A Time-of-Flight Image Sensor Using 8-Tap P-N Junction Demodulator Pixels

Abstract

1. Introduction

2. Principle and Design of the 8-Tap P-N Junction Demodulator (PND)

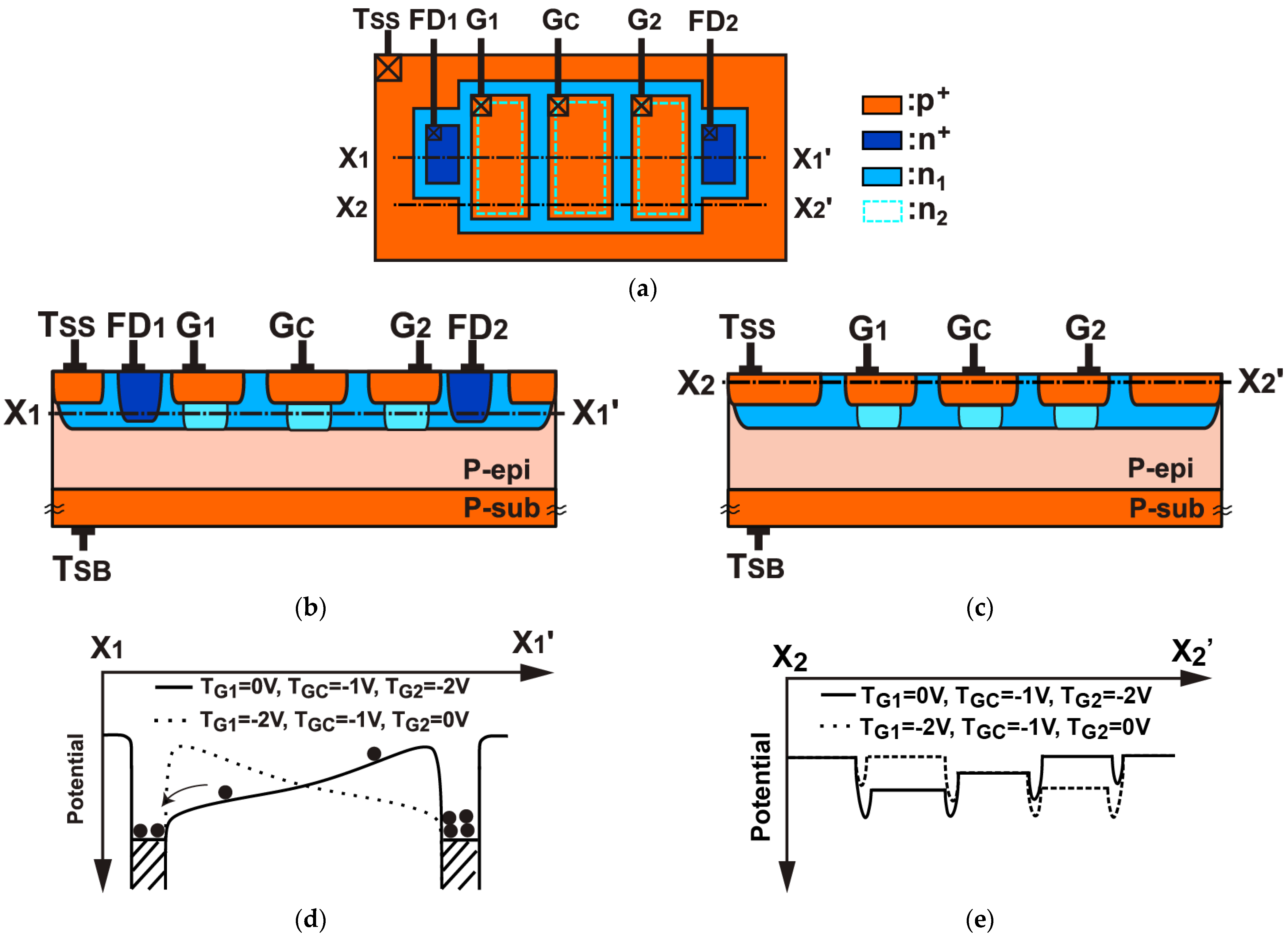

2.1. Basic PND Structure

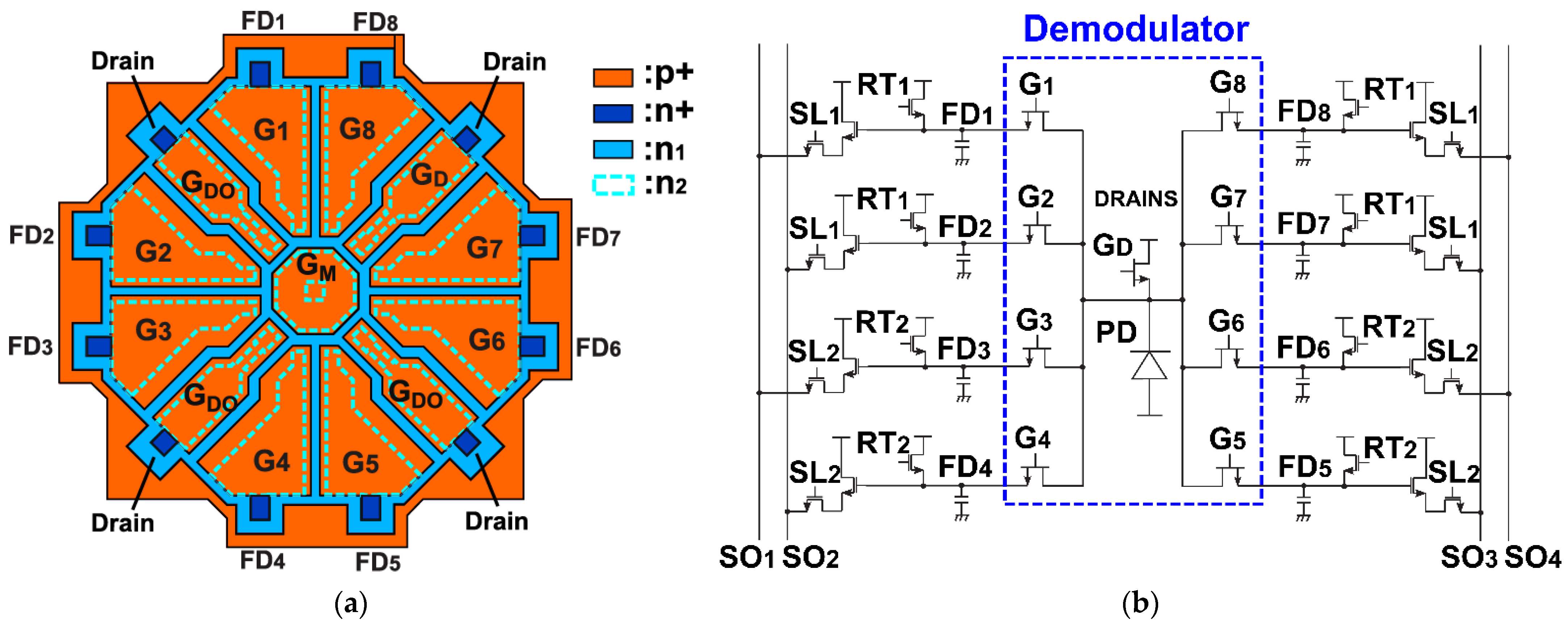

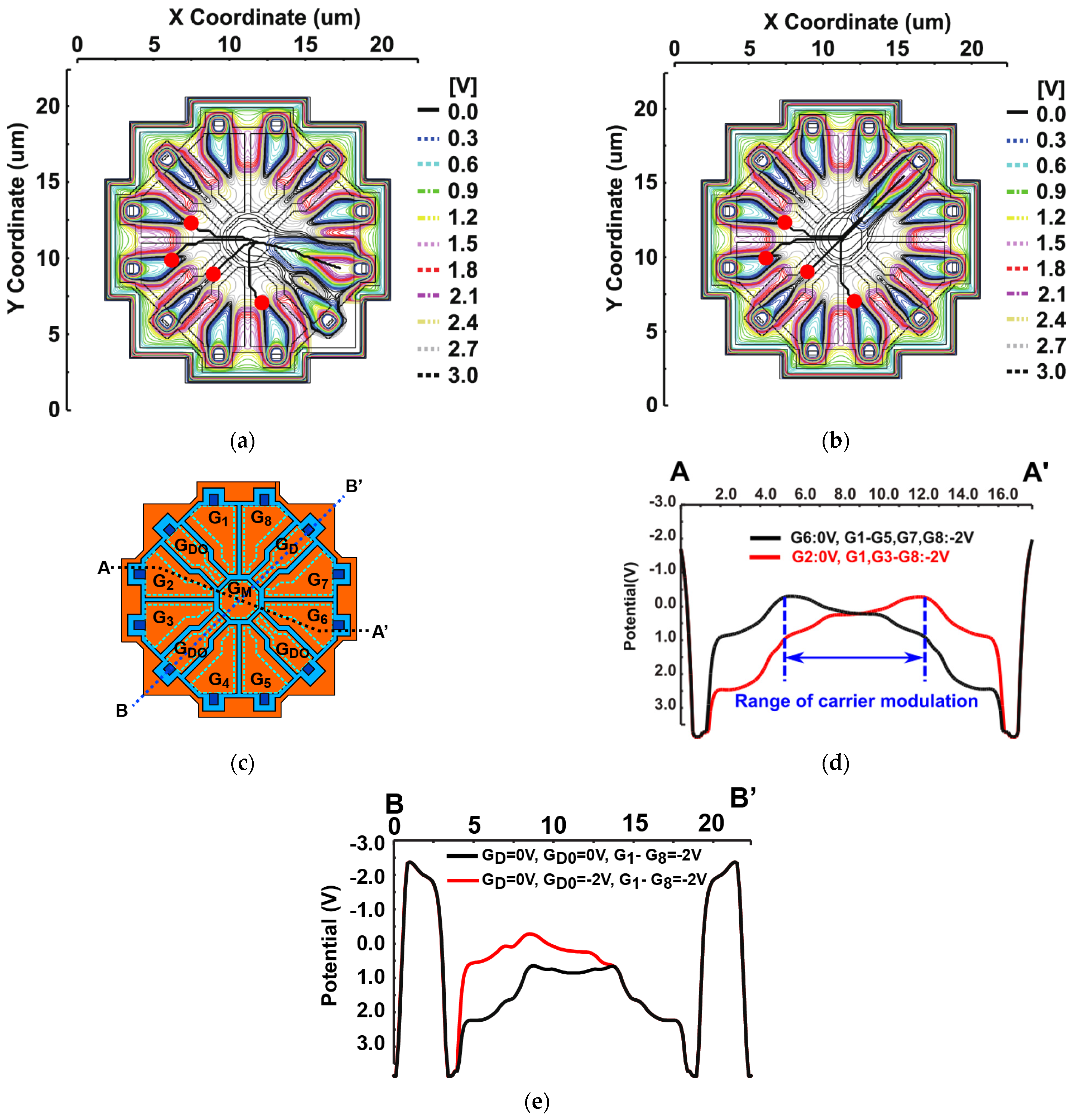

2.2. 8-Tap PND Pixel

3. ToF Measurements Using the 8-Tap PND Pixels

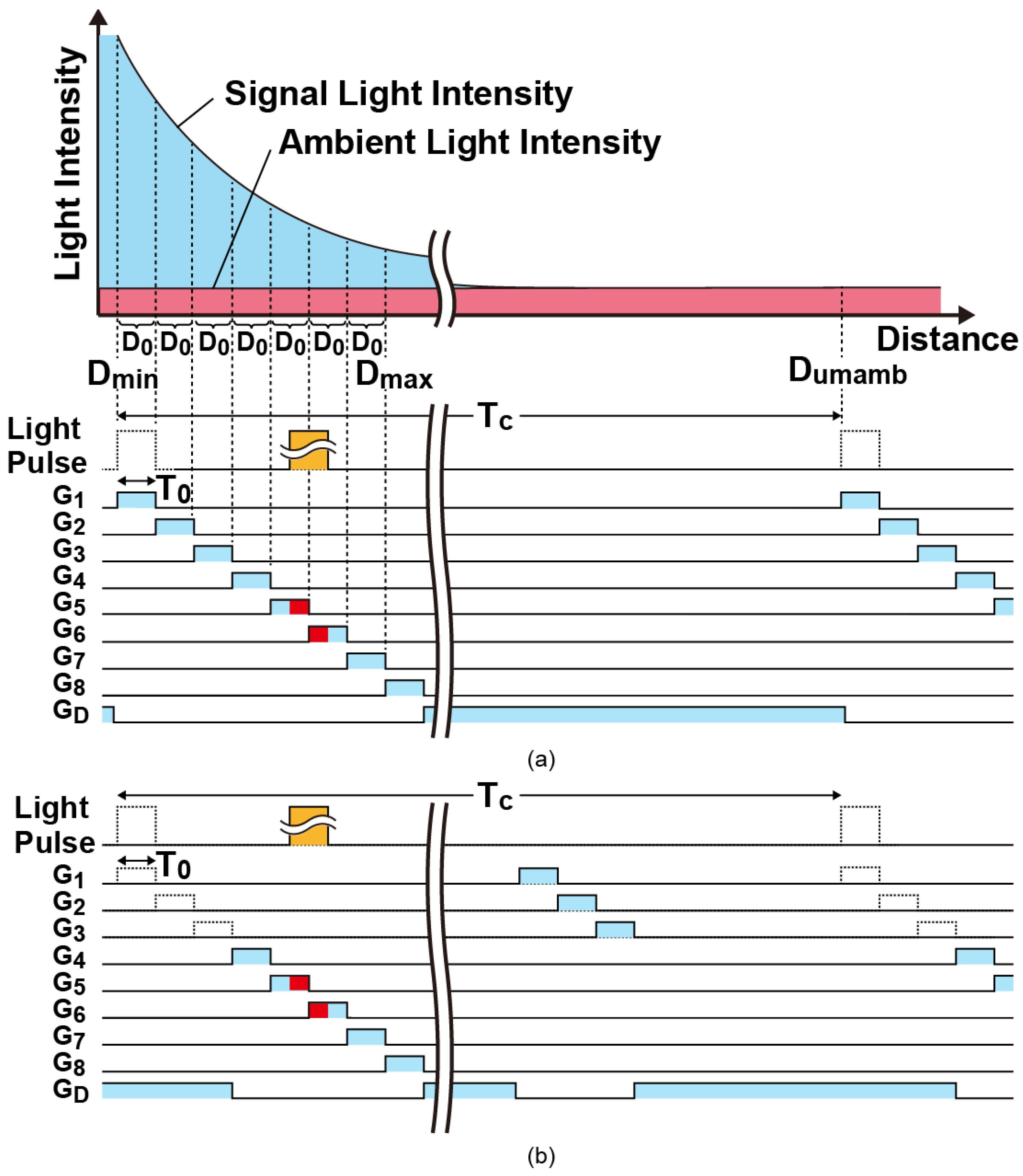

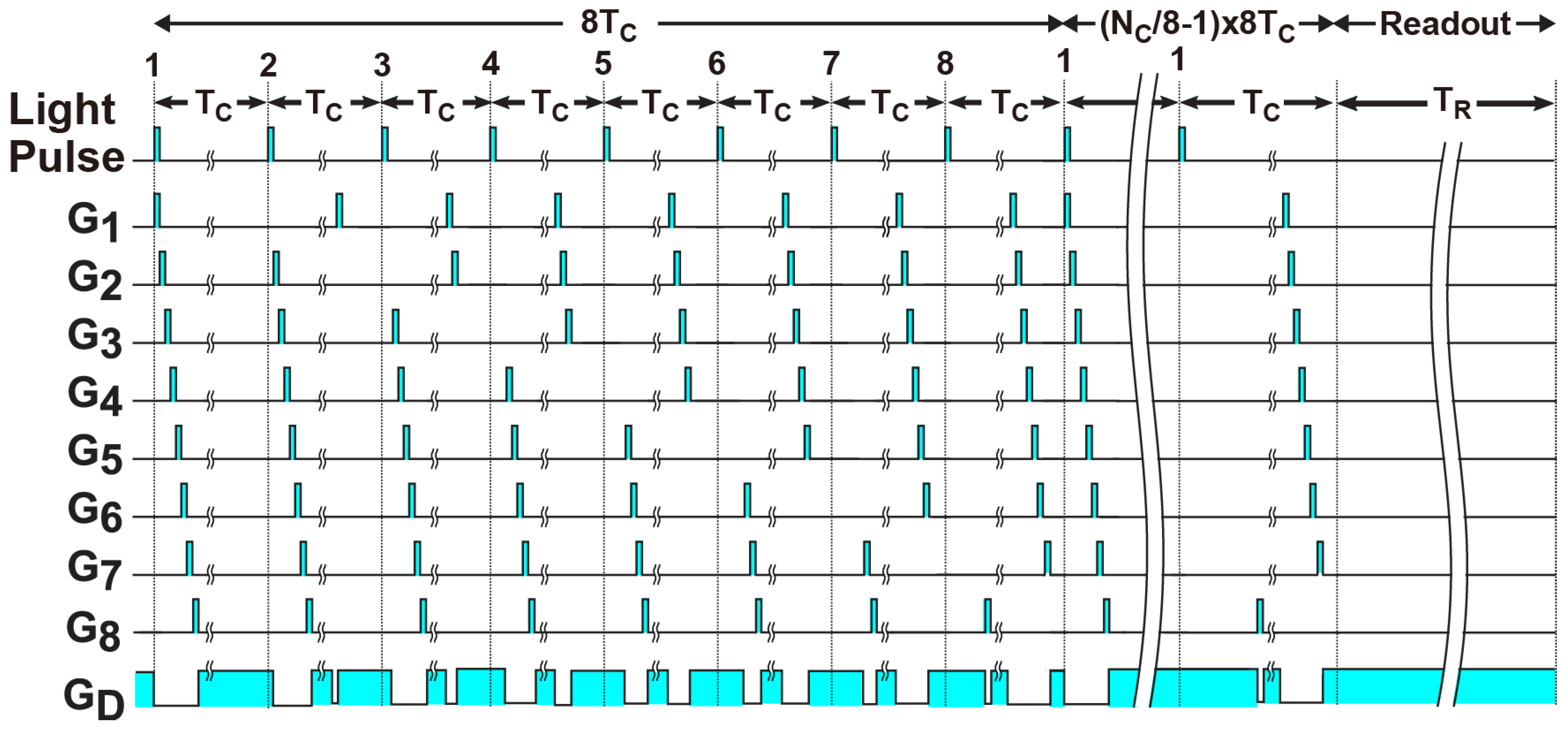

3.1. Depth Imaging Method Using Short Pulse and 8-Tap Pixels

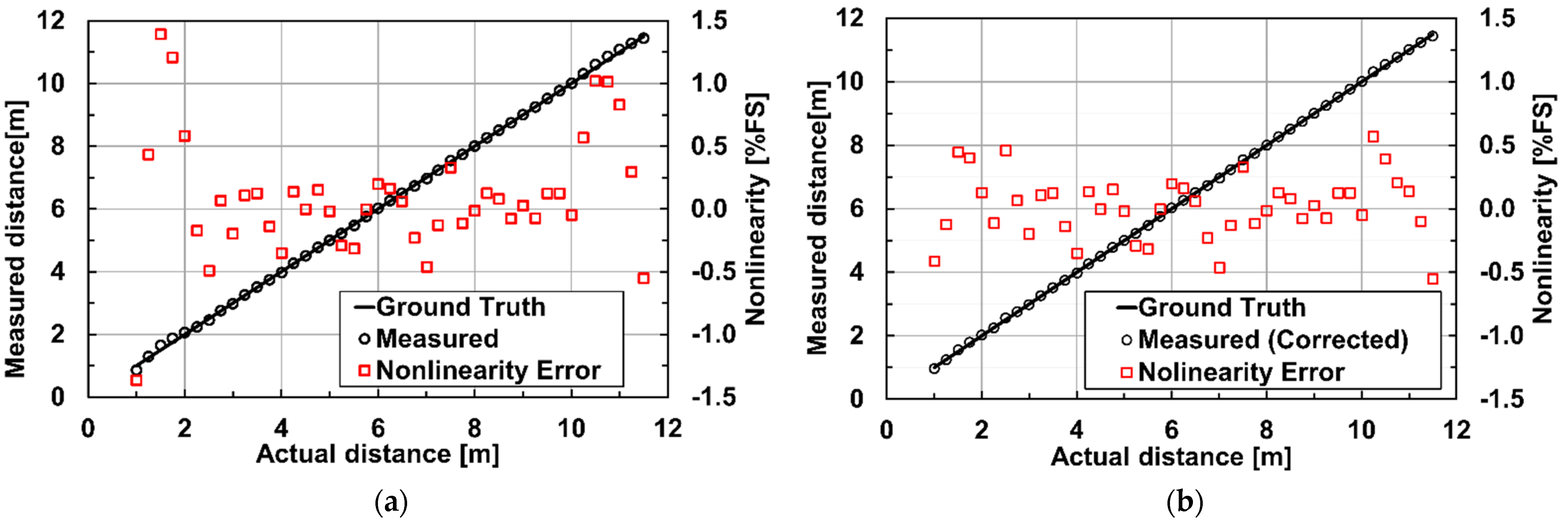

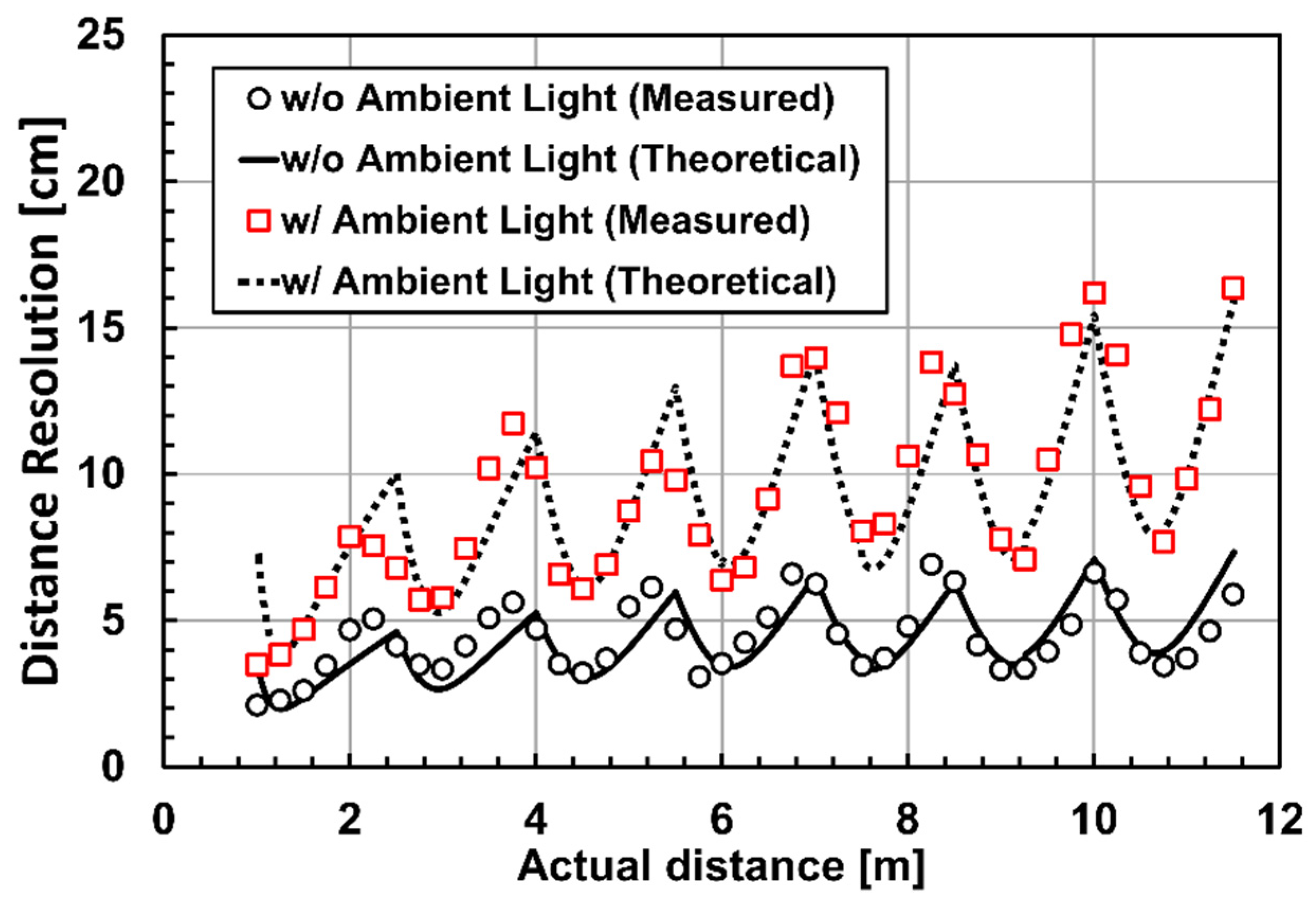

3.2. Linearity and Distance Resolution Using the Modified DATA Technique

4. Measurement Results

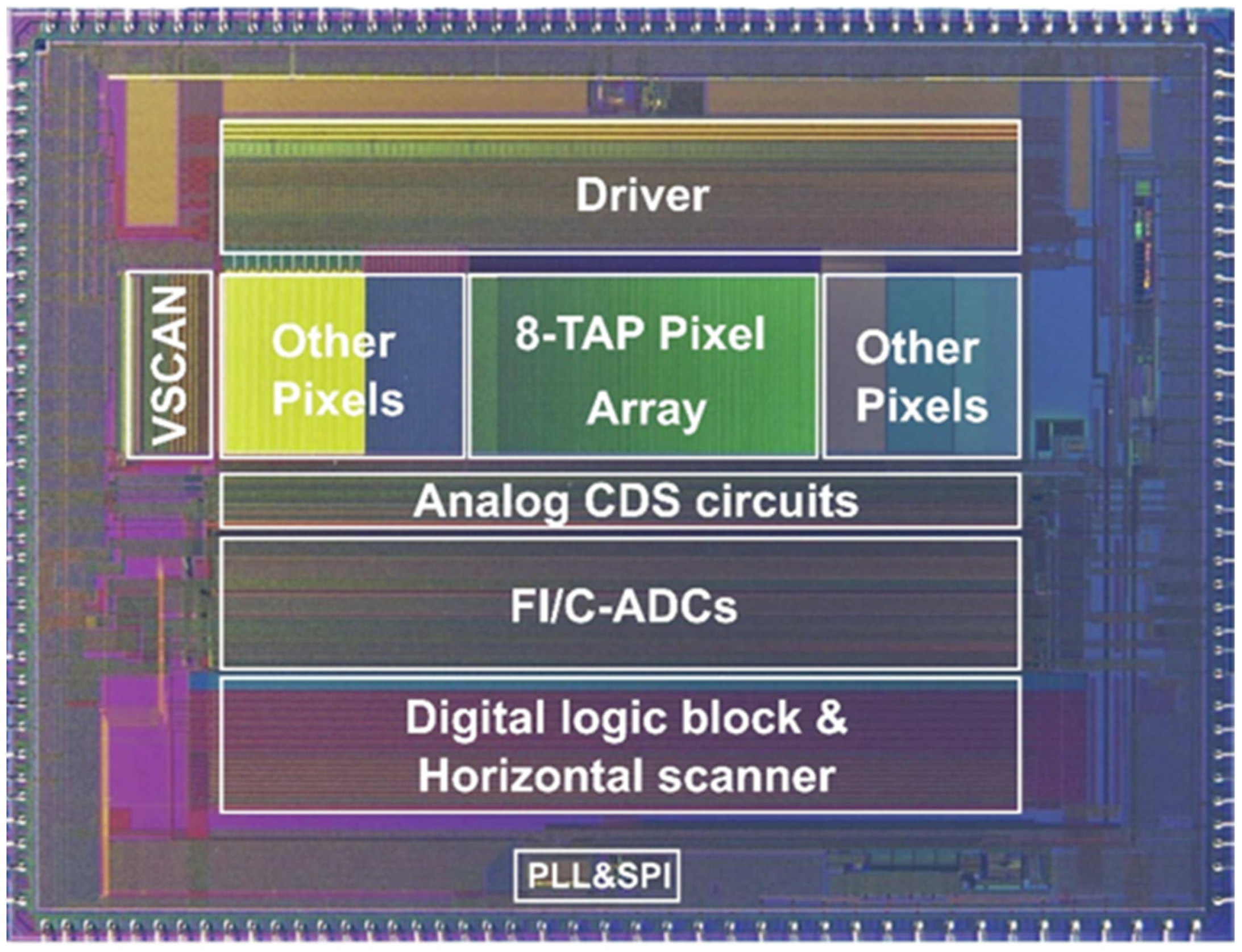

4.1. Implemented ToF Image Sensor Chip

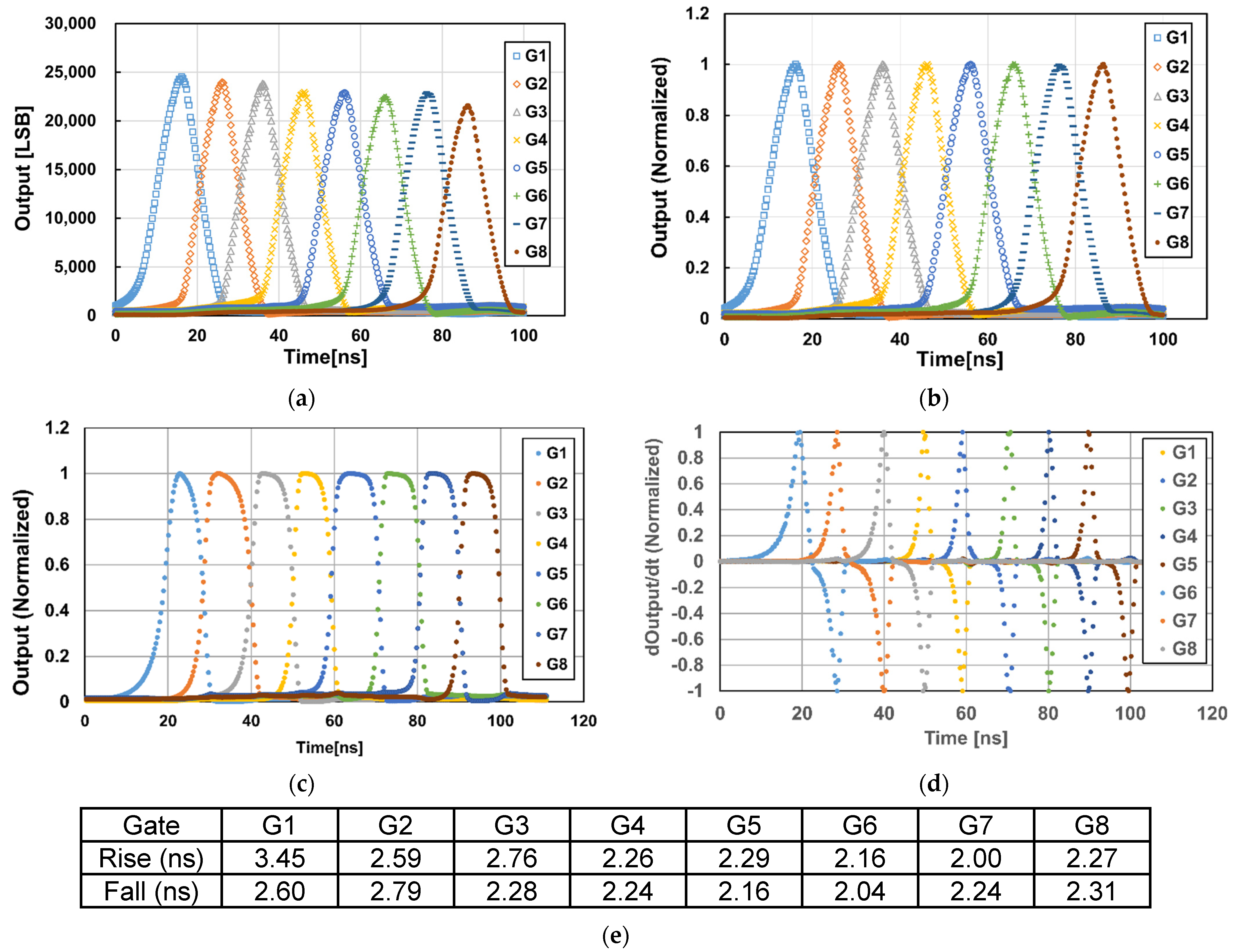

4.2. Response to Light Pulse Delay

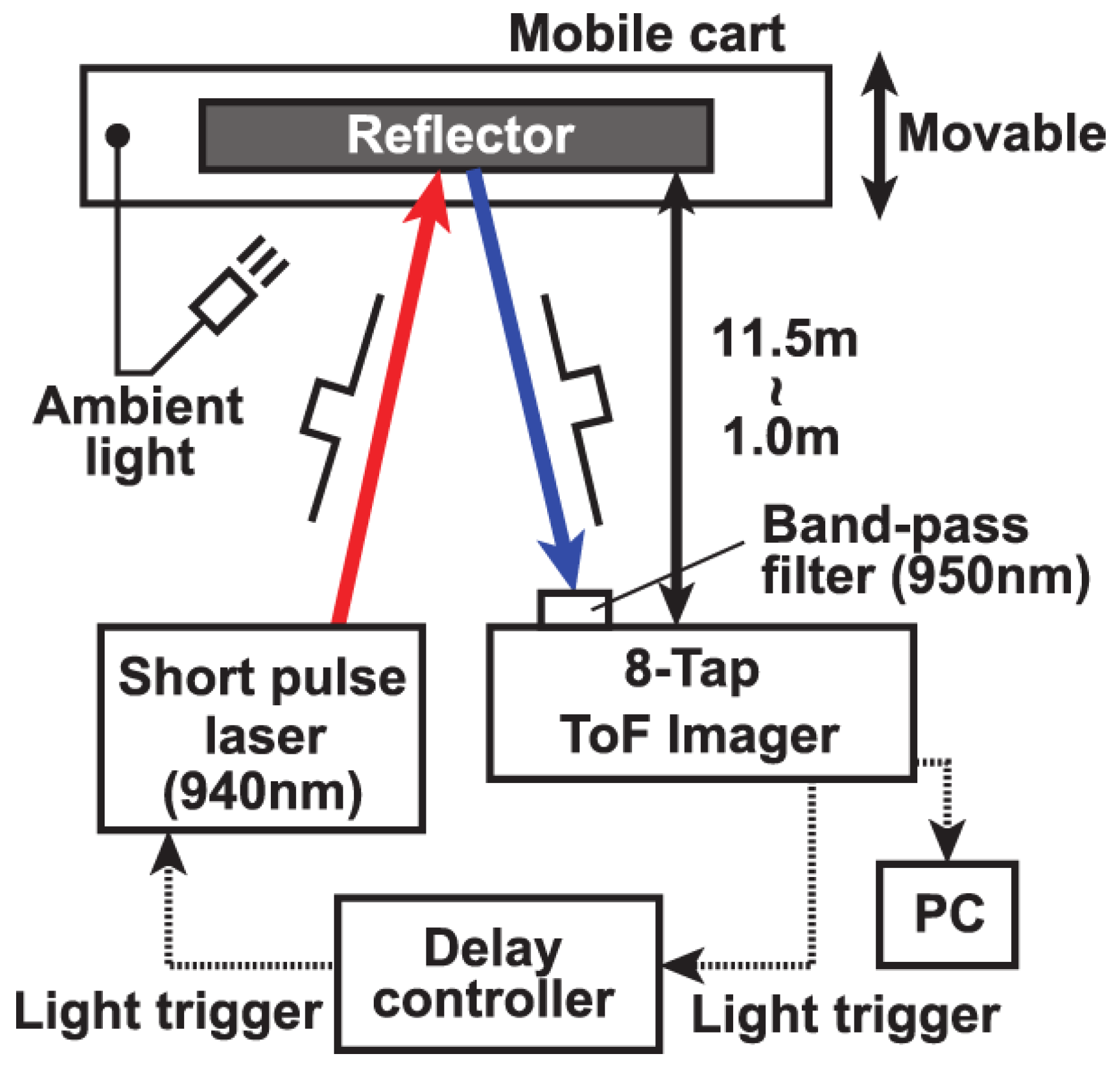

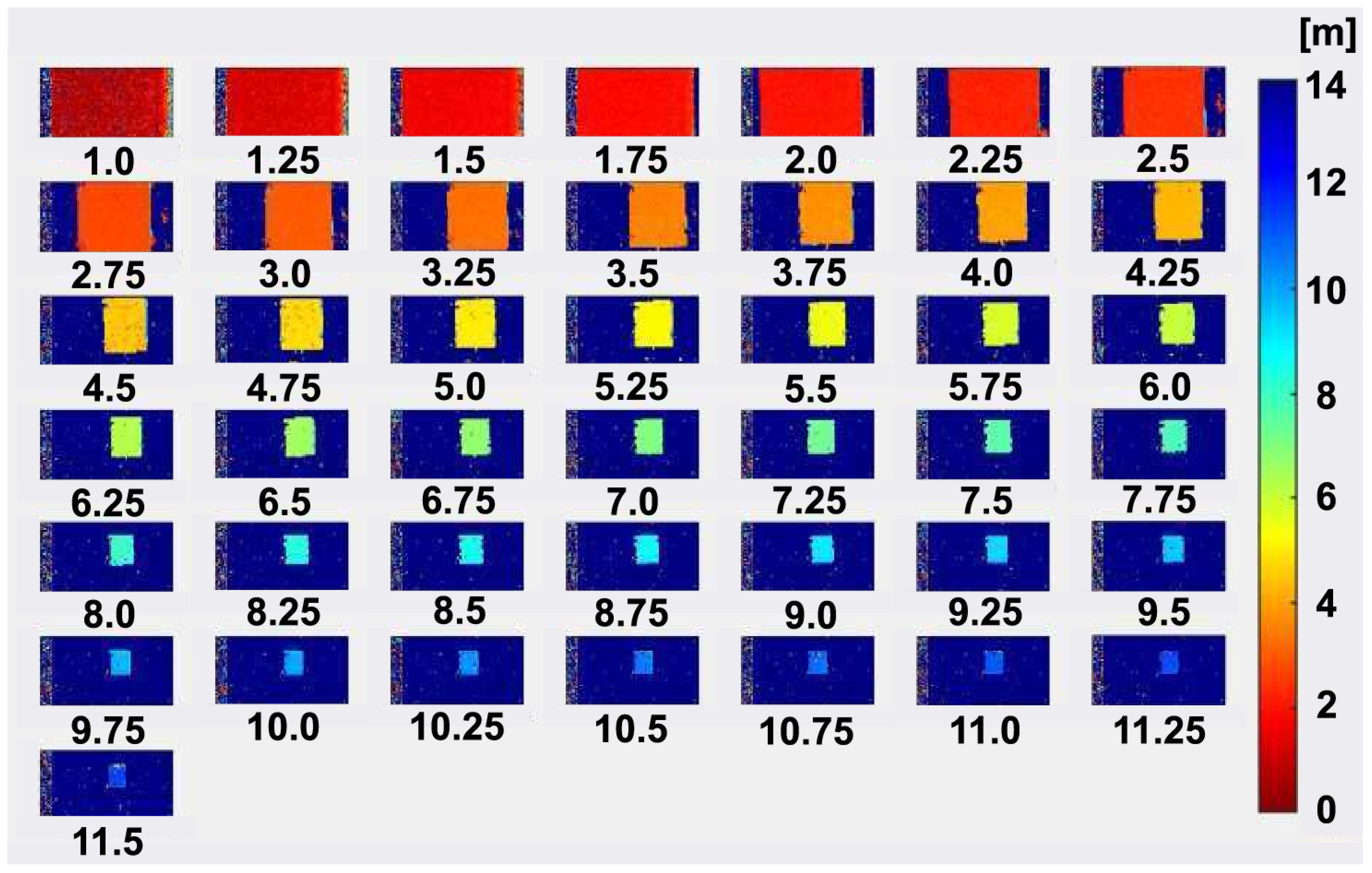

4.3. Range Measurement Performance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niclass, C.; Soga, M.; Matsubara, H.; Ogawa, M.; Kagami, M. A 0.18mm CMOS SoC for a 100-m-Range 10-Frame/s 200 96-Pixel Time-of-Flight Depth Sensor. IEEE J. Solid State Circuits 2014, 49, 315–330. [Google Scholar] [CrossRef]

- Kao, Y.-H.; Chu, T.-S. A Direct-Sampling Pulsed Time-of-Flight Radar with Frequency-Defined Vernier Digital-to-Time Converter in 65 nm CMOS. IEEE J. Solid State Circuits 2015, 50, 2665–2677. [Google Scholar] [CrossRef]

- Perenzoni, M.; Perenzoni, D.; Stoppa, D. A 64 × 64-Pixels Digital Silicon Photomultiplier Direct TOF Sensor With 100-MPhotons/s/pixel Background Rejection and Imaging/Altimeter Mode With 0.14% Precision Up To 6 km for Spacecraft Navigation and Landing. IEEE J. Solid State Circuits 2017, 52, 151–160. [Google Scholar] [CrossRef]

- Yoshioka, K.; Kubota, H.; Fukushima, T.; Kondo, S.; Ta, T.T.; Okuni, H.; Watanabe, K.; Hirono, M.; Ojima, Y.; Kimura, K.; et al. A 20-ch TDC/ADC Hybrid Architecture LiDAR SoC for 240×96 Pixel 200-m Range Imaging with Smart Accumulation Technique and Residue Quantizing SAR ADC. IEEE J. Solid State Circuits 2018, 53, 3026–3038. [Google Scholar] [CrossRef]

- Zhang, C.; Lindner, S.; Antolovic, I.M.; Pavia, J.M.; Wolf, M.; Charbon, E. 30-frames/s, 252 × 144 SPAD Flash LiDAR with 1728 Dual-Clock 48.8-ps TDCs, and Pixel-Wise Integrated Histogramming. IEEE J. Solid State Circuits 2019, 54, 1137–1151. [Google Scholar] [CrossRef]

- Ximenes, A.R.; Padmanabhan, P.; Lee, M.-J.; Yamashita, Y.; Yaung, D.-N.; Charbon, E. A Modular, Direct Time-of-Flight Depth Sensor in 45/65-nm 3-D-Stacked CMOS Technology. IEEE J. Solid State Circuits 2019, 54, 3203–3214. [Google Scholar] [CrossRef]

- Jahromi, S.; Jansson, J.-P.; Keränen, P.; Kostamovaara, J. A 32 × 128 SPAD-257 TDC Receiver IC for Pulsed TOF Solid-State 3-D Imaging. IEEE J. Solid State Circuits 2020, 55, 1960–1970. [Google Scholar] [CrossRef]

- Kashmiri, M.; Behroozpour, B.; Petkov, V.P.; Wojciechowski, K.E.; Lang, C. A 4-GS/s 80-dB DR Current-Domain Analog Frontend for Phase-Coded Pulse-Compression Direct Time-of-Flight Automotive Lidar. IEEE J. Solid State Circuits 2020, 55, 3131–3145. [Google Scholar] [CrossRef]

- Seo, H.; Yoon, H.; Kim, D.; Kim, J.; Kim, S.-J.; Chun, J.-H.; Choi, J. Direct TOF Scanning LiDAR Sensor with Two-Step Multievent Histogramming TDC and Embedded Interference Filter. IEEE J. Solid State Circuits 2021, 56, 1022–1035. [Google Scholar] [CrossRef]

- Kumagai, O.; Ohmachi, J.; Matsumura, M.; Yagi, S.; Tayu, K.; Amagawa, K.; Matsukawa, T.; Ozawa, O.; Hirono, D.; Shinozuka, Y.; et al. A 189 × 600 Back-Illuminated Stacked SPAD Direct Time-of-Flight Depth Sensor for Automotive LiDAR Systems. In Proceedings of the 2021 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 13–22 February 2021; pp. 110–112. [Google Scholar] [CrossRef]

- Henderson, R.; Johnston, N.; Hutchings, S.W.; Gyongy, I.; Abbas, T.A.; Dutton, N.; Tyler, M.; Chan, S.; Leach, J. A 256 × 256 40 nm/90 nm CMOS 3D-Stacked 120dB-Dynamic-Range Reconfigurable Time-Resolved SPAD Imager. In Proceedings of the 2019 IEEE International Solid- State Circuits Conference (ISSCC), San Francisco, CA, USA, 17–21 February 2019; pp. 106–107. [Google Scholar] [CrossRef]

- Lange, R.; Seitz, P. Solid-state time-of-flight range camera. IEEE J. Quantum Electron. 2001, 37, 390–397. [Google Scholar] [CrossRef]

- Kawahito, S.; Halin, I.A.; Ushinaga, T.; Sawada, T.; Homma, M.; Maeda, Y. A CMOS Time-of-Flight Range Image Sensor with Gates-on-Field-Oxide Structure. IEEE Sens. J. 2007, 7, 1578–1586. [Google Scholar] [CrossRef]

- Sawada, T.; Ito, K.; Nakayama, M.; Kawahito, S. A range-shift technique for TOF range image sensor. IEEJ Trans. Sens. Micromachines 2009, 129, 421–425. [Google Scholar] [CrossRef]

- Kim, S.-J.; Han, S.-W.; Kang, B.; Lee, K.; Kim, J.D.K.; Kim, C.-Y. A Three-Dimensional Time-of-Flight CMOS Image Sensor with Pinned-Photodiode Pixel Structure. IEEE Electron Device Lett. 2010, 31, 1272–1274. [Google Scholar] [CrossRef]

- Stoppa, D.; Massari, N.; Pancheri, L.; Malfatti, M.; Perenzoni, M.; Gonzo, L. A Range Image Sensor Based on 10-µm Lock-In Pixels in 0.18-µm CMOS Imaging Technology. IEEE J. Solid State Circuits 2011, 46, 248–258. [Google Scholar] [CrossRef]

- Spickermann, A.; Durini, D.; Süss, A.; Ulfig, W.; Brockherde, W.; Hosticka, B.J.; Schwope, S.; Grabmaier, A. CMOS 3D image sensor based on pulse modulated time-of-flight principle and intrinsic lateral drift-field photodiode pixels. In Proceedings of the 2011 Proceedings of the ESSCIRC (ESSCIRC), Helsinki, Finland, 12–16 September 2011; pp. 111–114. [Google Scholar] [CrossRef]

- Kim, S.-J.; Kim, J.D.K.; Kang, B.; Lee, K. A CMOS Image Sensor Based on Unified Pixel Architecture with Time-Division Multiplexing Scheme for Color and Depth Image Acquisition. IEEE J. Solid State Circuits 2012, 47, 2834–2845. [Google Scholar] [CrossRef]

- Kawahito, S.; Baek, G.; Li, Z.; Han, S.M.; Seo, M.W.; Yasutomi, K.; Kagawa, K. CMOS lock-in pixel image sensors with lateral electric field control for time-resolved imaging. In Proceedings of the International Image Sensor Workshop (IISW), Snowbird, UT, USA, 12–16 June 2013; pp. 361–364. [Google Scholar]

- Cho, J.; Choi, J.; Kim, S.-J.; Park, S.; Shin, J.; Kim, J.D.K.; Yoon, E. A 3-D Camera with Adaptable Background Light Suppression Using Pixel-Binning and Super-Resolution. IEEE J. Solid State Circuits 2014, 49, 2319–2332. [Google Scholar] [CrossRef]

- Han, S.-M.; Takasawa, T.; Yasutomi, K.; Aoyama, S.; Kagawa, K.; Kawahito, S. A time-of-flight range image sensor with background cancelling lock-in pixel based on lateral electric field charge modulation. IEEE J. Electron Devices Soc. 2015, 3, 267–275. [Google Scholar] [CrossRef]

- Bamji, C.S.; O’Connor, P.; Elkhatib, T.; Mehta, S.; Thompson, B.; Prather, L.A.; Snow, D.; Akkaya, O.C.; Daniel, A.; Payne, A.D.; et al. A 0.13 μm CMOS System-on-Chip for a 512 × 424 Time-of-Flight Image Sensor with Multi-Frequency Photo-Demodulation up to 130 MHz and 2 GS/s ADC. IEEE J. Solid State Circuits 2015, 50, 303–319. [Google Scholar] [CrossRef]

- Hsu, T.-H.; Liao, T.; Lee, N.-A.; Hsieh, C.-C. A CMOS Time-of-Flight Depth Image Sensor with In-Pixel Background Light Cancellation and Phase Shifting Readout Technique. IEEE J. Solid State Circuits 2018, 53, 2898–2905. [Google Scholar] [CrossRef]

- Keel, M.-S.; Jin, Y.-G.; Kim, Y.; Kim, D.; Kim, Y.; Bae, M.; Chung, B.; Son, S.; Kim, H.; An, T.; et al. A VGA Indirect Time-of-Flight CMOS Image Sensor With 4-Tap 7-μm Global-Shutter Pixel and Fixed-Pattern Phase Noise Self-Compensation. IEEE J. Solid State Circuits 2020, 55, 889–897. [Google Scholar] [CrossRef]

- Bamji, C.S.; Mehta, S.; Thompson, B.; Elkhatib, T.; Wurster, S.; Akkaya, O.; Payne, A.; Godbaz, J.; Fenton, M.; Rajasekaran, V.; et al. lMpixel 65 nm 320 MHz demodulated TOF image sensor with 3.5µm global shutter pixels and analog binning. In Proceedings of the 2018 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 11–15 February 2018; pp. 94–95. [Google Scholar] [CrossRef]

- Ebiko, Y.; Yamagishi, H.; Tatani, K.; Iwamoto, H.; Moriyama, Y.; Hagiwara, Y.; Maeda, S.; Murase, T.; Suwa, T.; Arai, H.; et al. Low power consumption and high resolution 1280 × 960 Gate Assisted Photonic Demodulator pixel for indirect Time of flight. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 721–724. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Park, D.; Piao, C.; Park, J.; Ahn, Y.; Cho, K.; Shin, J.; Song, S.M.; Kim, S.-J.; et al. Indirect Time-of-Flight CMOS Image Sensor with On-Chip Background Light Cancelling and Pseudo-Four-Tap/Two-Tap Hybrid Imaging for Motion Artifact Suppression. IEEE J. Solid State Circuits 2020, 55, 2849–2865. [Google Scholar] [CrossRef]

- Shirakawa, Y.; Yasutomi, K.; Kagawa, K.; Aoyama, S.; Kawahito, S. An 8-Tap CMOS Lock-In Pixel Image Sensor for Short-Pulse Time-of-Flight Measurements. Sensors 2020, 20, 1040. [Google Scholar] [CrossRef] [PubMed]

- Hatakeyama, K.; Okubo, Y.; Nakagome, T.; Makino, M.; Takashima, H.; Akutsu, T.; Sawamoto, T.; Nagase, M.; Noguchi, T.; Kawahito, S. A Hybrid ToF Image Sensor for Long-Range 3D Depth Measurement Under High Ambient Light Conditions. IEEE J. Solid State Circuits 2023, 58, 983–992. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Kuroda, R. A 4-Tap CMOS Time-of-Flight Image Sensor with In-pixel Analog Memory Array Achieving 10Kfps High-Speed Range Imaging and Depth Precision Enhancement. In Proceedings of the 2022 IEEE Symposium on VLSI Technology and Circuits (VLSI Technology and Circuits), Honolulu, HI, USA, 12–17 June 2022; pp. 48–49. [Google Scholar] [CrossRef]

- Kawahito, S.; Yasutomi, K.; Mars, K. Hybrid Time-of-Flight Image Sensors for Middle-Range Outdoor Applications. IEEE Open J. Solid-state Circuits 2022, 2, 38–49. [Google Scholar] [CrossRef]

- Nagae, H.; Daikoku, S.; Kondo, K.; Yasutomi, K.; Kagawa, K.; Kawahito, S. A Time-Resolved 4-tap Image Sensor Using Tapped PN-Junction Diode Demodulation Pixels. In Proceedings of the 2021 International Image Sensor Workshop, Online, 20–23 September 2021. [Google Scholar]

- Meidinger, N.; Andritschke, R.; Hartmann, R.; Herrmann, S.; Holl, P.; Lutz, G.; Strüder, L. PNCCD for photon detection from near infrared to X-rays. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2006, 565, 251–257. [Google Scholar] [CrossRef]

- Klauw, K. Vertical Charge Transport in Junction Charge-Coupled Devices. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1987. [Google Scholar]

- Seo, M.-W.; Suh, S.-H.; Iida, T.; Takasawa, T.; Isobe, K.; Watanabe, T.; Itoh, S.; Yasutomi, K.; Kawahito, S. A Low-Noise High Intrascene Dynamic Range CMOS Image Sensor With a 13 to 19b Variable-Resolution Column-Parallel Folding-Integration/Cyclic ADC. IEEE J. Solid State Circuits 2012, 47, 272–283. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Technology | 0.11 µm CMOS Image sensor |

| Number of Pixels | 272(H) × 60 (V) (Entire Array) 120 (H) × 60 (V) (8-Tap PND Pixel Array) |

| Pixel size | 22.4 µm × 22.4 µm |

| Chip size | 9.34 mm × 7.04 mm |

| ADC resolution | 16 bit |

| Readout time | 9.6 ms (16 bit) |

| Conversion gain | 10.8 µV/e− |

| Full well capacity | 79.2 ke− |

| Fill factor | 9.0% |

| Quantum Efficiency Read noise Dark Current @60 °C | 14.5% (940 nm) 69 e− 506 pA/cm2 (15.9 ke−/s) [G6: High, GD: Low] 166 pA/cm2 (5.6 ke−/s) [G6, GD: Pulsed] |

| This Work | Ref. [28] | Ref. [22] | Ref. [26] | Ref. [27] | Ref. [29] | |

|---|---|---|---|---|---|---|

| Process | 110 nm FSI | 110 nm FSI | 65 nm BSI | 65/90 nm BSI | 90 nm BSI | 110 nm BSI |

| Pixel pitch | 22.4 µm | 22.4 µm | 3.5 µm | 3.5 µm | 8.0 µm | 5.6 µm |

| Pixel Architecture | 8-tap 1-drain | 7-tap 1-drain | 2-tap | 2-tap | Pseudo 4-tap | 4-tap 1-drain |

| Storage (Global Shutter) | No | Yes | Yes | No | No | No |

| Light Modulation | SP | SP | CW | CW | CW | SP |

| Image Resolution | 120 × 60 | 134 × 128 | 1024 × 1024 | 1280 × 960 | 320 × 240 | 640 × 480 |

| Number of Subframes | 1 | 1 | 4 | 4 | 4 | 3 |

| Ambient Light Tolerance | 80 klux | n.a. | 25 klux | 80 klux (QVGA) | 130 klux | 100 klux |

| Depth Range | 1–11.5 m | 1–6.4 m | 0.4–4.2 m | 1–10 m | 0.75–4 m | 0.5–20 m (1–30 m@0 lux) |

| Precision (Depth noise) | 1.4%@11.5 m (80 klux) 0.6%@11.5 m (0 lux) | 0.24%@6.4 m (0 lux) | 0.7%@4 m (25 klux) | 1.6%@10 m (80 klux) | 0.54%@4 m (130 klux) | 1.3%@1–20 m (100 klux) |

| Max. Depth Nonlinearity | 0.6%@1–11.5 m (80 klux) | 1.56%@1–6.4 m (0 lux) | 0.05%@0.25–4 m (25 klux) | - | - | 1.5%@1–20 m (100 klux) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miyazawa, R.; Shirakawa, Y.; Mars, K.; Yasutomi, K.; Kagawa, K.; Aoyama, S.; Kawahito, S. A Time-of-Flight Image Sensor Using 8-Tap P-N Junction Demodulator Pixels. Sensors 2023, 23, 3987. https://doi.org/10.3390/s23083987

Miyazawa R, Shirakawa Y, Mars K, Yasutomi K, Kagawa K, Aoyama S, Kawahito S. A Time-of-Flight Image Sensor Using 8-Tap P-N Junction Demodulator Pixels. Sensors. 2023; 23(8):3987. https://doi.org/10.3390/s23083987

Chicago/Turabian StyleMiyazawa, Ryosuke, Yuya Shirakawa, Kamel Mars, Keita Yasutomi, Keiichiro Kagawa, Satoshi Aoyama, and Shoji Kawahito. 2023. "A Time-of-Flight Image Sensor Using 8-Tap P-N Junction Demodulator Pixels" Sensors 23, no. 8: 3987. https://doi.org/10.3390/s23083987

APA StyleMiyazawa, R., Shirakawa, Y., Mars, K., Yasutomi, K., Kagawa, K., Aoyama, S., & Kawahito, S. (2023). A Time-of-Flight Image Sensor Using 8-Tap P-N Junction Demodulator Pixels. Sensors, 23(8), 3987. https://doi.org/10.3390/s23083987