) | 0.544 |

| J (kg·m2) | 8.17 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| (N·mm) | 35.70 | (mm/s) | 0.26 |

| (N·mm) | 34.13 | (mm/s) | 1.02 |

| (N·mm) | 39.70 | (N/s) | 1.88 |

| (N·mm) | 35.81 | (N/s) | 1.65 |

| Parameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| (N·mm) | 31.94 | (mm/s) | 1.54 | 2.38 | |

| (N·mm) | −34.48 | (mm/s) | −1.42 | (N·mm) | 939.95 |

| (N·mm) | 27.14 | (N/s) | 2.05 | (mm/s2) | −201.239 |

| (N·mm) | 9.98 | (N/s) | 1.31 | (N·mm) | 1.20 |

| (rad) | 1.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, Y.; Wang, G.; Sang, L.; Li, D. A Novel Friction Compensation Method for Machine Tool Drive Systems in Insufficient Lubrication. Sensors 2024, 24, 4820. https://doi.org/10.3390/s24154820

Sheng Y, Wang G, Sang L, Li D. A Novel Friction Compensation Method for Machine Tool Drive Systems in Insufficient Lubrication. Sensors. 2024; 24(15):4820. https://doi.org/10.3390/s24154820

Chicago/Turabian StyleSheng, Yanliang, Guofeng Wang, Lingling Sang, and Decai Li. 2024. "A Novel Friction Compensation Method for Machine Tool Drive Systems in Insufficient Lubrication" Sensors 24, no. 15: 4820. https://doi.org/10.3390/s24154820

APA StyleSheng, Y., Wang, G., Sang, L., & Li, D. (2024). A Novel Friction Compensation Method for Machine Tool Drive Systems in Insufficient Lubrication. Sensors, 24(15), 4820. https://doi.org/10.3390/s24154820