Prediction of Dry-Low Emission Gas Turbine Operating Range from Emission Concentration Using Semi-Supervised Learning

Abstract

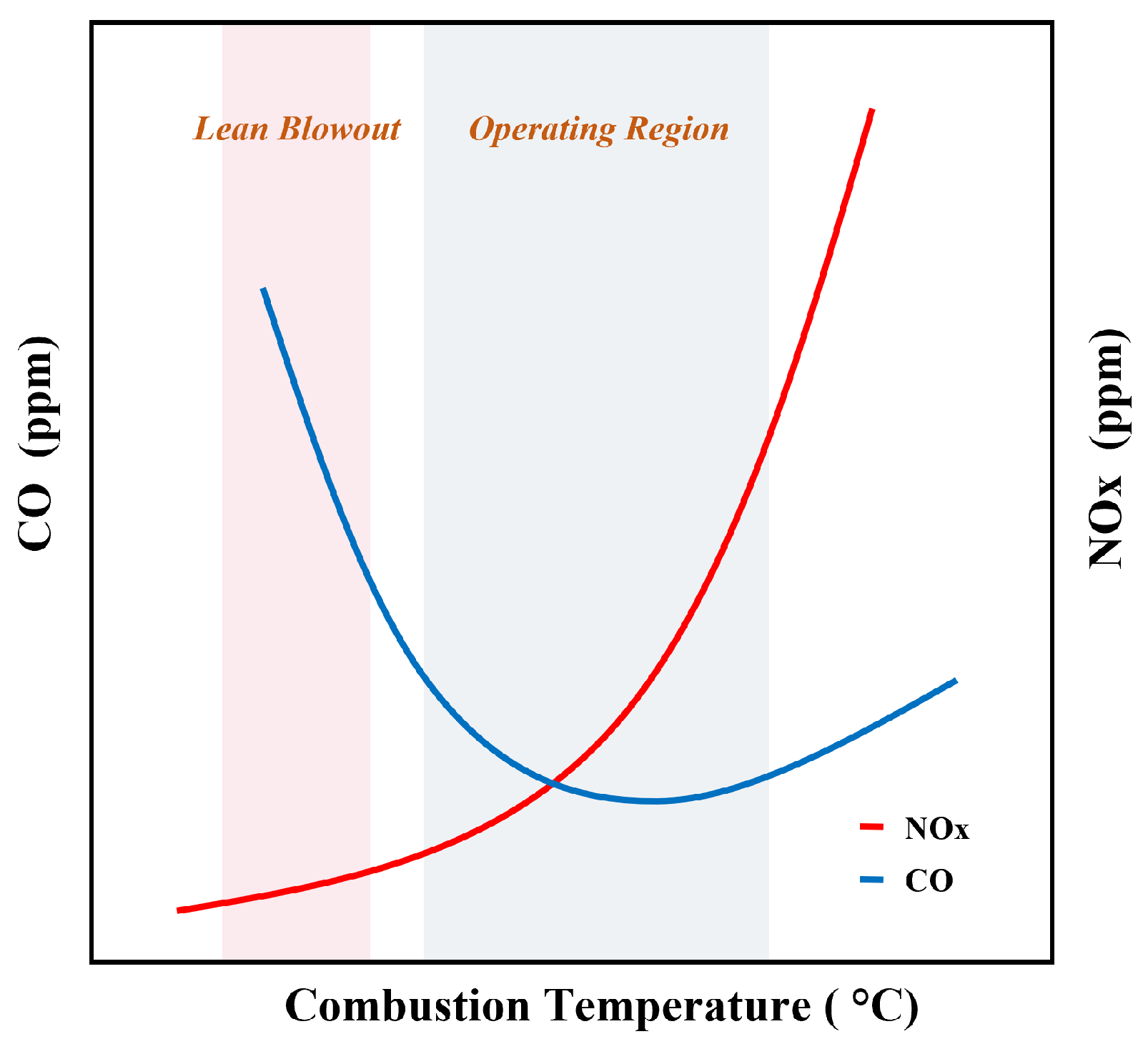

1. Introduction

- Develop a model to predict the emission of NOx and CO from DLE gas turbine using XGBoost. Additionally, the combustion temperature will be predicted.

- Develop a technique to predict the operating range of a DLE gas turbine based on gas emission concentration using K-means algorithm.

2. Semi-Supervised Learning for Operating Range Prediction of Dry-Low Emission Gas Turbine

2.1. XGBoost

2.2. K-Means

3. Data Collection and Preprocessing

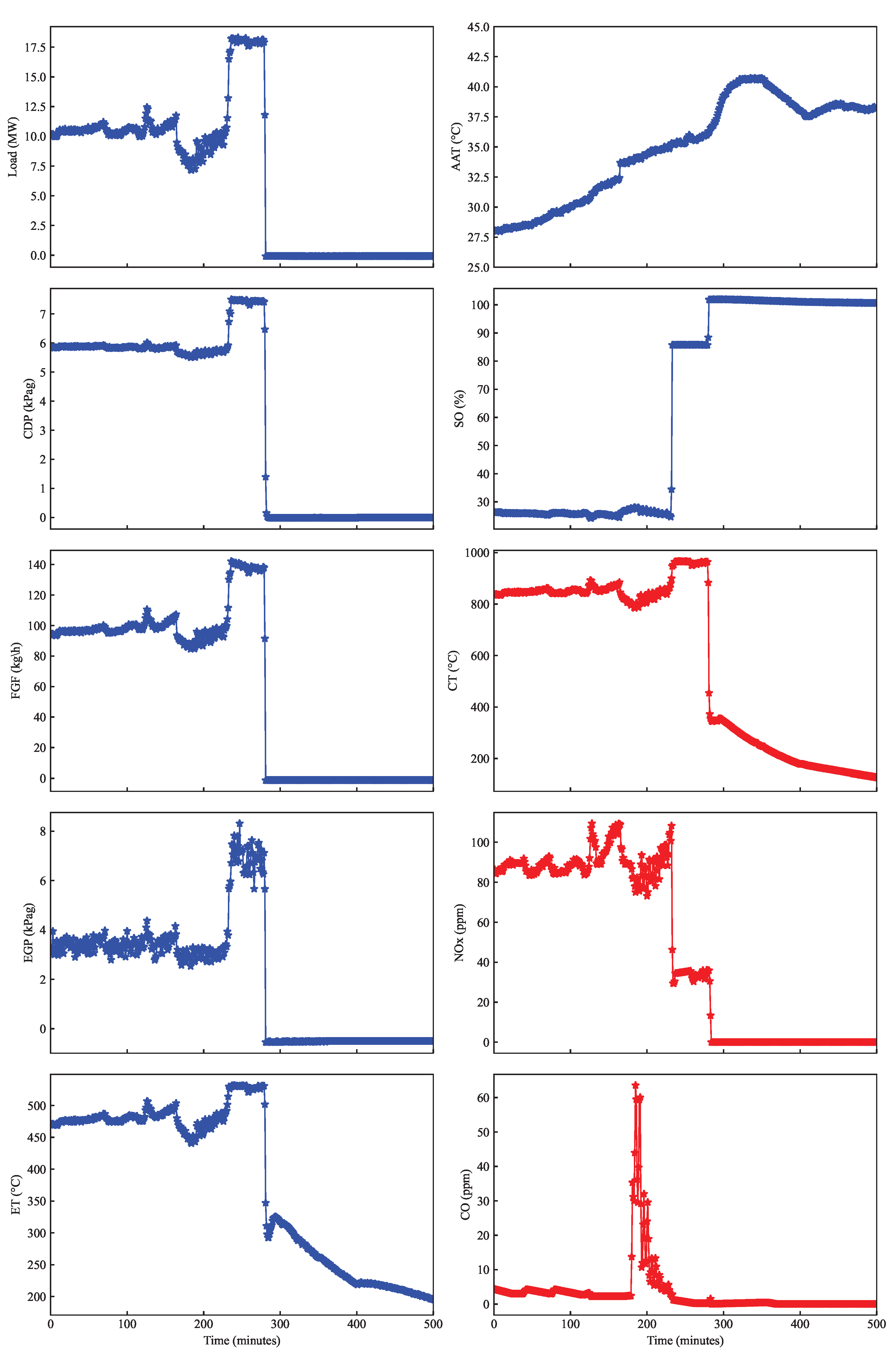

3.1. Data Collection

Data Analysis

3.2. Data Pre-Processing

4. Results and Discussion

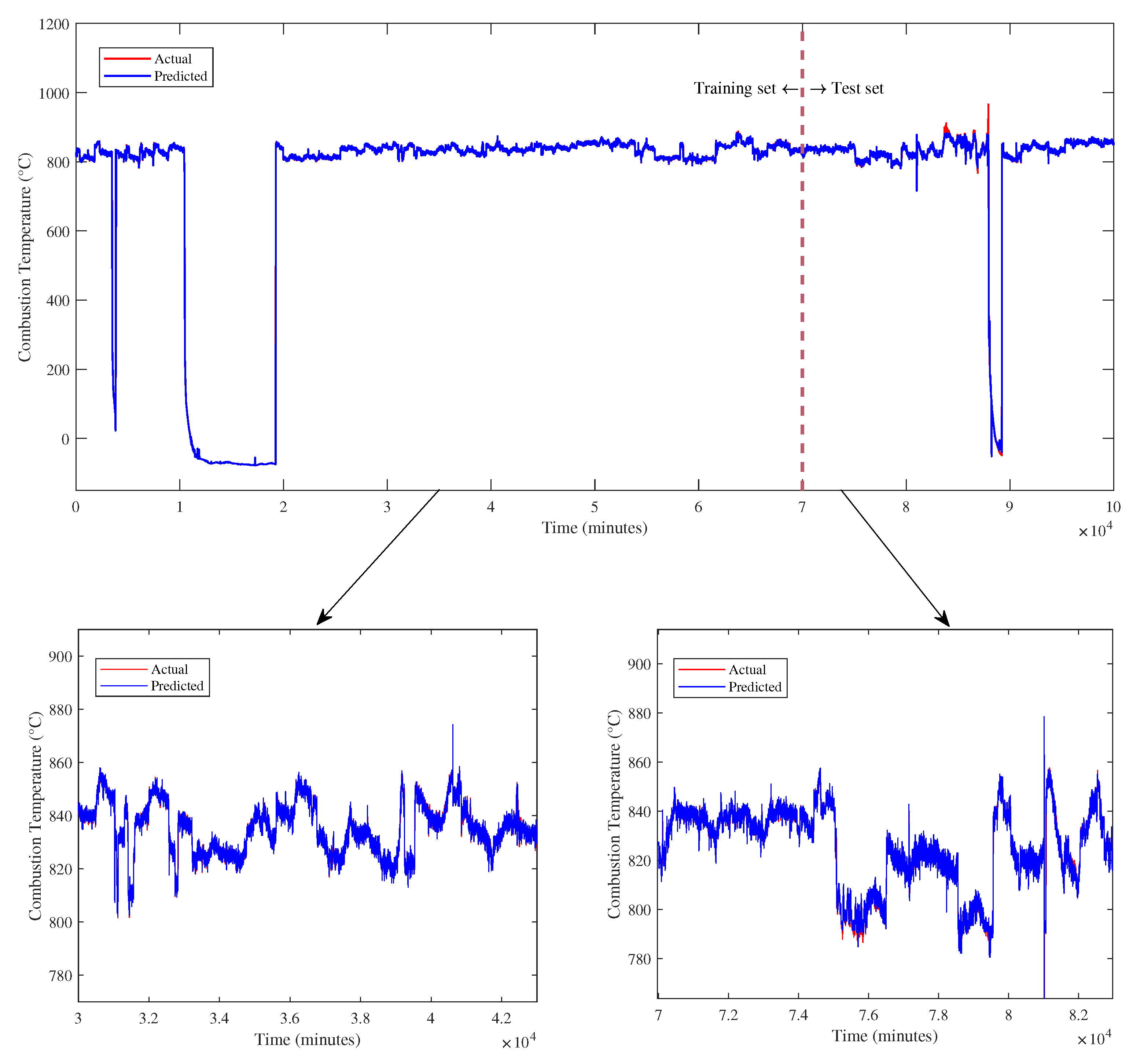

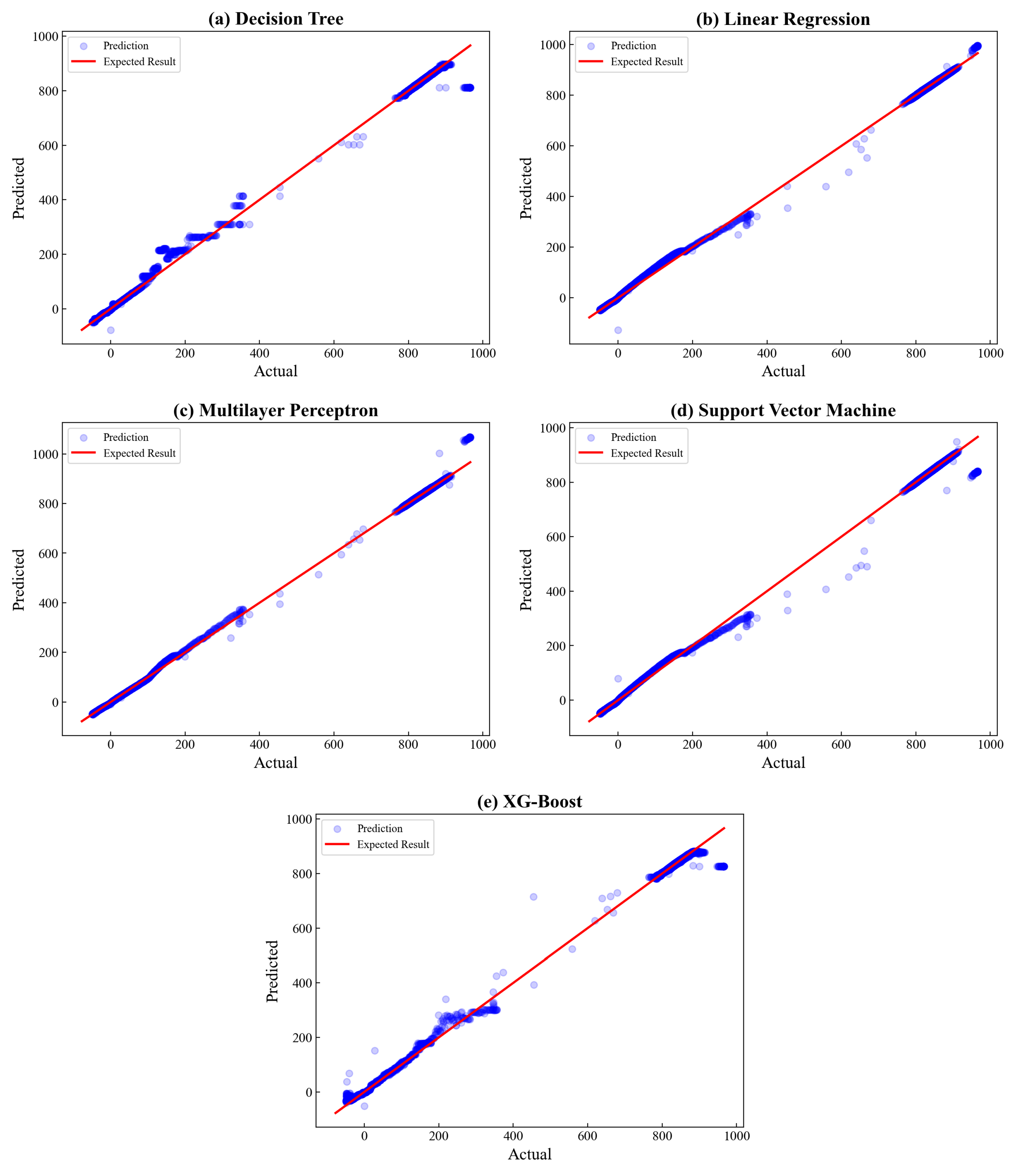

4.1. Prediction of Combustion Temperature, NOx, and CO Using XGBoost

4.1.1. Combustion Temperature Prediction

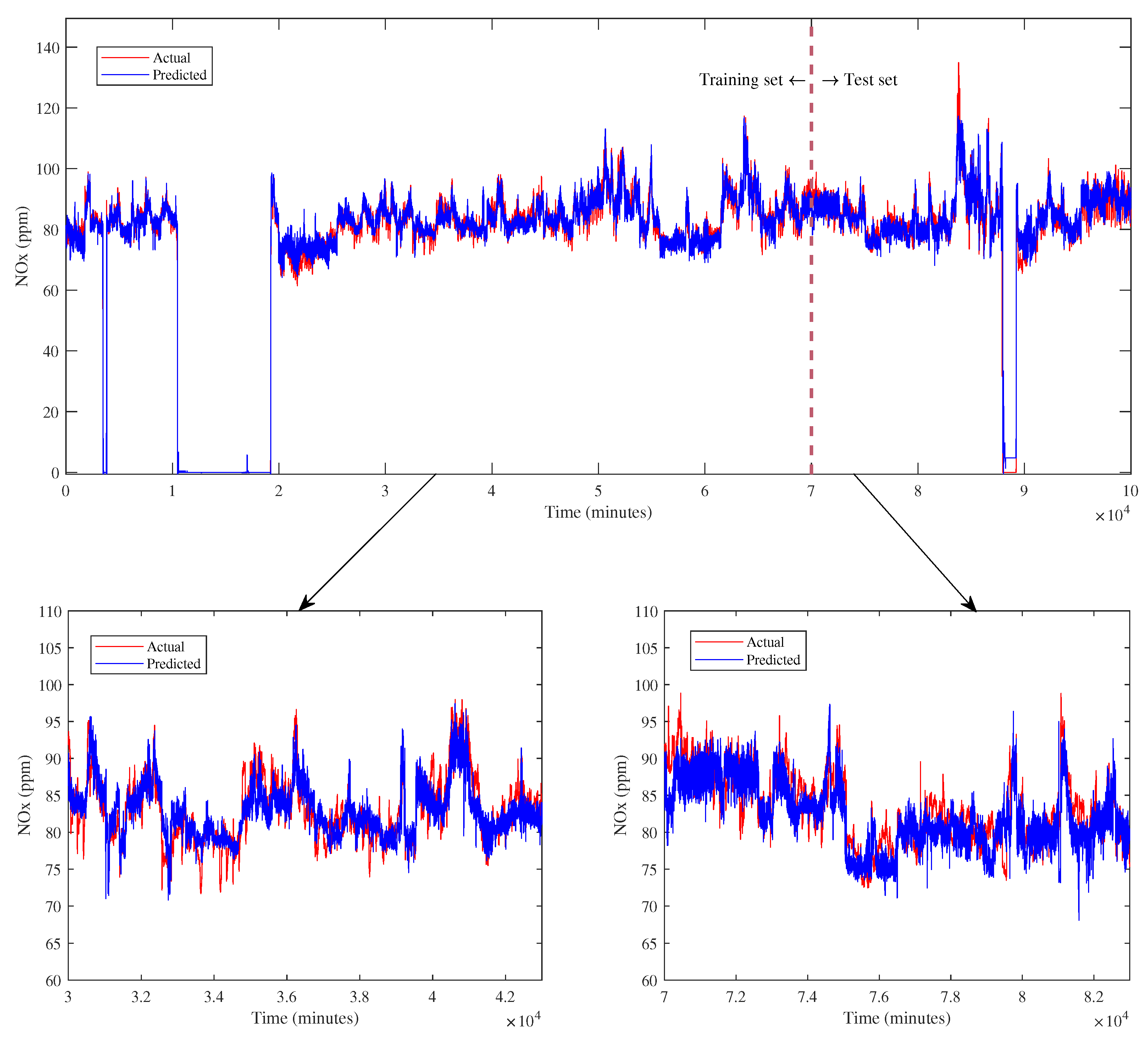

4.1.2. NOx Prediction

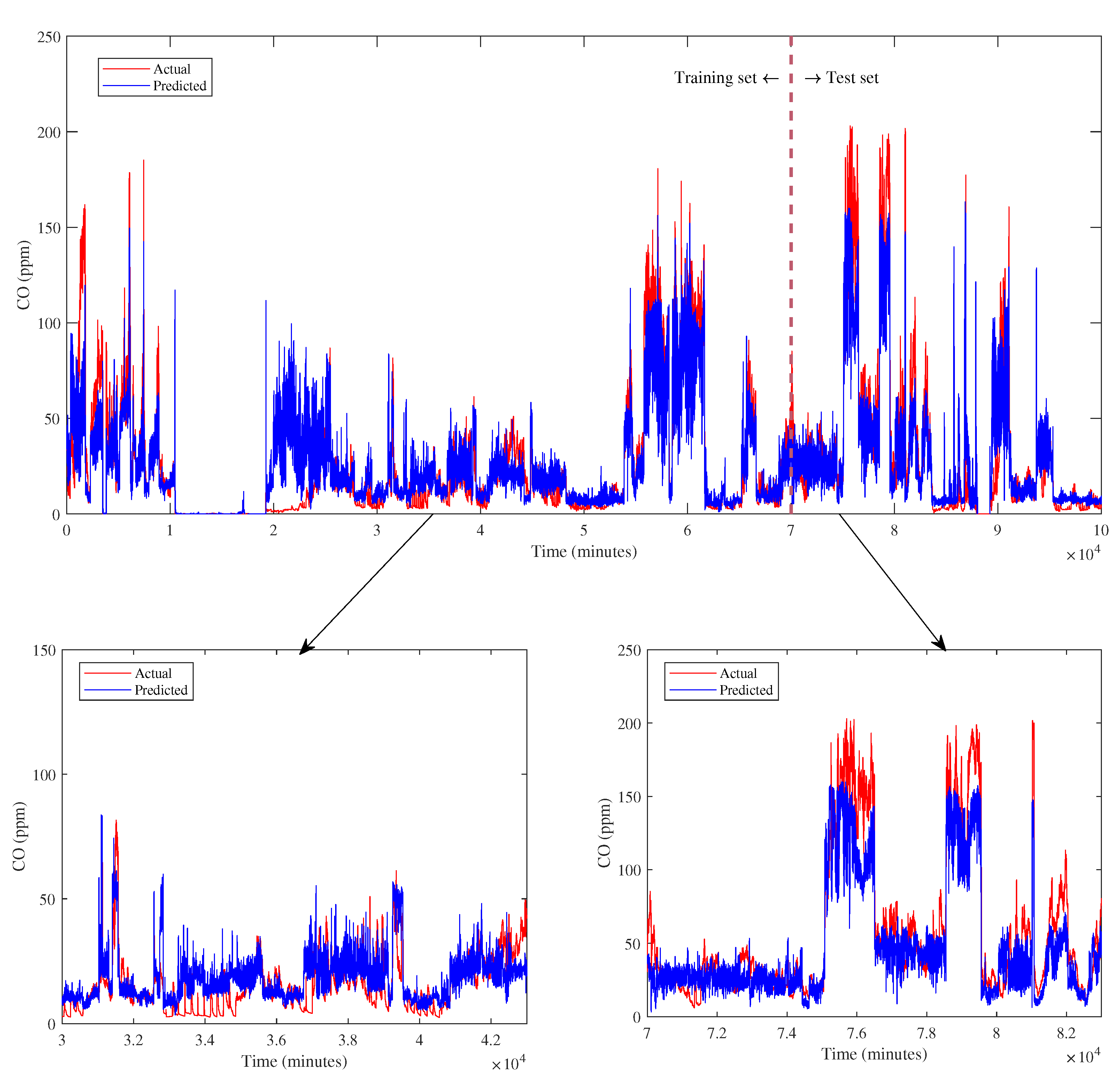

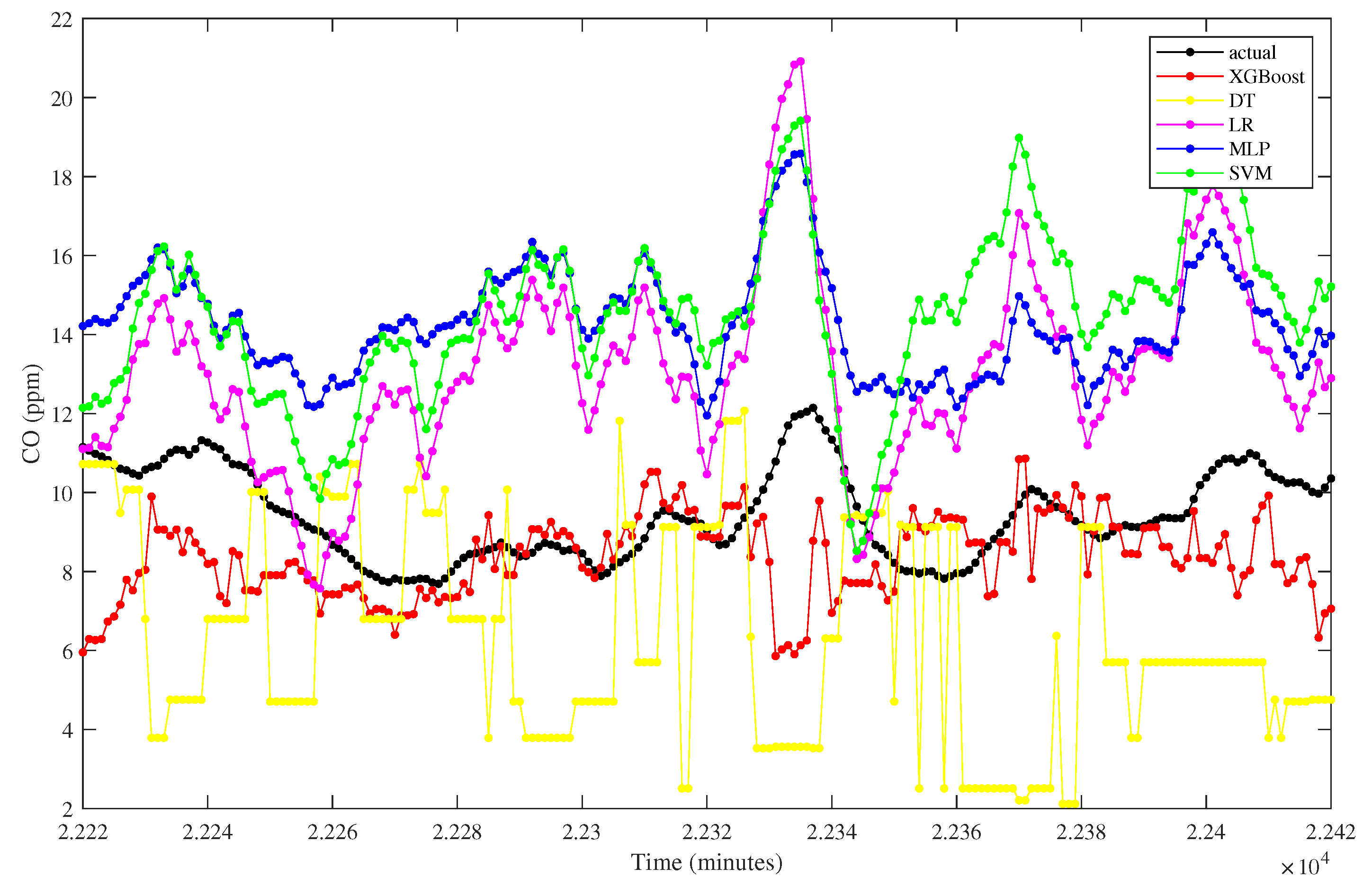

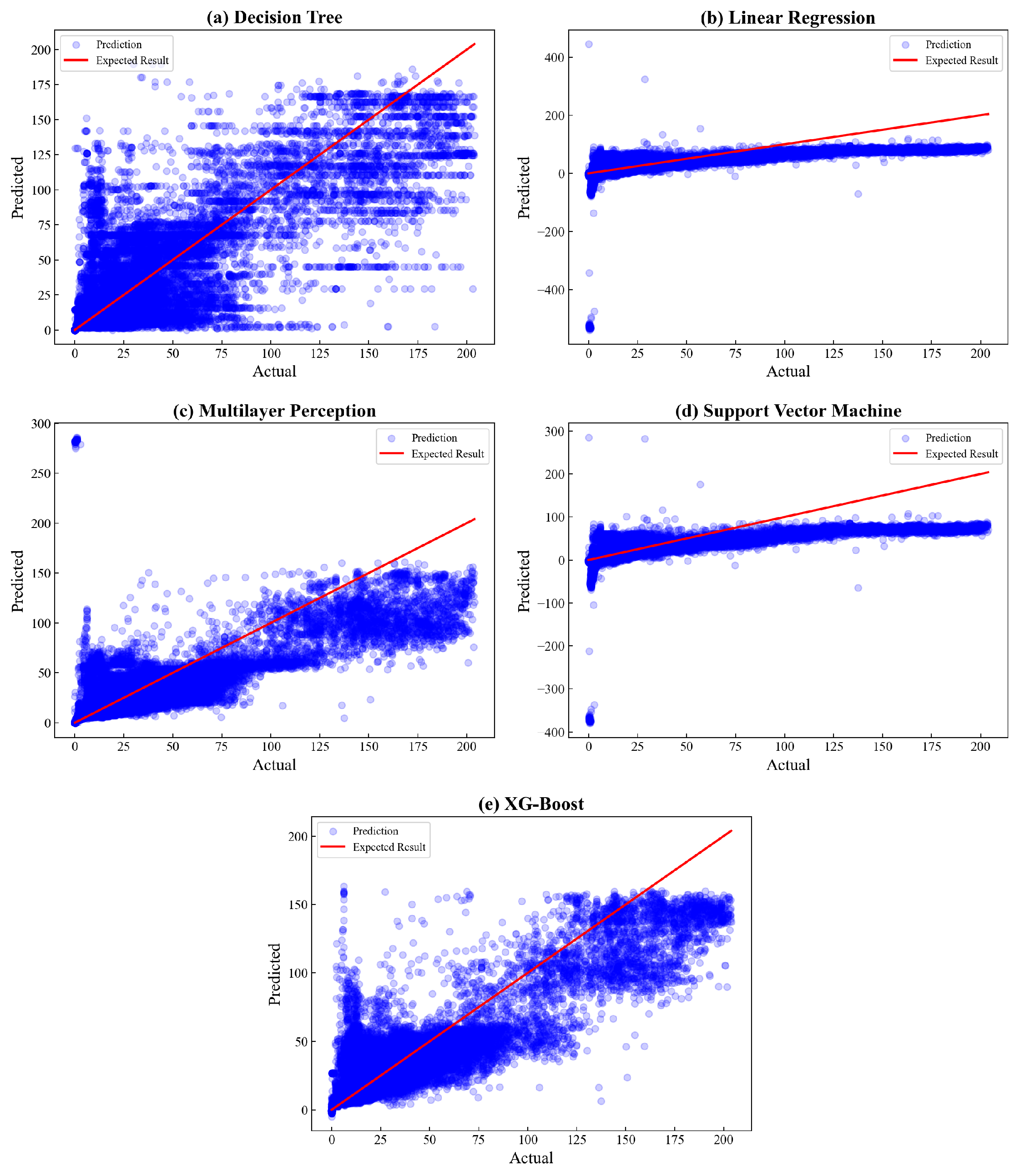

4.1.3. CO Prediction

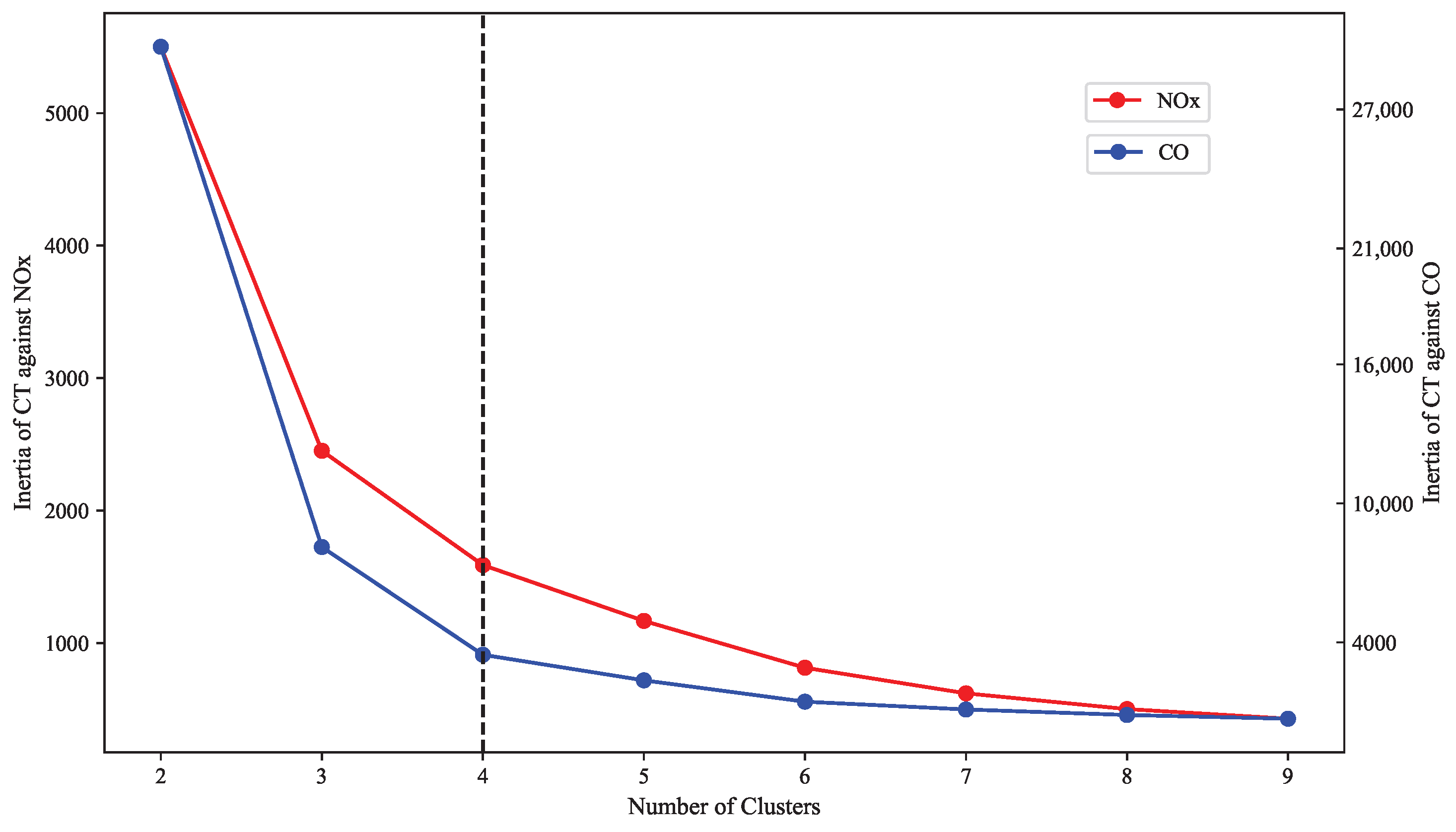

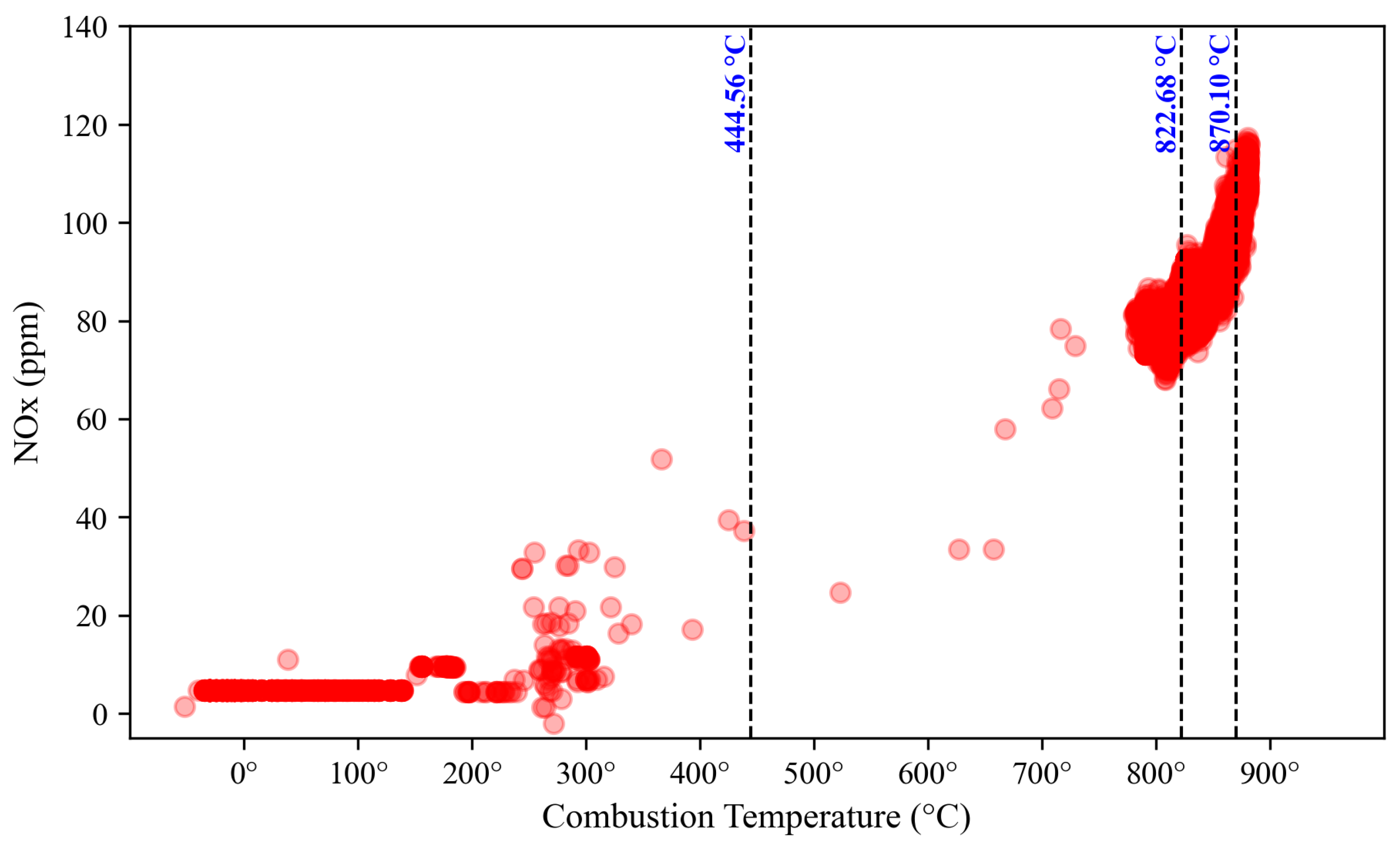

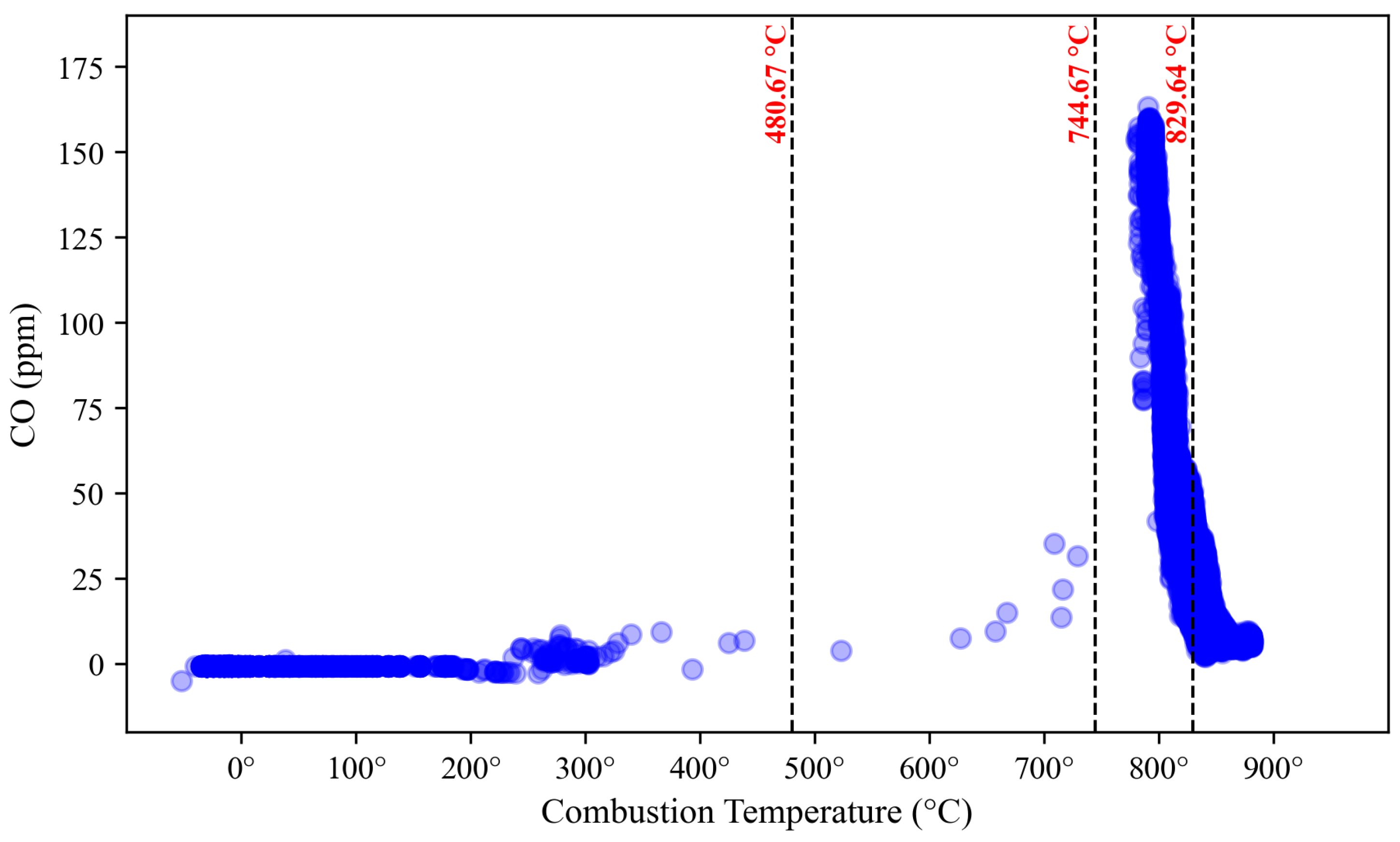

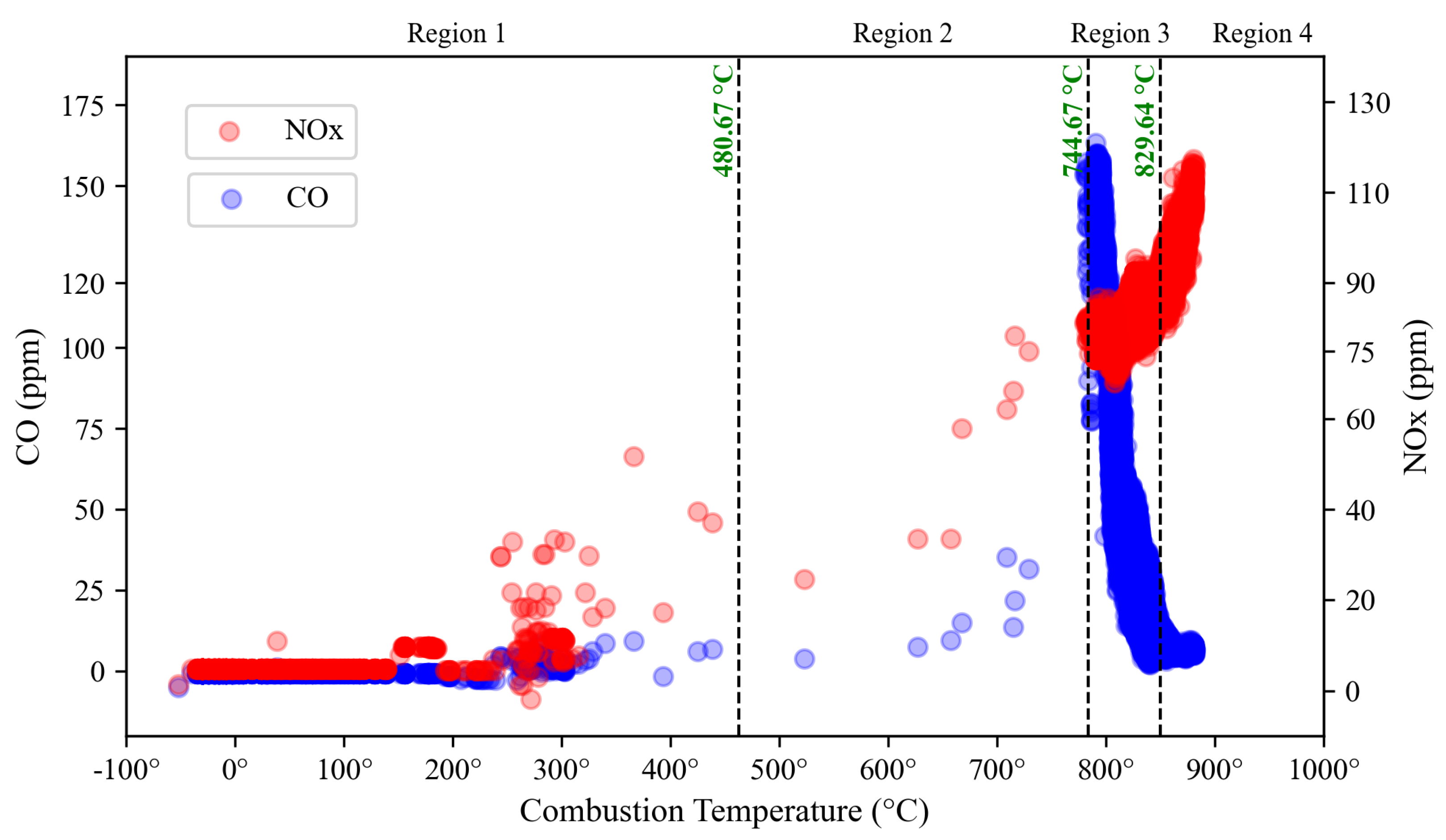

4.2. Clustering Model Development in K-Means

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stefanizzi, M.; Capurso, T.; Filomeno, G.; Torresi, M.; Pascazio, G. Recent Combustion Strategies in Gas Turbines for Propulsion and Power Generation toward a Zero-Emissions Future: Fuels, Burners, and Combustion Techniques. Energies 2021, 14, 6694. [Google Scholar] [CrossRef]

- Faqih, M.; Omar, M.B.; Ibrahim, R.; Bahaswan, A.A.O. Dry-Low Emission Gas Turbine Technology: Recent Trends and Challenges. Appl. Sci. 2022, 12, 10922. [Google Scholar] [CrossRef]

- Omar, M.; Tarik, M.H.M.; Ibrahim, R.; Abdullah, M.F. Suitability study on using rowen’s model for dry-low emission gas turbine operational performance. In Proceedings of the TENCON 2017-2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017; pp. 1925–1930. [Google Scholar]

- Nemitallah, M.A.; Rashwan, S.S.; Mansir, I.B.; Abdelhafez, A.A.; Habib, M.A. Review of novel combustion techniques for clean power production in gas turbines. Energy Fuels 2018, 32, 979–1004. [Google Scholar] [CrossRef]

- Bahashwan, A.A.; Rosdiazli, B.I.; Madiah, B.O.; Faqih, M. The Lean Blowout Prediction Techniques in Lean Premixed Gas Turbine: An Overview. Energies 2022, 15, 8343. [Google Scholar] [CrossRef]

- Sigfrid, I.R.; Whiddon, R.; Collin, R.; Klingmann, J. Influence of reactive species on the lean blowout limit of an industrial DLE gas turbine burner. Combust. Flame 2014, 161, 1365–1373. [Google Scholar] [CrossRef]

- Faqih, M.; Omar, M.B.; Ibrahim, R. Development of Rowen’s Model for Dry-Low Emission Gas Turbine Dynamic Simulation using Scilab. In Proceedings of the 2022 IEEE 5th International Symposium in Robotics and Manufacturing Automation (ROMA), Malacca, Malaysia, 6–8 August 2022; pp. 1–5. [Google Scholar]

- Tarik, M.H.M.; Omar, M.; Abdullah, M.F.; Ibrahim, R. Modelling of dry low emission gas turbine using black-box approach. In Proceedings of the TENCON 2017-2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017; pp. 1902–1906. [Google Scholar]

- Omar, M.B.; Ibrahim, R.; Abdullah, M.F.; Tarik, M.H.M. Modelling of Dry-Low Emission Gas Turbine Fuel System using First Principle Data-Driven Method. J. Power Technol. 2020, 100, 1–13. [Google Scholar]

- Meegahapola, L.; Flynn, D. Characterization of gas turbine lean blowout during frequency excursions in power networks. IEEE Trans. Power Syst. 2014, 30, 1877–1887. [Google Scholar] [CrossRef]

- Omar, M.; Ibrahim, R.; Abdullah, M.F.; Tarik, M.H.M. Modelling and System Identification of Gas Fuel Valves in Rowen’s Model for Dry Low Emission Gas Turbine. In Proceedings of the 2018 IEEE Conference on Big Data and Analytics (ICBDA), Langkawi, Malaysia, 21–22 November 2018; pp. 33–37. [Google Scholar]

- Emami, M.D.; Shahbazian, H.; Sunden, B. Effect of operational parameters on combustion and emissions in an industrial gas turbine combustor. J. Energy Resour. Technol. 2019, 141, 012202. [Google Scholar] [CrossRef]

- Kaluri, A.; Malte, P.; Novosselov, I. Real-time prediction of lean blowout using chemical reactor network. Fuel 2018, 234, 797–808. [Google Scholar] [CrossRef]

- Said, Z.; Le, D.T.N.; Sharma, S.; Nguyen, D.T.; Bui, T.A.E. Optimization of combustion, performance, and emission characteristics of a dual-fuel diesel engine powered with microalgae-based biodiesel/diesel blends and oxyhydrogen. Fuel 2022, 326, 124987. [Google Scholar] [CrossRef]

- Aliramezani, M.; Norouzi, A.; Koch, C.R. Support vector machine for a diesel engine performance and NOx emission control-oriented model. IFAC-PapersOnLine 2020, 53, 13976–13981. [Google Scholar] [CrossRef]

- Idzwan, S.; Phing, C.C.; Kiong, T.S. Prediction of NOx Using Support Vector Machine for Gas Turbine Emission at Putrajaya Power Station. J. Adv. Sci. Eng. Res. 2014, 4, 37–46. [Google Scholar]

- Tuttle, J.F.; Blackburn, L.D.; Powell, K.M. On-line classification of coal combustion quality using nonlinear SVM for improved neural network NOx emission rate prediction. Comput. Chem. Eng. 2020, 141, 106990. [Google Scholar] [CrossRef]

- Liu, B.; Hu, J.; Yan, F.; Turkson, R.F.; Lin, F. A novel optimal support vector machine ensemble model for NOx emissions prediction of a diesel engine. Measurement 2016, 141, 183–192. [Google Scholar] [CrossRef]

- Rezazadeh, A. Environmental pollution prediction of NOx by predictive modelling and process analysis in natural gas turbine power plants. Pollution 2021, 7, 481–494. [Google Scholar]

- Botros, K.K.; Siarkowski, L.; Barss, S.; Manabat, R. Measurements of NOx emissions from DLE and non-DLE gas turbine engines employed in natural gas compressor stations and comparison with PEM models. Int. Pipeline Conf. 2014, 46100, V001T04A001. [Google Scholar]

- Si, M.; Tarnoczi, T.J.; Wiens, B.M.; Du, K. Development of predictive emissions monitoring system using open source machine learning library-keras: A case study on a cogeneration unit. IEEE Access 2019, 7, 113463–113475. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Öztop, H.F. Forced convection and thermal predictions of pulsating nanofluid flow over a backward facing step with a corrugated bottom wall. Int. J. Heat Mass Transf. 2017, 110, 231–247. [Google Scholar] [CrossRef]

- Si, M.; Du, K. Development of a predictive emissions model using a gradient boosting machine learning method. Environ. Technol. Innov. 2020, 20, 101028. [Google Scholar] [CrossRef]

- Bagherzade Ghazvini, M.; Sanchez-Marre, M.; Bahilo, E.; Angulo, C. Operational modes detection in industrial gas turbines using an ensemble of clustering methods. Sensors 2021, 21, 8047. [Google Scholar] [CrossRef]

- He, Y.; Xing, Y.; Zeng, X.; Ji, Y.; Hou, H.; Zhang, Y.; Zhu, Z. Factors influencing carbon emissions from China’s electricity industry: Analysis using the combination of LMDI and K-means clustering. Environ. Impact Assess. Rev. 2022, 93, 106724. [Google Scholar] [CrossRef]

- Li, B.; Li, J. Probabilistic sizing of a low-carbon emission power system considering HVDC transmission and microgrid clusters. Appl. Energy 2021, 304, 117760. [Google Scholar] [CrossRef]

- Govender, P.; Sivakumar, V. Application of k-means and hierarchical clustering techniques for analysis of air pollution: A review. Atmos. Pollut. Res. 2020, 11, 40–56. [Google Scholar] [CrossRef]

- Cheng, S.; Chen, Y.; Meng, F.; Chen, J.; Liu, G.; Song, M. Impacts of local public expenditure on CO2 emissions in Chinese cities: A spatial cluster decomposition analysis. Resour. Conserv. Recycl. 2021, 164, 105217. [Google Scholar] [CrossRef]

- Yuan, K.; Chi, G.; Zhou, Y.; Yin, H. A novel two-stage hybrid default prediction model with k-means clustering and support vector domain description. Res. Int. Bus. Financ. 2022, 59, 101536. [Google Scholar] [CrossRef]

- Niu, G.; Ji, Y.; Zhang, Z.; Wang, W.; Chen, J.; Yu, P. Clustering analysis of typical scenarios of island power supply system by using cohesive hierarchical clustering based K-Means clustering method. Energy Rep. 2021, 7, 250–256. [Google Scholar] [CrossRef]

| Hyperparameters | Combustion Temperature | NOx Emission | CO Emission |

|---|---|---|---|

| max_depth | 6 | 4 | 6 |

| alpha | 1.88 | 2.88 | 1 |

| min_child_weight | 1 | 0 | 1 |

| reg_lambda | 1 | 0.03 | 0.59 |

| gamma | 1.95 | 3.59 | 3.86 |

| subsample | 0.86 | 0.42 | 0.78 |

| colsample_bytree | 1 | 0.79 | 0.40 |

| n_estimator | 500 | 100 | 100 |

| learning_rate | 0.077 | 0.415 | 0.054 |

| No. | Parameters | Abr. | Unit | Min. | Max. | Mean |

|---|---|---|---|---|---|---|

| 1 | Load | Load | MW | −0.10 | 18.31 | 8.66 |

| 2 | Speed | Speed | RPM | −0.0005 | 5133.29 | 4583 |

| 3 | Ambient Air Temperature | AAT | °C | 25.17 | 41.90 | 31.87 |

| 4 | Inlet Guide Vane Opening | IGVO | % | 41.26 | 85.11 | 54.37 |

| 5 | Compressor Discharge Pressure | CDP | kPag | −0.03 | 7.49 | 5.15 |

| 6 | Stop Ratio Valve Opening | SRVO | % | −0.37 | 36.90 | 22.76 |

| 7 | Gas Control Valve Opening | GCVO | % | 0 | 49.12 | 30.43 |

| 8 | Splitter Opening | SO | % | 0 | 101.92 | 34.06 |

| 9 | Fuel Gas Flow | FGF | kg/h | −1.31 | 142.13 | 86.48 |

| 10 | Fuel Gas Pressure | FGP | kPag | −0.003 | 16.31 | 14.34 |

| 11 | T5 Combustion Temperature | CT | °C | −77.94 | 966.27 | 742.89 |

| 12 | T7 Exhaust Temperature | ET | °C | 0 | 531.73 | 428.29 |

| 13 | Exhaust Gas Pressure | EGP | kPag | −0.55 | 8.31 | 2.99 |

| 14 | NOx | NOx | ppm | 0 | 137.69 | 75.04 |

| 15 | CO | CO | ppm | 0 | 203.86 | 26.98 |

| Variable | CT | NOx | CO |

|---|---|---|---|

| Load | 0.98 | 0.98 | 0.091 |

| Speed | 0.99 | 0.96 | 0.26 |

| AAT | −0.65 | −0.61 | −0.21 |

| IGVO | 0.99 | 0.95 | 0.25 |

| CDP | 1 | 0.97 | 0.23 |

| SRVO | 0.99 | 0.97 | 0.19 |

| GCVO | 0.99 | 0.97 | 0.2 |

| SO | −0.99 | −0.97 | −0.24 |

| FGF | 0.99 | 0.97 | 0.19 |

| FGP | 0.99 | 0.96 | 0.26 |

| ET | 1 | 0.97 | 0.2 |

| EGP | 0.97 | 0.95 | 0.16 |

| Output | Performance | DT | LR | MLP | SVM | XGBoost |

|---|---|---|---|---|---|---|

| Combustion Temperature | 0.9979 | 0.9996 | 0.9993 | 0.9986 | 0.9999 | |

| MAE | 1.3321 | 0.8624 | 1.2608 | 0.9227 | 1.1285 | |

| RMSE | 7.3604 | 3.1384 | 4.4781 | 6.0692 | 6.9549 | |

| % error | 0.0244 | 0.0037 | 0.0856 | 0.0053 | 0.0356 | |

| NOx emission | 0.9053 | 0.8008 | 0.9272 | 0.9211 | 0.9309 | |

| MAE | 4.1907 | 4.5393 | 3.2349 | 3.9201 | 3.5968 | |

| RMSE | 5.8276 | 8.7526 | 5.0762 | 5.6715 | 4.9765 | |

| % error | 7.2016 | 1.5261 | 1.1945 | 1.0638 | 0.1168 | |

| CO emission | 0.6687 | 0.4076 | 0.6918 | 0.4604 | 0.7109 | |

| MAE | 15.3233 | 17.4969 | 14.1294 | 17.8439 | 14.2486 | |

| RMSE | 24.9892 | 34.6808 | 24.8311 | 33.0383 | 23.7482 | |

| % error | 14.0473 | 30.7938 | 20.2803 | 20.0774 | 0.9200 |

| Region | Operating Range | Description |

|---|---|---|

| 1 | <480.67 °C | Trip |

| 2 | 480.68 °C–744.67 °C | Near to Trip |

| 3 | 744.68 °C–829.64 °C | Safe Operation |

| 4 | >829.64 °C | Unhealthy |

| Algorithms | Mode | Advantages | Disadvantages |

|---|---|---|---|

| XGBoost | Supervised | • Less time for model training • Excellent dealing with missing data and outliers • Few hyperparameters for model tuning | • Limited to supervised learning application, which is unable to capture the ambiguity in operating range prediction |

| Mulitlayer Perceptron | Supervised | • Has a self-learning function • Adaptive either for large or small data set with relatively same accuracy | • Computationally complex • Cannot perform well when data is insufficient |

| Support Vector Machine | Supervised | • Able to produce a model with low variance • Relatively insensitive to overfitting | • Time-consuming due to too many parameters connected • Sensitive to noisy data and outliers |

| Decision Tree | Supervised | • Computationally efficient and handle large datasets easily • Robust to outliers and noise in the data | • Struggle with missing data • Produce relatively high deviation in emission prediction |

| Linear Regression | Supervised | • Simple and easy to implement • Has a good generalizability to predict new data | • Limited to linear relationship between independent and dependent variables • May suffer from over-fitting when the model becomes too complex |

| K-Means | Unsupervised | • Excellent in clustering that can be used in range prediction cases • Good dealing with uneven distributed data • Able to handle huge data | • Bad in handling noisy data and outliers. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faqih, M.; Omar, M.B.; Ibrahim, R. Prediction of Dry-Low Emission Gas Turbine Operating Range from Emission Concentration Using Semi-Supervised Learning. Sensors 2023, 23, 3863. https://doi.org/10.3390/s23083863

Faqih M, Omar MB, Ibrahim R. Prediction of Dry-Low Emission Gas Turbine Operating Range from Emission Concentration Using Semi-Supervised Learning. Sensors. 2023; 23(8):3863. https://doi.org/10.3390/s23083863

Chicago/Turabian StyleFaqih, Mochammad, Madiah Binti Omar, and Rosdiazli Ibrahim. 2023. "Prediction of Dry-Low Emission Gas Turbine Operating Range from Emission Concentration Using Semi-Supervised Learning" Sensors 23, no. 8: 3863. https://doi.org/10.3390/s23083863

APA StyleFaqih, M., Omar, M. B., & Ibrahim, R. (2023). Prediction of Dry-Low Emission Gas Turbine Operating Range from Emission Concentration Using Semi-Supervised Learning. Sensors, 23(8), 3863. https://doi.org/10.3390/s23083863