TeCVP: A Time-Efficient Control Method for a Hexapod Wheel-Legged Robot Based on Velocity Planning

Abstract

1. Introduction

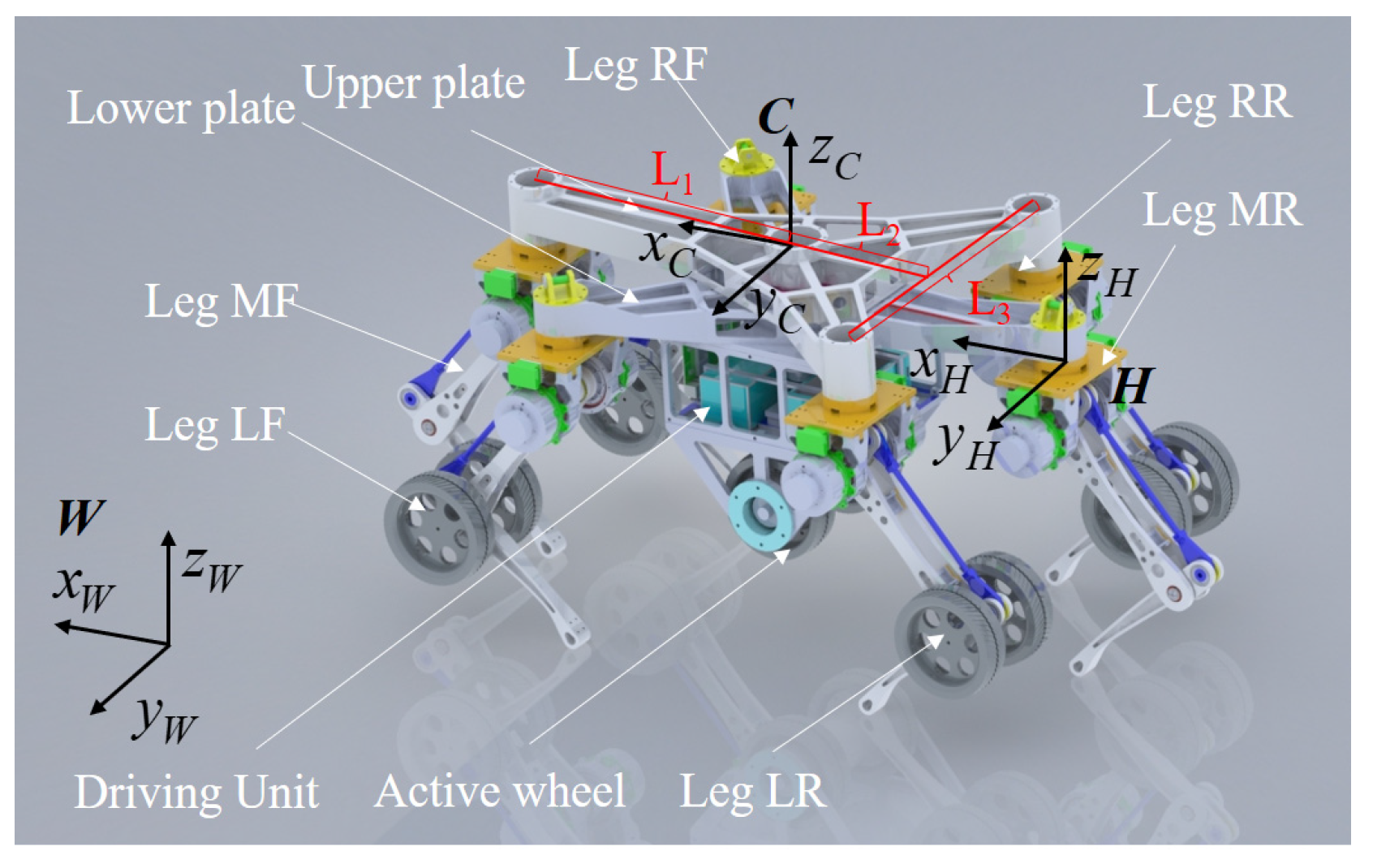

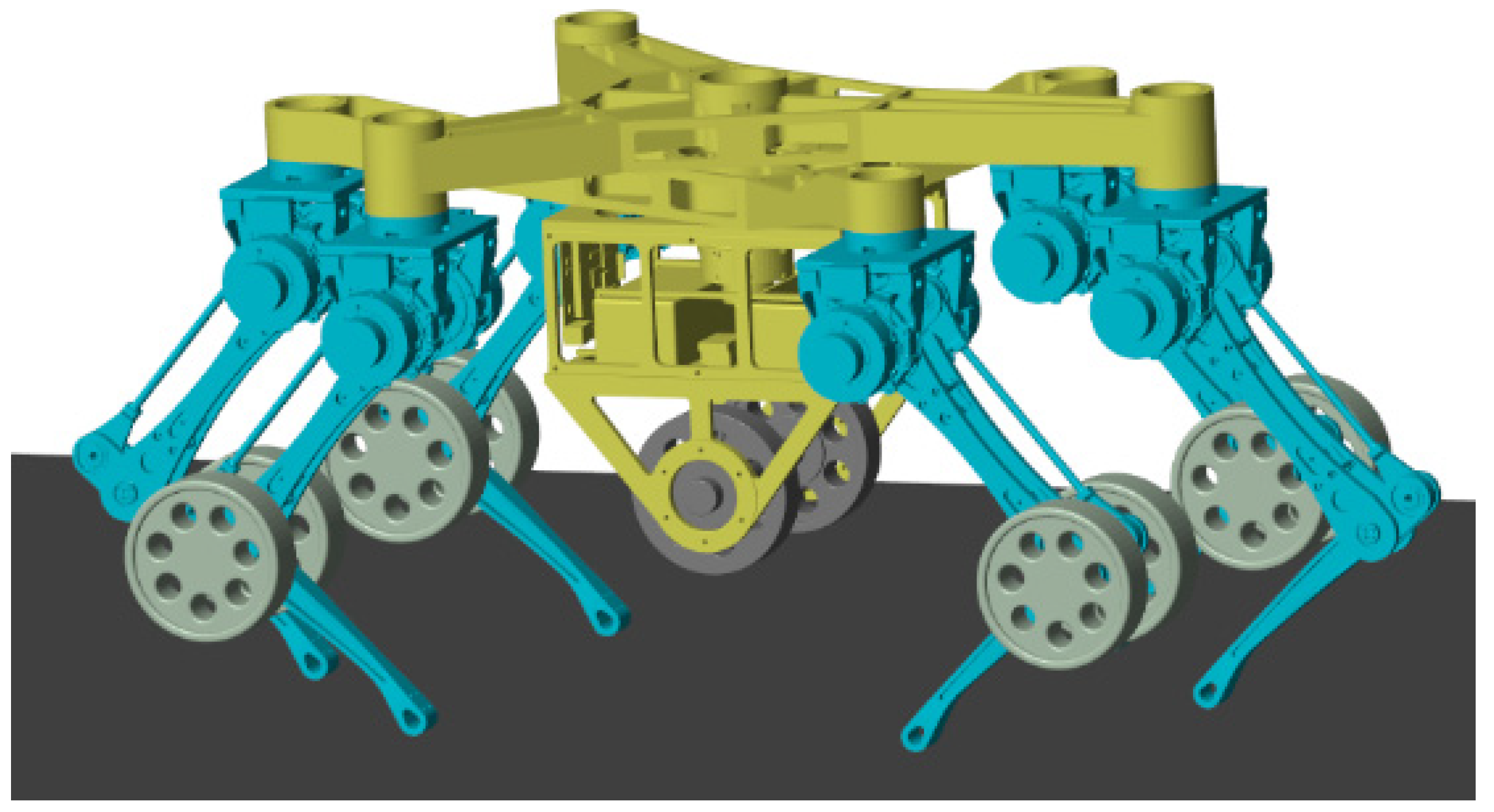

2. Description of the Wheel-Legged Robot

3. Control Method Based on Velocity Planning

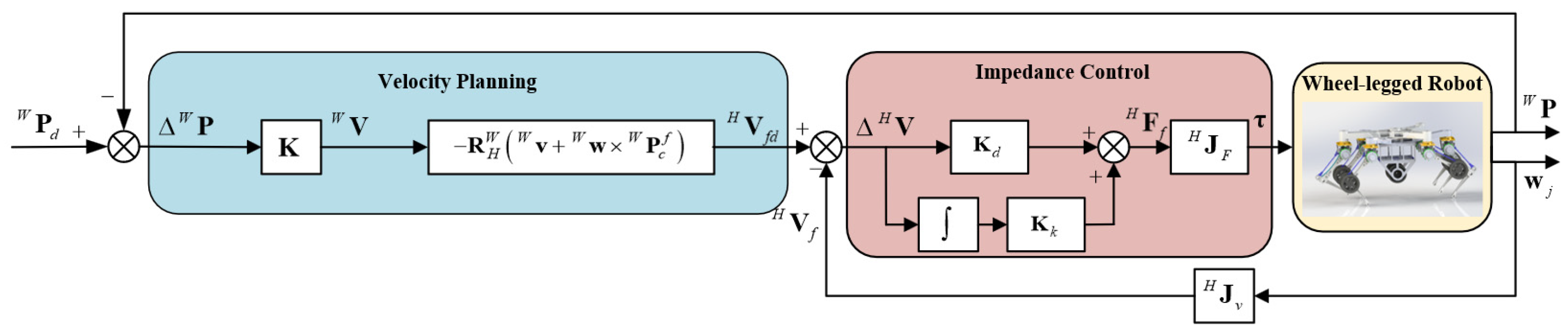

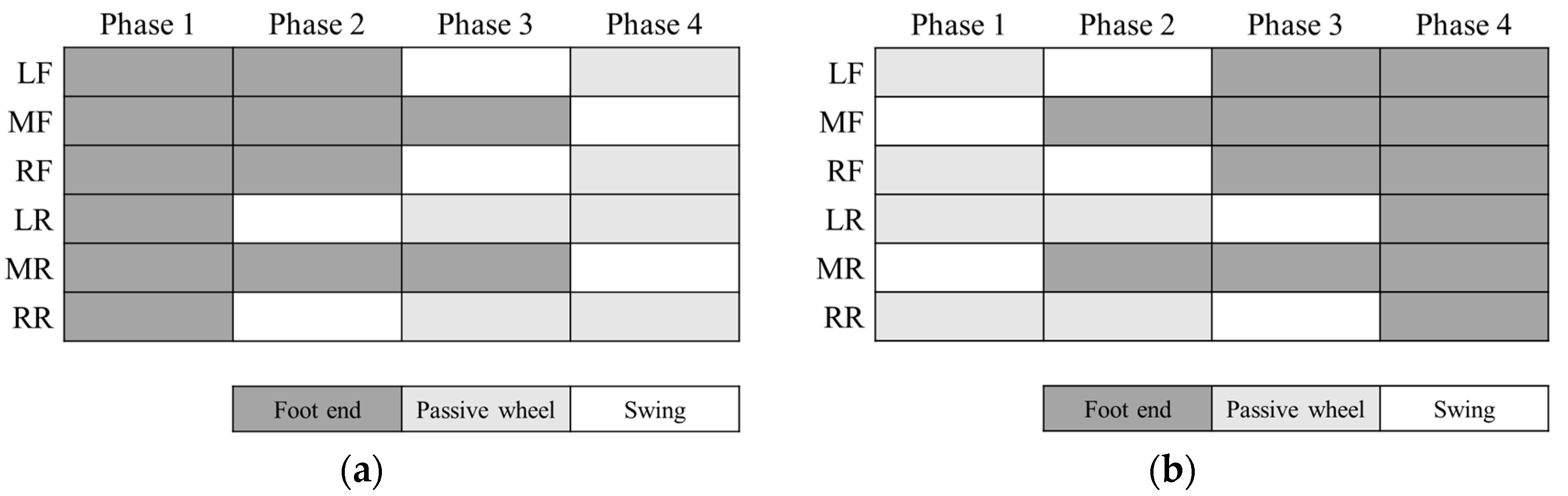

3.1. Legged Motion

3.1.1. Stance Phase

3.1.2. Swing Phase

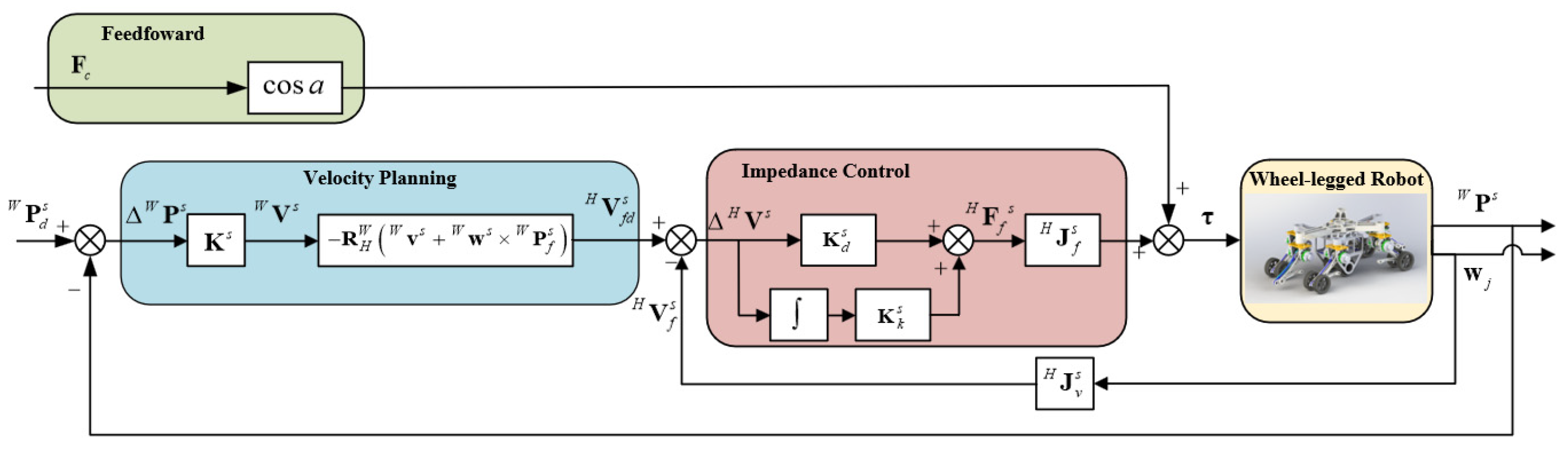

3.2. Wheeled Motion

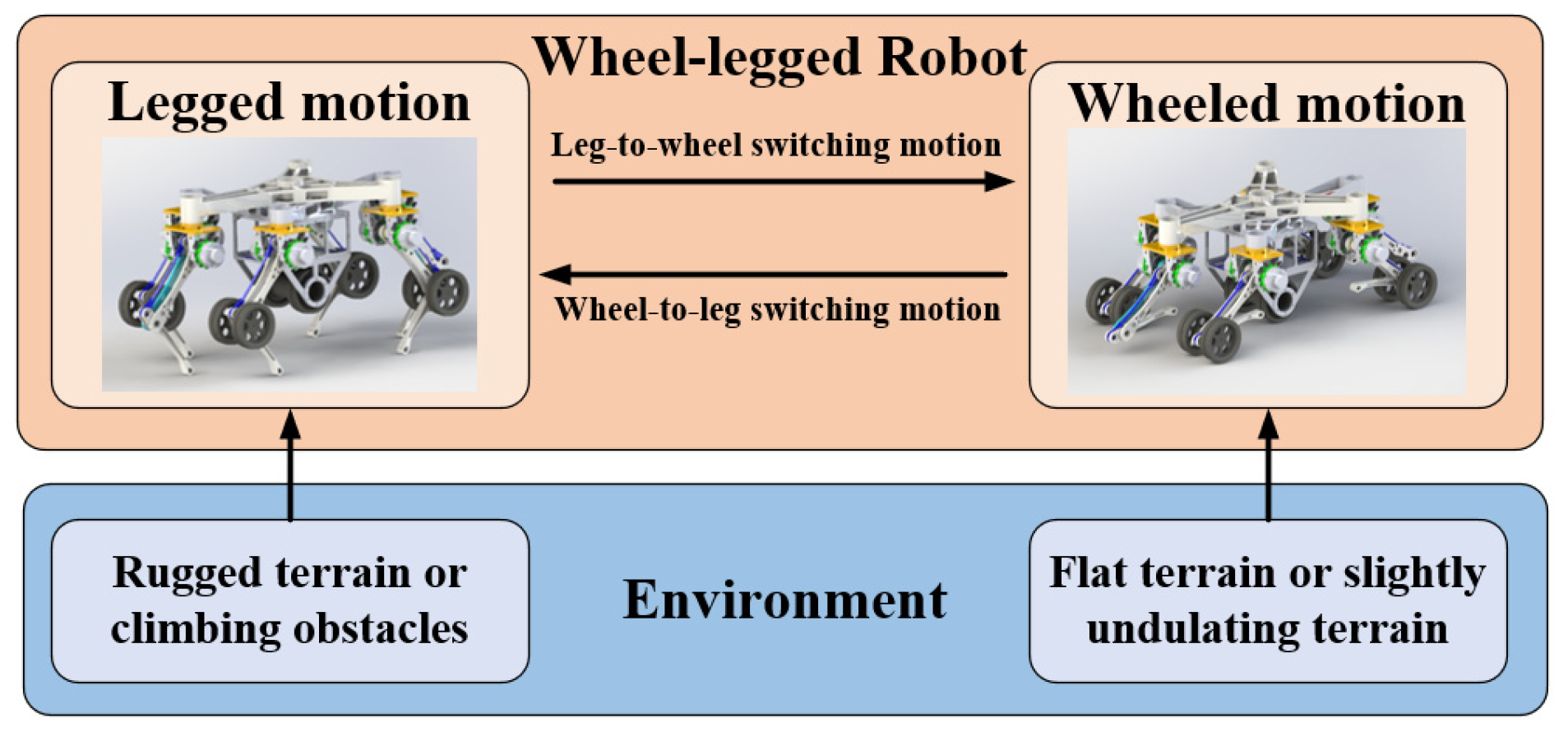

3.3. Wheel-Leg Switching Gait Planning

4. Complexity Analysis

4.1. Time Complexity

4.2. Times of Basic Operations

5. Simulations

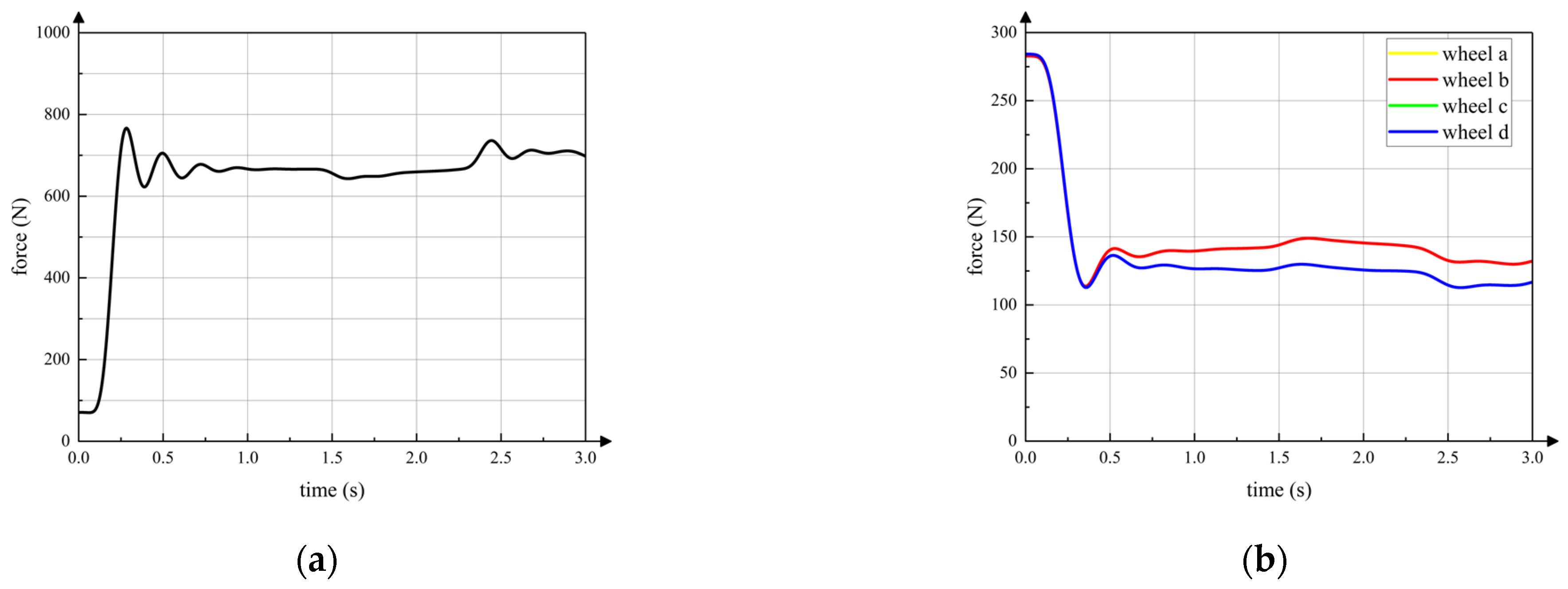

5.1. Tripod Gait Motion

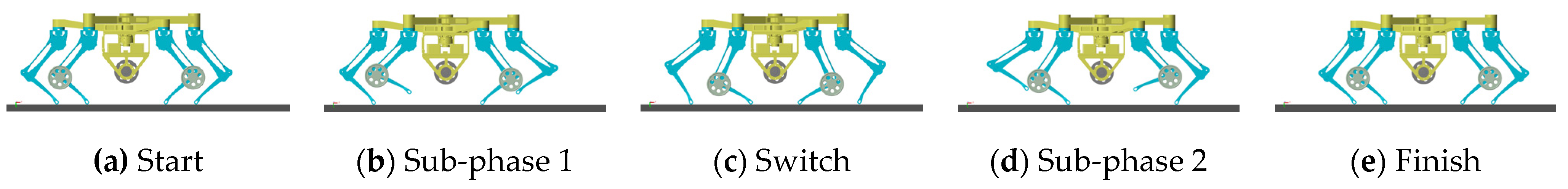

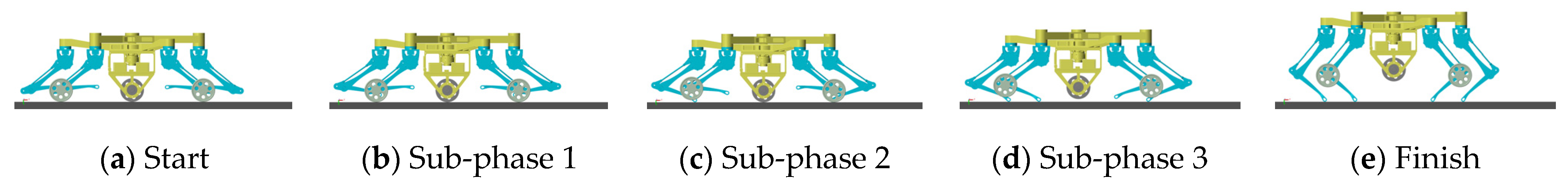

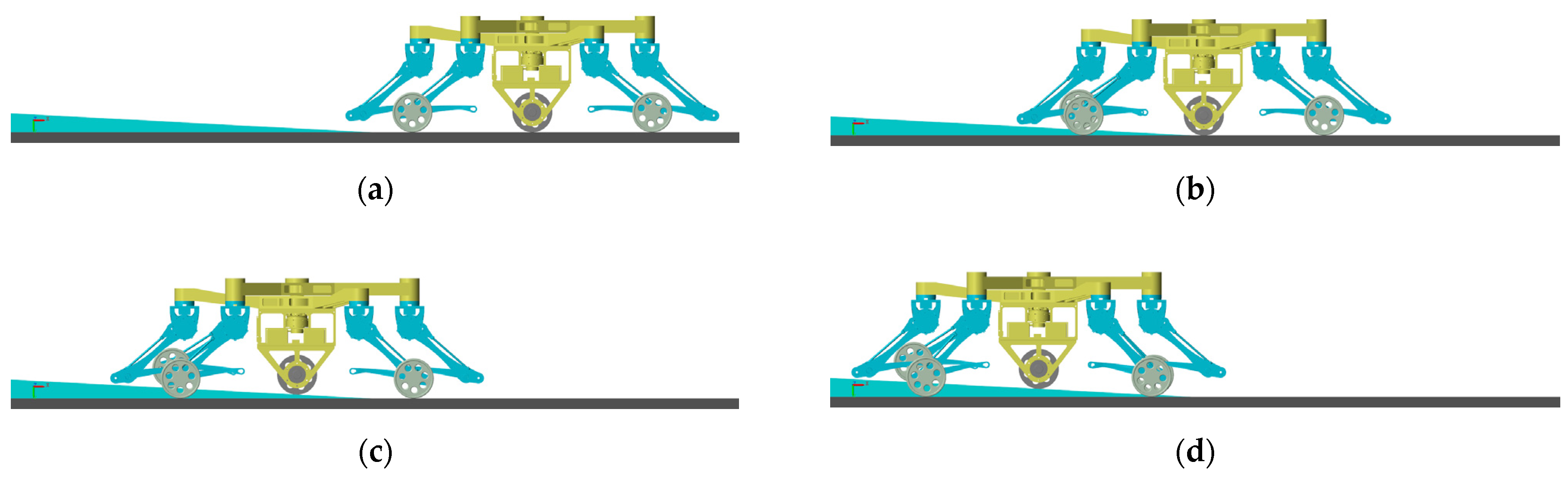

5.2. Switching Motion

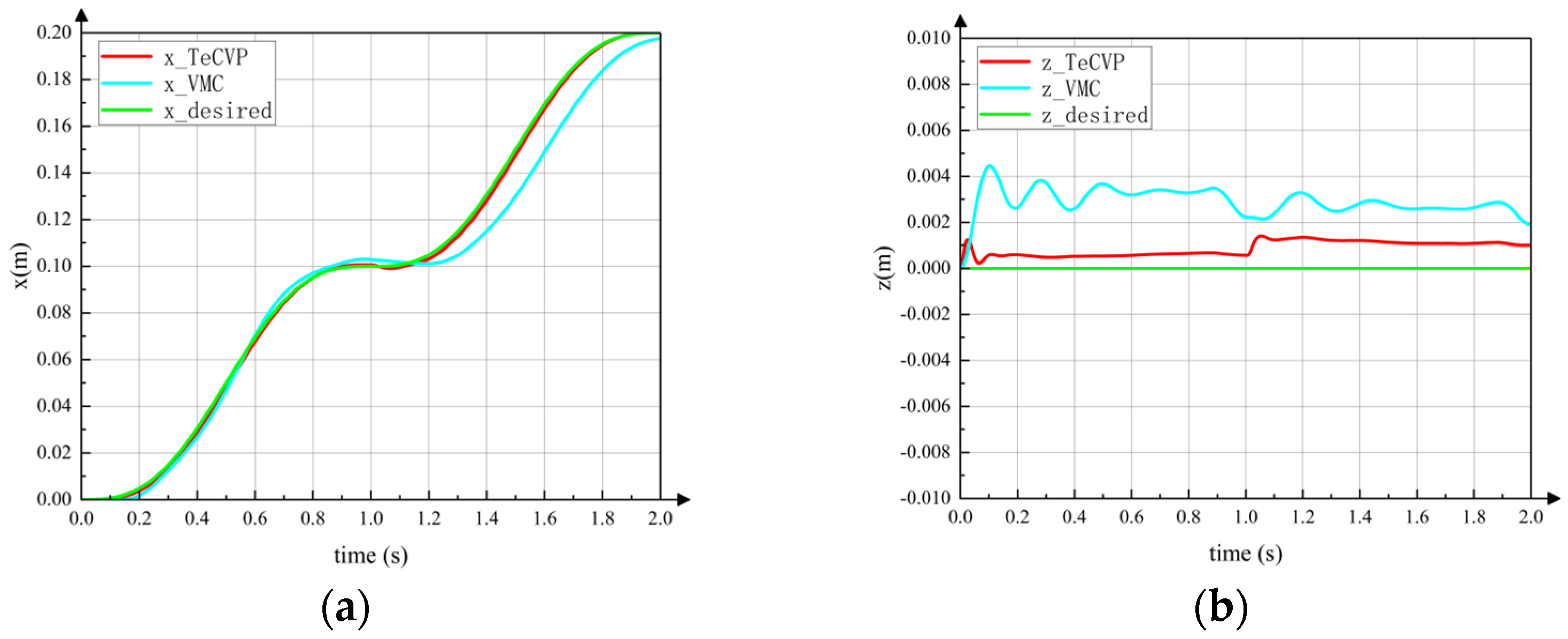

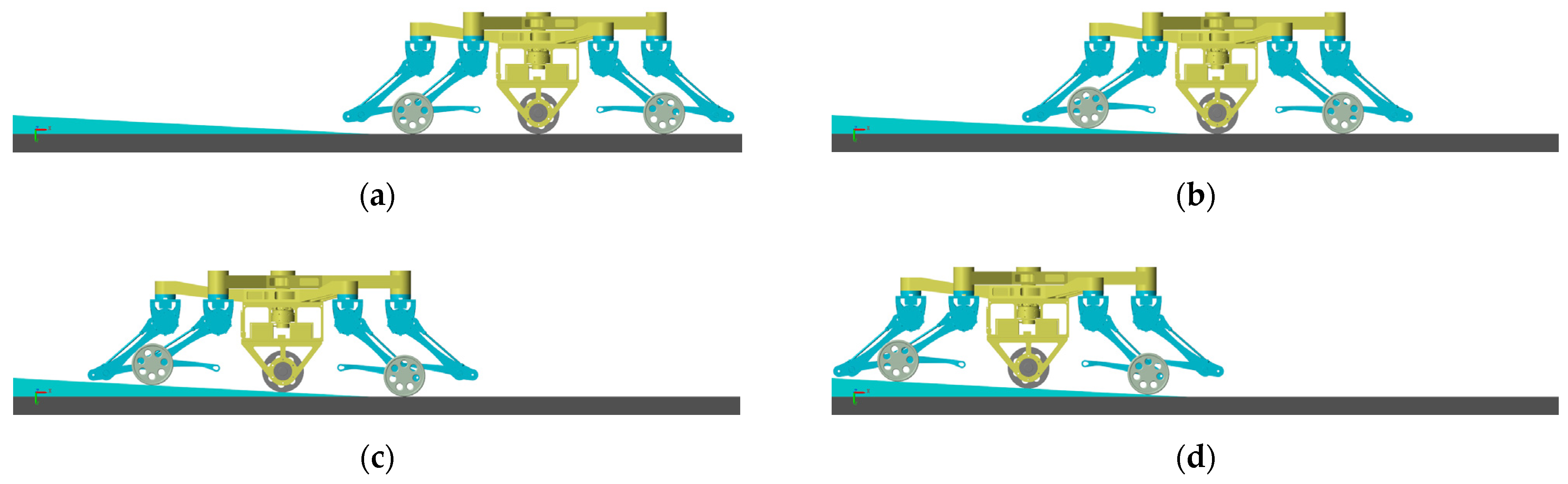

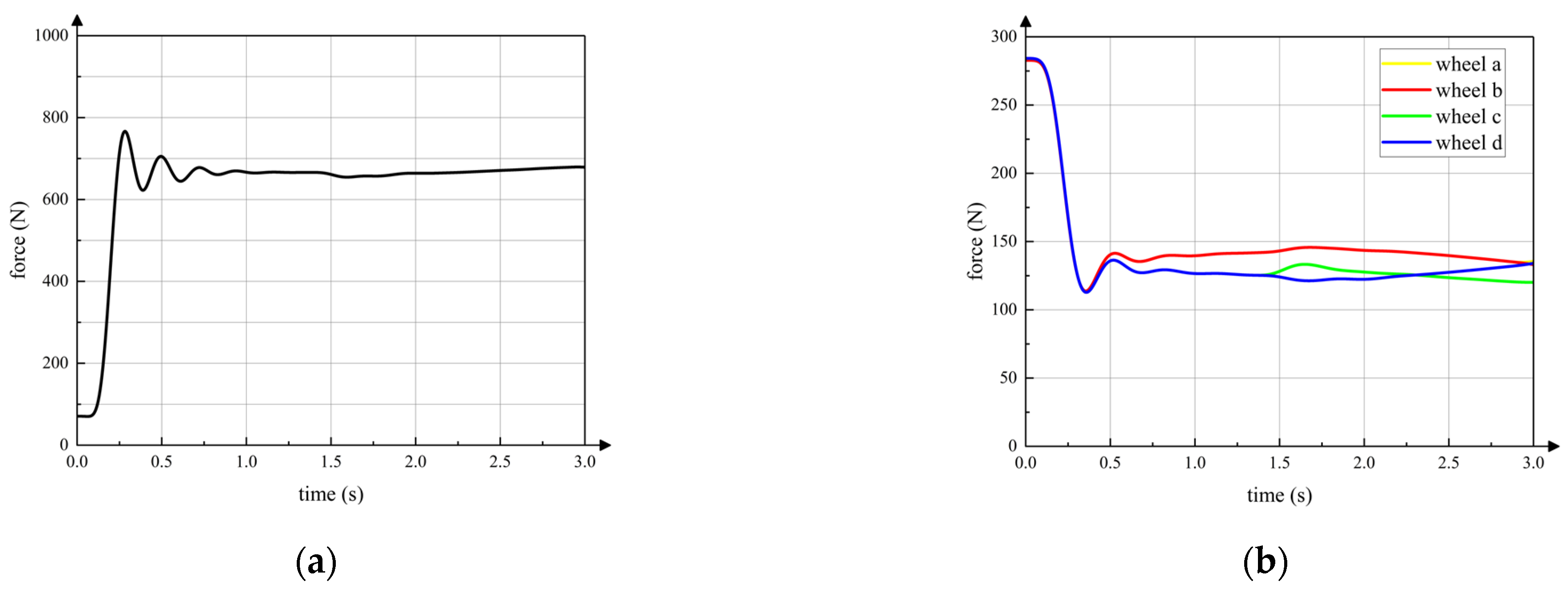

5.3. Wheeled Motion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, L.; Zhou, R.; Yu, T.; Gao, H.; Yang, H.; Li, J.; Yuan, Y.; Liu, C.; Wang, J.; Zhao, Y.Y.S.; et al. Surface characteristics of the Zhurong Mars rover traverse at Utopia Planitia. Nat. Geosci. 2022, 15, 171–176. [Google Scholar] [CrossRef]

- Wizte, A. A month on Mars: What NASA’s Perseverance rover has found so far. Nature 2021, 591, 509–510. [Google Scholar]

- Lin, X.U.; Zou, Y.; Jia, Y. China’s Planning for Deep Space Exploration and Lunar Exploration before 2030. Chin. J. Space Sci. 2018, 38, 591–592. [Google Scholar] [CrossRef]

- Grady, M.M. Exploring Mars with Returned Samples. Space Sci. Rev. 2020, 216, 51. [Google Scholar] [CrossRef]

- Lakdawalla, E. The Design and Engineering of Curiosity; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Toupet, O.; Biesiadecki, J.; Rankin, A.; Steffy, A.; Griffith, G.M.; Levine, D.; Schadegg, M.; Maimone, M. Terrain-adaptive wheel speed control on the Curiosity Mars rover: Algorithm and flight results. J. Field Robot. 2020, 37, 699–728. [Google Scholar] [CrossRef]

- Harrington, B.D.; Voorhees, C. The Challenges of Designing the Rocker-Bogie Suspension for the Mars Exploration Rover. In Proceedings of the 37th Aerospace Mechanisms Symposium, Galveston, TX, USA, 19–21 May 2004. [Google Scholar]

- Zheng, J.Q.; Gao, H.B.; Yuan, B.F.; Liu, Z.; Yu, H.T.; Ding, L.; Deng, Z.Q. Design and terramechanics analysis of a Mars rover utilising active suspension. Mech. Mach. Theory 2018, 128, 125–149. [Google Scholar] [CrossRef]

- Bartsch, S.; Birnschein, T.; Römmermann, M.; Hilljegerdes, J.; Kühn, D.; Kirchner, F. Development of the six-legged walking and climbing robot SpaceClimber. J. Field Robot. 2012, 29, 506–532. [Google Scholar] [CrossRef]

- Arm, P.; Zenkl, R.; Barton, P.; Beglinger, L.; Dietsche, A.; Ferrazzini, L.; Hampp, E.; Hinder, J.; Huber, C.; Schaufelberger, D.; et al. SpaceBok: A Dynamic Legged Robot for Space Exploration. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 6288–6294. [Google Scholar]

- He, J.; Gao, F. Mechanism, Actuation, Perception, and Control of Highly Dynamic Multilegged Robots: A Review. Chin. J. Mech. Eng. 2020, 33, 79. [Google Scholar] [CrossRef]

- Kolvenbach., H.; Hampp, E.; Barton, P.; Zenkl, R.; Hutter, M. Towards Jumping Locomotion for Quadruped Robots on the Moon. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 5459–5466. [Google Scholar]

- Bjelonic, M.; Bellicoso, C.D.; de Viragh, Y.; Sako, D.; Tresoldi, F.D.; Jenelten, F.; Hutter, M. Keep Rollin’—Whole-Body Motion Control and Planning for Wheeled Quadrupedal Robots. IEEE Robot. Autom. Lett. 2019, 4, 2116–2123. [Google Scholar] [CrossRef]

- Wilcox, B.H.; Litwin, T.; Biesiadecki, J.; Matthews, J.; Heverly, M.; Morrison, J.; Townsend, J.; Ahmad, N.; Sirota, A.; Cooper, B. Athlete: A cargo handling and manipulation robot for the moon. J. Field Robot. 2007, 24, 421–434. [Google Scholar] [CrossRef]

- Wilcox, B.H. ATHLETE: An Option for Mobile Lunar Landers. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2008; pp. 1–8. [Google Scholar]

- Wilcox, B.H. ATHLETE: A cargo and habitat transporter for the moon. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2009; pp. 1–7. [Google Scholar]

- Reid, W.; Paton, M.; Karumanchi, S.; Chamberlain, B.; Emanuel, B.; Gareth, M. Autonomous Navigation over Europa Analogue Terrain for an Actively Articulated Wheel-on-Limb Rover. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 1939–1946. [Google Scholar]

- Roehr, T.M.; Cordes, F.; Kirchner, F. Reconfigurable Integrated Multirobot Exploration System (RIMRES): Heterogeneous Modular Reconfigurable Robots for Space Exploration: Reconfigurable Integrated Multirobot Exploration System. J. Field Robot. 2014, 31, 3–34. [Google Scholar] [CrossRef]

- Cordes, F.; Kirchner, F.; Babu, A. Design and field testing of a rover with an actively articulated suspension system in a Mars analog terrain. J. Field Robot. 2018, 35, 1149–1181. [Google Scholar] [CrossRef]

- Reid, W.; Fitch, R.; Göktoğan, A.H.; Sukkarieh, S. Sampling-based hierarchical motion planning for a reconfigurable wheel-on-leg planetary analogue exploration rover. J. Field Robot. 2020, 37, 786–811. [Google Scholar] [CrossRef]

- Ding, X.; Li, K.; Xu, K. Dynamics and wheel’s slip ratio of a wheel-legged robot in wheeled motion considering the change of height. Chin. J. Mech. Eng. 2012, 25, 1060–1067. [Google Scholar] [CrossRef]

- Ding, X.; Zheng, Y.; Xu, K. Wheel-legged hexapod robots: A multifunctional mobile manipulating platform. Chin. J. Mech. Eng. 2017, 30, 3–6. [Google Scholar] [CrossRef]

- Peng, S.J.; Ding, X.L.; Yang, F.; Xu, K. Motion planning and implementation for the self-recovery of an overturned multi-legged robot. Robotica 2017, 35, 1107–1120. [Google Scholar] [CrossRef]

- Qin, R.P.; Xu, K.P.; Chen, J.W.; Han, L.L.; Ding, X.L. Design and motion planning of wheel-legged hexapod robot for planetary exploration. Acta Aeronaut. Astronaut. Sin. 2021, 42, 524244. [Google Scholar]

- Pratt, J.; Chew, C.M.; Torres, A.; Dilworth, P.; Pratt, G. Virtual model control: An intuitive approach for bipedal locomotion. Int. J. Robot. Res. 2001, 20, 129–143. [Google Scholar] [CrossRef]

- Semini, C.; Tsagarakis, N.G.; Guglielmino, E.; Focchi, M.; Cannella, F.; Caldwell, D.G. Design of HyQ–a hydraulically and electrically actuated quadruped robot. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2011, 225, 831–849. [Google Scholar] [CrossRef]

- Hutter, M. StarlETH & Co.: Design and Control of Legged Robots with Compliant Actuation; ETH Zurich: Zurich, Switzerland, 2013. [Google Scholar]

- Xue, J.F.; Li, J.H.; Chen, Z.H.; Wang, S.K.; Wang, J.Z.; Ma, R.J. Gait planning and control of hexapod robot based on velocity vector. In Proceedings of the IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Chongqing, China, 3–5 July 2021; pp. 616–620. [Google Scholar]

- Moreno, J. Constrained trajectory tracking control of a mobile robot by limited integrator anti-windup. IEEE Trans. Circuits Syst. II Express Briefs 2022, 69, 1422–1426. [Google Scholar]

- Hogan, N.; Buerger, S. Impedance and Interaction Control. In Robotics and Automation Handbook; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Mol, N.; Smisek, J.; Babuska, R.; Schiele, A. Nested compliant admittance control for robotic mechanical assembly of misaligned and tightly toleranced parts. In Proceedings of the IEEE international conference on systems, man, and cybernetics (SMC), Budapest, Hungary, 9–12 October 2016; pp. 002717–002722. [Google Scholar]

- Mao, L.H.; Tian, Y.; Gao, F.; Zhao, Y. Novel method of gait switching in six-legged robot walking on continuous-nondifferentiable terrain by utilizing stability and interference criteria. Sci. China Technol. Sci. 2020, 63, 2527–2540. [Google Scholar] [CrossRef]

| Number of Equations | Instances of Basic Operations | |

|---|---|---|

| Multiplication | Addition | |

| (6) | 0 | 4 |

| (7) | 4 | 0 |

| (8) | 2 | 3 |

| (9) | 0 | 2 |

| (10) | 4 | 2 |

| (11) | 4 | 2 |

| Total | 14 | 13 |

| Stage of Operating | Instances of Basic Operations | |

|---|---|---|

| Multiplication | Addition | |

| Calculation of CoM desired force | 8 | 12 |

| LU decomposition | 70 | 70 |

| Calculation of joint torques | 12 | 6 |

| Total | 90 | 88 |

| Coefficients | Value | |

|---|---|---|

| stance phase | coefficient vector of sliding mode surface | [1000;1000;1000;1000] |

| damping vector of impedance control | [10;10] | |

| stiffness vector of impedance control | [200;200] | |

| swing phase | damping vector of impedance control | [100;100] |

| stiffness vector of impedance control | [3000;3000] | |

| wheeled motion | coefficient vector of sliding mode surface | [1000;1000] |

| damping vector of impedance control | [10] | |

| stiffness vector of impedance control | [200] |

| Coefficients | Value |

|---|---|

| virtual stiffness vector of VMC | [10,000;10,000;10,000;10,000] |

| virtual damping vector of VMC | [100;100;100;100] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Sun, Z.; Li, J.; Wang, C.; Jing, X.; Wei, Q.; Liu, B.; Yan, C. TeCVP: A Time-Efficient Control Method for a Hexapod Wheel-Legged Robot Based on Velocity Planning. Sensors 2023, 23, 4051. https://doi.org/10.3390/s23084051

Sun J, Sun Z, Li J, Wang C, Jing X, Wei Q, Liu B, Yan C. TeCVP: A Time-Efficient Control Method for a Hexapod Wheel-Legged Robot Based on Velocity Planning. Sensors. 2023; 23(8):4051. https://doi.org/10.3390/s23084051

Chicago/Turabian StyleSun, Junkai, Zezhou Sun, Jianfei Li, Chu Wang, Xin Jing, Qingqing Wei, Bin Liu, and Chuliang Yan. 2023. "TeCVP: A Time-Efficient Control Method for a Hexapod Wheel-Legged Robot Based on Velocity Planning" Sensors 23, no. 8: 4051. https://doi.org/10.3390/s23084051

APA StyleSun, J., Sun, Z., Li, J., Wang, C., Jing, X., Wei, Q., Liu, B., & Yan, C. (2023). TeCVP: A Time-Efficient Control Method for a Hexapod Wheel-Legged Robot Based on Velocity Planning. Sensors, 23(8), 4051. https://doi.org/10.3390/s23084051