A Method for Spatially Registered Microprofilometry Combining Intensity-Height Datasets from Interferometric Sensors

Abstract

1. Introduction

2. Materials and Methods

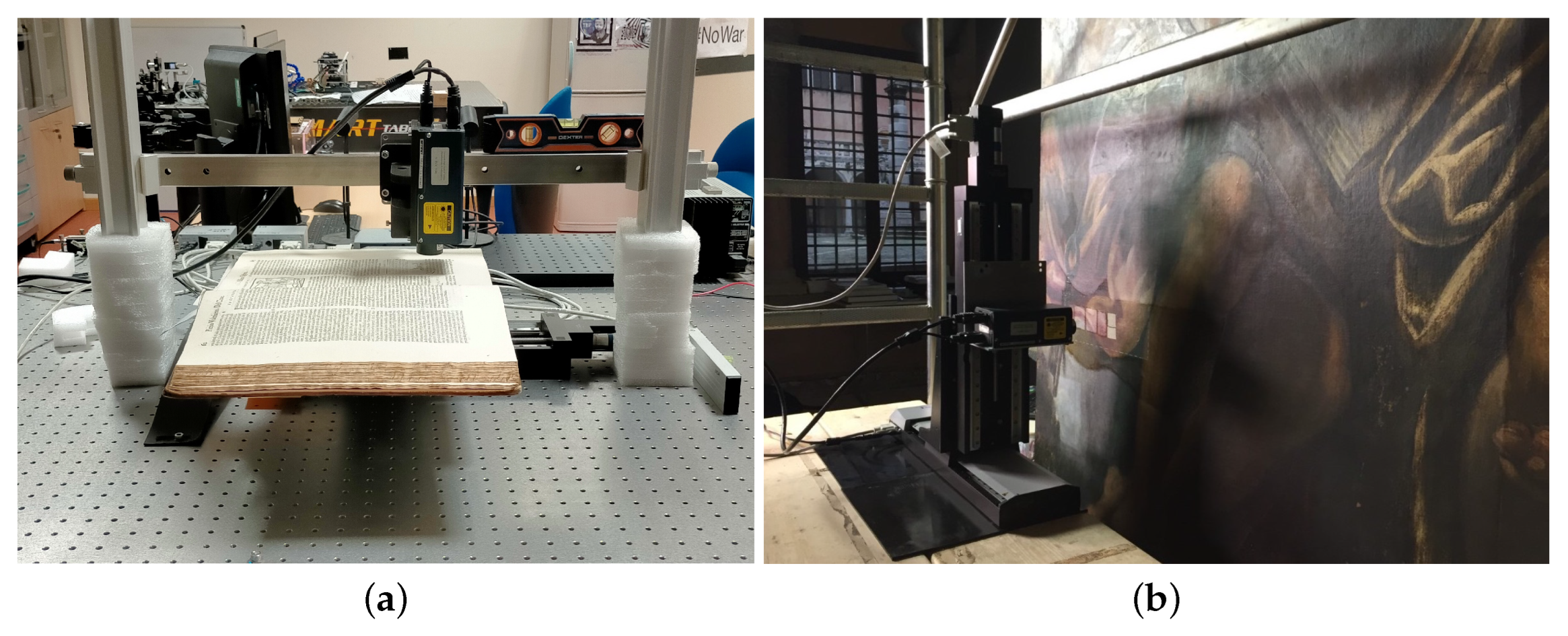

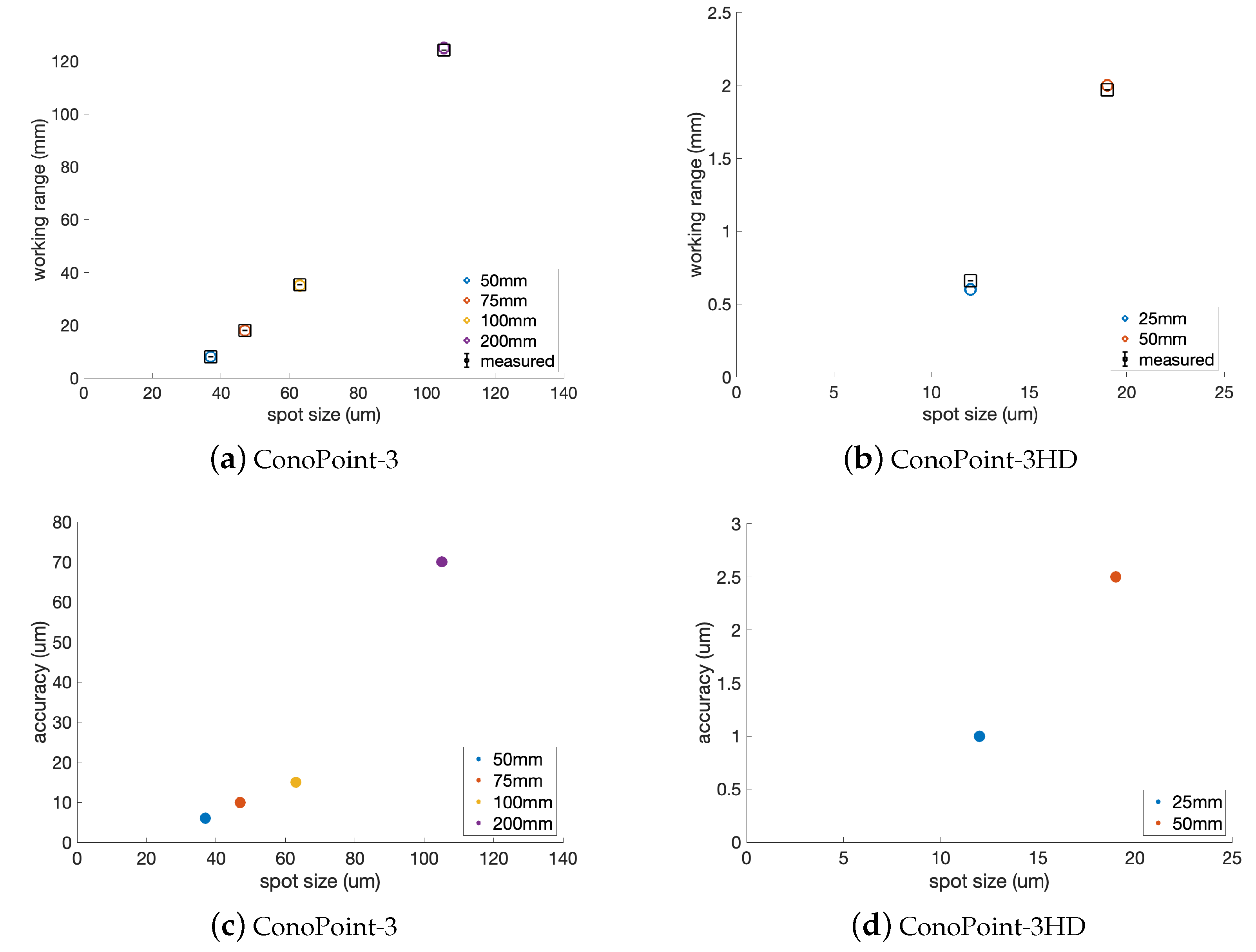

2.1. The Optical Scanner Microprofilometer

2.2. Multiple Dataset Acquisition

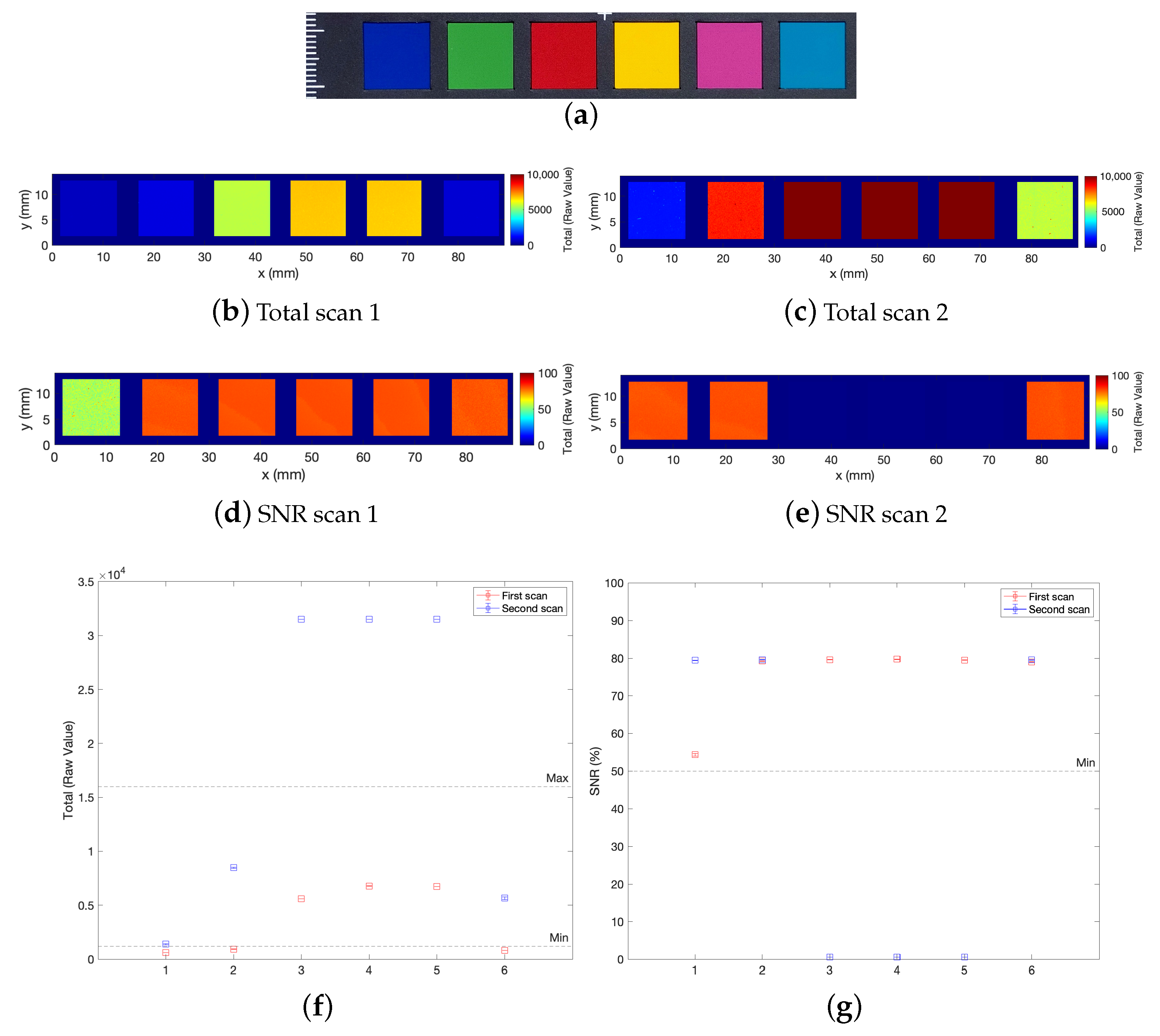

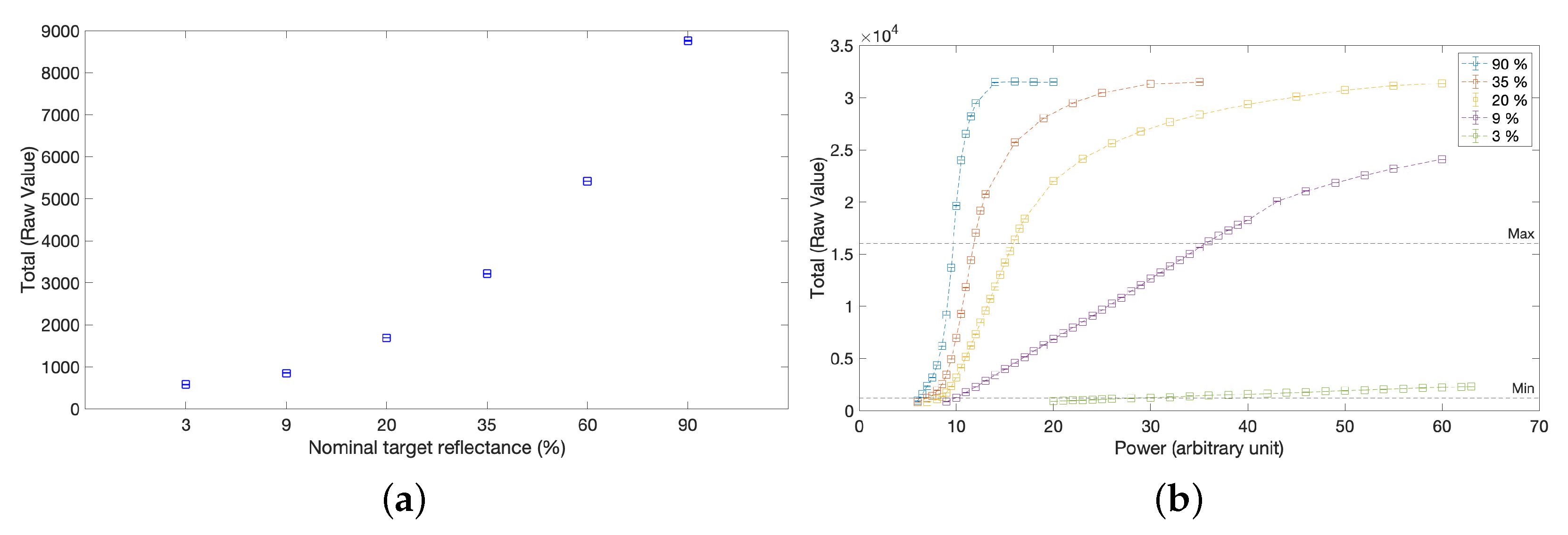

3. Validation Test of the Intensity Signal Total

4. Proof of Concept Applications

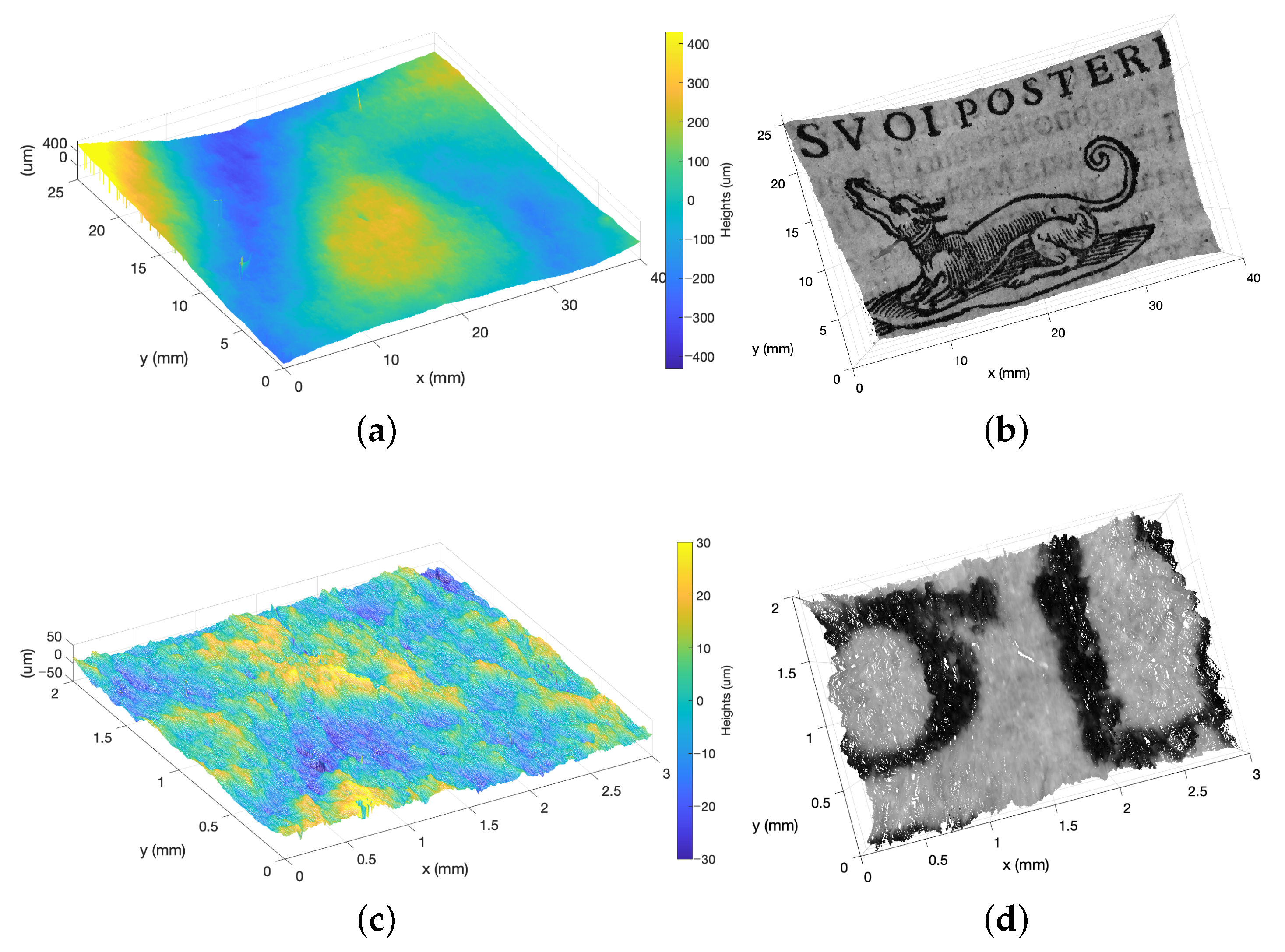

- an ancient book, as example of variegate materials on a flat support, in which the Total map enables sub-domain segmentation on surface height data.;

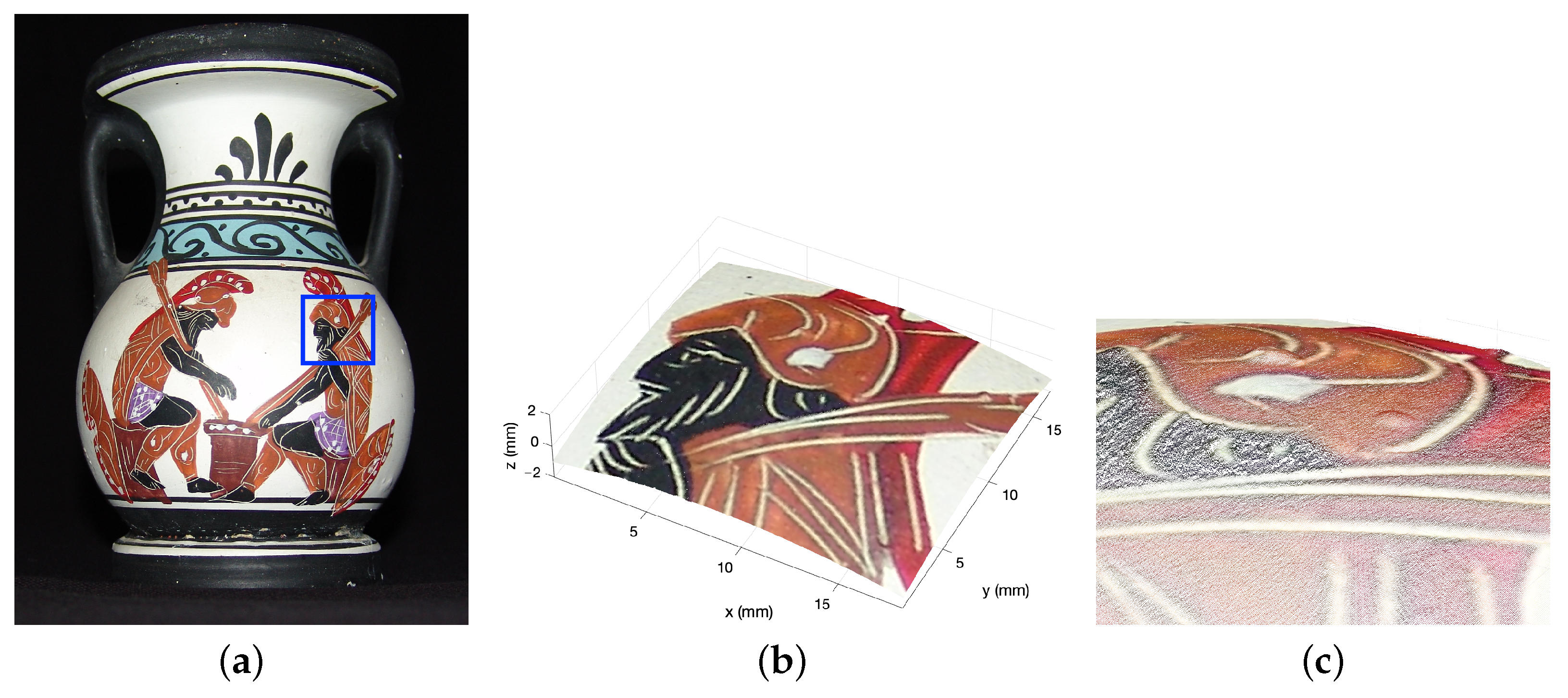

- a painted vase, as example of three-dimensional polychrome archaeological artifact, in which the Total map is used for spatial registration and data fusion;

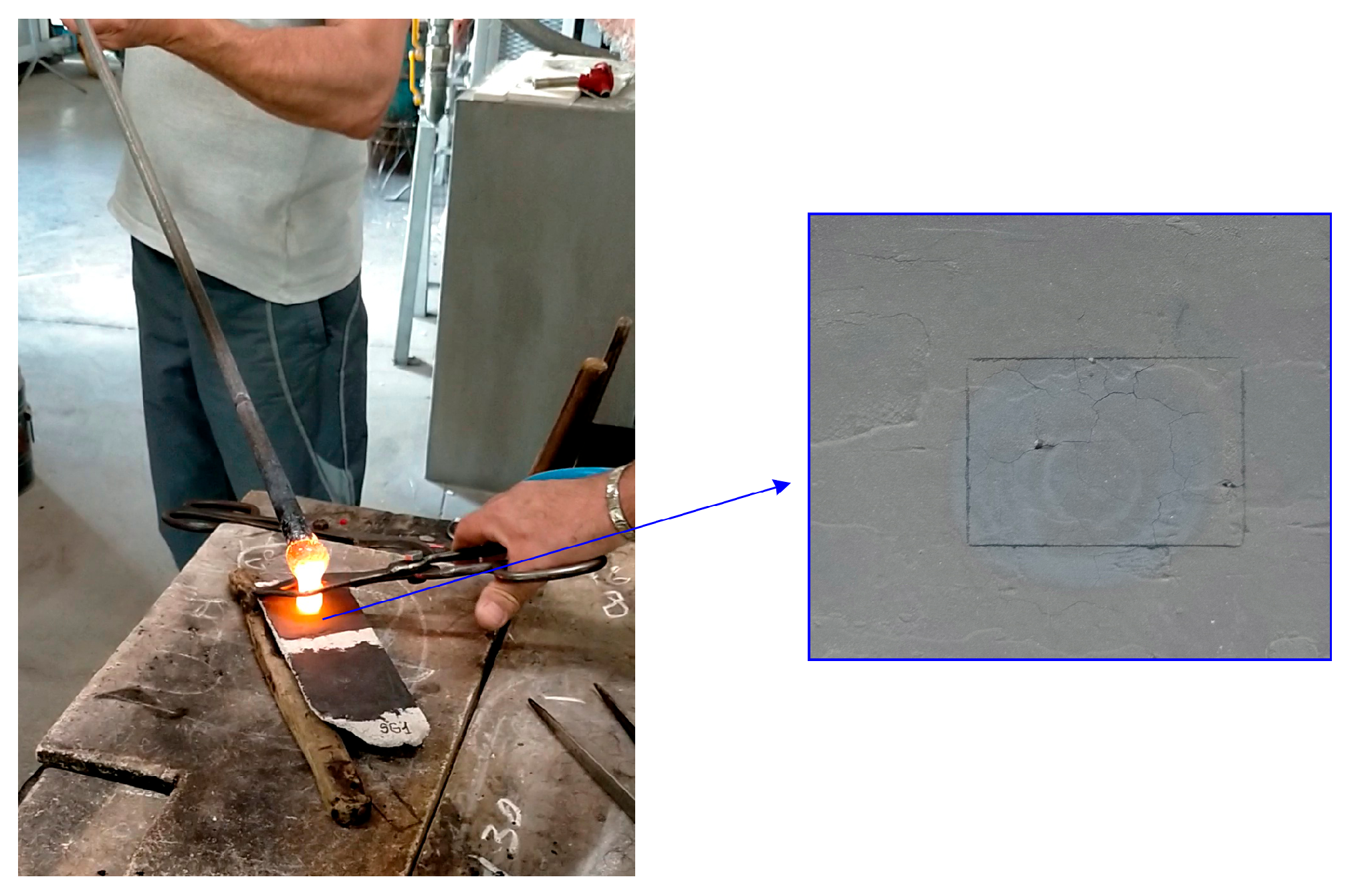

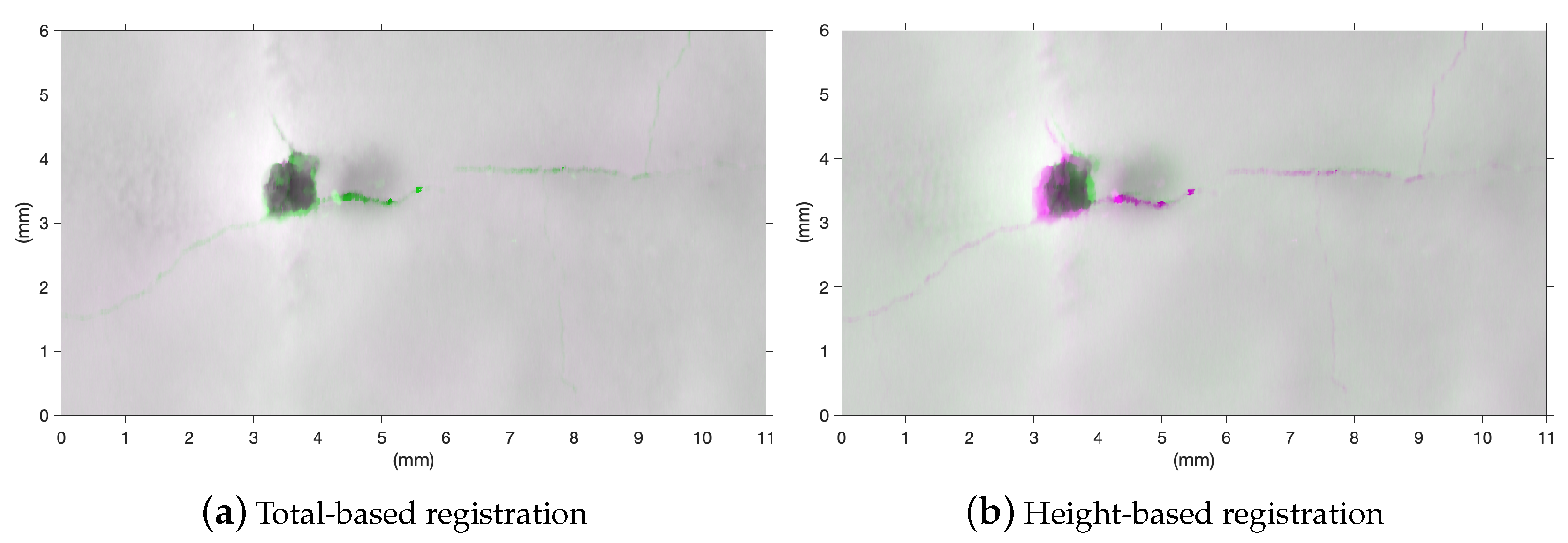

- the multi-temporal monitoring of a surface texture subject to treatments, in which the total map is crucial to reliably perform surface metrology.

4.1. Book Heritage

4.2. Three-Dimensional Polychrome Artifacts

4.3. Multi-Temporal Monitoring in Murano Glassworks, Venice

5. Conclusions

- The first demonstration on book heritage (variegate materials on a flat support) showed that the intensity total map enabled sub-domain segmentation on surface height data, otherwise not possible.The method allowed the computation of roughness parameters on local features such as the paper support and the ink text.

- The second demonstration on a polychrome vase showed that the dual intensity-height datasets enabled spatial registration and data fusion.As the intensity signal turned out to be highly sensitive to a polychrome surface, the micrometric height information was explored by visualizing the surface painted features through the intensity dataset. A visible image was mapped onto the surface data by performing the image-based registration on the intensity domain.

- The third demonstration on the temporal monitoring of surface treatments showed that the intensity total map was crucial for a reliable surface metrology.The combined use of intensity-height datasets allowed to define the regions involved in the treatment and to compute the roughness parameters on the correct domain of interest, while an unsupervised analysis would have led to a sampling bias with subsequent errors in the surface estimators.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ROI | region of interest |

| SNR | signal-to-noise ratio |

| RMS | root mean square |

References

- Gorthi, S.S.; Rastogi, P. Fringe projection techniques: Whither we are? Opt. Lasers Eng. 2010, 48, 133–140. [Google Scholar] [CrossRef]

- Marrugo, A.G.; Gao, F.; Zhang, S. State-of-the-art active optical techniques for three-dimensional surface metrology: A review. J. Opt. Soc. Am. A 2020, 37, B60–B77. [Google Scholar] [CrossRef] [PubMed]

- Palma, G.; Pingi, P.; Siotto, E.; Bellucci, R.; Guidi, G.; Scopigno, R. Deformation analysis of Leonardo da Vinci’s “Adorazione dei Magi” through temporal unrelated 3D digitization. J. Cult. Herit. 2019, 38, 174–185. [Google Scholar] [CrossRef]

- Mironova, A.; Robache, F.; Deltombe, R.; Guibert, R.; Nys, L.; Bigerelle, M. Digital Cultural Heritage Preservation in Art Painting: A Surface Roughness Approach to the Brush Strokes. Sensors 2020, 20, 6269. [Google Scholar] [CrossRef]

- Elkhuizen, W.S.; Callewaert, T.W.J.; Leonhardt, E.; Vandivere, A.; Song, Y.; Pont, S.C.; Geraedts, J.M.P.; Dik, J. Comparison of three 3D scanning techniques for paintings, as applied to Vermeer’s ‘Girl with a Pearl Earring’. Herit. Sci. 2019, 7, 89. [Google Scholar] [CrossRef]

- Blais, F.; Cournoyer, L.; Beraldin, J.A.; Picard, M. 3D imaging from theory to practice: The Mona Lisa story. Proc. SPIE 2008, 7060, 70600L. [Google Scholar] [CrossRef]

- Cacciari, I.; Nieri, P.; Siano, S. 3D Digital Microscopy for Characterizing Punchworks on Medieval Panel Paintings. J. Comput. Cult. Herit. 2014, 7, 1–15. [Google Scholar] [CrossRef]

- Hengstum, M.J.W.v.; Essers, T.T.W.; Elkhuizen, W.S.; Dodou, D.; Song, Y.; Geraedts, J.M.P.; Dik, J. Development of a High Resolution Topography and Color Scanner to Capture Crack Patterns of Paintings. In Proceedings of the Eurographics Workshop on Graphics and Cultural Heritage, Vienna, Austria, 12–15 November 2018; Sablatnig, R., Wimmer, M., Eds.; The Eurographics Association: Eindhoven, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Manfredi, M.; Bearman, G.; Williamson, G.; Kronkright, D.; Doehne, E.; Jacobs, M.; Marengo, E. A New Quantitative Method for the Non-Invasive Documentation of Morphological Damage in Paintings Using RTI Surface Normals. Sensors 2014, 14, 12271–12284. [Google Scholar] [CrossRef]

- Borg, B.; Dunn, M.; Ang, A.S.M.; Villis, C. Canvas Painting Analysis Using Spectroscopic Analysis and Microcharacterisation Techniques. Sensors 2022, 22, 1442. [Google Scholar] [CrossRef]

- Malet, Y.; Sirat, G.Y. Conoscopic holography application: Multipurpose rangefinders. J. Opt. 1998, 29, 183–187. [Google Scholar] [CrossRef]

- Álvarez, I.; Enguita, J.M.; Frade, M.; Marina, J.; Ojea, G. On-Line Metrology with Conoscopic Holography: Beyond Triangulation. Sensors 2009, 9, 7021–7037. [Google Scholar] [CrossRef] [PubMed]

- Zapico, P.; Valiño, G.; Rico, J.C.; Meana, V.M.; Fernández, P. On-machine non-contact roughness verification system based on Conoscopic holography. Precis. Eng. 2022, 73, 115–127. [Google Scholar] [CrossRef]

- Lathrop, R.; Hackworth, D.; Webster, R. Minimally invasive holographic surface scanning for soft-tissue image registrationy. IEEE Trans. Biomed. Eng. 2010, 57, 1497–1506. [Google Scholar] [CrossRef] [PubMed]

- Schirripa Spagnolo, G.; Cozzella, L.; Simonetti, C. Linear conoscopic holography as aid for forensic handwriting expert. Optik 2013, 124, 2155–2160. [Google Scholar] [CrossRef]

- Fontana, R.; Gambino, M.C.; Mazzotta, C.; Greco, M.; Pampaloni, E.; Pezzati, L. High-resolution 3D survey of artworks. Proc. SPIE 2004, 5457, 719–726. [Google Scholar] [CrossRef]

- Gaburro, N.; Marchioro, G.; Daffara, C. A versatile optical profilometer based on conoscopic holography sensors for acquisition of specular and diffusive surfaces in artworks. Proc. SPIE 2017, 10331, 48–56. [Google Scholar] [CrossRef]

- Daffara, C.; Mazzocato, S.; Marchioro, G. Multiscale roughness analysis by microprofilometry based on conoscopic holography: A new tool for treatment monitoring in highly reflective metal artworks. Eur. Phys. J. Plus 2022, 137, 430. [Google Scholar] [CrossRef]

- Daffara, C.; Mazzocato, S. Surface Metrology Based on Scanning Conoscopic Holography for In Situ and In-Process Monitoring of Microtexture in Paintings. Sensors 2022, 22, 6637. [Google Scholar] [CrossRef]

- Striova, J.; Fontana, R.; Barucci, M.; Felici, A.; Marconi, E.; Pampaloni, E.; Raffaelli, M.; Riminesi, C. Optical devices provide unprecedented insights into the laser cleaning of calcium oxalate layers. Microchem. J. 2016, 124, 331–337. [Google Scholar] [CrossRef]

- Zhu, L.; Barhak, J.; Srivatsan, V.; Katz, R. Efficient registration for precision inspection of free-form surfaces. Int. J. Adv. Manuf. Technol. 2007, 32, 505–515. [Google Scholar] [CrossRef]

- He, W.; Zhong, K.; Li, Z.; Meng, X.; Cheng, X.; Liu, X.; Shi, Y. Accurate calibration method for blade 3D shape metrology system integrated by fringe projection profilometry and conoscopic holography. Opt. Lasers Eng. 2018, 110, 253–261. [Google Scholar] [CrossRef]

- Godin, G.; Rioux, M.; Baribeau, R. Three-dimensional registration using range and intensity information. SPIE Proc. 1994, 2350, 279–290. [Google Scholar] [CrossRef]

- Lemesle, J.; Guibert, R.; Bigerelle, M. A Novel 3D Topography Stitching Algorithm Based on Reflectance and Multimap. Appl. Sci. 2023, 13, 857. [Google Scholar] [CrossRef]

- Mazzocato, S.; Daffara, C. Experiencing the Untouchable: A Method for Scientific Exploration and Haptic Fruition of Artworks Microsurface Based on Optical Scanning Profilometry. Sensors 2021, 21, 4311. [Google Scholar] [CrossRef] [PubMed]

- Fernández, P.; Blanco, D.; Rico, C.; Valiño, G.; Mateos, S. Influence of Surface Position along the Working Range of Conoscopic Holography Sensors on Dimensional Verification of AISI 316 Wire EDM Machined Surfaces. Sensors 2014, 14, 4495–4512. [Google Scholar] [CrossRef] [PubMed]

- Optimet Ophir Photonics. ConoPoint Series. User Manual; Optimet Ophir Photonics: Jerusalem, Israel, 2015. [Google Scholar]

- Optimet Ophir Photonics. OEM Manual for OPTIMET’S Family of Ethernet Probes; Optimet Ophir Photonics: Jerusalem, Israel, 2009. [Google Scholar]

- Rico, J.C.; Valiño, G.; Fernández, P.; Zapico, P.; Blanco, D.; Mateos, S. Adjustment recommendations of a conoscopic holography sensor for a reliable scanning of surfaces with roughness grades obtained by different processes. Precis. Eng. 2015, 42, 335–345. [Google Scholar] [CrossRef]

- POR FESR 2014–2020 Veneto Project. D3Vero (Stampa 3D nel Settore del Vetro Artistico per Rilanciare ed Innovare la Filiera Produttiva), 2020–2022. Available online: https://d3vero.it/ (accessed on 7 February 2023).

- MATLAB. Version 9.13.0.2105380 (R2022b); The MathWorks Inc.: Natick, MA, USA, 2022. [Google Scholar]

| Surface Map | Description | Reference |

|---|---|---|

| Surface heights | Interferometric data reporting the distance between the object and the sensor. | TMeasurement.Distance |

| Signal-to-noise ratio | Dataset with the signal quality of each measured point. An optimal measurement requires an SNR value greater than 50%. | TMeasurement.Snr |

| Total | Energy collected by the detector (raw intensity signal in arbitrary unit). Optimal values for Total are between 1200 and 16,000 counts (900 to 18,000 in extreme cases). | TMeasurement.Total |

| Before treatment | |||

| After treatment (Supervised) | |||

| After treatment (Unsupervised) | |||

| Estimation error (%) | 25.13 | 634.656 | 206.668 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazzocato, S.; Daffara, C. A Method for Spatially Registered Microprofilometry Combining Intensity-Height Datasets from Interferometric Sensors. Sensors 2023, 23, 4144. https://doi.org/10.3390/s23084144

Mazzocato S, Daffara C. A Method for Spatially Registered Microprofilometry Combining Intensity-Height Datasets from Interferometric Sensors. Sensors. 2023; 23(8):4144. https://doi.org/10.3390/s23084144

Chicago/Turabian StyleMazzocato, Sara, and Claudia Daffara. 2023. "A Method for Spatially Registered Microprofilometry Combining Intensity-Height Datasets from Interferometric Sensors" Sensors 23, no. 8: 4144. https://doi.org/10.3390/s23084144

APA StyleMazzocato, S., & Daffara, C. (2023). A Method for Spatially Registered Microprofilometry Combining Intensity-Height Datasets from Interferometric Sensors. Sensors, 23(8), 4144. https://doi.org/10.3390/s23084144